Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Increase the tempo" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

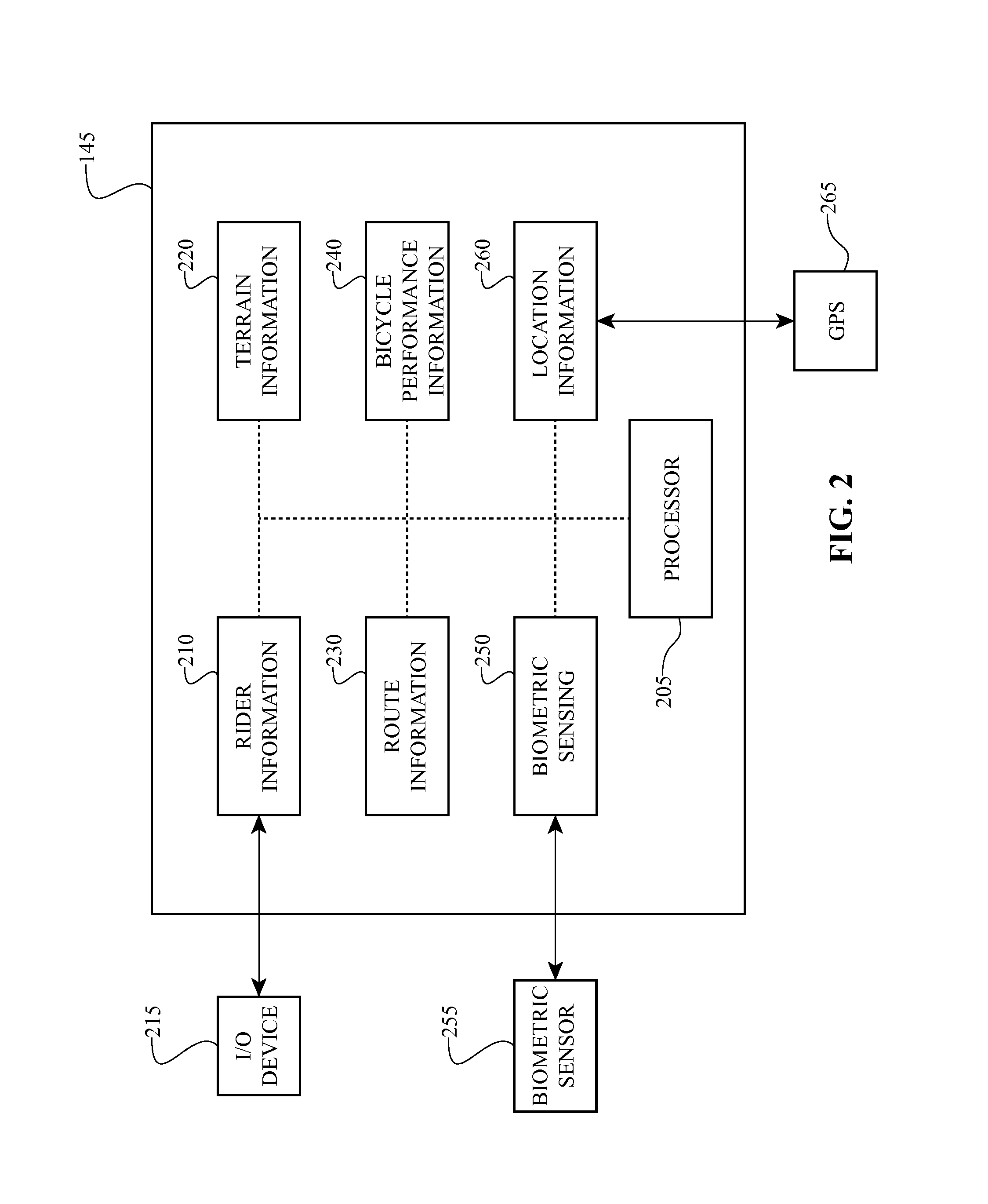

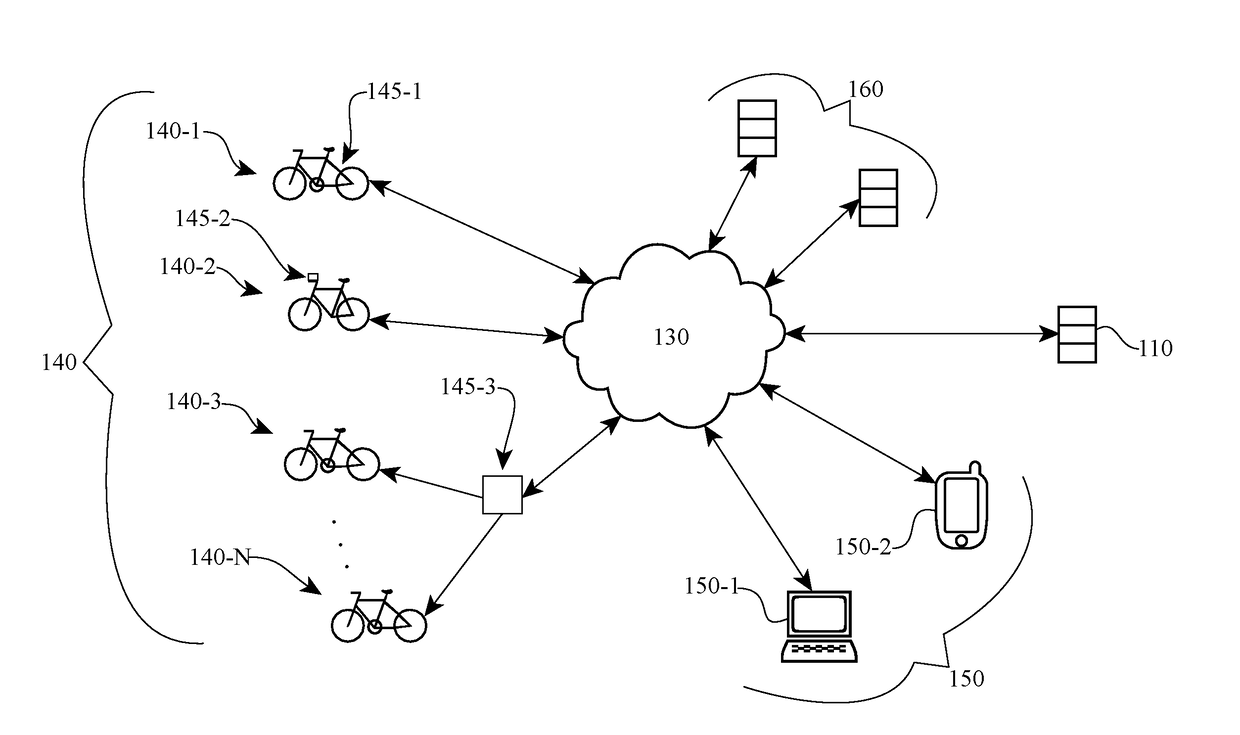

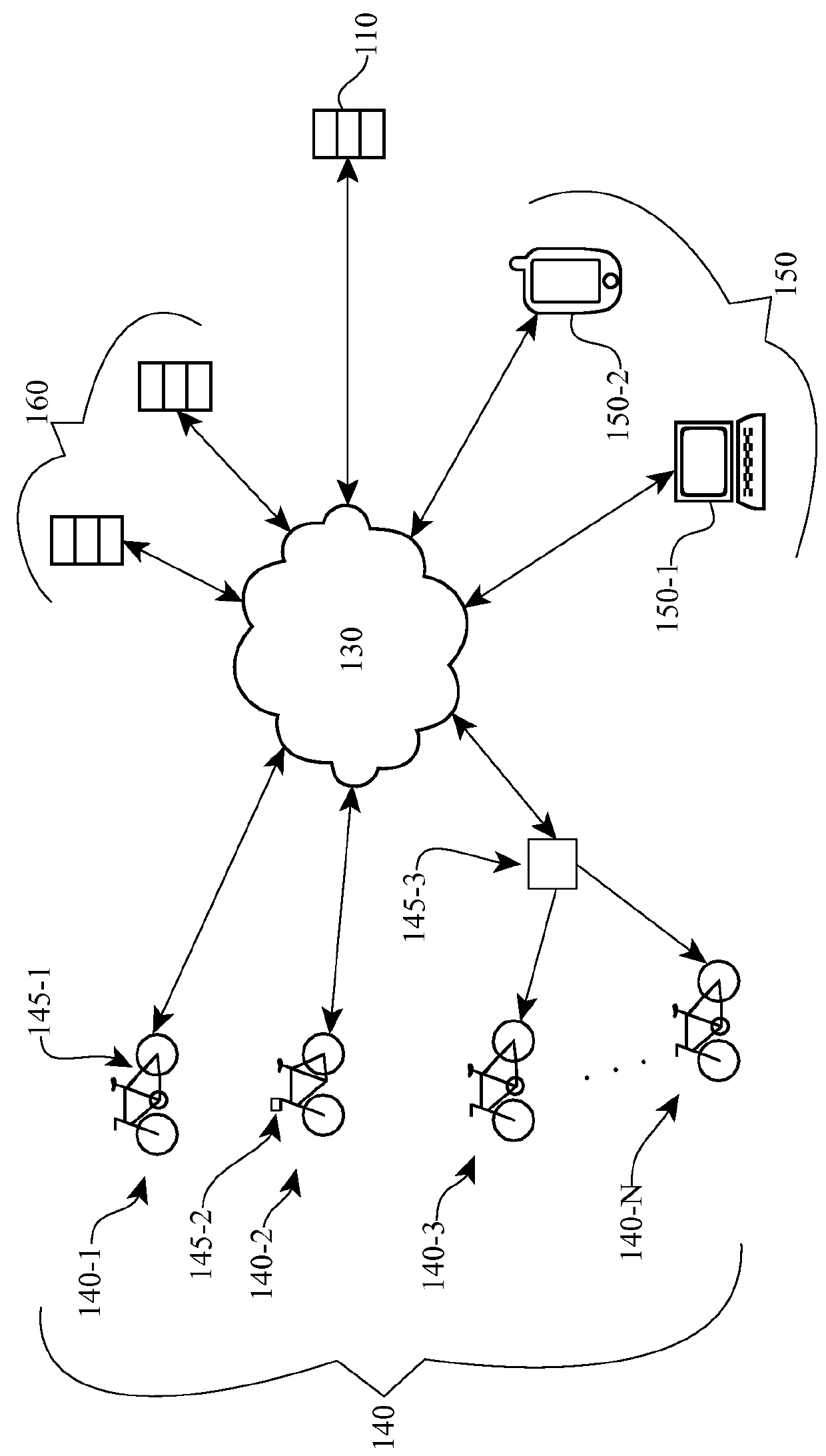

Components, systems and methods of bicycle-based network connectivity and methods for controlling a bicycle having network connectivity

InactiveUS20160039496A1Improve experienceImprove a rider's rideDigital data processing detailsGearing controlThird partyGuideline

A bicycle configured for communication with other bicycles, a centralized server, client computing devices and third party servers allows the rider to be connected with friends, coaches / trainers, and third party vendors including vendors associated with lodging, food, and other conveniences, vendors associated with bike servicing, equipment, warranties, and other bike related products and services, and vendors associated with routes, areas or destinations. Information may be communicated in real time or stored in memory and communicated to servers, client devices, other riders, etc., at a later date. Information may be communicated to the bike controller for route planning, service scheduling, training purposes and the like. Information communicated to or from the bicycle may be performed as indicated by the rider or there may be predetermined rules or guidelines for what information is collected and to whom the information may be sent to or received from.

Owner:FALLBROOK INTPROP COMPANY

Components, systems and methods of bicycle-based network connectivity and methods for controlling a bicycle having network connectivity

InactiveUS20170225742A1Improve experienceImprove a rider's rideWheel based transmissionAnti-theft cycle devicesControl systemNetwork connectivity

A bicycle configurable for operating using a speed based control system and scheme or a torque based control system and scheme. A speed sensor or a torque sensor may detect an operating characteristic of the bicycle and a controller may determine whether to operate using a speed based control system and scheme or a torque based control system and scheme based on the operating characteristic. A signal from a speed sensor or a torque sensor may be used for determining the mechanical limits of a CVT range and when to incorporate an electric motor.

Owner:FALLBROOK INTPROP COMPANY

Components, systems and methods of bicycle-based network connectivity and methods for controlling a bicycle having network connectivity

InactiveUS9963199B2Improve experienceImprove a rider's rideGearing controlVehicle transmissionThird partyGuideline

A bicycle configured for communication with other bicycles, a centralized server, client computing devices and third party servers allows the rider to be connected with friends, coaches / trainers, and third party vendors including vendors associated with lodging, food, and other conveniences, vendors associated with bike servicing, equipment, warranties, and other bike related products and services, and vendors associated with routes, areas or destinations. Information may be communicated in real time or stored in memory and communicated to servers, client devices, other riders, etc., at a later date. Information may be communicated to the bike controller for route planning, service scheduling, training purposes and the like. Information communicated to or from the bicycle may be performed as indicated by the rider or there may be predetermined rules or guidelines for what information is collected and to whom the information may be sent to or received from.

Owner:FALLBROOK INTPROP COMPANY

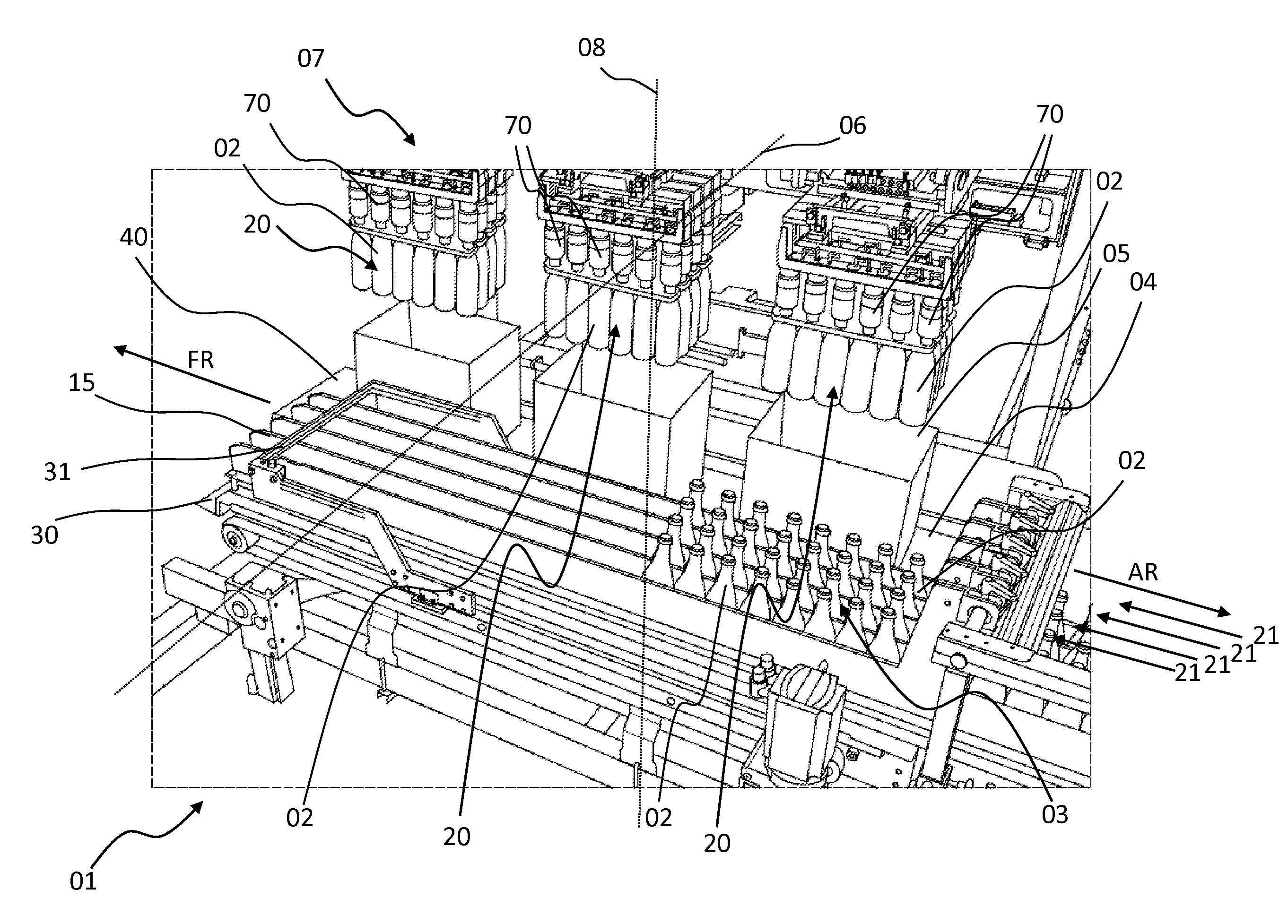

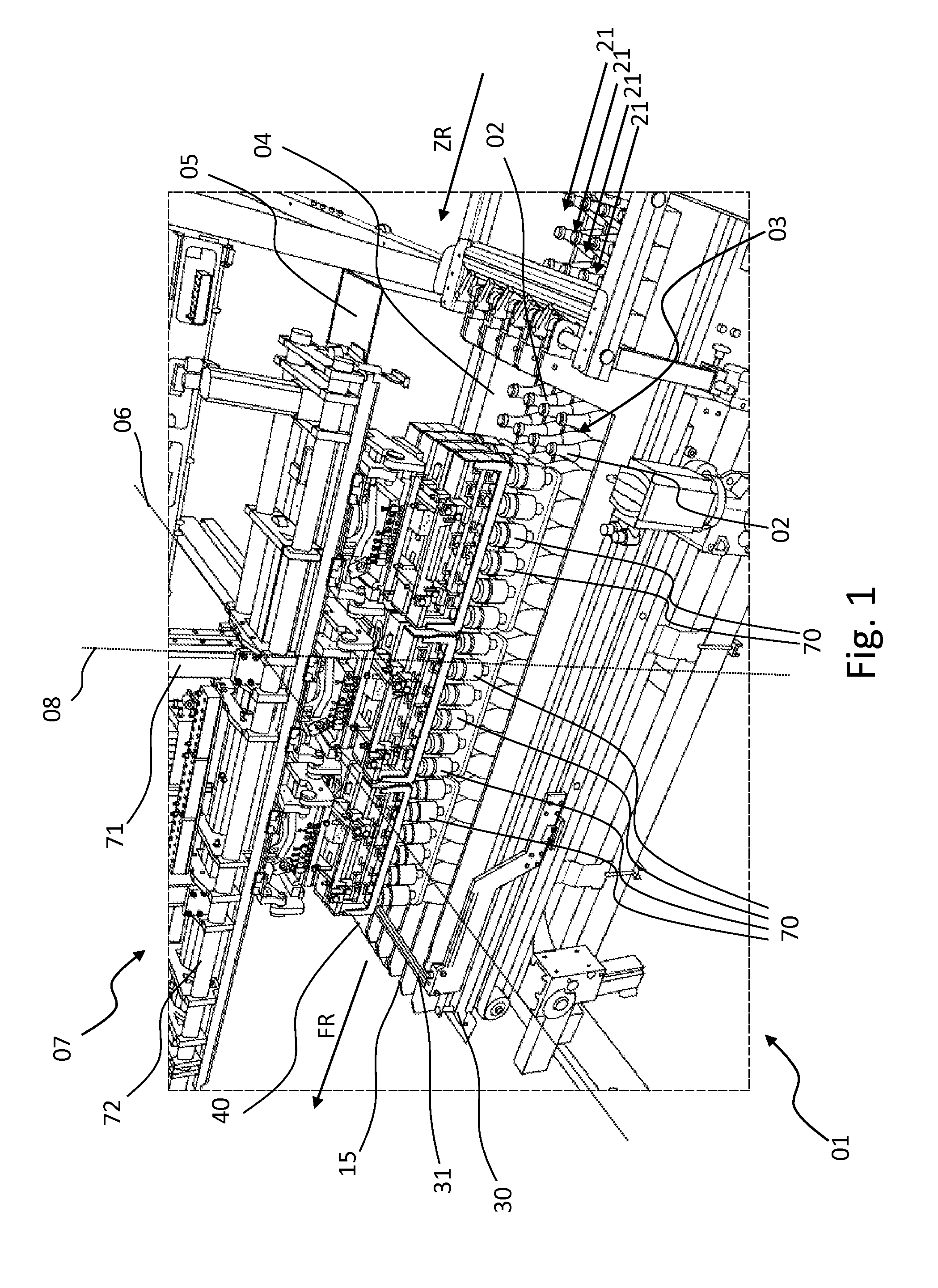

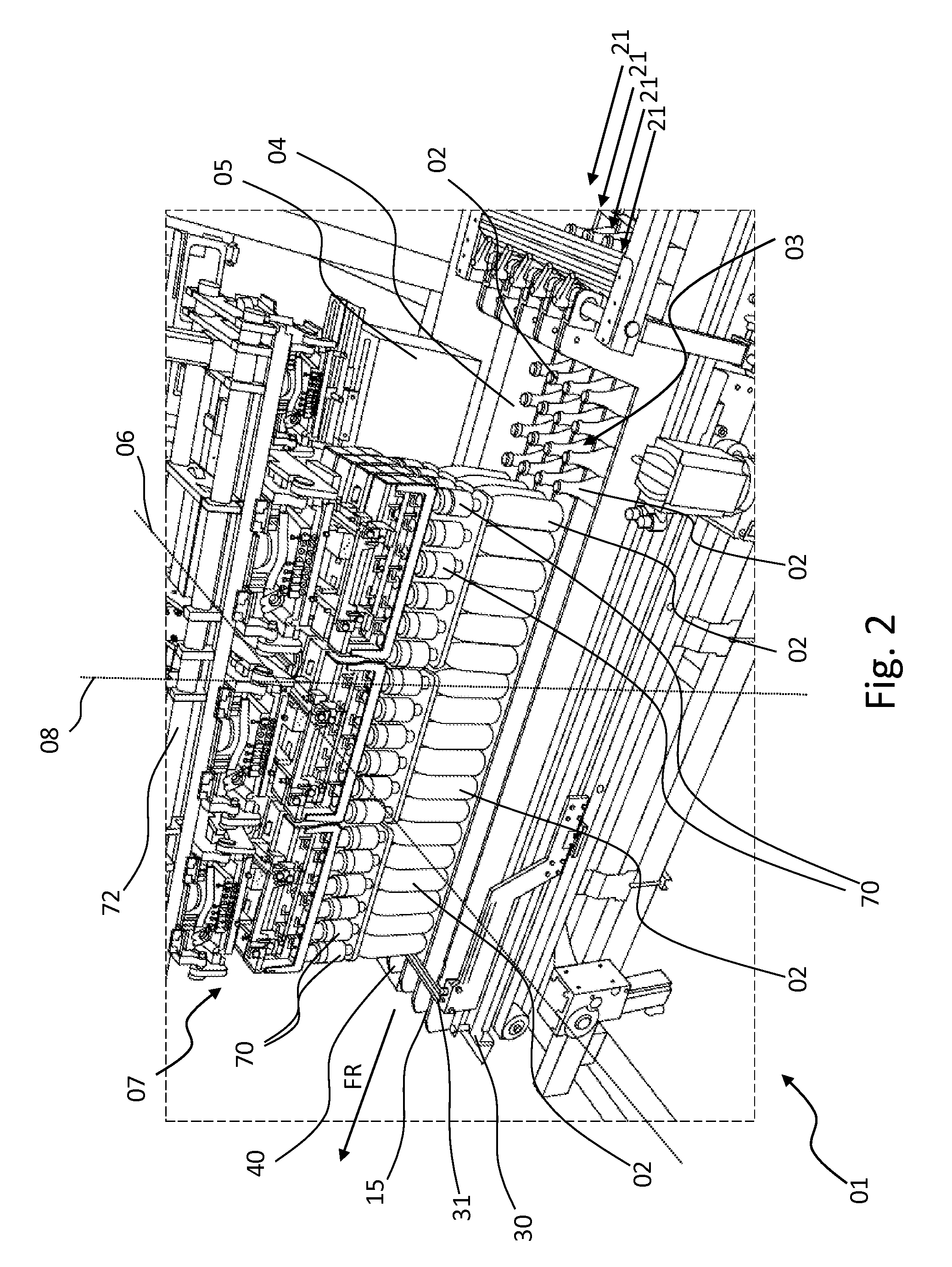

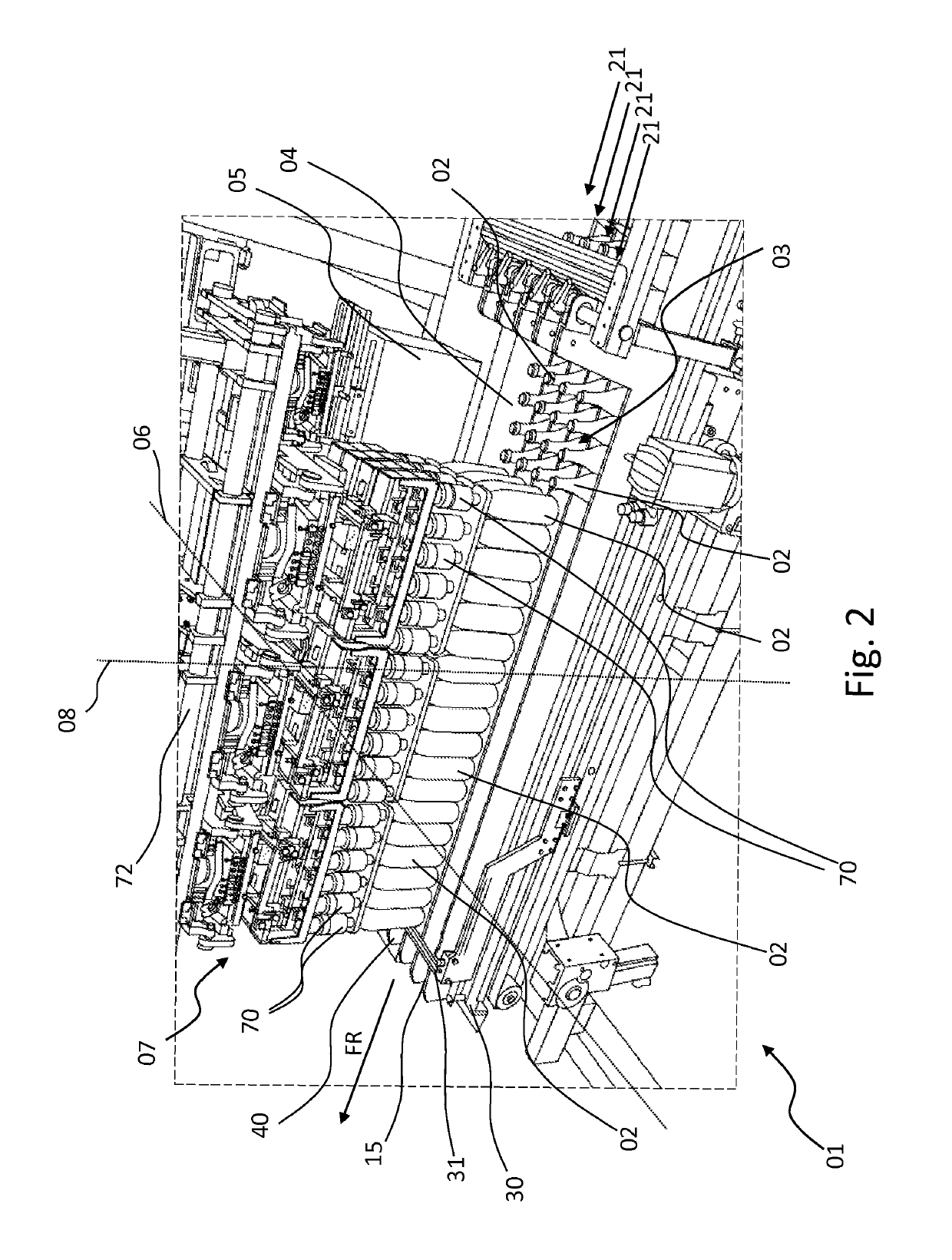

Apparatus and method for handling articles

ActiveUS20160137326A1Increase the tempoEliminate standstill periodPackaging automatic controlSolid materialManipulatorEngineering

The method of the present invention removes at least a plurality of articles (02) arriving consecutively in a transport direction (FR) from an infeed (03), and subsequently, arranging and grouping the articles (02), while simultaneously lifting and collectively transferring the article (02) from the infeed (03) to a staging surface (04). At the staging area are one or more outer packagings (05), and into which the articles (02) are placed. Individually or groupwise, as seen in a direction in parallel to the transport direction (FR), the individual distances between the articles (02) corresponding to a defined arrangement (20) are increased and / or decreased, and finally, the articles (02) are simultaneously lowered and released into the one or a plurality of outer packagings (05). The apparatus of the present invention comprises an infeed (03) of articles (02) being transported, at least one staging surface (04) arranged next to the infeed (03). On the staging surface (04), outer packagings (05) are staged, and which will be filled with articles (02) removed from the infeed (03). From the staging surface (04), the filled outer packagings (05) are discharged. A gripping device (07) is used to simultaneously seize a plurality of articles (02) from the infeed (03). The gripping device (07) has one gripper head (70) per article. The gripping device (07) has at least one manipulator (71) with a horizontally and vertically movable manipulator head (72).

Owner:KRONES AG

Magnetic earphones holder

ActiveUS20170318376A1Increase the tempoDecrease beatMicrophonesElectrophonic musical instrumentsAccelerometerEarcon

One or more accelerometers embedded with an earbud and / or a set of earphones are able to sense a moving pace of a user. Based on a moving pace of the user, a signal is sent to a remotely connected electronic device. The electronic device is able to separately increase and decrease a beat or rhythm of the audio from the electronic device based on a pace of the user. In some embodiments, an audio alert is sent to the user to inform the user of pace and whether the user has increased or decreased their pace. Additionally, in some embodiments, a program stored on the electronic device is used to compare the user's current progress and / or speed based on past runs and workouts.

Owner:SNIK

Turnover device

InactiveUS7909156B2Increase the tempoIncrease production capacityControl devices for conveyorsCharge manipulationEngineering

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

Turnover device

ActiveUS20080283359A1Increase the tempoIncrease production capacityControl devices for conveyorsCharge manipulationEngineering

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

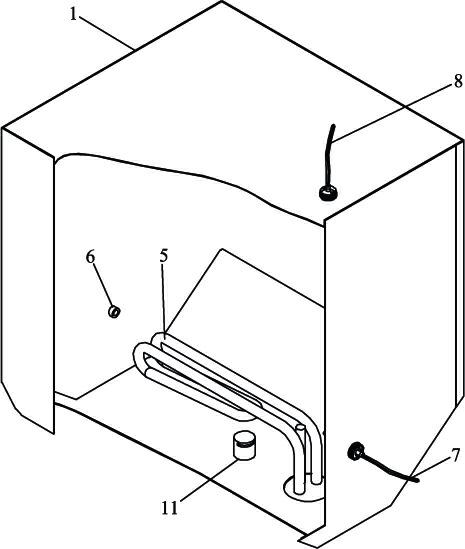

Liquid heating device and control method thereof

ActiveCN102095249ASolve convection dead angle and low temperature stagnant waterImprove water qualityWater heatersElectric heatingEngineering

The invention provides a liquid heating device. The liquid heating device comprises a heating container which is equipped with a water replenishing pipe and a water outlet pipe, wherein, the water replenishing pipe is connected with an external water source via a water inlet valve; the heating container is internally equipped with an electric heating tube and a temperature sensor; the bottom of the side wall of the heating container is in a straight cuboid shape, wherein the bottom of the opposite two side wall is separately inward tilt and form a taper closing; a low-liquid-level sensor and a high-liquid-level sensor are also respectively arranged in the heating container; the water replenishing pipe extends into the heating container from the bottom thereof; the electric heating tube and the temperature sensor are sequentially arranged above an outlet of the water replenishing pipe; signal output terminals of the temperature sensor, the low-liquid-level sensor and the high-liquid-level sensor are respectively and electrically connected to a control unit; and an output terminal of the control unit is connected to a control end of the water inlet valve. By operating and controlling the liquid heating device, liquid can be stably heated in a stepping manner; and meanwhile the liquid heating device has the characteristics of high space utilization ratio, no stored water dead corner, high heating efficiency, reliable supply water temperature and the like, thus being efficient, sanitary, safe and reliable.

Owner:JIANGXI WOTAI ENVIRONMENTAL PROTECTION TECH CO LTD

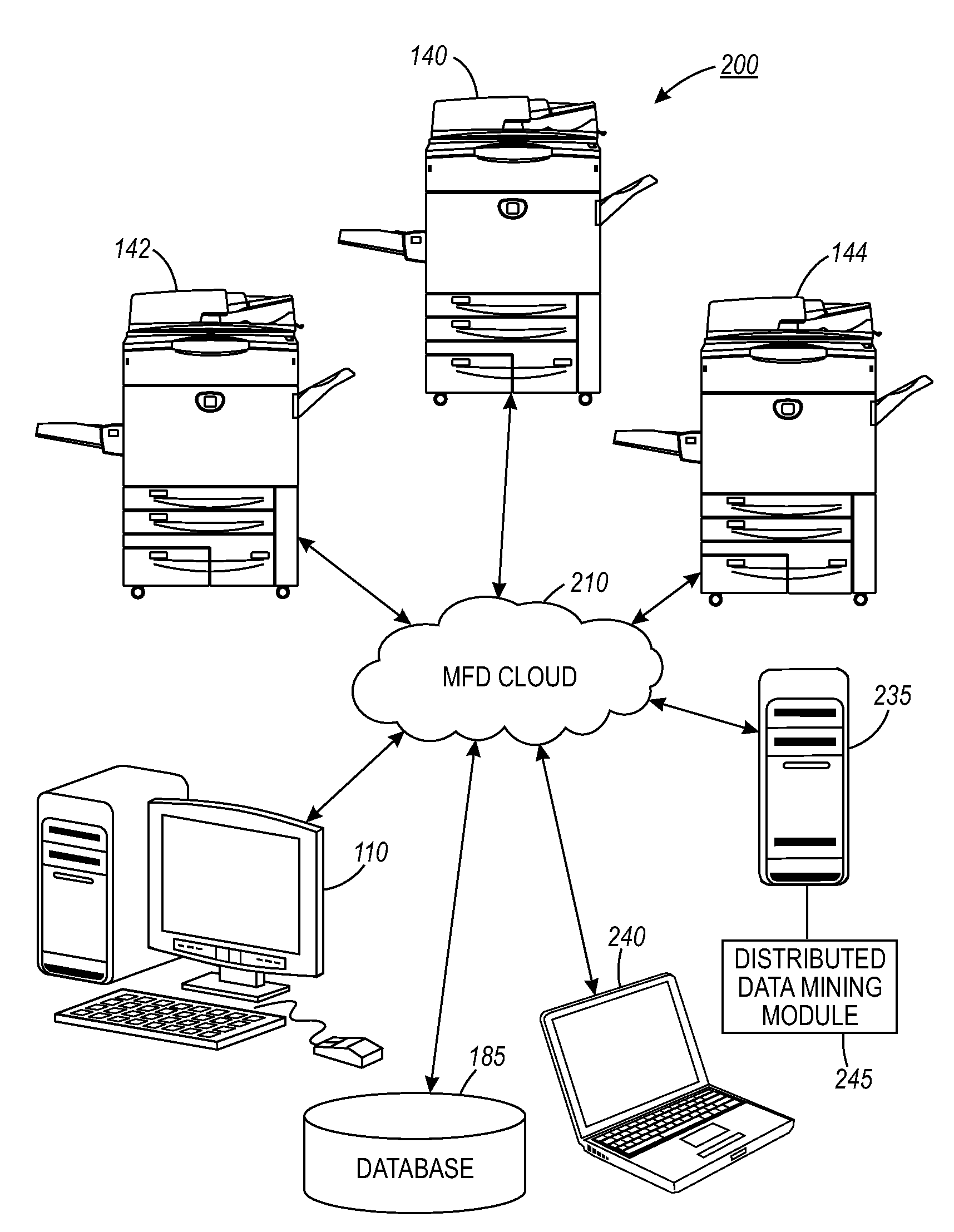

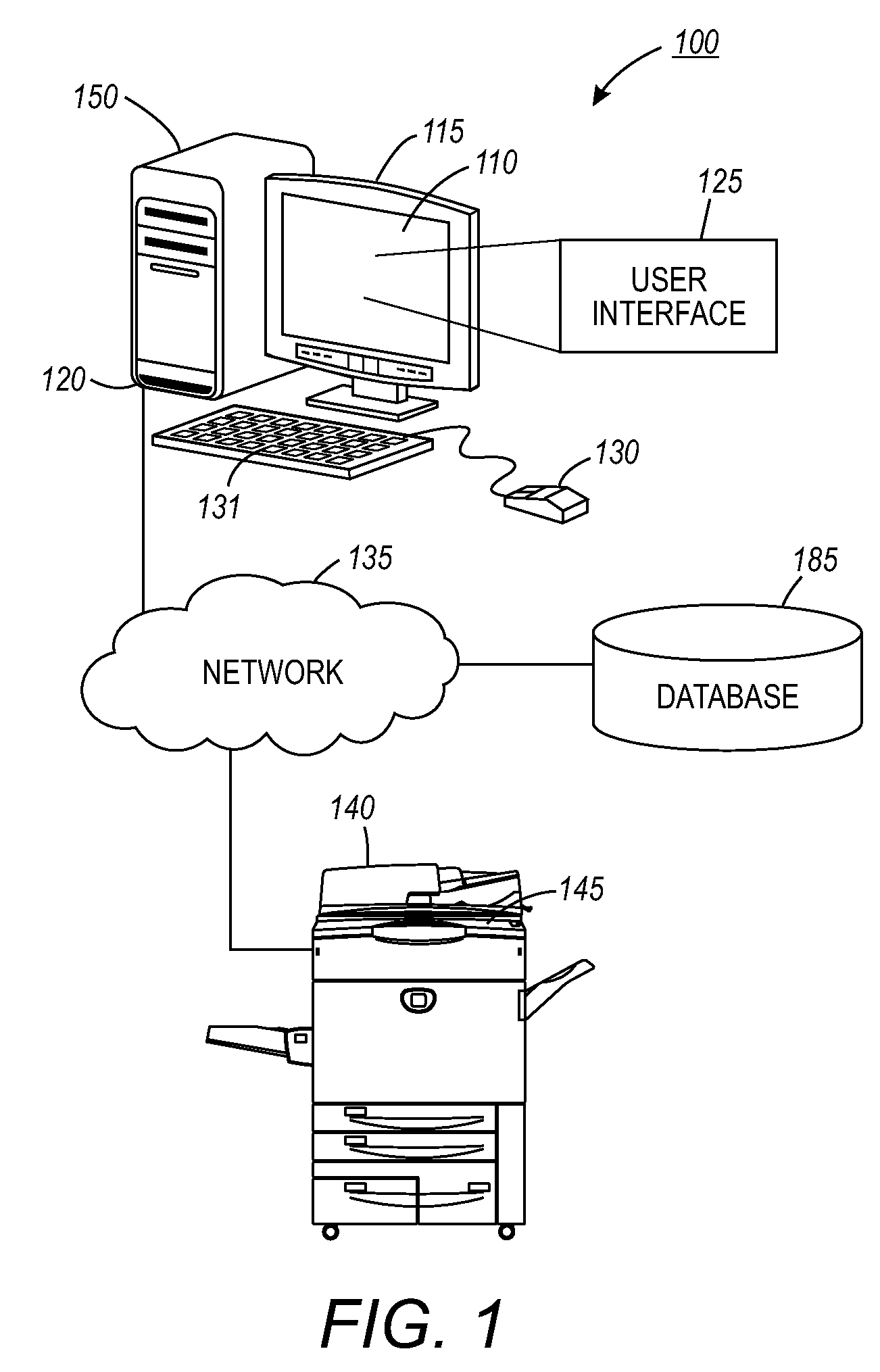

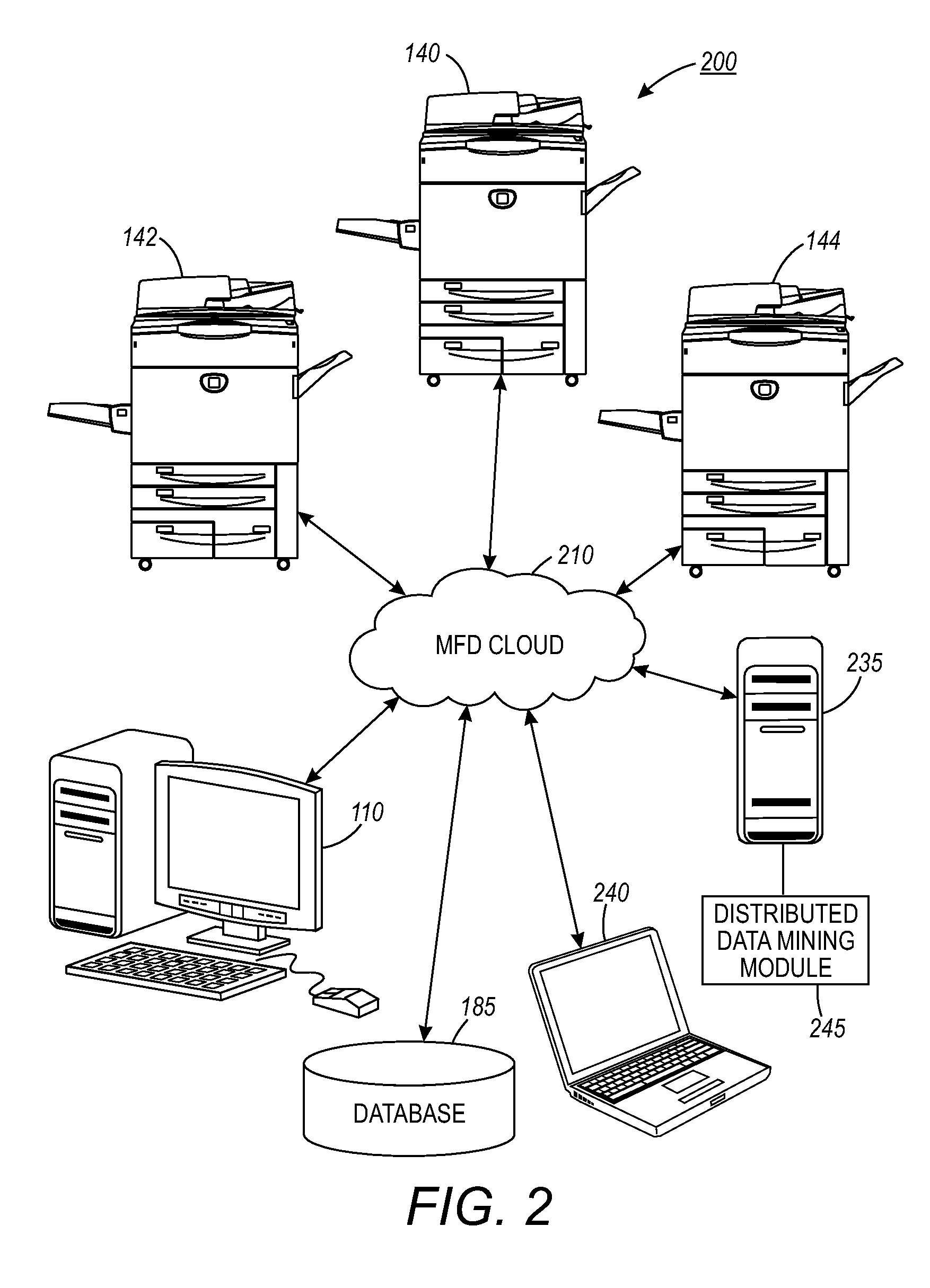

Method and system for determining root cause of problems in members of a fleet of multi-function devices

ActiveUS8264702B2Increase the tempoFine granularityDigitally marking record carriersError detection/correctionFile systemGranularity

Owner:XEROX CORP

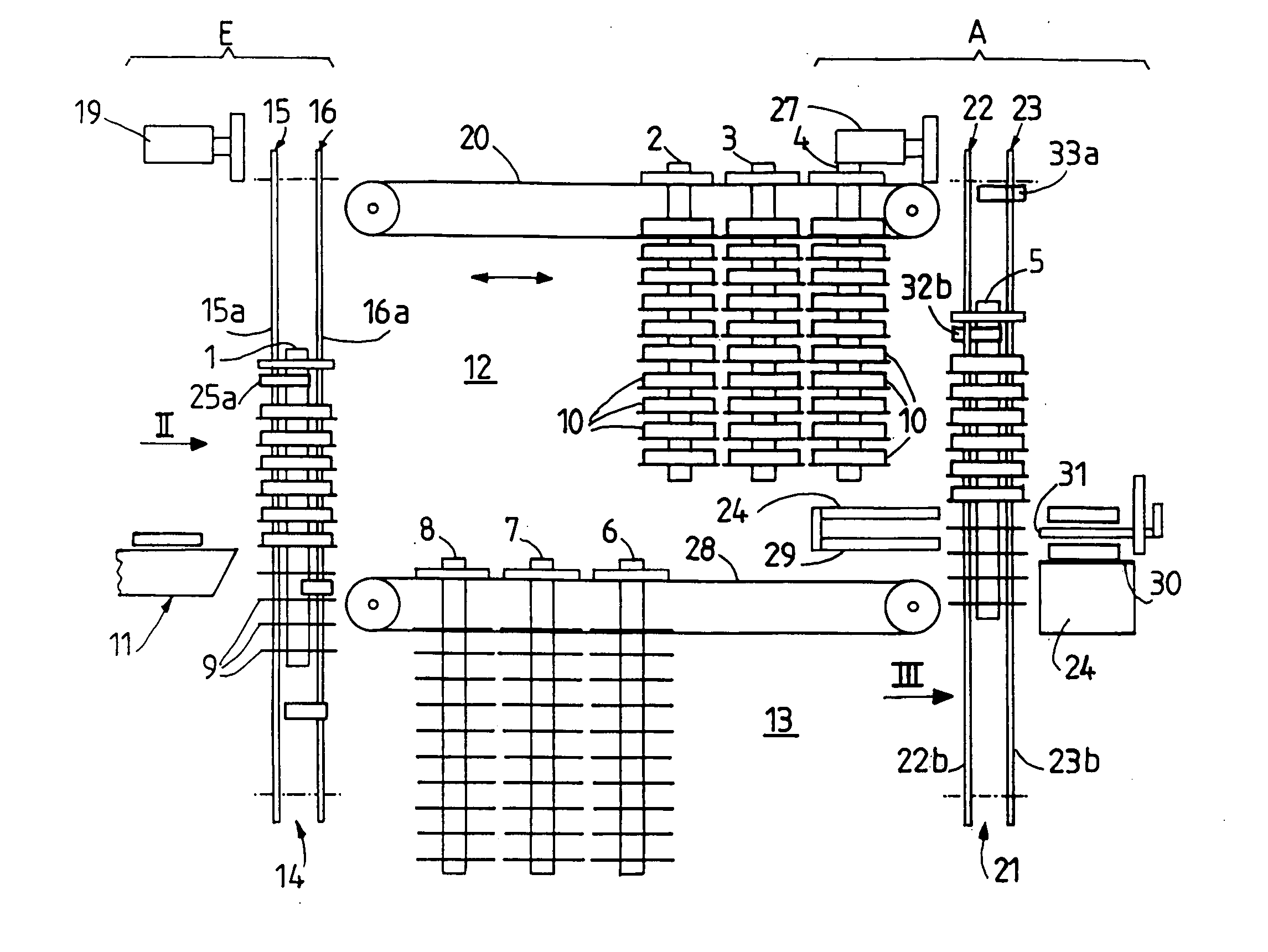

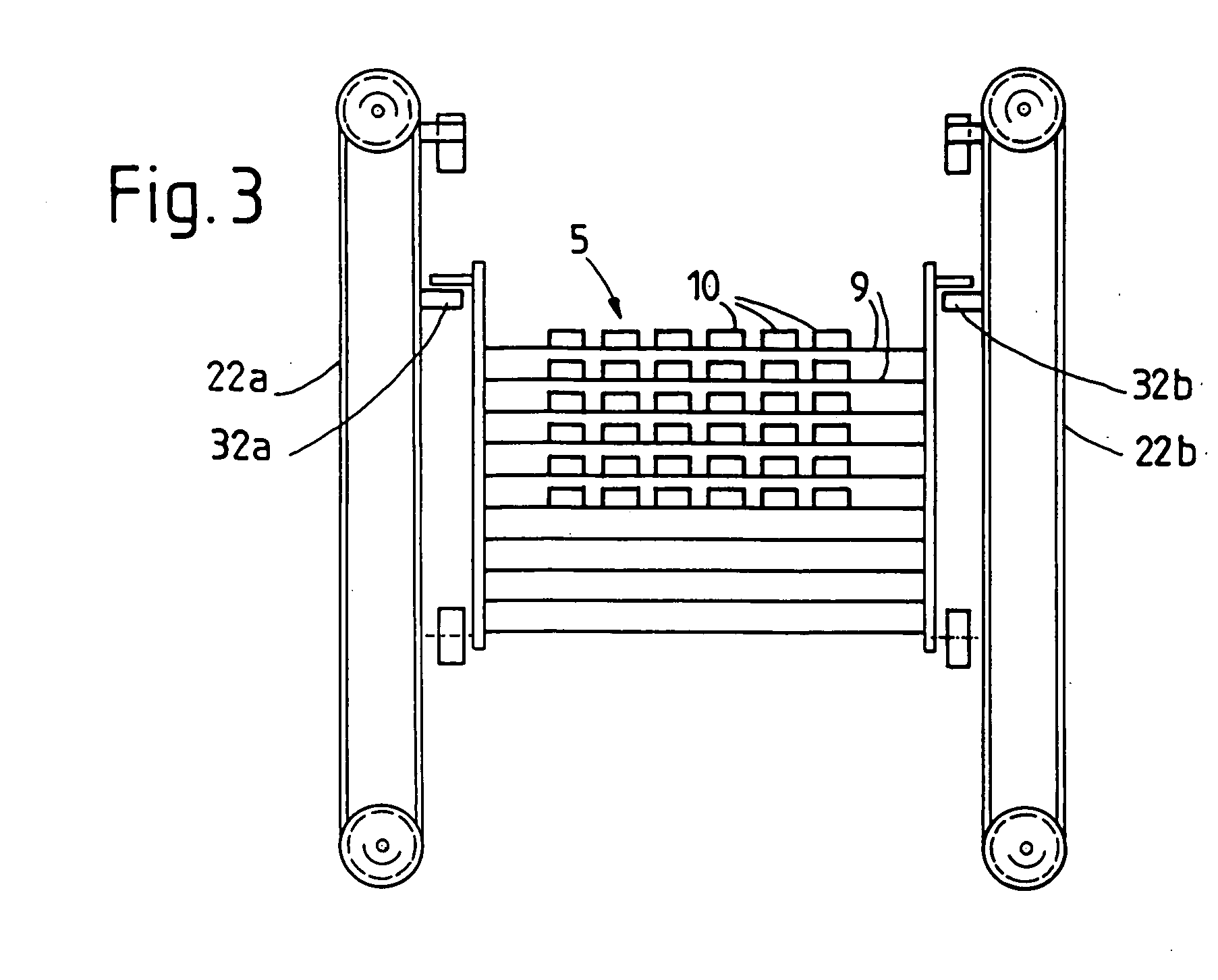

Intermediate store

InactiveUS20050232732A1Constant production speedConstant speedConfectioneryCocoaControl theoryBuffer zone

The intermediate store has an input station for loading and an output station for unloading transport racks circulating in buffer zones between these two stations. The two stations each have a vertical conveyor for the transport racks, each of the two vertical conveyors being equipped with two pairs of chains driven independently of one another. The two pairs of chains in the input station alternately transport one transport rack each stepwise past a loading device and subsequently, after being decoupled from synchronous operation, transport them further, with the result that loading of the transport racks without interruption is permitted. The output station is formed analogously so that there too there are no interruptions between the emptying of two successive transport racks.

Owner:ROTZINGER AKTIENGES

Systems and methods for music instruction

ActiveUS20160267805A1Increase the tempoElectrophonic musical instrumentsMusicAudio frequencyRemote computing

Disclosed are systems and methods for instructing a musician to play an instrument. Methods can include importing a video file into a directory of a remote computing device. The video file can include video of a second musician playing the instrument and audio of the second musician playing the instrument. Methods can include playing the video file with the remote computing device, and decreasing a tempo of the video. The audio can continue to remain in pitch while the tempo of the video has been decreased.

Owner:MASTERMIND DESIGN LTD

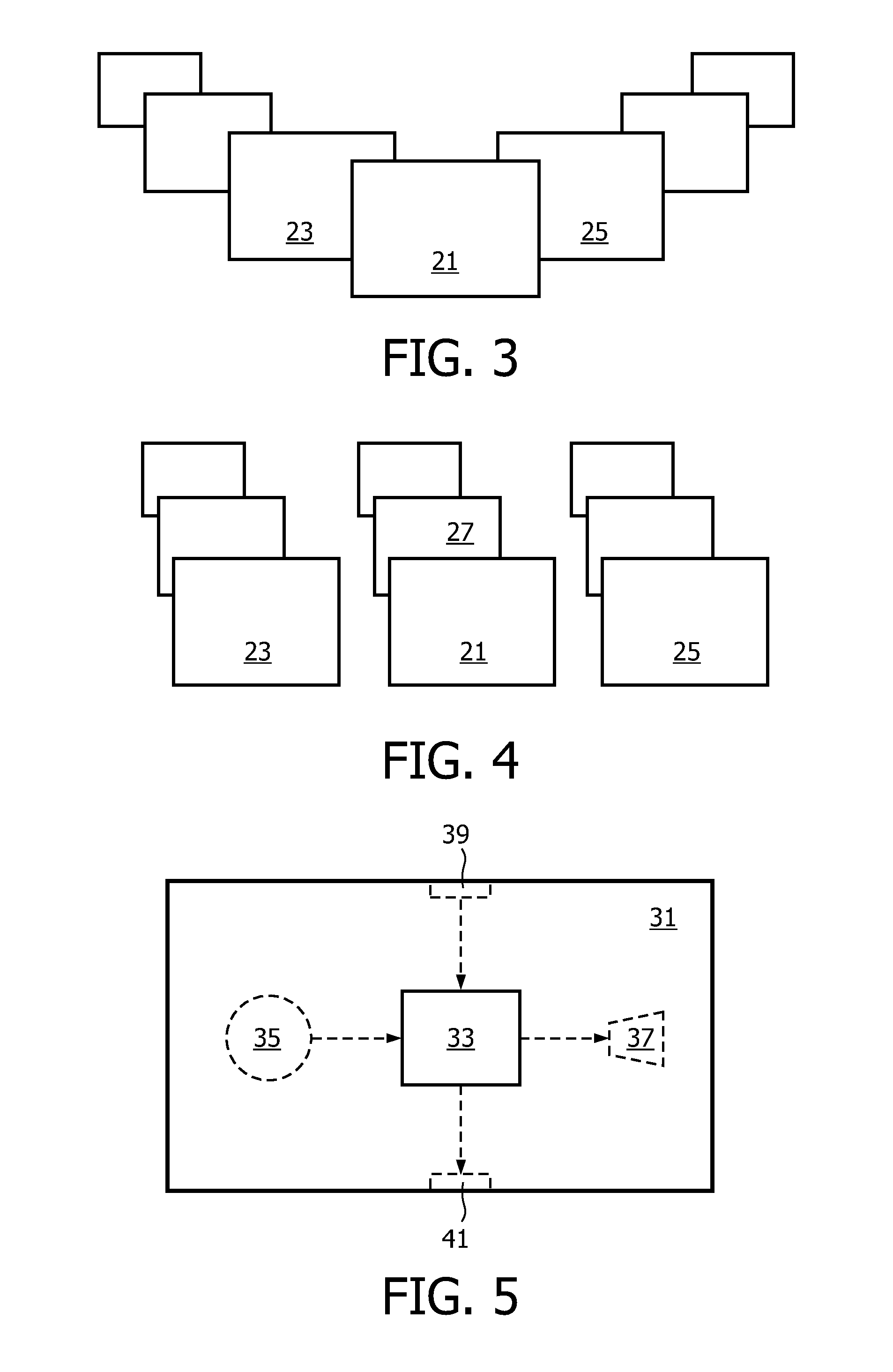

Method and device for enabling selection of an item from a plurality of items

InactiveUS20110010671A1Quick navigationIncrease the tempoRecord information storageCarrier indicating arrangementsHuman–computer interactionAudio segment

The method of the invention enables selection of an item (21) from a plurality of items (21, 23, 25). The method comprises the steps of visually representing a selected item (21) and reproducing at least part of an audio segment representing the selected item (21). The method further comprises applying a visual spatial effect to the visual representation of the selected item (21) and applying a spatial audio effect corresponding to the visual spatial effect to the reproduction of the audio segment. The device of the invention comprises electronic circuitry which is operative to perform the method of the invention. The computer program product of the invention enables a programmable device to perform the method of the invention.

Owner:MMD HONG KONG HLDG LTD

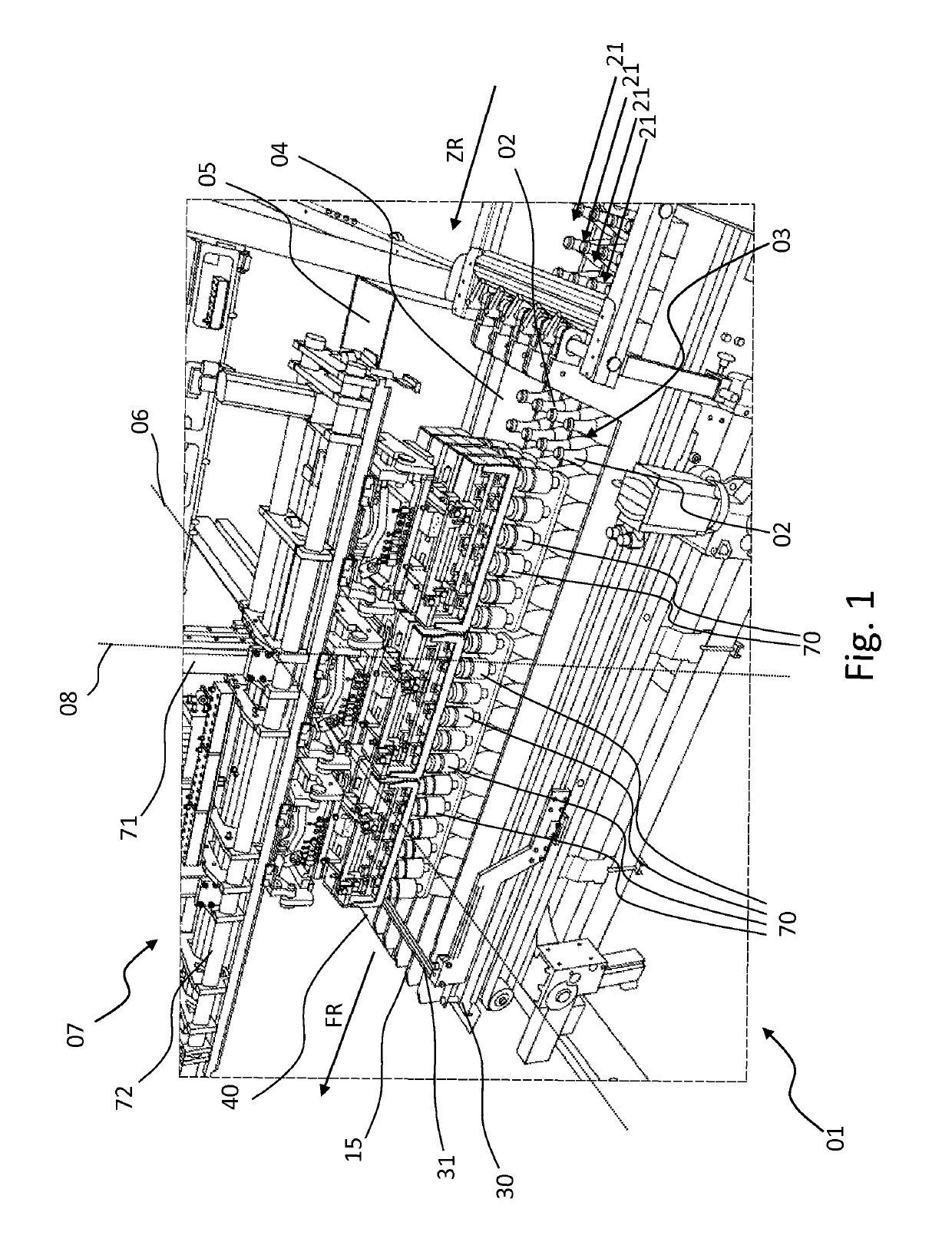

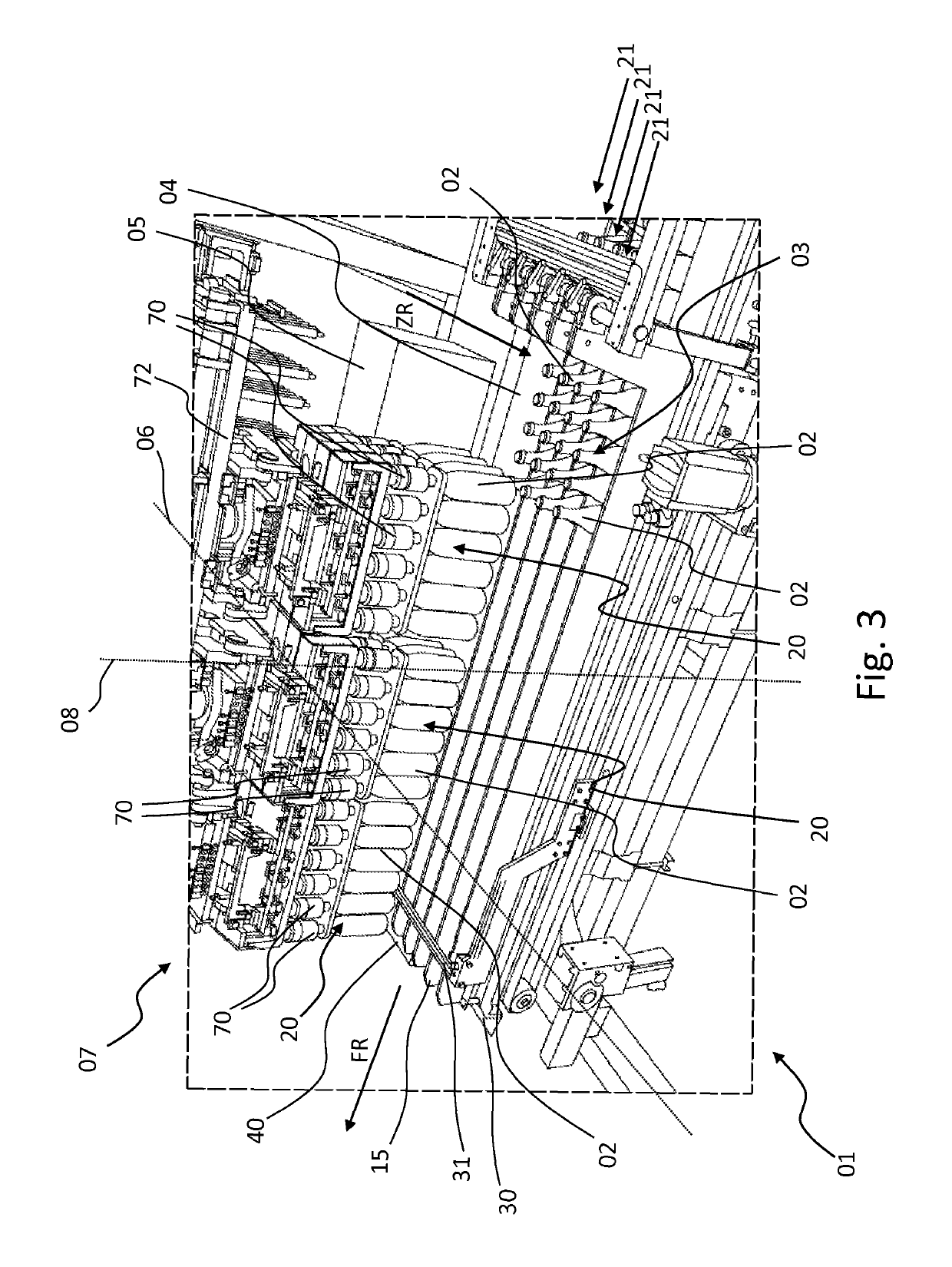

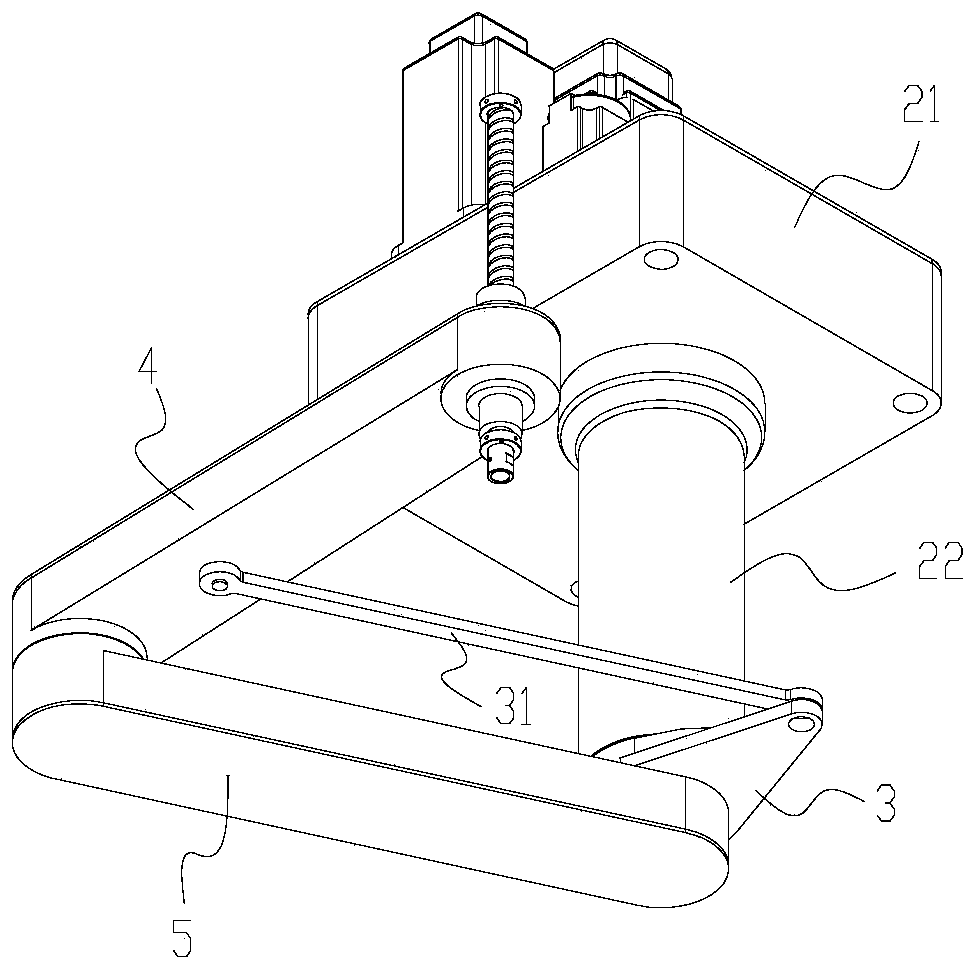

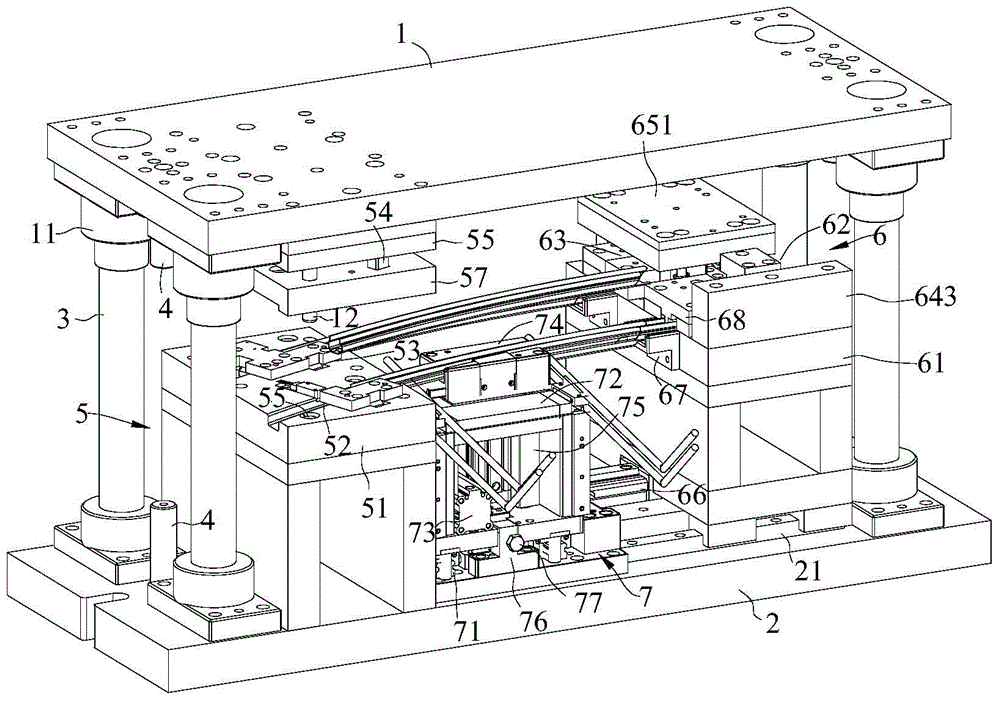

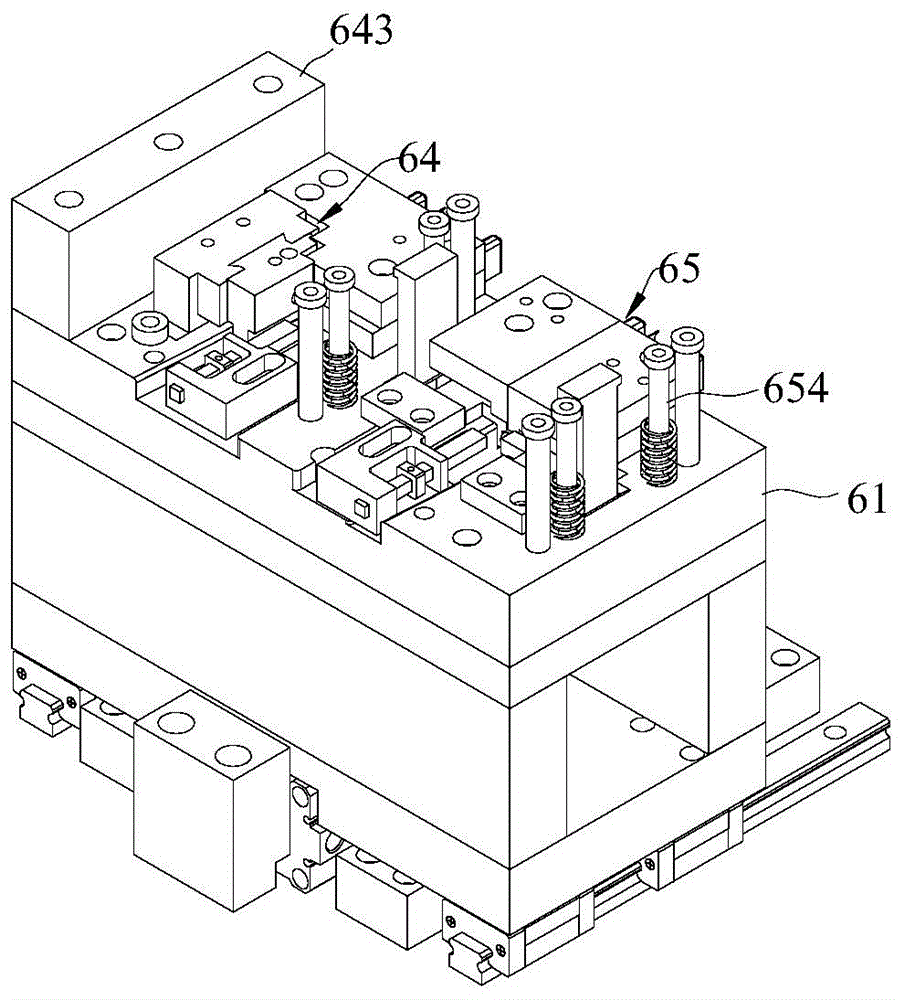

Apparatus and method for handling articles

ActiveUS10322833B2Increase the tempoIncrease variabilityPackaging automatic controlPackaging bottlesManipulatorHorizontal and vertical

The method of the present invention removes at least a plurality of articles (02) arriving consecutively in a transport direction (FR) from an infeed (03), and subsequently, arranging and grouping the articles (02), while simultaneously lifting and collectively transferring the article (02) from the infeed (03) to a staging surface (04). At the staging area are one or more outer packagings (05), and into which the articles (02) are placed. Individually or groupwise, as seen in a direction in parallel to the transport direction (FR), the individual distances between the articles (02) corresponding to a defined arrangement (20) are increased and / or decreased, and finally, the articles (02) are simultaneously lowered and released into the one or a plurality of outer packagings (05). The apparatus of the present invention comprises an infeed (03) of articles (02) being transported, at least one staging surface (04) arranged next to the infeed (03). On the staging surface (04), outer packagings (05) are staged, and which will be filled with articles (02) removed from the infeed (03). From the staging surface (04), the filled outer packagings (05) are discharged. A gripping device (07) is used to simultaneously seize a plurality of articles (02) from the infeed (03). The gripping device (07) has one gripper head (70) per article. The gripping device (07) has at least one manipulator (71) with a horizontally and vertically movable manipulator head (72).

Owner:KRONES AG

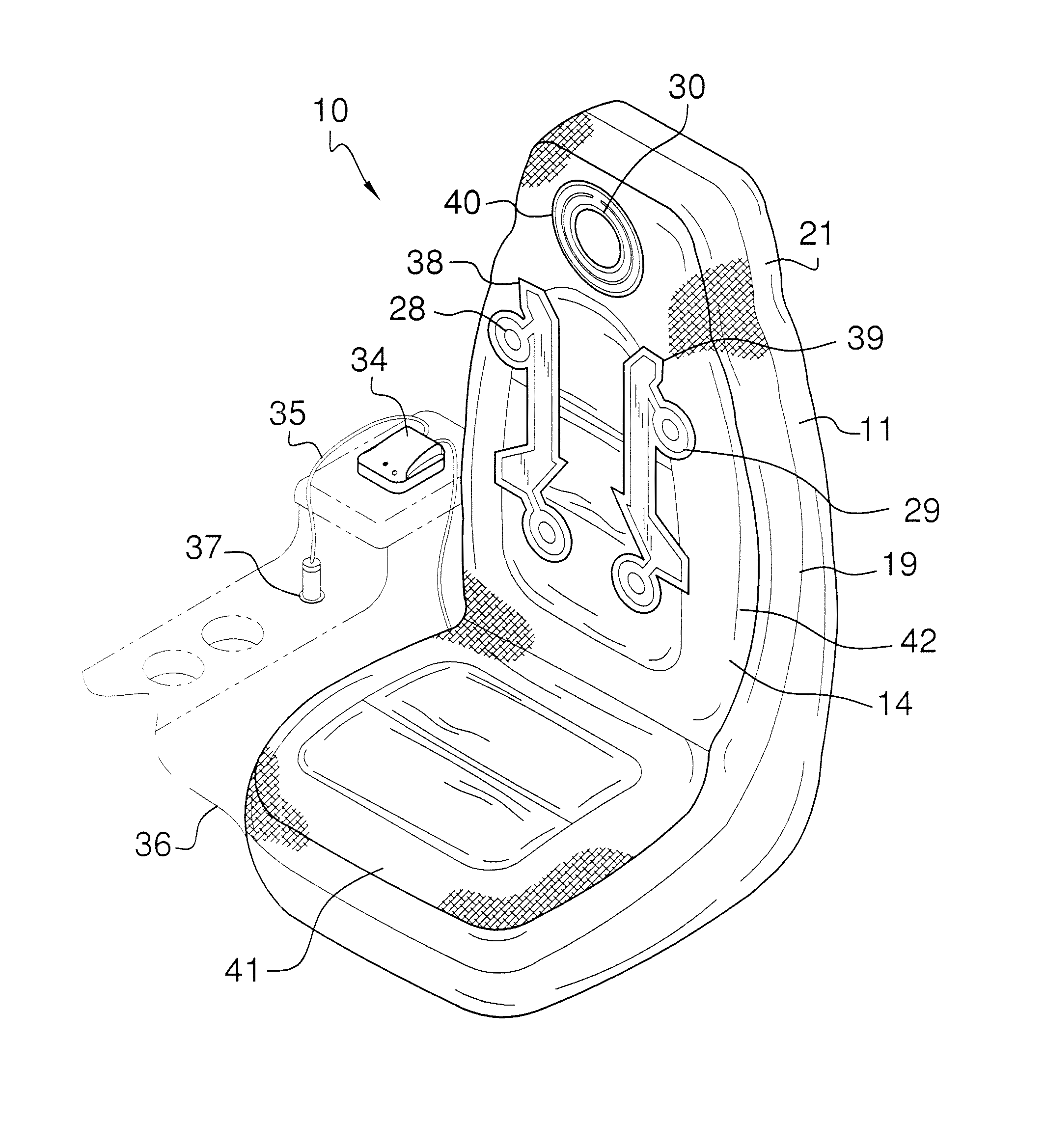

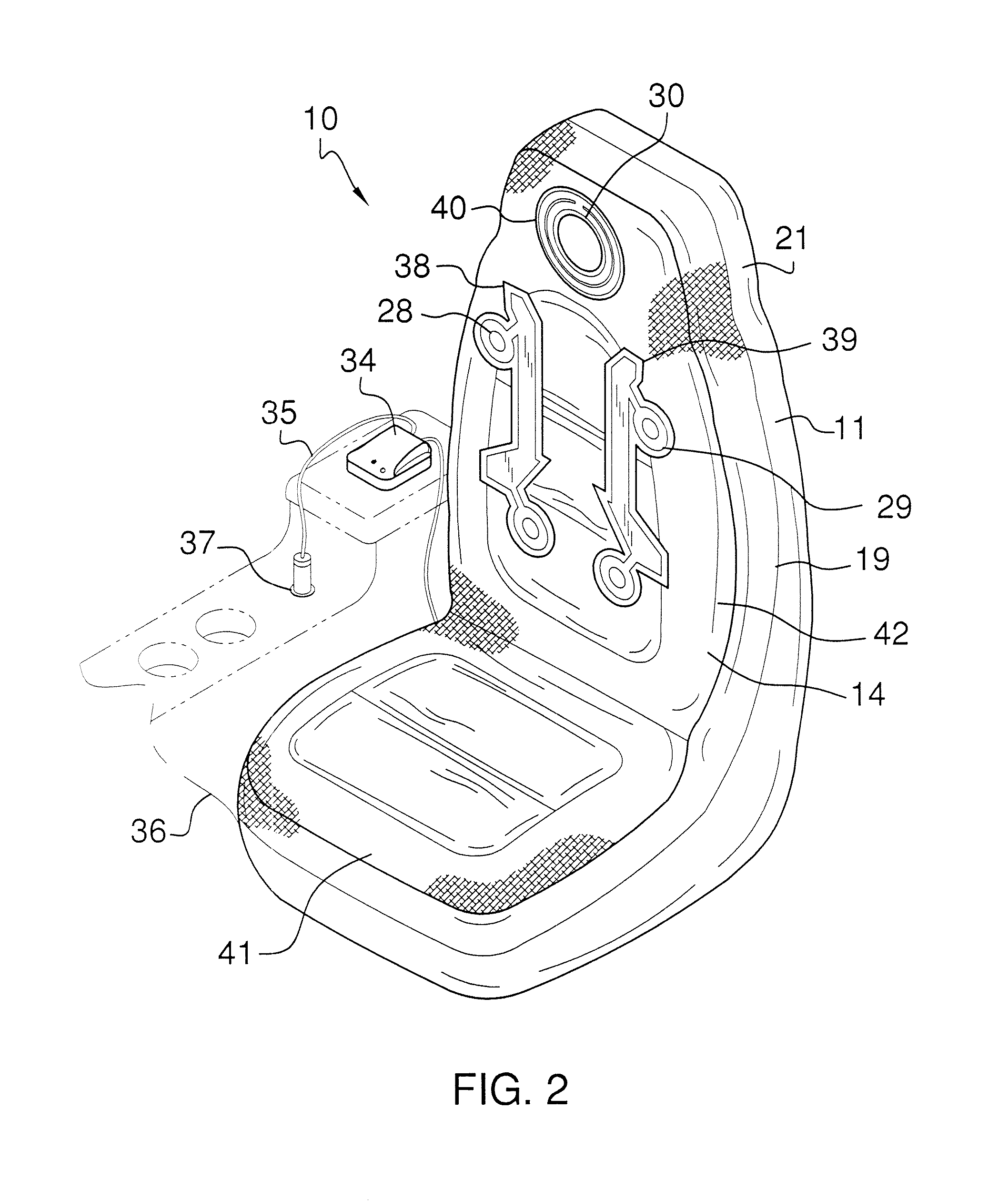

Illuminated circuit print seat cover assembly

InactiveUS9505344B1Enhance beatIncrease the tempoSeat coveringsLighting circuitsEngineeringMechanical engineering

An illuminated circuit print seat cover assembly for synchronizing the lighting up of tape arranged in a pattern on the seat cover with the playing of music in the vehicle. The illuminated circuit print seat cover assembly includes a seat cover including a front sheet of material and a back sheet of material attached to one another; and a lighting assembly attached to the seat cover for displaying flashing and pulsating light with varying degrees of brightness and intensity.

Owner:BOBO DEMETRIS A +1

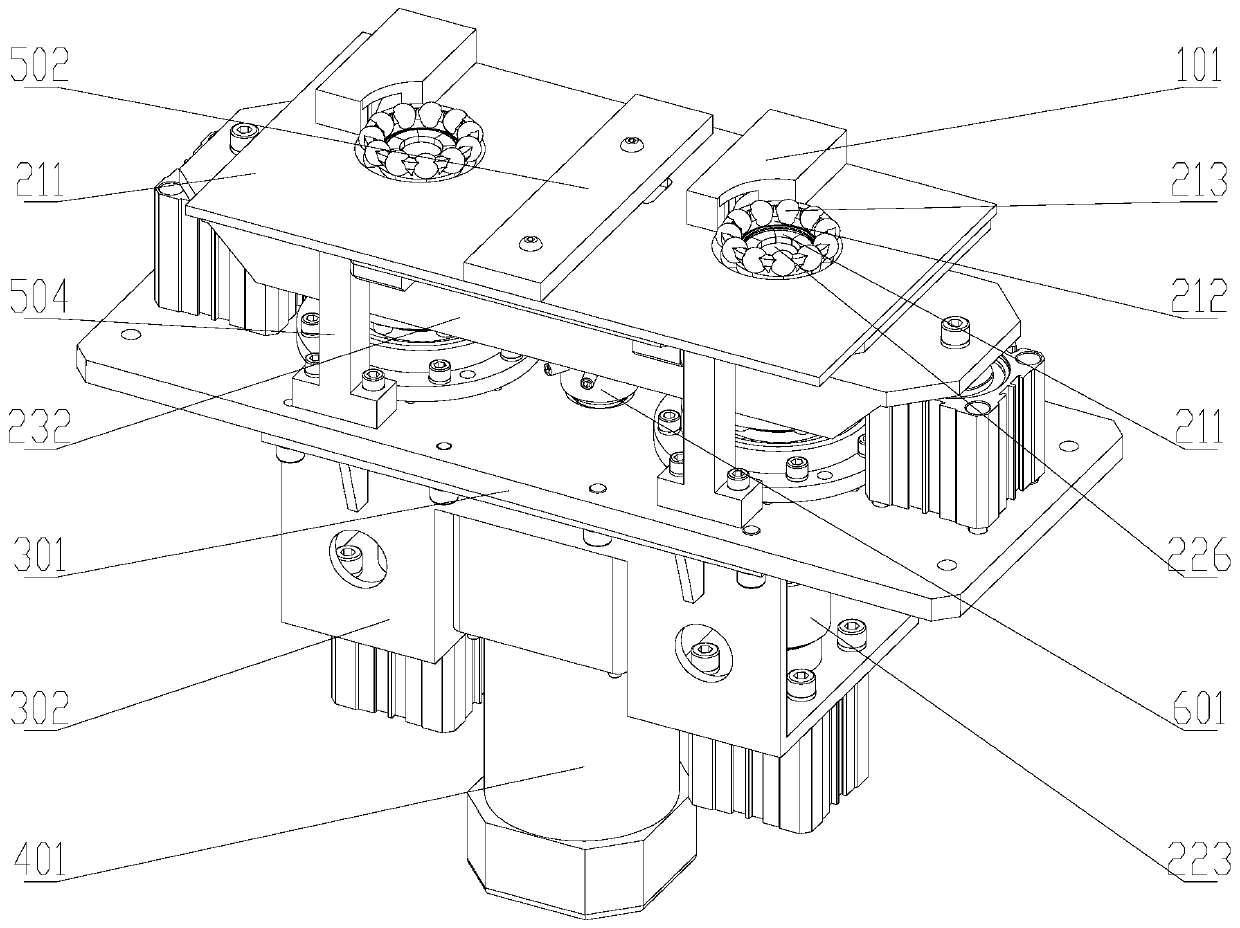

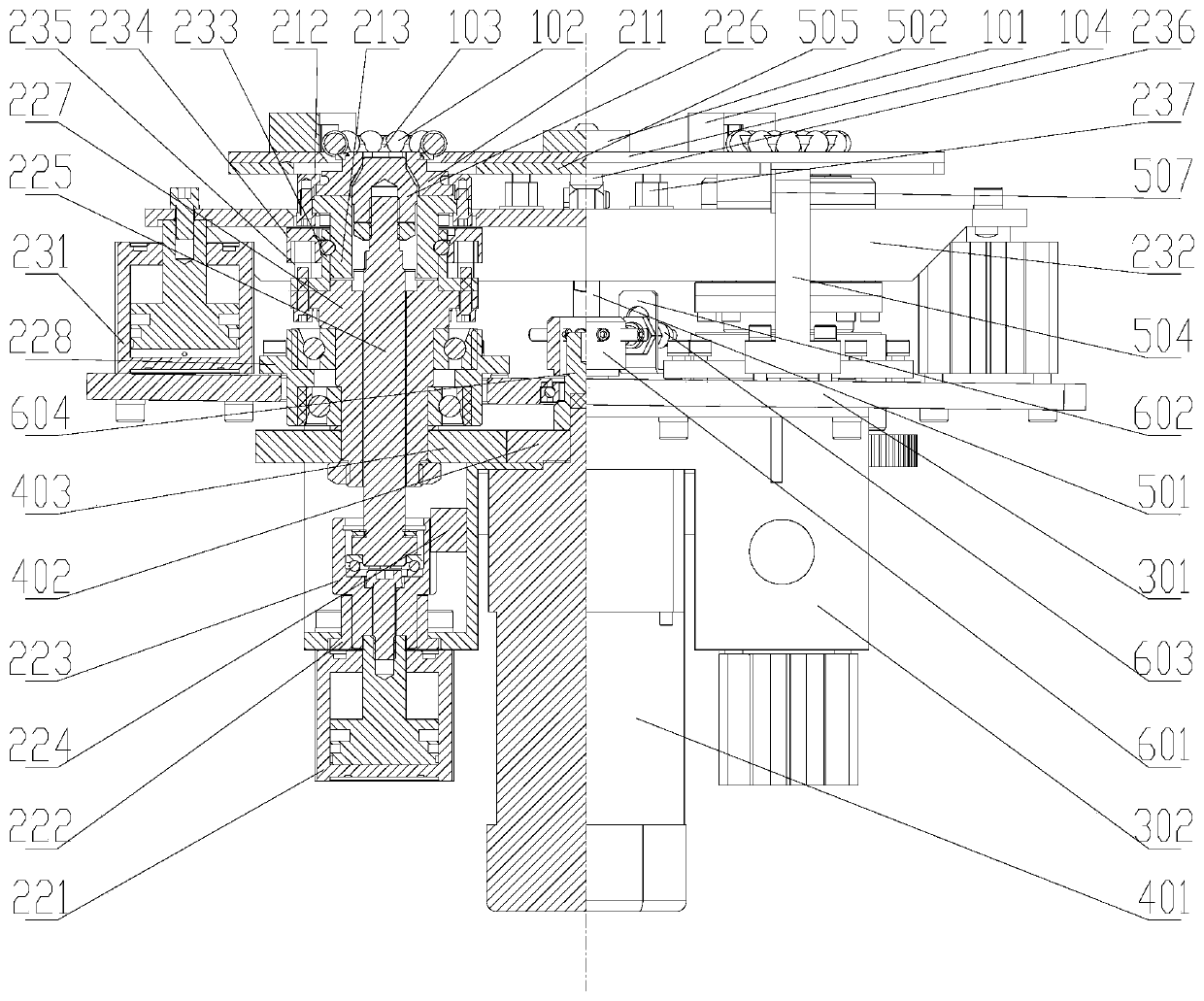

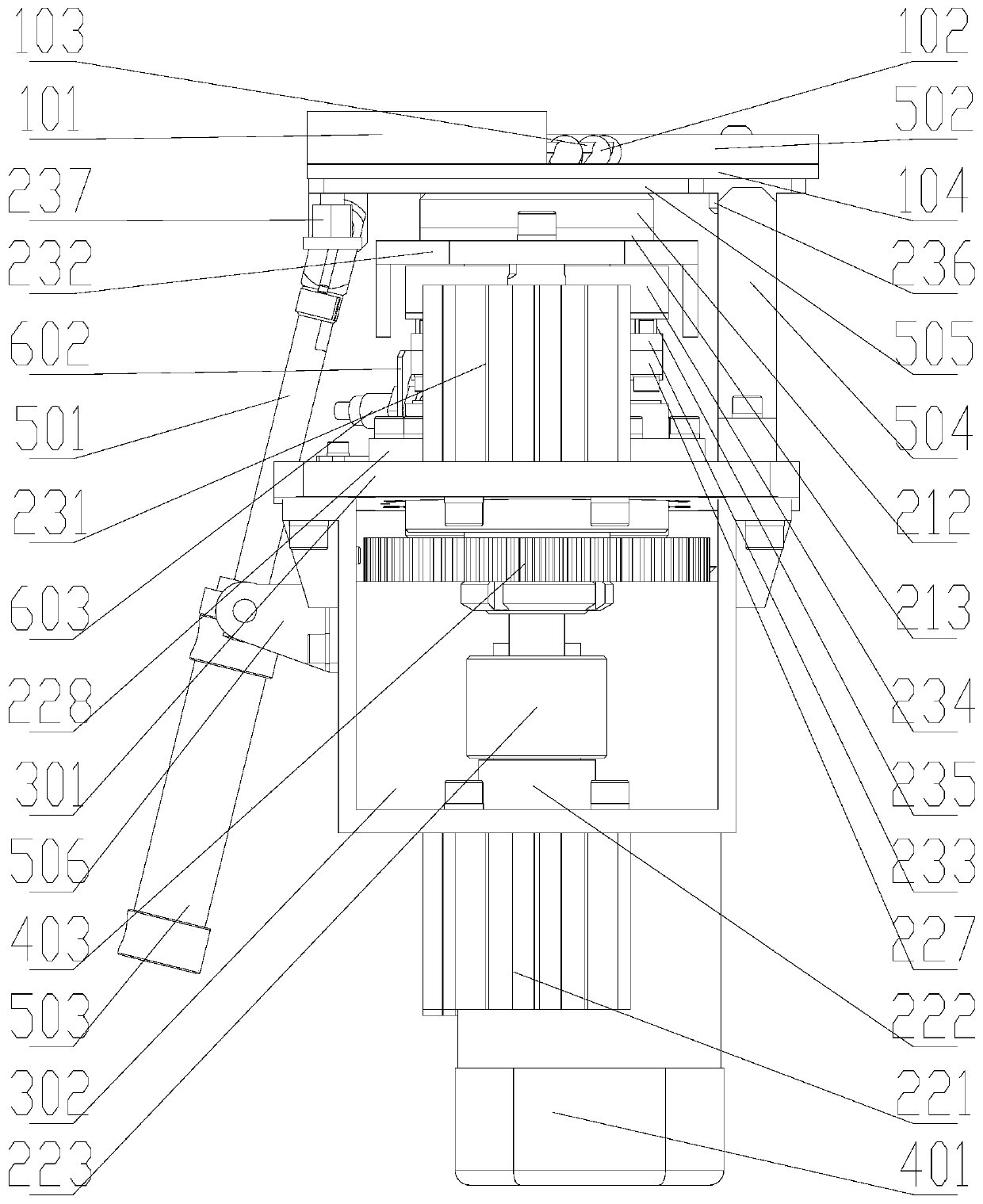

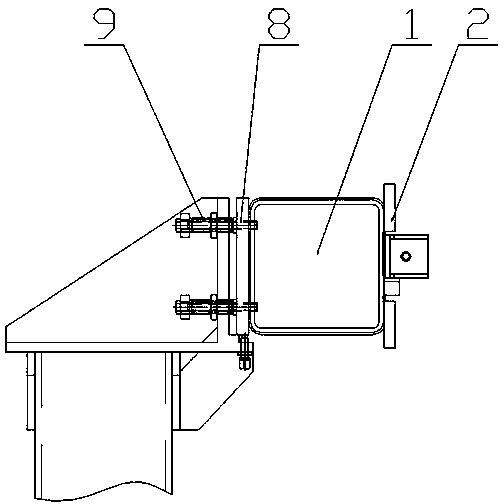

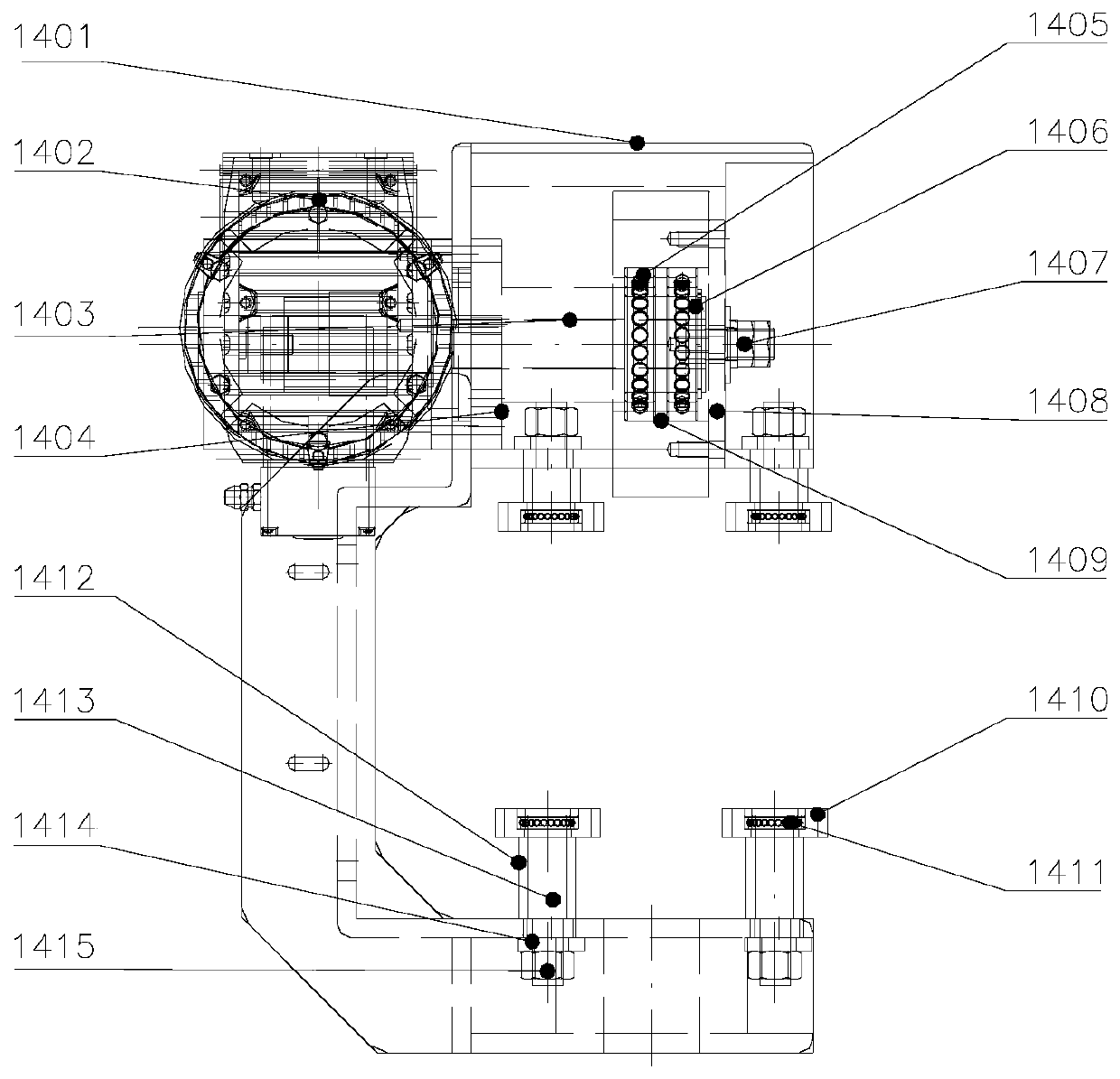

Expanding and squeezing mechanism of vehicle bearing retainer rolling body assembly device

InactiveCN110735862AQuick changeMeet assembly efficiencyBearing componentsMetal working apparatusEngineeringMechanical engineering

The invention discloses an expanding and squeezing mechanism of a vehicle bearing retainer rolling body assembly device, and relates to the technical field of assembly of vehicle hub bearings, in particular to an expanding and squeezing mechanism which can achieve quick replacement of expanding modules, is suitable for various vehicle hub bearing retainers, and is used for the vehicle bearing retainer rolling body assembly device. A driving device is installed at the lower portion of a bearing structure and connected with two expanding mechanisms symmetrically installed on the bearing structure, and two squeezing mechanisms are installed at the upper portions of the two expanding mechanisms respectively; a discharge device is installed at the rear portion of the bearing structure and connected with the two expanding mechanisms and the two squeezing mechanisms at the upper portion of the bearing structure; a counting device is installed on the bearing structure and connected with the driving device. By means of the expanding and squeezing mechanism, the problems in the prior art are solved that retainers and rolling bodies are easily damaged to different degrees, the product percentof pass is relatively low, and even the quality and service life of vehicle hub bearings will be severely influenced.

Owner:DALIAN MARITIME UNIVERSITY

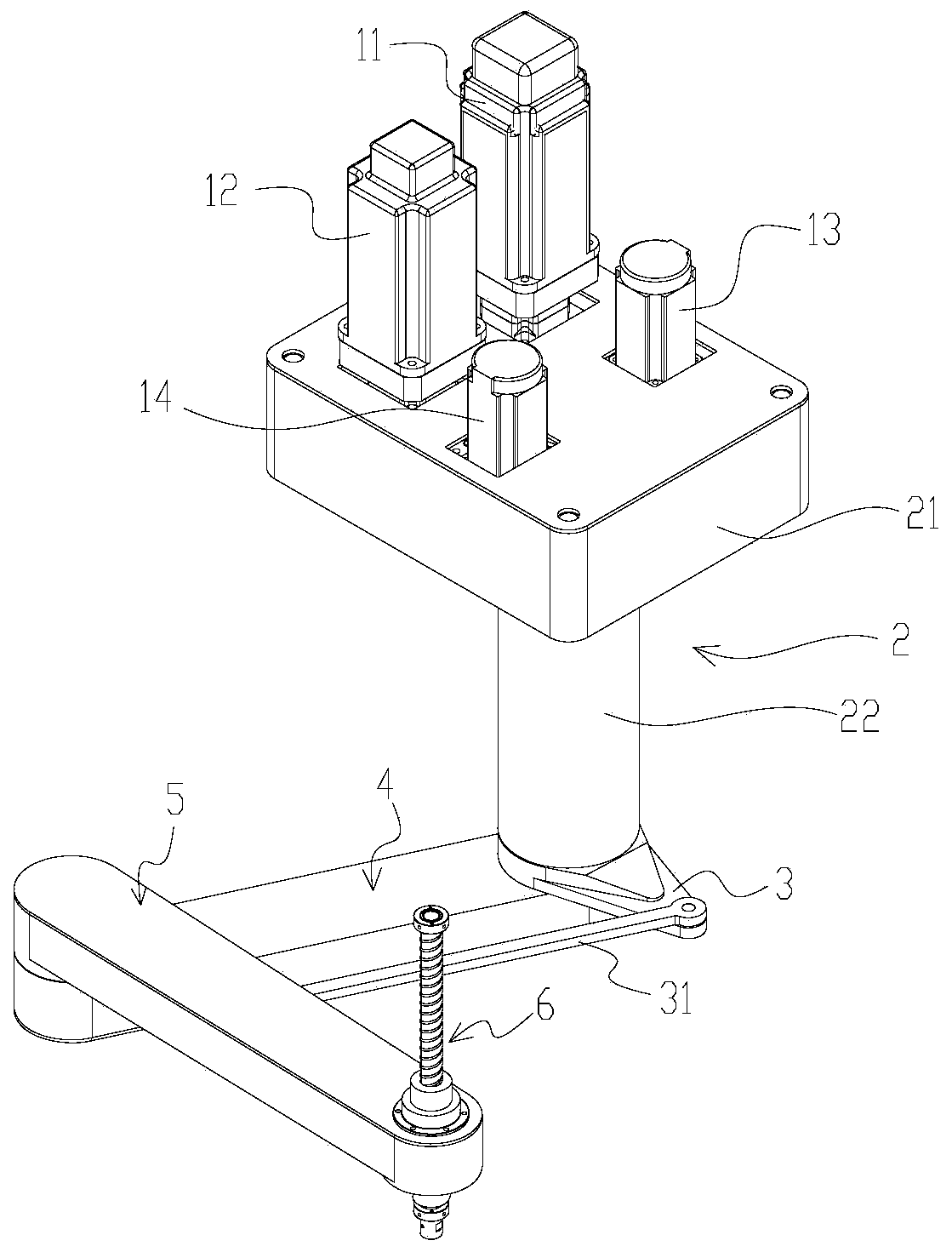

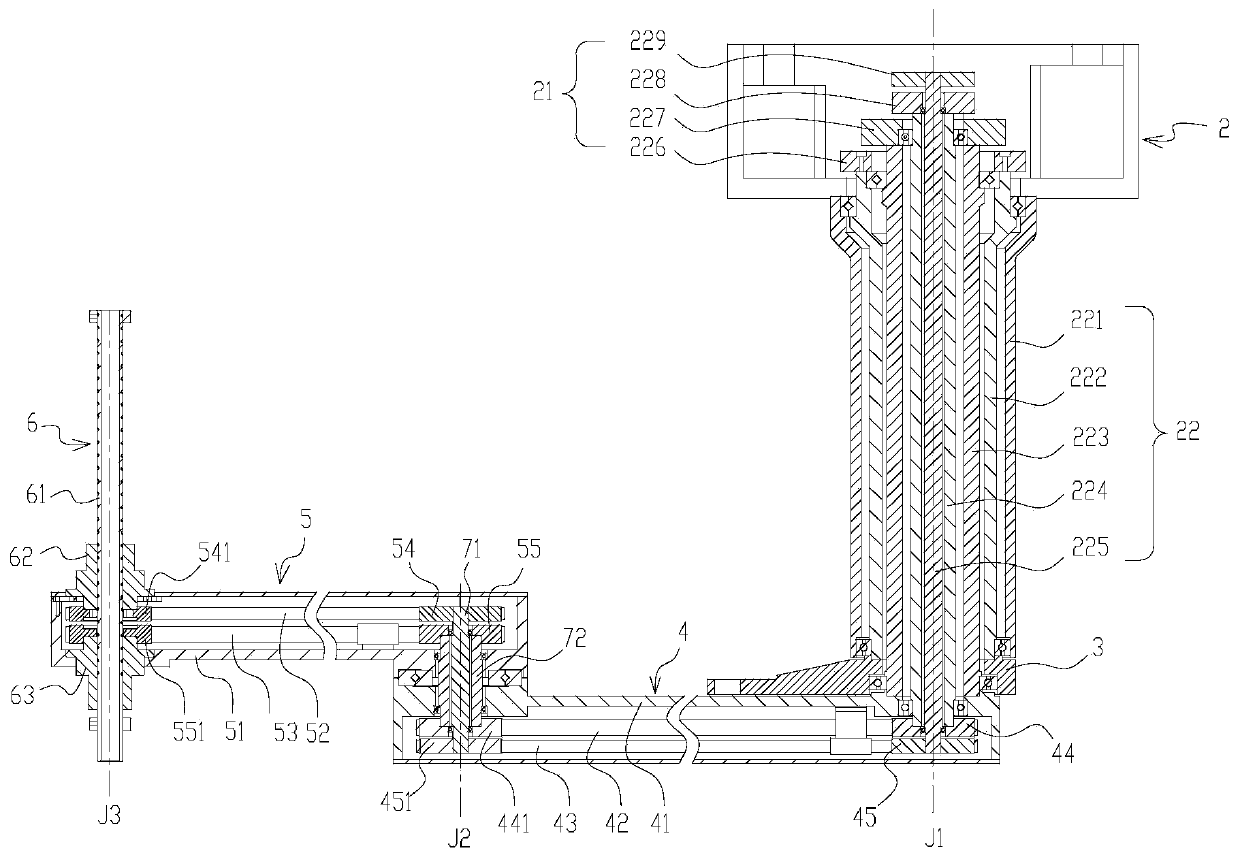

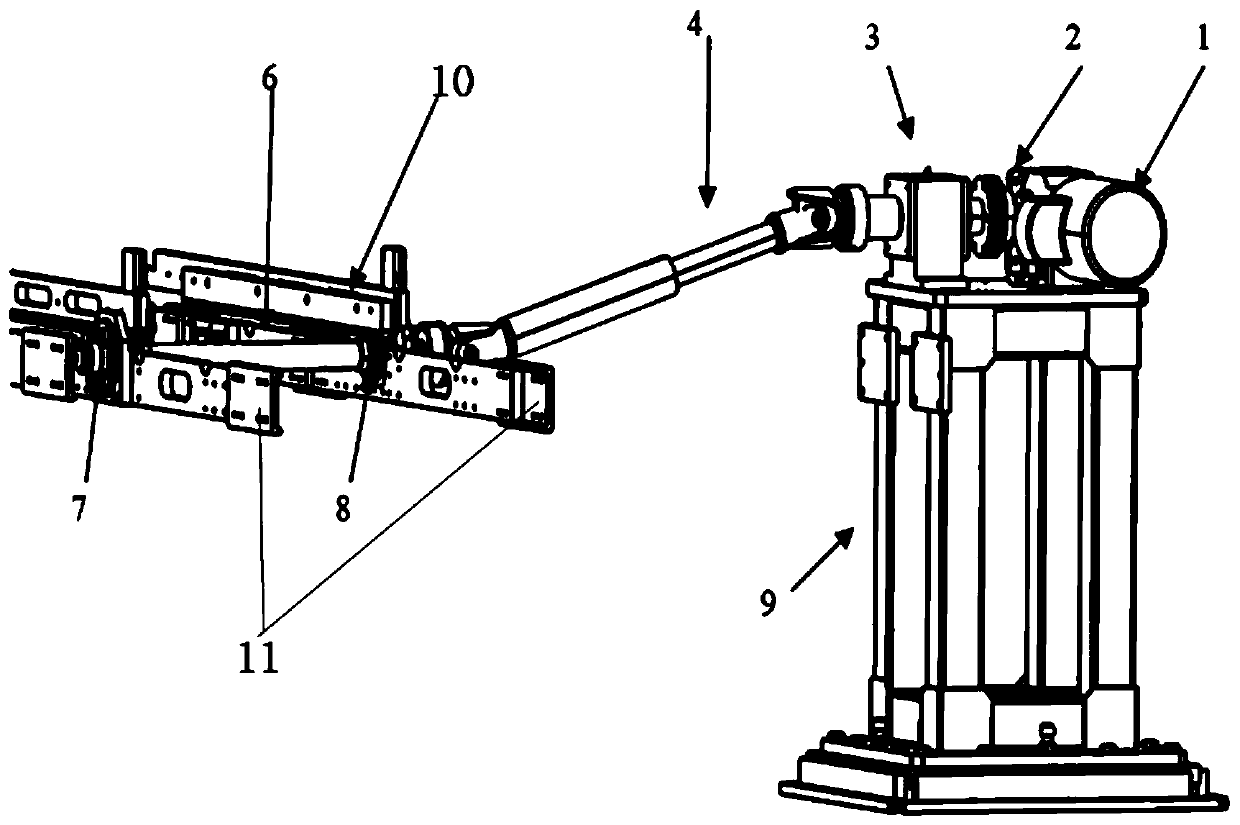

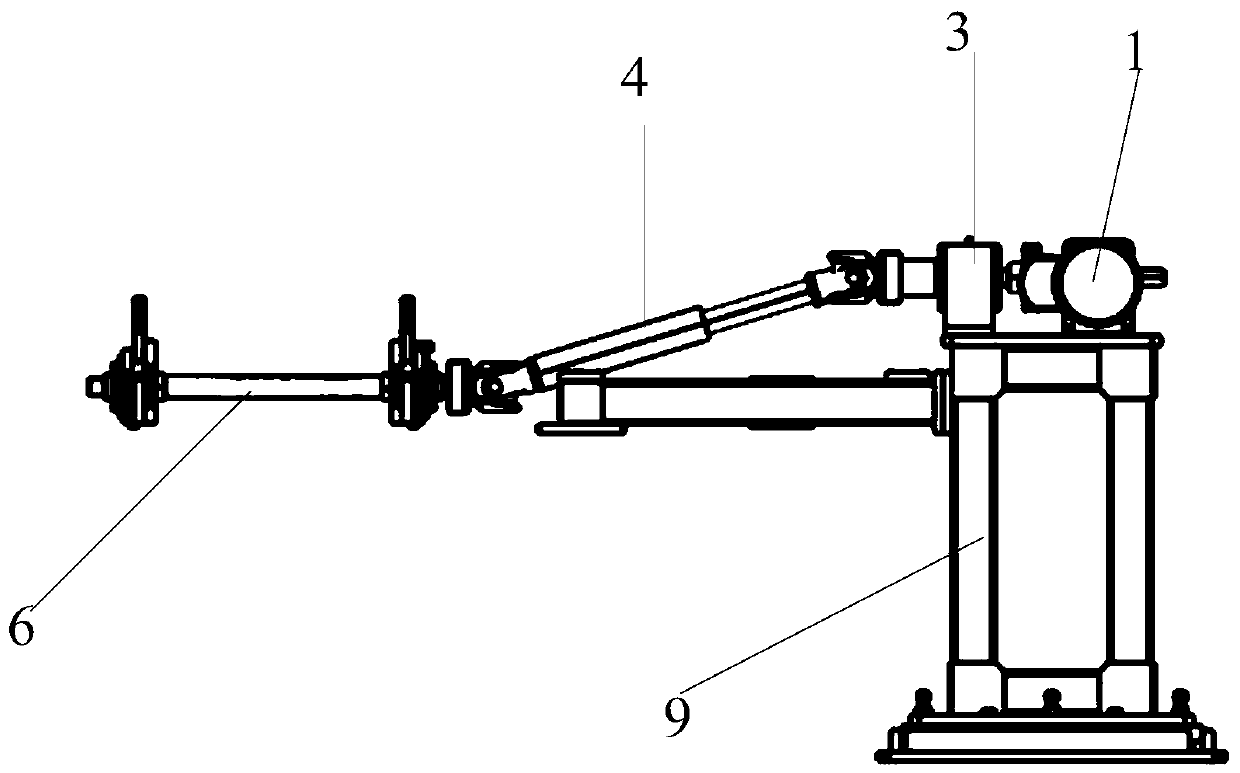

Horizontal multi-joint robot

PendingCN110948476ALight in massReduce manufacturing costProgramme-controlled manipulatorMulti jointFour-bar linkage

The invention discloses a horizontal multi-joint robot which comprises a base, a large arm component, a small arm component and an action shaft, wherein the base comprises a pedestal and an arm cylinder; a driving unit is arranged in the pedestal; a transmission unit is arranged in the arm cylinder; the large arm component is connected with the pedestal through the arm cylinder and can rotate around the axis J1; a driving arm is arranged between the large arm component and the arm cylinder and rotates around the axis J1; the front end of the driving arm is connected with an attached rod; the other end of the attached rod is connected with the small arm component; the small arm component rotates around an axis J2 under the driving of a planar four-link mechanism; and the action shaft is arranged at the other end of the small arm component and can rotate around an axis J3 and move up and down. The invention realizes low manufacturing cost and high-speed movement of the robot.

Owner:NANJING ESTUN ROBOTICS CO LTD

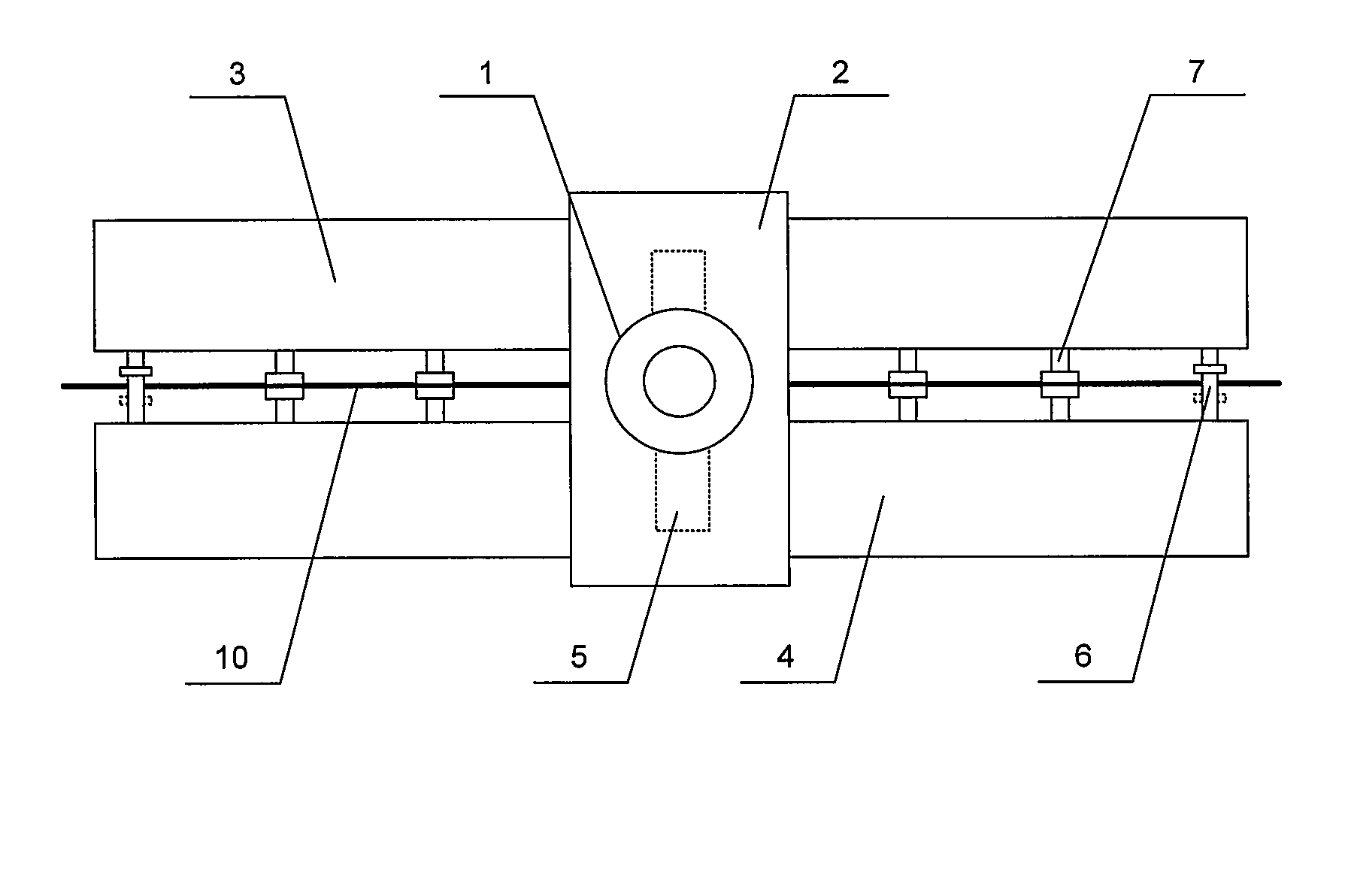

Cross shaft automatic assembling mechanism

PendingCN109676355ASimple and efficient operationReduce processMetal working apparatusPush and pullEngineering

The invention discloses a cross shaft automatic assembling mechanism. A main machine framework (2), a table plate fixed below the main machine framework (2), a servo electric cylinder (1) installed onthe upper portion of the main machine framework (2), a floating pressing head mechanism (3) installed on the main machine framework (2) and connected with the servo electric cylinder (1), a shaft rodauxiliary floating support (5) installed on the table plate, capable of moving left and right and capable of being locked, a flange yoke auxiliary floating support (6) fixedly connected with the table plate, a lower positioning auxiliary support (7) and a cross shaft auxiliary floating support (8) are included; the center height of the flange yoke auxiliary floating support (6) can be adjusted vertically and can be pushed and pulled left and right to be fixed; and the lower positioning auxiliary support (7) and the floating pressing head mechanism (3) are concentric. The cross shaft automaticassembling mechanism achieves manual one-time feeding, bearing bushes at the two ends of a cross shaft and a snap spring at one end are subjected to press fitting, after press fitting is completed, repeated pressing is not needed, operation is easy and convenient, and meanwhile the safety and the beat are improved.

Owner:儒拉玛特自动化技术(长春)有限公司

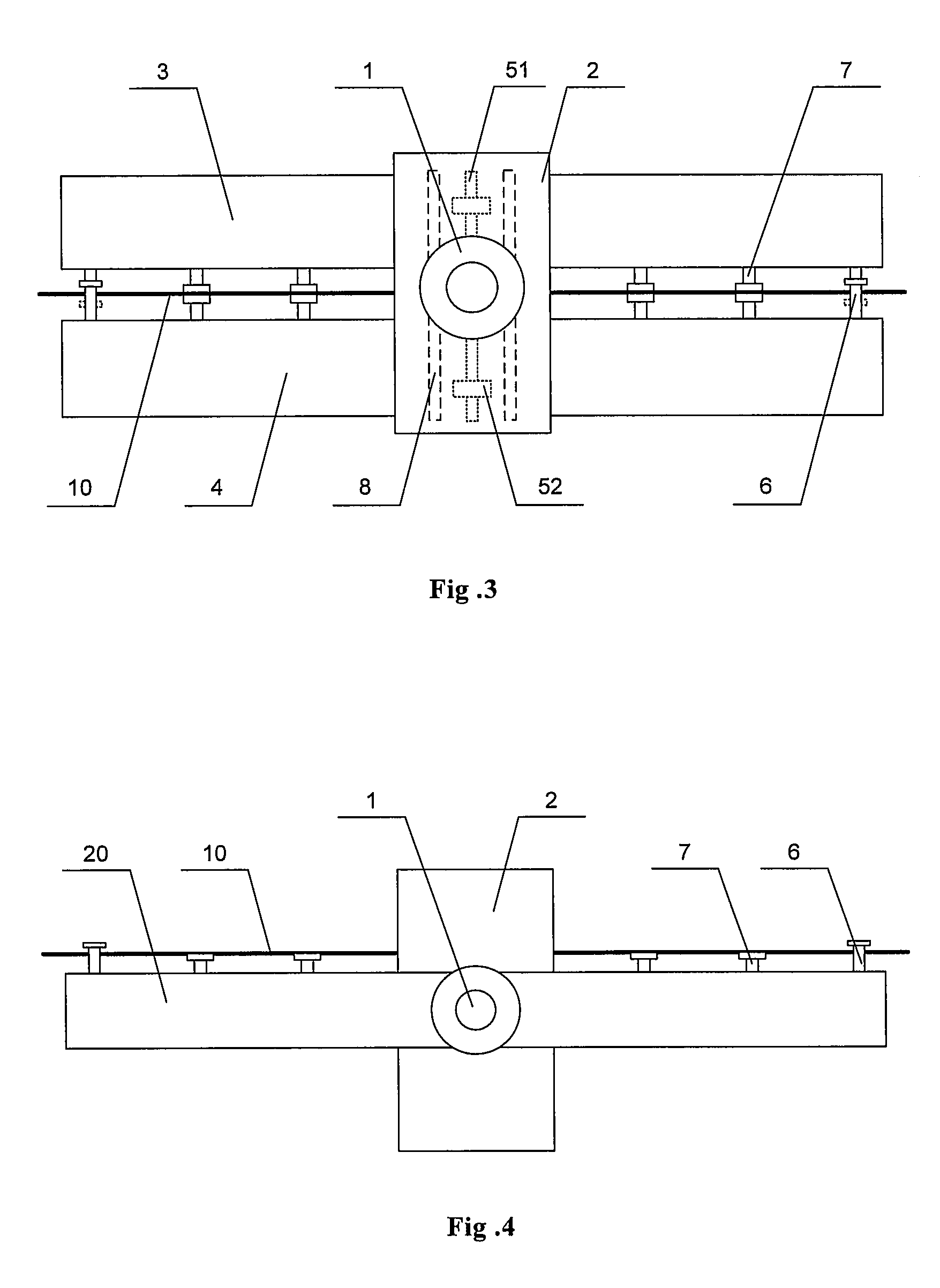

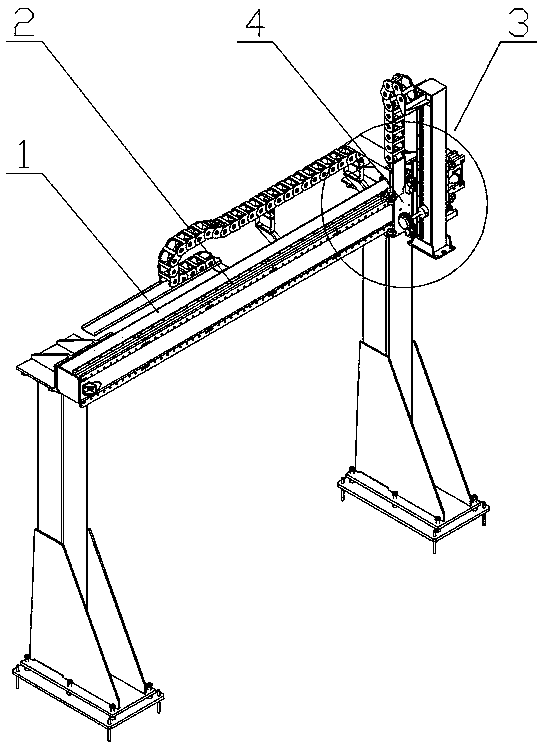

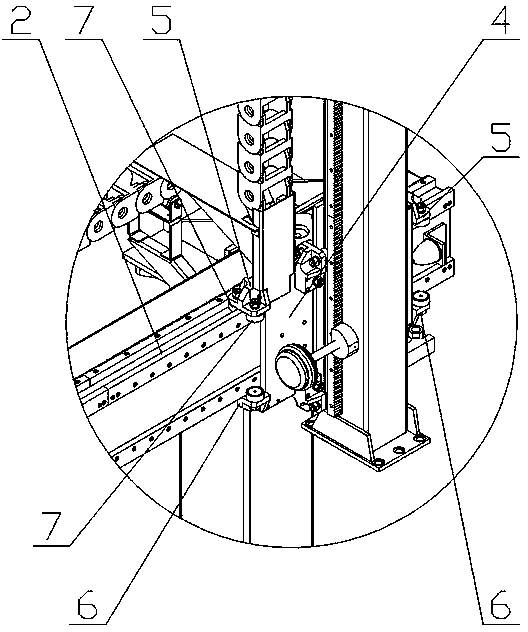

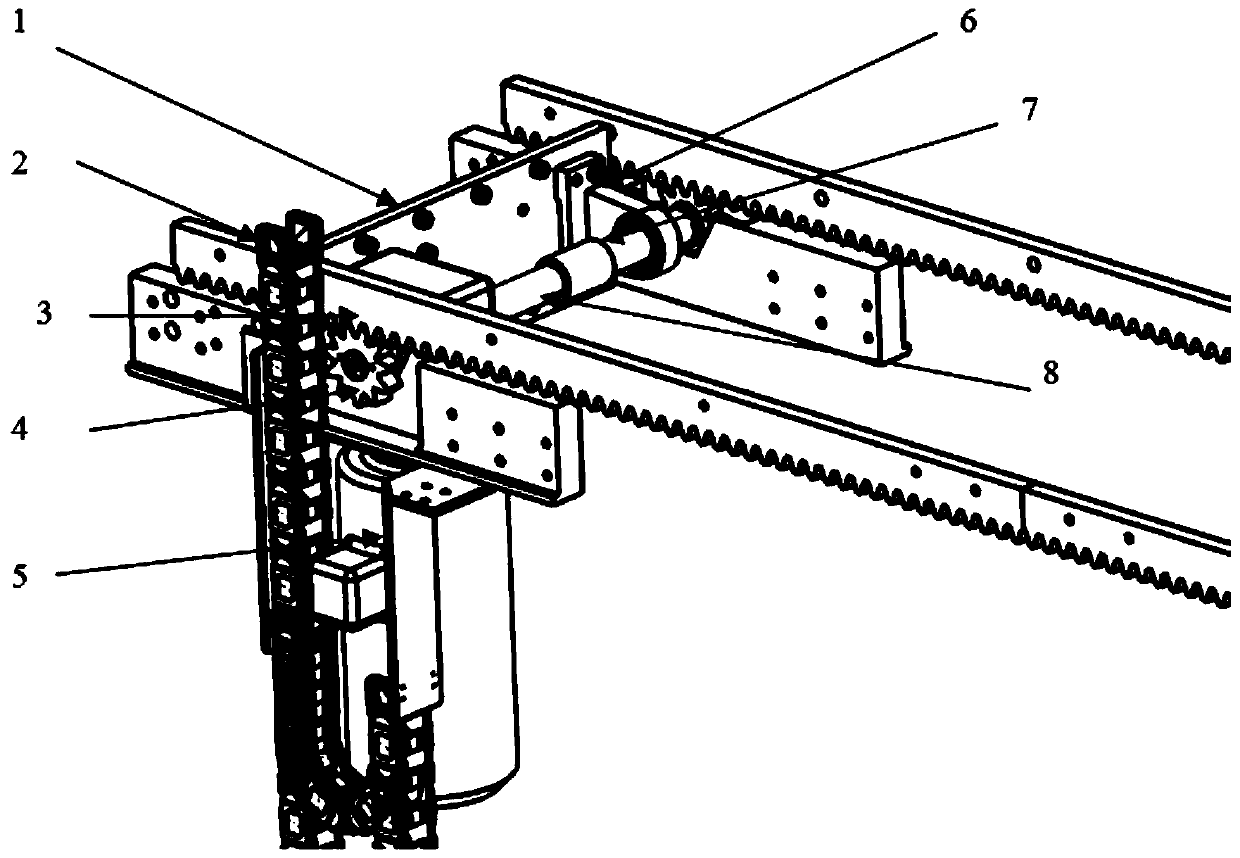

High-speed and heavy-duty truss mechanical arm

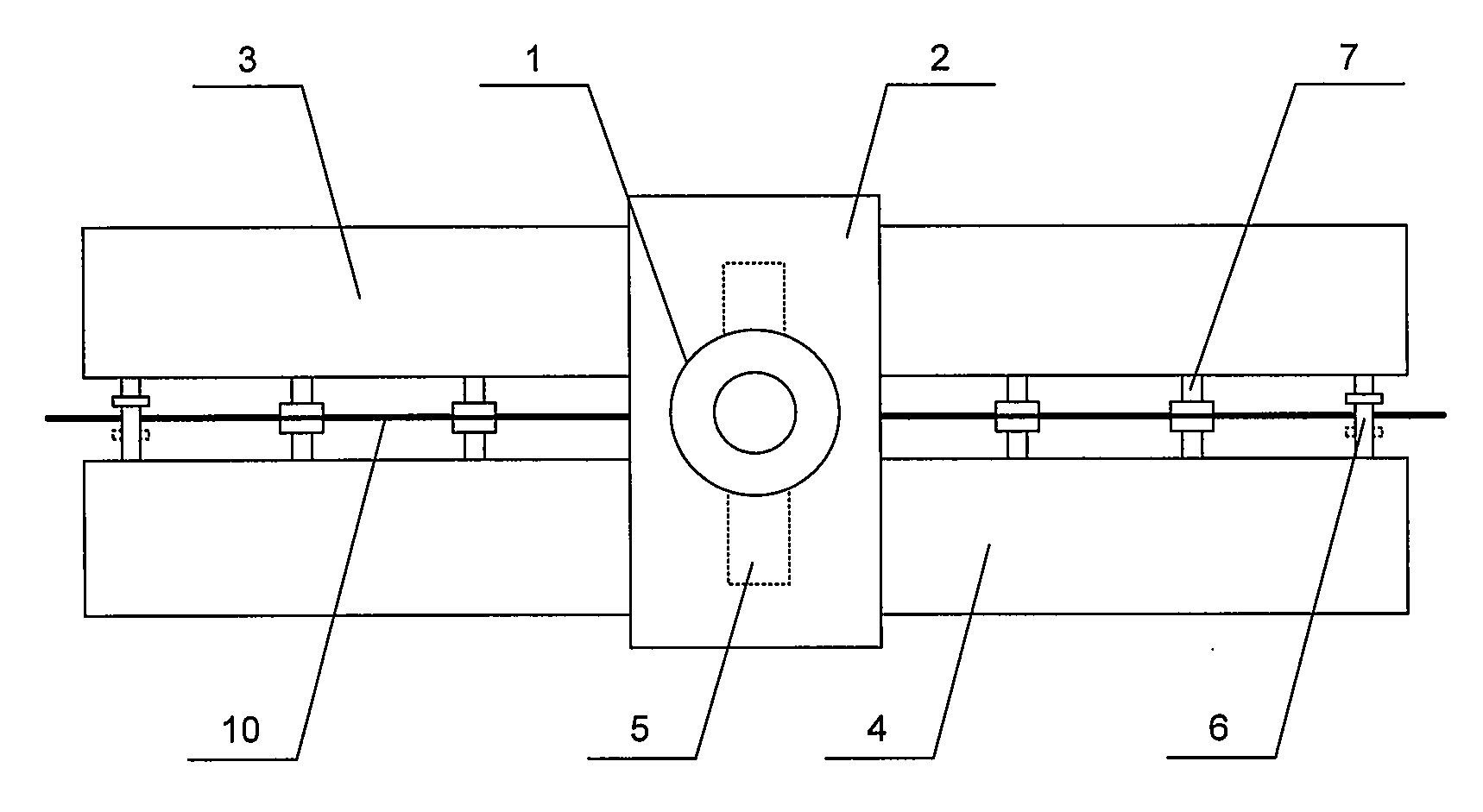

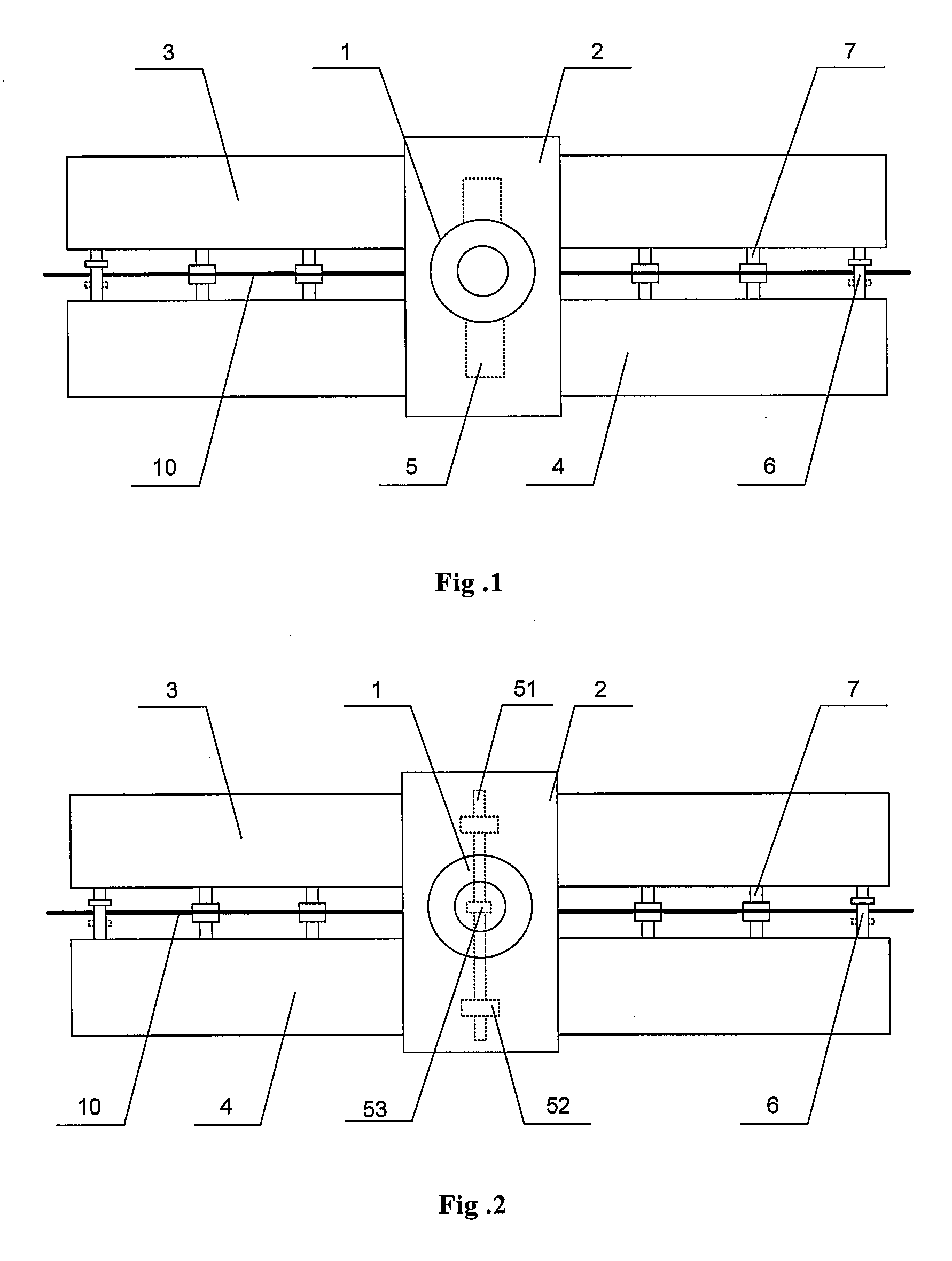

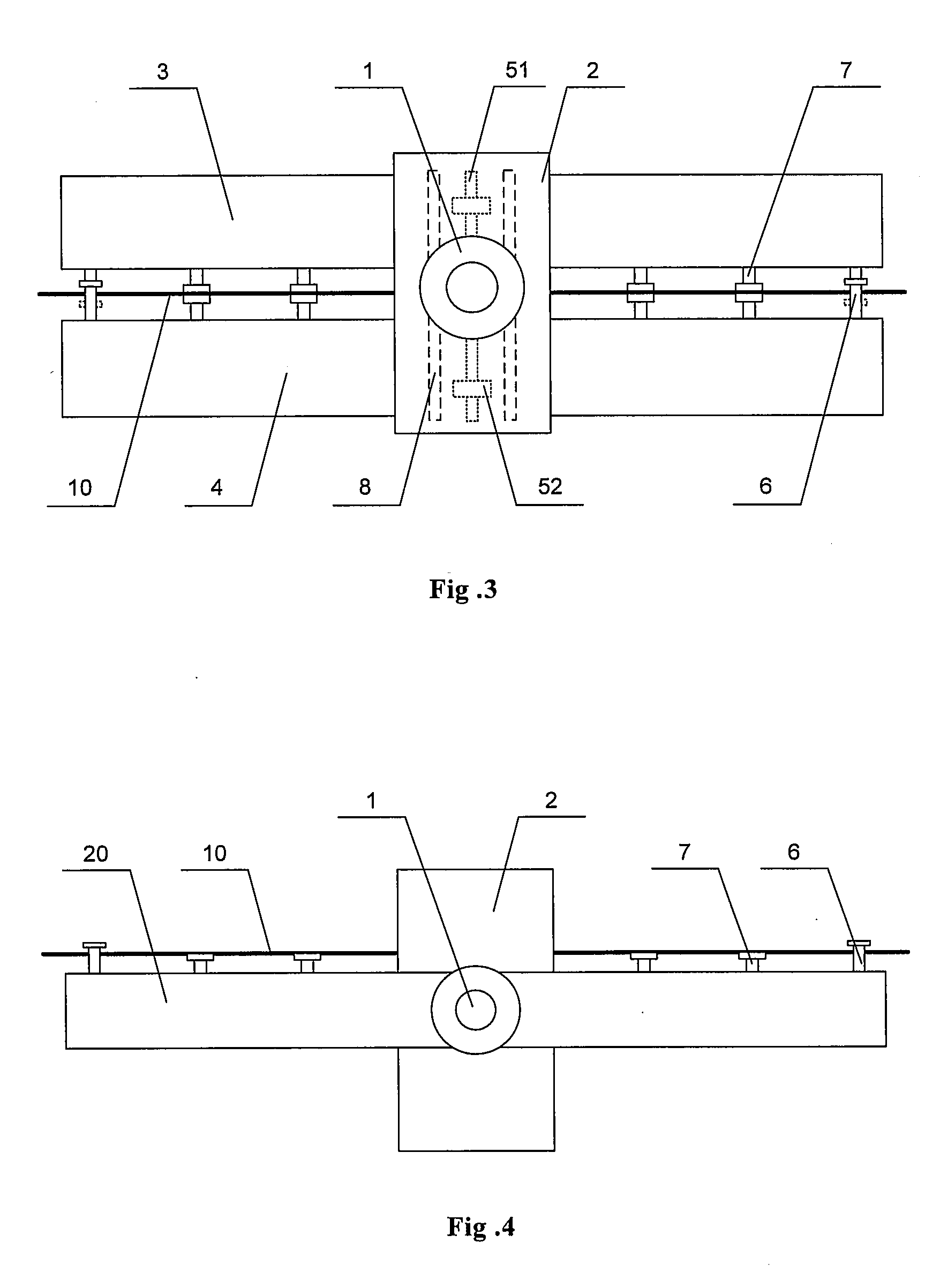

The invention discloses a high-speed and heavy-duty truss mechanical arm. The high-speed and heavy-duty truss mechanical arm comprises two supporting legs which are arranged symmetrically, a transverse beam (1) is supported between the two supporting legs, a guide rail (2) is fixedly connected to the transverse beam (1), and a lifting device (3) is in sliding connection with the guide rail (2). The high-speed and heavy-duty truss mechanical arm is characterized in that two upper roller sets (5) and two lower roller sets (6) are symmetrically arranged on a base (4) of the lifting device (3), each roller set is composed of two rollers (7), every two rollers (7) are clamped on two sides of the guide rail (2), the upper roller sets (5) make contact with the upper portion of the guide rail (2), and the lower roller sets (6) make contact with the lower portion of the guide rail (2). The high-speed and heavy-duty truss mechanical arm is simple in structure, ingenious in design, and capable of achieving high-speed movement in the heave-duty condition. Besides, accurate positioning of the mechanical arm can be guaranteed.

Owner:DALIAN HAOSEN EQUIP MFG

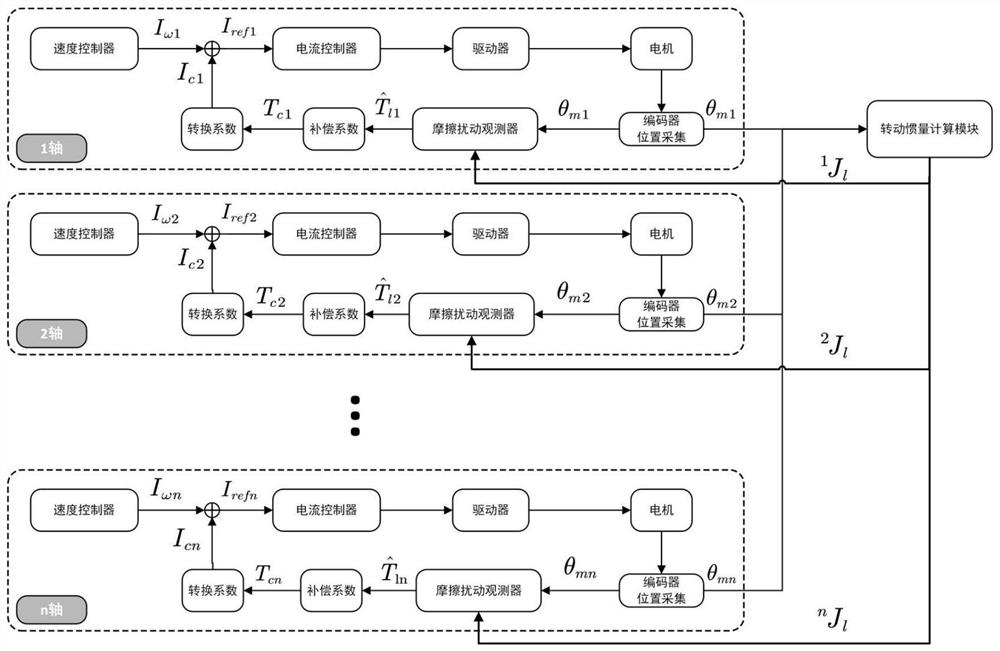

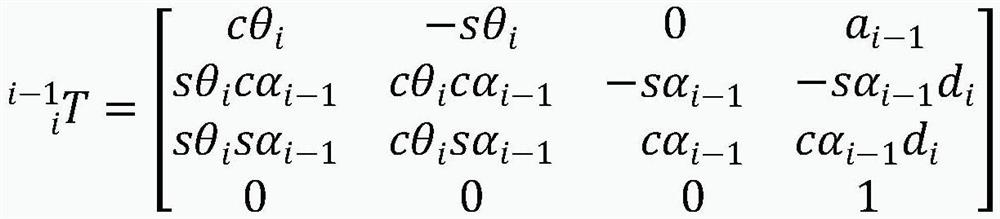

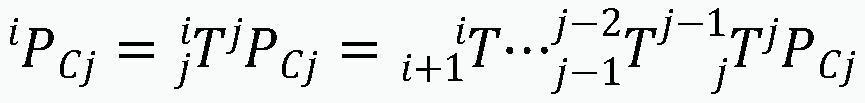

Industrial robot joint friction compensation method based on disturbance observation

ActiveCN114750167AHigh precisionImprove riding performanceProgramme-controlled manipulatorFriction torqueClassical mechanics

The invention discloses an industrial robot joint friction compensation method based on disturbance observation, and relates to the technical field of industrial robots, and the method comprises the following steps: 1) collecting the motor rotor angle of each joint motor encoder; (2) the motor rotor angles of all the joints are input into a rotational inertia calculation module, and the rotational inertia calculation module outputs the total load rotational inertia, converted to the motor side, of all the joints; 3) inputting the total load rotational inertia of the motor side and the motor rotor angle into a disturbance observer module to obtain an observed value of the friction torque; and converting the observed value into a friction compensation current, and then adding the friction compensation current into a torque current instruction in a servo controller to realize friction compensation. Compensation of robot joint friction force can be achieved, joint speed errors are reduced, the dynamic performance of a joint motor is improved, and the track precision of the robot is improved.

Owner:CHENGDU CRP ROBOT TECH CO LTD

Liquid mixing device with electronic control of high dynamic regulation and operating method thereof

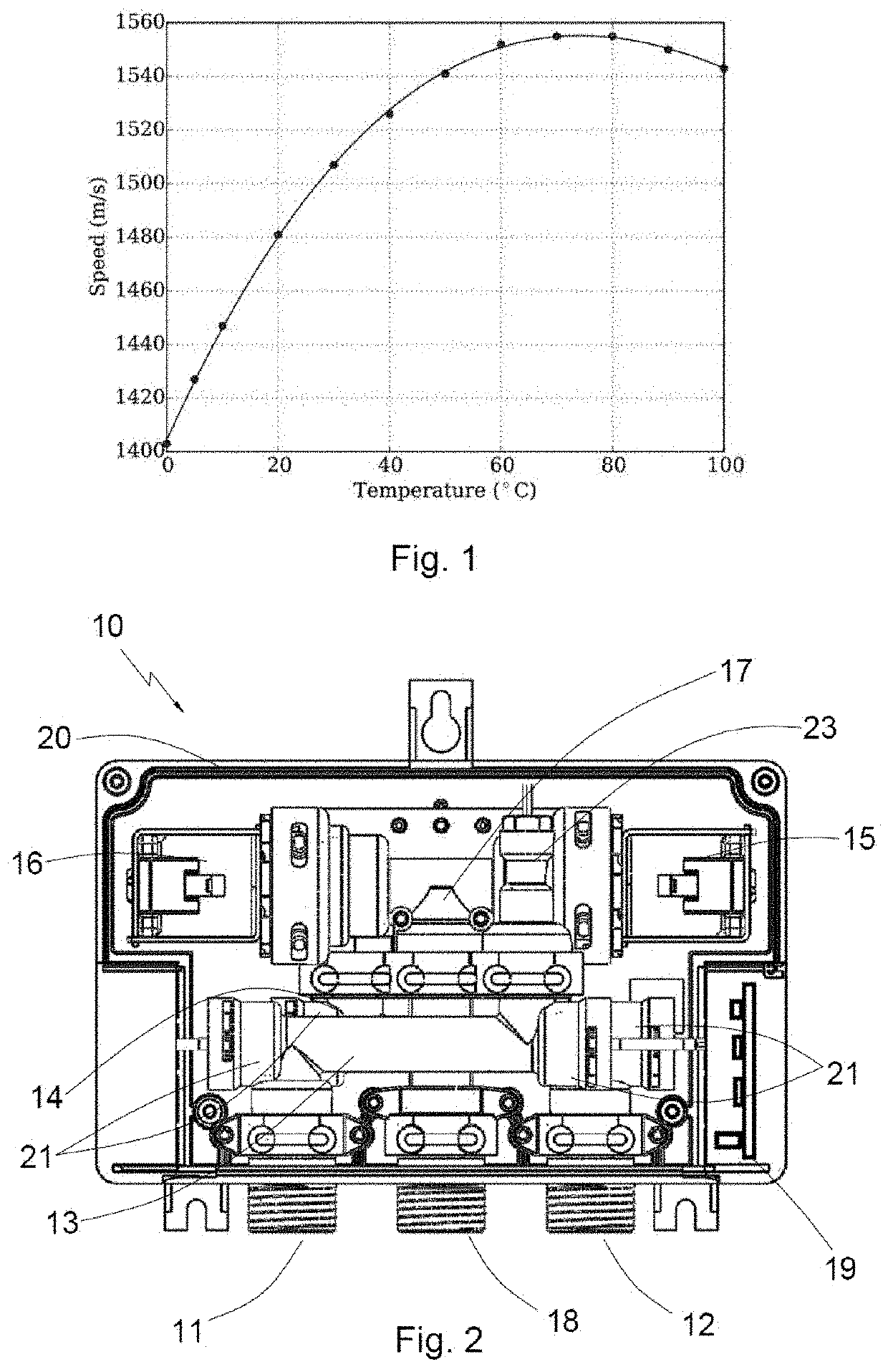

ActiveUS20190381464A1Reduce liquid turbulenceGreat radiusLighting and heating apparatusTemperatue controlUltrasonic sensorControl system

The present invention relates to a liquid mixing device which has a control system and electronic regulation, in charge of receiving the parameters set with respect to the liquid which is expected to be supplied by the tap or supply means whereto said device is connected and which acts on the regulation means of the different supply lines of liquids to mix to achieve said parameters, which has a high measurement and actuation dynamic thanks to measuring sections with ultrasonic transducers and proportional solenoid valves and a configuration and geometry of said measuring sections which allows having a multitude of reliable measurements per second.

Owner:SEDAL SL

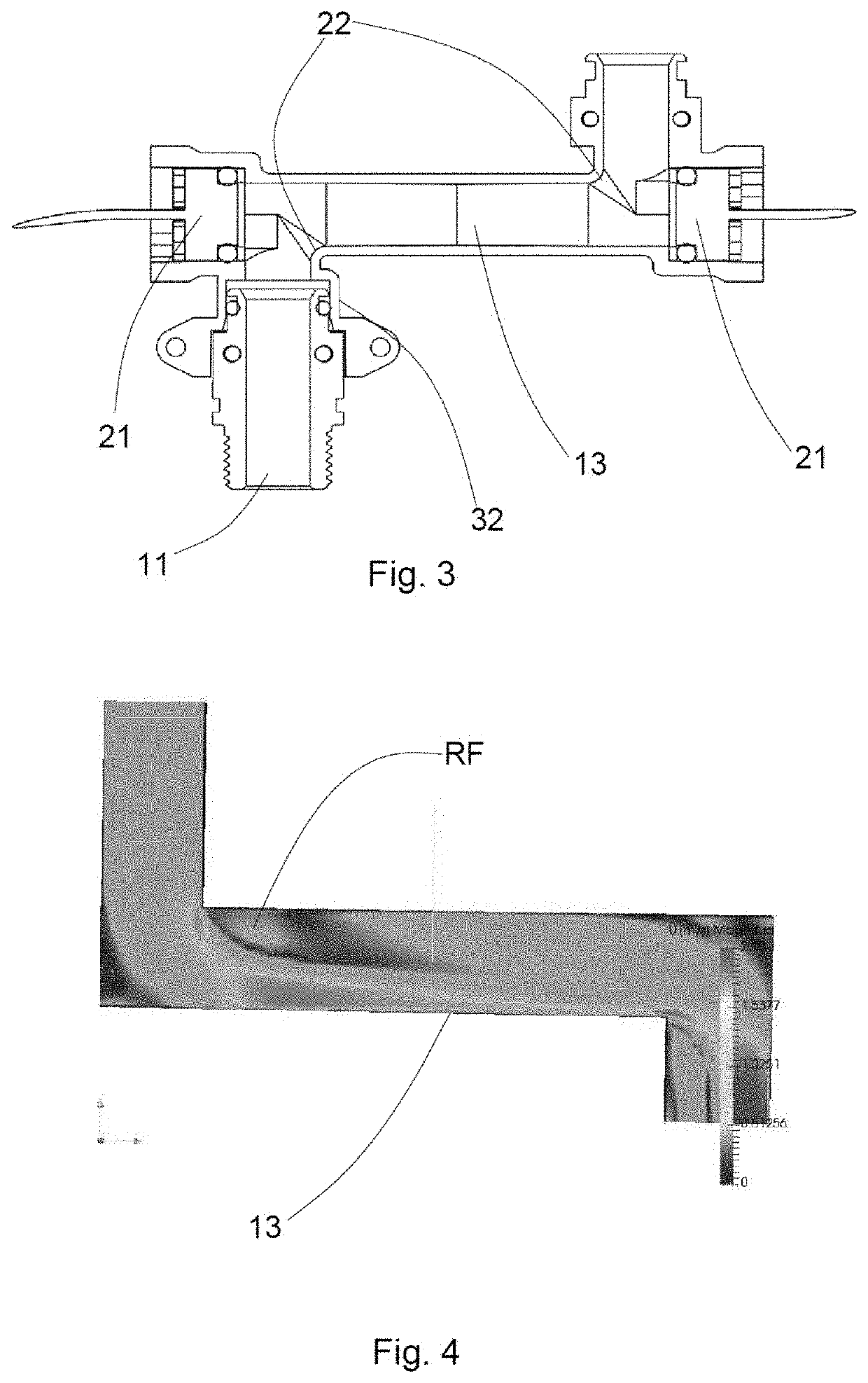

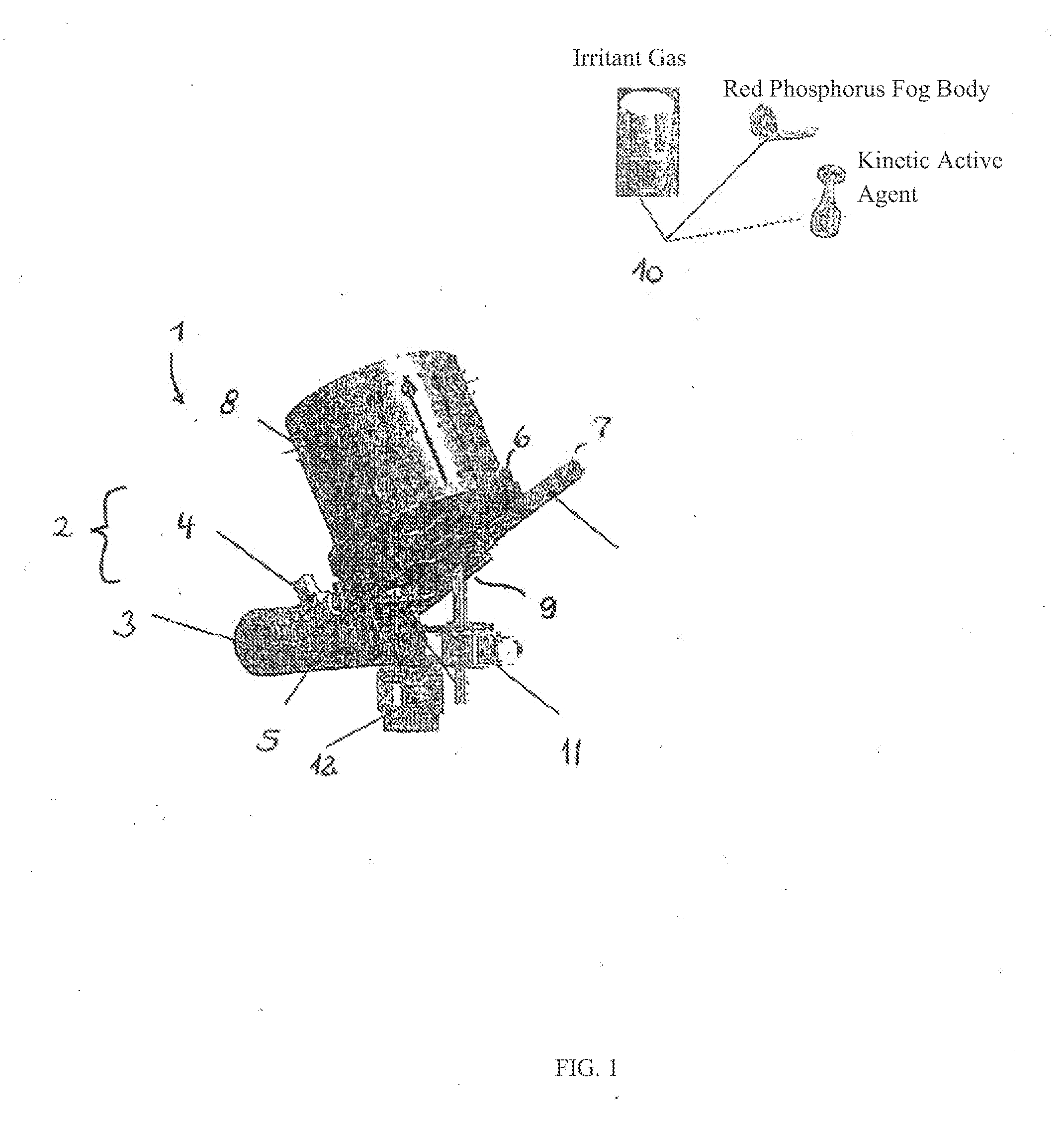

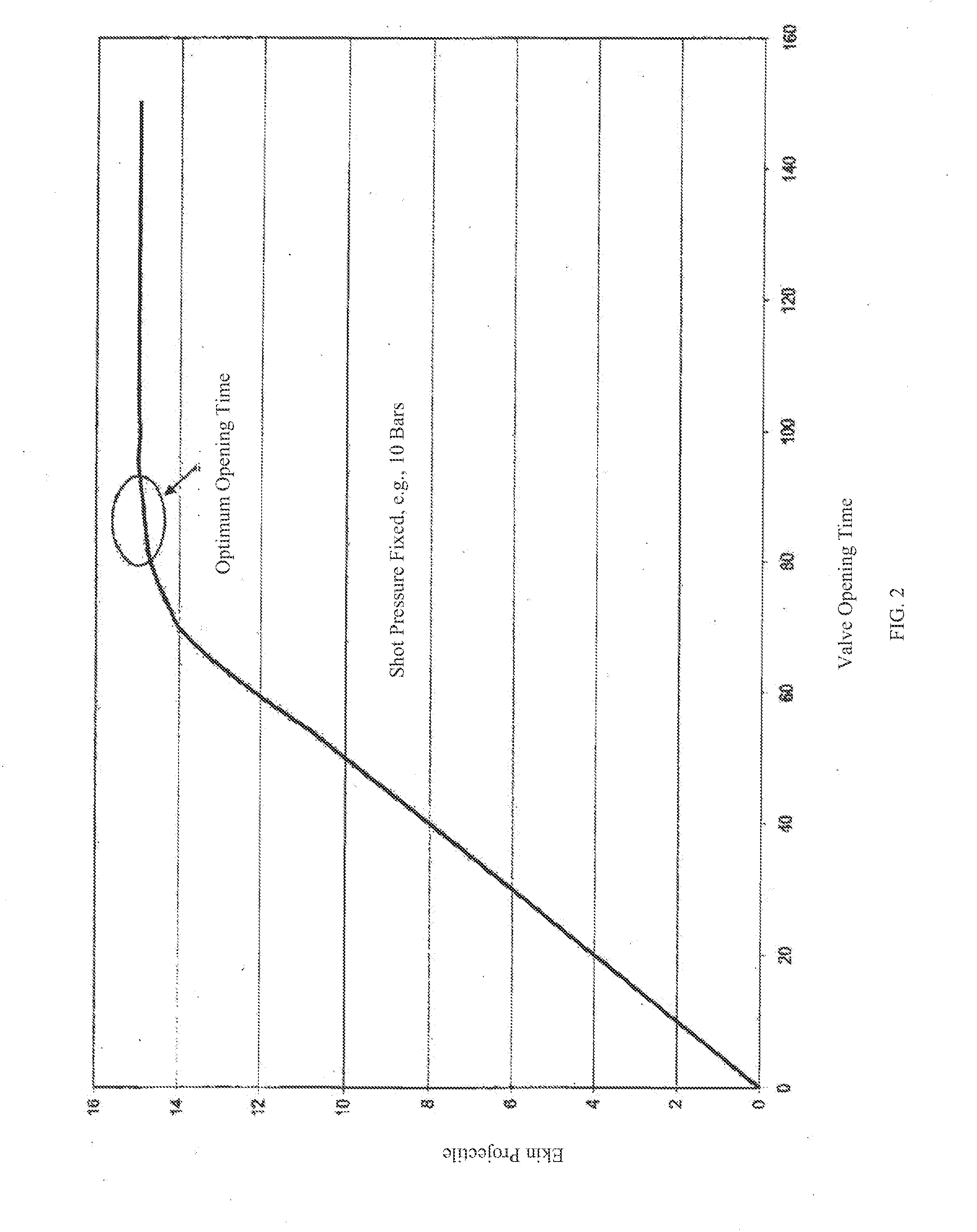

Weapon, in particular range-controlled compressed air weapon

The invention pertains to a weapon that provides a range control (2), by means of which it is possible to set firing velocity, and thus impact velocity, of the ammunition or active bodies (10) to a distance to be discharged in such a way that, in particular, the non-lethal ammunition (10) continues to have a non-lethal effect. To this end, a type of pneumatic weapon (1) is described that, with the use of a shot pressure control, e.g. by means of a proportional pressure regulator (3), and / or additionally in combination with breech technology and valve technology, has a continuously variable range control.

Owner:RHEINMETALL WAFFE MUNITION GMBH

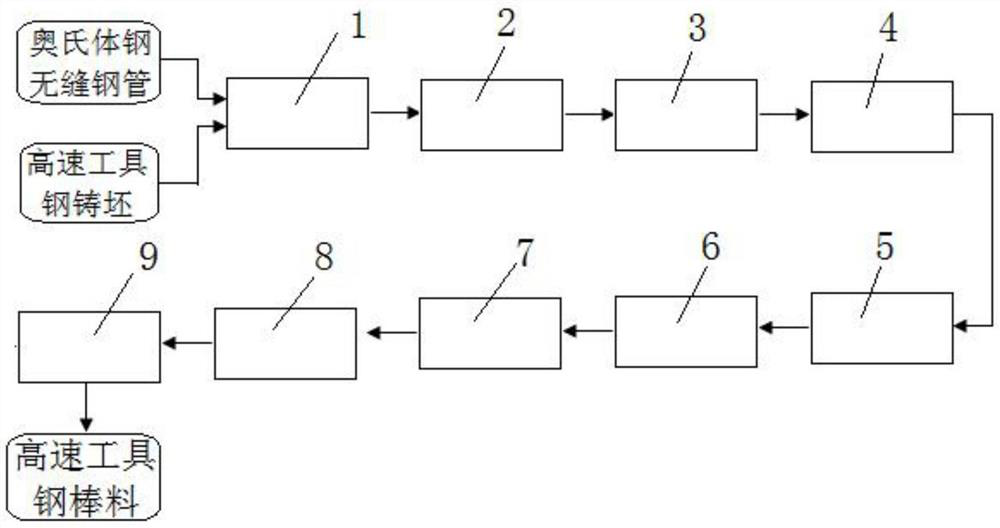

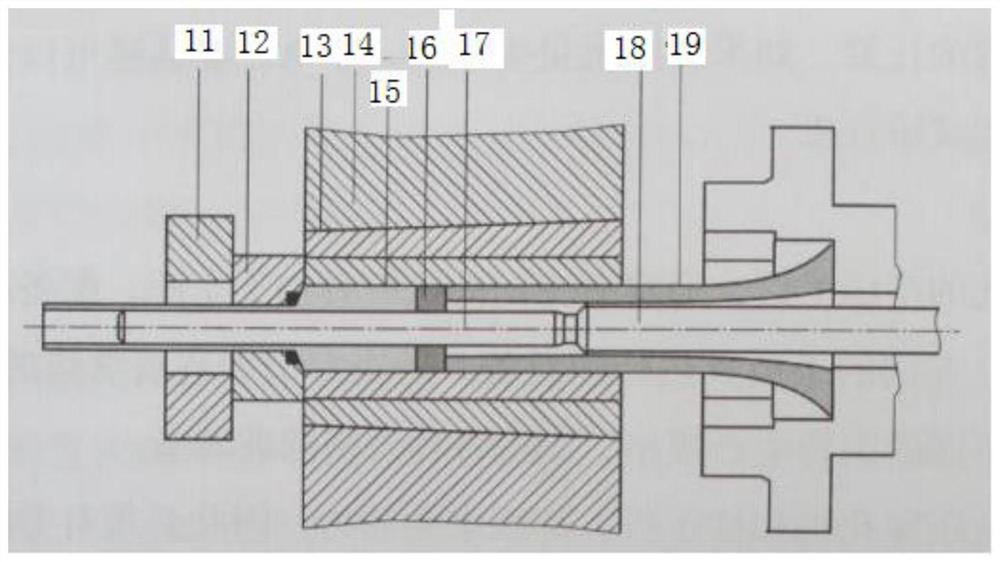

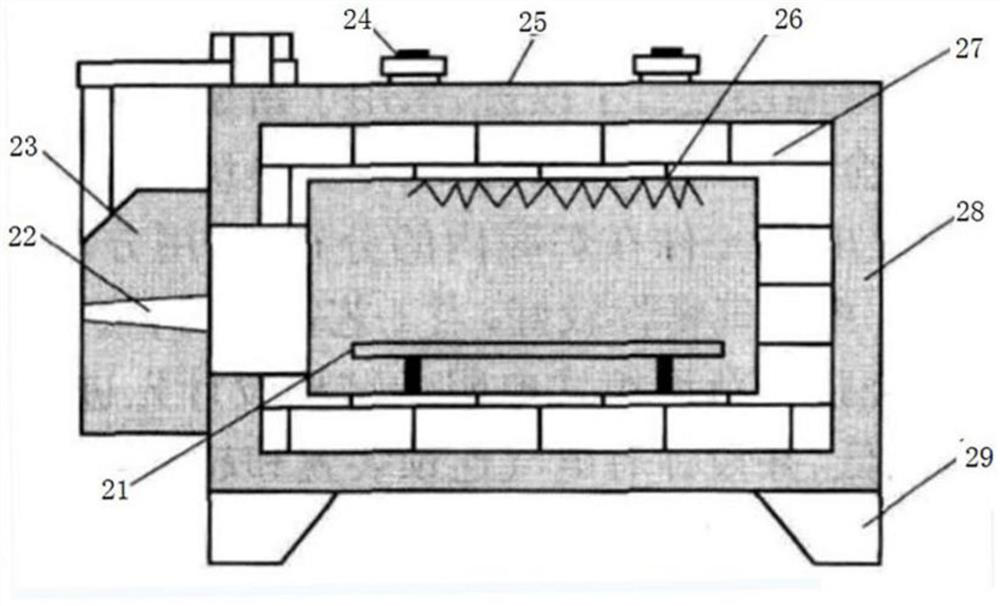

Forming method of high-speed tool steel bar

PendingCN113857283AReduce consumptionInsufficient to avoid extrusion crackingExtrusion diesIncreasing energy efficiencyAlloyPipe

The invention relates to a forming method of a high-speed tool steel bar. The forming method comprises the following forming steps: (1) calculating the size of a double-alloy blank; (2) smelting a high-speed tool steel casting blank; (3) producing an austenitic steel seamless steel pipe; (4) performing sawing and segmenting; (5) machining the raw materials; (6) preparing a double-alloy blank; (7) vacuumizing the double-alloy blank; (8) processing the double-alloy blank; (9) heating to 1120 DEG C; (10) performing electromagnetic induction heating at 1150-1160 DEG C; (11) performing double-alloy extrusion forming; (12) performing annealing; (13) performing pressure straightening; and (14) removing outer austenitic steel, and manufacturing the high-speed tool steel bar. The double-layer blank is prepared and formed through the hot extrusion process, the defects that high-speed steel is high in heat dissipation speed, poor in plasticity and prone to oxidation at high temperature, and extrusion cracking is caused are overcome, and the qualified rate of products is increased.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

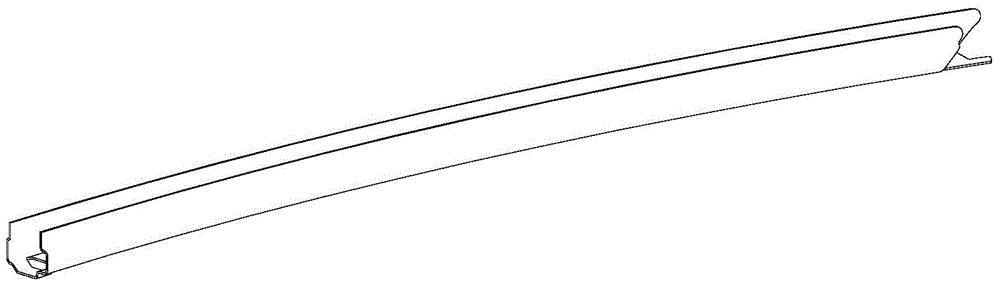

Punching die for door and window glass guide groove

The invention discloses a punching die for a door and window glass guide groove. The punching die comprises an upper die plate, a lower die plate, guide posts, a left side punching mechanism, a right side punching mechanism and a movable clamping claw; the left side punching mechanism comprises a left side punching base with a left side first punching position and a left side second punching position, a plunger chip is installed on the upper die plate, and the right side punching mechanism comprises a right side punching base with a right side first punching position, a right side second punching position, a right side first plunger chip mechanism and a right side second plunger chip mechanism; the left side first punching position and the right side first punching position form a first station, and the left side second punching position and the right side second punching position form a second station. Punching of the two stations is achieved on one die, the two stations share one oil press, the space occupancy rate is small, the punching die is convenient and fast to operate, manual operation time is shortened, the product quality is promoted, the tatk is accelerated, the product qualification precision is met, and defective products are eradicated.

Owner:GUANGZHOU MINTH AUTOMOBILE PARTS CO LTD

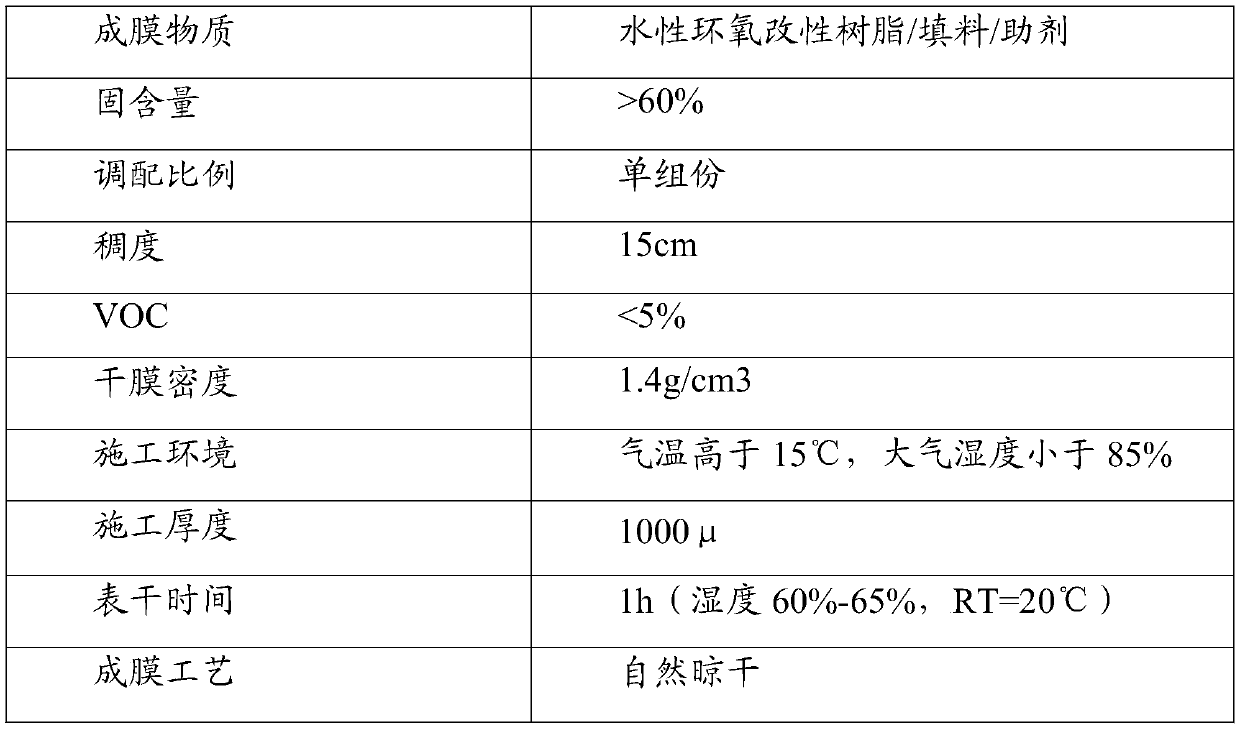

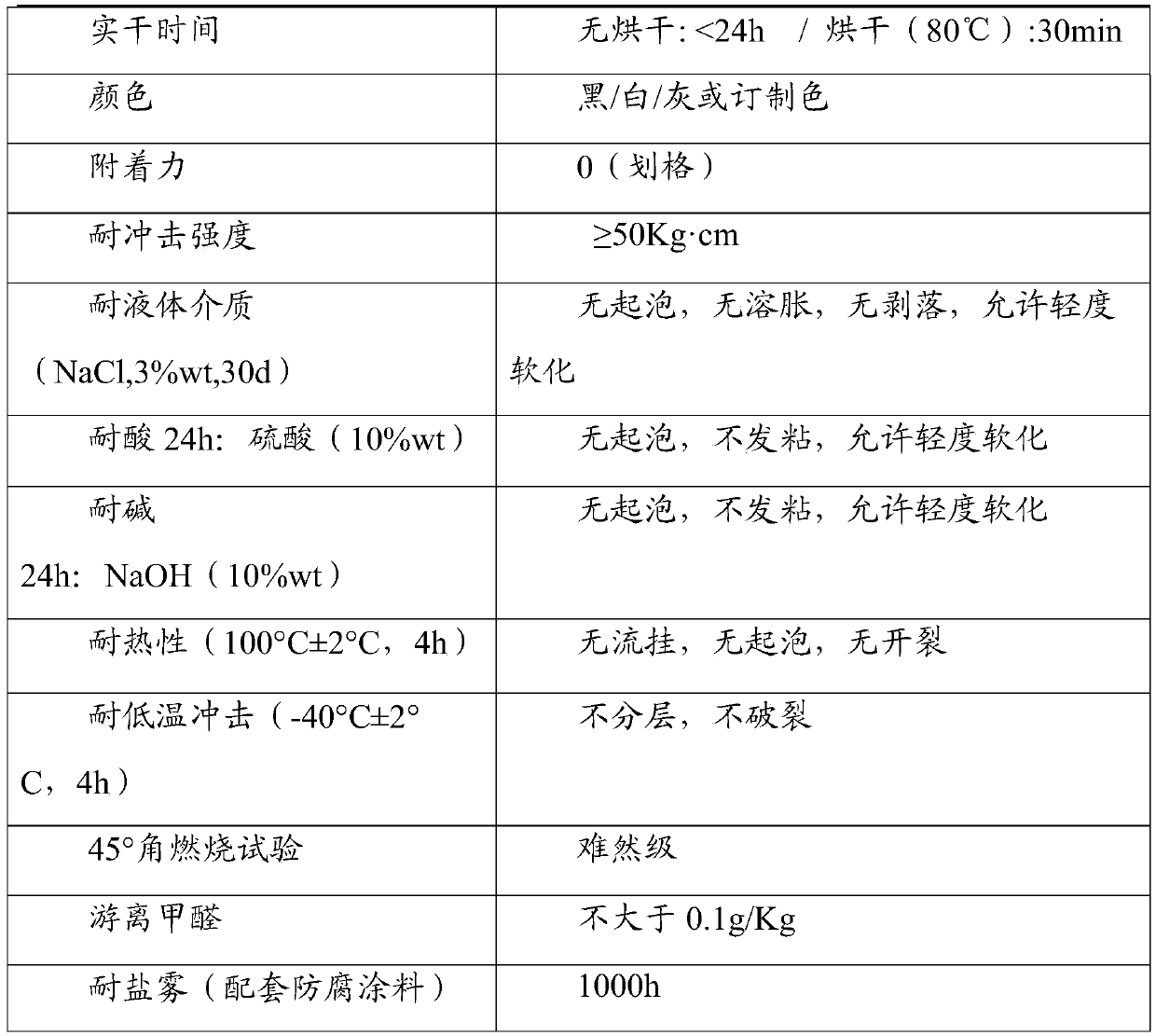

Quick-drying coating for new energy automobile battery tray chassis armor

InactiveCN111303707AGood workmanshipImprove processing efficiencyFireproof paintsAnti-corrosive paintsAutomotive batteryNew energy

The invention discloses a quick-drying coating for new energy automobile battery tray chassis armor and belongs to the technical field of high polymer materials. An acrylic emulsion, an epoxy emulsionand a polyurethane emulsion are used as resin materials, ceramic microbeads, glass microbeads, talcum powder, mica powder, titanium dioxide and calcium sulfate are used as main fillers, and color paste, toner, a wetting agent, a thickening agent, a defoaming agent, a flame retardant, an anti-cracking agent and a cosolvent are used as auxiliary materials to prepare the novel quick-drying water-based armor coating special for the new energy automobile chassis armor. The process performance is excellent, under the condition that the thickness of the coating is not less than 500 microns, the coating can be directly dried and cured at 120 DEG C, the process efficiency and beat of the chassis armor coating are greatly improved, the production efficiency of the product can be greatly improved, meanwhile, the product has excellent ultraviolet resistance, weather resistance and chemical corrosion resistance, and the impact resistance, fire resistance, flame retardance and breakdown resistanceof the product all meet the special requirements of automobile chassis armor and meet the requirements of environmental protection policies.

Owner:青岛碳之光新材料科技有限公司

Side wall conveying transmission system

InactiveCN111039235ASimple installation and debuggingEasy maintenanceLifting devicesGear wheelUniversal joint

The invention provides a side wall conveying transmission system. The system comprises a driving mechanism, a linkage mechanism, a telescopic universal joint and a conveying line mechanism, the conveying line mechanism comprises a conveying line driving mechanism and a transmission shaft; the driving mechanism is connected with the linkage mechanism, the linkage mechanism is connected with the telescopic universal joint, the telescopic universal joint is connected with the transmission shaft, the transmission shaft is installed on the conveying line driving mechanism, the driving mechanism sequentially drives the linkage mechanism, the telescopic universal joint and the transmission shaft to rotate, and the transmission shaft drives the conveying line driving mechanism to move through rotation. When the conveying line mechanism reciprocates up and down, the telescopic universal joint can automatically adjust the distance between the transmission shaft and the linkage mechanism in the process that the transmission shaft ascends and descends along with the conveying line mechanism. The side wall conveying transmission system has the beneficial effects that 1, a motor of the side wallconveying transmission system is fixed outside the conveying line, and the motor is simple to install, debug and maintain; and 2, gear racks at the two sides of the side wall conveying transmission system are transmitted through one transmission shaft, and conveying synchronism is guaranteed.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

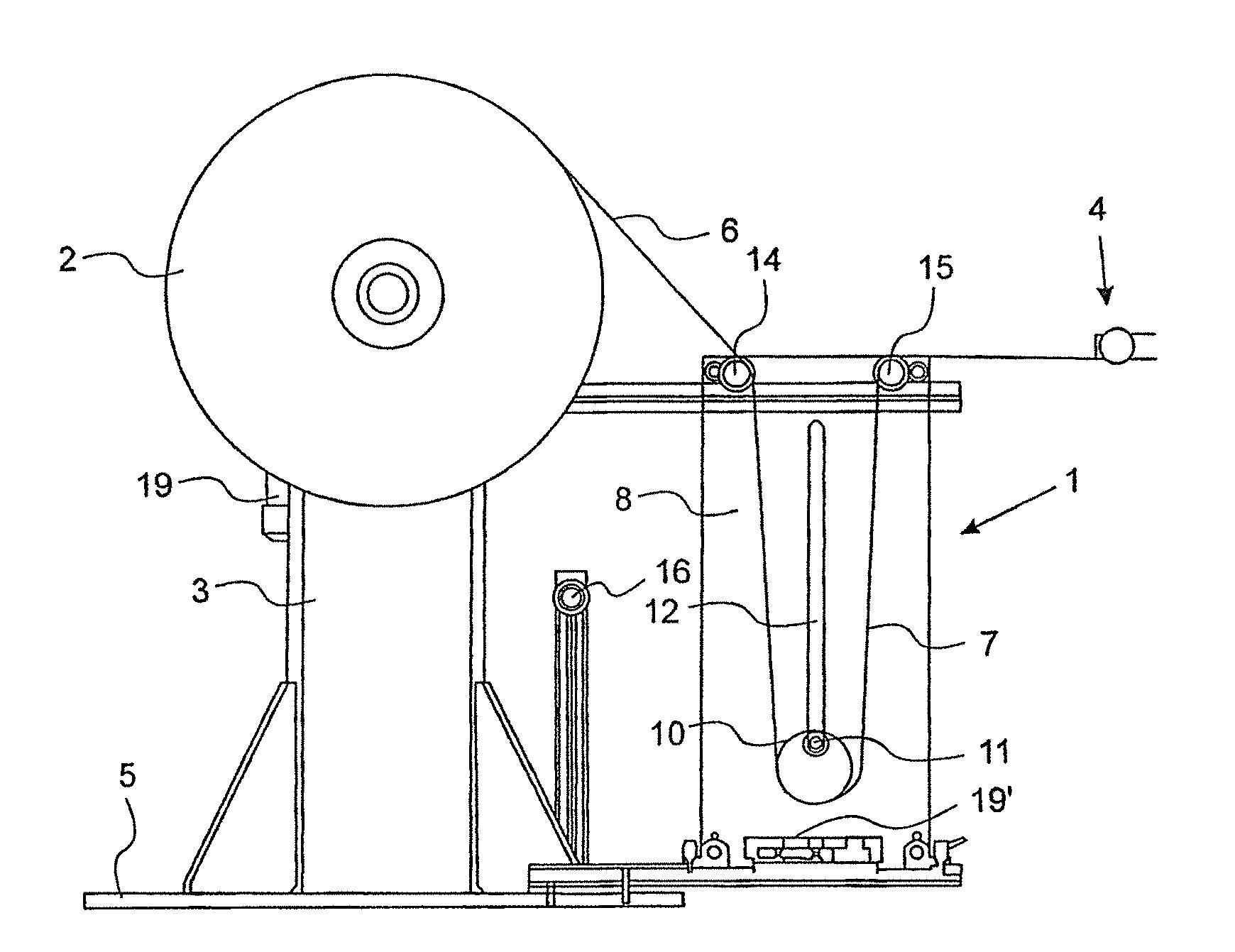

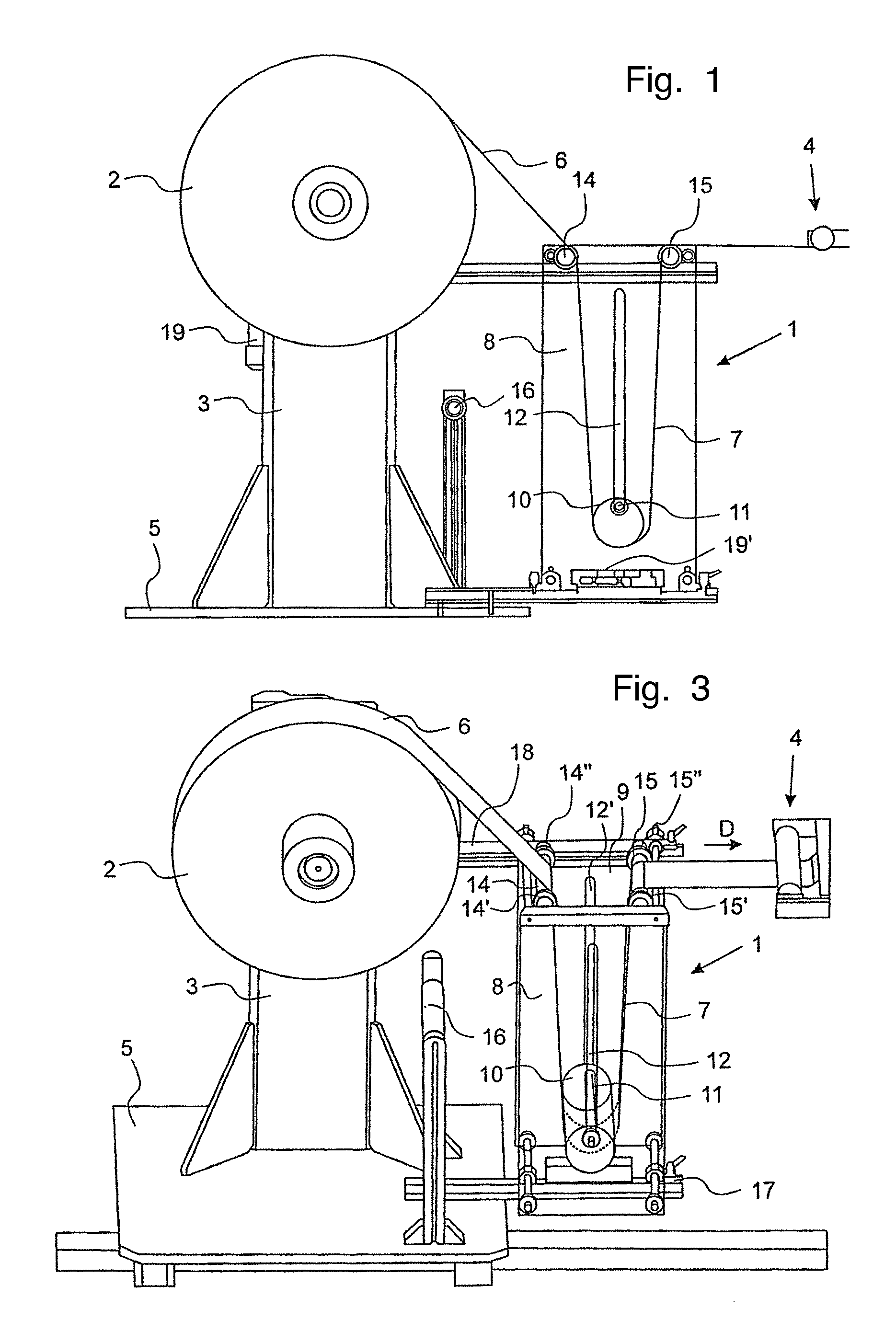

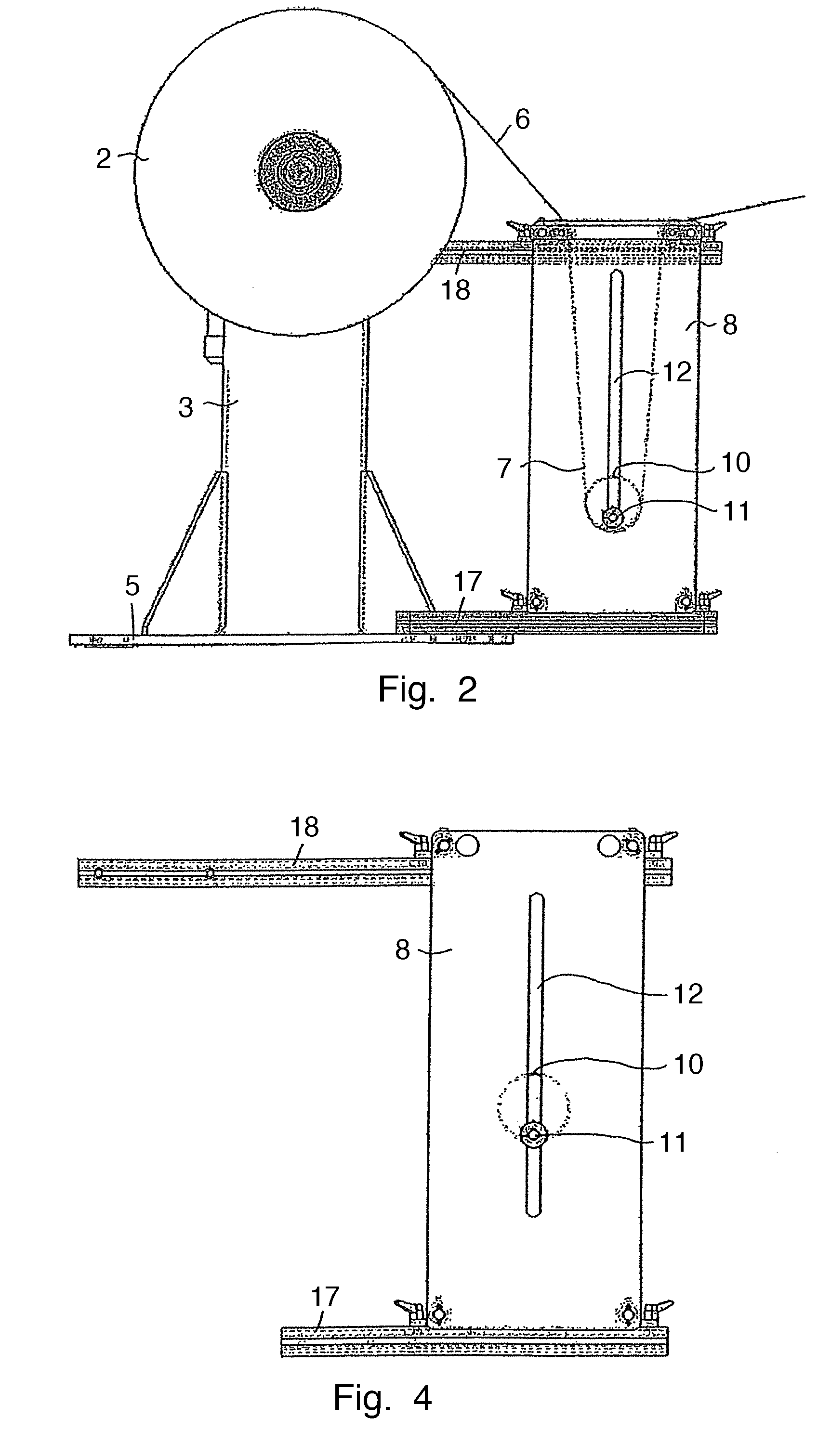

Arrangement for forming a band loop and method and device for manufacturing peel-off lids

InactiveUS20130028685A1Strong of step lengthReduce deflectionMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

When handling a foil band (6) which is to be uncoiled from a delivery spool (2) and is drawn in gradually by a drawing-in device (4), a foil band loop (7) is produced. In order that this can take place without any errors with high production cadences, provision is made of an arrangement (1) in which a hollow cylinder (10) rests loosely on the band with a limited freedom of movement so as to form the band loop. Such an arrangement is preferably provided for the production of peel-off lids, in which a foil band is uncoiled from a band delivery spool and fed to a stamping and sealing station.

Owner:SOUDRONIC

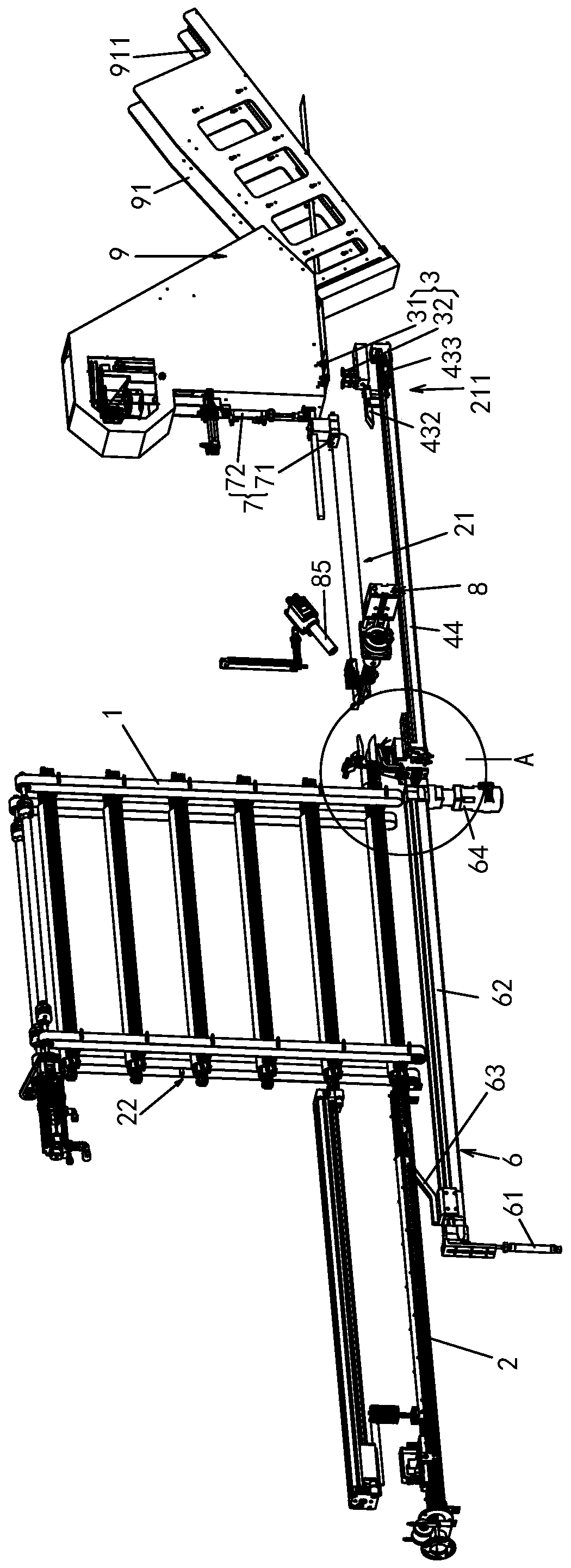

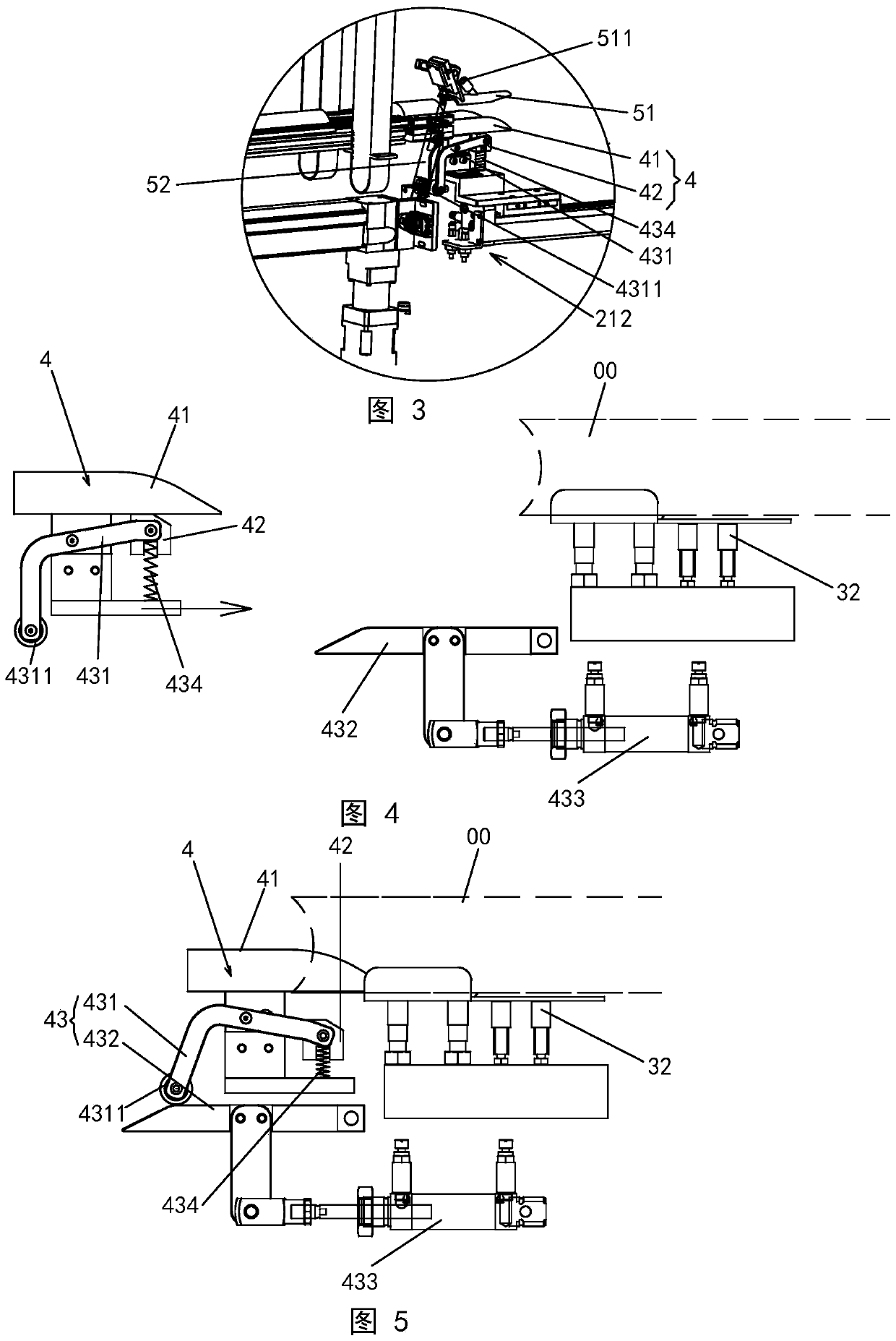

Pop can cover body packing device

PendingCN111483642AThe device is cleverly designedImprove bagging efficiencyWrapper twisting/gatheringIndividual articlesStructural engineeringMechanical engineering

The invention discloses a pop can cover body packing device. The device is characterized by comprising a rack (1) and a cover body rail (2), wherein one section of the cover body rail (2) serves as acover pushing and bagging section (21), one end of the cover pushing and bagging section (21) serves as a packaging bag supply position (211), and the other end of the cover pushing and bagging section (21) serves as a cover body bagging position (212); a packaging bag positioning and opening assembly (3) is arranged at the packaging bag supply position (211); a bag grabbing assembly (4) is connected between the cover body bagging position (212) and the packaging bag supply position (211) in a sliding mode, and when the bag grabbing assembly (4) is located at the packaging bag supply position(211), a first opening supporting piece (41) can stretch into an opening of a packaging bag (00), a bag pressing block (42) is matched with the first opening supporting piece (41) to clamp the edge ofone side of the opening of the packaging bag (00); a bag opening supporting assembly (5) is arranged at the cover body bagging position (212); and the pop can cover body packing device further comprises a cover body pushing mechanism (6).

Owner:SUZHOU SLAC PRECISION EQUIP CO LTD

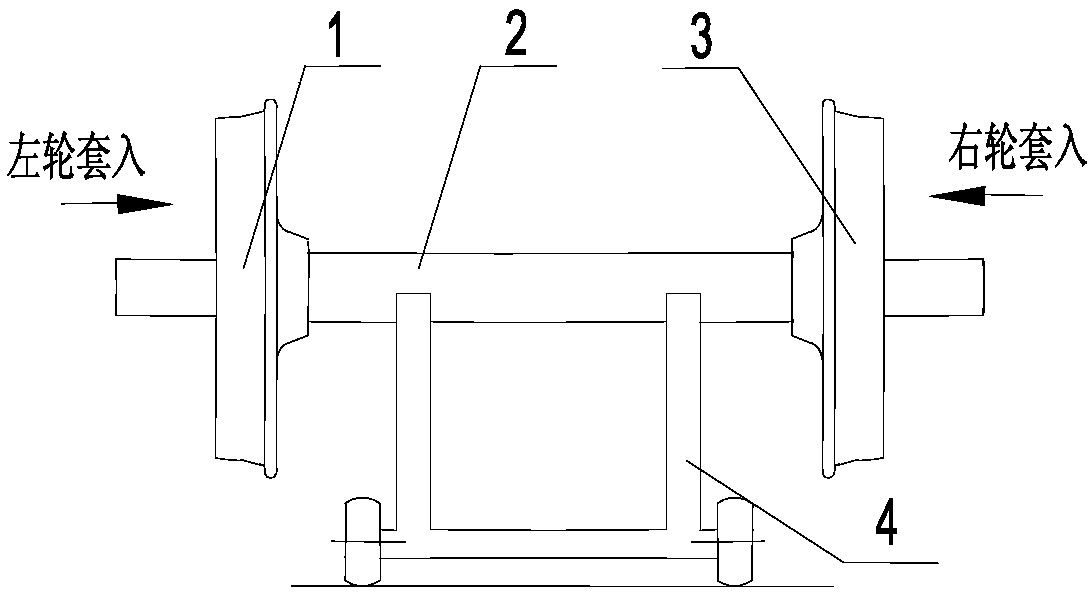

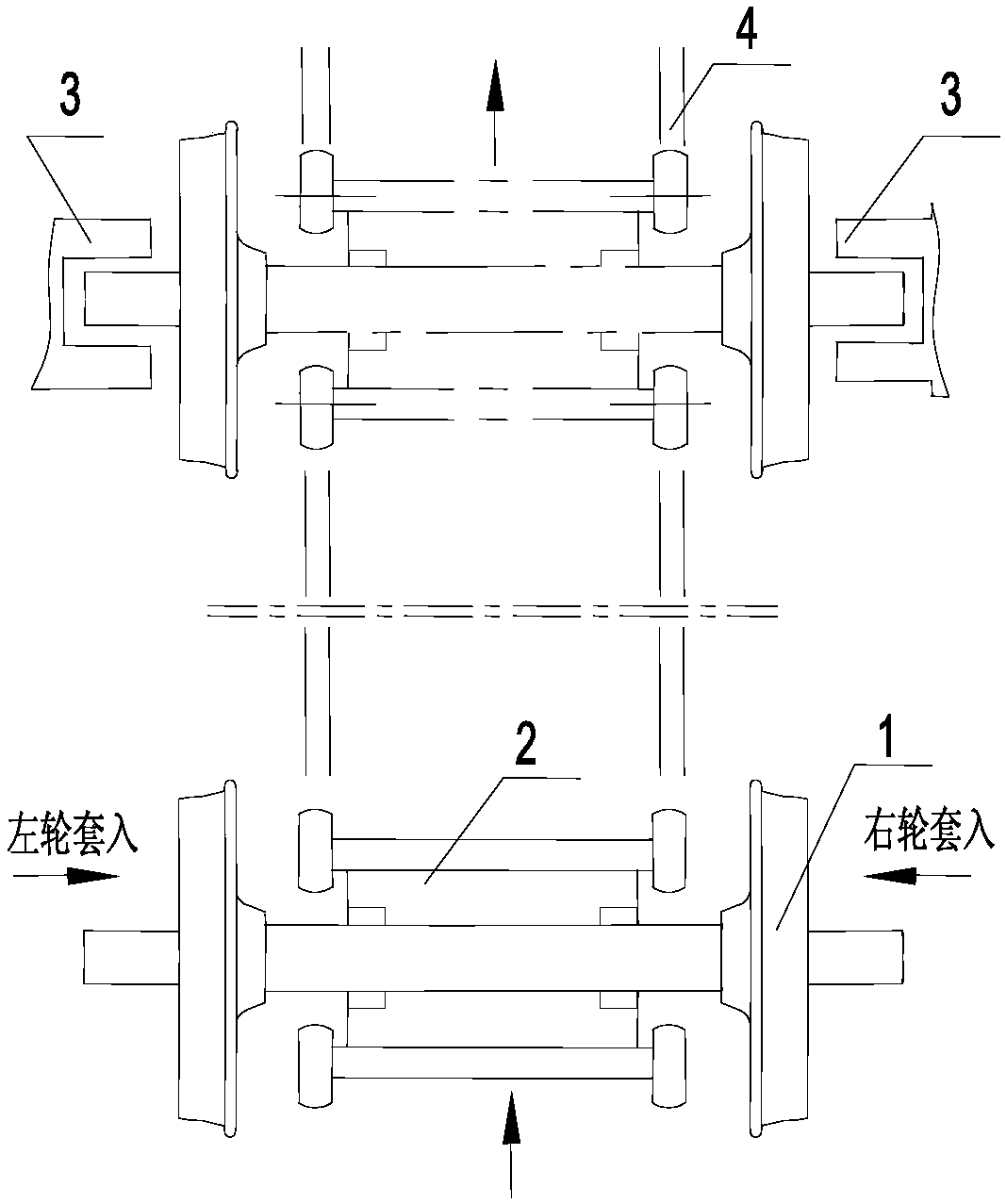

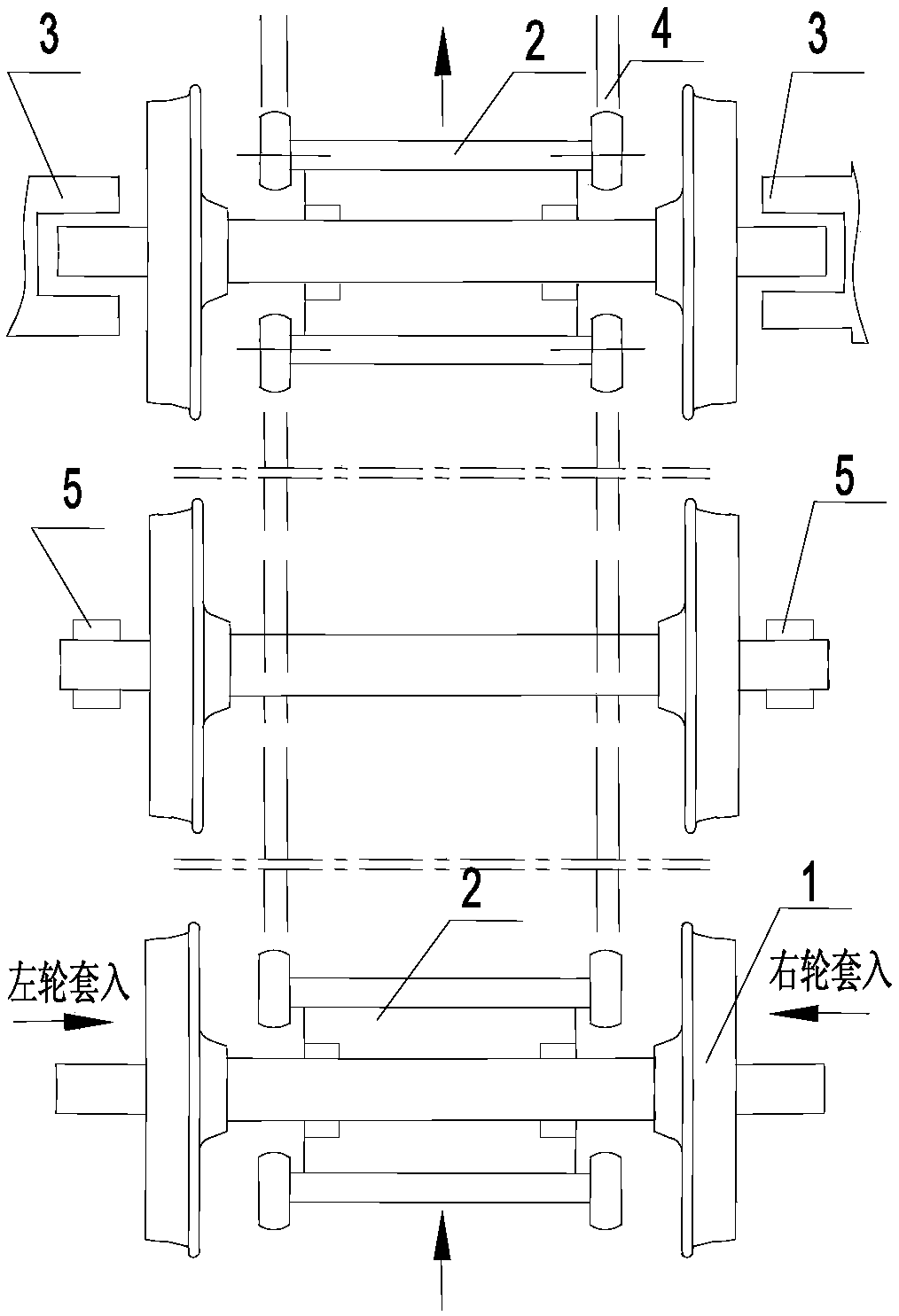

Automatic press fitting rapid conversion device and method for railway wagon wheel pairs

PendingCN108015515AShorten the running distanceIncrease the tempoMetal working apparatusProduction lineReciprocating motion

The invention relates to an automatic press fitting rapid converting device and a method for railway wagon wheel pairs. The device comprises a trolley track and bracket trolleys which can move back and forth on the trolley track, and a fixed lifting bracket assembly is arranged above the trolley rail and is positioned below a press fitting assembly for pressing the to-be-pressed wheel pairs, so that the railway wagon wheel pairs can be lifted to the press fitting assembly to carry out press-fitting for the to-be-pressed wheel pairs. According to the automatic press fitting rapid converting device and the method for the railway wagon wheel pairs, fixed lifting brackets are additionally arranged in the middle of an automatic press fitting unit of original wheel pairs, exchange of the two-bracket moving trolleys to the to-be-pressed wheel pairs is completed through the fixed lifting brackets, and the operation distance of a single trolley is shortened; the same bracket moving trolleys arearranged at the inlet ends and the outlet ends of the fixed lifting brackets correspondingly, the working time of the to-be-to-be-pressed wheel pairs bracket moving trolleys and the working time of the press fitting bracket moving trolleys are set to be the same, and a beat production pattern is formed; the efficiency is improved by one time, and a bottleneck in production is solved; and the device is simple in structure, the production line does not need to be changed greatly, and the production cost is low.

Owner:CRRC YANGTZE CO LTD

Whole-flow intelligent production method for forging round steel

The invention discloses a whole-flow intelligent production method for forging round steel, and relates to the field of metal processing. Raw materials are sequentially and online subjected to the procedures of heating, dephosphorization, forging, sizing, concurrent heating, quenching, tempering, cooling, straightening, peeling, saw cutting, nondestructive testing, weighing, steel seal marking, stenciling, dye marking, surface preservative spraying, and packaging, and the finished round steel is obtained; and the heating procedure is that the raw materials are conveyed into a continuous furnace by a charge manipulator to be heated. By combining the abovementioned process flow with equipment, the whole production process for the product, that is, from the beginning of the production flow, namely, from heating for the raw materials to warehousing for the finished product, is always online operation, so that a whole-flow intelligent production line for forging the round steel is realized;and during production, whole-flow intelligent control is realized only by presetting system program setting by operating personnel in the field, so that the consumption of manpower and material resources is saved, energy consumption in the production process is reduced, the production efficiency and rhythm are increased, the appearance quality of the product is improved to a large extent, and theyield and the production efficiency are increased to a large extent.

Owner:YANGZHOU CHENGDE HEAVY IND CO LTD

Overhead underslung trolley conveying system for body-in-white side shell plates

InactiveCN111056245AIncrease tempo and speedImprove production taktControl devices for conveyorsMechanical conveyorsPulleyIndustrial engineering

The invention discloses an overhead underslung trolley conveying system for body-in-white side shell plates. The system comprises an overhead underslung trolley assembly used for overhead suspending and travel conveying of the body-in-white side shell plates, a side shell plate hoisting frame assembly used for clamping and fixing the left and right side shell plates, a four-belt pulley lifting assembly used for ascending and descending the side shell plate hoisting frame assembly in the vertical direction and a shear fork balancing assembly used for preventing the side shell plate hoisting frame assembly from swinging. The four-belt pulley lifting assembly is fixed to the overhead underslung trolley assembly; the shear fork balancing assembly is arranged between the four-belt pulley lifting assembly and the side shell plate hoisting frame assembly; and the top of the shear fork balancing assembly is connected with the four-belt pulley lifting assembly, and the bottom of the shear forkbalancing assembly is connected with the side shell plate hoisting frame assembly. The overhead underslung trolley conveying system for the body-in-white side shell plates has the advantages of beinghigh in conveying efficiency, high in production takt, low in noise, stable in operation, good in conveying effect and the like.

Owner:广州德恒汽车装备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com