Cleaning method and cleaning system of tubular membrane

A cleaning system and tubular membrane technology, applied in the field of water treatment, can solve the problems of failure to achieve recovery of particles after cleaning, loss of particle concentration control, etc., and achieve the effect of maintaining uniform stability, simple structure and improving cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

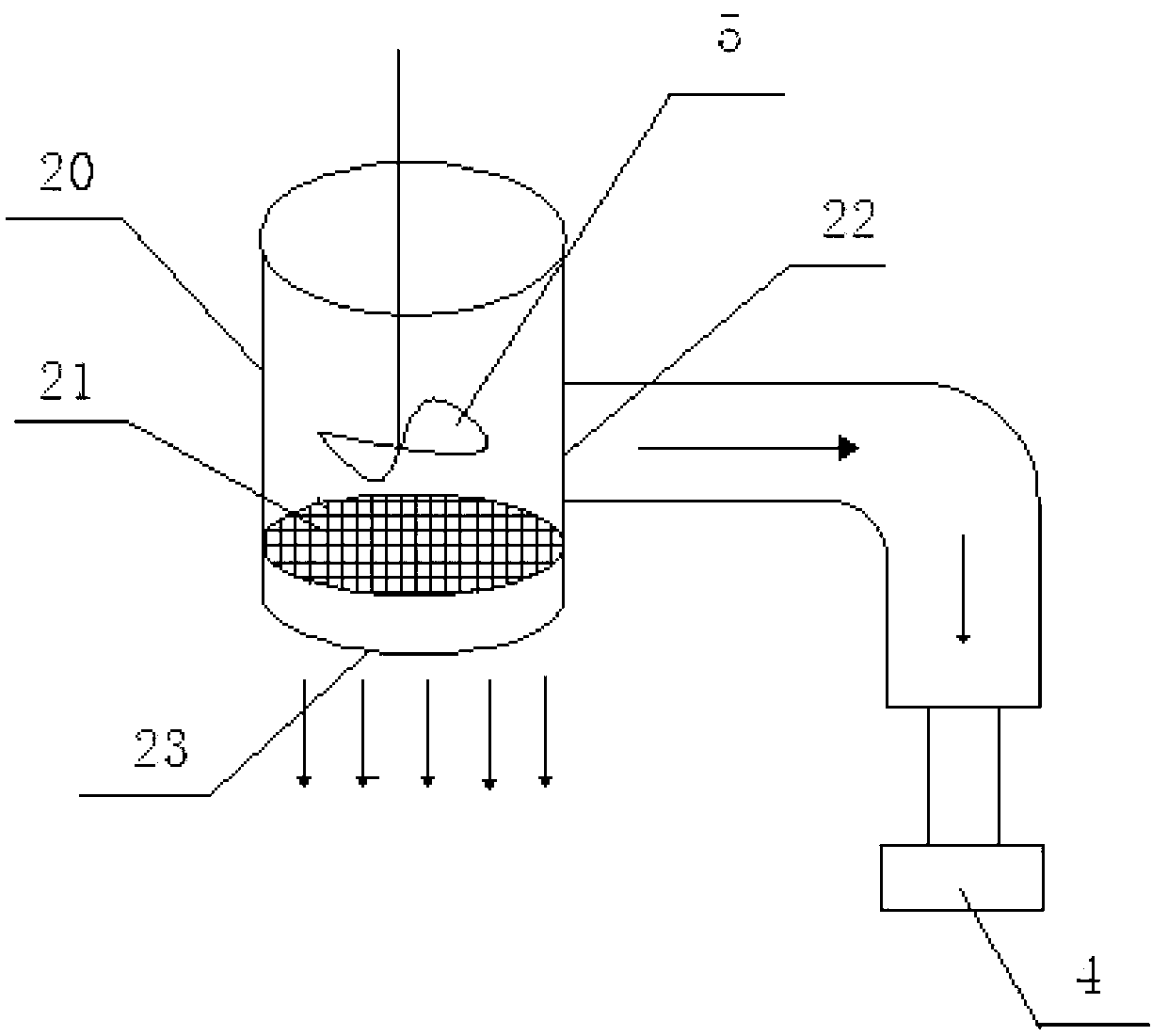

Image

Examples

Embodiment 1

[0046] Embodiment 1: the steps of using the cleaning system of the present invention to clean are as follows:

[0047] 1. Measure the membrane flux before cleaning: open the water inlet valve 8, the clean water inlet control valve 9, the particle circulation control valve 16 and the backflow control valve 17, and close other valves. Clean water enters the flow meter 2 from the circulation tank 19 through the circulation pump 1 and the valve 8, controls the flow rate at the outlet of the water inlet valve 8, controls the reading of the second pressure gauge 18 through the backflow control valve 17, and measures the flux under the corresponding pressure size. When the flux reaches the condition that needs to be cleaned, the cleaning of the membrane module is carried out.

[0048] 2. Cleaning with clean water: open the water inlet valve 8, the clean water inlet control valve 9, the particle circulation control valve 16 and the backflow control valve 17, and all other valves are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com