High-speed and heavy-duty truss mechanical arm

A manipulator and truss technology, applied in the field of high-speed and heavy-duty truss manipulators, can solve problems such as inability to achieve fast movement, inability to move laterally, and affecting production beats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

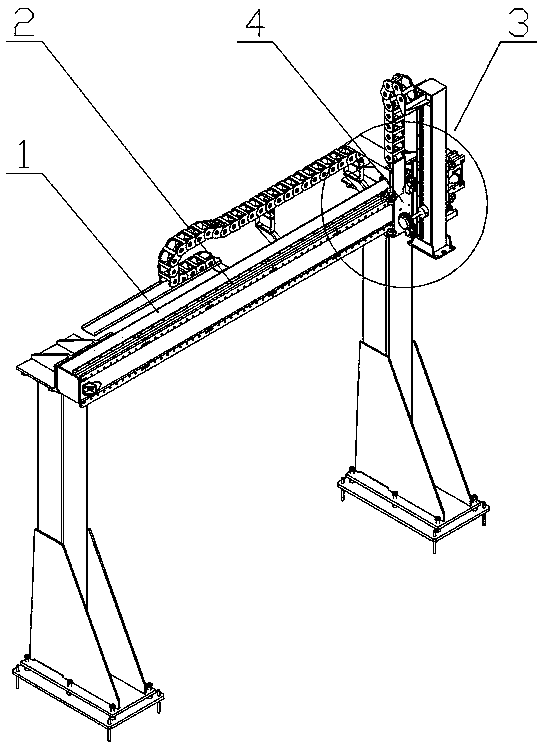

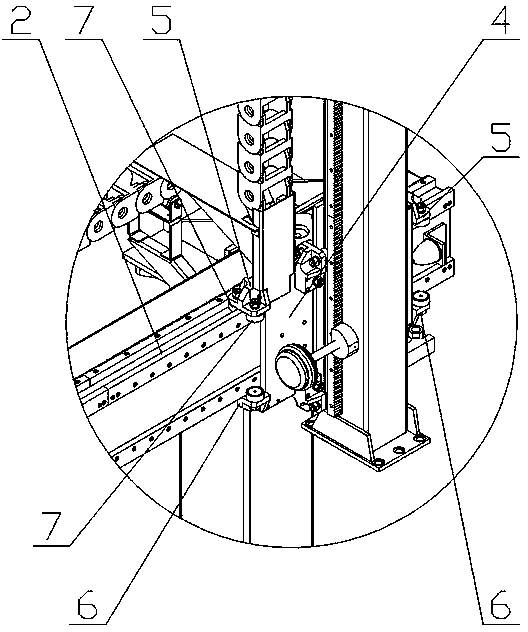

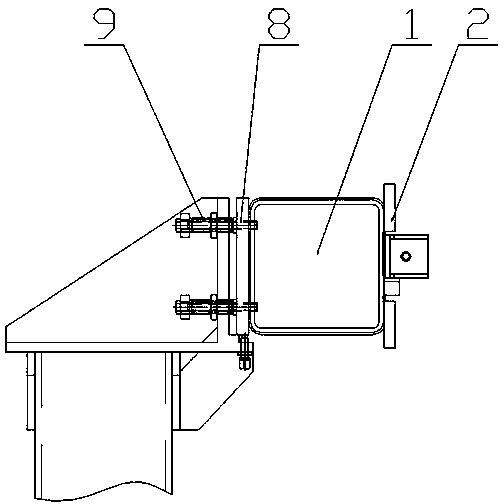

[0012] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 , figure 2 , image 3 Shown: a high-speed heavy-duty truss manipulator, including two symmetrically arranged legs, a beam 1 is supported between the two legs, a guide rail 2 is connected to the beam 1 through an adjustment mechanism, and a lifting device 3 is connected to the guide rail 2 Sliding connection, that is, the lifting device 3 can slide laterally on the guide rail 2, and two upper roller groups 5 and two lower roller groups 6 are symmetrically arranged on the base 4 of the lifting device 3, and each roller group is composed of two symmetrical roller groups. The set rollers 7 are formed, and these two rollers 7 are also located on both sides of the guide rail 2, that is to say, the two rollers 7 clamp the guide rail 2, the upper roller set 5 is in contact with the upper part of the guide rail 2, and the lower roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com