Full-automatic laser welding equipment for lithium battery and battery welding method

A laser welding and lithium battery technology, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problem of easy wear and tear of the butt welding needle, and achieve the effect of small machinery and large number of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

[0046] combine Figure 14 : the top of the mechanical support chassis 14-2 is connected with a screw to install the mechanical bottom plate 14-1. Place the laser fan hot water tank 14-4 on the right side of the mechanical support chassis 14-2. The internal space of mechanical support chassis 14-2 is divided into two front and back, and tool drawer 14-3, control computer host 14-5, vacuum generator 14-6, laser host 14-7 are installed in the front.

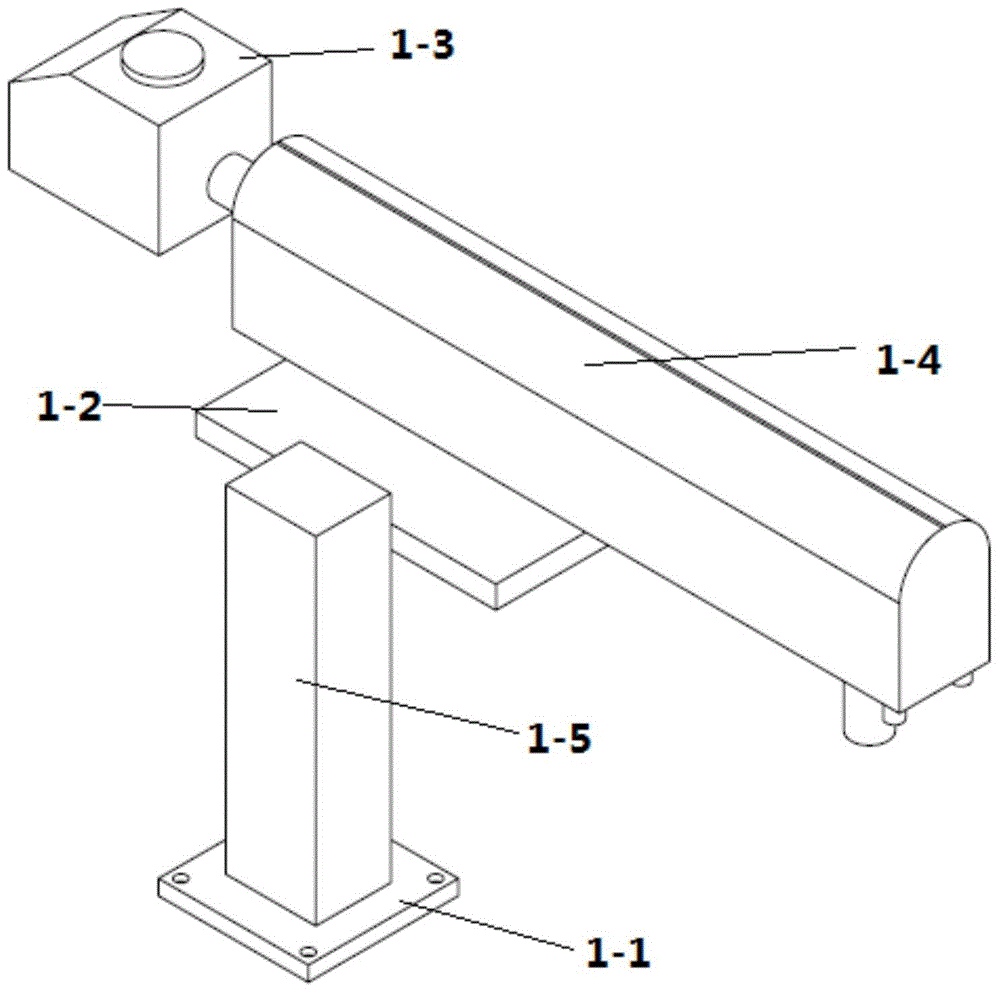

[0047] Such as figure 1 , the laser base 1-1 is placed on the mechanical base plate 14-1, the laser up and down adjuster 1-5, vertically installed on the laser connection base 1-1, the laser mount 1-2 is installed on the laser up and down adjuster 1-5, the laser The generating unit 1-4 is flatly placed on the laser mount 1-2, and the high-definition camera 1-3 is installed on the laser port of the laser generating unit 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com