Construction method of expansion joint shape setting formwork

A technology for shaping formwork and construction method, applied in formwork/formwork/work frame, processing of building materials, preparation of building components on site, etc., can solve the problem of increasing construction costs, wasting materials, and difficult to ensure the structural quality of expansion joints And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

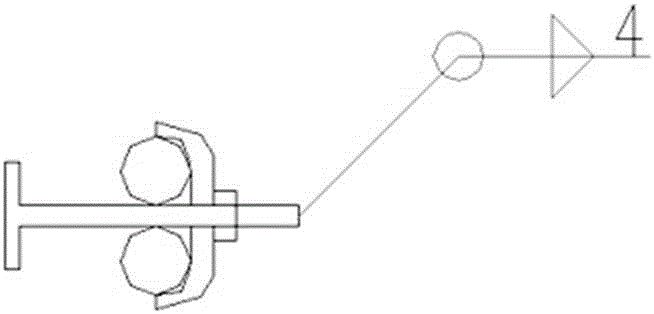

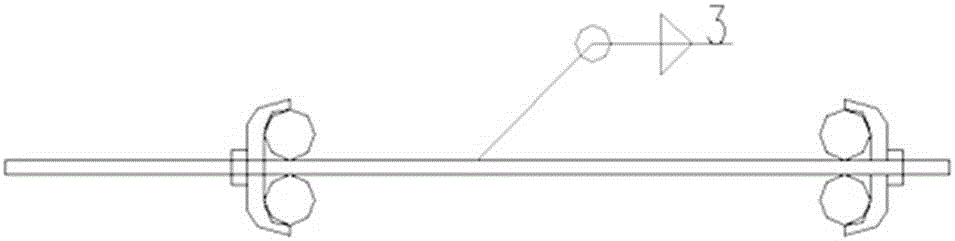

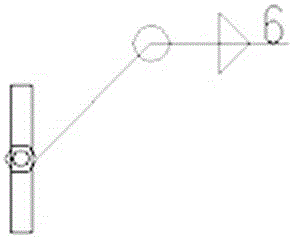

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] A construction method for expansion joint shaped formwork, the steps are as follows:

[0026] Step 1. Design the expansion joint. The design is calculated according to the measured thickness. The width of the expansion joint is ≥ 2 thicknesses of multilayer boards + 2 corrugated heights + 2 steel pipe diameters + 2 nut thicknesses;

[0027] Step 2. Formwork processing. Use multi-layer boards with a thickness of 12-18mm to make the formwork to ensure that the drilling positions of the formwork on both sides of the expansion joint are strictly aligned. The distance between the fastening screws is the same as that of the conventional shear wall. In addition to the screw, it is necessary to add a reverse fixed keel shaping screw to ensure that the primary and secondary keels are integrated with the wooden formwork;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com