Arrangement for forming a band loop and method and device for manufacturing peel-off lids

a technology of band loops and loops, which is applied in the direction of metal-working feeding devices, positioning devices, metal-working storage devices, etc., can solve the problems of limiting the free mobility of hollow cylinders and the limitation of the path of hollow cylinders, and achieves the effect of strong fluctuation of step length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

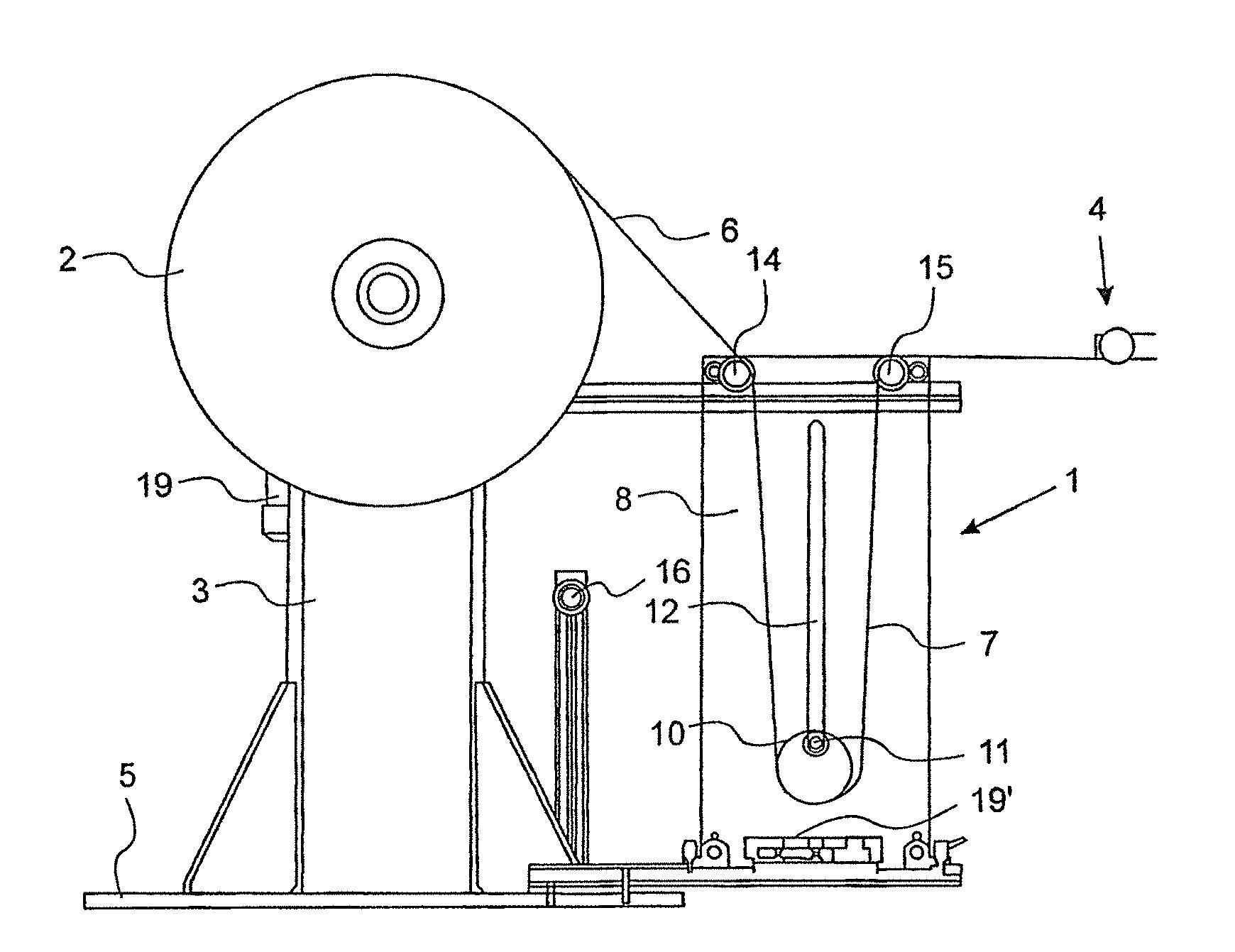

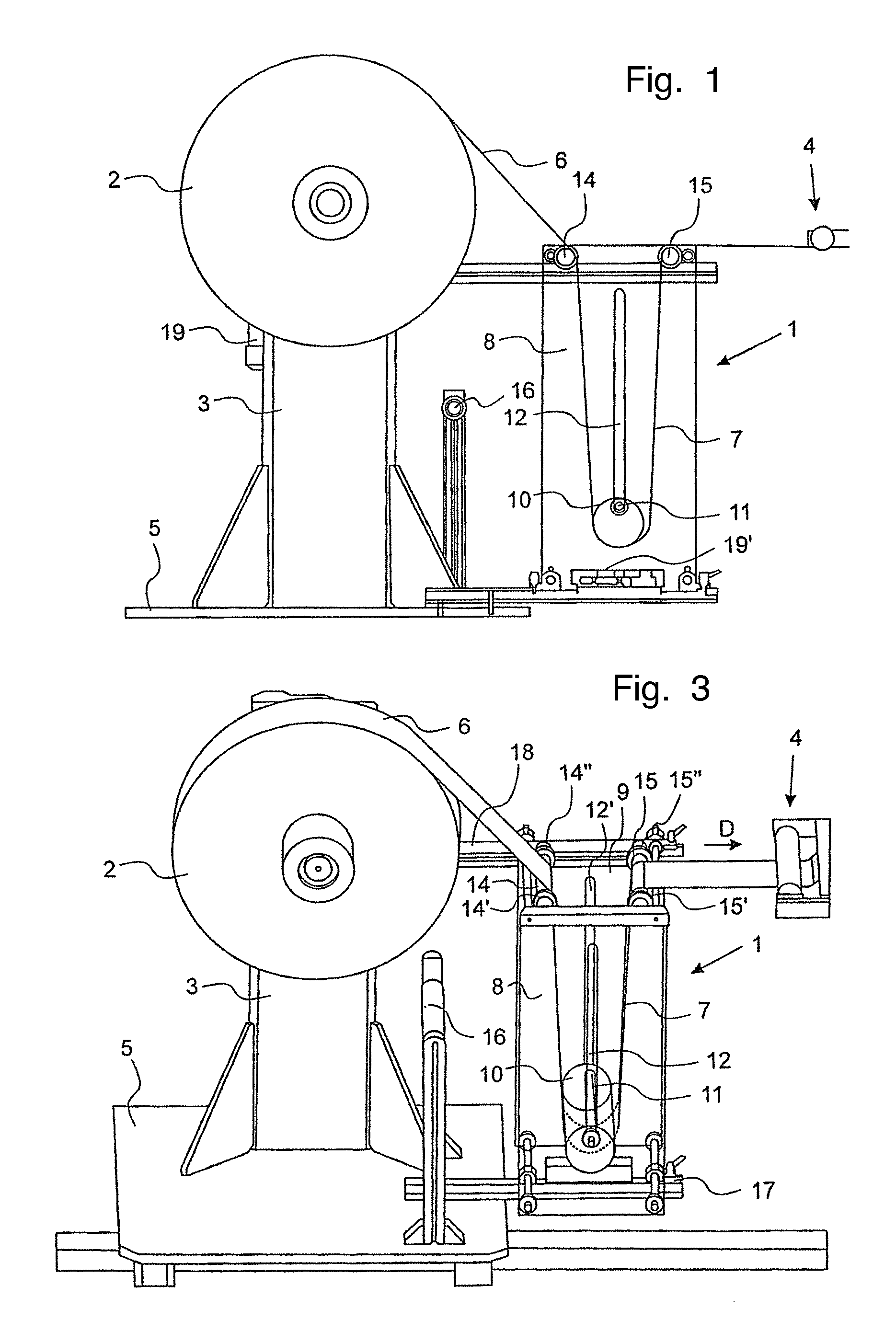

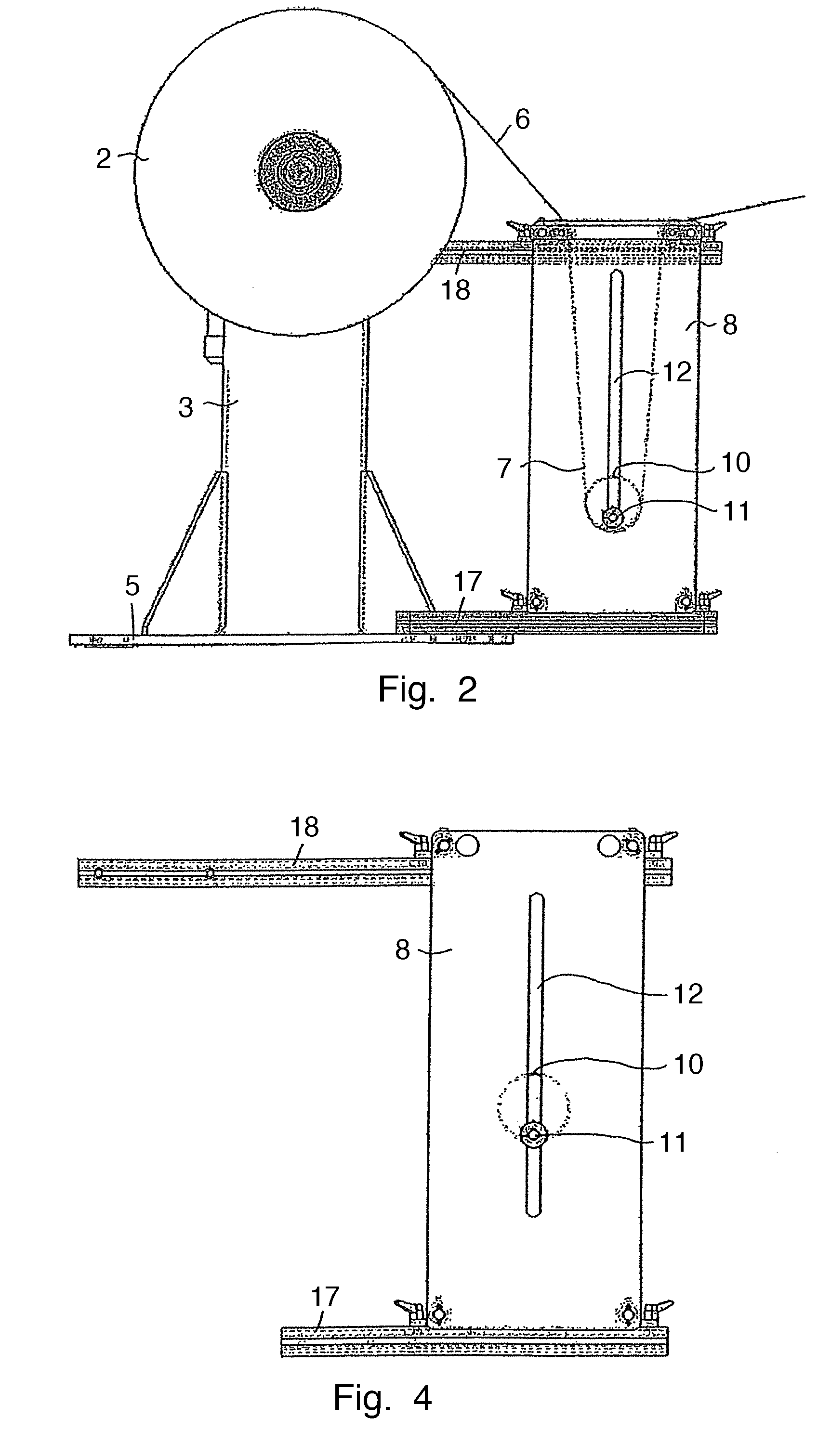

[0018]FIGS. 1 to 4 show an embodiment of an arrangement 1 according to the invention. It is provided and adapted to form a band loop 7 in a band 6. The band 6 is uncoiled from a band delivery spool 2 in an actuated manner and thereafter gets into the arrangement 1. Thereafter, the band is transported by a drawing-in device 4 which belongs to a device inside which the band is used or processed respectively. An example of such a device is explained in the following. The shown band transport reveals the band transport direction D. The uncoiling from the band delivery spool is normally done with constant speed or it may be adjusted to fast speed changes of the drawing-in device 4 via the actuator 19 only comparatively slowly. Particularly, the drawing-in device 4 can cause a stepwise drawing-in of the band with changing drawing-in lengths. Thereby, the arrangement 1 has the purpose to compensate for the drawing-in fluctuations with respect to speed and / or drawing-in step lengths by mean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com