Automobile headrest frame semi-finished product double-row hanging frame

A technology for automobile headrests and suspension frames, which is applied in the direction of tool storage devices and manufacturing tools, and can solve the problems of collapsed headrest frame semi-finished products, deformation or scratches, and large space occupation, so as to achieve good suspension effect and prevent deformation or scratches A wound, the effect that movement is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

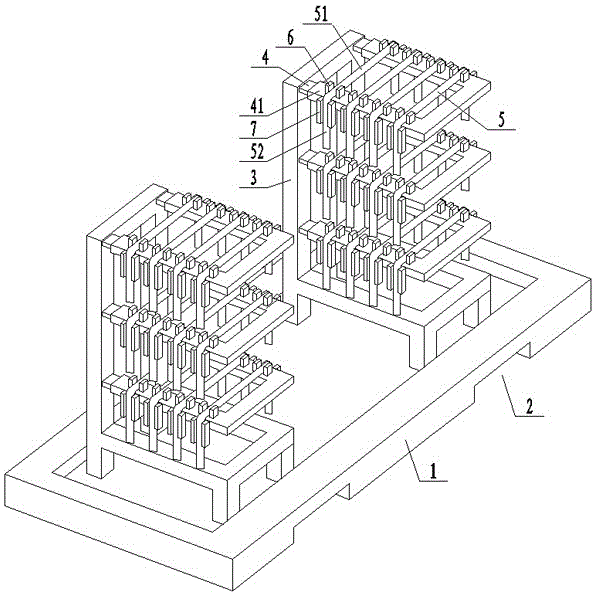

[0009] Such as figure 1 As shown, the semi-finished double-row suspension frame of the automobile headrest frame includes: a base 1, on both sides of the lower end of the base 1, there are forklift grooves 2 that cooperate with the forklift, and the two sides of the upper end of the base 1 are symmetrical A frame 3 is arranged, and several U-shaped suspension frames 4 are uniformly arranged on the frame 3, and a rubber coating 41 is arranged on the outside of the U-shaped suspension frame 4, and evenly arranged on the U-shaped suspension frame 4. A plurality of U-shaped headrest frame semi-finished products 5 are hung, and the structure of the U-shaped headrest frame semi-finished product 5 includes: a main rod 51 hung on the upper end of the U-shaped suspension frame 4 and a main rod 51 hung on both sides of the U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com