Construction method of garage roof structure

A construction method and roof technology, which can be applied to floor slabs, building components, building structures, etc., can solve the problems of waste of mechanical labor, high construction cost, and easily damaged weight, etc., to save machinery, reduce concrete consumption, and simple construction technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

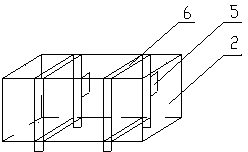

[0041] Such as image 3 As shown, a cavity inner membrane of a concrete structure comprises at least one inner membrane component 2, an outer fireproof coating is arranged on the surface of the inner membrane component 2, and at least one PVC fixed outer frame 6; the inner membrane component 2 is Density greater than 15Kg / m 3 Flame retardant solid polystyrene foam block. There are two inner membrane components 2, and two PVC fixed outer frames 6. Each PVC fixed outer frame 6 has a rectangular baffle 5 on one side, and the baffle 5 is 10 cm wide to ensure that the inner membrane components 2 are installed with a distance of 10 cm between them, and horizontal displacement will not occur during the construction process; Figure 5 As shown, the top of the inner membrane component 2 is laid with two anti-floating steel bars 7 that are firmly overlapped with the densely ribbed beam 4. The anti-floating steel bars are two secondary threaded steel bars with a diameter of not less t...

Embodiment 2

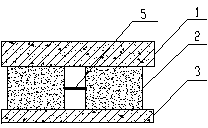

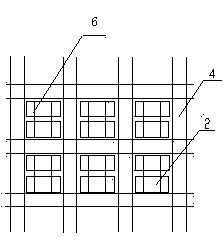

[0043] The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is that it is a garage roof structure using a concrete structure cavity inner membrane, such as Figure 1-2 As shown, it includes from top to bottom the upper roof 1, the densely ribbed beam 4 and the lower roof 3, all of which are reinforced concrete structures. Concrete structure cavity inner membrane; said concrete structure cavity inner membrane, which includes at least one inner membrane component 2, an outer layer of fireproof coating is arranged on the surface of the inner membrane component 2, and at least one PVC fixed outer frame 6; said inner Membrane module 2 has a density greater than 15Kg / m 3 Flame-retardant solid polystyrene foam blocks to ensure the thickness of the concrete protective layer; the arrangement of the ribbed beams corresponding to the inner membrane components is a continuous well-shaped arrangement of 1000×1000mm and 1000mm×800mm.

Embodiment 3

[0045] Such as Figure 4 Shown, a kind of garage roof structure construction method, it comprises the steps:

[0046] 1. Lay the base plate formwork;

[0047] 1) The formwork and support system should be designed and calculated according to the actual load and construction height, and the inner membrane load can be ignored;

[0048] 2) The bottom formwork is fully laid, and the formwork should be arched according to the design requirements when supporting the formwork, and the formwork at the post-pouring belt should be laid separately;

[0049] 2. Determine the installation position of the inner membrane; determine the installation position of the inner membrane after the bottom plate and the rib beam steel bars are bound, and pop up the edge of the rib beam, which is the position line of the outer edge of the inner membrane, according to the axis size of the construction drawing, so as to ensure the accurate positioning of the inner membrane; The total size of the engineer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com