Construction method of integral type movement of formwork trolley through cast-in-place pipe gallery

A formwork trolley and moving formwork technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as low construction efficiency, unstable quality, and a large number of labor, reducing pouring joints, and achieving good social benefits. The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing of specification sheet, technical scheme of the present invention is described further:

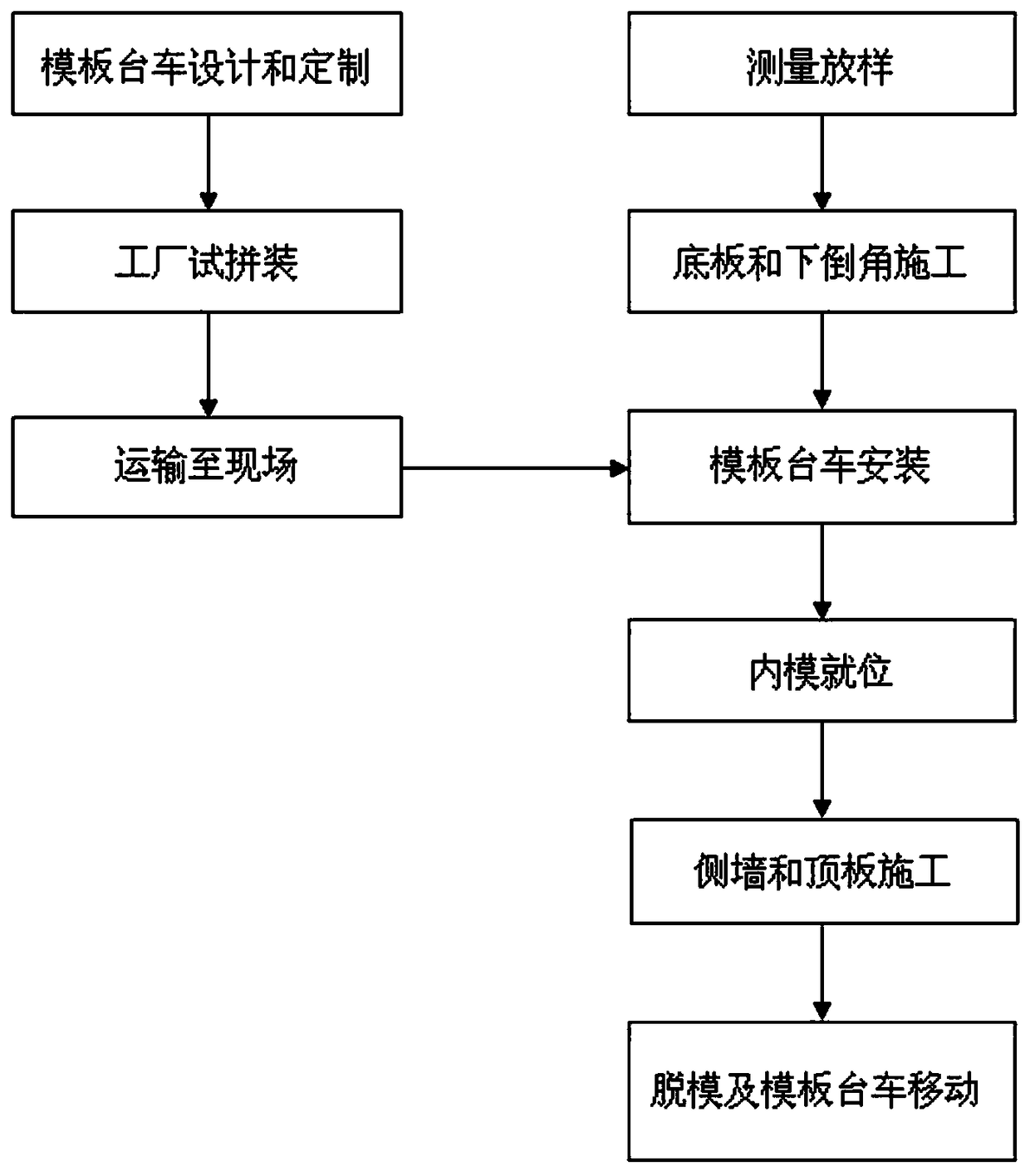

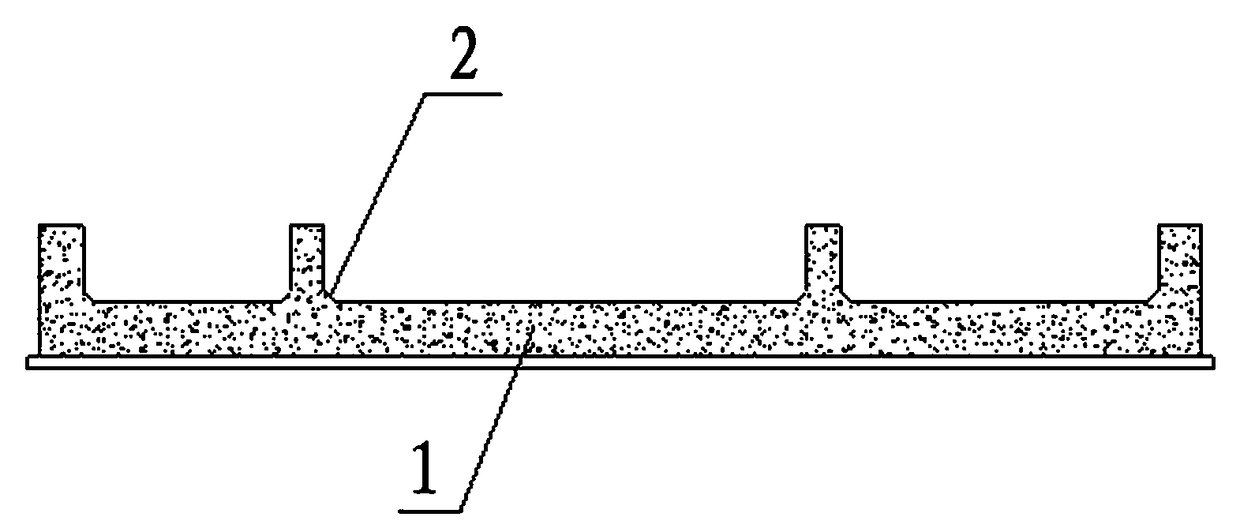

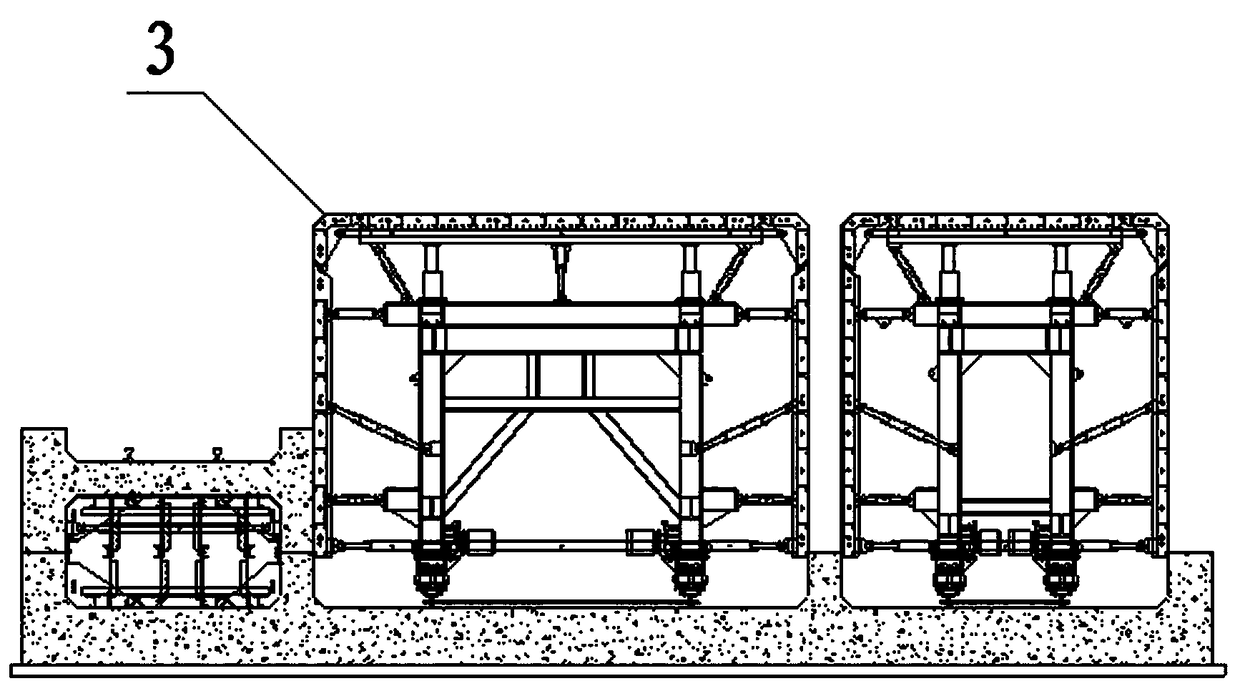

[0040] Such as Figures 1 to 6 As shown, the construction method of the integral mobile formwork trolley of the cast-in-place pipe gallery of the present invention includes measurement and lofting, construction of the bottom plate 1 and the bottom chamfer 2, installation of the formwork trolley 3, internal mold in place, and construction of the side wall 4 and the top plate 5 , demoulding and movement of template trolley 3, specifically including the following steps:

[0041] 1. Measurement and stakeout

[0042] The pipe gallery structure box is composed of top plate 5, bottom plate 1 and side wall 4. When setting out, pay special attention to the alignment of the plane and vertical curves of the wall or plate with the road design alignment, and also pay attention to the cross slope setting of the structural top plate 5 and bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com