Automatic press fitting rapid conversion device and method for railway wagon wheel pairs

A railway freight car, fast conversion technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of unmatched production tact, long time, etc., and achieve the effect of low production cost, improved efficiency, and bottleneck solving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

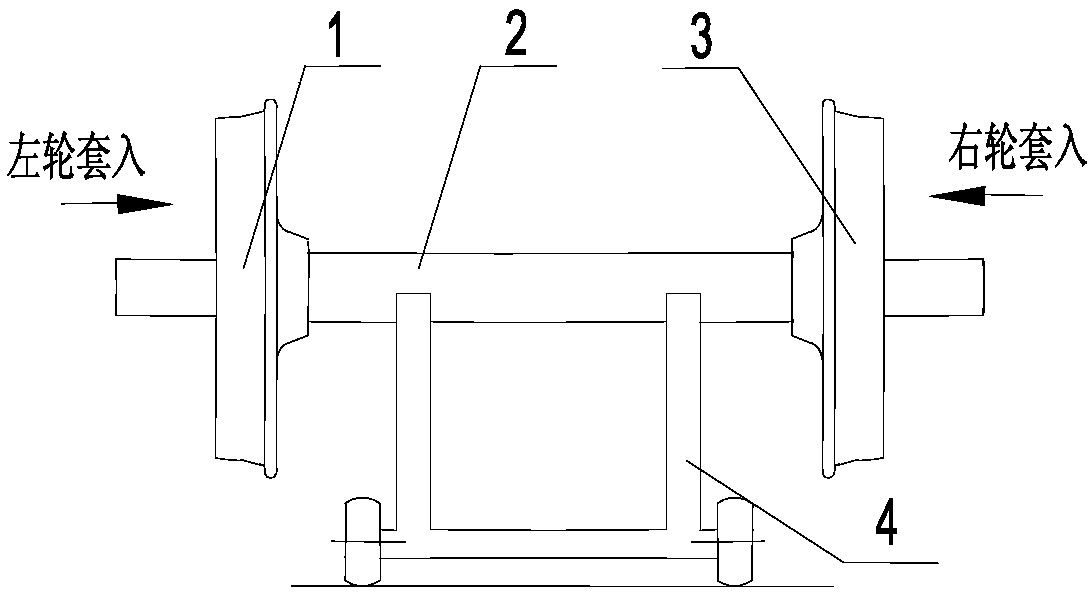

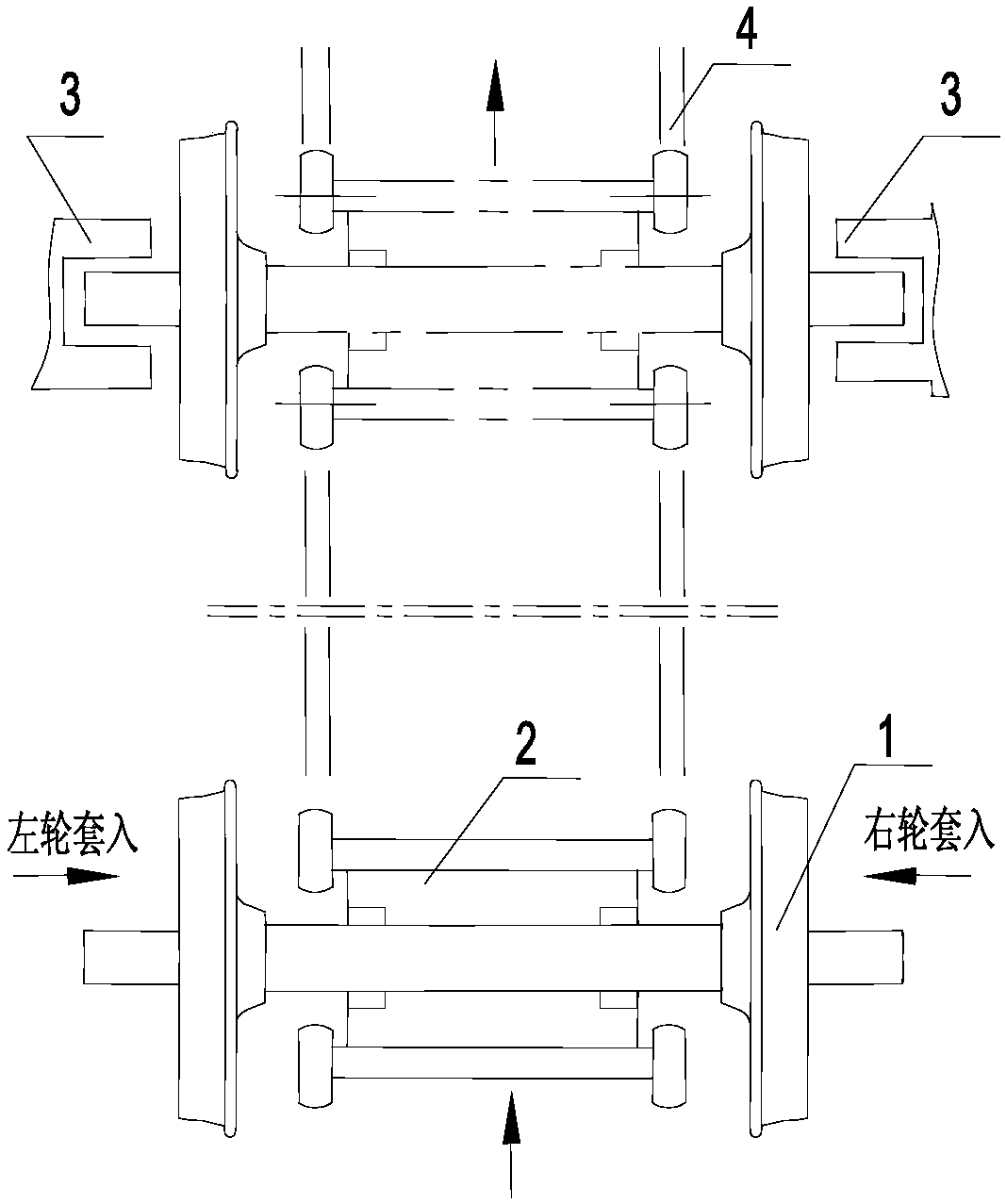

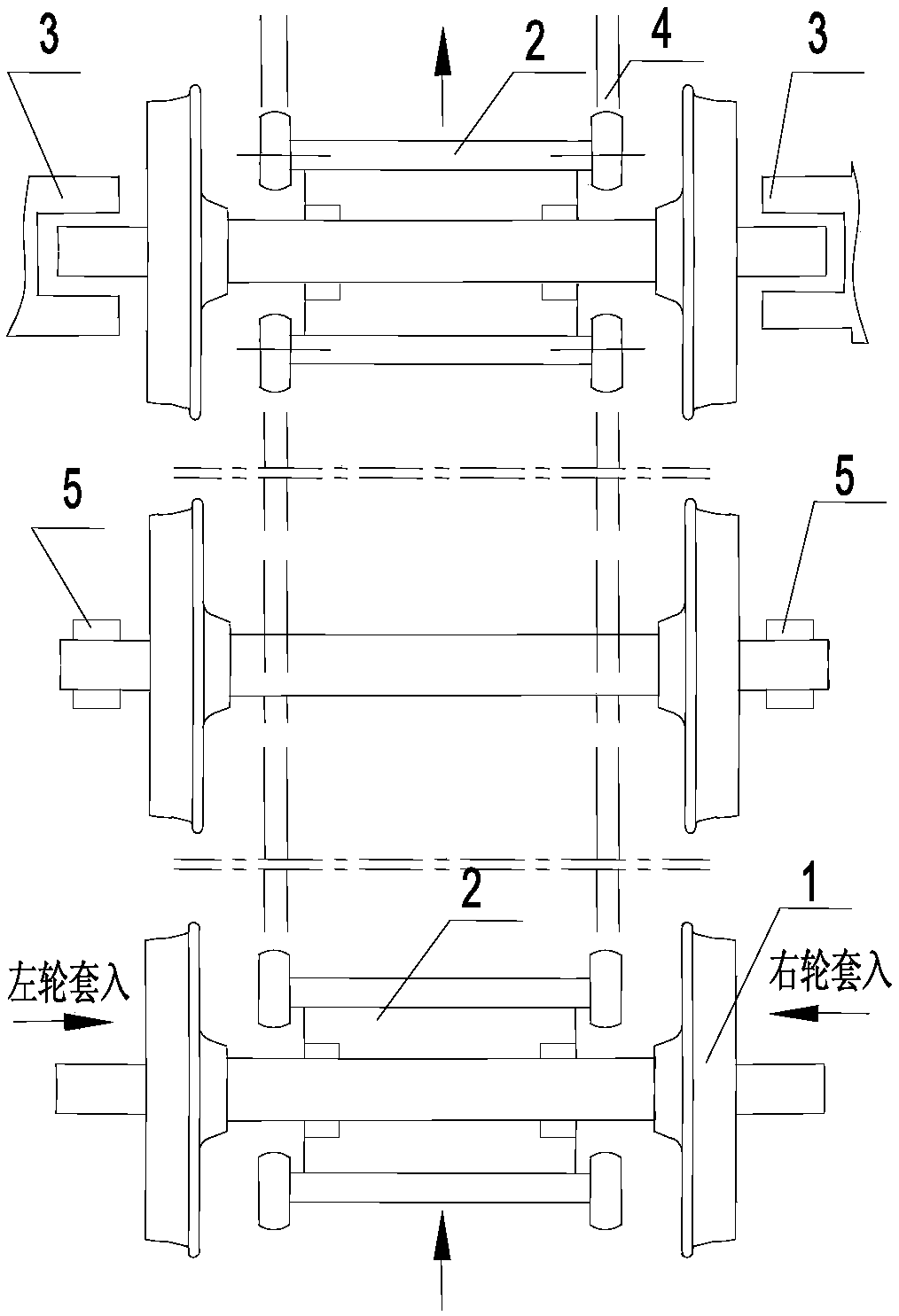

[0030] Such as figure 1 As shown, it includes the trolley track and the bracket trolley that can reciprocate back and forth on the trolley track. The fixed lifting bracket assembly is arranged above the trolley track and below the press-fit assembly for the press-fitting wheel to be pressed. The railway freight wheel pair is lifted to the press-fit assembly for press-fitting the wheel pair to be pressed.

[0031] The fixed lifting bracket assembly includes two fixed lifting brackets symmetrically arranged on both sides of the trolley track and a driving mechanism for driving the vertical movement of the fixed lifting bracket. For wheels running on rails, a pair of brackets are symmetrically arranged on the frame. The brackets include a support rod and a positioning frame with a bracket on the top of the support rod. The two ends of the axles of the wheels to be pressed can be placed on the positioning frame. superior.

[0032] In this embodiment, the positioning frame is Y-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com