Slope irrigation purifier

A technology for purification devices and slopes, applied in watering devices, chemical instruments and methods, multi-stage water treatment, etc. and vehicles and other problems, to achieve the effect of economical reliability, prolonging the maintenance period and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

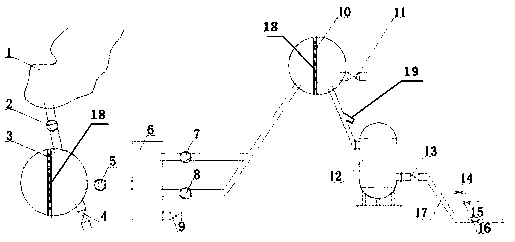

[0017] see figure 1 , a slope irrigation purification device, comprising the Yellow River water source 1, a primary water pump 2, a sedimentation tank 3, a sedimentation tank sewage valve 4, a secondary water pump 5, an inclined tube sedimentation tank 6, a tertiary water pump 7, and a tertiary standby water pump 8 , inclined pipe sedimentation tank sewage valve 9, hilltop pool 10, hilltop pool sewage valve 11, backwash filter 12, pressure reducing valve 13, high slope regulating valve 14, green belt regulating valve 15 and drain valve 16, first level The water inlet of water pump 2 is connected to the water source 1 of the Yellow River through a pipeline. The water source 1 of the Yellow River is naturally formed. The outlet of the primary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com