Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Less machinery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

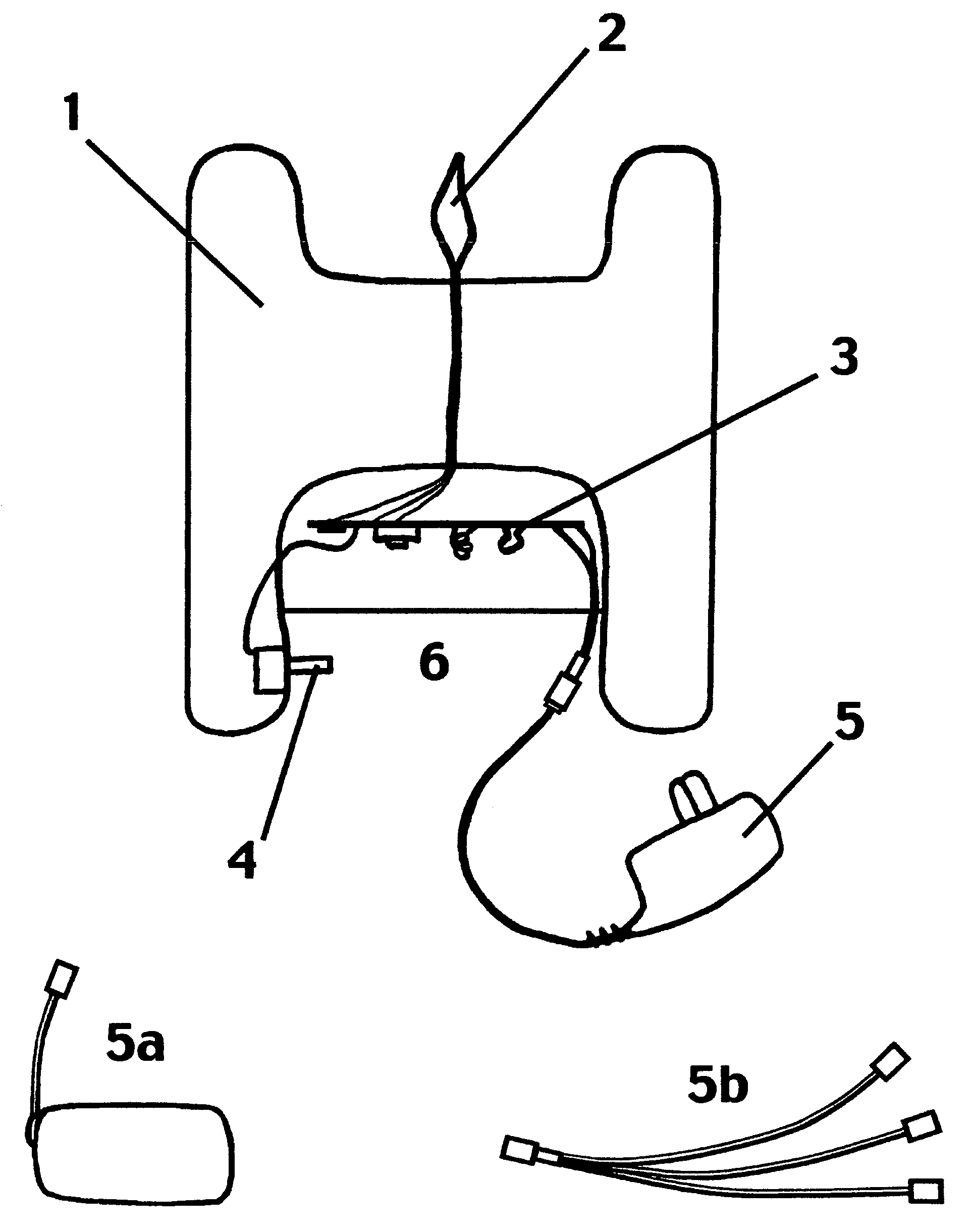

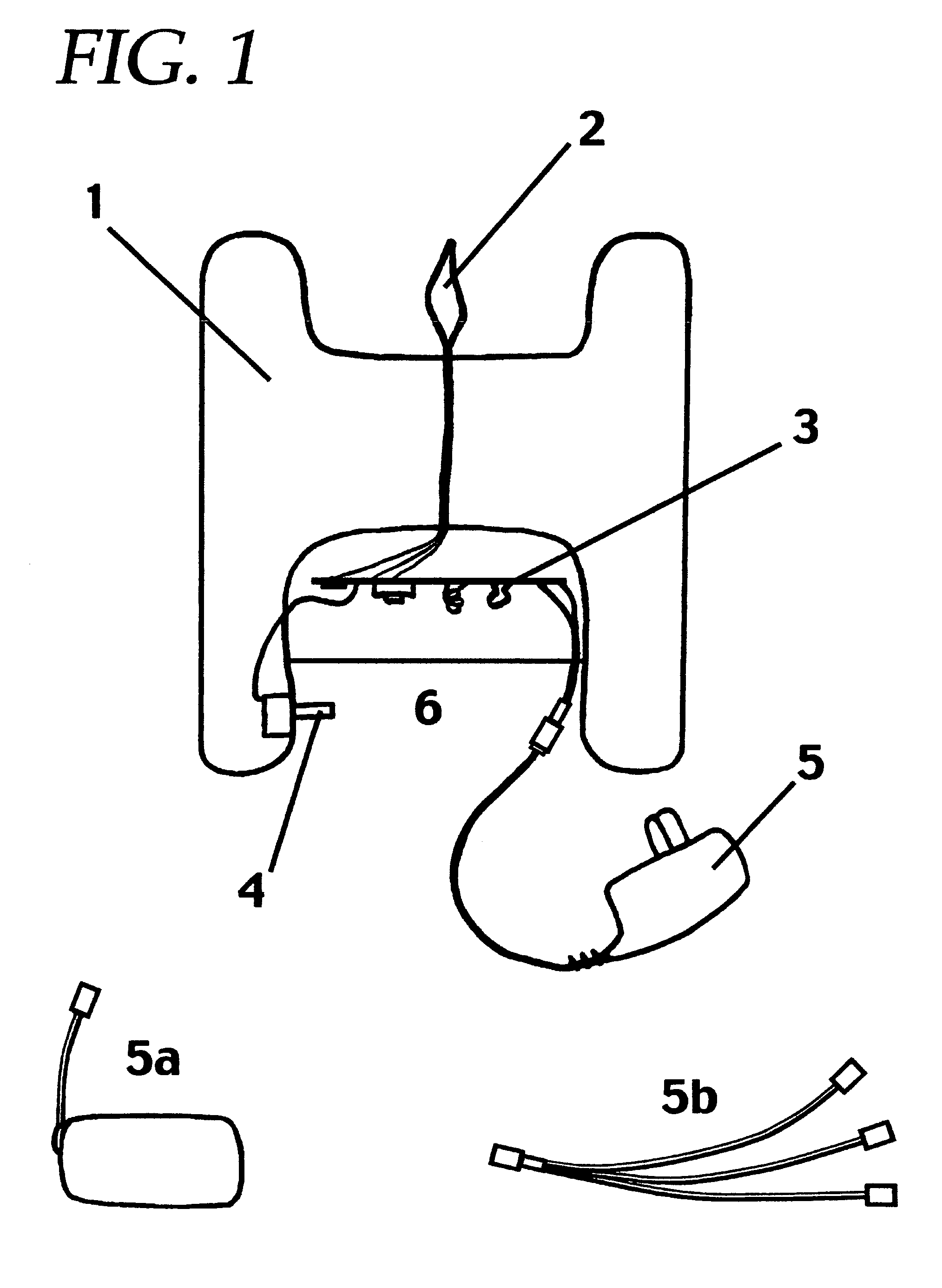

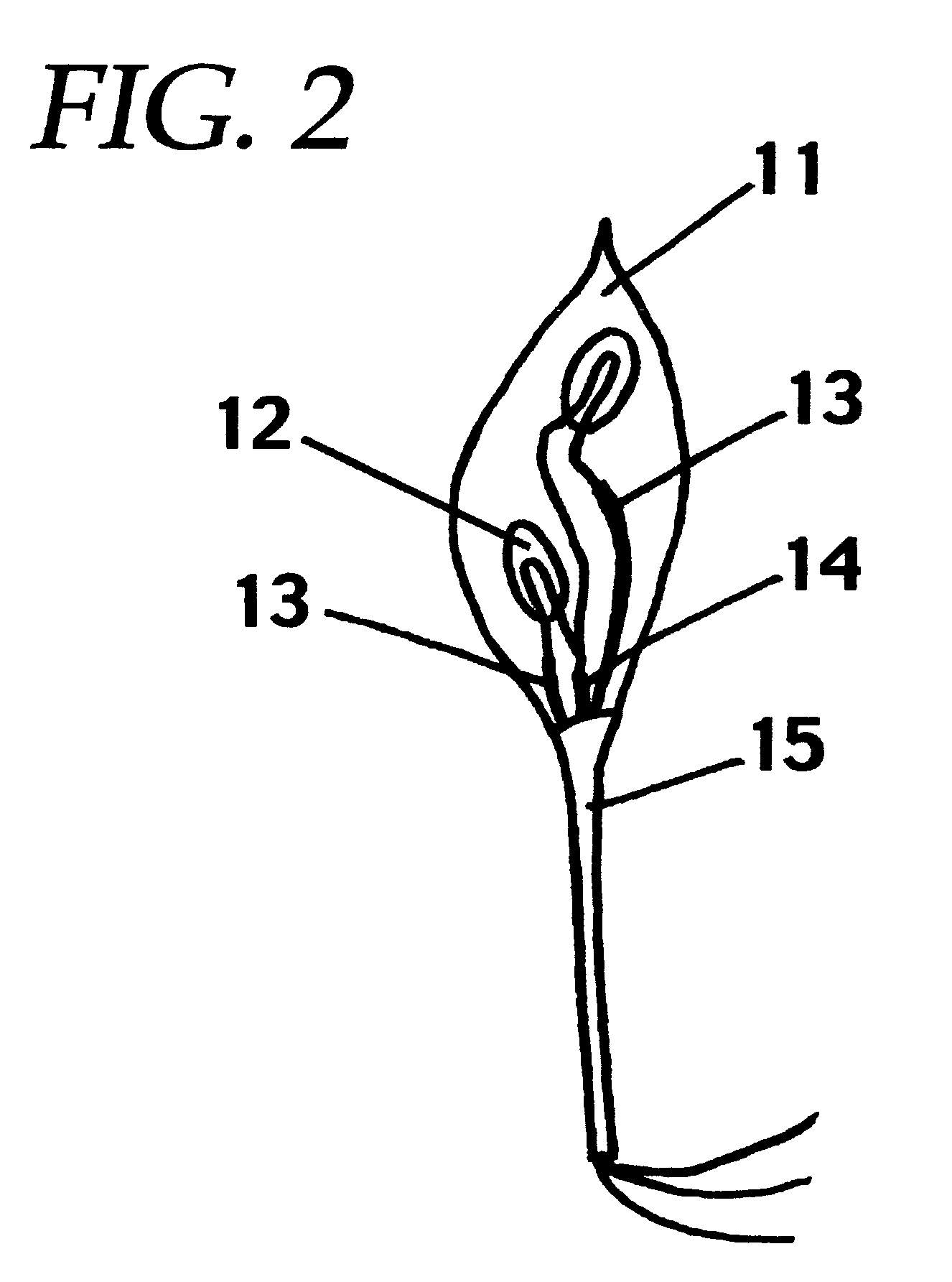

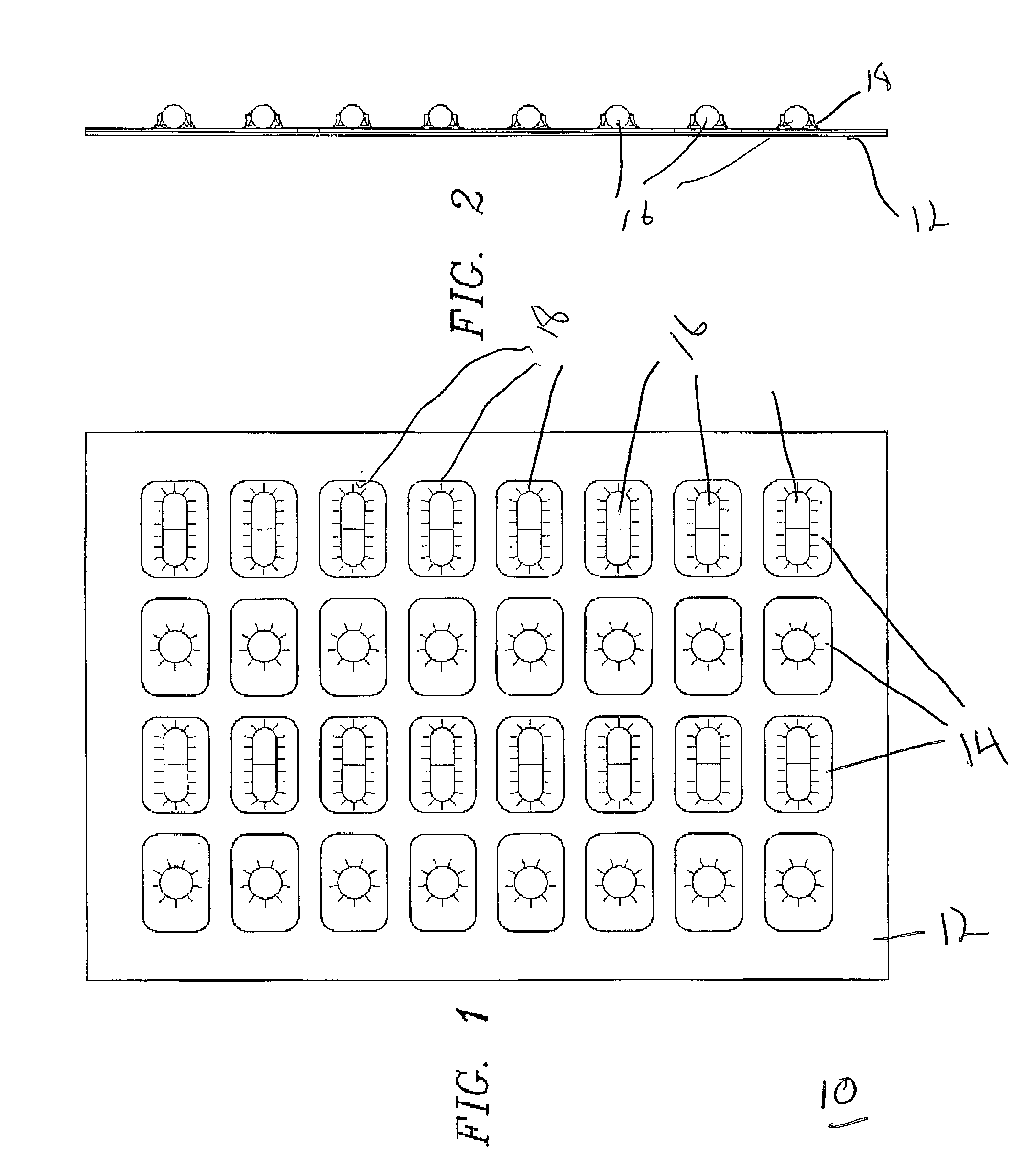

Flameless candle

InactiveUS7029146B2Easy to useAdds to asthetic appealCandle holdersPoint-like light sourceWaxEffect light

An electric lighting device created for use as a safe, long lasting, authentic looking alternative to a flame bearing candle. This electric ‘candle’ being made from real candle wax, or hollowed out candles with the wicks removed. The ‘candle’ can be scented or colored, and the glow is authentic and pleasing being viewed through real candle wax. Miniature lamps suspended in a clear or yellowish heat resistant medium provide the source lighting. The glow of the artificial flame is color and volume-of-output matched to that of a real flame and realism is added by simulated flame movement with the use of an adjustable oscillator circuit hidden inside the candle. This flameless ‘candle’ can be used safely unattended, and is realistic in that real candle wax, or real used candles, are used for the body of the device.

Owner:KITCHEN EDWARD F

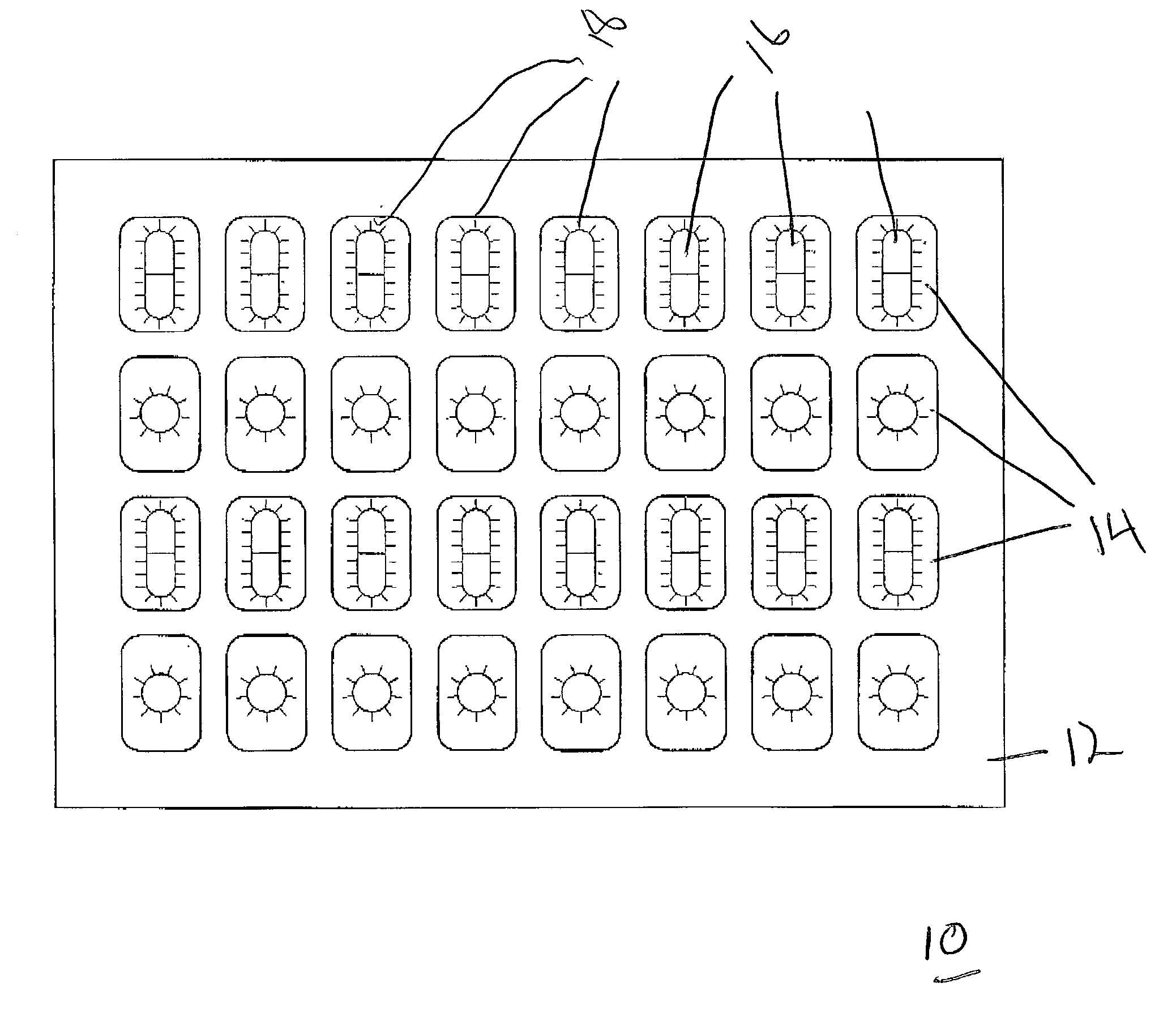

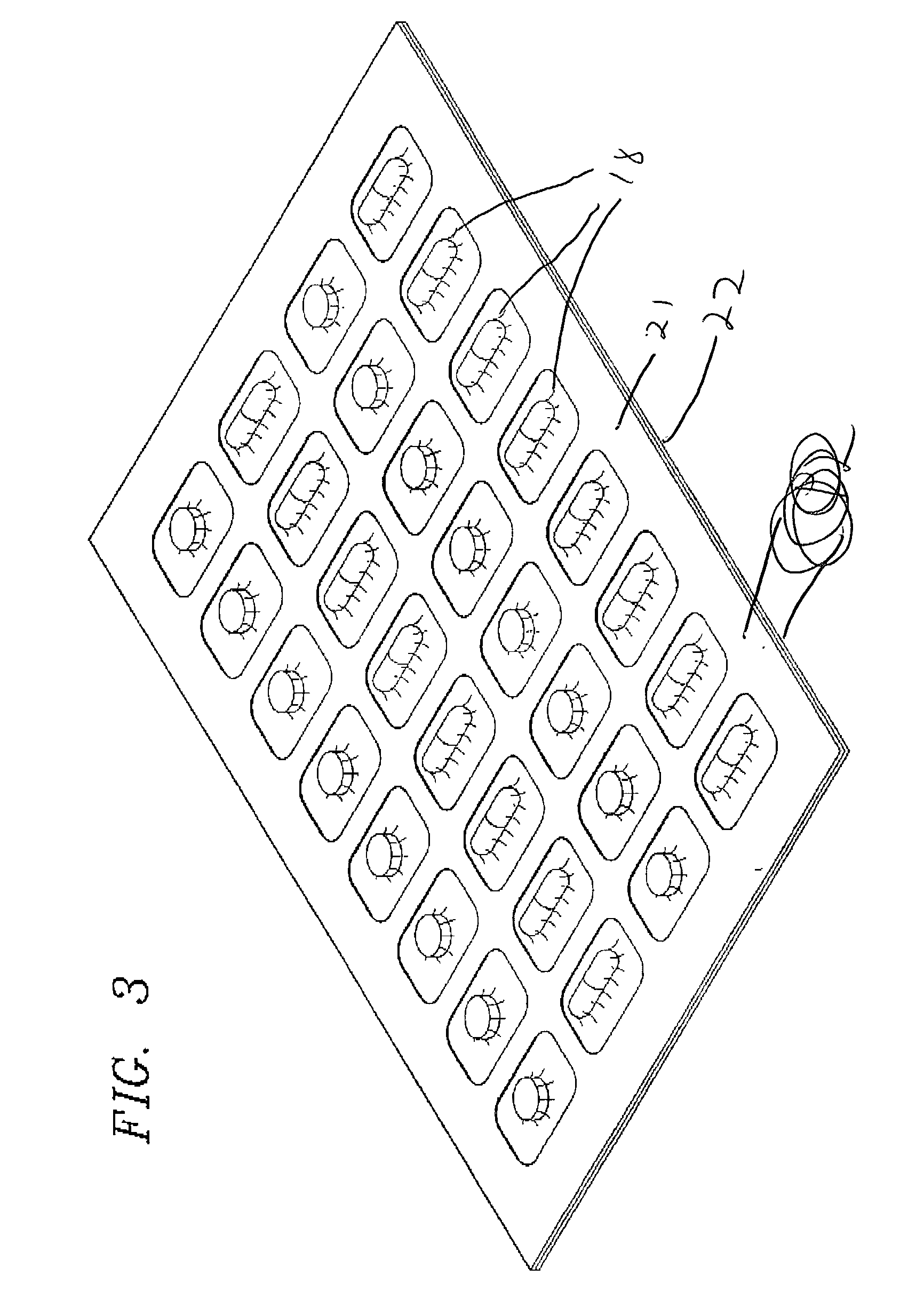

Systems and methods for forming blister packages with support members for pharmaceutical product packaging

InactiveUS20040093835A1Few machine and processing stepEfficiently formedWrappingSolid materialBlistersBlister pack

Systems and methods are provided for forming both backing and support members of a solid pharmaceutical product package as well as the blister portions for the packages. The disclosed solid pharmaceutical product packaging solutions utilize fewer machines and processing steps in order to form an overall solid pharmaceutical product package. In accordance with the preferred exemplary embodiments of the present invention, the manufacturing processing steps associated with the formation of the blister members in the clear plastic sheets is integrated in line with manufacturing of the backing material.

Owner:MTS MEDICATION TECH

Method for rapid treatment of damage of cavity beneath cement concrete pavement slab

InactiveCN102900016AEfficient fillingImprove waterproof performanceRoads maintainenceRoad surfaceSlurry

The invention provides a method for rapid treatment of damage of a cavity beneath a cement concrete pavement slab and has the advantages of low cost, a fast repairing speed and a good effect. According to the invention, a falling weight deflectometer and a ground penetrating radar are used for determination of a cavity position at corners and a center position of a cement concrete pavement slab; then grouting holes are arranged in the cement concrete pavement slab, wherein an emulsified asphalt cement-based composite material is used as a grouting slurry; a grouting pump is employed to pump the grouting slurry from a mixer, and the grouting slurry is injected into the cavity position of the cement concrete pavement after pumping pressing by a high-pressure rubber hose; after grouting is finished, the cement concrete pavement is maintained for 4 to 6 h; and mortar is used to plug the grouting holes, after the grouting holes are stood for 8 to 12 h, and then parts of the pavement higher than the pavement is polished until the parts of the pavement are as high as the original pavement.

Owner:SHANXI LUZHONG ROAD & BRIDGE CO LTD

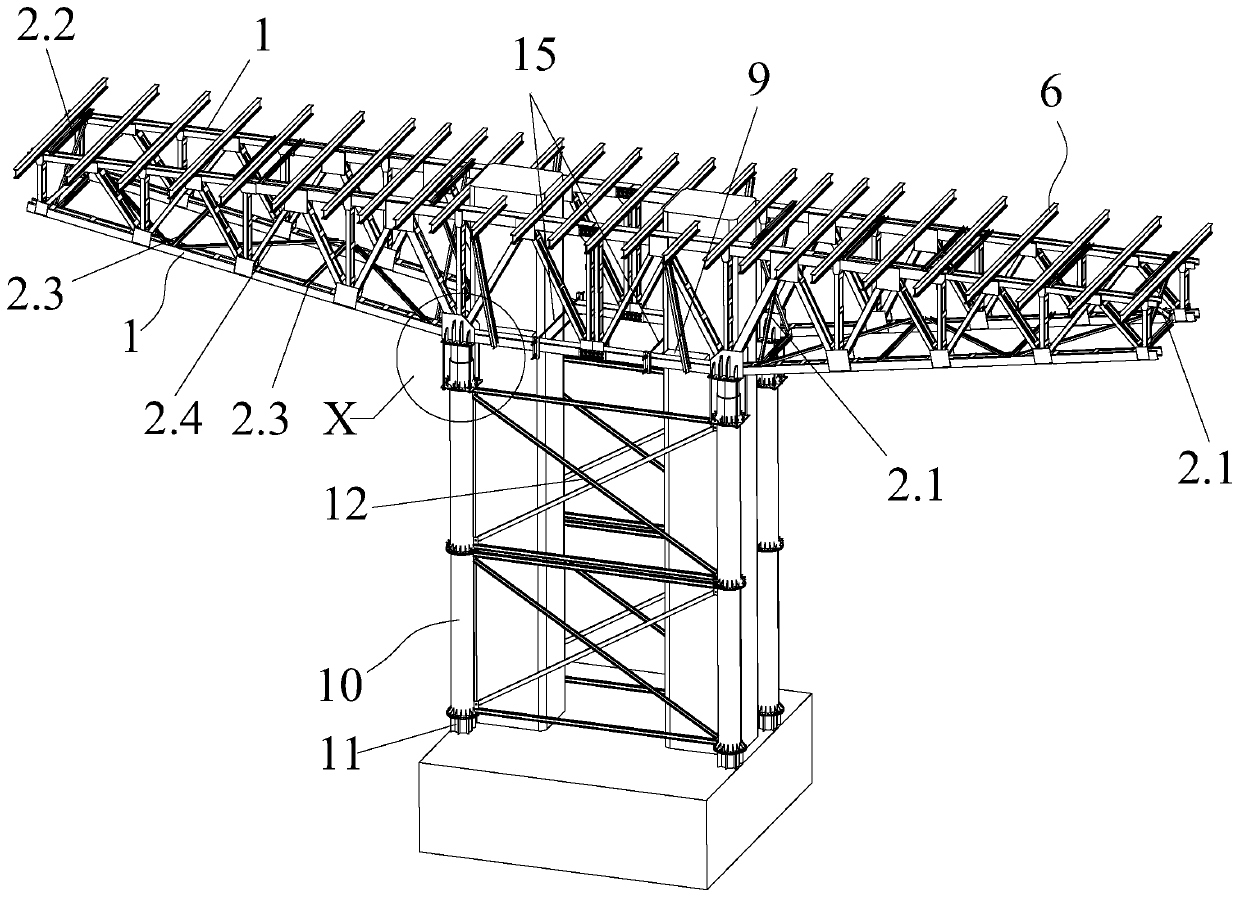

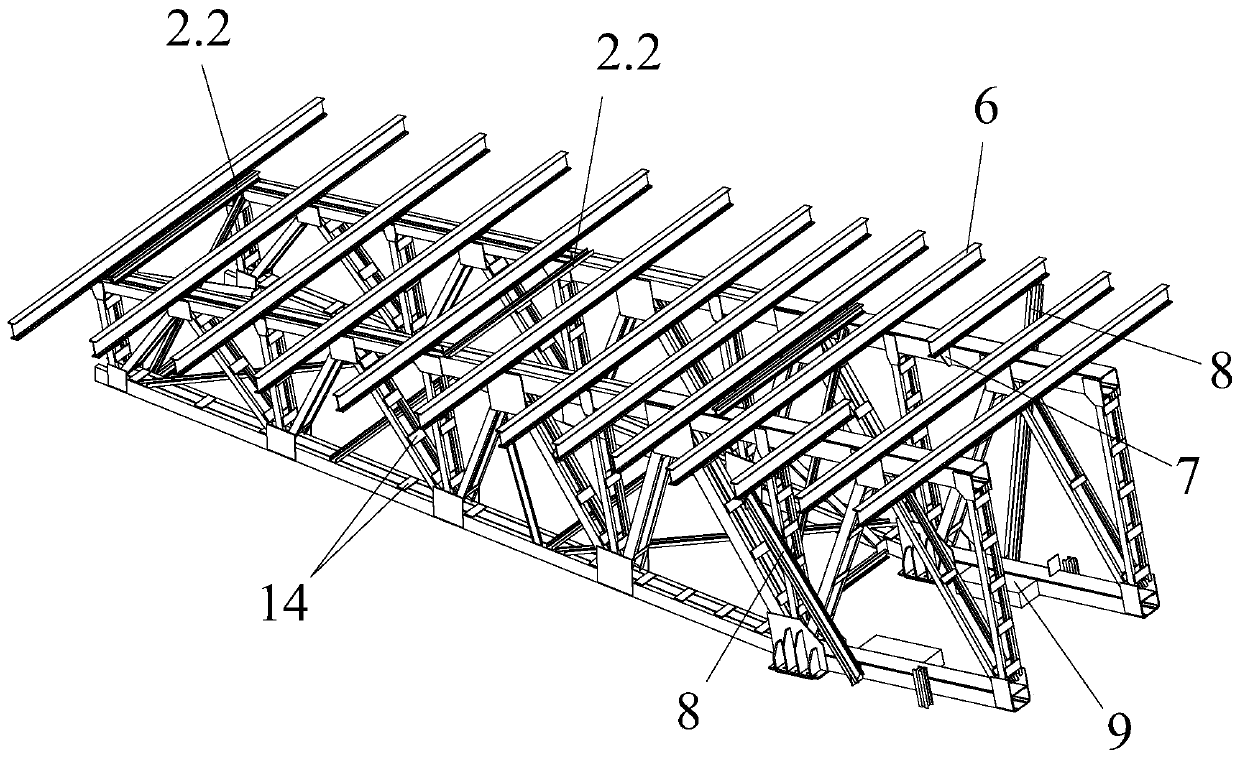

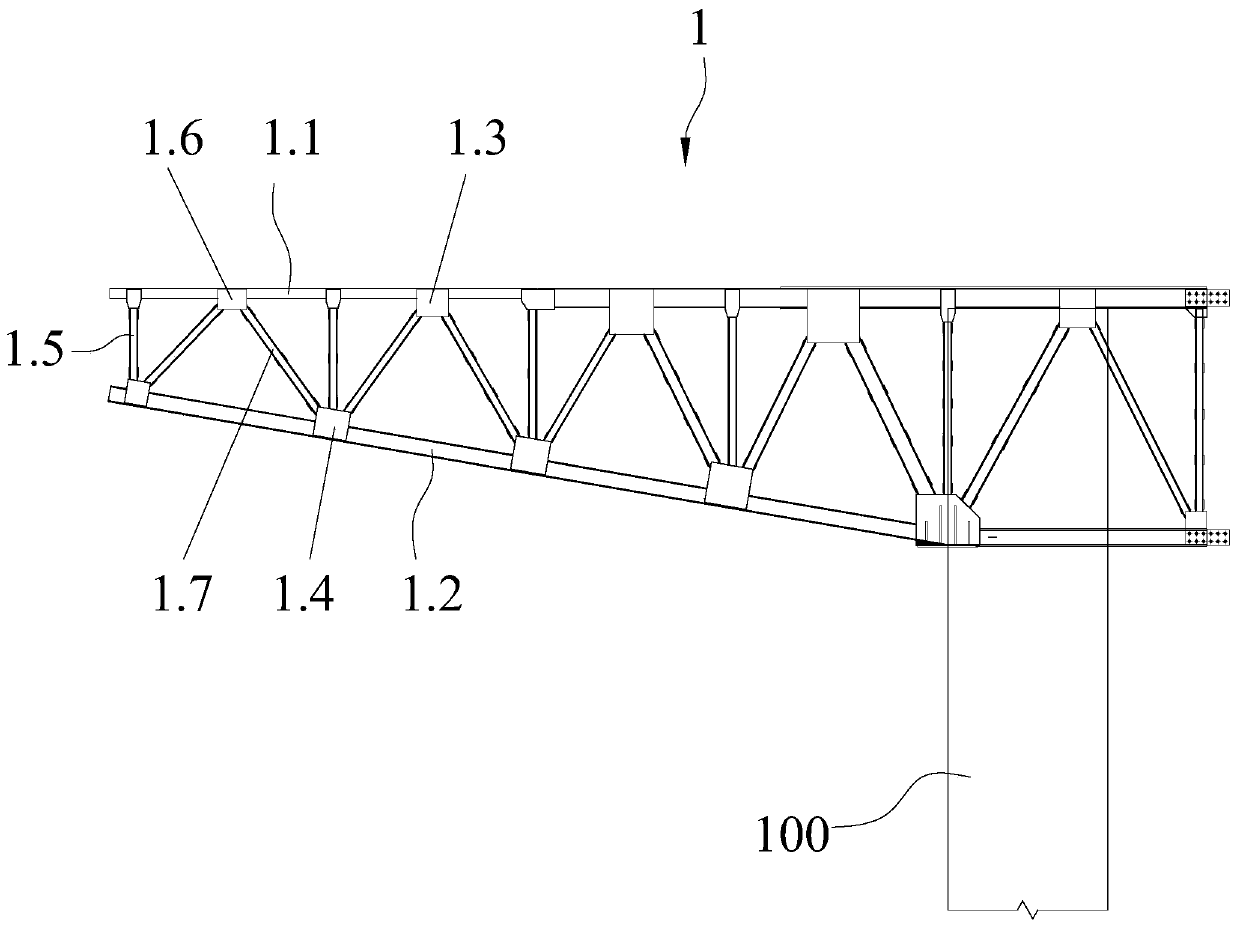

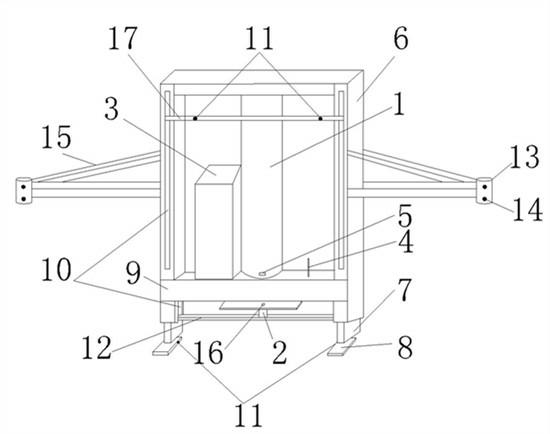

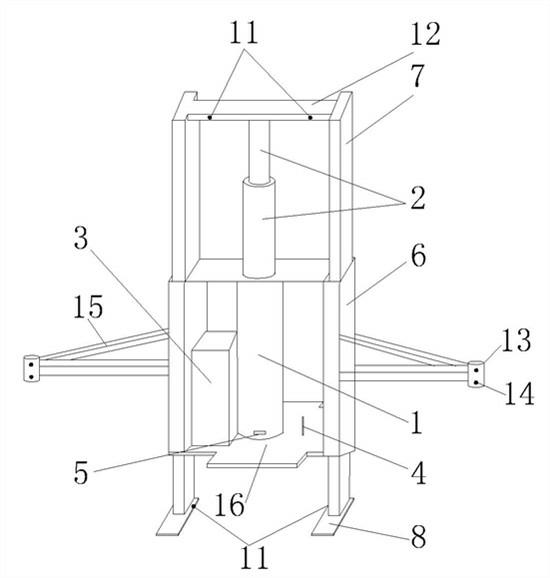

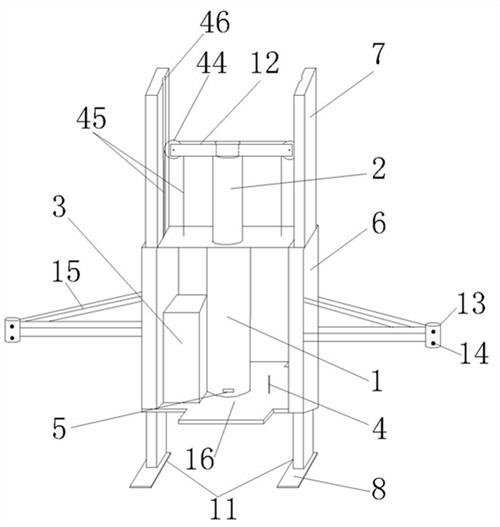

Large-span cantilever truss type capping beam bracket system and construction method thereof

PendingCN110004832AReduce your weightDoes not affect normal trafficBridge erection/assemblyUpper jointEngineering

The invention discloses a large-span cantilever truss type capping beam bracket system. The large-span cantilever truss type capping beam bracket system sequentially comprises a bearing device, an elevation adjusting device, a truss mechanism and an operation platform from bottom to top; the truss mechanism comprises two truss bodies, each truss body comprises two truss assemblies, each truss assembly comprises an upper chord member and a lower chord member, each upper chord member is provided with a plurality of upper joints, each lower chord member is provided with a plurality of lower joints, and a straight web member is arranged between each upper joint and the corresponding lower joint; and a center joint is arranged in the midpoint between every two adjacent upper joints, inclined web members distributed in a splay shape are arranged between each center joint and the two corresponding adjacent lower joints. The invention further discloses a construction method of the large-span cantilever truss type capping beam bracket system. According to the large-span cantilever truss type capping beam bracket system and the construction method thereof, demounting, mounting and construction are convenient, the amount of steel used is small, and the height of an overall truss structure can be adjusted; and normal driving of a car is not affected in a working state.

Owner:NINGBO MUNICIPAL ENG CONSTR GROUP

Construction method of expansion joint shape setting formwork

InactiveCN105201082AReduce wasteLabor savingForms/shuttering/falseworksBuilding material handlingExpansion jointRebar

The invention discloses a construction method of an expansion joint shape setting formwork. The construction method comprises the steps that an expansion joint template is designed, the shape setting formwork is processed, fastener welding is performed, columns and wall board steel bars are bound, indoor columns and wall board templates are installed, screw penetration is performed, screw rod penetration is performed from insides of rooms after preparation is completed, the axis position and perpendicularity are calibrated, opposite-pull screw rods are tightened, a lower opening of the formwork and concrete floors are caulked with cement mortar, concrete is cast after acceptance inspection is passed, and the formwork and the opposite-pull screw rods are dismounted. The construction method has no special requirement for the formwork and other accessory materials, the demand can be met only by selecting conventional qualified materials, labors, machinery and materials are saved, a construction period is greatly shortened, and the input shape setting formwork can be used cyclically. Compared with a traditional method, material waste is reduced, the working efficiency of construction workers in operation and usage is improved by means of the construction method, a good role is played on structure forming of the expansion joint position, and on-site actual operation support is provided for the forming quality of the position of a similar ultra-long building.

Owner:THE SECOND CONSTR ENG CO LTD CCSEB

Integrally-moving device for railway turnout junctions

The invention relates to an integrally-moving device for railway turnout junctions, which solves the problems that a turnout junction rail jack, a rail car and a rail crane are needed in the existing railway turnout junction replacement method, the cost is high, transportation resources are occupied when vehicles run, a great amount of blocking time is used during replacement in fault removal, a great amount of labor and material resources are needed and the construction process is unsafe. In the integrally-moving device for railway turnout junctions, a turnout junction to be laid is integrally moved to a position to be replaced by a sliding rail, and a plurality of guide sliding rails are distributed in a transversely moving range of the turnout junction to be laid; the technical points are as follows: the device at least comprises 5-15 groups of moving units, each group of the moving units are provided with two turnout junction replacement dollies which are respectively distributed on sliding rails at two ends of each of two adjacent switch ties (preferentially, two switch ties with equal length) of the turnout junction to be laid, and each turnout junction replacement dolly consists of a hydraulic pressure lifting device, a transverse moving device, a longitudinal adjusting device. The device has the advantages of economy, safety, convenience and rapidness and the like.

Owner:孙晓伟

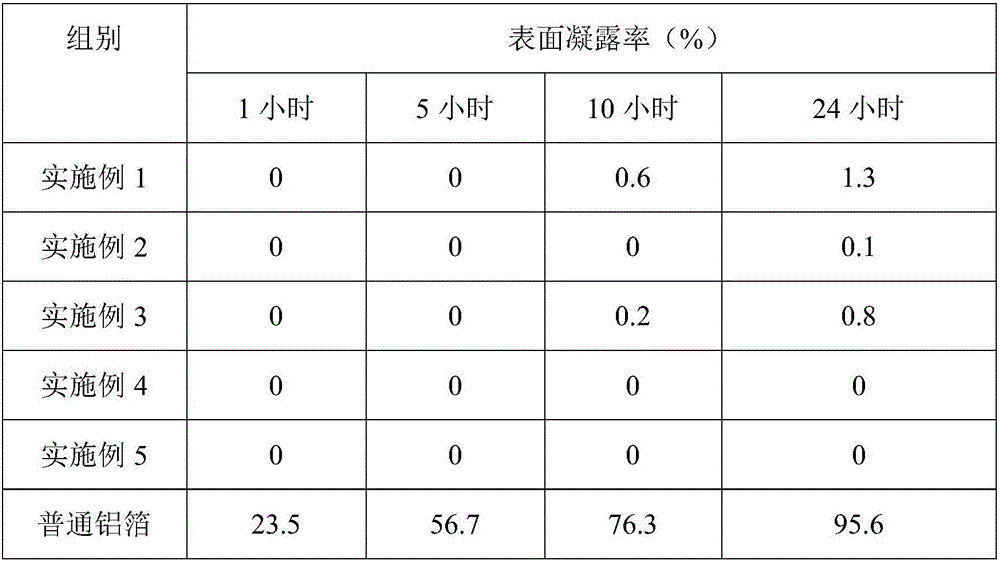

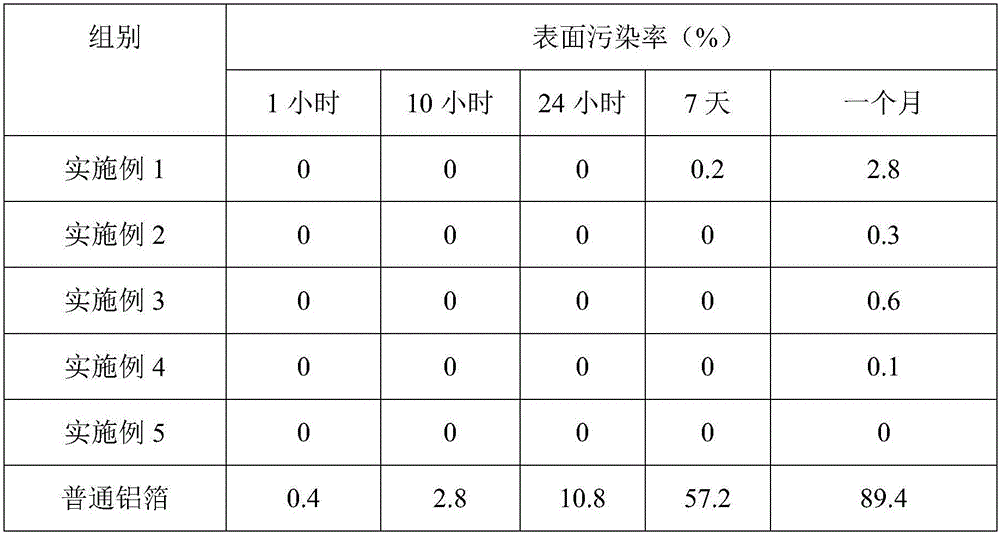

Ultra-hydrophobic aluminum foil and production method thereof

InactiveCN106381033AImprove corrosion resistanceExtended service lifeAnti-corrosive paintsPolyester coatingsFucoidanAqueous sodium hydroxide

The invention discloses an ultra-hydrophobic aluminum foil and a preparation method thereof. The preparation method of the ultra-hydrophobic aluminum foil comprises the following steps: processing an aluminum foil substrate by an aqueous solution of sodium hydroxide, cleaning the processed aluminum foil substrate, immersing the cleaned aluminum foil substrate in a prepared acidic solution to carry out etching treatment, cleaning the etched aluminum foil, immersing the aluminum foil in a prepared liquid hydrophobic material, and carrying out solidifying drying treatment to obtain the ultra-hydrophobic aluminum foil, wherein the liquid hydrophobic material is prepared from, by weight, 26-32 parts of a stearic acid solution, 16-20 parts of modified alkyd resin, 14-20 parts of nanometer titanium dioxide, 6-10 parts of fucoidan, 2-6 parts of neryl isovalerate, 2-8 parts of carboxymethylcellulose sodium and 4-8 parts of fluorinated polyethylene. The ultra-hydrophobic aluminum foil has the advantages of ultra-strong hydrophobicity, effective inhibition of condensation, substantial increase of the corrosion resistance of the aluminum foil and substantial prolongation of the service life of the aluminum foil, and the production method has the advantages of simplicity, small substrate damages, good apparent quality, and suitableness for wide promotion.

Owner:HUANGSHAN TIANMA ALUMINUM

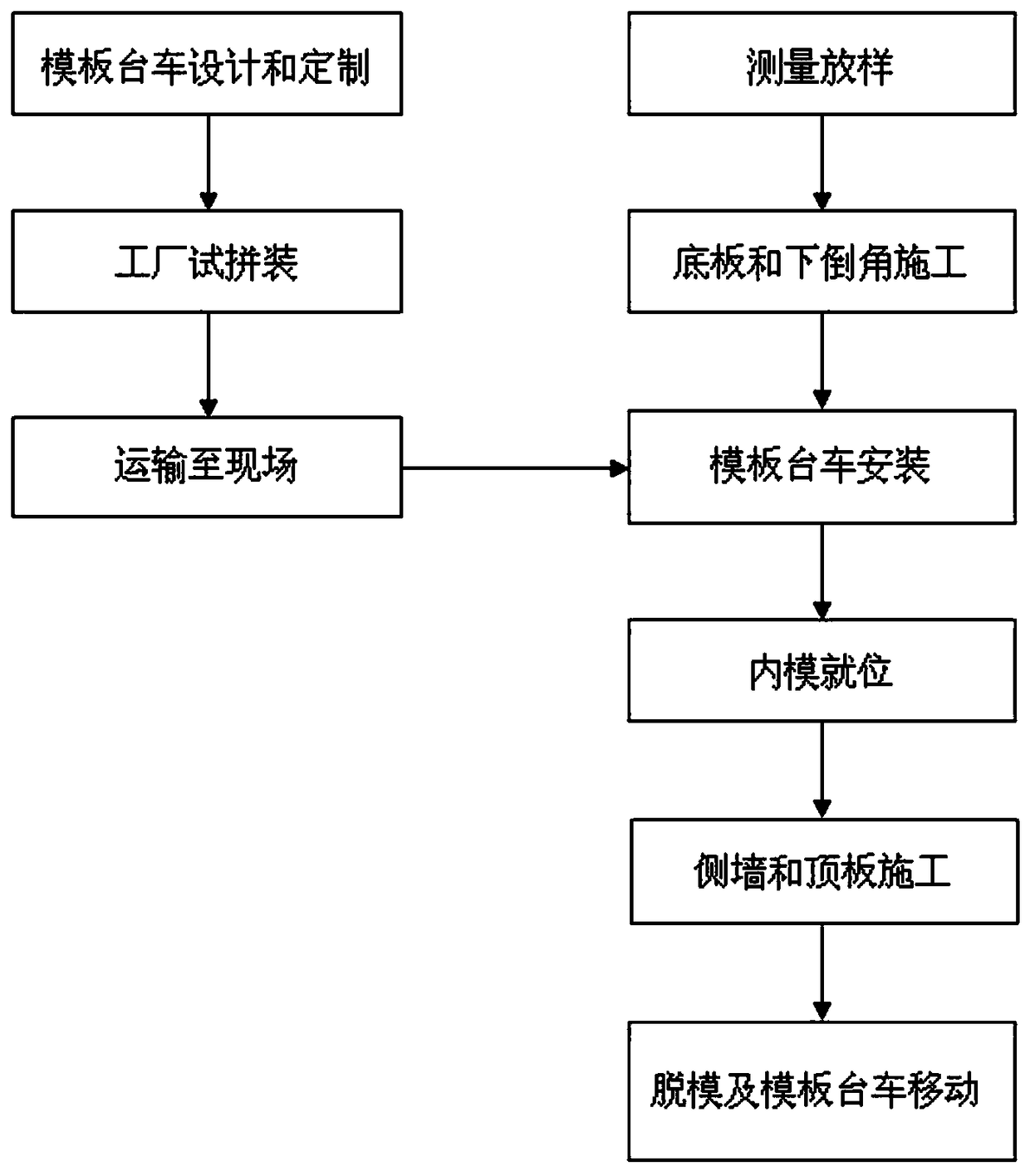

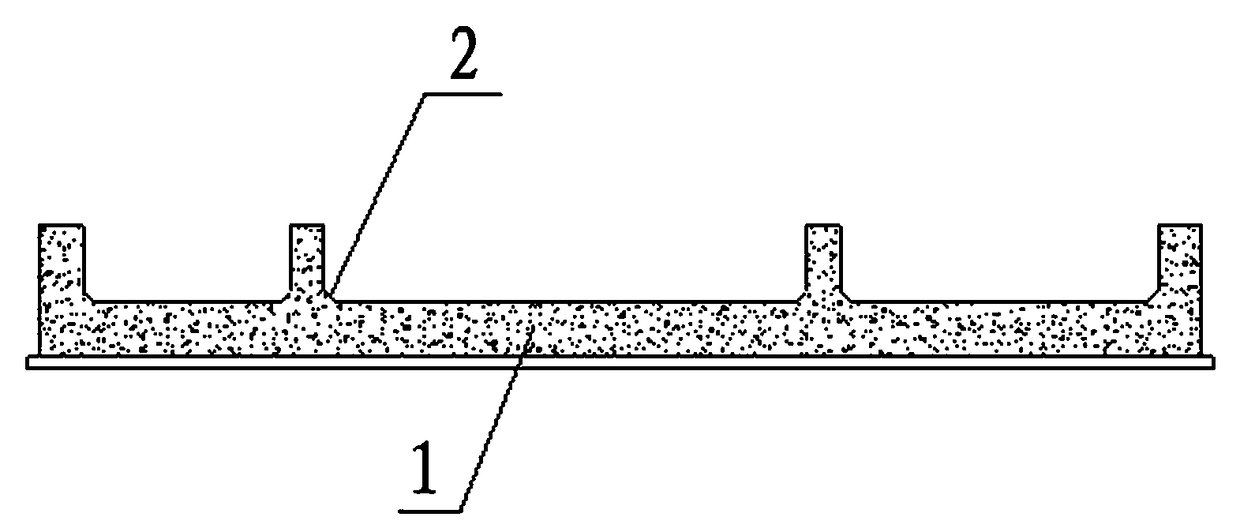

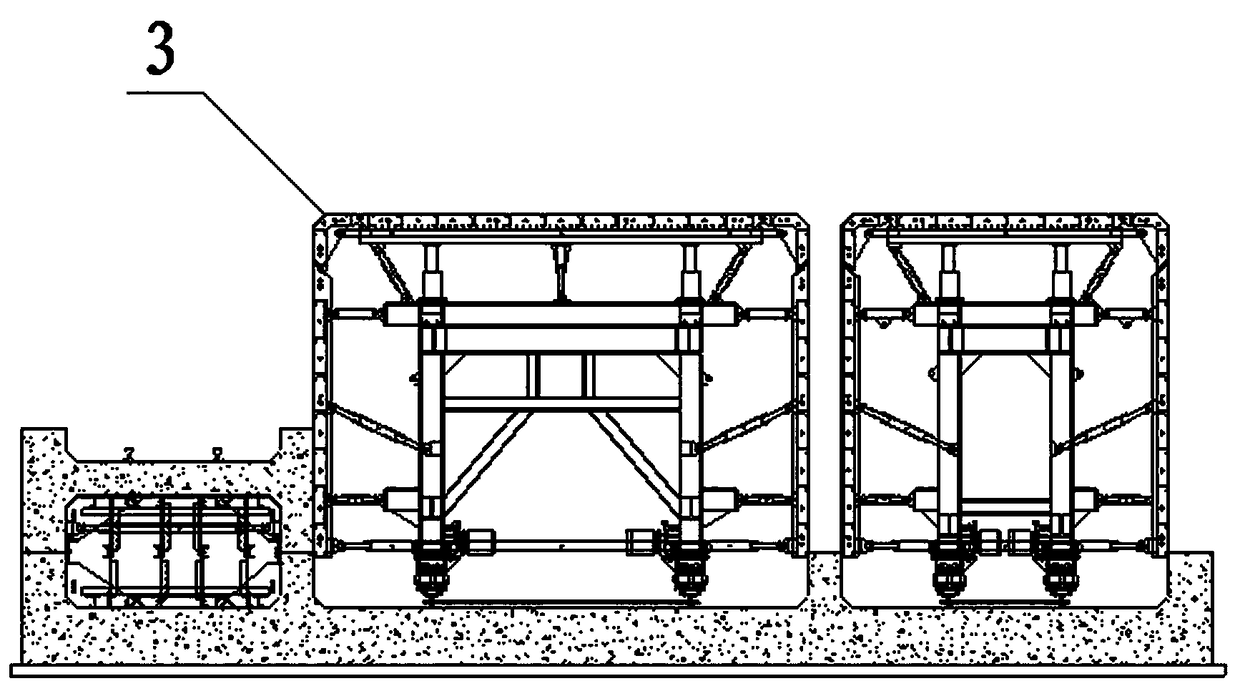

Construction method of integral type movement of formwork trolley through cast-in-place pipe gallery

InactiveCN109487814AReduce pouring jointsGood anti-seepage, anti-seismic and anti-freeze performanceArtificial islandsUnderwater structuresContinuous useFastener

The invention discloses a construction method of integral type movement of a formwork trolley through a cast-in-place pipe gallery. The construction method includes the steps of measurement and lofting, bottom plate and lower chamfer construction, formwork trolley installation, internal mould emplacement, side wall and top plate construction, and demoulding and formwork trolley movement. Accordingto the construction method, the construction progress is effectively improved, and the construction cost is lowered; except for first installation and final removal completing of the whole section ofpipe gallery construction, the formwork trolley is not required to be installed and disassembled, a great deal of labor and machinery is reduced, waste of intermediate materials is reduced, the formwork trolley can be used continuously only by proper maintenance and repair, good economic benefits are achieved; pipe gallery pouring seams are reduced, anti-seepage, anti-seismic and anti-freezing properties are good after pouring, late operation and maintenance costs are effectively reduced, and meanwhile, attractiveness of a pipe gallery is improved; and compared with a full framing method, waste of a fastener, a support and other resources can be effectively reduced, pollution is reduced, and social benefits are good.

Owner:HANGZHOU MUNICIPAL CONSTR GRP CO LTD

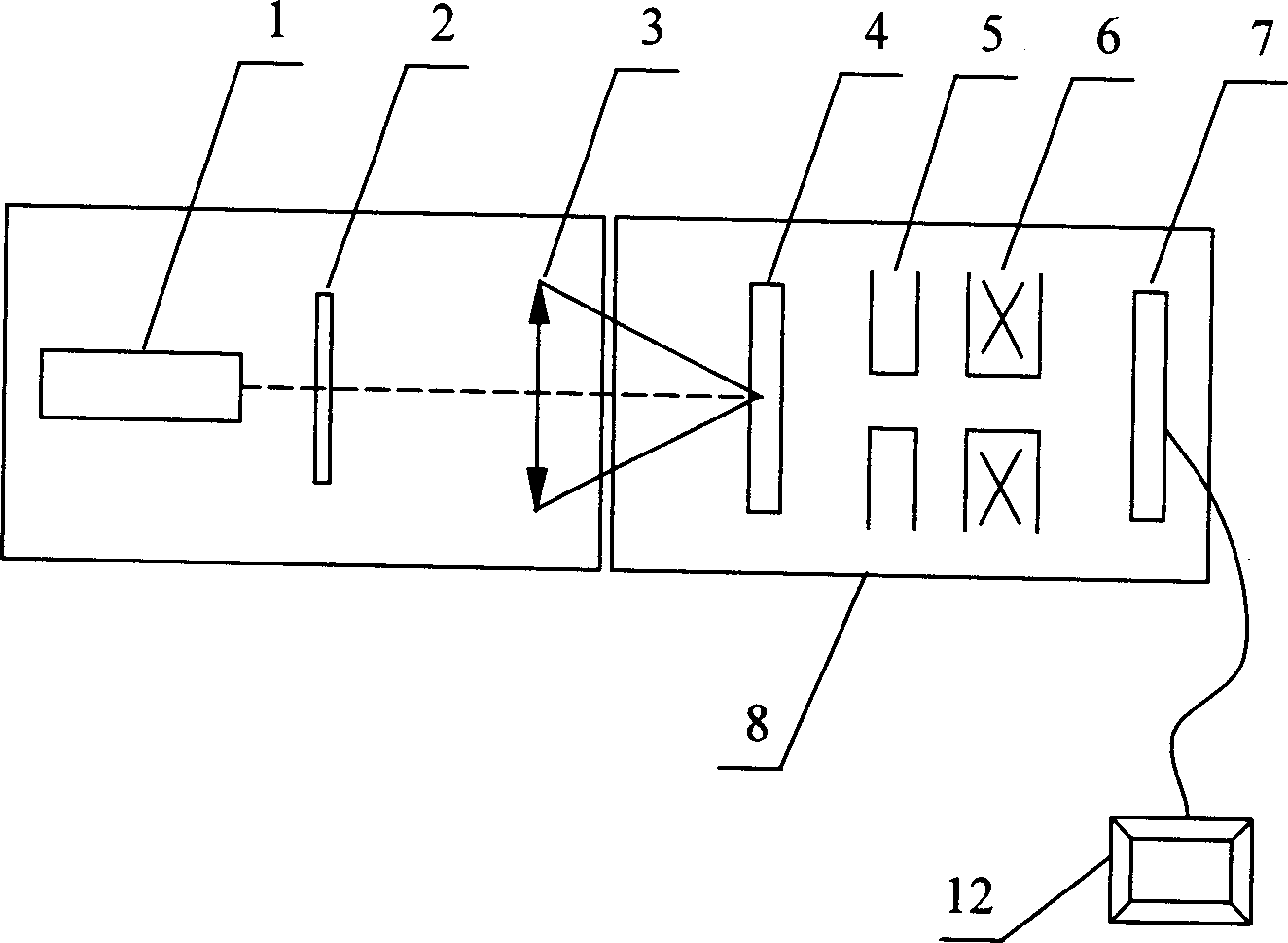

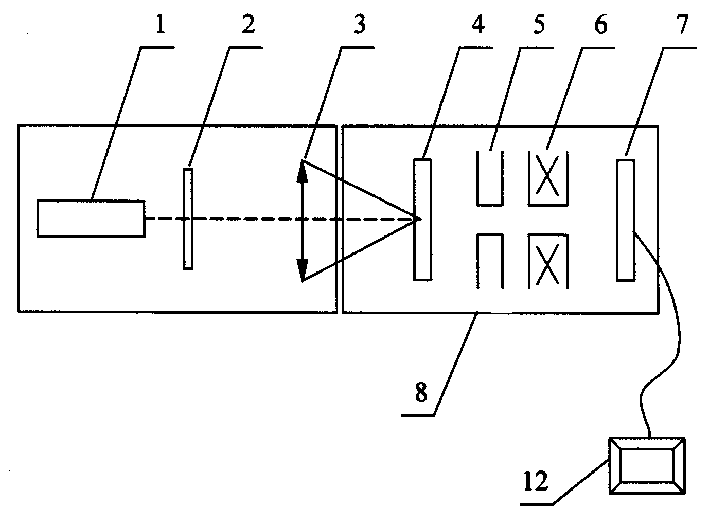

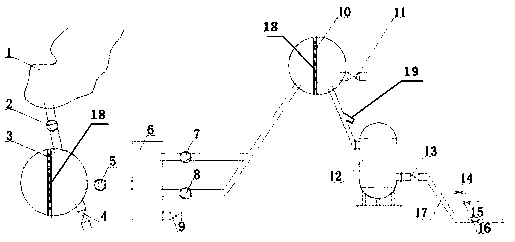

Femto second heavy current high brightness electron microscope device

InactiveCN1448980ALess machineryReduce shielding requirementsElectric discharge tubesConfocalFemto second laser

The femto-second powerful current high brightness electronic microscope plant consists of two parts, the first part includes femto-second laser, optical filter and lens combination; and the second part includes one vacuum casing and inside optical cathode, accelerating cathode, electromagnetic lens and acceptor fluorescent screen. The femto-second laser is one Nd:YAG double-frequency laser, the optical filter is used in regulating the output power density of the femto-second laser, the lens combination is a achromatic one, and the optical cathode is made of metal compound LaB6. The plant may operate in continuous state or high-repeated frequency femto-second supershort pulse state for observing various superfast courses.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

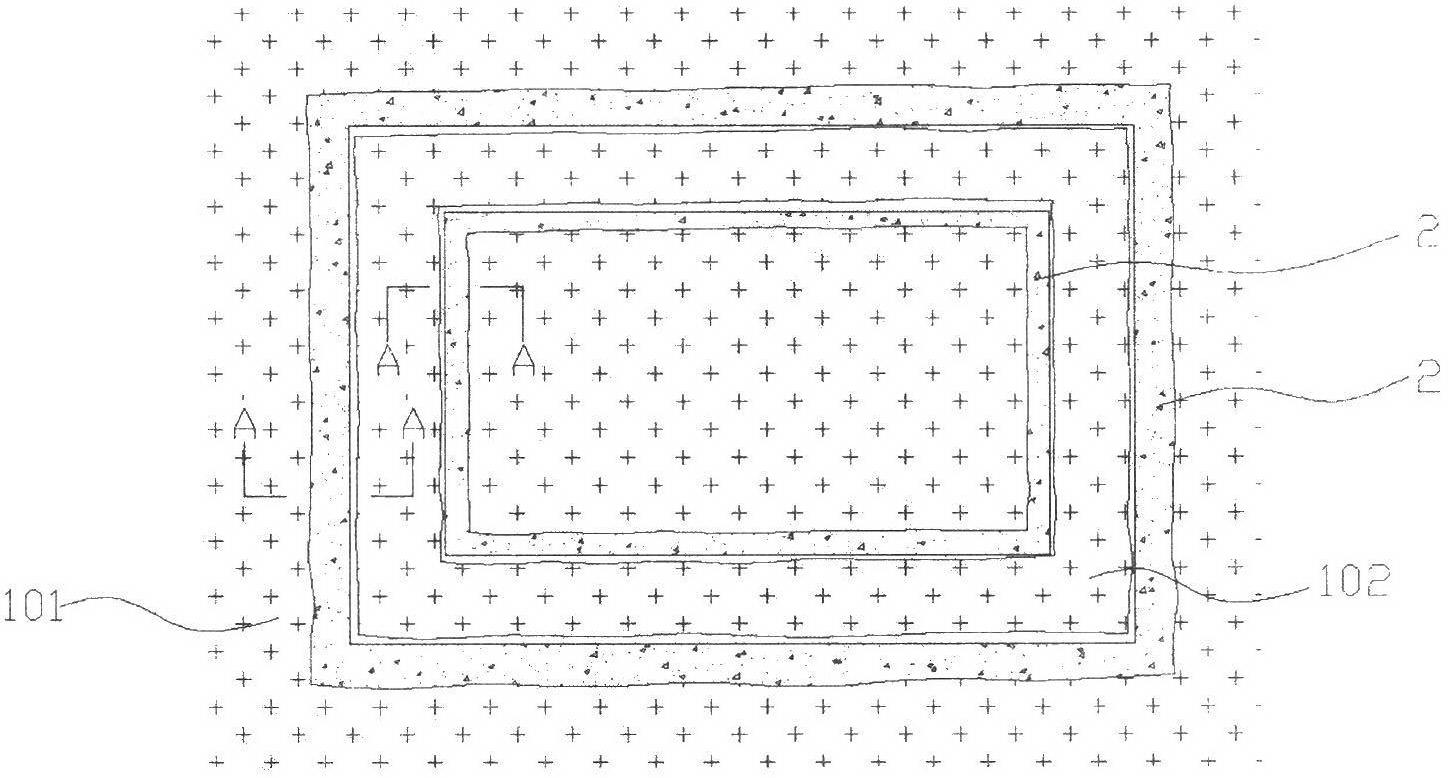

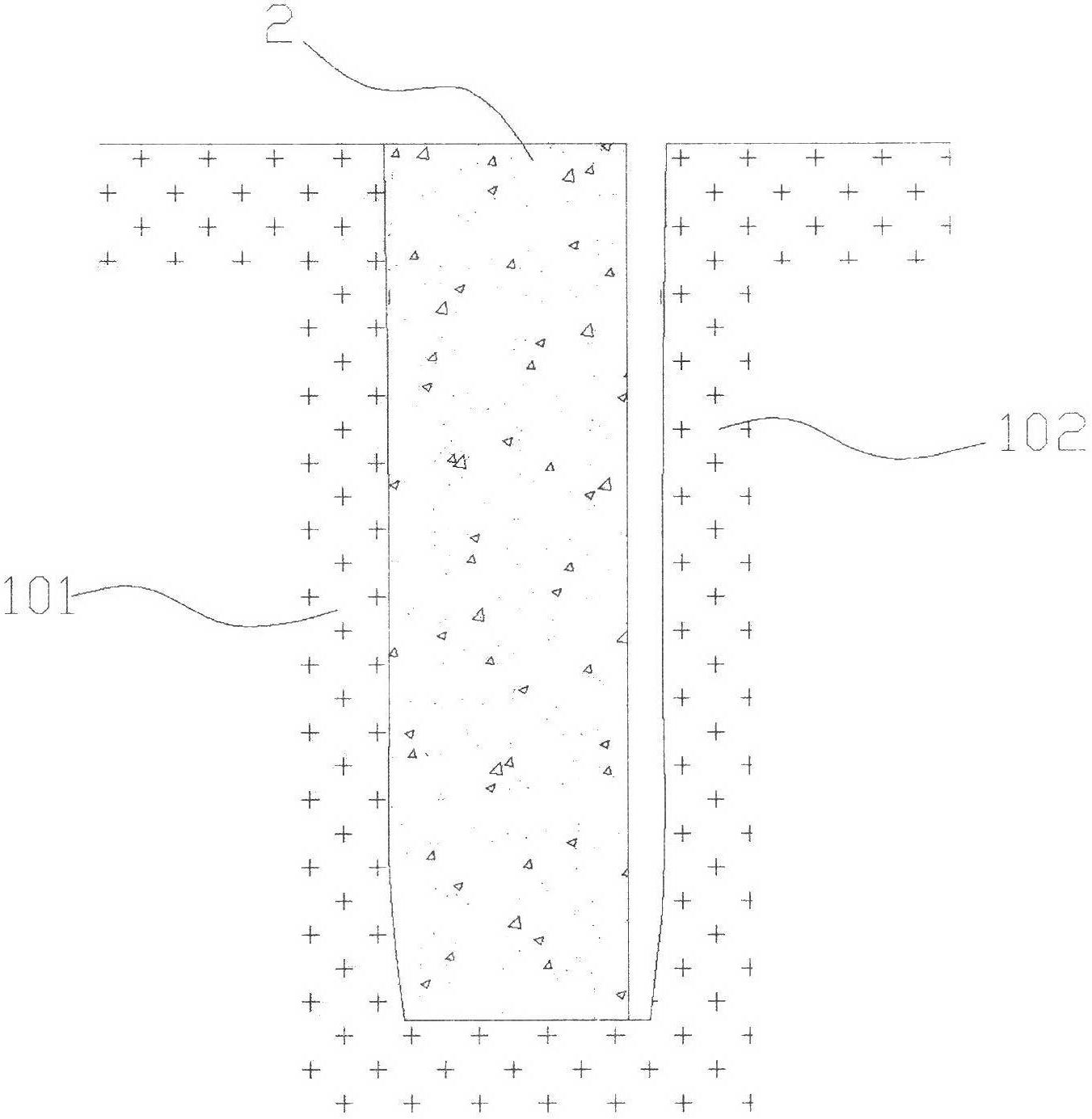

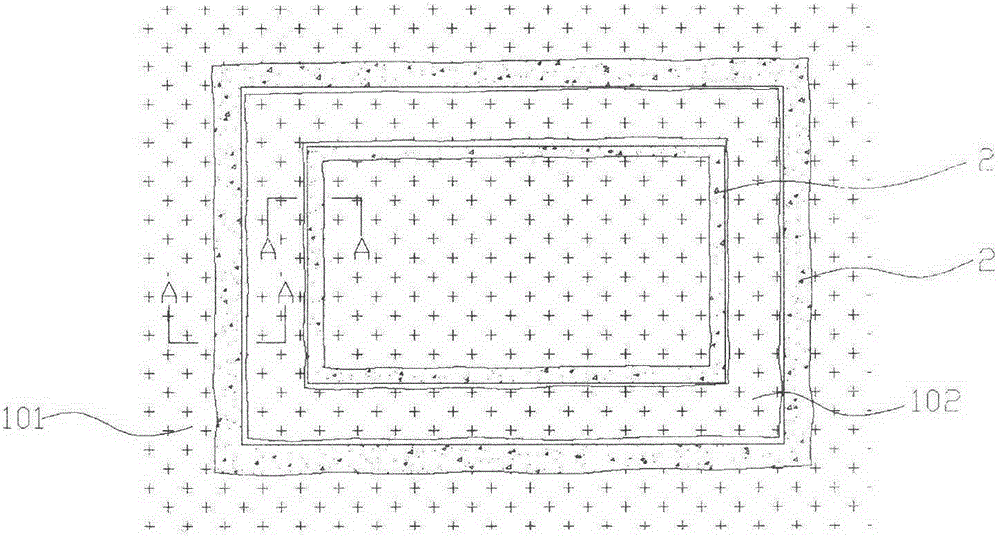

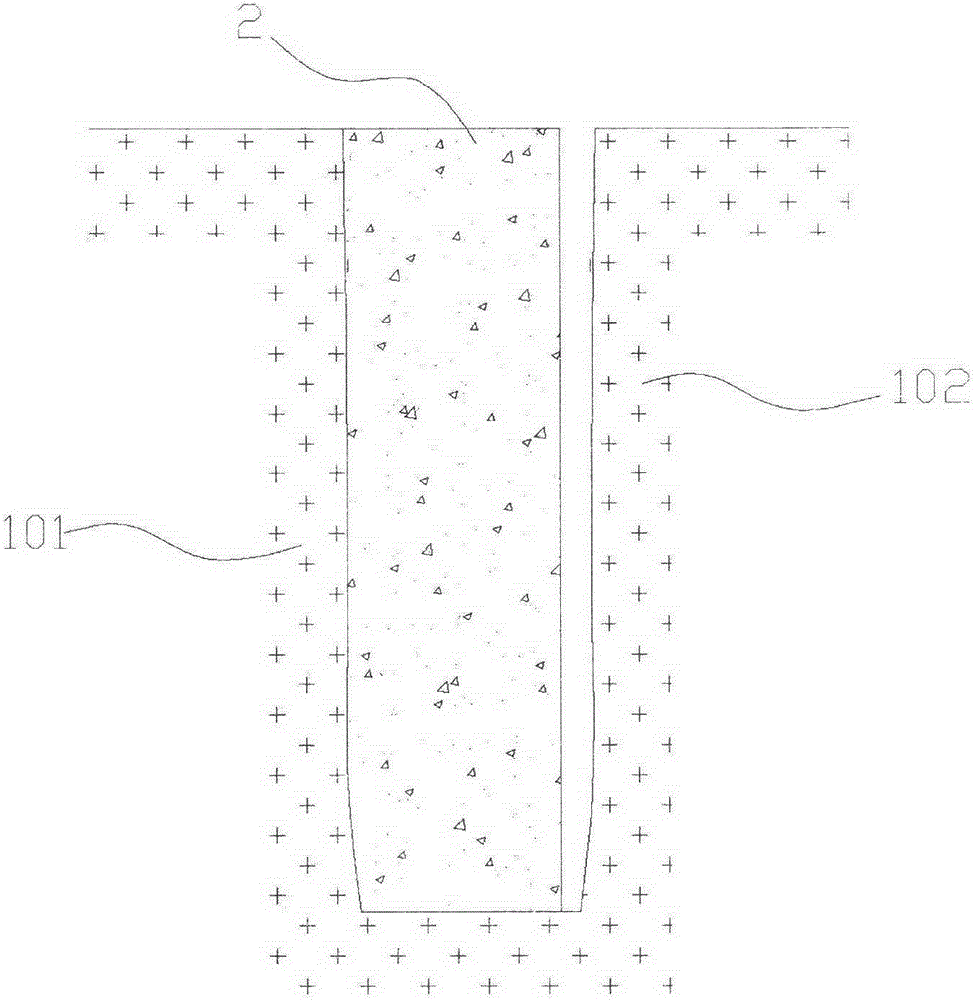

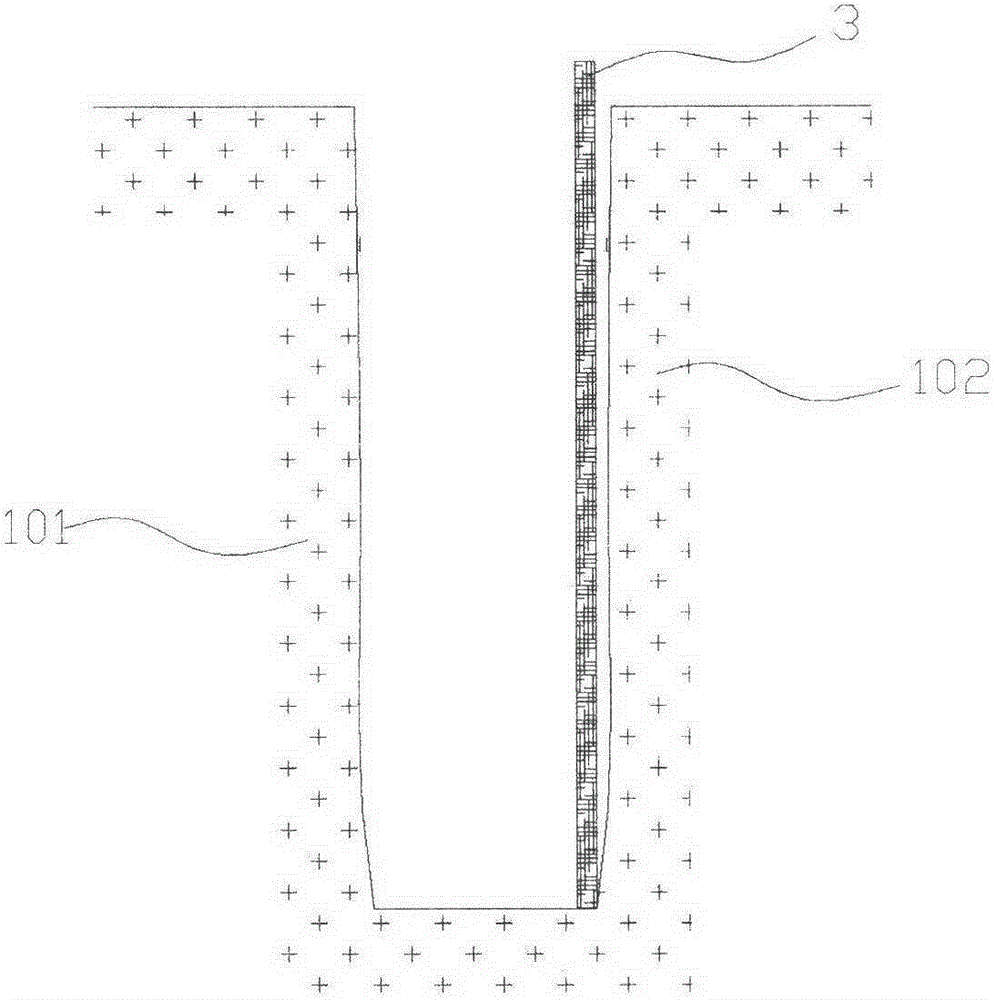

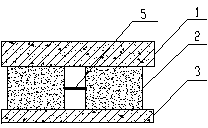

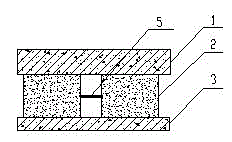

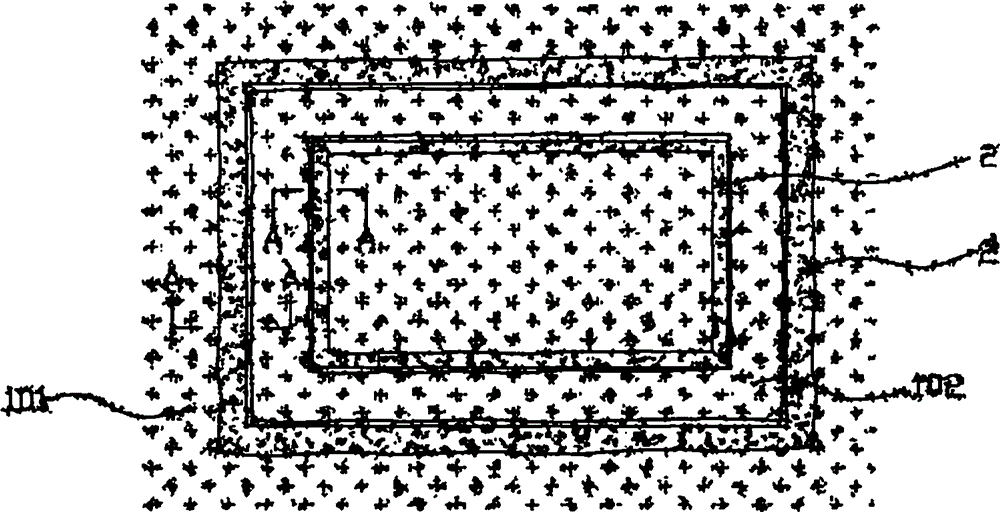

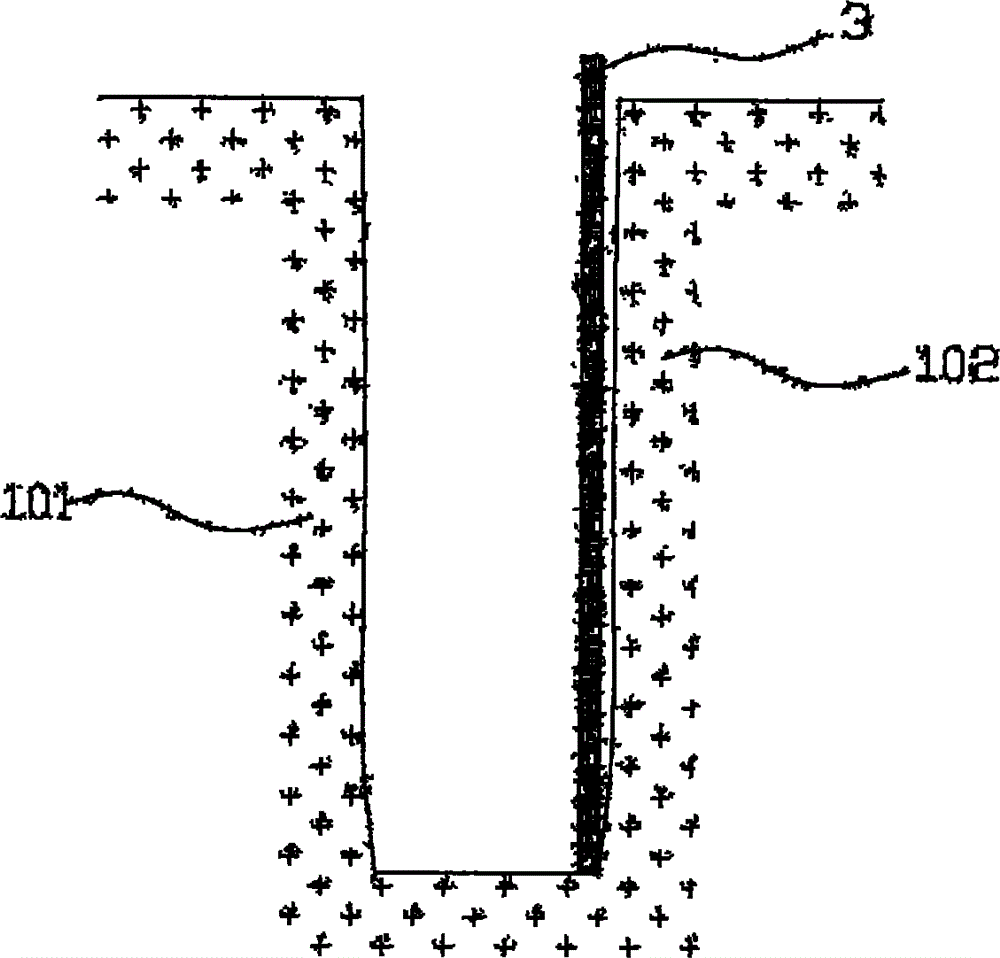

Concrete moulding bed structure and pouring method

The invention discloses a concrete moulding bed structure and a pouring method, belonging to the treatment before pouring of concrete on the foundation in the building construction. The invention aims to solve the problems frequently occurred in the existing common brick moulding bed construction that a great quantity of clay bricks are needed, one-time moulding cannot be realized and a great quantity of backfill is needed after the completion of the construction. The invention provides a structure and pouring method which are time-saving, labor-saving and are beneficial to the environmental protection. The concrete moulding bed structure provided by the invention is composed of a concretemoulding bed, a foundation pit outer wall and a moulding bed foundation pit inner wall, wherein the concrete moulding bed is formed by pouring along the foundation pit outer wall and molded in the longitudinal direction, and the concrete tie shuttering tightly contacts the foundation pit outer wall. The pouring method of the concrete moulding bed structure provided by the invention comprises the steps of performing earth excavation, performing foundation pit dewatering, setting up a concrete moulding bed inner side formwork, pouring the concrete moulding bed, removing the formwork and the like.

Owner:薛忠群

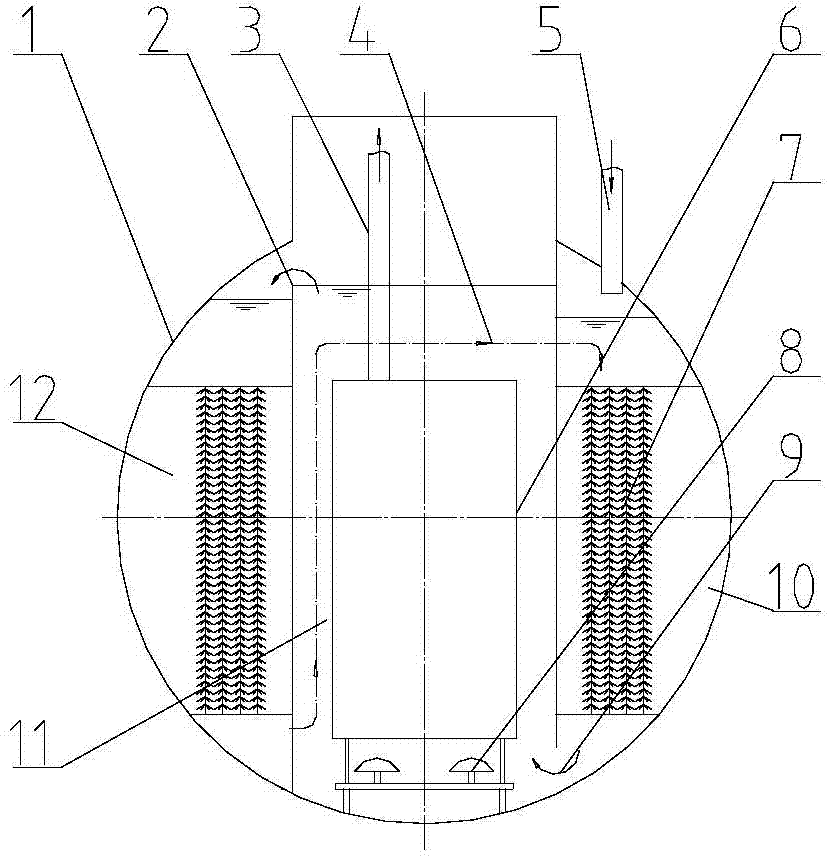

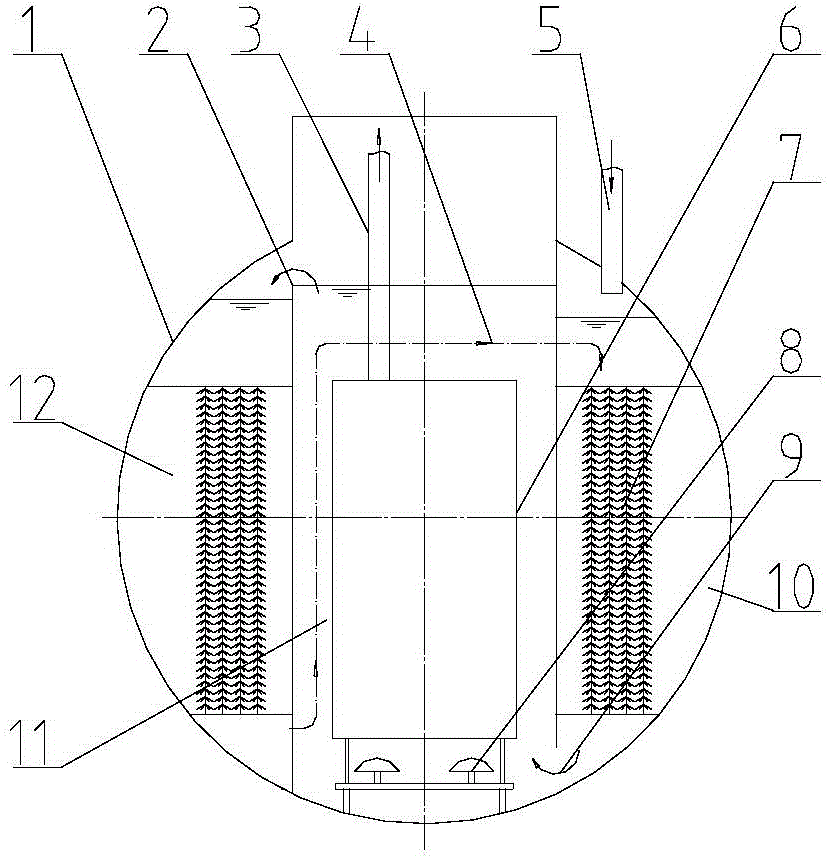

Integrated sewage treatment facility based on MBR (membrane bioreactor) membrane technique and sewage treatment method thereof

ActiveCN103936156AFull biochemical reactionCompact structureTreatment with aerobic and anaerobic processesMembrane bioreactorBiological organism

The invention discloses an integrated sewage treatment facility based on an MBR (membrane bioreactor) membrane technique, which comprises a tank body, and an anaerobic biochemical region, an anoxic biochemical region and an aerobic and MBR membrane bioreaction region which are arranged in the tank body, wherein the anaerobic biochemical region, aerobic and MBR membrane bioreaction region and anoxic biochemical region are distributed on the left, in the middle and on the right of the cross section of the tank body; the anaerobic biochemical region and the aerobic and MBR membrane bioreaction region are communicated with each other only through the bottoms; the top liquid level of the aerobic and MBR membrane bioreaction region is higher than the top liquid level of the anoxic biochemical region; the top of the aerobic and MBR membrane bioreaction region is provided with a water outlet pipe extending into the aerobic and MBR membrane bioreaction region, and an overflow weir communicated with the anoxic biochemical region; the upper part liquid level of the anoxic biochemical region is higher than the upper part liquid level of the anaerobic biochemical region; the bottom of the anoxic biochemical region is communicated with the upper part of the anaerobic biochemical region through a gravity pipeline; and the tank body is provided with a water inlet pipe communicated with the anaerobic biochemical region in the tank body. The invention also discloses a sewage treatment method using the facility.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

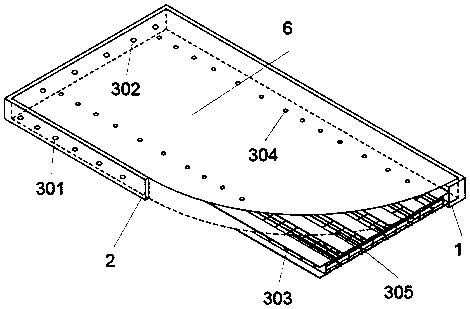

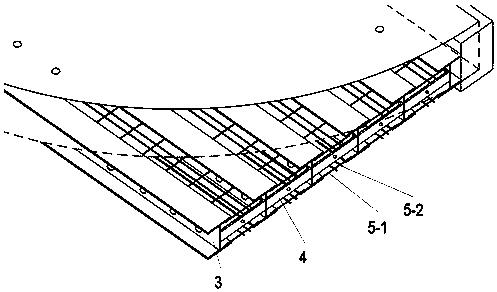

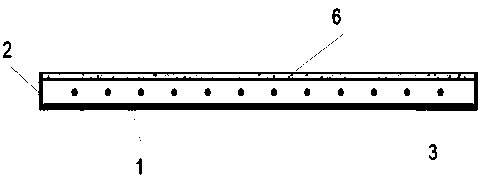

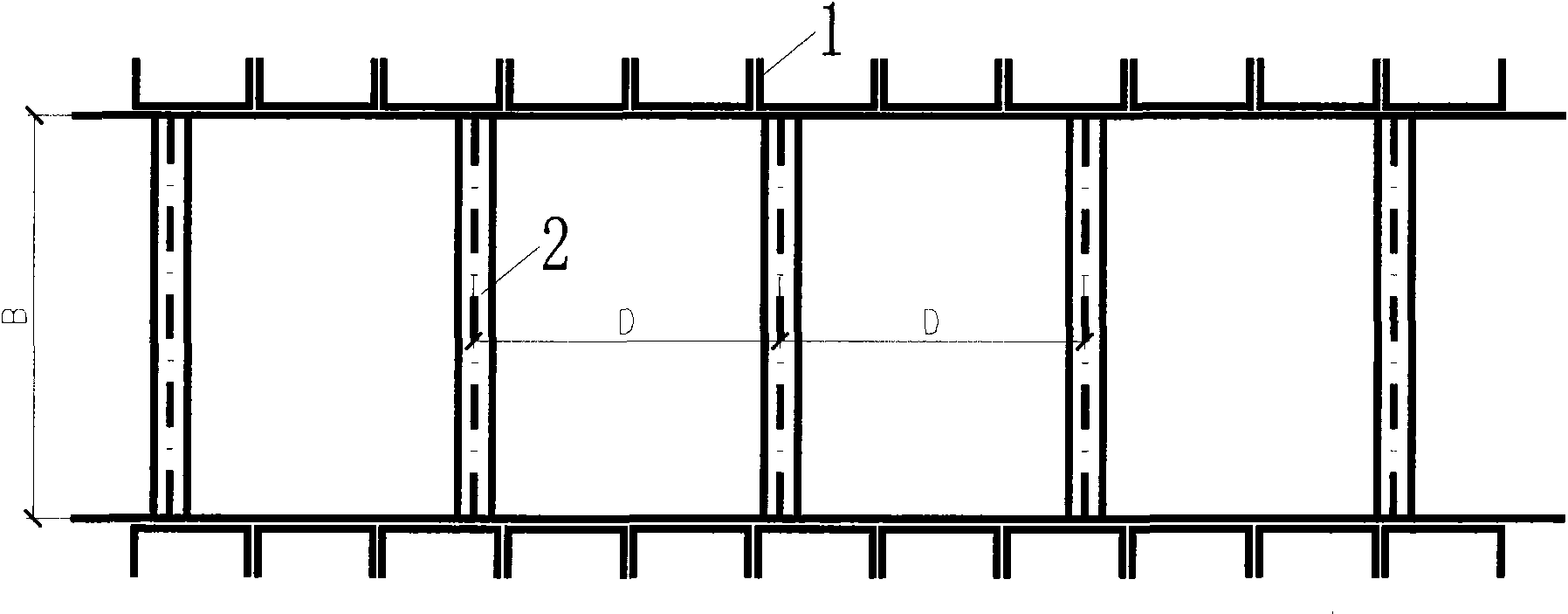

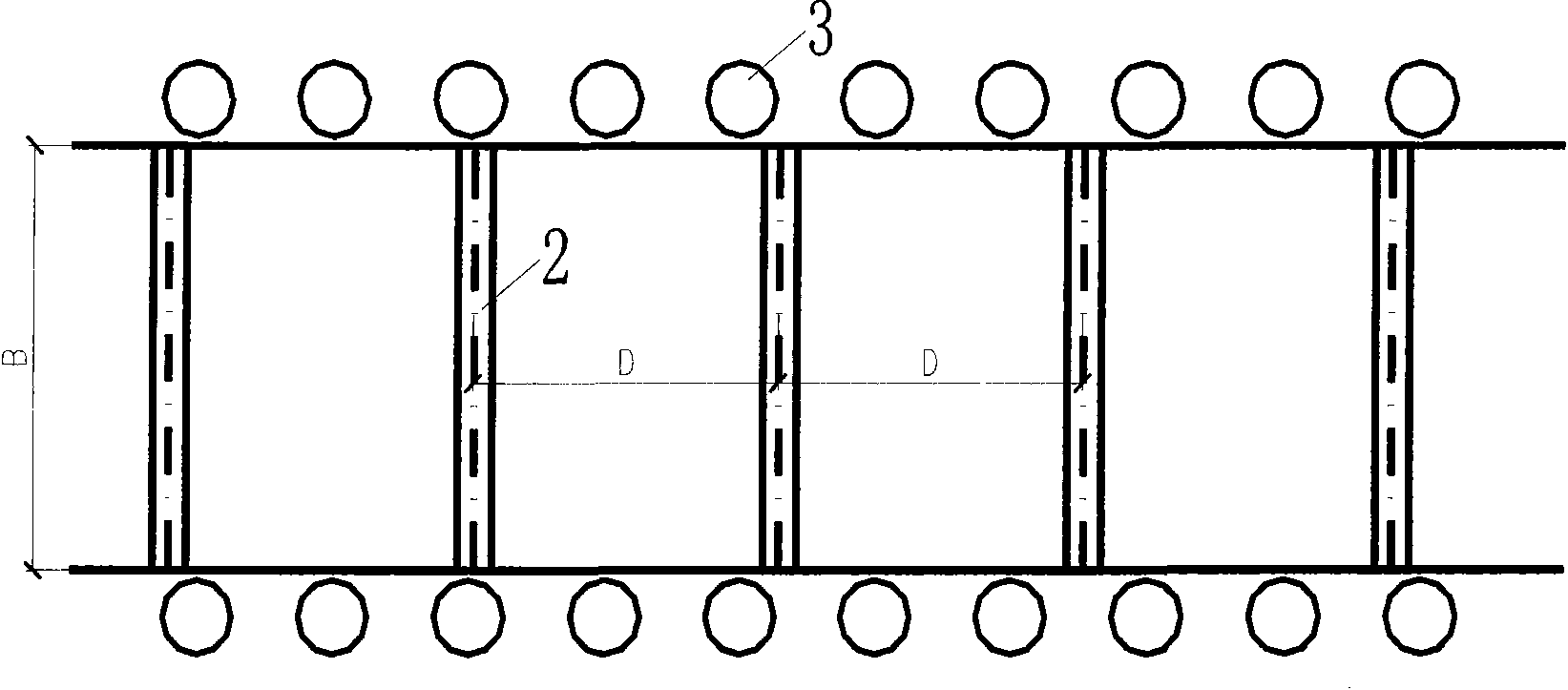

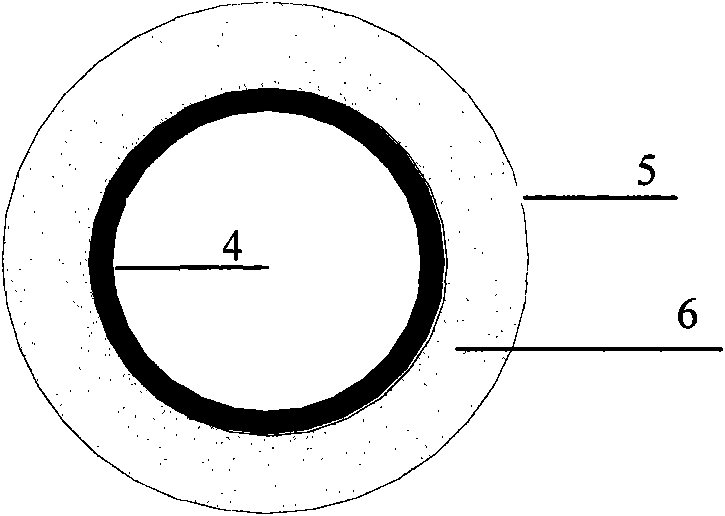

Prefabricated assembled FRP-profile steel-concrete combined bridge deck slab and construction method thereof

ActiveCN110983968ALightweight and high strengthIncreased durabilityBridge structural detailsBridge materialsWhole bodyPre stress

The invention relates to a prefabricated assembled FRP-profile steel-concrete combined bridge deck slab and a construction method thereof. The prefabricated assembled FRP-profile steel-concrete combined bridge deck slab comprises an FRP formwork, prestressed I-shaped steel, reinforcing meshes, corrugated pipes and concrete. The FRP formwork comprises an FRP bottom formwork and four FRP baffles. The prestressed I-shaped steel comprises I-shaped steel, prestress memory alloy ribs and connecting pieces. The prestressed I-shaped steel is arranged on the FRP bottom formwork at intervals in the transverse direction of the bridge, and circular holes are reserved in webs of the I-shaped steel. The reinforcing meshes are connected to the upper and lower flanges of the prestressed I-shaped steel. The corrugated pipes are connected in the holes of the formwork and the section steel. The concrete, the FRP template, the prestressed I-shaped steel and the reinforcing meshes form a whole body to be stressed together. According to the combined bridge deck slab, the bearing capacity of a bridge is greatly enhanced, the consumption of steel can be obviously reduced, the manufacturing cost is reduced, and the self-weight of the bridge deck slab structure is reduced. Through the use of the FRP bottom formwork, corrosion resistance can be achieved, and durability is improved. Moreover, the characteristics of light weight and high rigidity are achieved, the construction efficiency can be improved, and the combined bridge deck slab has wide application prospects.

Owner:YANGZHOU UNIV

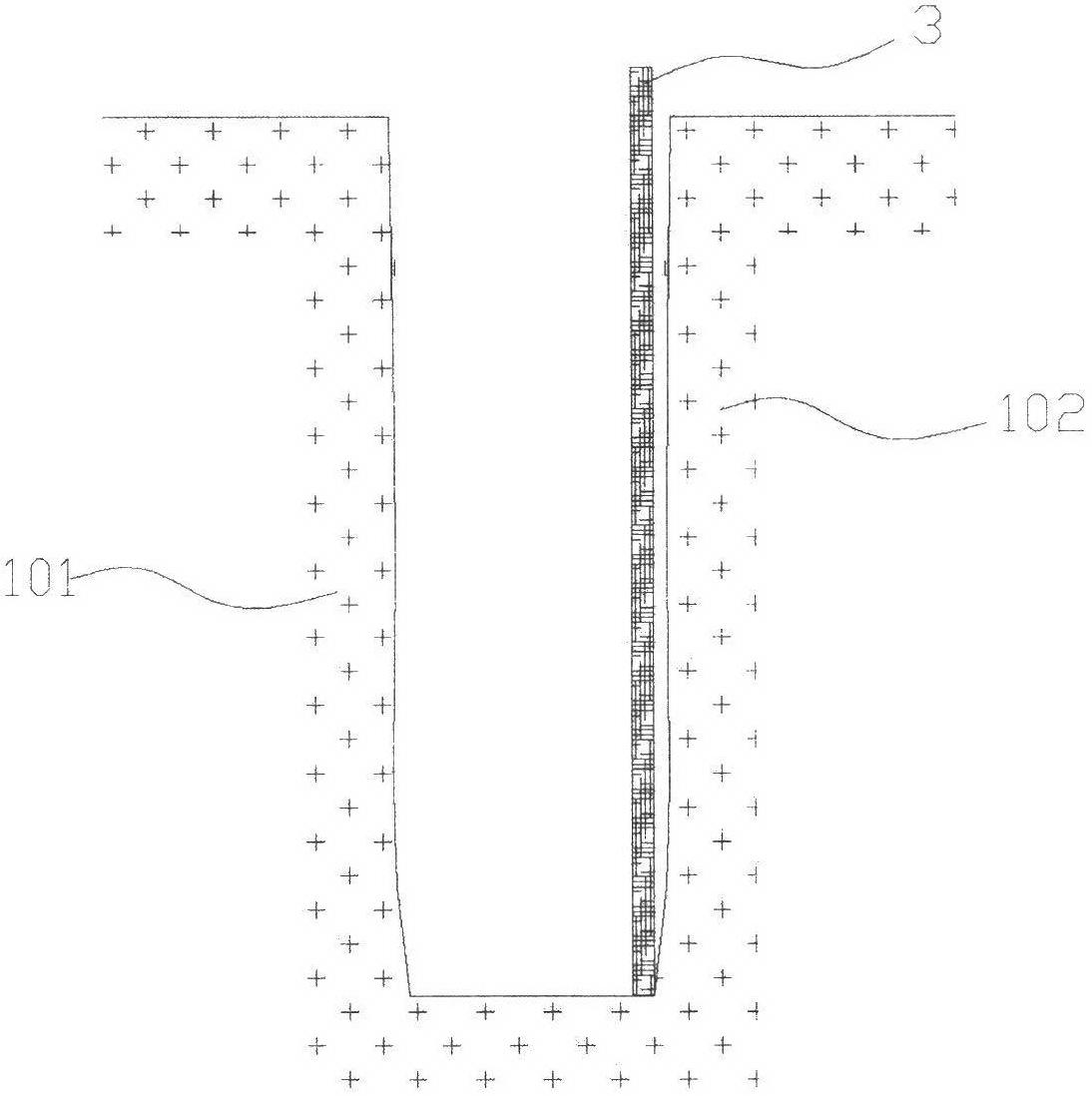

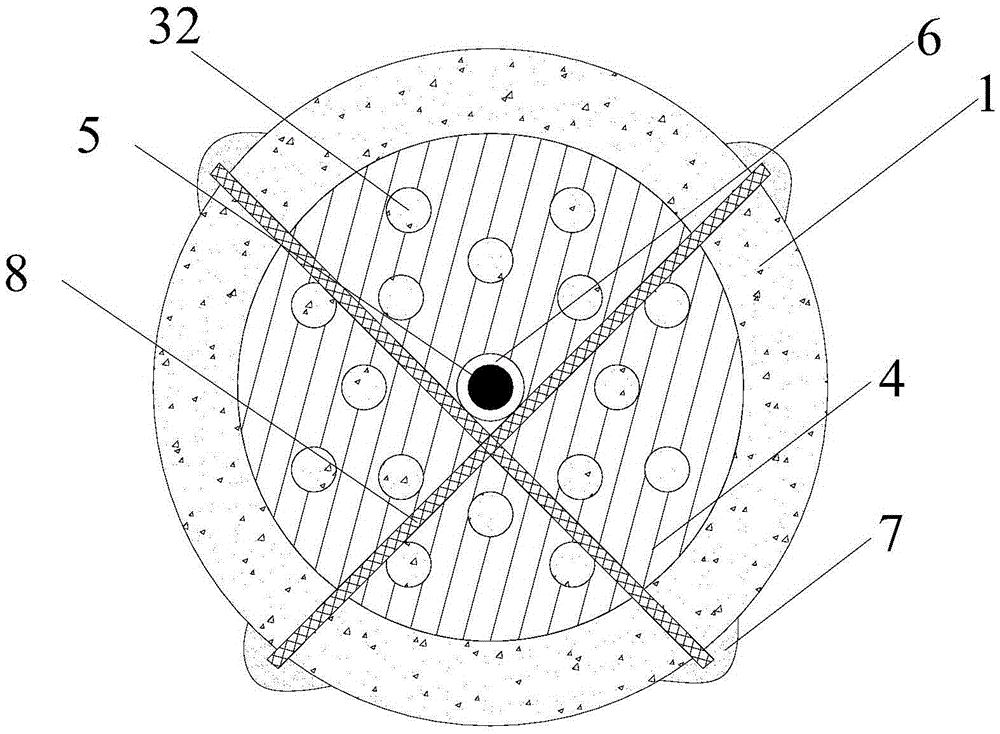

Construction method of cylindrical slurry core pile for retaining and protecting foundation pit

The invention relates to a method of a cylindrical slurry core pile for retaining and protecting a foundation pit, belonging to a foundation pit construction method and the field of machines in municipal engineering. In the method, before dredging the foundation pit, cylindrical slurry core piles which are formed by field slurry molding bodies which are connected by center pre-setting hollow core materials and outer walls are arranged along the two wall bodies of the foundation pit at interval, that is, the core materials are pre-arranged and located in a pile hole which is drilled mechanically through the location of the pile hole, the hole between the core materials and the pile hole is injected with colloidal slurry, after the slurry is coagulated, the slurry and the core materials form single cylindrical slurry core pile; according to the design, after retaining and protecting the rows of the slurry core piles at the two sides of the wall body of the foundation pit, the foundation pit is dredged, the earth is backfilled after carrying out the construction, the pre-setting core materials are pulled out from the pile, and the pile hole is backfilled with sandy soil; the method is a simple retaining and protecting method of hollow cylindrical piles aiming at the earth with good quality, the mechanical hole-forming is adopted, the occupying area is small without big dredging construction, the environment is beneficial to being protected, the core materials of steel tubes can be used repeatedly, the resource is saved, and the method has wide application range.

Owner:WUHAN MUNICIPAL ENG DESIGN & RES INST

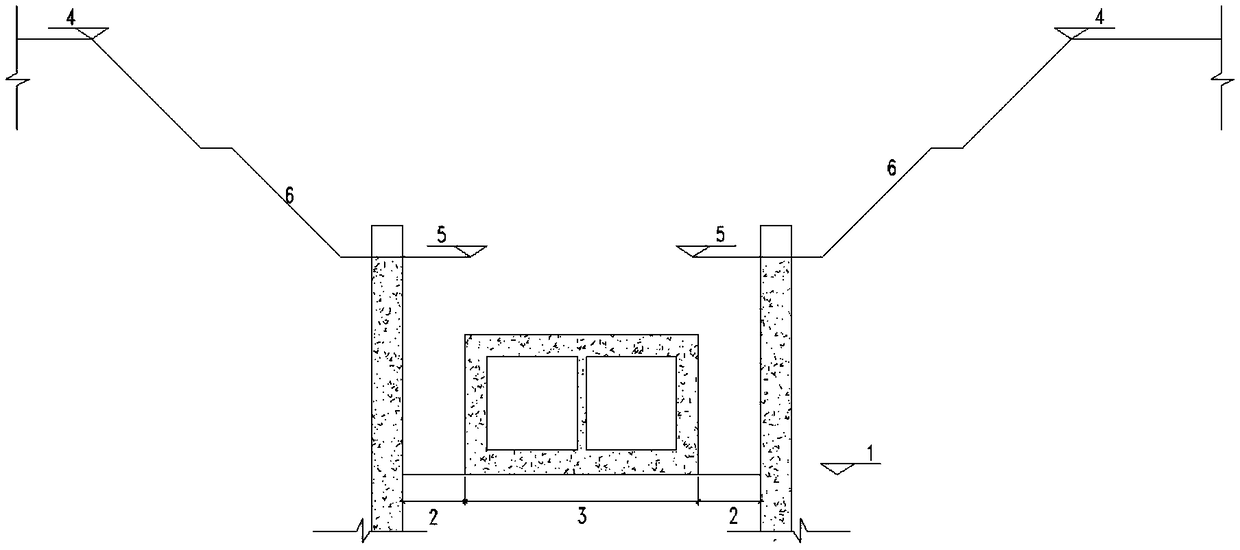

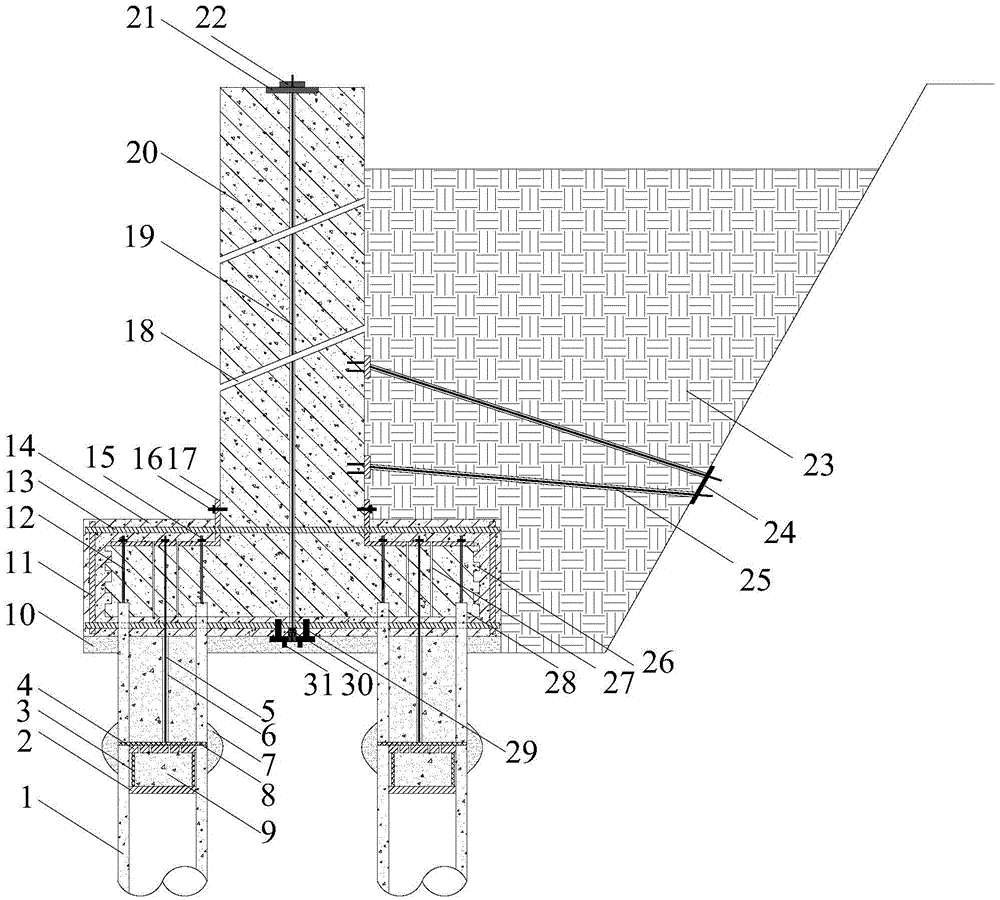

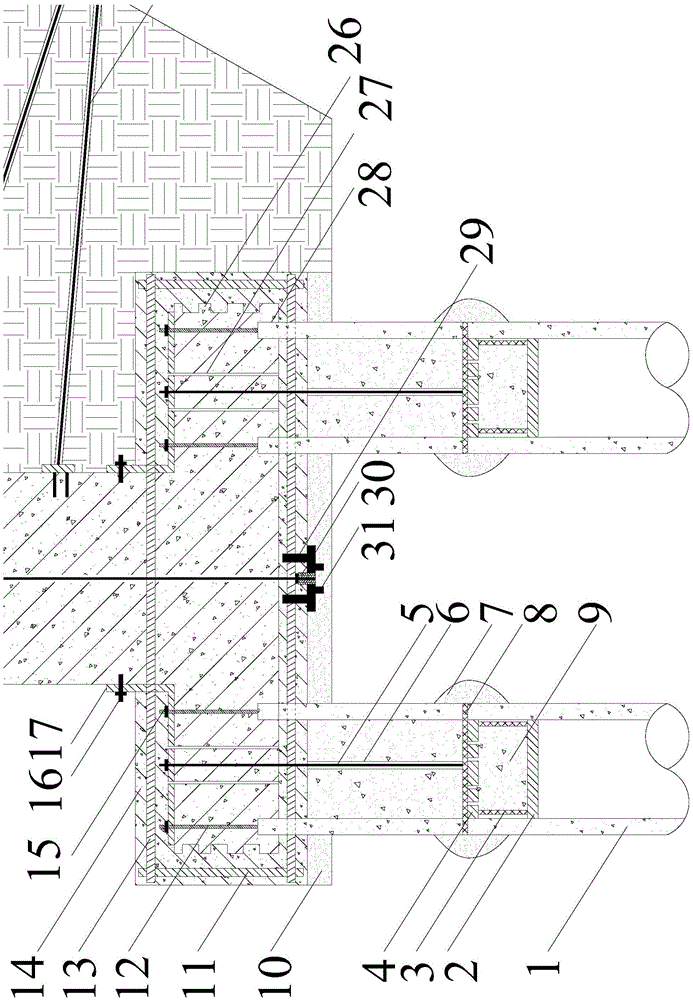

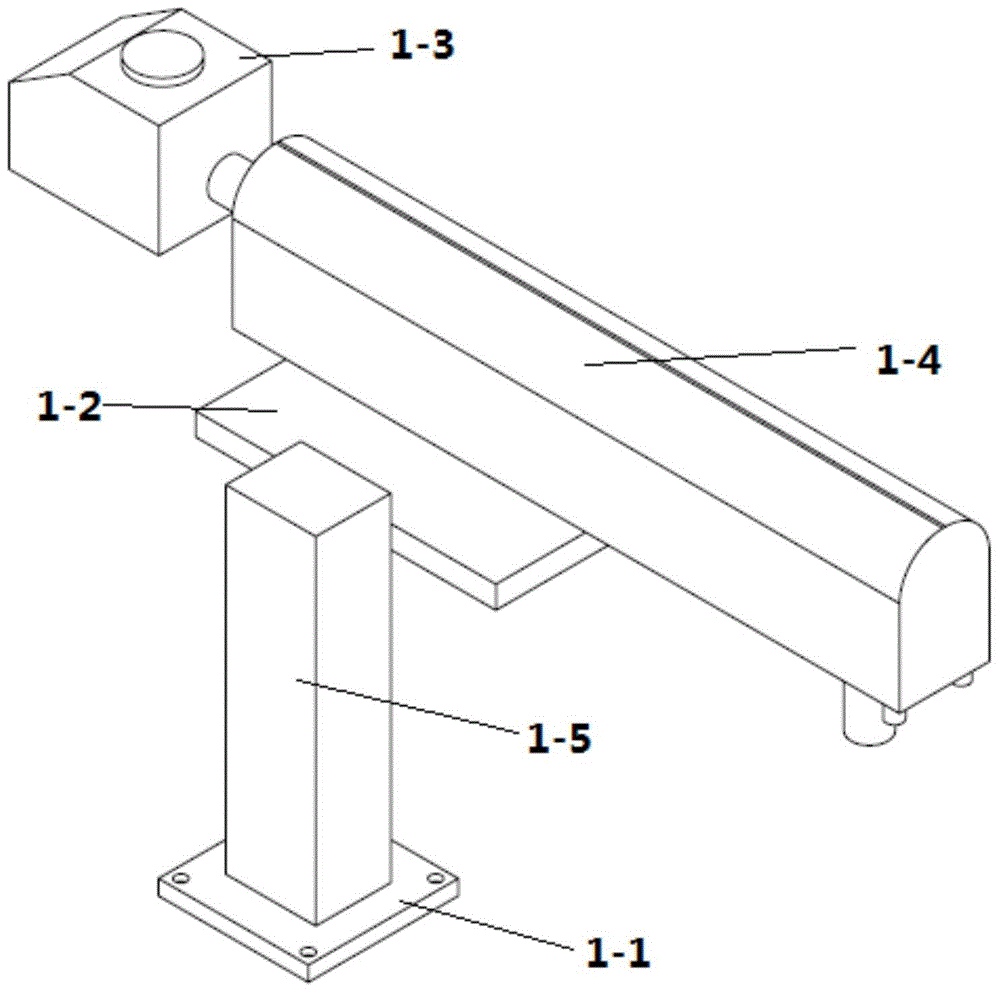

Composite supporting method used for ultra-deep comprehensive pipe rack foundation ditch in water crossing riverway

InactiveCN108951641ALess machineryReduce support costsArtificial islandsExcavationsEngineeringHigh pressure

The invention discloses a composite supporting method used for an ultra-deep comprehensive pipe rack foundation ditch in a water crossing riverway, and belongs to the technical field of underground urban comprehensive pipe rack deep foundation pit supporting. The method comprises the steps that firstly, a riverway cofferdam is constructed, and a drainage tube is mounted; secondly, riverway dredging within the construction range is carried out; thirdly, slope excavation to the top of a cast-in-place pile is carried out; fourthly, slope surface soil nails are put, and jet-anchor execution is carried out; fifthly, cast-in-situ bored pile construction is carried out; sixthly, a crown beam is constructed; seventhly, a pile back side high-pressure rotary jet grouting waterstop curtain is constructed; ninthly, excavation of foundation pit and construction of a crossed pipe rack main structure are carried out, after the lower foundation pit supporting and maintaining period is finished, earthwork on the foundation pit on the lower portion begins to be excavated and constructed, the earthwork is dug to the bottom at a time, and crossed main body structure is constructed. The currently-conventional supporting method is combined, supporting structure reliability is improved, construction cost is reduced, the construction proceed is quickened, and the influence on the environment and watercan be reduced.

Owner:CHINA MCC17 GRP

Assembly-type protective construction method for slab-pile wall through pre-stressed anchor cables

InactiveCN105464128AShorten construction timeGood economic benefitsArtificial islandsUnderwater structuresPre stressingEngineering

The invention relates to an assembly-type protective construction method for a slab-pile wall through pre-stressed anchor cables. The slab-pile wall mainly comprises a prefabricated pipe pile, a prefabricated slab-pile wall body, the in-wall pre-stressed anchor cable, a post-pouring foundation and the fill side pre-stressed anchor cable. The assembly-type protective construction method comprises the steps that 1, the prefabricated pipe pile is internally provided with an upper end plate and a lower end plate, core grouting is conducted between the lower end plate and the top of the pipe pile through concrete, the pre-stressed anchor cables are arranged on the top of the upper end plate, and the tops of the anchor cables and reserved reinforcing steel bars on a pile wall are together anchored to the top of a prefabricated slab-pile wall body foundation; 2, the prefabricated slab-pile wall body is internally provided with the vertical pre-stressed anchor cables and a drainage channel, the bottom of the slab-pile wall body foundation is embedded in the top of the prefabricated pipe pile, and the post-pouring foundation is arranged around the slab-pile wall body foundation; and 3, the slab-pile wall body and a side slope are pulled and connected through the pre-stressed anchor cables, and gas bubble light soil is backfilled between the slab-pile wall body and the side slope. According to the assembly-type protective construction method for the slab-pile wall through the pre-stressed anchor cables, integral assembly-type installing of the protective structure of the slab-pile wall is achieved, and meanwhile the stability of the slab-pile wall is effectively ensured by arranging the structures of the pre-stressed anchor cables and the like.

Owner:SHANGHAI JIASHI (GROUP) CO LTD

Concrete moulding bed structure and pouring method

The invention discloses a concrete moulding bed structure and a pouring method, belonging to the treatment before pouring of concrete on the foundation in the building construction. The invention aims to solve the problems frequently occurred in the existing common brick moulding bed construction that a great quantity of clay bricks are needed, one-time moulding cannot be realized and a great quantity of backfill is needed after the completion of the construction. The invention provides a structure and pouring method which are time-saving, labor-saving and are beneficial to the environmental protection. The concrete moulding bed structure provided by the invention is composed of a concretemoulding bed, a foundation pit outer wall and a moulding bed foundation pit inner wall, wherein the concrete moulding bed is formed by pouring along the foundation pit outer wall and molded in the longitudinal direction, and the concrete tie shuttering tightly contacts the foundation pit outer wall. The pouring method of the concrete moulding bed structure provided by the invention comprises the steps of performing earth excavation, performing foundation pit dewatering, setting up a concrete moulding bed inner side formwork, pouring the concrete moulding bed, removing the formwork and the like.

Owner:薛忠群

U-shaped anti-changing column and chute template system for rammed earth walls

PendingCN108571163AImprove general performanceQuality improvementForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSupporting systemDynamic compaction

The invention discloses a U-shaped anti-changing column and chute template system for rammed earth walls, which can be used for special template for the construction of the linear rammer body and theL-shaped wall body. The supporting system mainly comprises three aspects: a wood-shaped smooth mold plate, a long-length U-shaped anti-changing column suitable for layer-by-layer compaction, and an adjustable high-strength section steel triangular support frame. The wooden mold plate is inserted into the standard fixed-type long-length U-shaped anti-variable column to form a whole, and the supportside is supported by the adjustable high-strength section steel triangular support frame., and mainly comprises a vertical rod, an inclined rod and a horizontal sliding rod. The two sides of the wallbody are symmetrically arranged to be supported to ensure the stable and follow layer-by-layer support and layer-by-layer compaction, the steel braced tripod square steel tube members are connected with the U-shaped anti-changing columns by pin bolts, and two U-shaped anti-changinge columns at L-shaped corner of rammed earth wall are welded together to ensure that the lateral pressure meets the strength requirements. The U-shaped anti-changing column and chute template system not only can satisfy the linear rammer, but also can realize the dynamic compaction of the L-type wall body with highquality.

Owner:TIANJIN CHENGJIAN UNIV

The Method of Utilizing Vegetable Modified Sand Body to Control Gobi

ActiveCN103348833BImprove economyLow costCultivating equipmentsHorticulturePlanting seedWater soluble

The invention discloses a method for governing gobi by utilizing vegetal modified sand. The vegetal modified sand is paved on the surface of gobi to be governed, and is formed by dissolving a water-soluble solid organic matter in water to form a cohesive and adhesive solution, and mixing the cohesive and adhesive solution with plant seeds and sand; after moisture evaporates, the water-soluble solid organic matter can bond sand, and can be dissolved in water again after meeting water to form the cohesive and adhesive solution to bond sand. According to the invention, common sand can serve as soil; the interaction among sand grains is changed fundamentally; a particle pore structure with binding force (sticking force) is formed; materials cannot run off easily due to the cohesive and adhesive properties; the vegetal modified sand can be as stable as soil, and can store water and nutrients as soil; plants can grow directly after the vegetal modified sand is mixed with the plant seeds. Therefore, the method provides a solid condition for tree growth, and is an ideal gobi governing measure.

Owner:易志坚 +1

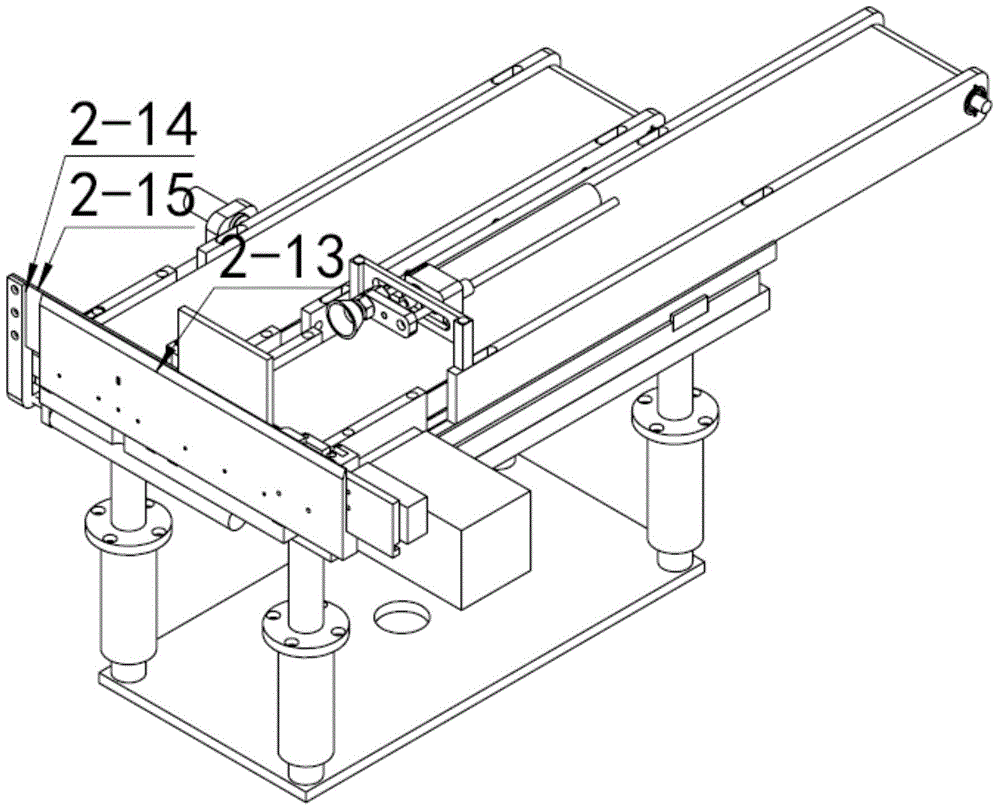

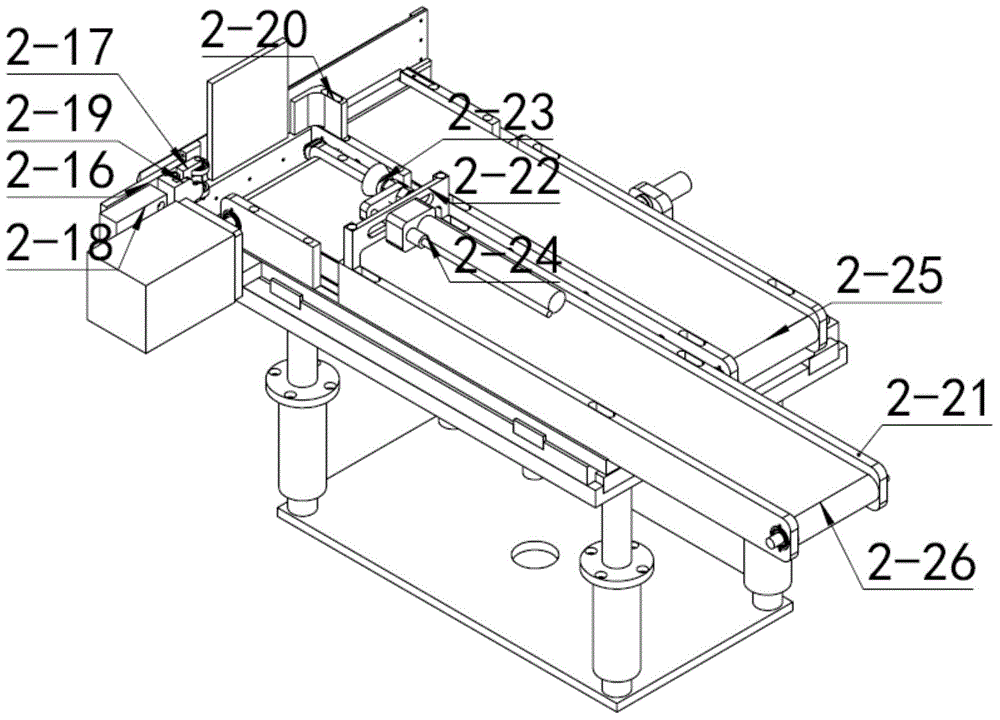

Full-automatic laser welding equipment for lithium battery and battery welding method

InactiveCN104907692APlace a large numberLess machineryWelding/soldering/cutting articlesMetal working apparatusElectrical batteryWork flow

The invention provides full-automatic laser welding equipment for a lithium battery and a battery welding method. The full-automatic laser welding equipment comprises a battery positioning mechanism, a PCB positioning mechanism, a connecting piece positioning mechanism and a laser positioning mechanism, wherein the battery positioning mechanism, the PCB positioning mechanism, the connecting piece positioning mechanism and the laser positioning mechanism automatically feed the battery, a PCB protective board and a connecting piece and finish automatic laser welding. The battery welding method includes the steps that the battery, the PCB and the connecting piece are positioned through the welding equipment, and then the positive electrode and the negative electrode of the lithium battery are welded simultaneously through laser. The full-automatic laser welding equipment for the lithium battery adopts the layout of four-direction centering (the front, rear, left and right directions moves towards the center simultaneously) in the design work process, has the advantages that a large amount of materials can be placed and a machine is small, can be correspondingly adjusted according to the different sizes and specifications of lithium batteries, and adjusts the operation speed according to the production number.

Owner:陈名裕

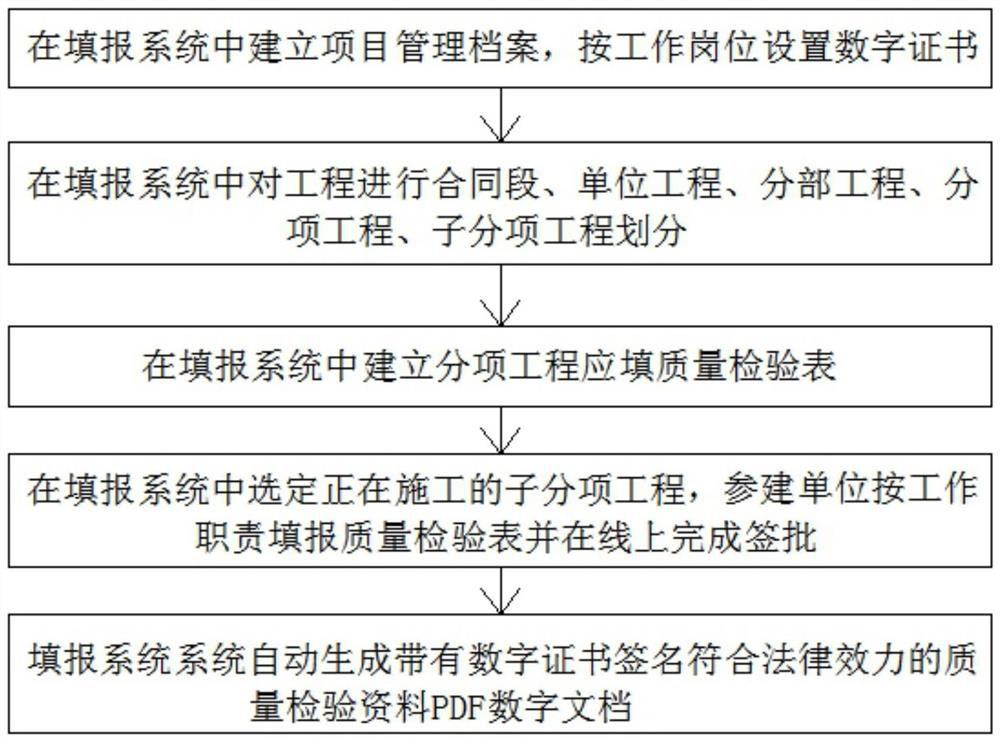

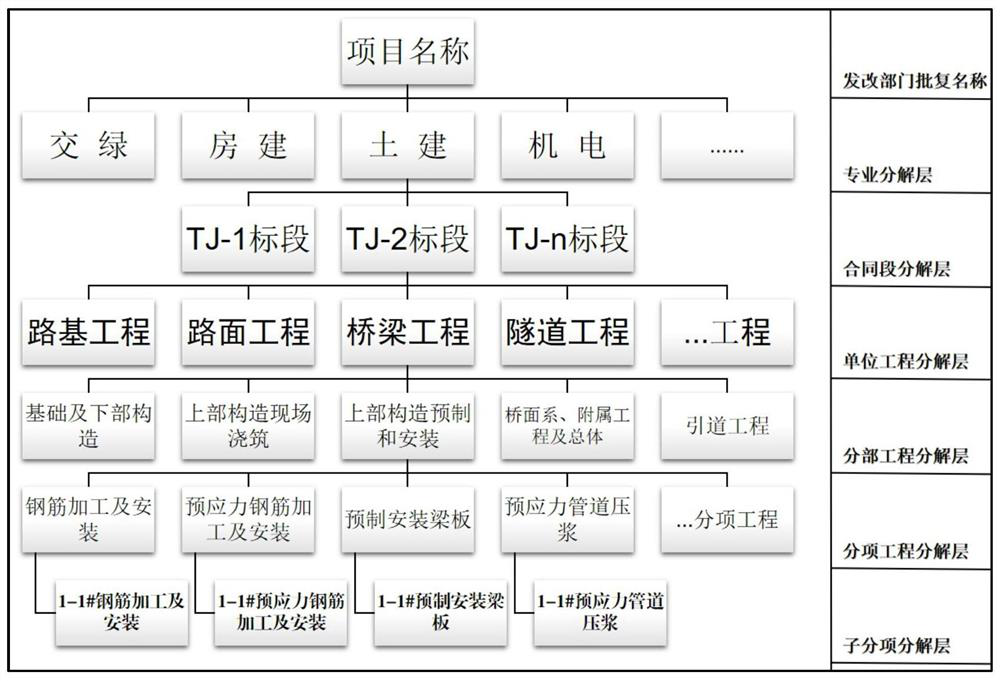

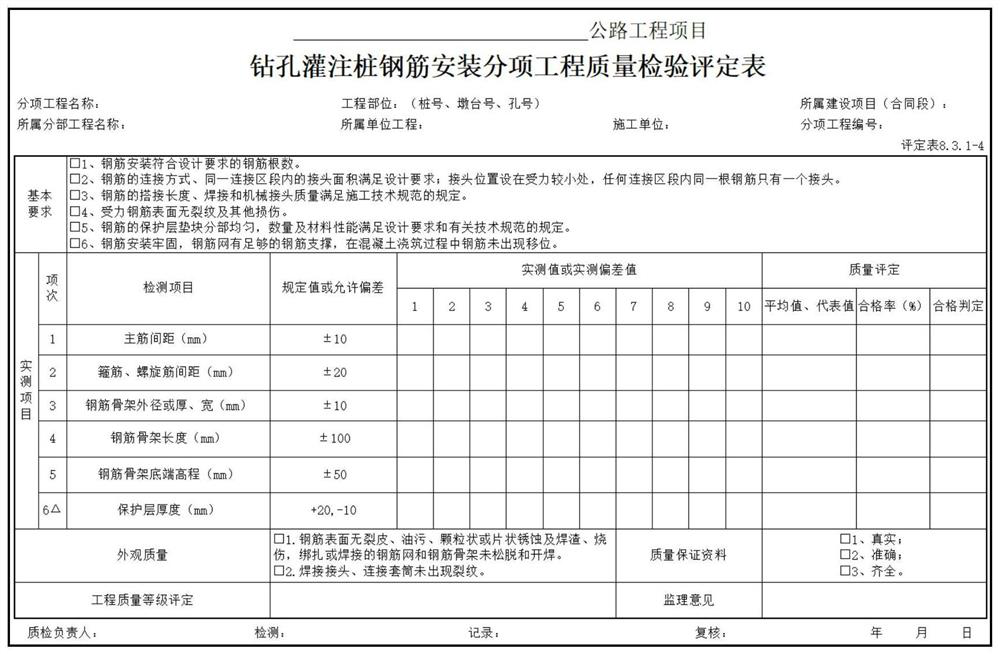

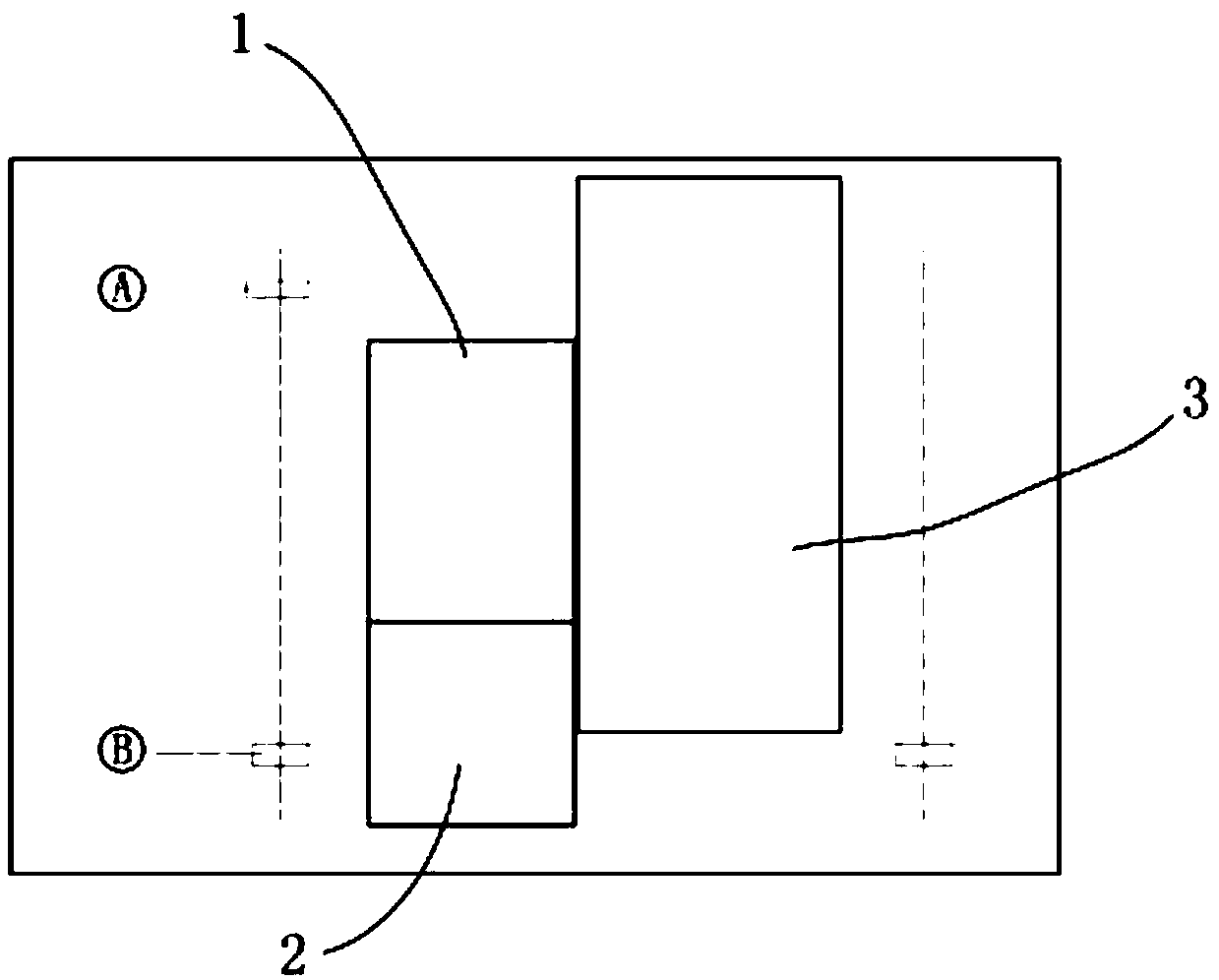

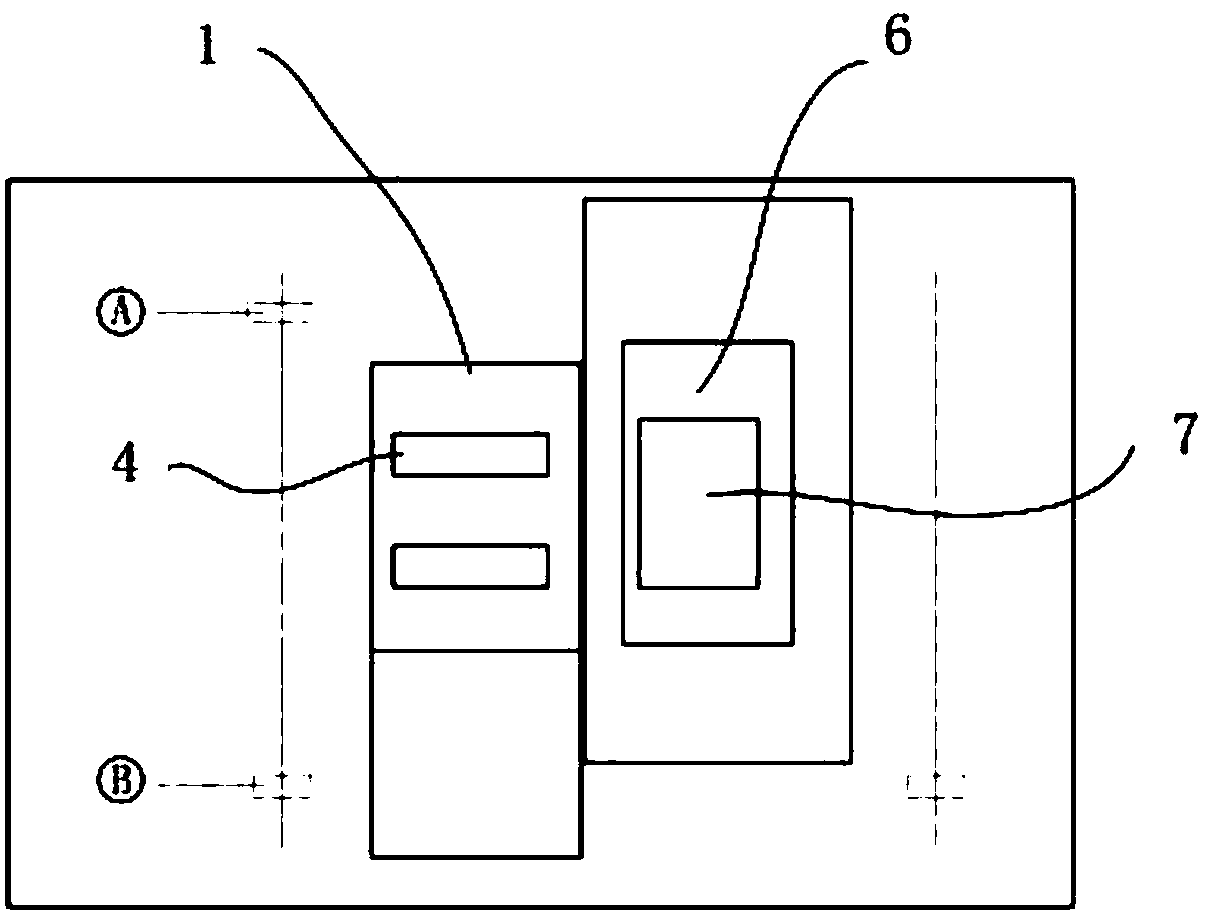

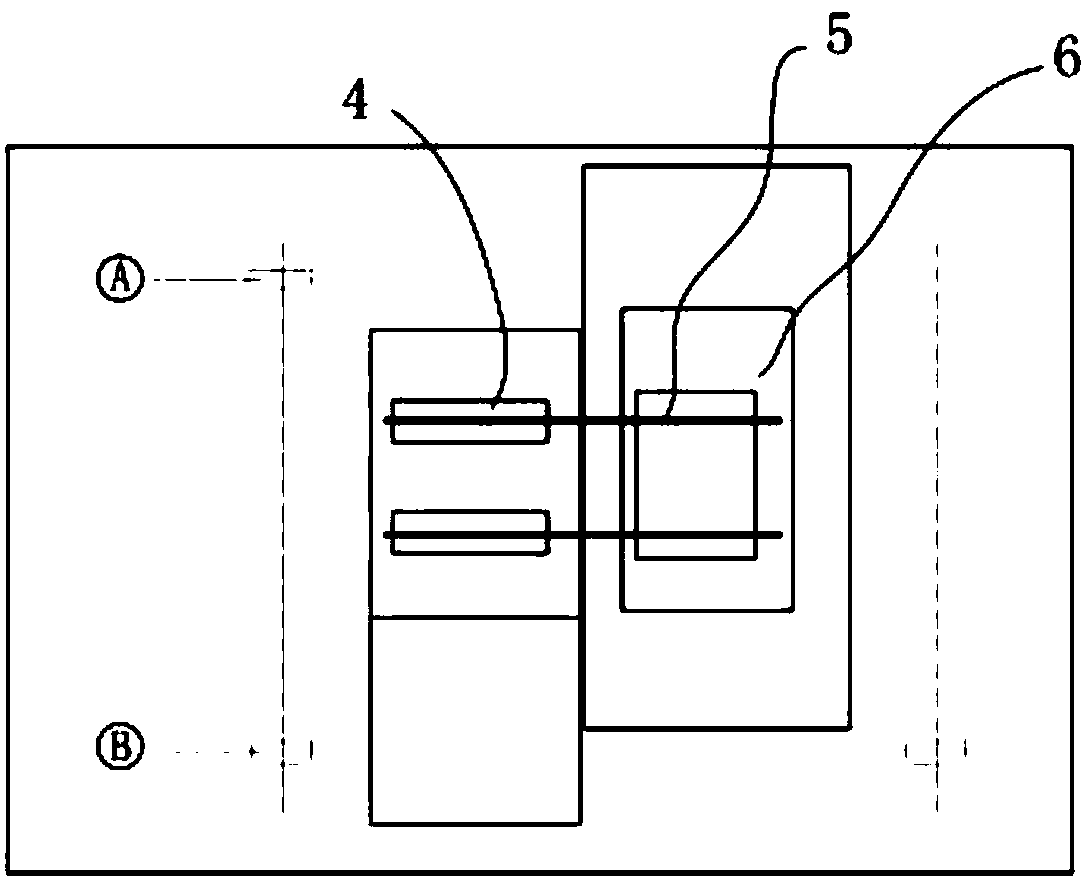

Highway engineering quality inspection data filling and reporting method based on digital technology

PendingCN113222340AAchieve sustainable developmentReduce usageNatural language data processingOffice automationEngineeringProject management

The invention discloses a highway engineering quality inspection data filling and reporting method based on a digital technology, and the method comprises the following steps: building a project management file in a filling and reporting system, and setting a digital certificate according to a working post; dividing the project into contract segments, unit projects, branch projects, subentry projects and sub-subentry projects in the filling system; establishing a subentry project filling quality check table in the filling system; selecting a sub-item project which is being constructed in a filling system, filling a quality inspection table by a construction participating unit according to work responsibilities, and completing signing on line; and enabling the filling and reporting system to automatically generate a quality inspection data PDF digital document which is provided with a digital certificate signature and accords with legal potency. According to the invention, the number of data personnel is effectively reduced, and the mechanical and repeated labor of quality personnel is reduced, so that more energy is provided for field quality management and control; and the artificial intelligence of quality inspection data processing and the digitalization of the quality inspection data are realized.

Owner:四川沿江攀宁高速公路有限公司

Hydraulic ejecting type mounting in-place method for generator of large gas turbine

InactiveCN109163170ASolve technical problems in installationReduce the cost of renting a shiftEngine bedsGas turbinesElectric generator

The invention aims to provide a hydraulic ejecting type mounting in-place method for a generator of a large gas turbine for solving the technical problem that the generator of the large gas turbine ismounted in place in a narrow space. The hydraulic ejecting type mounting in-place method for the generator of the large gas turbine comprises the following steps: I, backfilling a generator base; II,arranging a sleeper platform; and III, transferring the generator.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

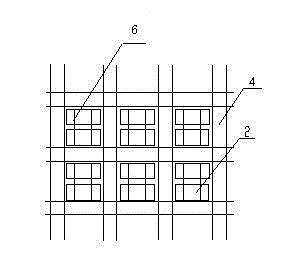

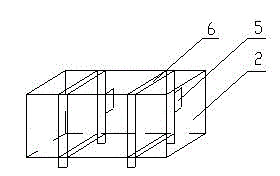

Construction method of garage roof structure

InactiveCN104234432AMeet pressure requirementsReduce dosageFloorsBuilding material handlingReinforced concreteFixed frame

The invention discloses a construction method of a garage roof structure. The construction method is characterized by comprising the following steps: 1, laying a bottom plate template; 2, determining the mounting position of an internal membrane component; 3, mounting the internal membrane component; 4, binding and fixing anti-floating reinforcing steel bars; 5, casting concrete. The garage roof structure sequentially comprises an upper layer roof, a multi-ribbed beam and a lower layer roof which are all of reinforced concrete structures from top to bottom; a concrete structure cavity internal membrane is placed in a closed cavity enclosed by the upper layer roof, the lower layer roof and the multi-ribbed beam, and comprises at least one internal membrane component; the surface of the internal membrane component is provided with an outer layer fire-proof coating and at least one PVC (Polyvinyl Chloride) fixed frame; the internal membrane component is a flame-retardant solid polystyrene foam block with density of being greater than 15 Kg / m<3>.

Owner:SHANDONG LIAOCHENG CONSTR +1

Method for governing gobi by utilizing vegetal modified sand

ActiveCN103348833AWith mechanical stabilityWith mechanical stability; from water retentionCultivating equipmentsHorticulturePlanting seedWater soluble

The invention discloses a method for governing gobi by utilizing vegetal modified sand. The vegetal modified sand is paved on the surface of gobi to be governed, and is formed by dissolving a water-soluble solid organic matter in water to form a cohesive and adhesive solution, and mixing the cohesive and adhesive solution with plant seeds and sand; after moisture evaporates, the water-soluble solid organic matter can bond sand, and can be dissolved in water again after meeting water to form the cohesive and adhesive solution to bond sand. According to the invention, common sand can serve as soil; the interaction among sand grains is changed fundamentally; a particle pore structure with binding force (sticking force) is formed; materials cannot run off easily due to the cohesive and adhesive properties; the vegetal modified sand can be as stable as soil, and can store water and nutrients as soil; plants can grow directly after the vegetal modified sand is mixed with the plant seeds. Therefore, the method provides a solid condition for tree growth, and is an ideal gobi governing measure.

Owner:易志坚 +1

Modified sandy soil with plant seeds

The invention discloses modified sandy soil with plant seeds, formed by mixing solution with a cohesive property and an adhesion property and sandy soil, wherein the solution is formed by the dissolving of water-soluble solid state organic substance into water, and adding with the plant seeds; after being mixed with the sand, the solution can bond sandy soil particles to form the modified sandy soil provided with a particle pore structure; after the moisture is evaporated, the water-soluble solid state organic substance can bond the sandy soil particles, and can be dissolved into the water again to form the solution with the cohesive property and the adhesion property to bond the sandy soil particles when in contact with the water. The modified sandy soil enables the general sandy soil to be in 'pedogenesis', and forms the particle pore structure with binding force (cohesive force); when the modified sandy soil is in the use process, substance is difficult to run off due to the characteristics of the cohesive property and the adhesion property; the sandy soil is enabled to have same properties of the stability and the storing of the moisture and the nutrient as the property of the soil, the planting can be carried out at any time by the direct adding of the plant seeds, and the modified sandy soil is an ideal measure to quickly govern desert; meanwhile the modified sandy soil can also be taken as a means to utilize other sand resources to carry out plant planting.

Owner:易志坚 +1

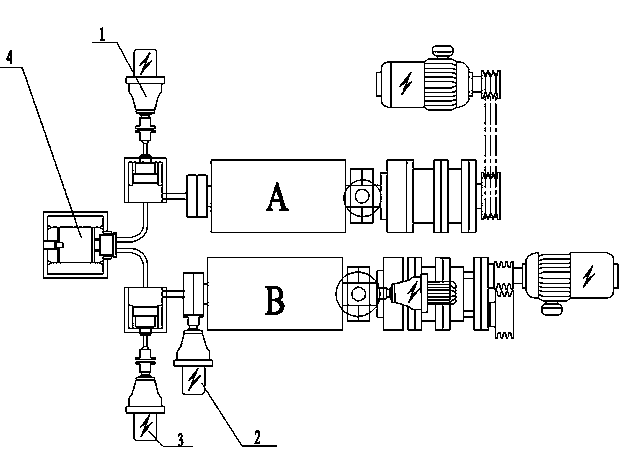

Efficient and short-process multi-component melt spinning device

InactiveCN104073894AEvenly blendedAvoid degradationArtificial thread manufacturing machinesMelt spinning methodsMetering pumpExtrusion Granulation

The invention relates to an efficient and short-process multi-component melt spinning device, which belongs to the technical field of melt spinning devices. The efficient and short-process multi-component melt spinning device comprises a single-screw extruder and a double-screw extruder, wherein a first metering pump is arranged at the head of the single-screw extruder A; a booster pump is arranged at the head of the double-screw extruder B; the booster pump is connected with a second metering pump through a pipeline; the metering pumps are connected with a spinning assembly through independent pipelines respectively. The single-screw extruder A is capable of independently realizing single-component spinning, and the double-screw extruder B is capable of much uniformly blending multi-component polymers, thus avoiding degradation on the secondary hot-pressing for hot-pressed sensitive polymers caused by pre-using the double-screw extruder for blending, extruding and granulating is avoided, and realizing short-process blending spinning, and the two screw extruders can be used simultaneously to carry out composite spinning, thus realizing three independent functions; the spinning assembly can be replaced according to the component and structure requirements of formed fibres, thus expanding the use range of the device, saving machines, and decreasing the use cost.

Owner:WUHAN TEXTILE UNIV

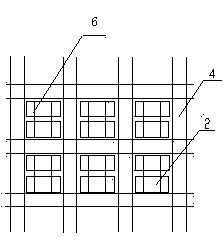

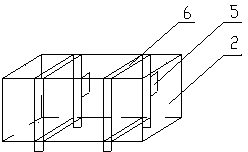

Garage top slab structure and construction method and inner concrete structure cavity membrane thereof

A garage top slab structure comprises an upper layer of top slab, ribbed beams and a lower layer of top slab sequentially from the top down, and inner concrete structure cavity membranes are placed in the closed cavities defined by the upper layer of top slab, the lower layer of top slab and the ribbed beams; each inner concrete structure cavity membrane comprises at least one inner membrane module, and an outer layer of fire-retardant coating and at least one PVC (polyvinyl chloride) fixing frame are arranged on the surface of the inner membrane module; and the inner membrane modules is aare flame-retardant solid polystyrene foam blocks, the density of which is greater than 15Kg / m<3>. The invention also discloses the inner concrete structure cavity membrane, which comprises at least one inner membrane module with the outer layer of fire-retardant coating at the outer surface and at least one PVC fixing frame arranged on the surface of the inner membrane module; and the inner membrane module is the flame-retardant solid polystyrene foam block, the density of which is greater than 15Kg / m<3>. A construction method for the garage top slab structure is characterized in that the construction method includes the following steps: (1) laying a bottom slab formwork; (2) determining the mounting positions of the inner membrane modules; (3) installing the inner membrane modules; (4) tying and fixing anti-floating reinforcements; (5) pouring concrete.

Owner:SHANDONG LIAOCHENG CONSTR +1

Slope irrigation purifier

InactiveCN109179719AReduce sloshingReduce the possibility of being blockedWatering devicesTreatment involving filtrationPipe waterRiver water

The invention discloses a slope irrigation purifier. The slope irrigation purifier comprises a Yellow River water source, a primary water pump, a sedimentation tank, a sedimentation tank dirt discharging valve, a secondary water pump, an inclined pipe sedimentation tank, a tertiary water pump, a tertiary standby water pump, an inclined pipe sedimentation tank dirt discharging valve, a peak water pool, a peak pool dirt discharging valve, a backwashing filter, a pressure reducing valve, a high-slope regulating valve, a greening belt regulating valve and a water draining valve, the water outlet of the tertiary pump is connected with the peak water pool by a pipeline, the water outlet of the water reducing valve is connected with the water inlet pipeline of the high-slope regulating valve through an irrigation branch pipe to form a branch pipe water feeding pipeline, and the water outlet main pipe of the pressure reducing valve is connected with the water inlet of the greening belt regulating valve through an irrigation branch pipe to form a branch water pipe water feeding pipeline, and is also connected with the water inlet pipeline of the water draining valve. The automatic sedimentation, filtration and purification system of irrigation water is used in watering without artificial control, so compared with traditional artificial water spraying, the purifier has the advantages ofsaving of the use amount of water, economical property, good reliability, and saving of machines and manpower.

Owner:李剑心

Moulding bed structure and pouring method

InactiveCN104963345AHigh strengthReduce secondary constructionProtective foundationExcavationsBrickMaterials science

The invention discloses a moulding bed structure and a pouring method and relates to treatment before foundation concrete is poured in the building construction. The moulding bed structure and the pouring method aim at solving the problems that in existing brick moulding bed construction, a large number of clay bricks are needed, one-time forming can not be achieved, and a large amount of backfill is needed after construction is completed. The structure and the pouring method save time and labor and facilitate environmental protection. The moulding bed structure is composed of a moulding bed, an outer foundation pit wall and an inner moulding bed foundation pit wall, wherein the moulding bed is formed by being poured on the outer foundation pit wall in the longitudinal direction; the moulding bed makes tight contact with the outer foundation pit wall. The pouring method of the moulding bed structure comprises the steps of earth excavation, foundation pit dewatering, supporting of a moulding bed inner side formwork, pouring of the moulding bed, detaching of the formwork and the like.

Owner:黄勤

A kind of MBR membrane technology integrated sewage treatment equipment and sewage treatment method thereof

ActiveCN103936156BFull biochemical reactionCompact structureTreatment with aerobic and anaerobic processesBiochemical engineeringMembrane technology

The invention discloses an integrated sewage treatment facility based on an MBR (membrane bioreactor) membrane technique, which comprises a tank body, and an anaerobic biochemical region, an anoxic biochemical region and an aerobic and MBR membrane bioreaction region which are arranged in the tank body, wherein the anaerobic biochemical region, aerobic and MBR membrane bioreaction region and anoxic biochemical region are distributed on the left, in the middle and on the right of the cross section of the tank body; the anaerobic biochemical region and the aerobic and MBR membrane bioreaction region are communicated with each other only through the bottoms; the top liquid level of the aerobic and MBR membrane bioreaction region is higher than the top liquid level of the anoxic biochemical region; the top of the aerobic and MBR membrane bioreaction region is provided with a water outlet pipe extending into the aerobic and MBR membrane bioreaction region, and an overflow weir communicated with the anoxic biochemical region; the upper part liquid level of the anoxic biochemical region is higher than the upper part liquid level of the anaerobic biochemical region; the bottom of the anoxic biochemical region is communicated with the upper part of the anaerobic biochemical region through a gravity pipeline; and the tank body is provided with a water inlet pipe communicated with the anaerobic biochemical region in the tank body. The invention also discloses a sewage treatment method using the facility.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

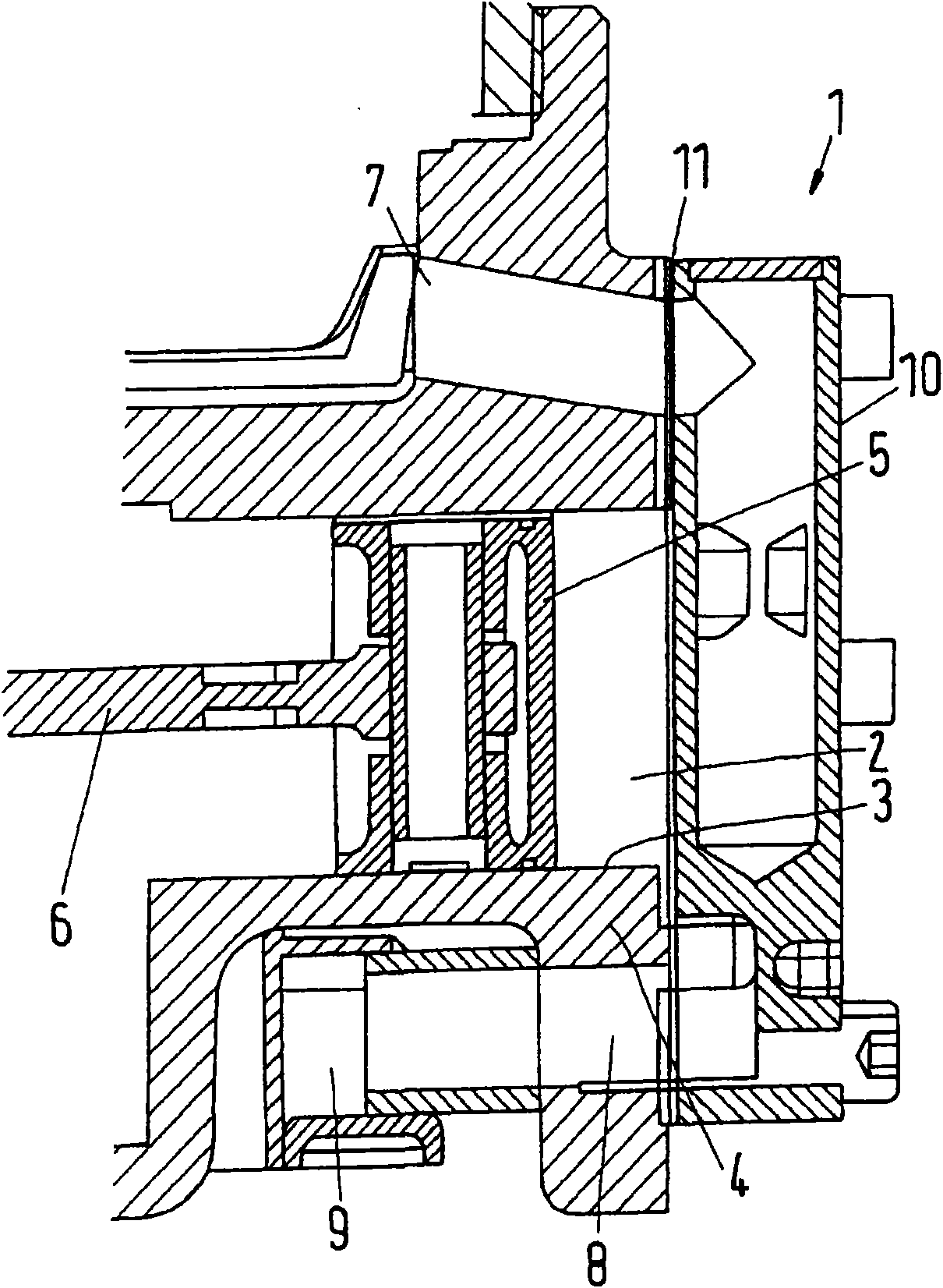

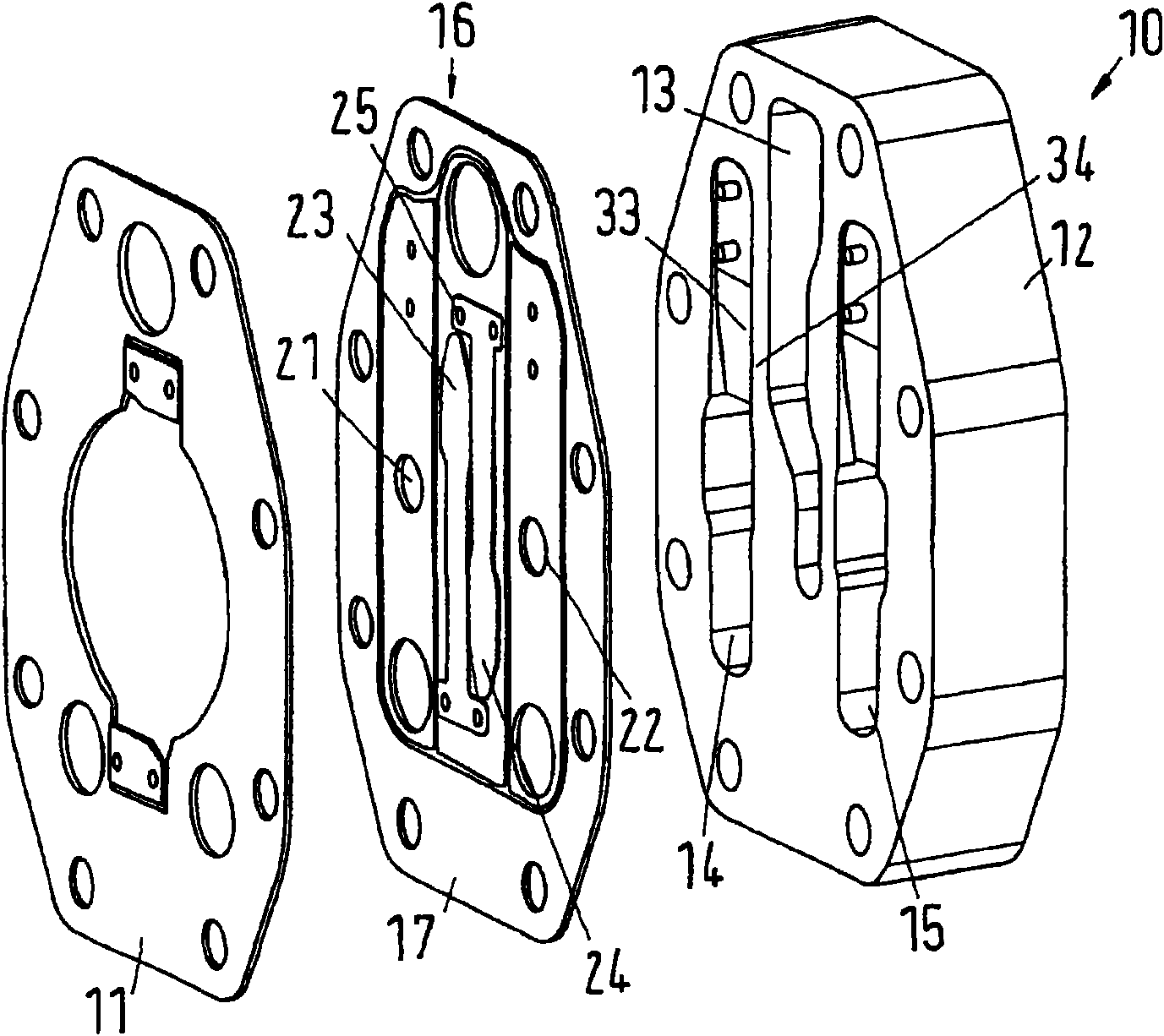

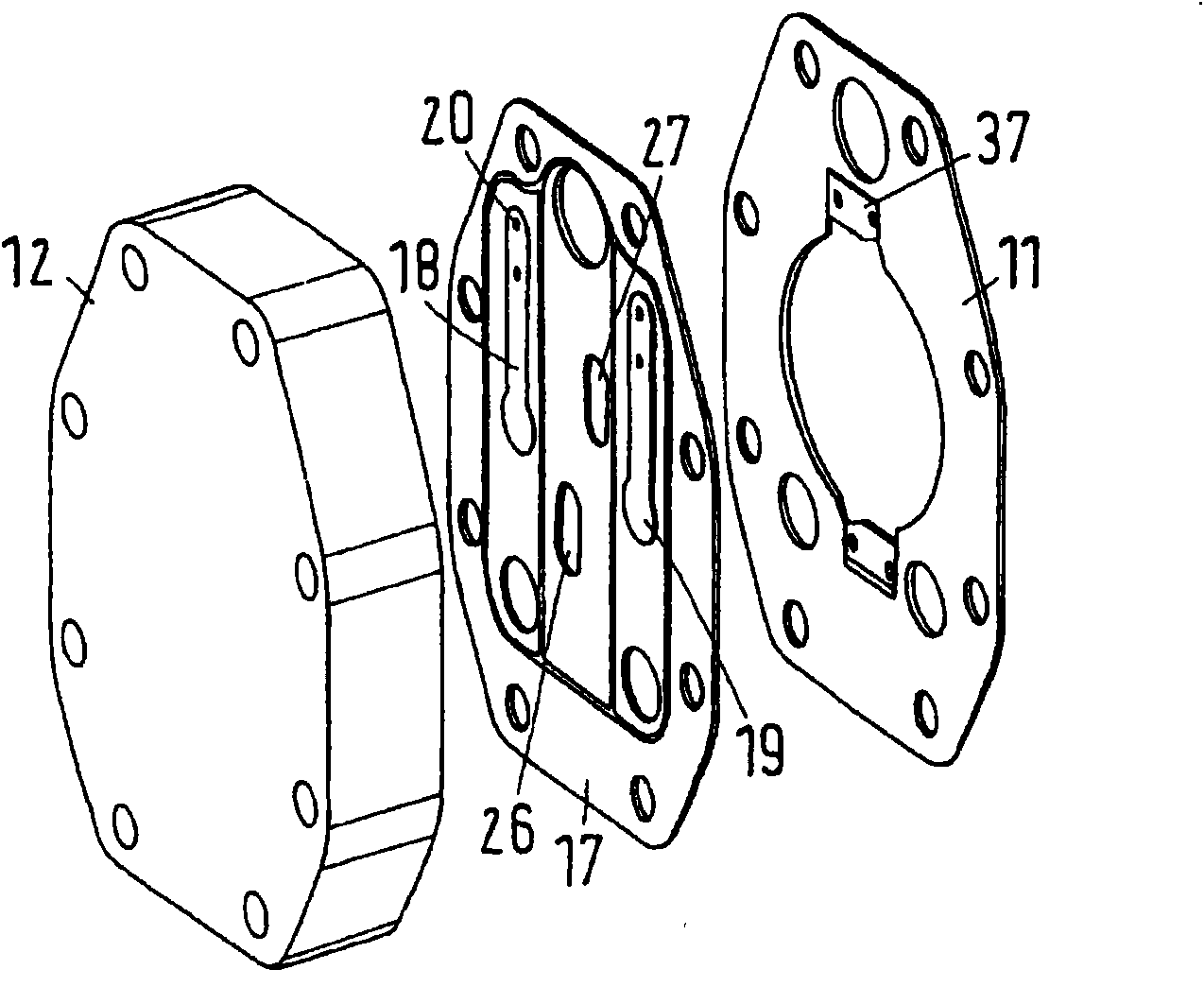

Piston compressor and refrigerant compressor

InactiveCN101649827AAvoid surface treatmentReduce sealPositive displacement pump componentsPositive-displacement liquid enginesCylinder headEngineering

The invention relates to a piston compressor, especially a refrigerant compressor, which has a compression chamber arranged in a compressor block and limited by a cylinder head (10), the cylinder headhas at least one suction valve (23, 24) and at least one pressure valve (21, 22) as well as at least one plate valve arrangement of a valve cover (12). The invention intends to realize low manufacture cost, and good efficiency. Therefore, the valve plate arrangement (16) is formed by a support plate (17) comprising suction valves (23, 24, 26, 27) and pressure valves (18, 19, 21, 22), and the support plate (17) is connected to the valve cover (12) by at least one airtight connecting seam (28, 31), a suction area (22) and a compression area (32) are separated each other by the connecting seam (28, 31), and at least the compression area (29, 30) is sealed relatively to the outside.

Owner:DANFOSS AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com