Temperature-sensitive paraffin perfusion film as well as preparation and application thereof

A temperature-sensitive, paraffin technology, applied in the field of membrane materials, to achieve the effect of simple preparation process and high flux recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: a kind of temperature-sensitive type paraffin perfusion membrane and preparation method thereof, concrete steps are:

[0051] (1) mixing paraffin wax and n-hexane with a mass ratio of 1:5, and melting at 50°C;

[0052] (2) Suction filter 1 mL of the paraffin and n-hexane mixture described in (1) while hot to the area prepared in Comparative Example 1 of 12.56 cm 2 The surface of the polyethersulfone fluorinated membrane, wherein the suction filtration pressure is 0.01MPa.

[0053] Through the above steps, a temperature-sensitive paraffin perfusion membrane based on a polyethersulfone porous membrane is obtained, wherein the content of paraffin on the surface of the polyethersulfone fluorinated membrane is 0.579 mg / cm 2 .

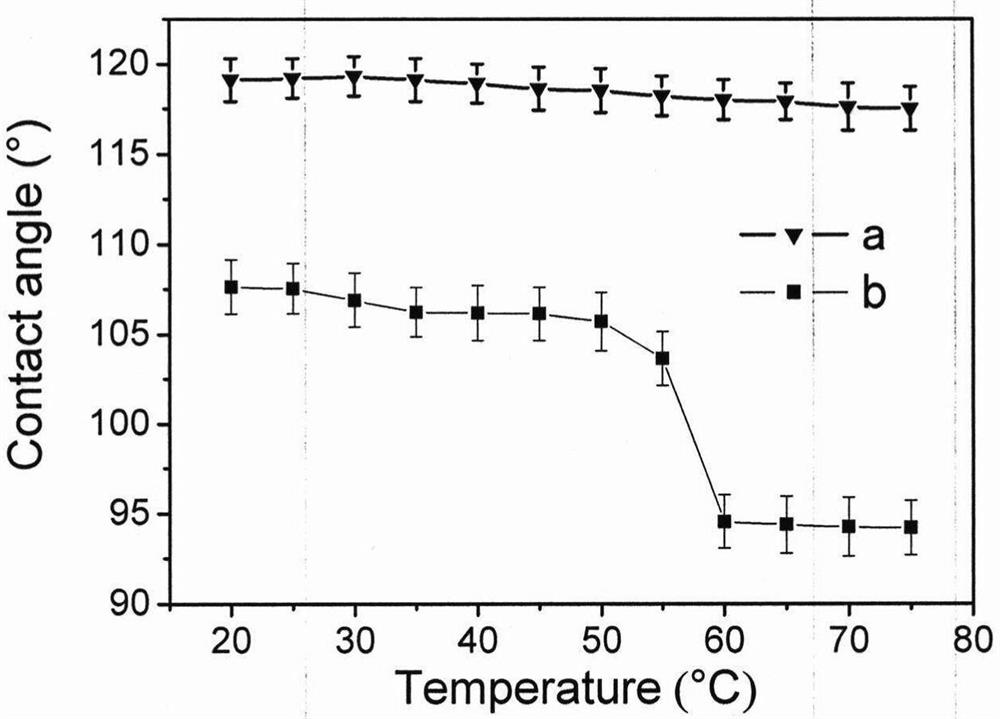

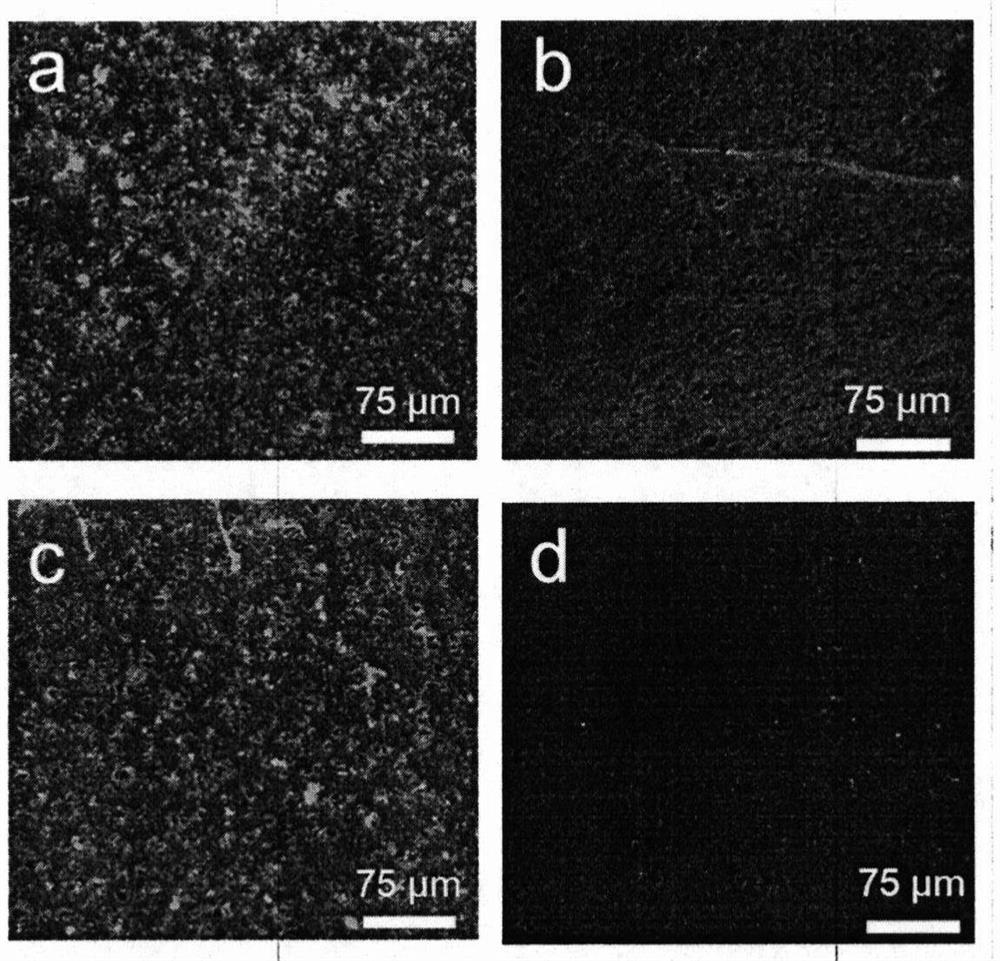

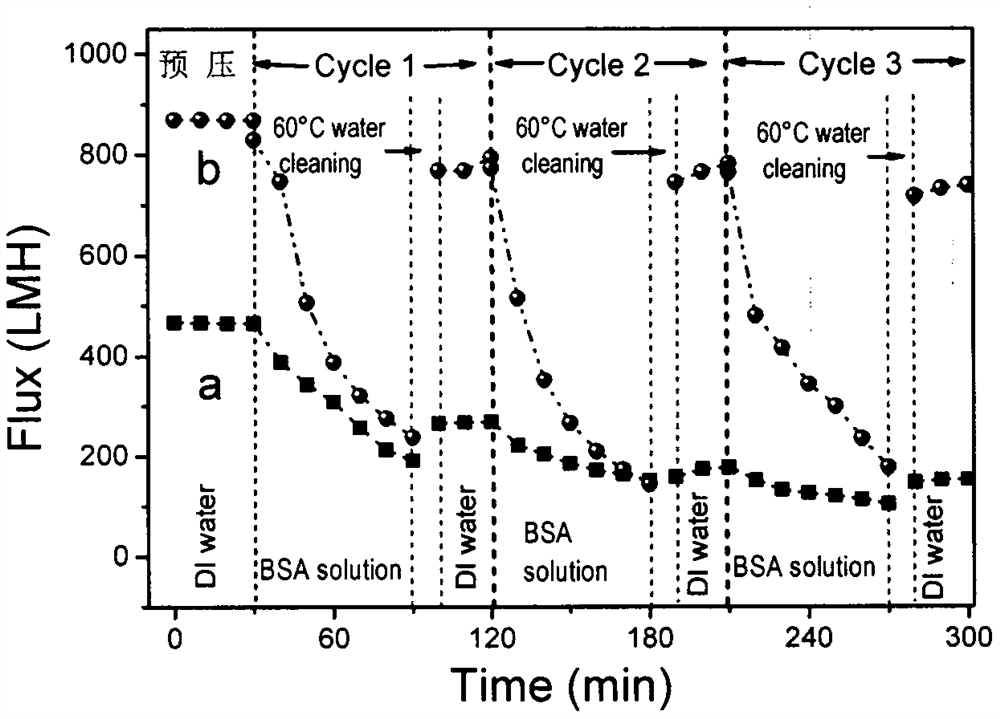

[0054] Compared with the polyethersulfone fluorinated membrane, the prepared temperature-sensitive paraffin perfusion membrane has temperature-sensitive characteristics in surface wettability and anti-pollution: such as figure 1 As sh...

Embodiment 2

[0061] Embodiment 2: a kind of temperature-sensitive type paraffin perfusion membrane and preparation method thereof, concrete steps are:

[0062] (1) According to the method of Comparative Example 1, the polypropylene membrane with a porosity of 72% and an average pore diameter of 0.6 μm is used as the base membrane to prepare a polypropylene membrane with a fluorinated rough layer on the surface, which is denoted as a polypropylene fluorinated membrane ;

[0063] (2) mixing paraffin wax and n-hexane with a mass ratio of 1:7, and melting at 50°C;

[0064] (3) Suction filter 1.5mL of the paraffin and n-hexane mixture described in (2) while hot until the area prepared in (1) is 18.84cm 2 The surface of the polypropylene fluorinated membrane, wherein the suction pressure is 0.01MPa.

[0065] Through the above steps, a temperature-sensitive paraffin perfusion membrane based on a polypropylene porous membrane is obtained, wherein the content of paraffin on the surface of the pol...

Embodiment 3

[0073] Embodiment 3: a kind of temperature-sensitive paraffin perfusion membrane and preparation method thereof, concrete steps are:

[0074] (1) According to the method of Comparative Example 1, with a porosity of 55%, and a polyvinylidene fluoride film with an average pore diameter of 0.5 μm as the base film, a polyvinylidene fluoride film with a fluorinated rough layer on the surface is prepared, which is denoted as polyvinylidene fluoride film. Vinylidene fluoride film;

[0075] (2) mixing paraffin wax and n-hexane with a mass ratio of 1:10, and melting at 50°C;

[0076] (3) Suction filter 2 mL of the paraffin and n-hexane mixture described in (2) while hot until the area prepared by (1) is 24 cm 2 The surface of the polyvinylidene fluoride fluoride membrane, wherein the suction filtration pressure is 0.01MPa.

[0077] Through the above steps, a temperature-sensitive paraffin perfusion membrane based on a polyvinylidene fluoride porous membrane is obtained, wherein the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com