Concrete moulding bed structure and pouring method

A technology of concrete and pouring concrete, which is applied in basic structure engineering, excavation, construction, etc., can solve problems such as waste of manpower and material resources, environmental hazards, and delay in construction time, so as to save formwork and labor, save labor and machinery, and save manpower and material resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Pouring concrete tire mold of the present invention comprises the following steps:

[0019] The first step is to discharge the accumulated water in the foundation pit;

[0020] The second step is to excavate the earthwork to the design depth of the foundation pit;

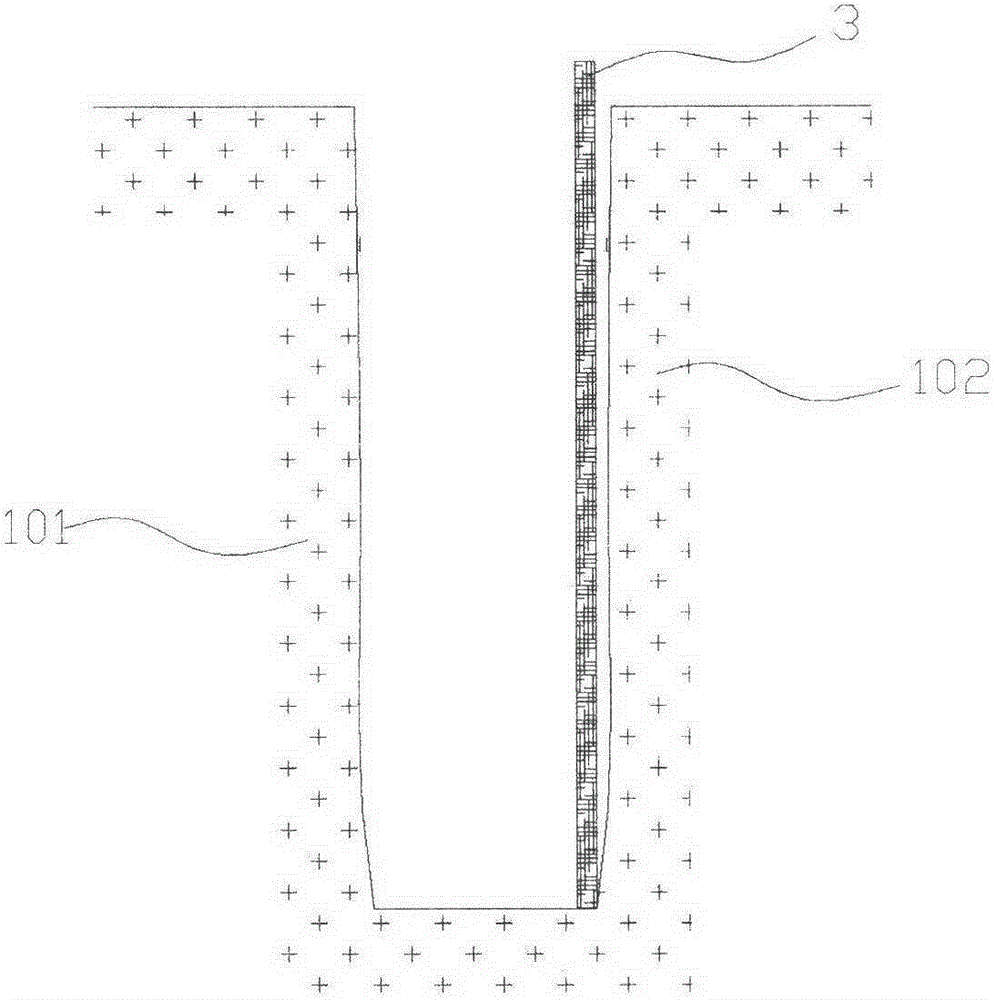

[0021] The third step is as image 3 As shown, the first template 3 is supported along the inner wall of the membrane foundation pit 102;

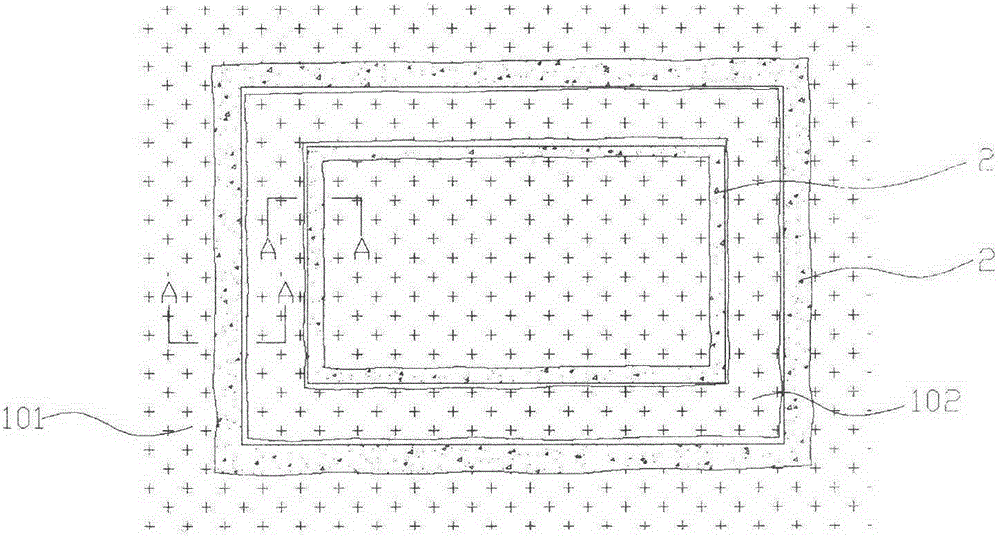

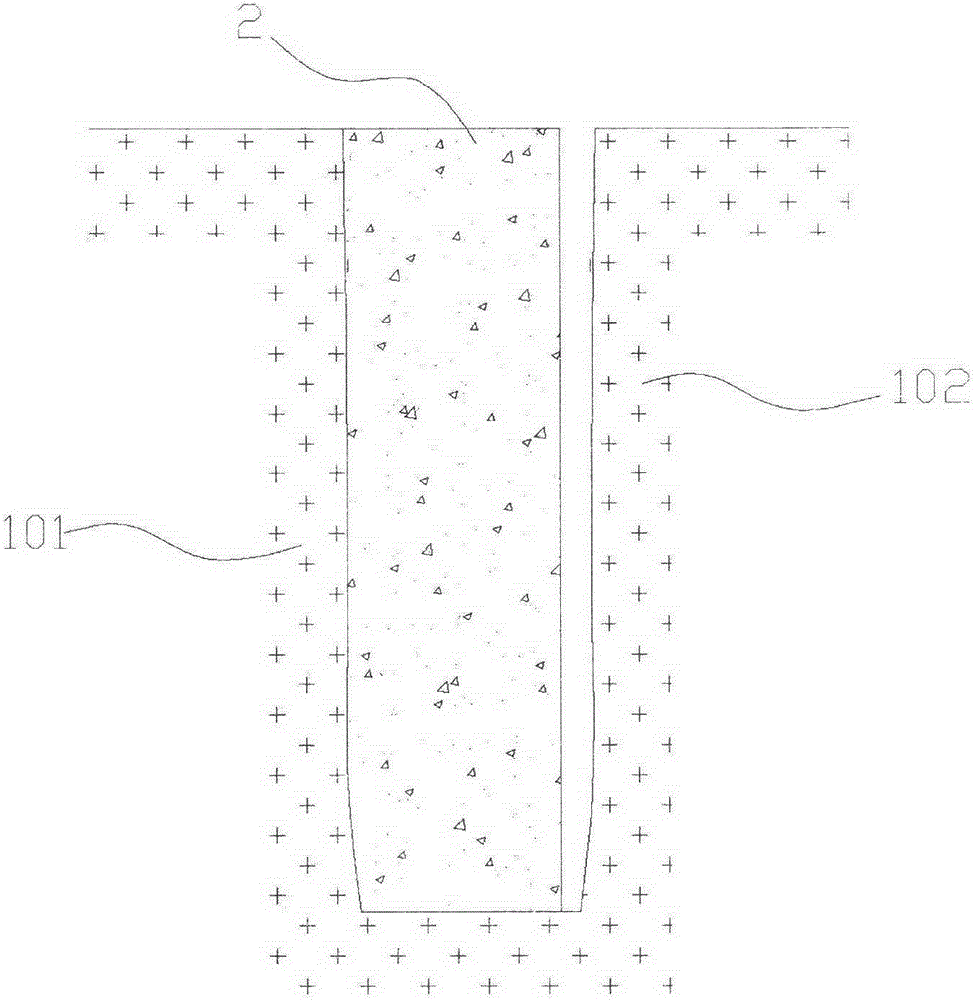

[0022] The fourth step is as Figure 4 As shown, concrete is poured between the outer wall of the foundation pit 101 and the first formwork 3 and compacted by vibrating to complete the pouring of the concrete tire mold 2;

[0023] The fifth step is as Figure 5 As shown, after the strength of the concrete reaches the standard, the template 3 is removed to complete the pouring of the entire concrete tire form.

[0024] From the perspective of this embodiment, when pouring the concrete tire formwork structure described in this embodiment, only a circle of formwork 3 i...

Embodiment 2

[0026] During the process of pouring the concrete tire form 2, since the outside of the concrete tire form 2 directly uses the excavated foundation pit outer wall 101 as a template, the condition of the foundation pit outer wall 101 affects the pouring of concrete.

[0027] If water seepage enters the foundation pit from the outer wall 101 of the foundation pit, it will definitely affect the strength of the concrete tire mold.

[0028] If the stability of the outer wall 101 of the foundation pit is poor, the soil layer on the outer wall 101 of the foundation pit falls off into the foundation pit, which will affect the smooth progress of concrete pouring. In the process of pouring concrete, once the soil layer of the outer wall 101 of the foundation pit collapses or falls into the concrete, not only will the strength of the concrete be reduced, but also the regularity of the shape of the concrete tire form 2 will be broken, resulting in uneven stress.

[0029] In this embodimen...

Embodiment 3

[0039] Such as Figure 7 , Figure 8 and Figure 9 As shown, the difference with embodiment 2 is that when the fifth step of embodiment 2 is carried out, the steel formwork 5 is not raised after the concrete injection is completed, but the steel formwork 5 is lifted while injecting concrete, and at the same time Vibrate. This embodiment is suitable for deep foundation pits. The deeper the foundation pit, the more concrete needs to be injected. If the steel formwork is lifted after the concrete is poured, it will inevitably be squeezed by the outer wall 101 of the foundation pit and the concrete on the steel formwork 5. Due to the strong friction formed by the pressure, a large mechanical force is needed to lift the steel formwork out of the foundation pit. If just mention steel formwork 5 after concrete pouring is finished, just need to overcome powerful pressure and frictional force, as the power of machinery is less, just can't finish this work. On the contrary, the cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com