Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Increase discharge gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

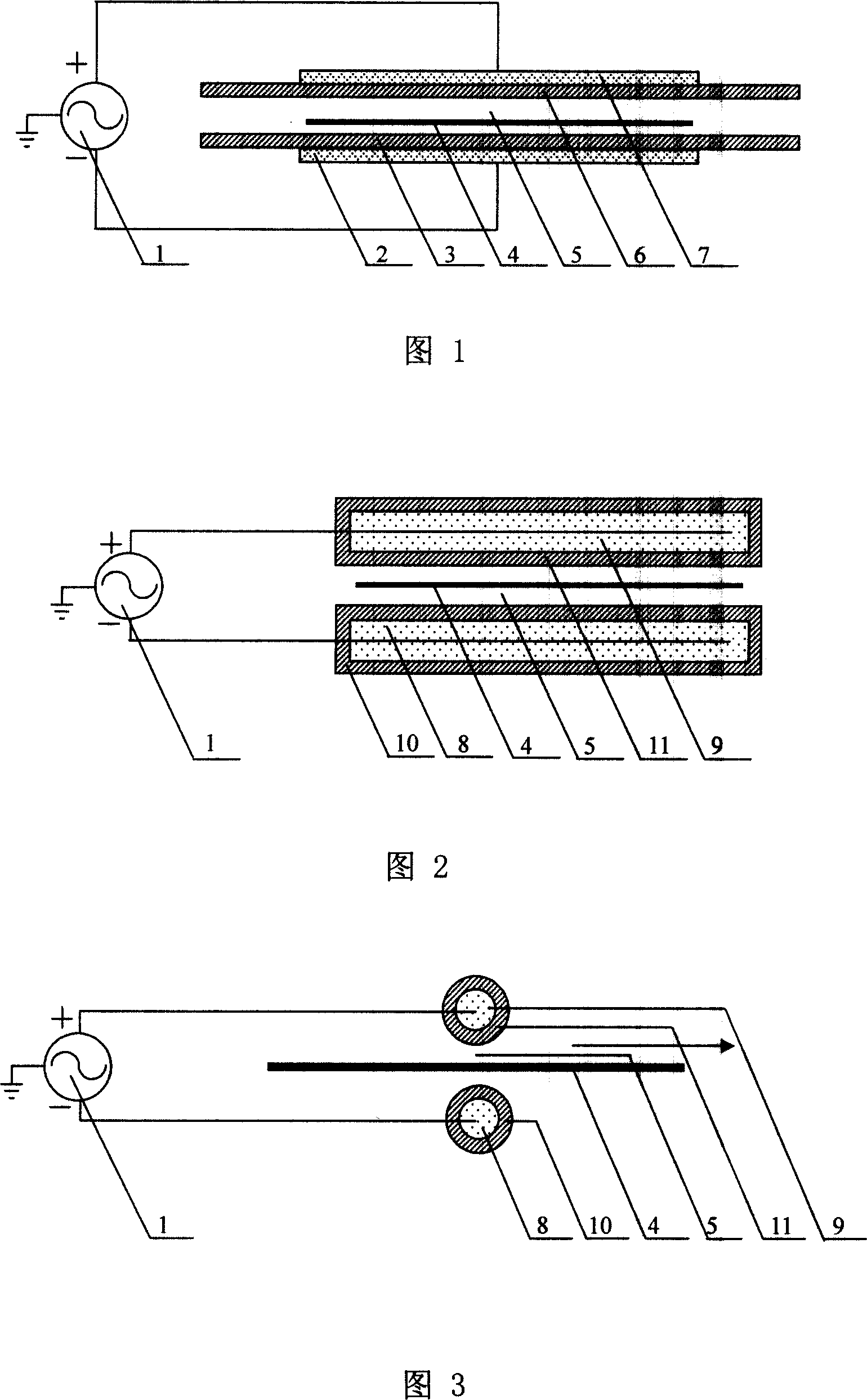

Differential feed dielectric barrier discharging low-temperature plasma device

InactiveCN101022074ALow insulation design requirementsLow costElectric discharge tubesPlasma techniquePhase differenceEngineering

This invention relates to a low temperature plasma device for blocking discharge by a differential feeder medium including a difference output high voltage supply, two high voltage electrodes, in which, the output of the differential output high voltage supply is connected with the two high voltage electrodes, a layer of medium is covered on one of the electrodes or set at any place between the two electrodes, and the gas between them is the load and the voltages to the earth of the two output ends of the supply connected to the two electrodes are equal or almost equal, the phase difference is 180 deg. or approaching to 180deg, which can generate DBD of large discharge clearance for producing large volume of gas discharge low temperature plasma and reduce the supply output voltage necessary for gas discharge.

Owner:万京林 +1

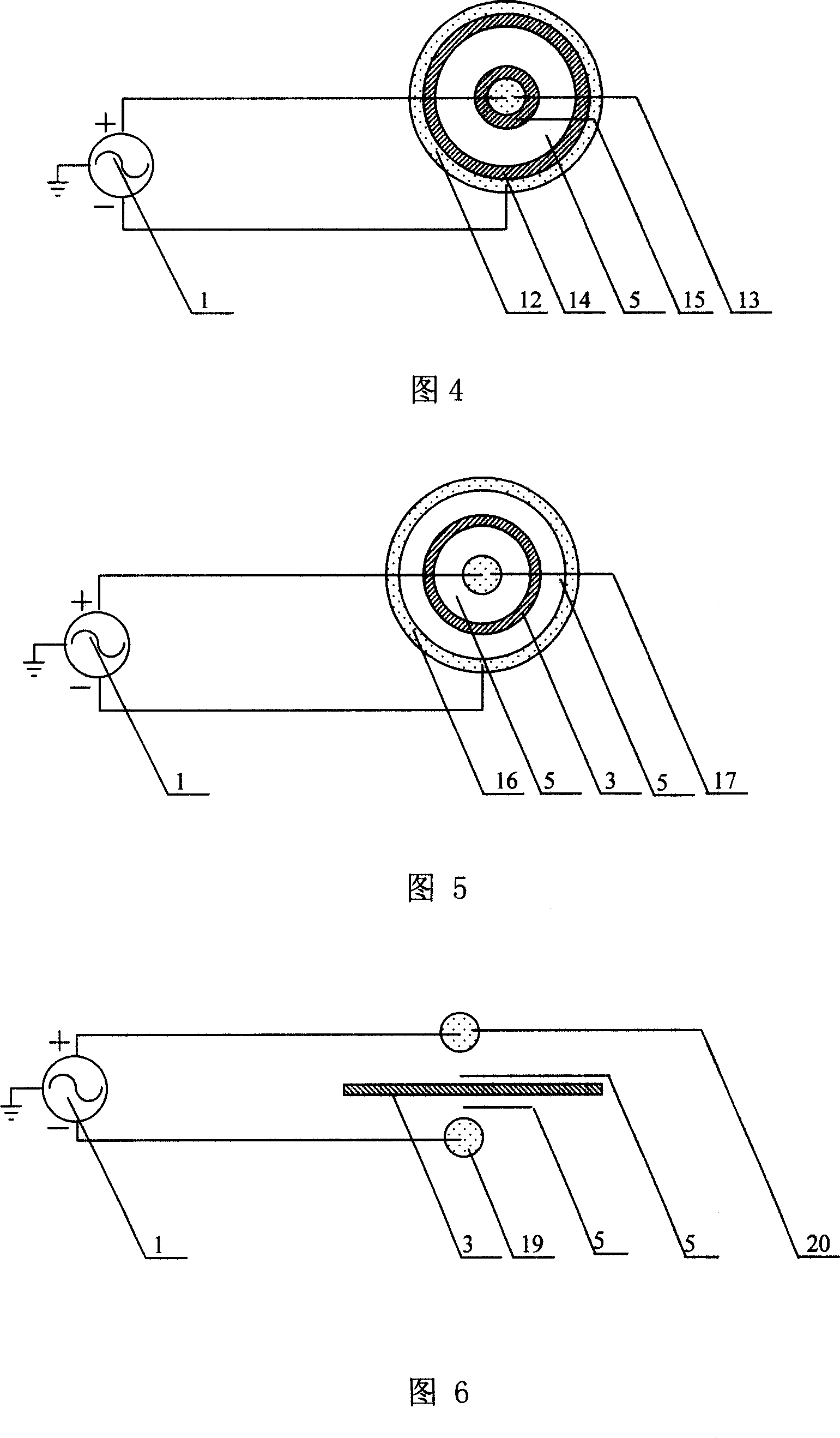

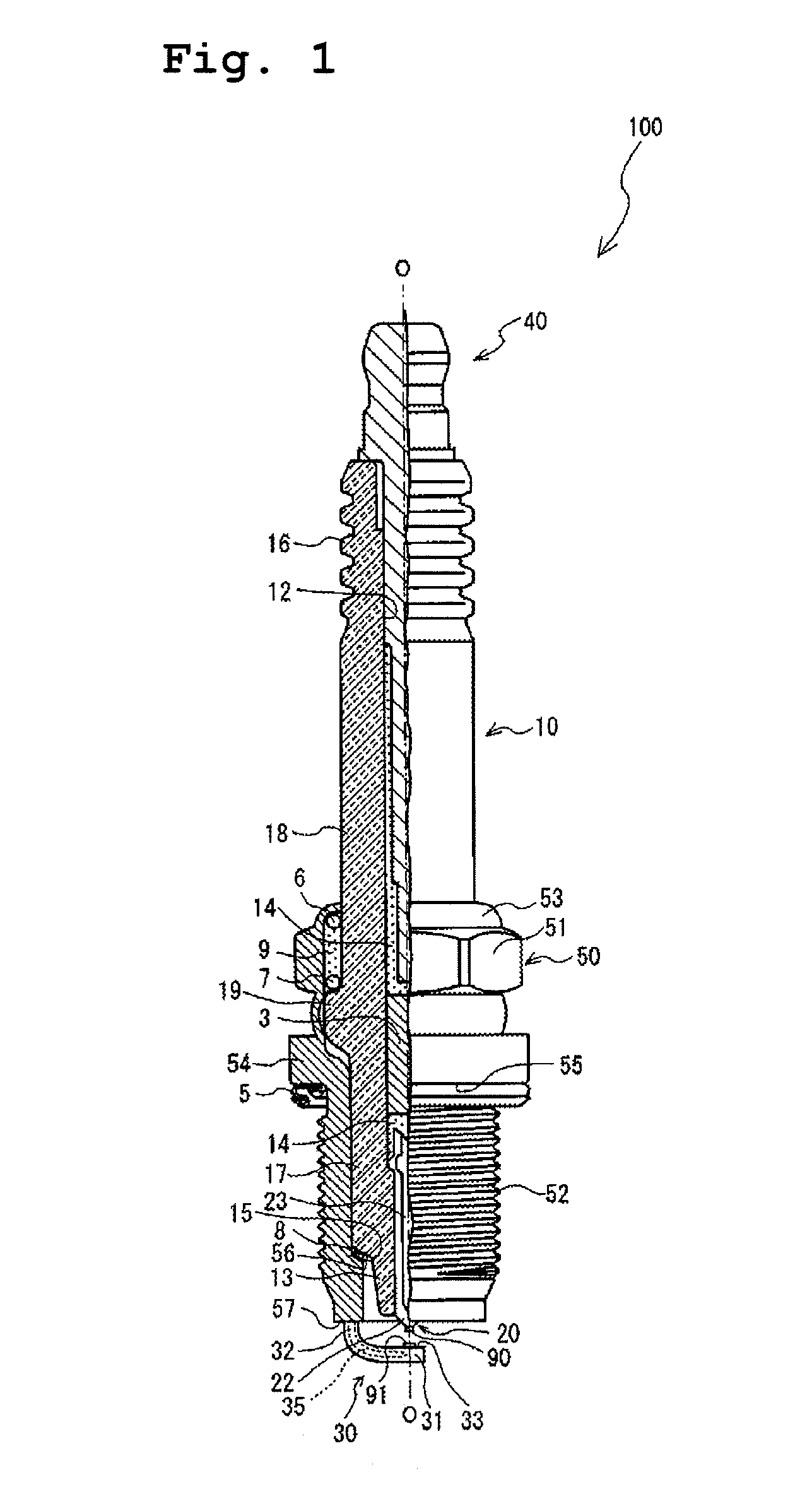

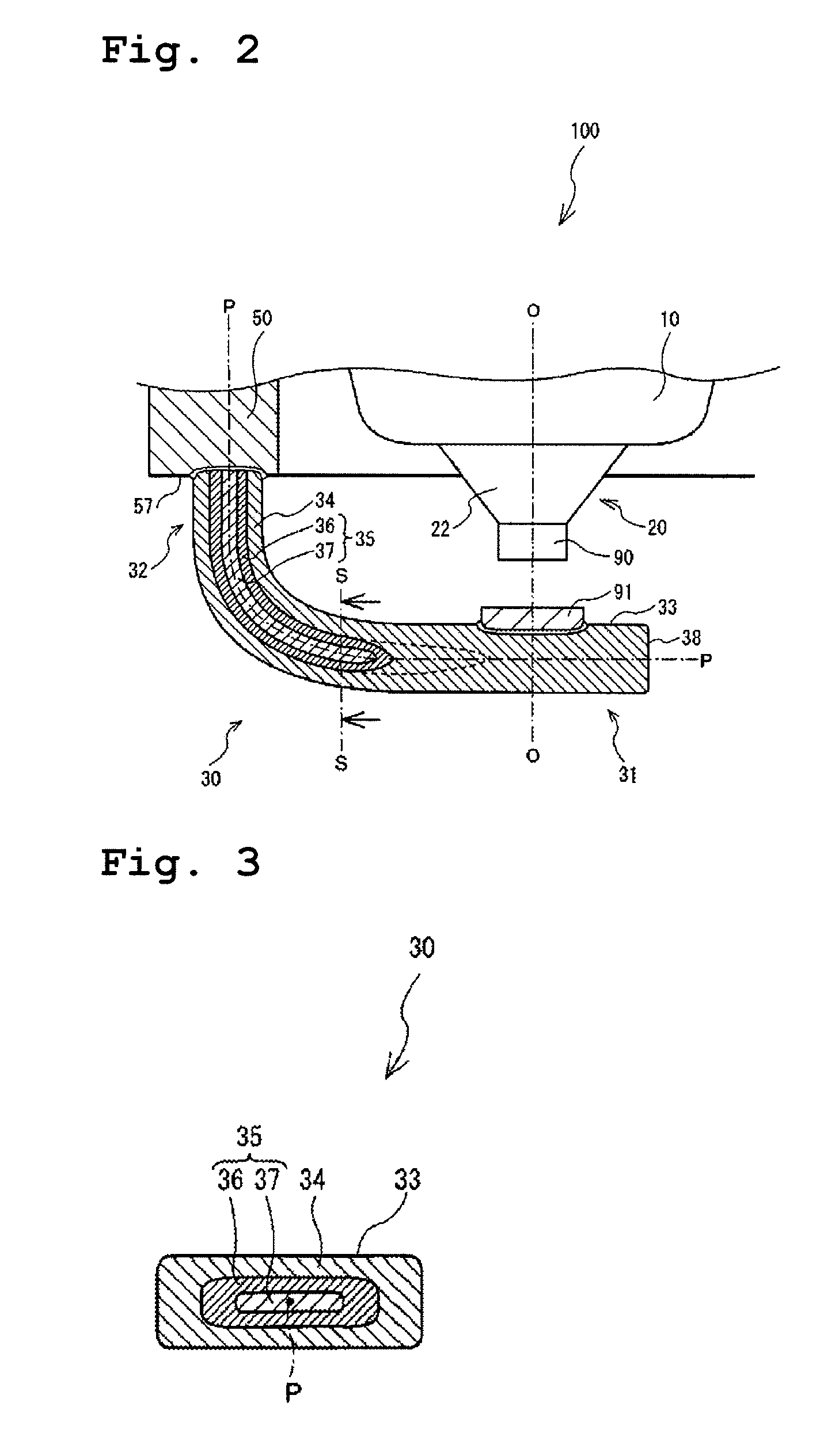

Spark plug

ActiveUS20080122334A1Increased durabilityImprove cooling effectSparking plugsCombustion chamberNuclear engineering

A spark plug including a ground electrode which has an excellent heat sinking ability. The ground electrode includes a core material therein. Heat received from a combustion chamber during a drive of an internal-combustion engine can be conducted to the core material. More effective heat sinking ability can be achieved because of the core material.

Owner:NGK SPARK PLUG CO LTD

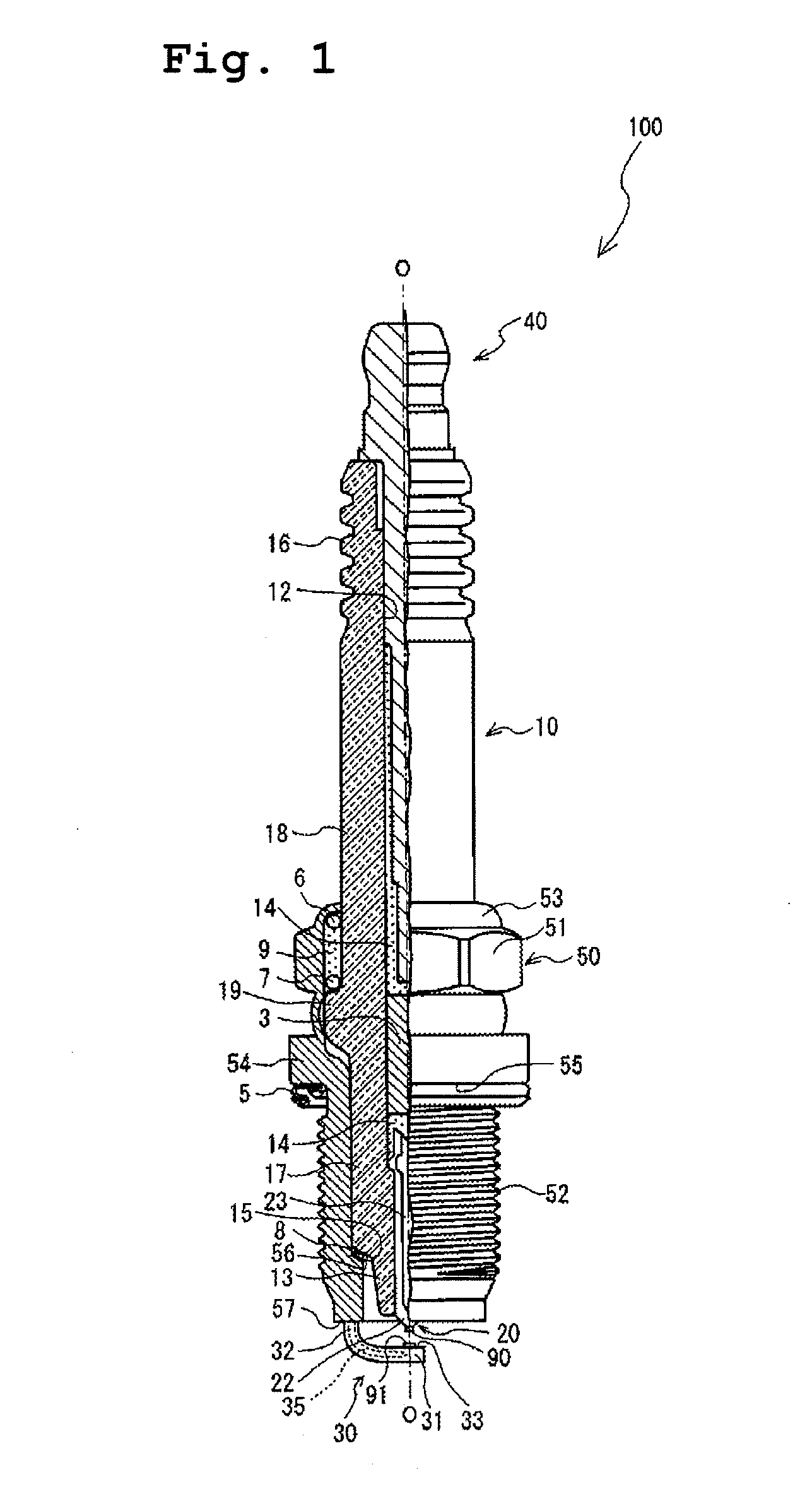

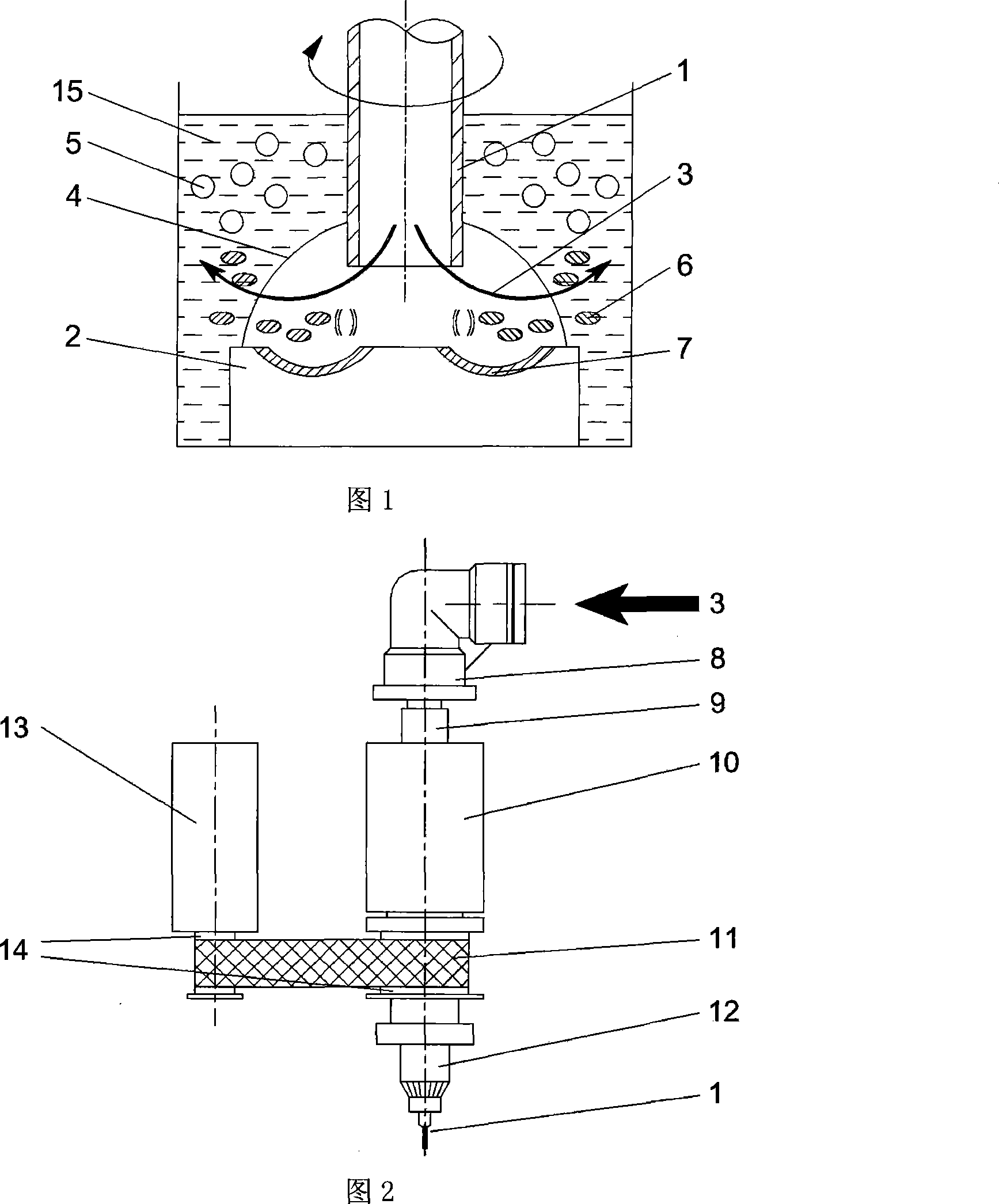

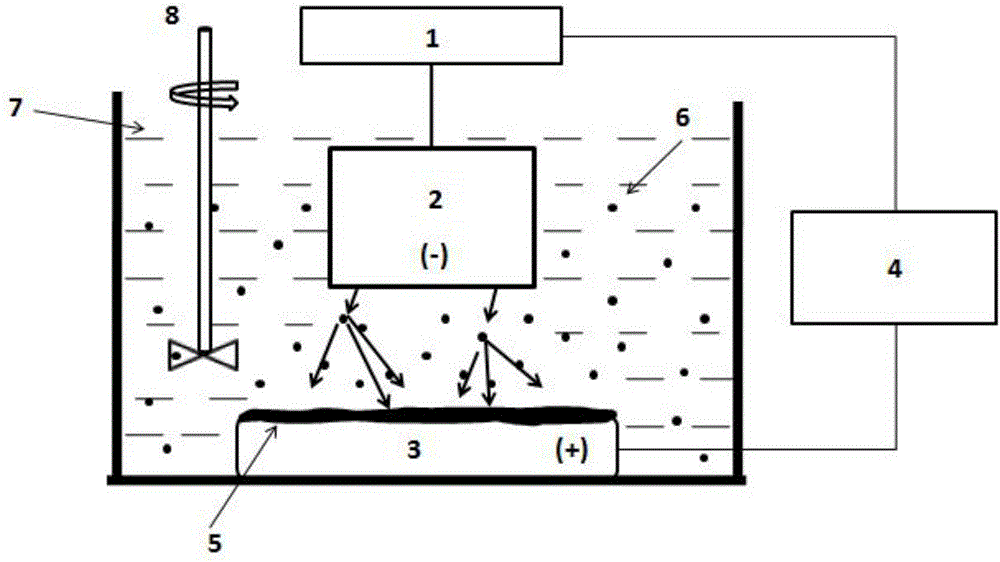

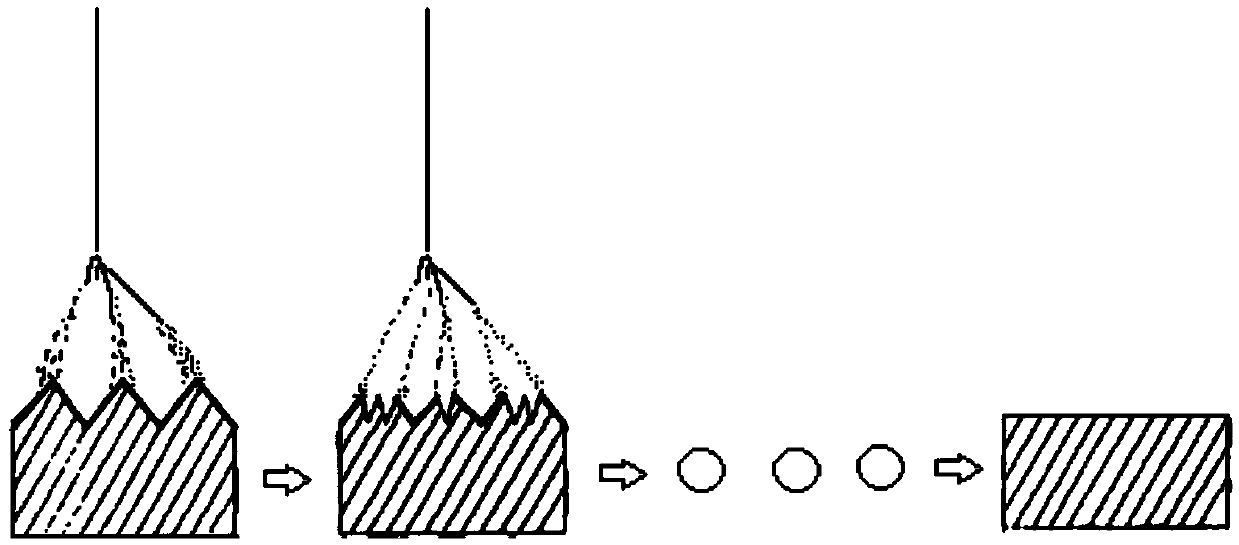

Powder-mixed near-dry type electric spark machining device and method thereof

The invention discloses a mixed powder quasi-dry typed electric spark processing device and a method, which has the advantages of low processing roughness, high precision, good processing stability, quick processing speed and the like. The structure of the electric spark processing device comprises an electric spark processing machine tool; the pipe-shaped tool electrode of the electric spark processing machine tool is connected with a slight lubrication device which is connected with an air compressor.

Owner:SHANDONG UNIV

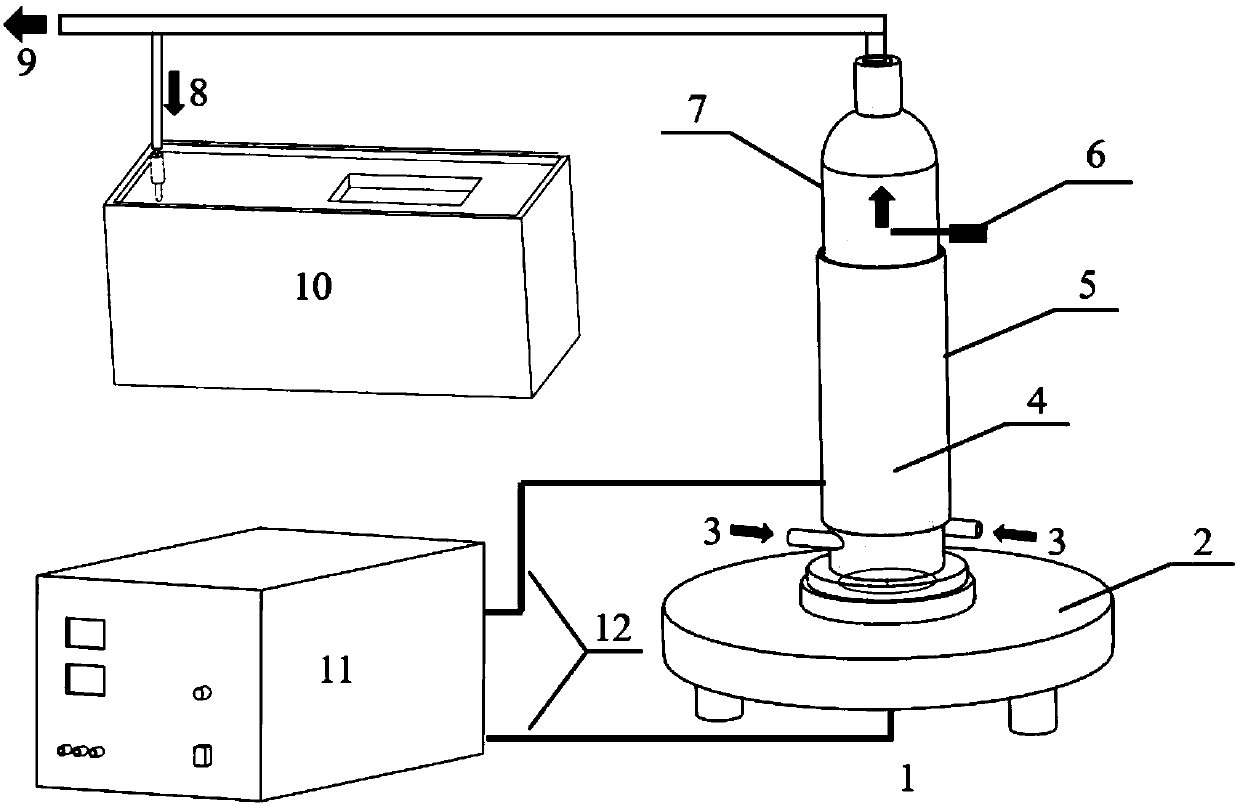

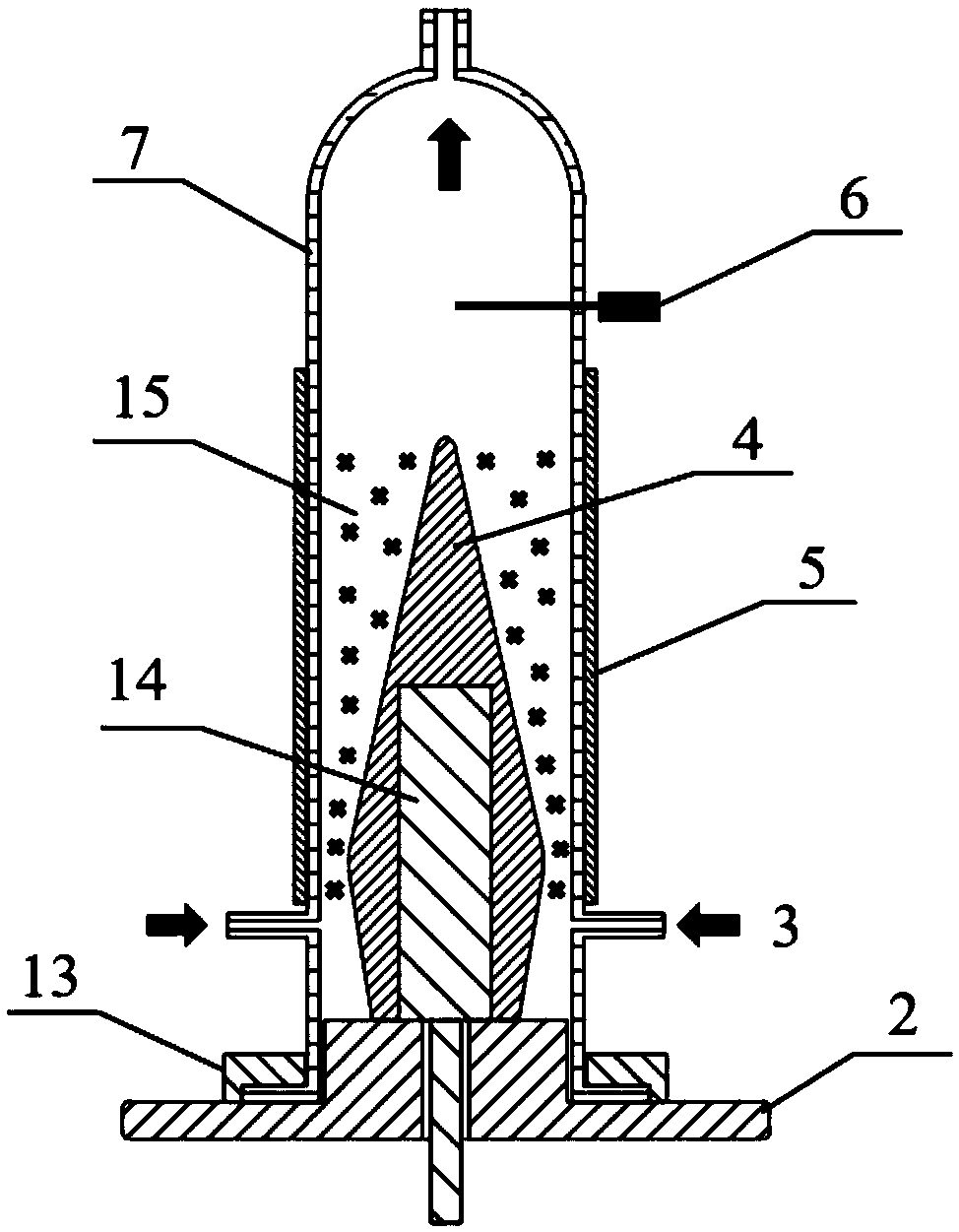

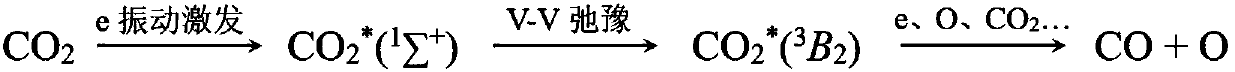

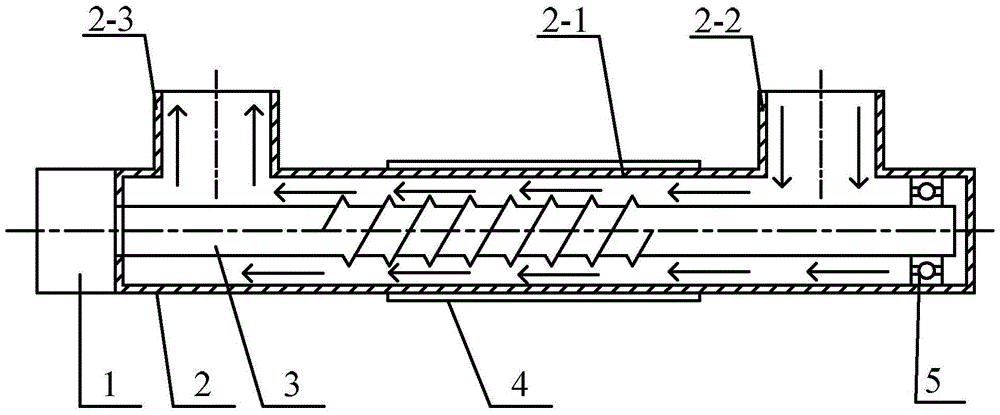

Reaction device and method for activation of carbon dioxide by disturbance enhanced dielectric barrier discharge

ActiveCN109663556AStrengthen the degree of disturbanceExtended stayGas treatmentDispersed particle separationFully developedHigh energy

The invention discloses a reaction device and a method for activation of carbon dioxide by disturbance enhanced dielectric barrier discharge, wherein the device comprises a dielectric barrier discharge reactor, a high-voltage pulse power source and an online infrared analyzer. The dielectric barrier discharge reactor mainly comprises a tangential inlet, an inner electrode, an outer electrode, a quartz tube and the like. The inner electrode is an integral shape of the lower round table and the upper cone. The outer electrode is arranged around the outer wall of the quartz tube. The carbon dioxide forms a spiraling airflow through the two-way tangential flow. A filament discharge formed between the inner and outer electrodes is violently disturbed under the impetus of the spiral airflow, fully develops toward the increase direction of the pole gap, and forms a large-area, disturbance-enhancing discharge region. The carbon dioxide is efficiently activated and decomposed by high energy electrons and active particles. The reaction device and the method for activation of carbon dioxide by disturbance enhanced dielectric barrier discharge have the advantages that the gas residence time ofis long, the reaction zone is highly disturbed, the high-efficiency vibration excitation decomposition is fully developed, and the carbon dioxide activation effect is optimized.

Owner:ZHEJIANG UNIV

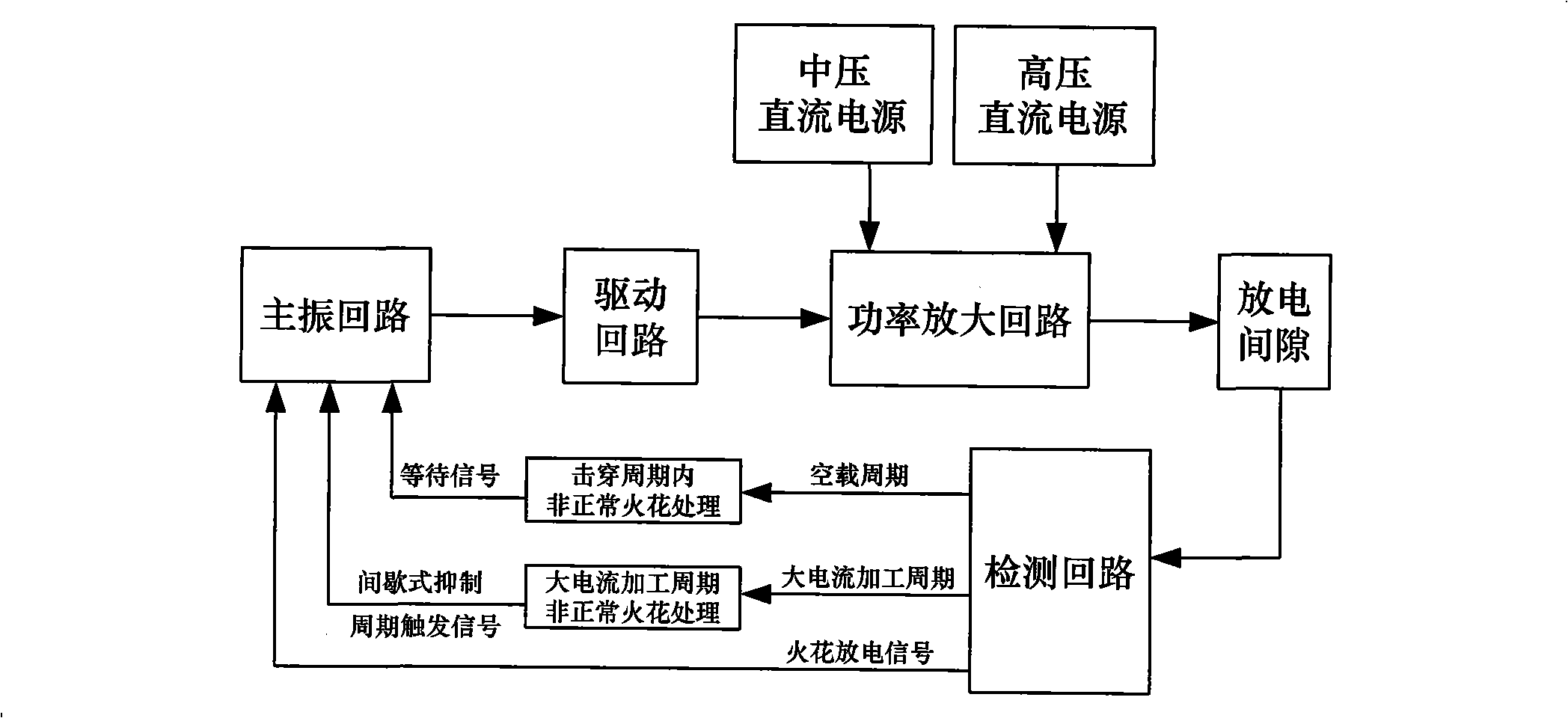

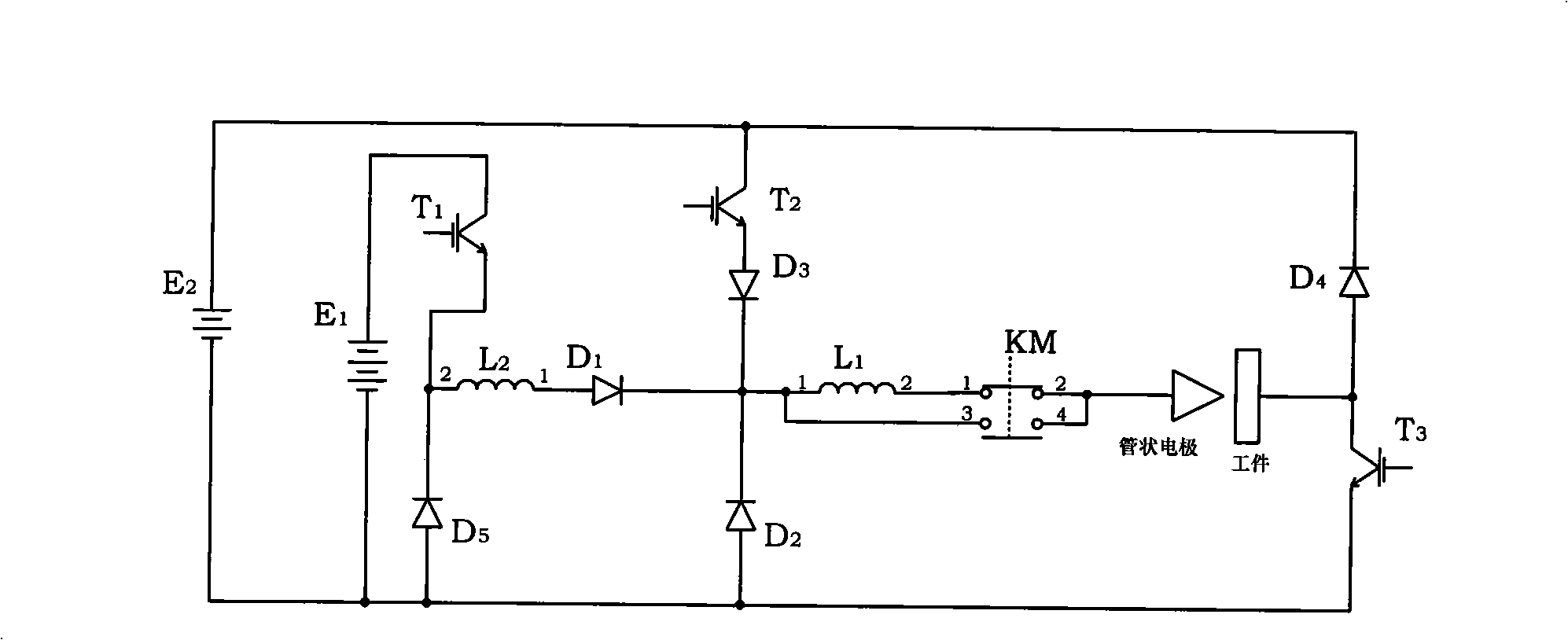

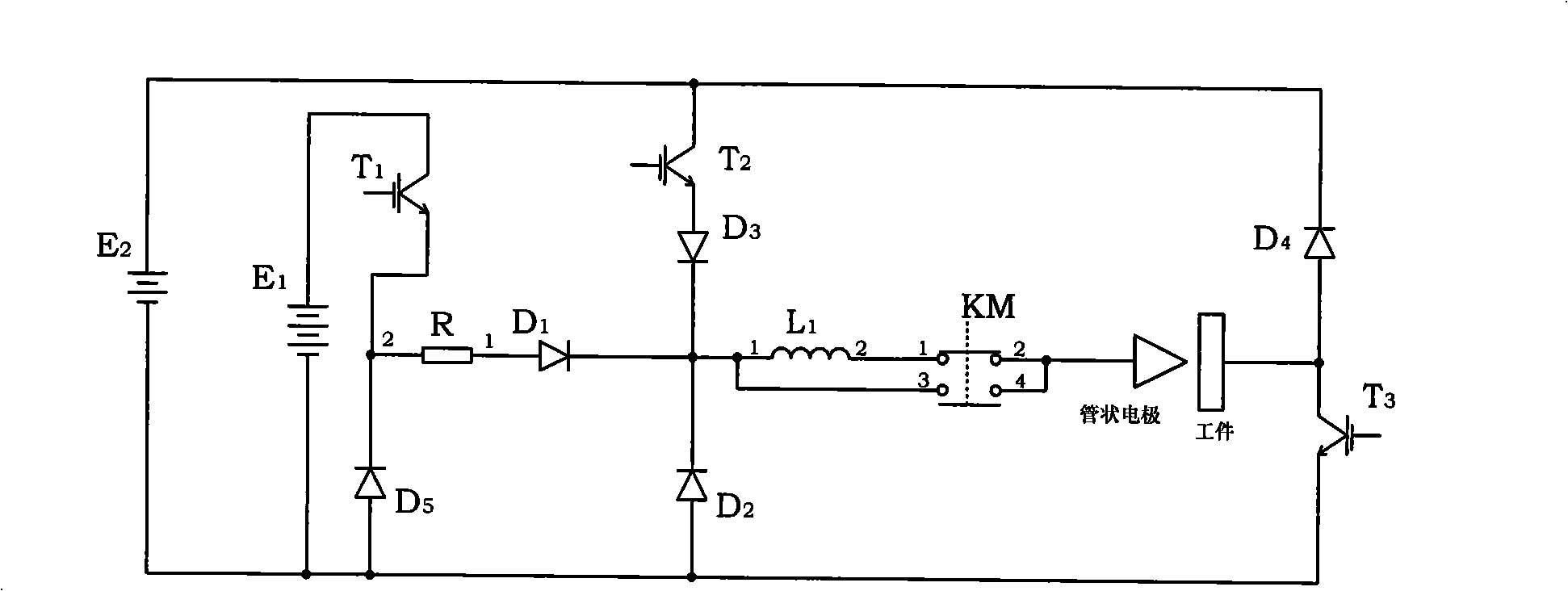

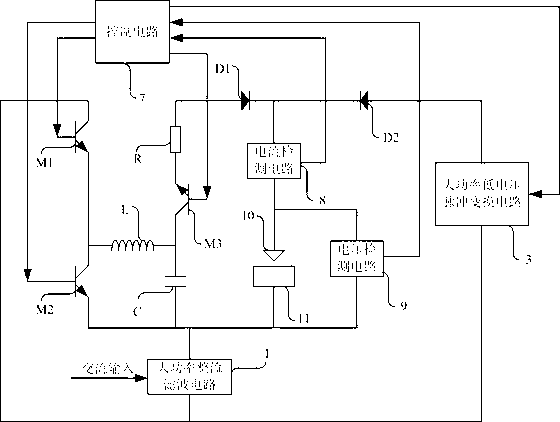

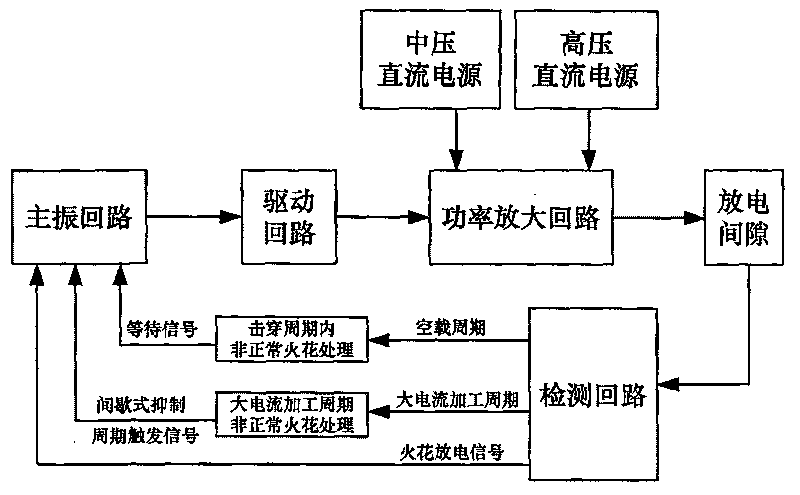

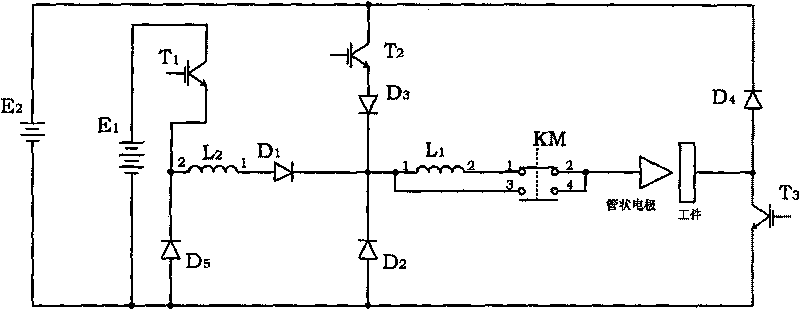

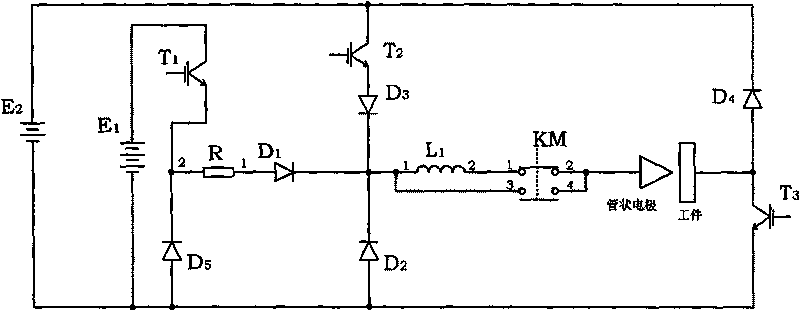

Impulsing power source for spark pinhole processing

InactiveCN101318241AReduce lossAvoid lossElectric circuitsNumerical controlHigh-voltage direct current

The invention discloses electric spark microhole processing pulse power supply suitable for the numerical control electrical discharge wire-cutting, which comprises a main vibration circuit, a driving circuit, a detection circuit, a non-normal spark treatment module in breakdown cycle, a non-normal spark treatment module in heavy current processing cycle, the high voltage direct current power supply, the medium voltage direct current and a power amplification circuit; wherein, the non-normal spark treatment module in breakdown cycle and the non-normal spark treatment module in heavy current processing cycle are arranged between the main vibration circuit and the detection circuit which is used in the real time online detection of gap discharge state; the signals of the no-loaded cycle in breakdown are adopted as the waiting signals of the main vibration circuit, and the signals of the heavy current processing cycle are adopted as trigger signals of the intermittent inhibitive cycle of the main vibration circuit; the switching of the multifunctional processing circuit and the working modes of two power supplies on the same wire-cutting machine can be realized by controlling the on and off time of a first power switch tube (T1).

Owner:HARBIN INST OF TECH +1

Air blast electric spark processing method in liquid

InactiveCN101168204ALow processing short circuit rateGood stabilityElectrical-based machining electrodesProduct gasEngineering

Provided is an electric spark processing method of spraying gas to liquid of a special processing technology. Hollow-tube-shaped tool electrode is employed, when the electric spark is used to process, high-pressure gas is sprayed from the hollow-tube-shaped tool electrode, the tool electrode and work-pieces are immersed in treatment liquid. The invention has the advantage that liquid treatment medium is blended based on the processing method of gas electric spark, the gas is the treatment medium, the water-based treatment liquid does not directly participate power discharging, but produces a beneficial assistant effect to the processing. The invention also has the advantages of lower short circuiting rate of the processing, good stability, high removal rate of materials, good quality of treatment surface, and being in accordance with the trend of green manufacturing.

Owner:SHANGHAI JIAO TONG UNIV

Discharge plasma vehicle exhaust gas treatment device with rotating spiral electrode and treatment method thereof

ActiveCN104941400BImprove purification efficiencyIncrease discharge gapDispersed particle separationMotor driveEngineering

The invention relates to a discharge plasma vehicle tail gas treatment apparatus with spiral electrode rotating, and a discharge plasma vehicle tail gas treatment method with spiral electrode rotating, and belongs to the technical field of vehicle tail gas treatment. A purpose of the present invention is to solve problems of non-uniform plasma generation and low purification efficiency of the existing low temperature plasma reactor for the vehicle tail gas treatment. The discharge plasma vehicle tail gas treatment apparatus comprises a motor, a tail gas plasma treatment tube, a spiral electrode and a copper tube, wherein the space between the spiral electrode and the tail gas plasma treatment tube is the vehicle tail gas channel and is the plasma reaction zone, one end of the spiral electrode is connected with the motor, and the other end is fixed at the head end of the horizontal tail gas treatment section. According to the method, the copper tube and the spiral electrode are connected to the power supply, and then the motor drives the spiral electrode to rotate, such that the treatment on the vehicle tail gas is achieved under the effect of the plasma in the horizontal tail gas treatment section. The apparatus and the method of the present invention are used for the vehicle tail gas treatment.

Owner:HARBIN INST OF TECH

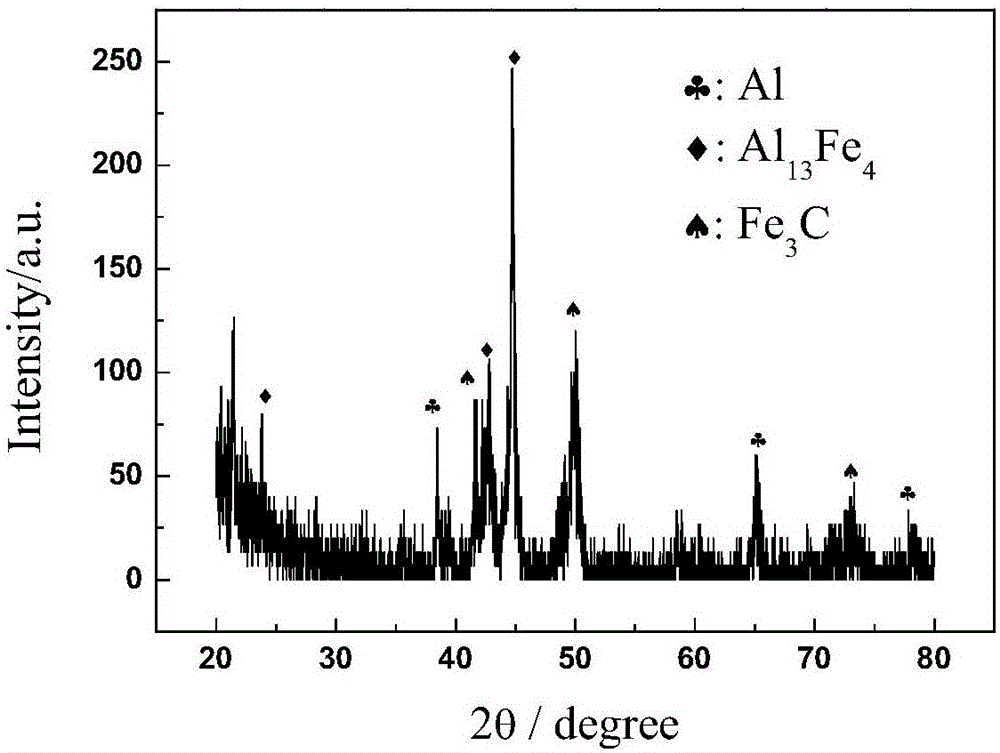

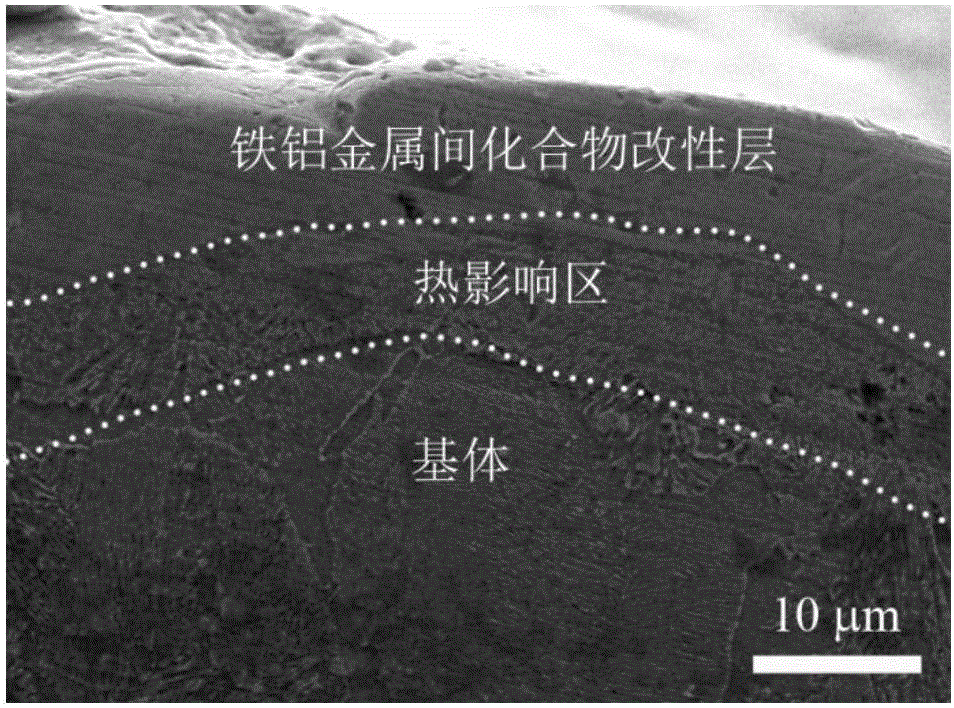

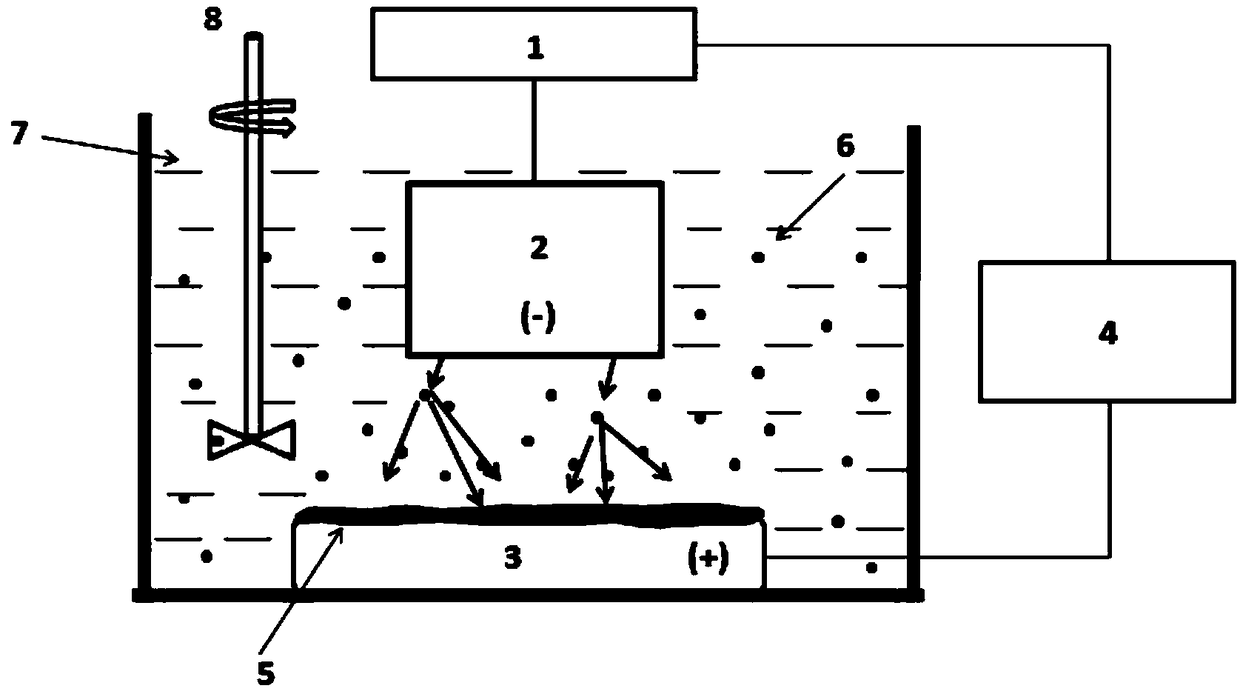

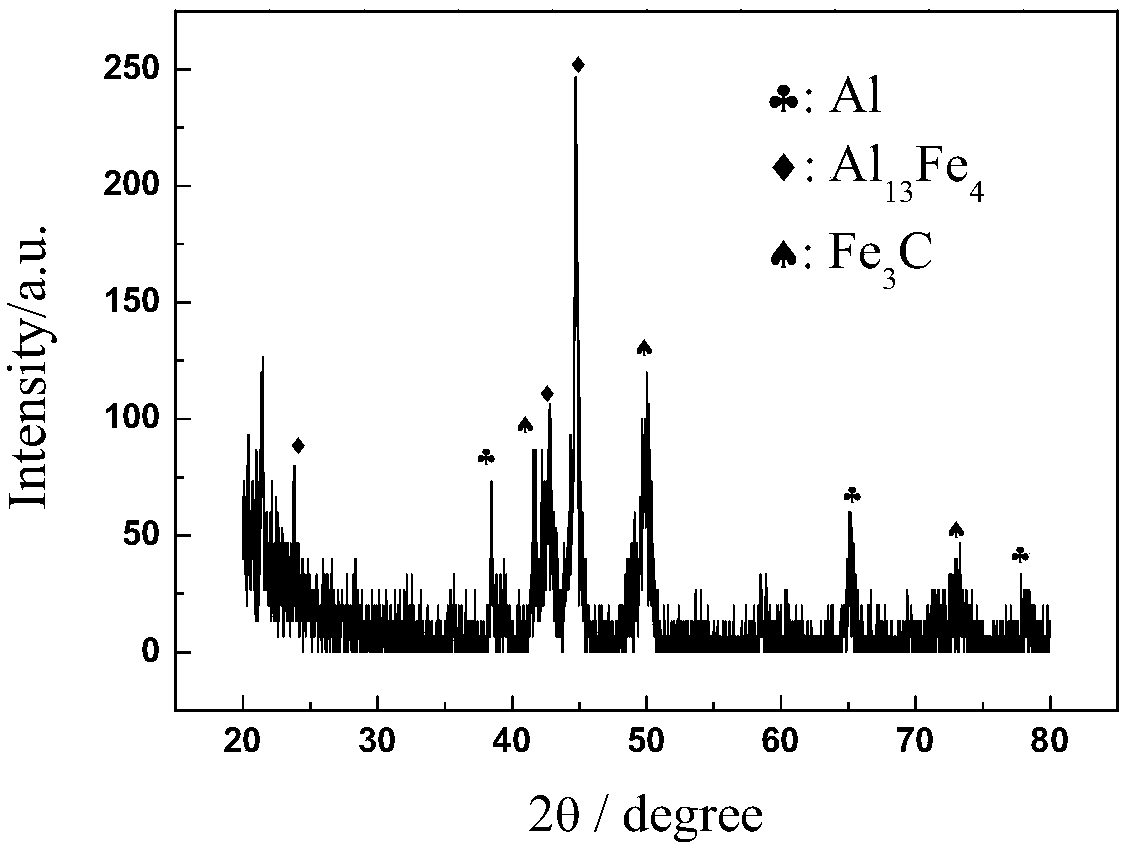

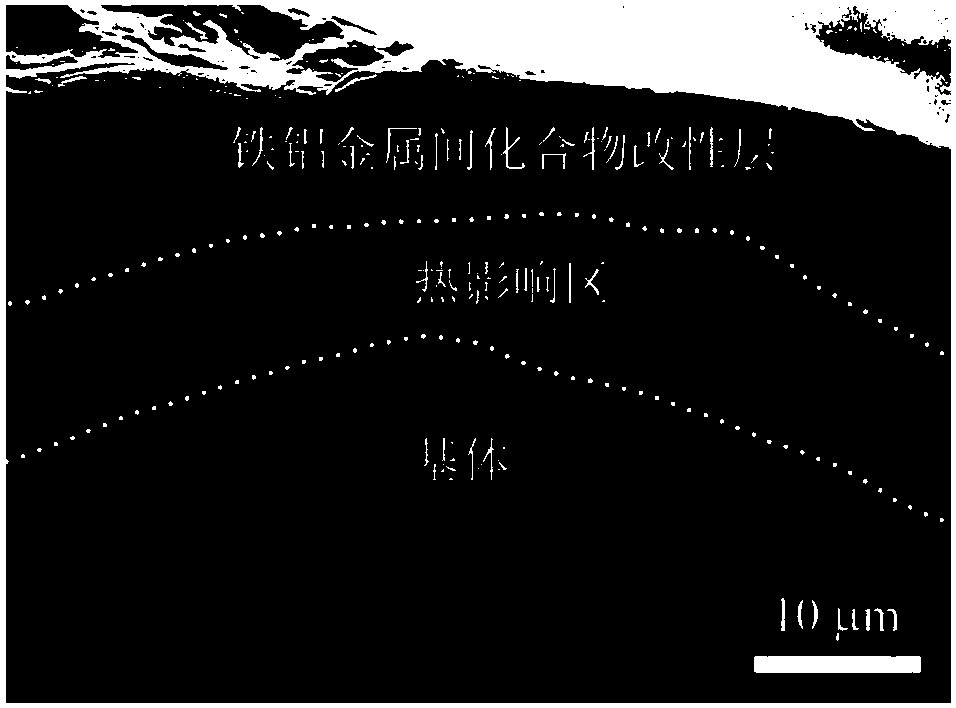

Preparation method of surface modification layer containing iron and aluminum intermetallic compound

ActiveCN106245023AImprove production efficiencyLow costHeat inorganic powder coatingPulse dischargeBinding force

The invention discloses a surface modification layer containing an iron and aluminum intermetallic compound and a preparation method of the surface modification layer. The preparation method comprises the following steps: taking an aluminum powder pressing body as a tool electrode, taking aluminum powder and coal oil mixed liquid as working liquid, and taking common low-carbon steel as a workpiece; enabling pulse discharge to be generated between the electrode and the workpiece in the working liquid by using a common electric spark machine tool; enabling the electrode, aluminum in the working liquid and iron in the workpiece to carry out in-situ alloying reaction with the aid of discharge energy; and finally, forming the surface modification layer containing the iron and aluminum intermetallic compound on the surface of the workpiece. The modification layer prepared by the method has the advantages of compact structure, good basic binding force and the like, and is expected to be widely used in the field of surface modification for improvement of corrosion resistance and wear resistance of structure materials.

Owner:GUANGDONG UNIV OF TECH

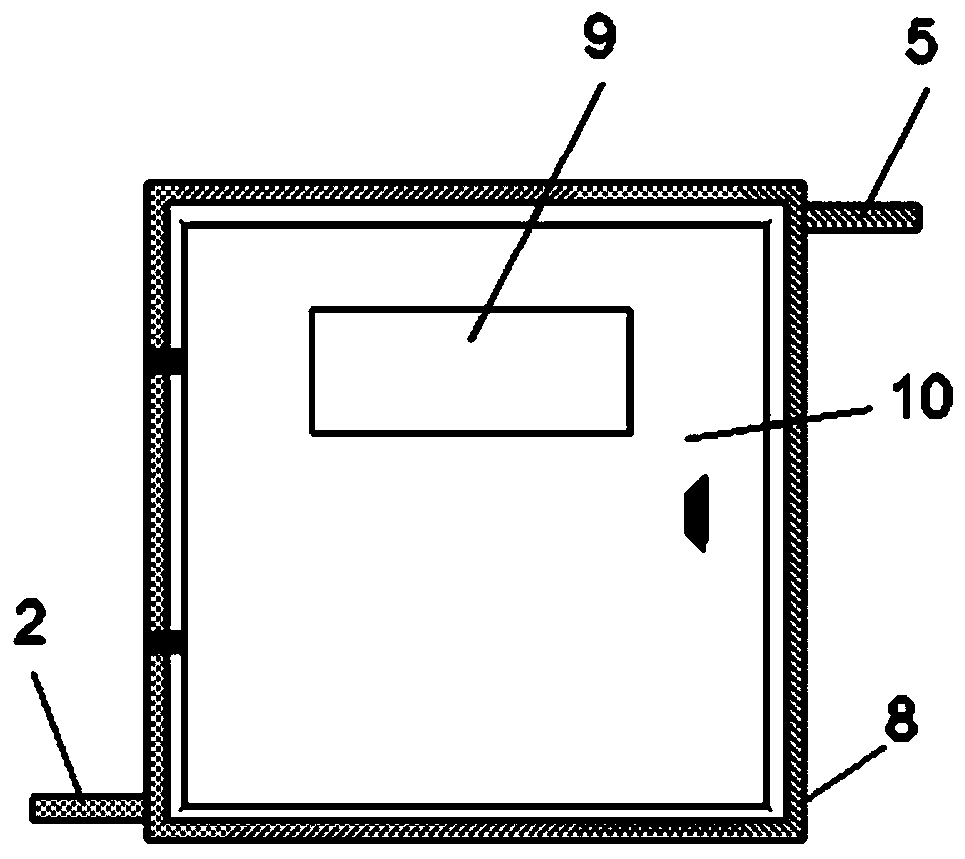

Device and method for processing VOCs through asymmetrical single-medium barrier discharge

PendingCN108554136AReduce cleaning frequencyReduce replacement frequencyGas treatmentDispersed particle separationHigh densityConductive materials

The invention belongs to the technical field of VOCs processing devices, and relates to a device and method for processing VOCs through asymmetrical single-medium barrier discharge. The device comprises a draught fan, a power supply and a box body. A flow equalizing plate, an electrode fixing plate and a discharging unit are arranged in the box body. The discharging unit is of an asymmetrical discharging electrode structure, and comprises a metal electrode and an insulating medium pipe. The metal electrode is prepared from a metal rod with threads and fins. A medium internal electrode preparedfrom a conductive material is arranged in the insulating medium pipe. Gas containing VOCs enters the device from the inlet, is equalized by the flow equalizing plate and then enters a high-density strong plasma discharging area to collide and react with high-activity particles produced by discharging for degradation, coking substances produced in the discharging process are collected by a groovein the metal electrode, and the discharging stability and the high processing effect and efficiency are kept. The device has the advantages of being long in cleaning cycle, high in VOCs processing efficiency and the like, and is suitable for processing VOCs pollution in related industries.

Owner:DALIAN UNIV OF TECH

Spark plug

ActiveUS7781949B2Efficient heatingIncreased durabilitySparking plugsCombustion chamberNuclear engineering

Owner:NGK SPARK PLUG CO LTD

A kind of preparation method of surface modification layer of iron-containing aluminum intermetallic compound

ActiveCN106245023BImprove production efficiencyLow costHeat inorganic powder coatingPulse dischargeBinding force

The invention discloses a surface modification layer containing an iron and aluminum intermetallic compound and a preparation method of the surface modification layer. The preparation method comprises the following steps: taking an aluminum powder pressing body as a tool electrode, taking aluminum powder and coal oil mixed liquid as working liquid, and taking common low-carbon steel as a workpiece; enabling pulse discharge to be generated between the electrode and the workpiece in the working liquid by using a common electric spark machine tool; enabling the electrode, aluminum in the working liquid and iron in the workpiece to carry out in-situ alloying reaction with the aid of discharge energy; and finally, forming the surface modification layer containing the iron and aluminum intermetallic compound on the surface of the workpiece. The modification layer prepared by the method has the advantages of compact structure, good basic binding force and the like, and is expected to be widely used in the field of surface modification for improvement of corrosion resistance and wear resistance of structure materials.

Owner:GUANGDONG UNIV OF TECH

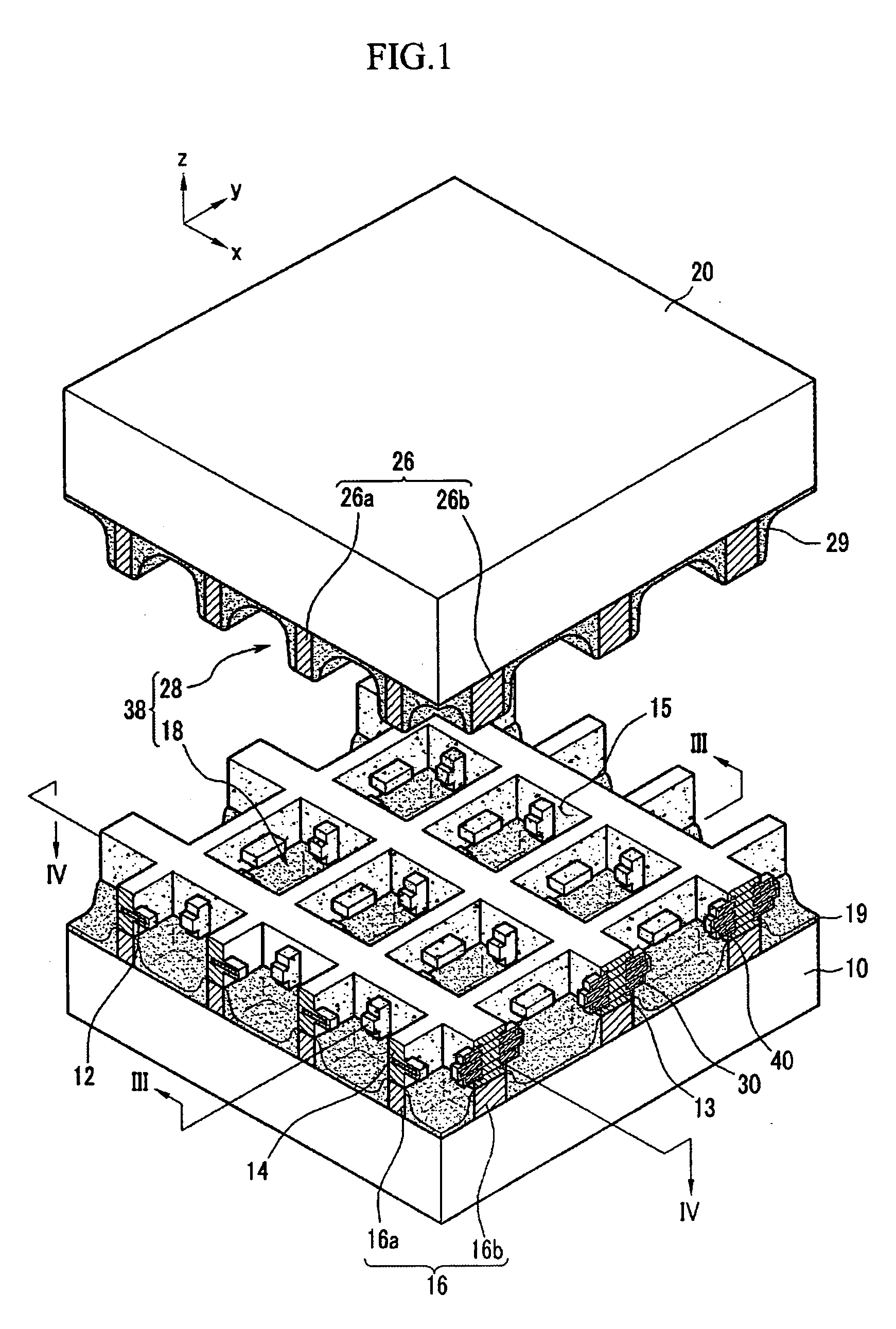

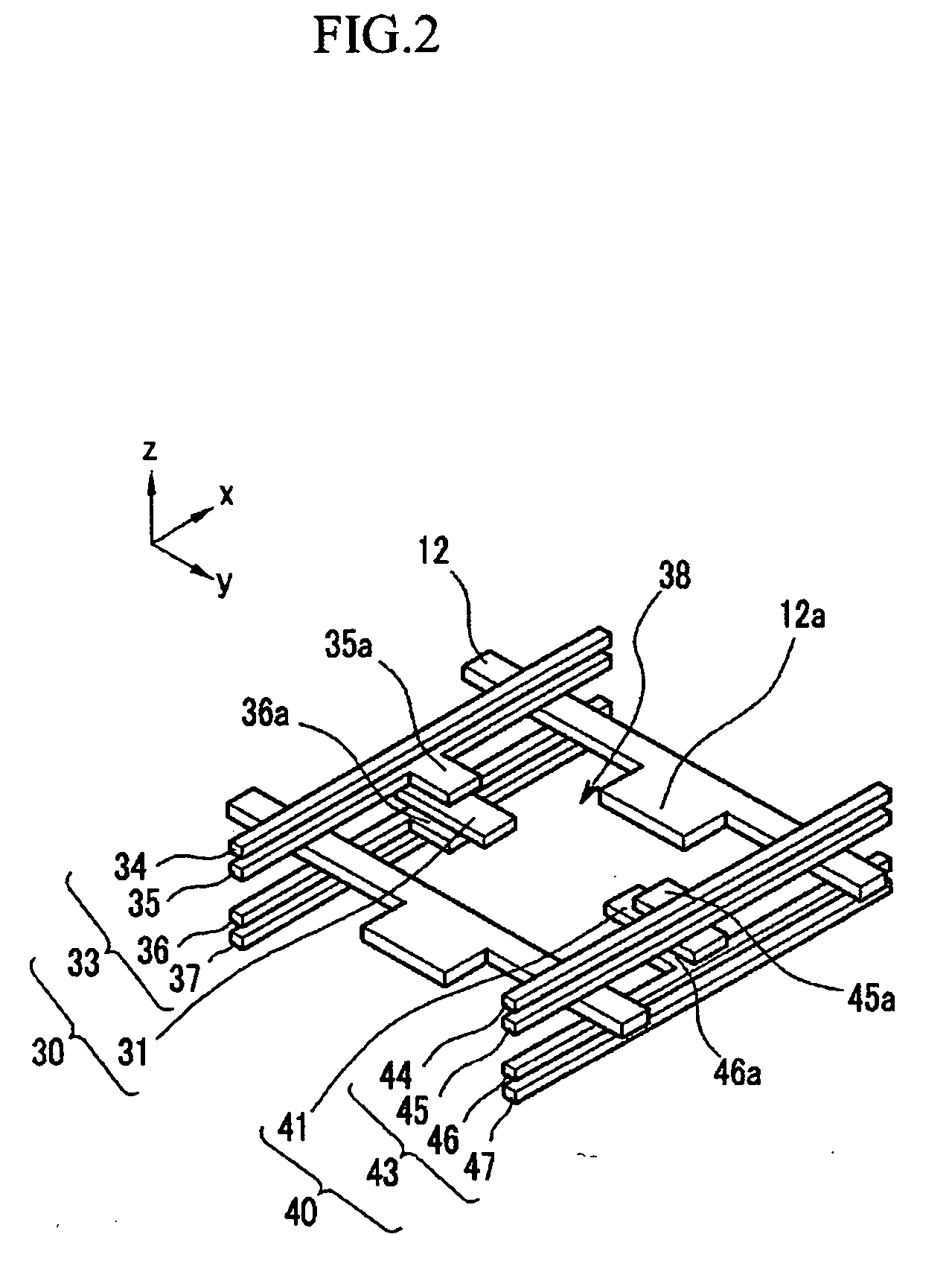

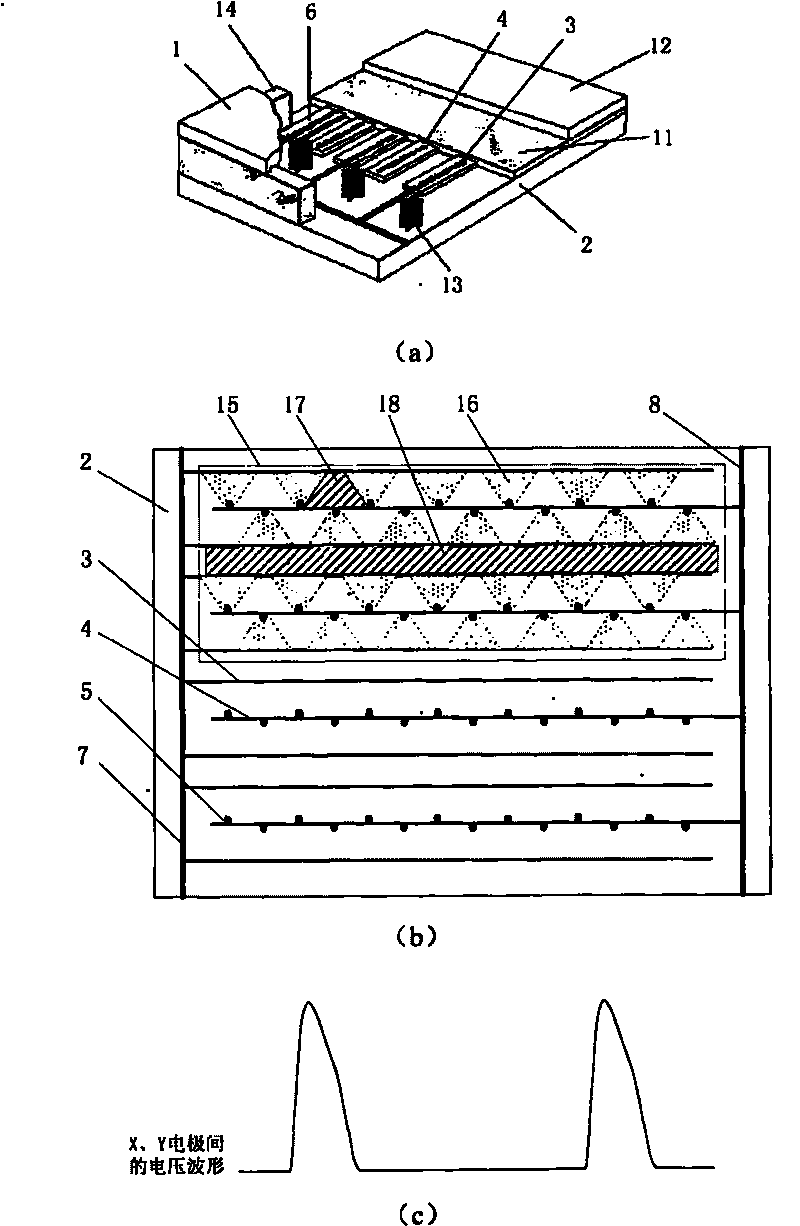

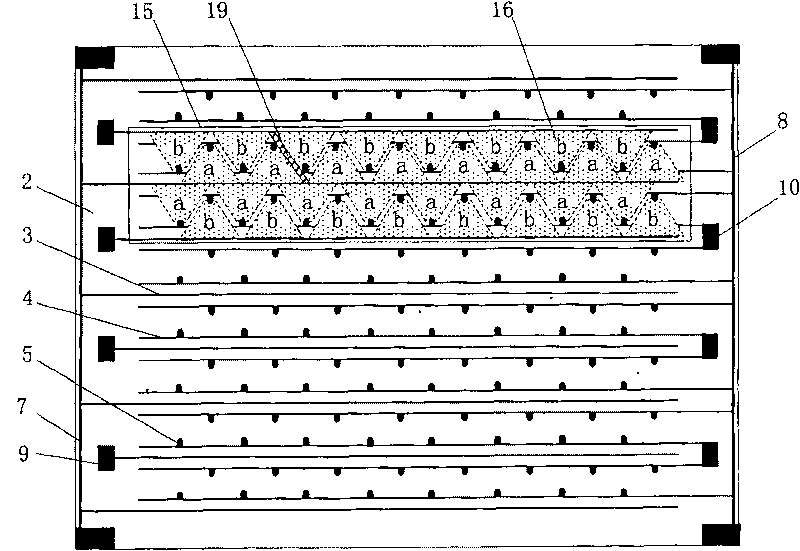

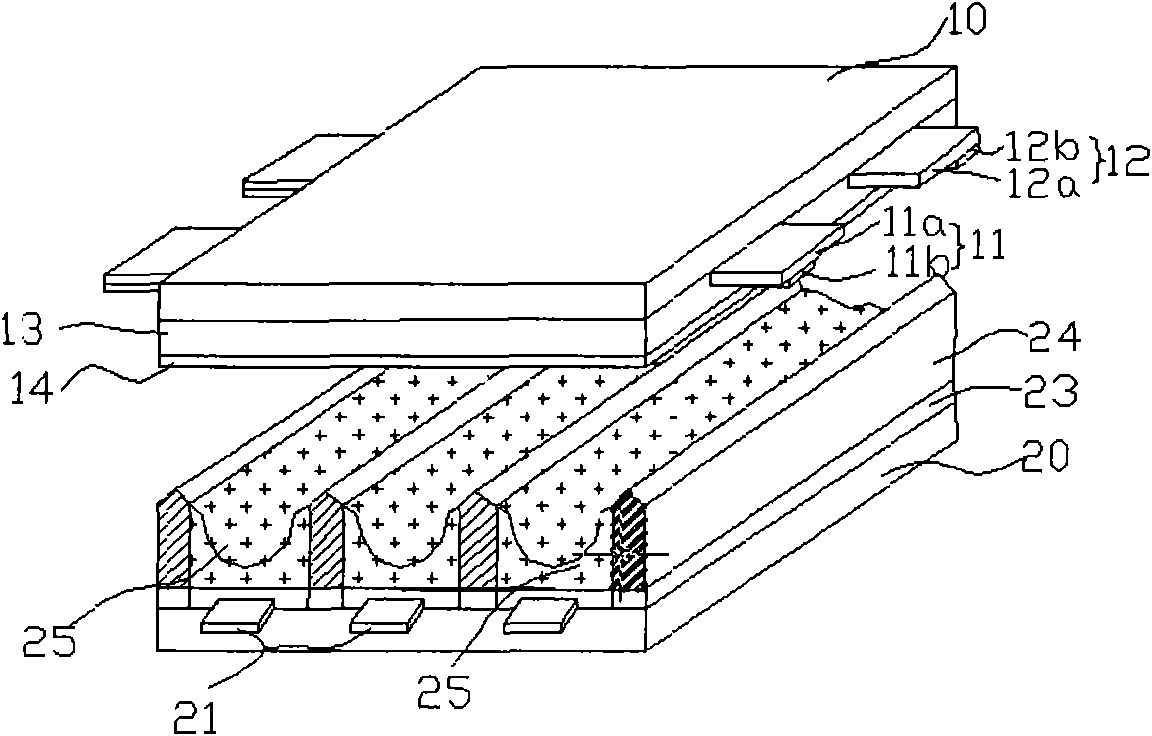

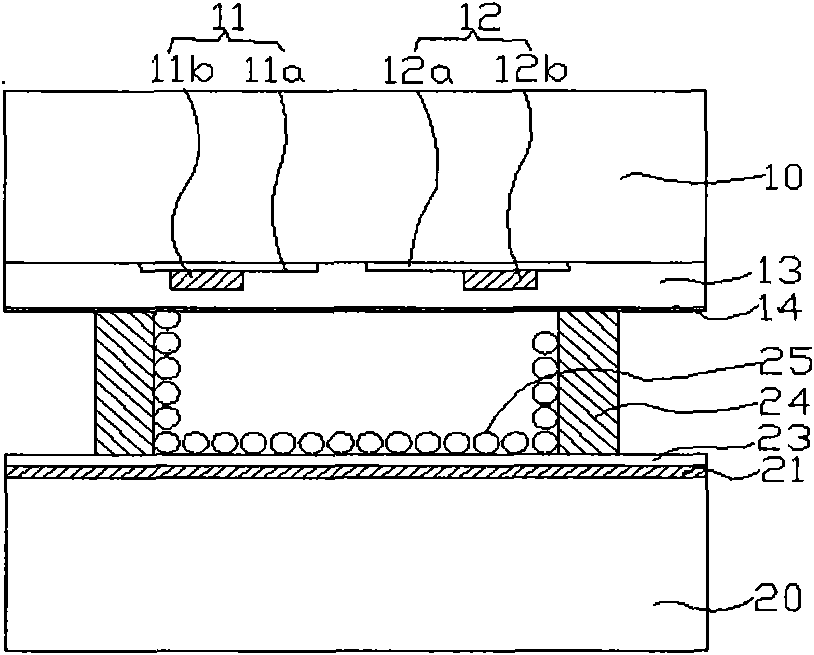

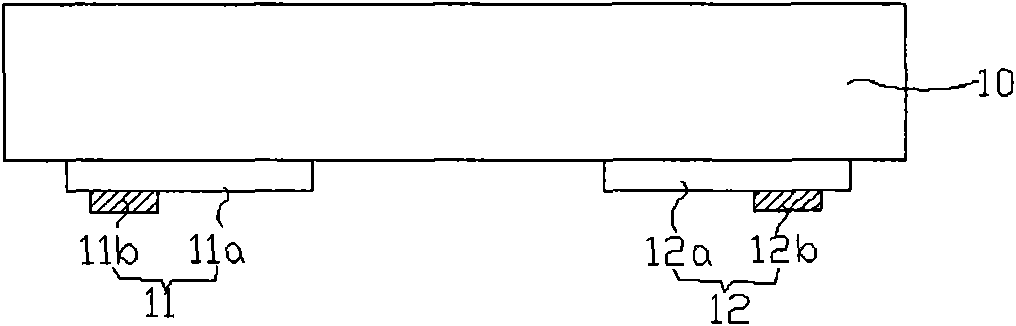

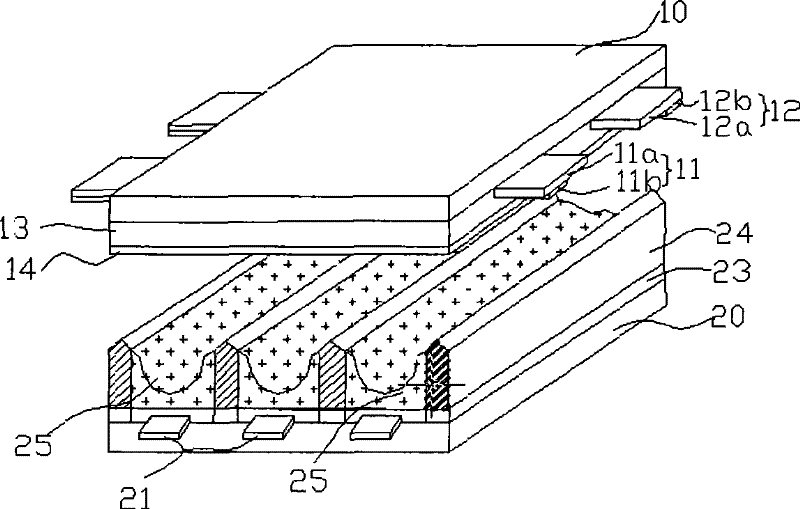

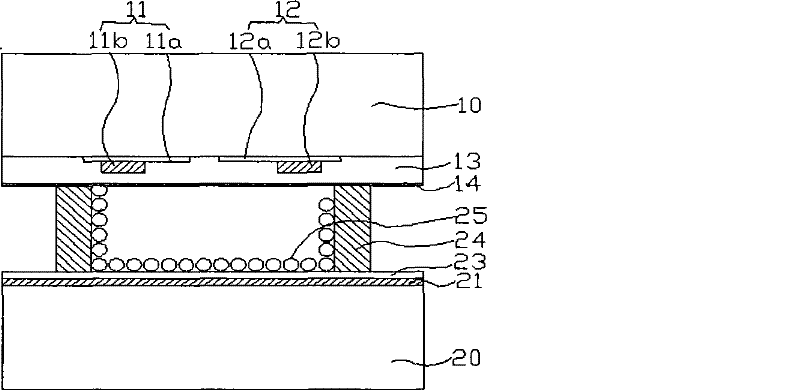

Plasma display panel (PDP)

InactiveUS20060175974A1Improve efficiencyLow production costAddress electrodesSustain/scan electrodesPhosphorPlasma display

A Plasma Display Panel (PDP) having enhanced efficiency includes: first and second substrates arranged facing each other and defining a space therebetween partitioned into at least one discharge cell; a phosphor layer arranged in the at least one discharge cell; an address electrode arranged along a first direction in the space between the first and second substrates; and first and second electrodes electrically insulated from the address electrode and arranged along a second direction crossing the first direction at opposite sides of each of the at least one discharge cells in the space between the first and second substrates. At least one of the first and second electrodes includes a plurality of electrode portions that are separate from each other.

Owner:SAMSUNG SDI CO LTD

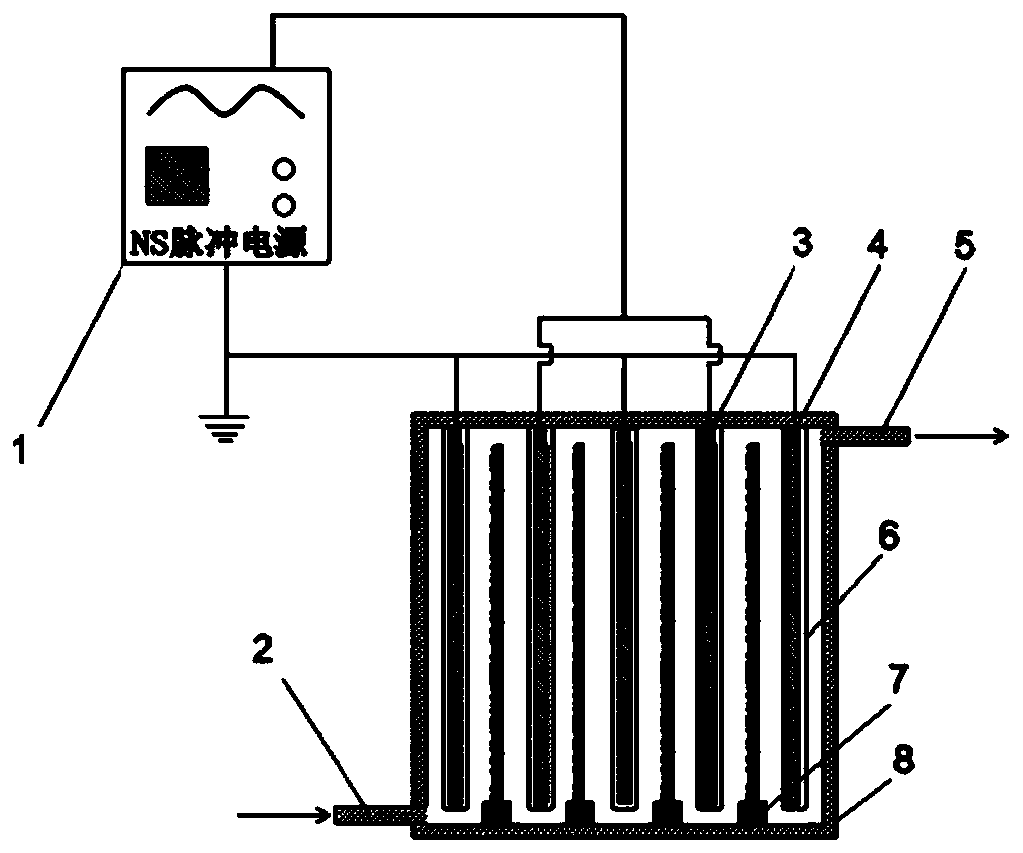

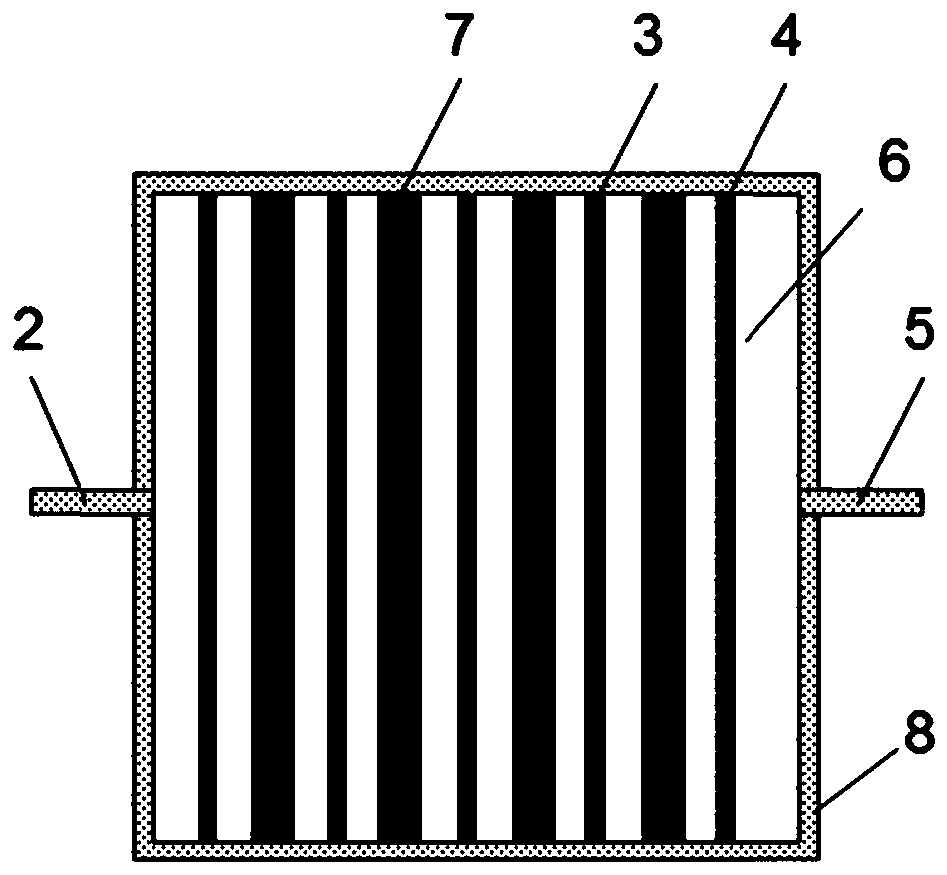

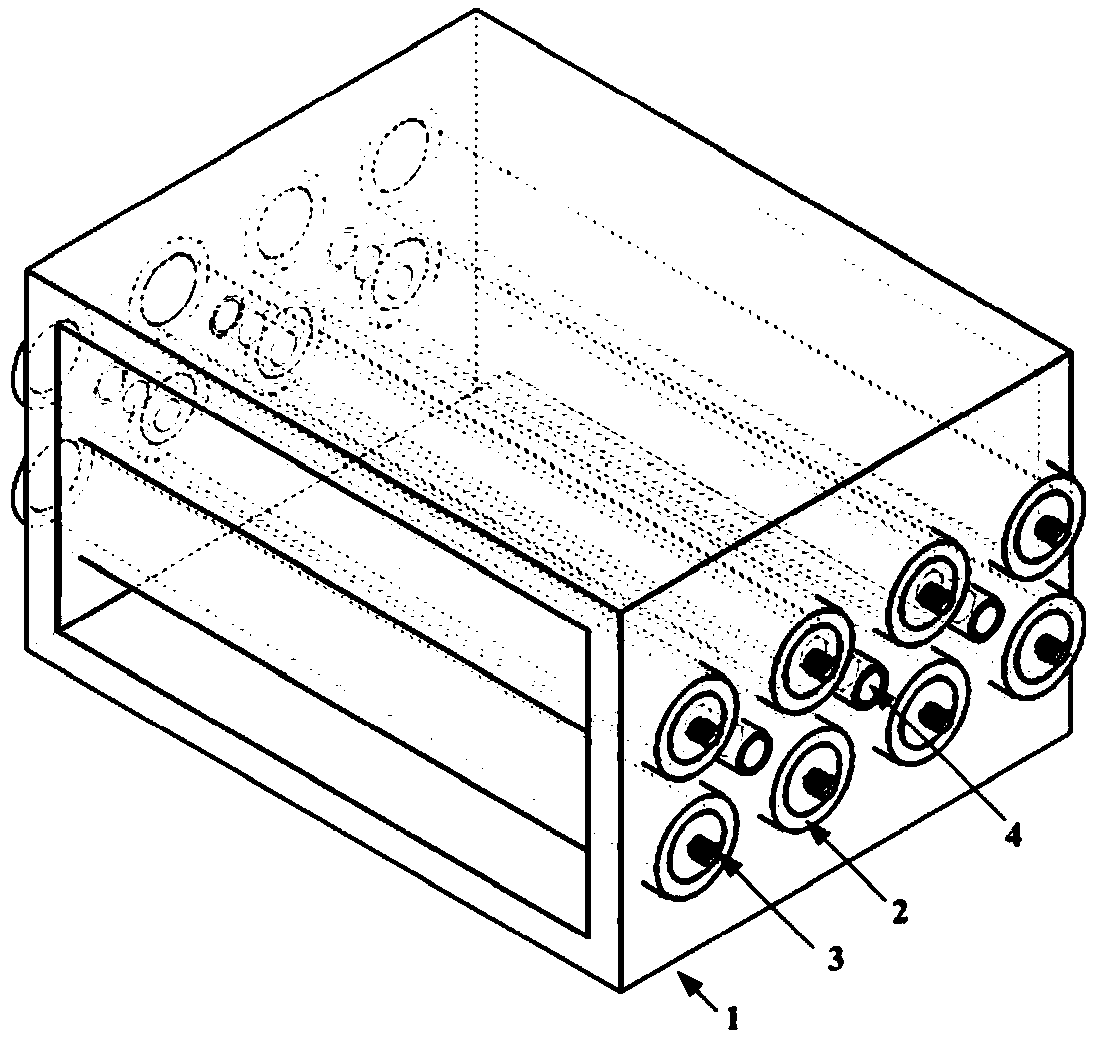

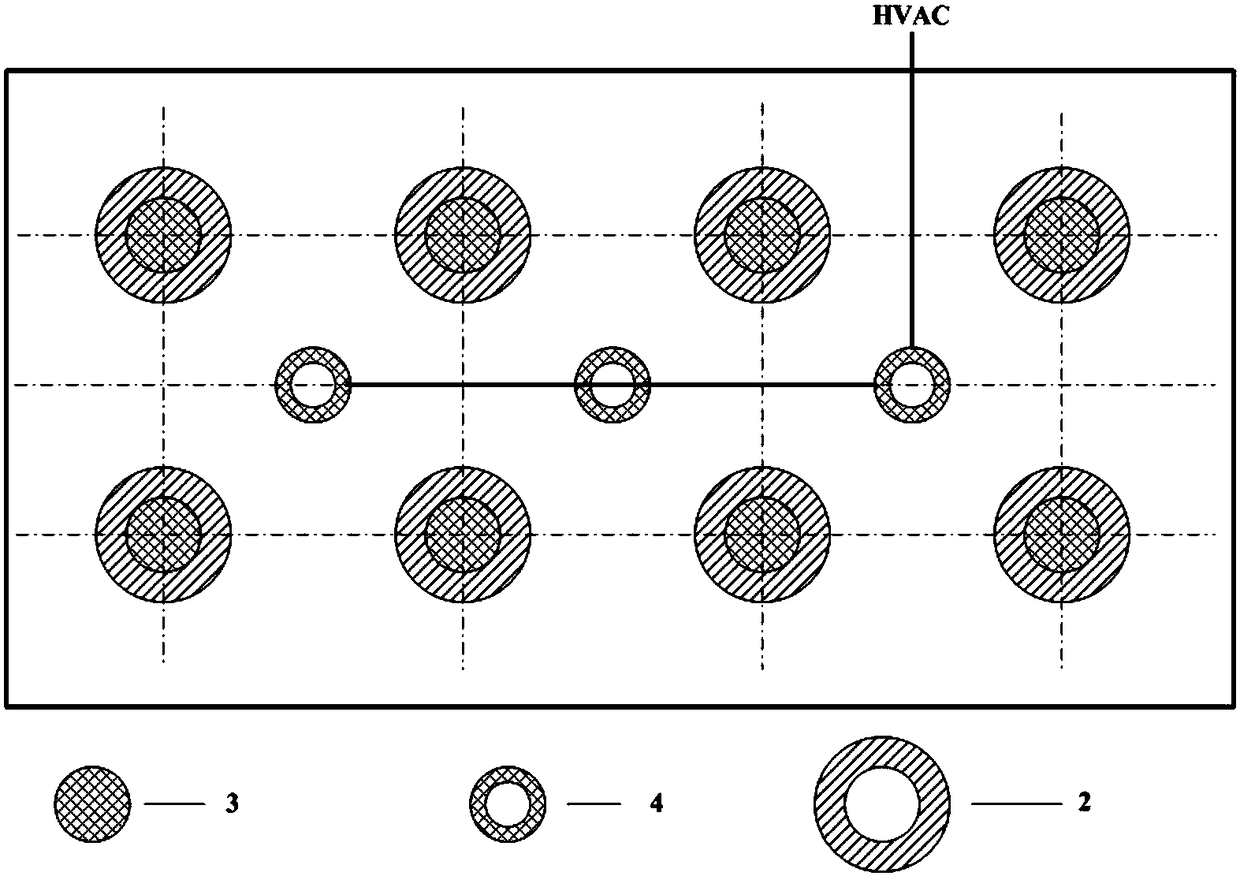

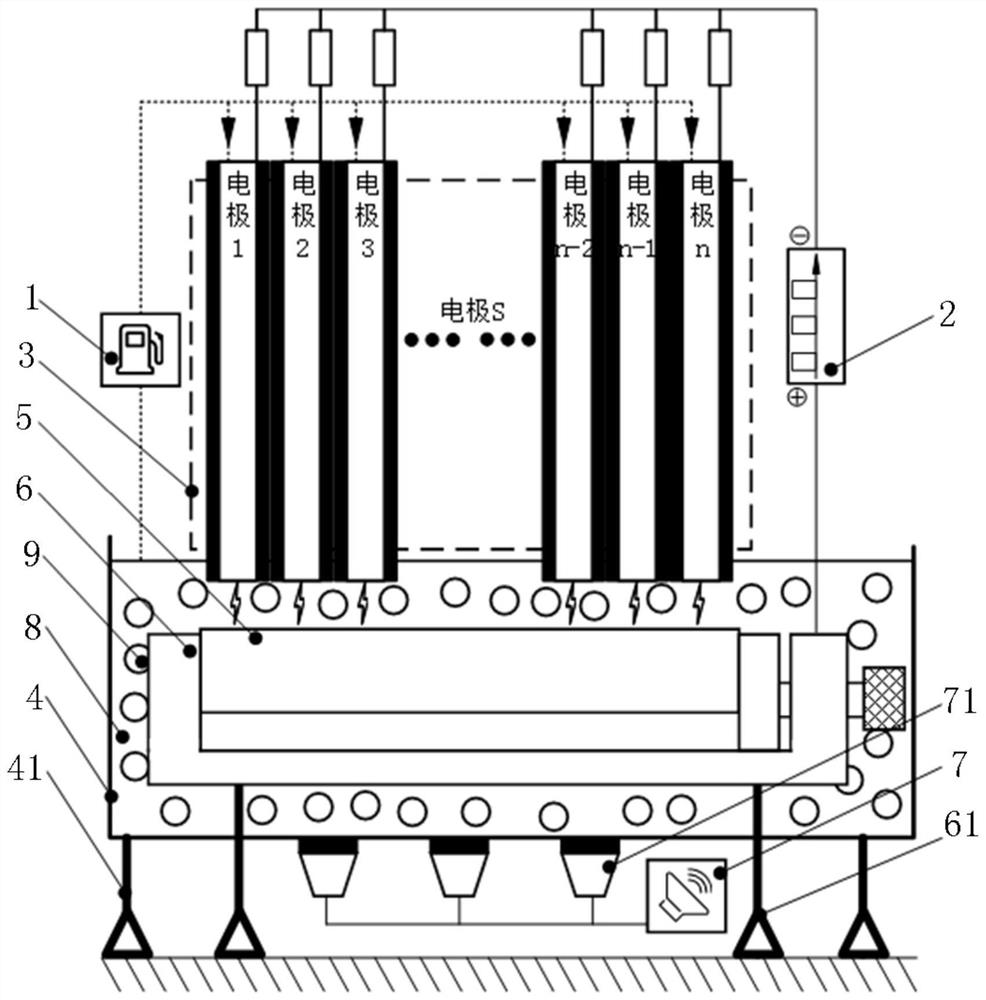

Large-gap uniform dielectric barrier discharge plasma surface treatment device under atmospheric pressure

The invention relates to a large-gap uniform dielectric barrier discharge plasma surface treatment device under atmospheric pressure. The treatment device comprises a closed reaction container, a working electrode arranged in the closed reaction container and a nanosecond pulse power supply (1) connected with the working electrode, wherein the working electrode comprises a plurality of outer-layercovering electrode media (6), low-voltage electrodes (4) and high-voltage electrodes (3), wherein the low-voltage electrodes (4) and the high-voltage electrodes (3) are distributed alternately; a fixing groove (7) used for fixing materials to-be treated is formed between adjacent electrodes; the closed reaction container comprises an air inlet (2) and an air outlet (5), and an S-shaped air flow channel is formed between the air inlet 2 and the air outlet 5. Compared with the prior art, uniform dielectric barrier discharge with the discharge gap larger than 5 mm can be achieved, proper gas canbe introduced in the discharge process, and meanwhile the treatment device has the advantages of being large in discharge gap, large in discharge power, capable of achieving normal-pressure operation, uniform in material surface treatment and the like.

Owner:SHANGHAI JIAO TONG UNIV

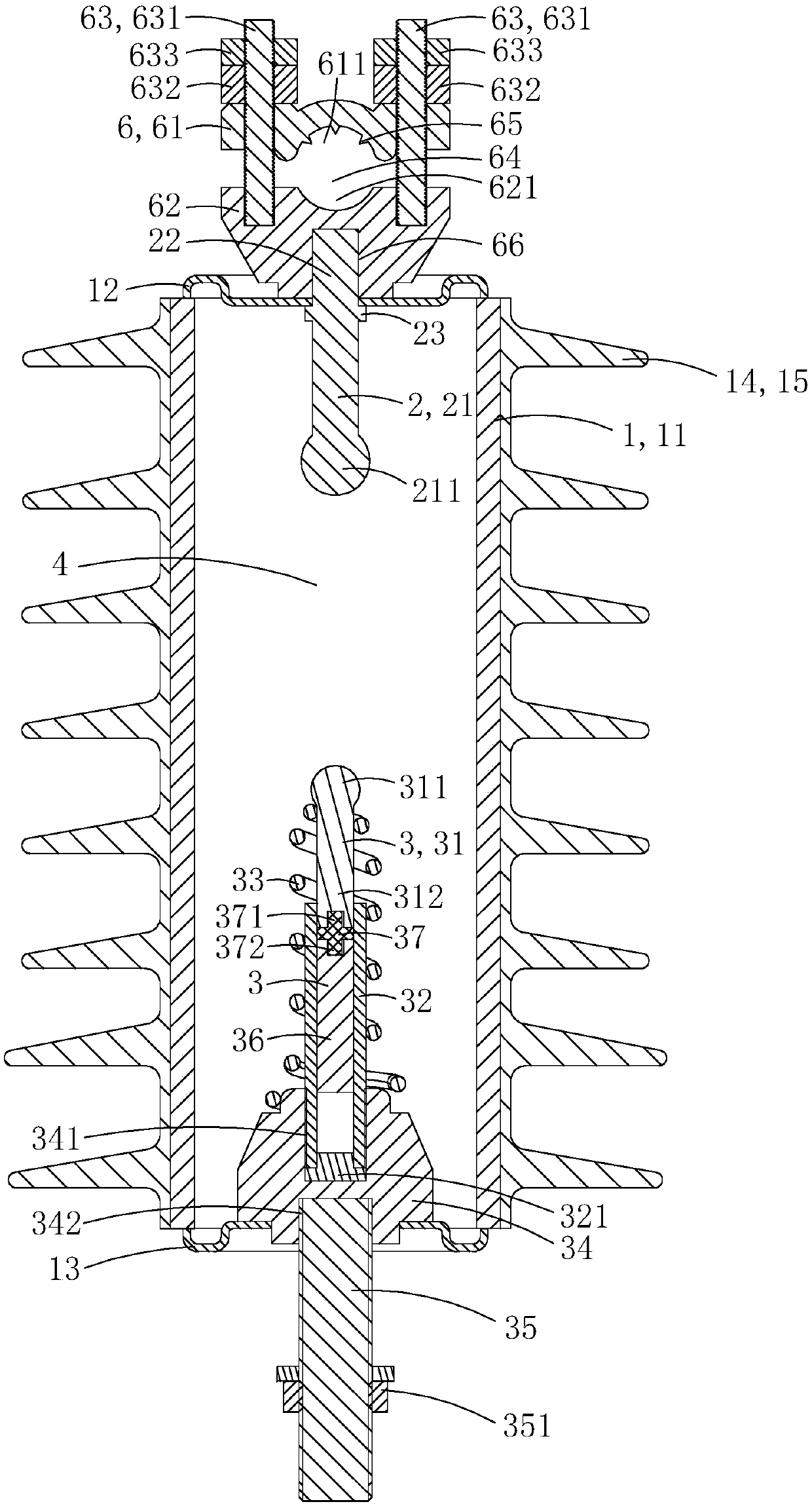

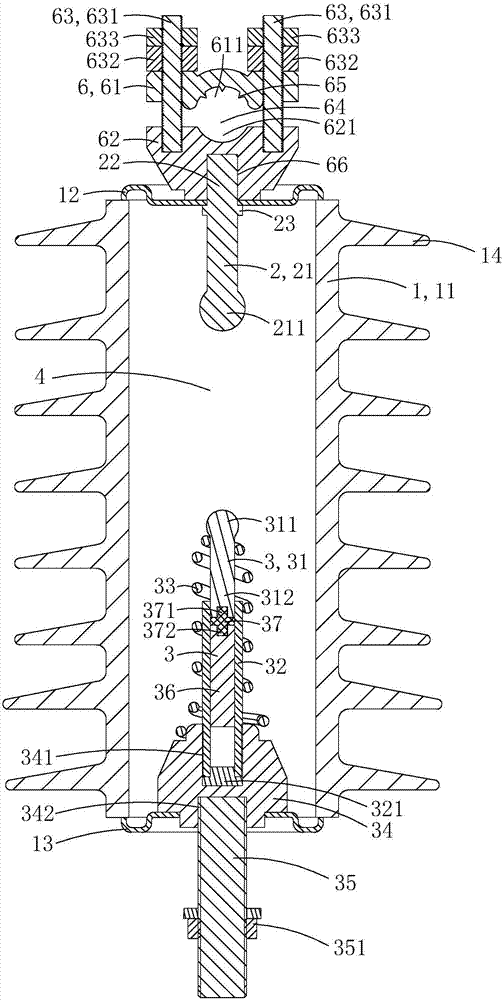

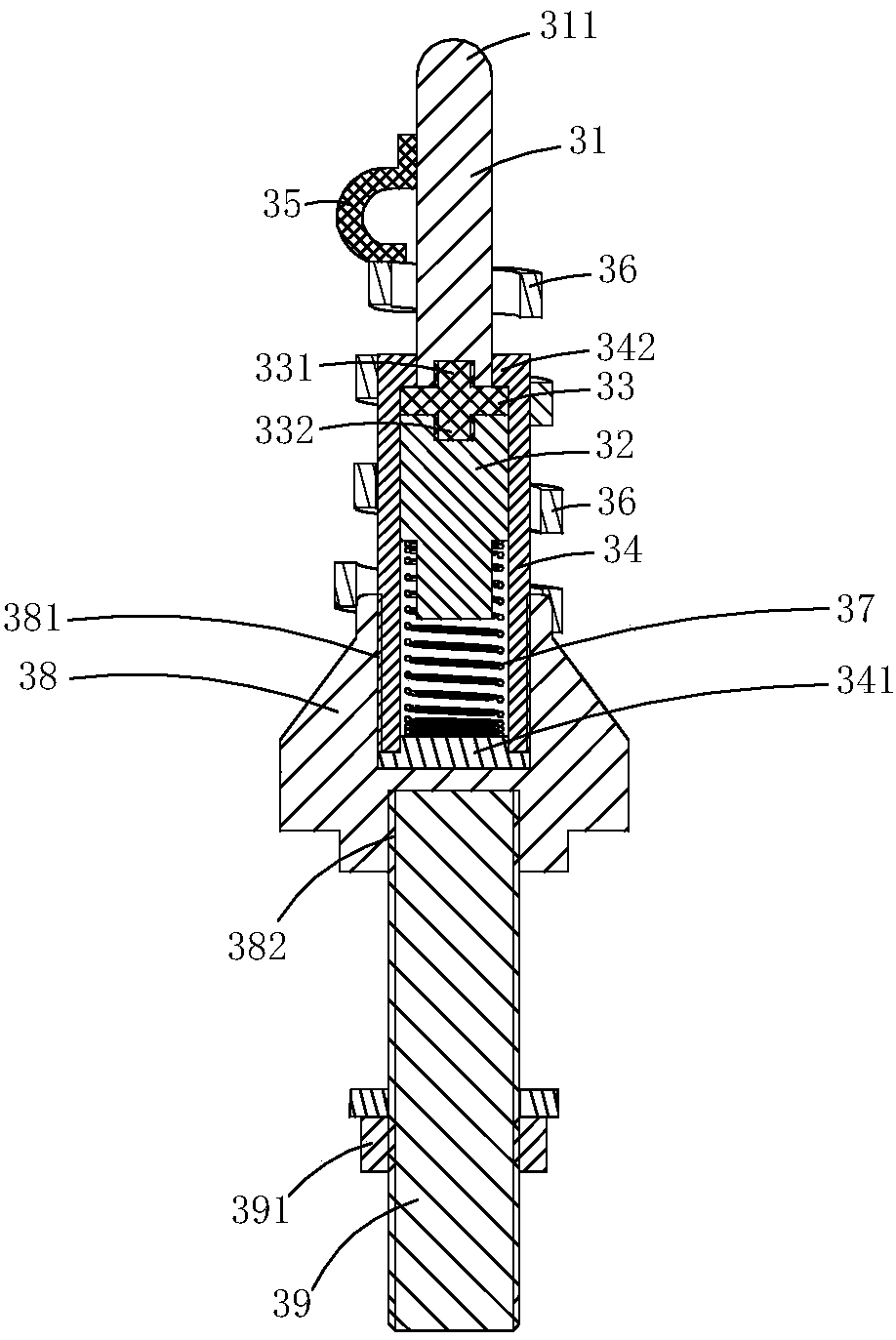

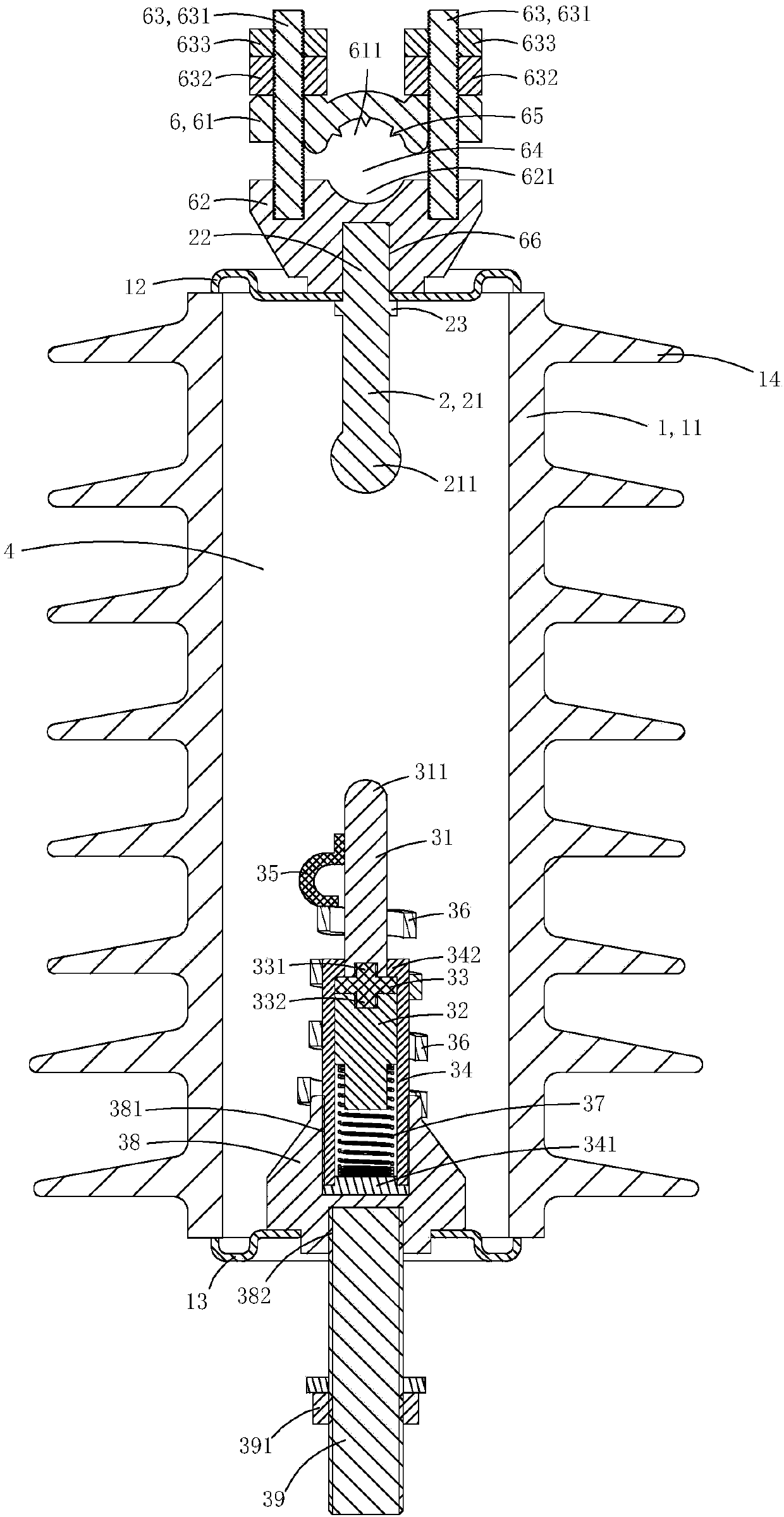

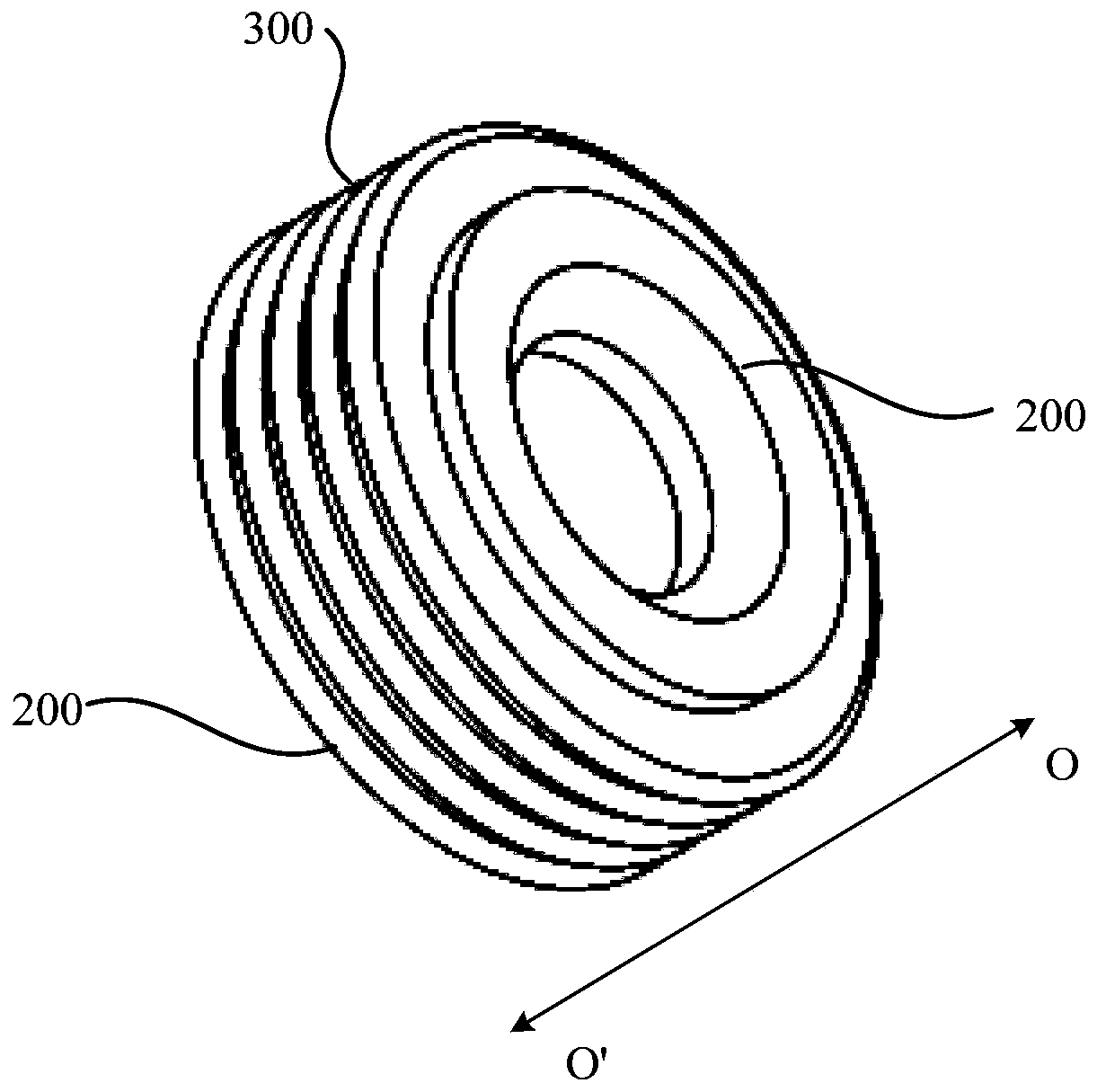

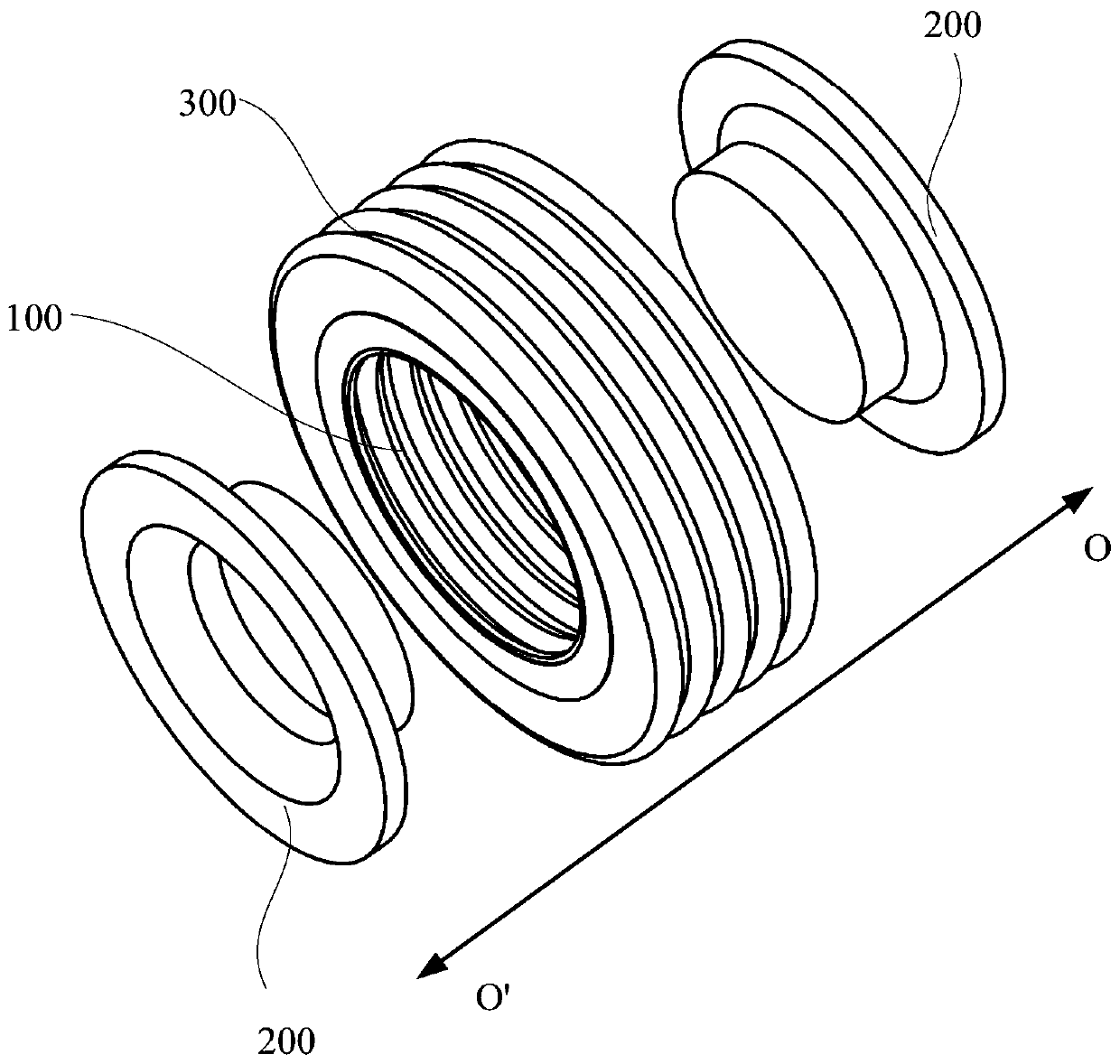

Lightning protection supporting column insulator capable of enlarging discharge gap by elastic conductive coil

The invention discloses a lightning protection supporting column insulator capable of enlarging discharge gap by an elastic conductive coil. The lightning protection supporting column insulator comprises an insulator, an upper discharge part and a lower discharge part; a sealing cavity is formed in the insulator; the upper discharge part has an upper discharge end on the upper part of the sealingcavity; the lower discharge part comprises a lower discharge rod with a lower discharge end, an insulating sliding pipe, a core rod glidingly arranged in the insulating sliding pipe, an insulation connecting piece used for connecting the lower discharge rod and the core rod in an insulating manner, the elastic conductive coil arranged on the insulating sliding pipe in a sleeving manner and used for generating electromagnetic force, a conductive mounting base and a conductive mounting supporting column; the upper end of the elastic conductive coil is fixedly connected with the lower discharge rod while the lower end of the elastic conductive coil is fixedly arranged on the conductive mounting base; and a discharge gap is formed between the upper discharge end of the upper discharge part andthe lower discharge end of the lower discharge rod. By virtue of the elastic conductive coil, electromagnetic force can be generated to drive the core rod and the lower discharge part to move downwardly to enlarge the discharge gap instantaneously; and in addition, reset elasticity can be provided for the lower discharge part, so that the initial position can be recovered after downward movement.

Owner:苏州麦飞尔电子科技有限公司

Lightning protection post insulator for resetting discharging gap by means of elastic conductive coil

The invention discloses a lightning protection post insulator which utilizes an elastic conductive coil to reset the discharge gap, which comprises an insulator, an upper discharge part and a lower discharge part; the inside of the insulator is provided with a sealed cavity; the upper discharge part is provided with an upper discharge terminal located on the upper part of the sealed cavity The lower discharge part includes a lower discharge rod, an insulating slide tube, an elastic conductive coil for providing a reset force for the lower discharge rod, a conductive installation base and a conductive installation pillar; the lower discharge rod is provided with a lower discharge end located at the lower part of the sealed cavity and a The end of the sliding column inserted into the insulating slide tube; the upper end of the elastic conductive coil is fixedly connected with the lower discharge rod, and the lower end of the elastic conductive coil is fixed on the conductive installation base; the upper discharge end of the upper discharge part and the lower discharge end of the lower discharge part There is a discharge gap. The invention utilizes the elastic conductive coil to generate electromagnetic force to drive the lower discharge part to move down to increase the discharge gap; on the other hand, it provides reset elastic force for the lower discharge part, which helps to reduce parts and simplify the structure.

Owner:苏州麦飞尔电子科技有限公司

A device for treating waste gas based on dielectric barrier discharge plasma

ActiveCN105920985BUniform discharge energyImprove processing efficiencyGas treatmentDispersed particle separationProduct gasHigh pressure

Owner:XI AN JIAOTONG UNIV

A multi-channel electrical discharge machining device based on ultrasonic vibration and its application method

ActiveCN113828873BEasy dischargeIncrease discharge gapMachining working media supply/regenerationElectrical-based auxillary apparatusElectric dischargeElectrolysis

The invention discloses a multi-channel electrical discharge machining device based on ultrasonic vibration and a method of use thereof, which includes a discharge circuit and a working fluid circulation pump. The sub-electrodes are correspondingly connected, and all the sub-electrodes are fixed in parallel as a multi-channel electrode. The upper end of the multi-channel electrode is the liquid inlet end, and the lower end is the discharge end. The positive pole of the power supply is connected to a metal fixture for fixing the workpiece to be processed. The metal fixture is erected in the working fluid tank through the fixture bracket. The outer wall of the working fluid tank is cemented with an ultrasonic vibrator, and the ultrasonic vibrator is equipped with an ultrasonic generator. The electrolytic gas film generated on the electrode surface is broken into bubbles by ultrasonic waves, and cavitation bubbles are generated. The generated bubbles cause electric field distortion in the working fluid, enhance discharge, increase the discharge gap, and make multi-channel discharge easier to occur.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Lower discharge piece used for gap lightning protection

InactiveCN107564629AReduce adverse factorsImprove stabilitySupporting insulatorsElectricityPower flow

The invention discloses a lower discharge piece used for gap lightning protection. The lower discharge piece comprises an insulating sliding pipe, a conducting coil which is arranged on the insulatingsliding pipe in a sleeving manner and is used for generating electromagnetic force, a lower discharge rod arranged at a lower discharge end, a flexible connector for electrically connecting the lowerdischarge rod and the top of the conducting coil, a core rod arranged in the insulating sliding pipe in a sliding manner, a reset spring for providing reset elastic force for the core rod, a conducting mounting base electrically connected with the bottom end of the conducting coil and a conducting mounting rack which stretches out an insulator downwards and is used for being mounted on a cross arm; and the lower discharge rod is fixedly connected with the core rod. The lower discharge piece is beneficial for turning off power-flow current.

Owner:卢永星

Plane fluorescent lamp

InactiveCN101114566BReduce or completely eliminate non-luminous areasHigh densityGas discharge lamp detailsPhosphorFluorescence

Owner:XI AN JIAOTONG UNIV

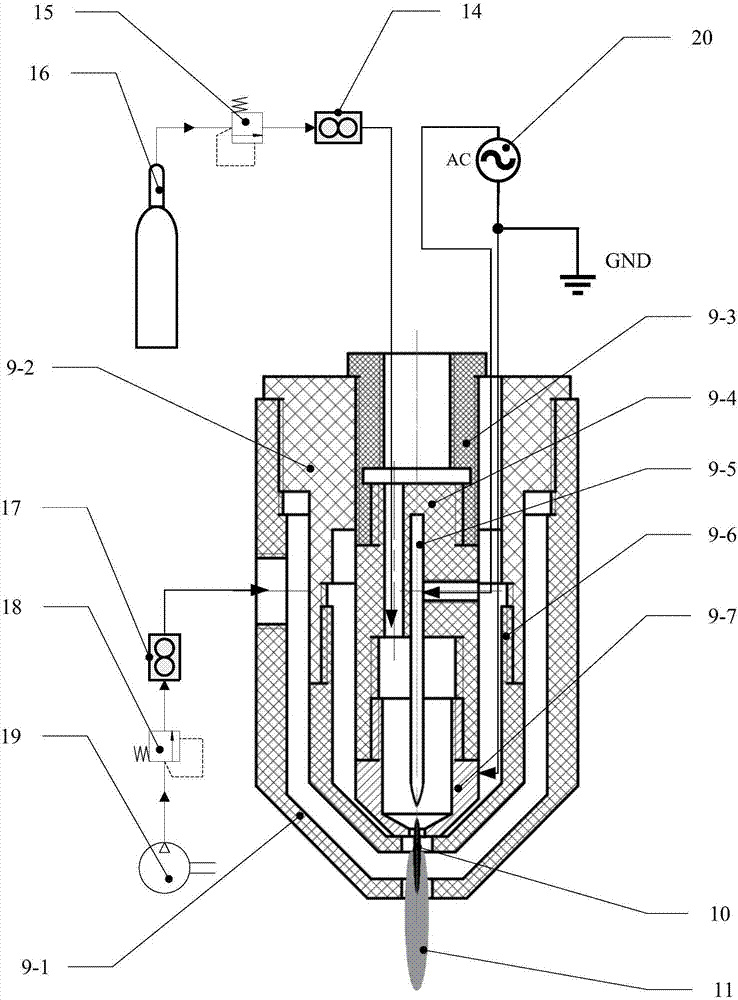

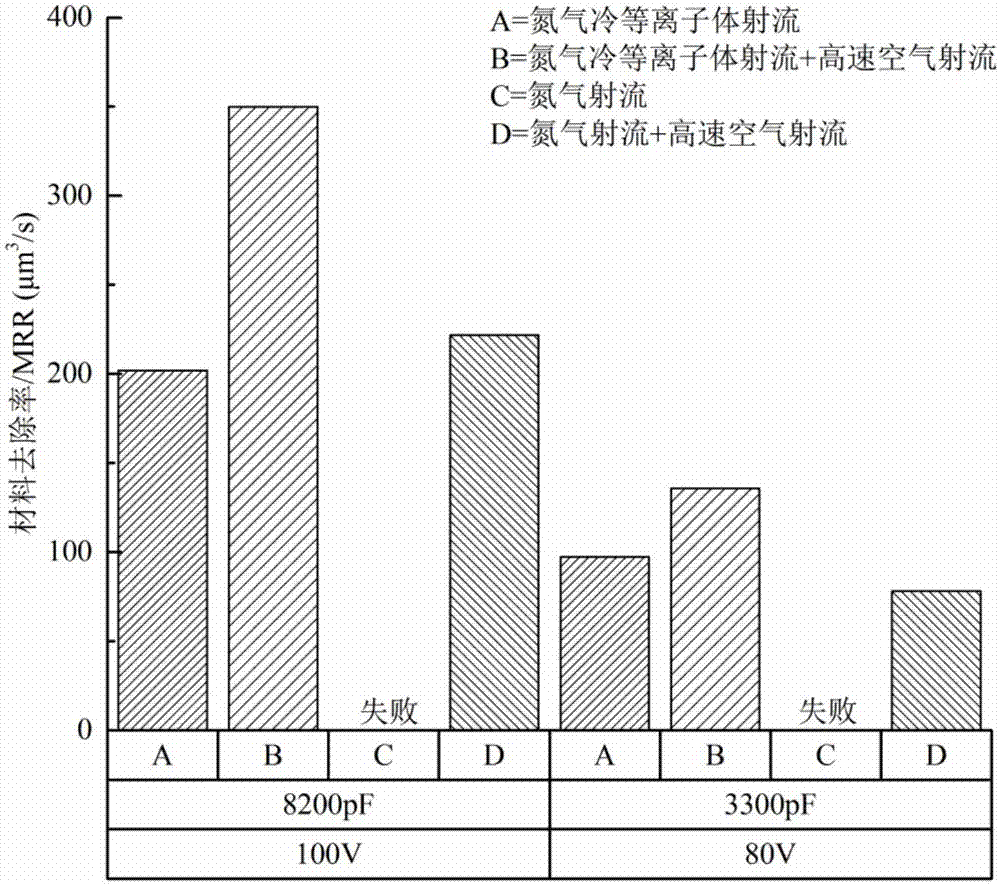

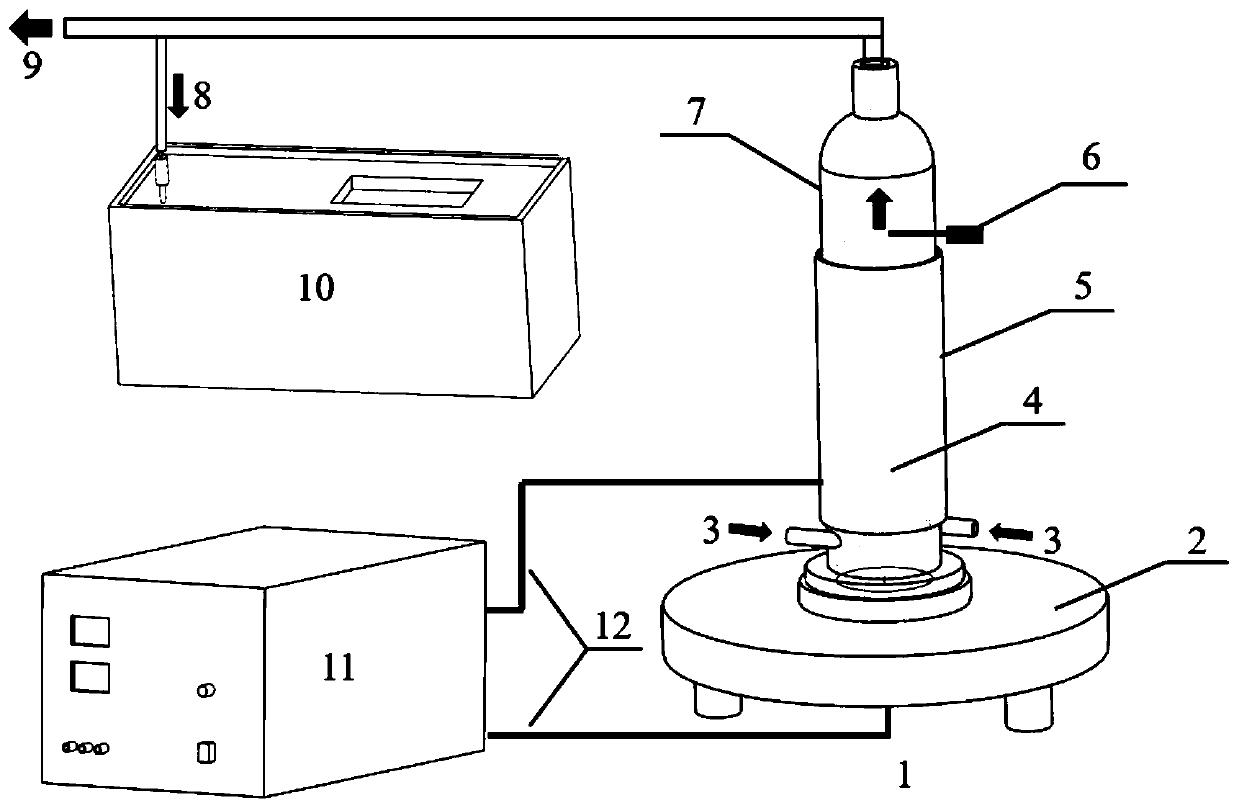

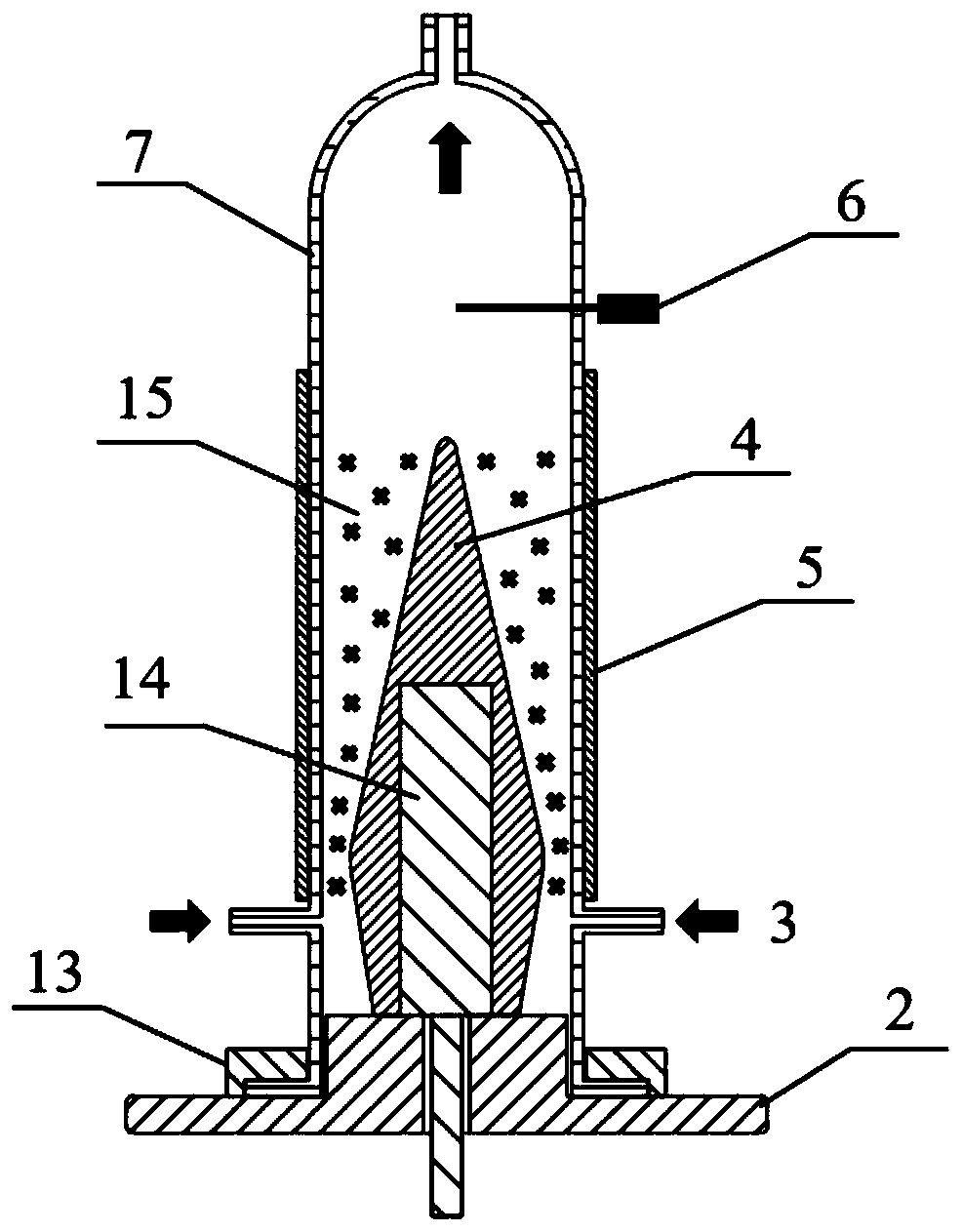

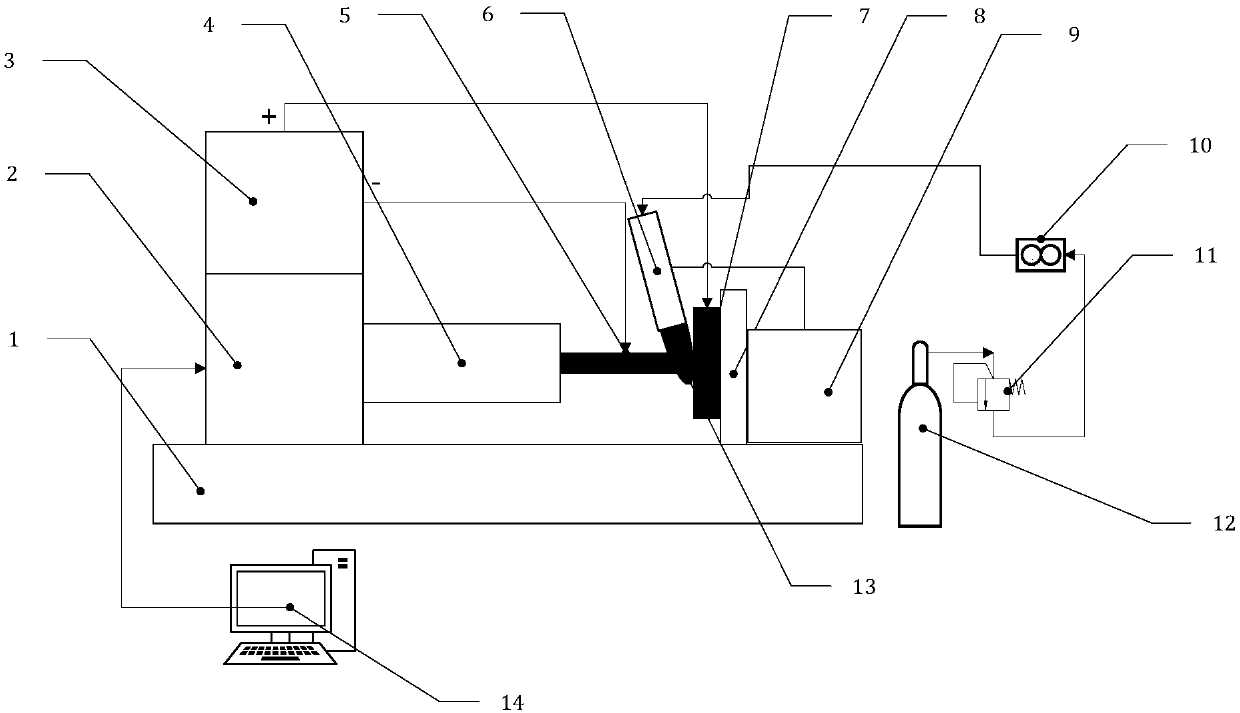

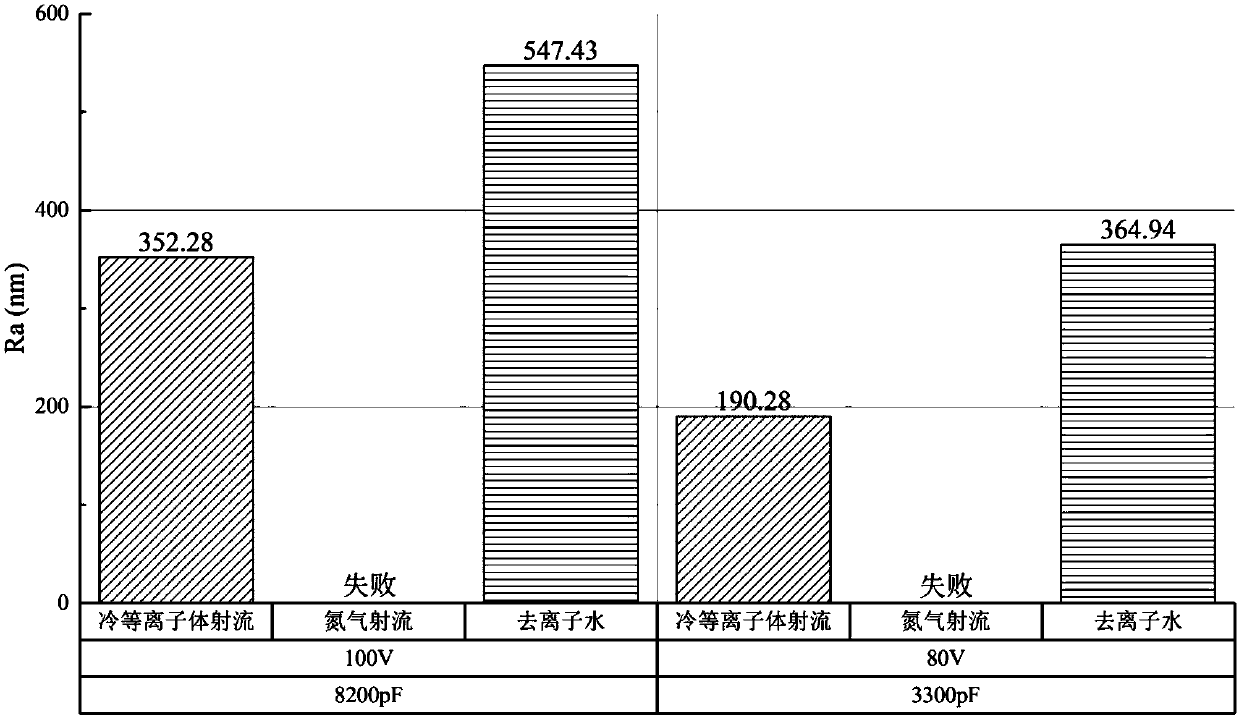

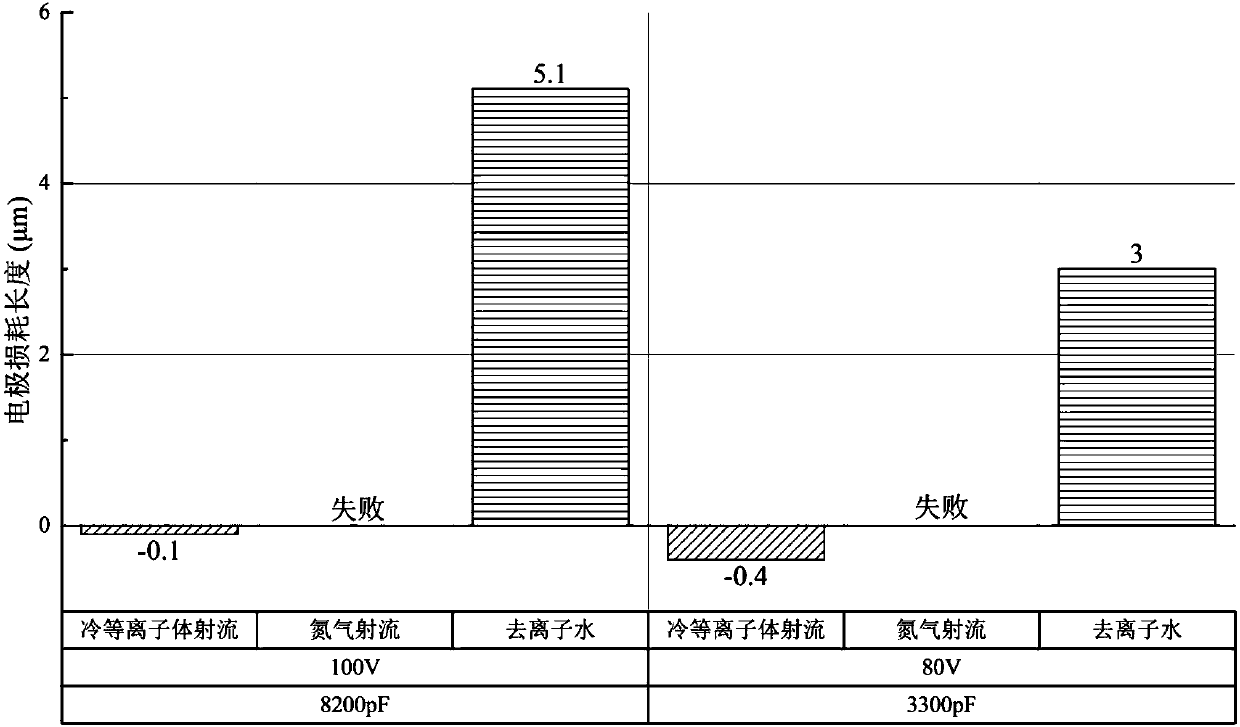

An Atmospheric Pressure Cooled Plasma Jet Electric Discharge Machining Device

InactiveCN106513881BHigh removal rateAtmospheric Cooled Plasma Jet with Coaxial High Removal EfficiencyPlasma jetElectric discharge

The invention relates to a method and device capable of improving the machining efficiency of electric sparks in atmospheric pressure cold plasma jet, and belongs to the field of machining and tools. According to the method, a mixed medium based on the cold plasma jet and cold plasma jet and coaxial high-speed jet generated by a coaxial high-speed jet composite generation device serves as an electric spark machining medium; before machining, a workpiece, a tool electrode and the corresponding polarity of a pulse generator are connected, the positions of a cold plasma jet generator and a coaxial high-speed airflow nozzle are adjusted, and therefore the electrode end and the to-be-machined area of the workpiece are completely immersed in the mixed medium; according to the method and device capable of improving the machining efficiency of the electric sparks in atmospheric pressure cold plasma jet, under the same machining condition, the material removing rate higher than that of a pure cold plasma jet is obtained, and the machining quality better than that in the mixed medium of nitrogen gas jet and high-speed air jet is obtained.

Owner:DALIAN UNIV OF TECH

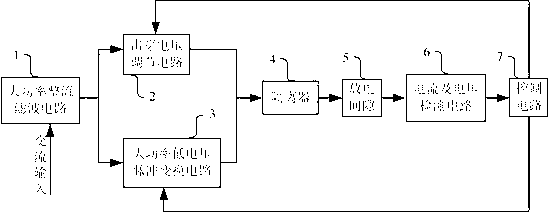

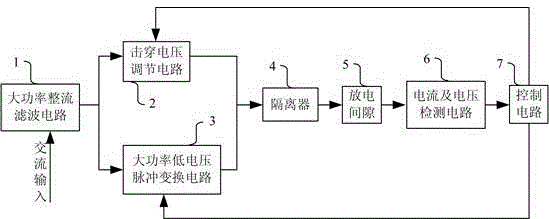

High-instantaneous-energy-density electric spark high-speed milling power supply device

ActiveCN103008803AIncrease energy densityReduce relative lossElectric circuitsLow voltagePeak current

The invention relates to an electric spark machining power supply device, i.e., a high-instantaneous-energy-density electric spark high-speed milling power supply device, in the field of machining. The device comprises a high-power rectifying and filtering circuit 1, a breakdown voltage regulating circuit 2, a high-power low-voltage pulse conversion circuit 3, an isolator 4, a current and voltage detection circuit 6 and a control circuit 7. According to the power supply device, on one hand, higher breakdown voltage can be provided for a discharge gap to increase the discharge gap and reduce collision probability of machining chips and a tool electrode, so as to reduce relative loss of the tool electrode, and on the other hand, the power supply device can also provide higher peak current for a discharge passage, so that the energy density of a discharge passage acting on the surface of a workpiece is guaranteed, and the machining efficiency can be greatly increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A gas discharge tube and overvoltage protection device

ActiveCN108257835BIncrease discharge gapPrevent cracking and air leakageElectrode dispositionOvervoltageEngineering

The embodiment of the invention discloses a gas discharge tube and an overvoltage protection device. The gas discharge tube comprises a sealing discharge cavity and at least two conductive electrodes,wherein the inner portion of the sealing discharge cavity is filled with discharge gas; discharge electrode faces of the at least two conductive electrodes are located on the inner surface and / or inner portion of the sealing discharge cavity; the sealing discharge cavity comprises at least one telescopic part, and the at least one telescopic part seals partial regions of the sealing discharge cavity; the at least one telescopic part is used for discharging between the at least two conductive electrodes, so that when the discharge gas is heated to expand, the at least one telescopic part stretches or retracts to enlarge a discharging gap between the discharge electrode faces of the at least two conductive electrodes, and so that the follow current of the gas discharge tube is blocked. According to the technical scheme of the gas discharge tube and the overvoltage protection device, effective overvoltage protection can be realized, and after the overvoltage disappears, the follow current flowing through the gas discharge tube can be automatically and effectively blocked.

Owner:SHENZHEN BENCENT ELECTRONICS CO LTD

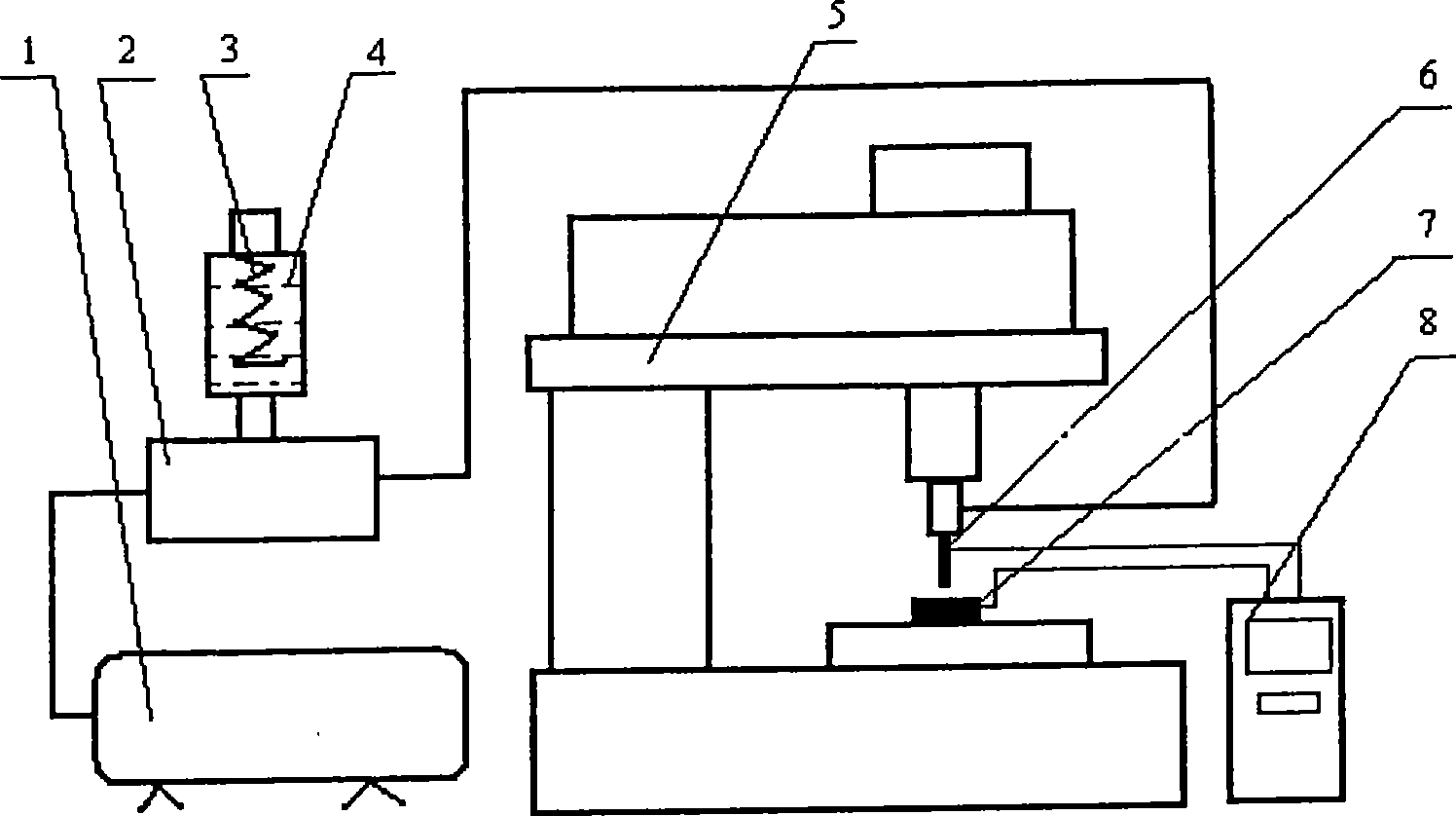

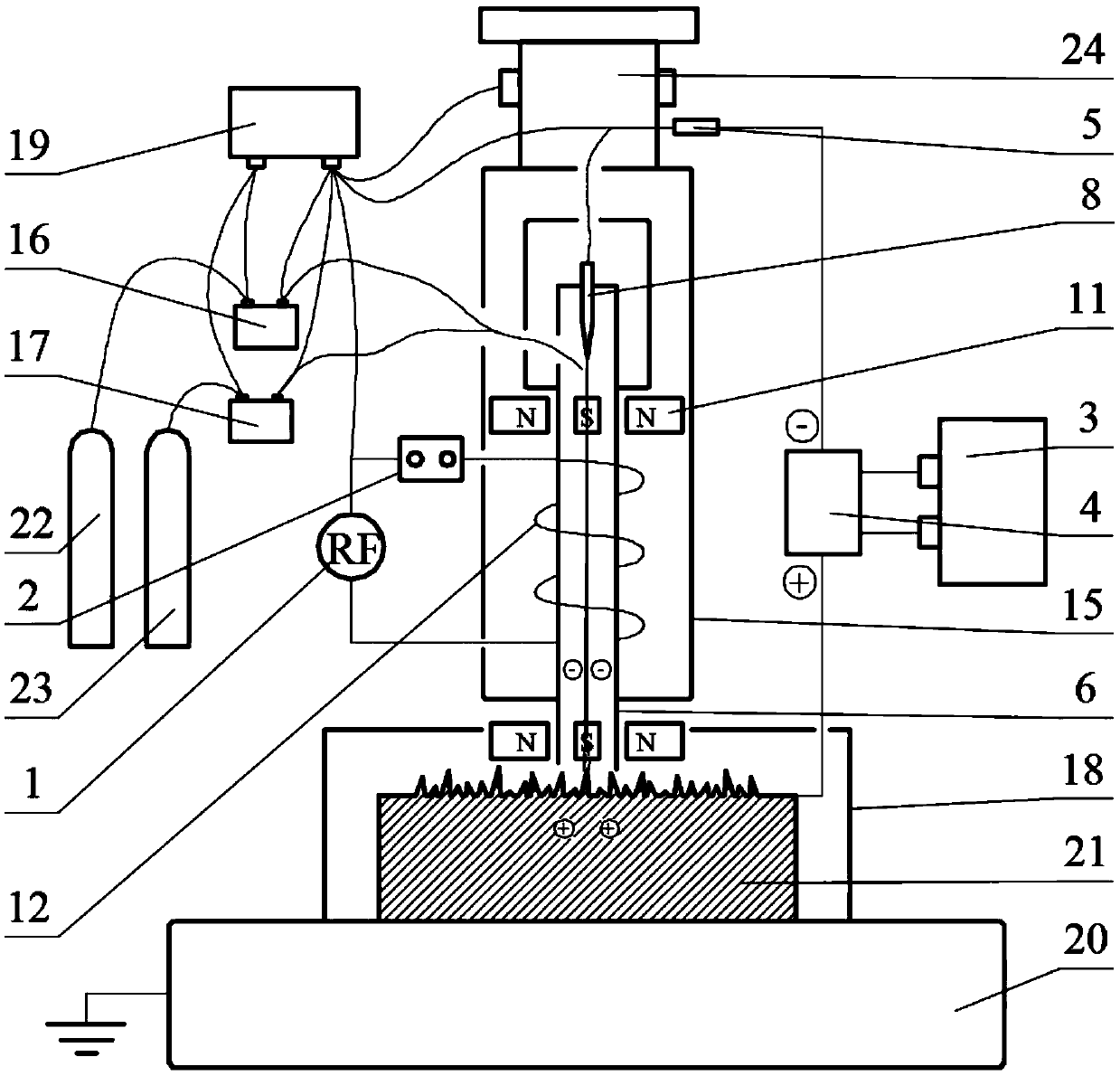

Plasma and pulse discharge composite polishing processing device for large complex metal surfaces

ActiveCN104108054BNo lossAvoid problems such as pollutionHigh-voltage direct currentPulse power supply

The invention relates to a plasma and pulse discharge composite polishing device for a large-scale complicated metal surface. The plasma and pulse discharge composite polishing device for the large-scale complicated metal surface aims to solve the problems that according to a conventional metal surface precise polishing method, the polishing efficiency is low, machining stress is prone to generation, and the surface is prone to damage are solved. The plasma and pulse discharge composite polishing device comprises a radio frequency power supply, a radio frequency power supply adapter, a high-voltage direct-current pulse power supply, a pulse power supply polarity adjusting device, a high-voltage direct-current pulse power supply impedor, a plasma torch, a polishing protective cover, a control circuit and a linkage mechanism. According to the plasma and pulse discharge composite polishing device for the large-scale complicated metal surface, precise machining and polishing are conducted on the metal surface at the atmosphere pressure, a vacuum chamber and a special polishing solution are not needed, equipment cost can be reduced, the application range is widened, the machining efficiency is several times as high as that of a traditional polishing method, unstressed machining is conducted, surface damage and subsurface damage are avoided, surface pollution is avoided, and the surface roughness of a polished workpiece can reach Ra0.2 micrometer.

Owner:HUAZHONG UNIV OF SCI & TECH

Impulsing power source for spark pinhole processing

InactiveCN101318241BReduce lossAvoid lossElectric circuitsNumerical controlHigh-voltage direct current

The invention discloses electric spark microhole processing pulse power supply suitable for the numerical control electrical discharge wire-cutting, which comprises a main vibration circuit, a drivingcircuit, a detection circuit, a non-normal spark treatment module in breakdown cycle, a non-normal spark treatment module in heavy current processing cycle, the high voltage direct current power supply, the medium voltage direct current and a power amplification circuit; wherein, the non-normal spark treatment module in breakdown cycle and the non-normal spark treatment module in heavy current processing cycle are arranged between the main vibration circuit and the detection circuit which is used in the real time online detection of gap discharge state; the signals of the no-loaded cycle in breakdown are adopted as the waiting signals of the main vibration circuit, and the signals of the heavy current processing cycle are adopted as trigger signals of the intermittent inhibitive cycle ofthe main vibration circuit; the switching of the multifunctional processing circuit and the working modes of two power supplies on the same wire-cutting machine can be realized by controlling the on andoff time of a first power switch tube (T1).

Owner:HARBIN INST OF TECH +1

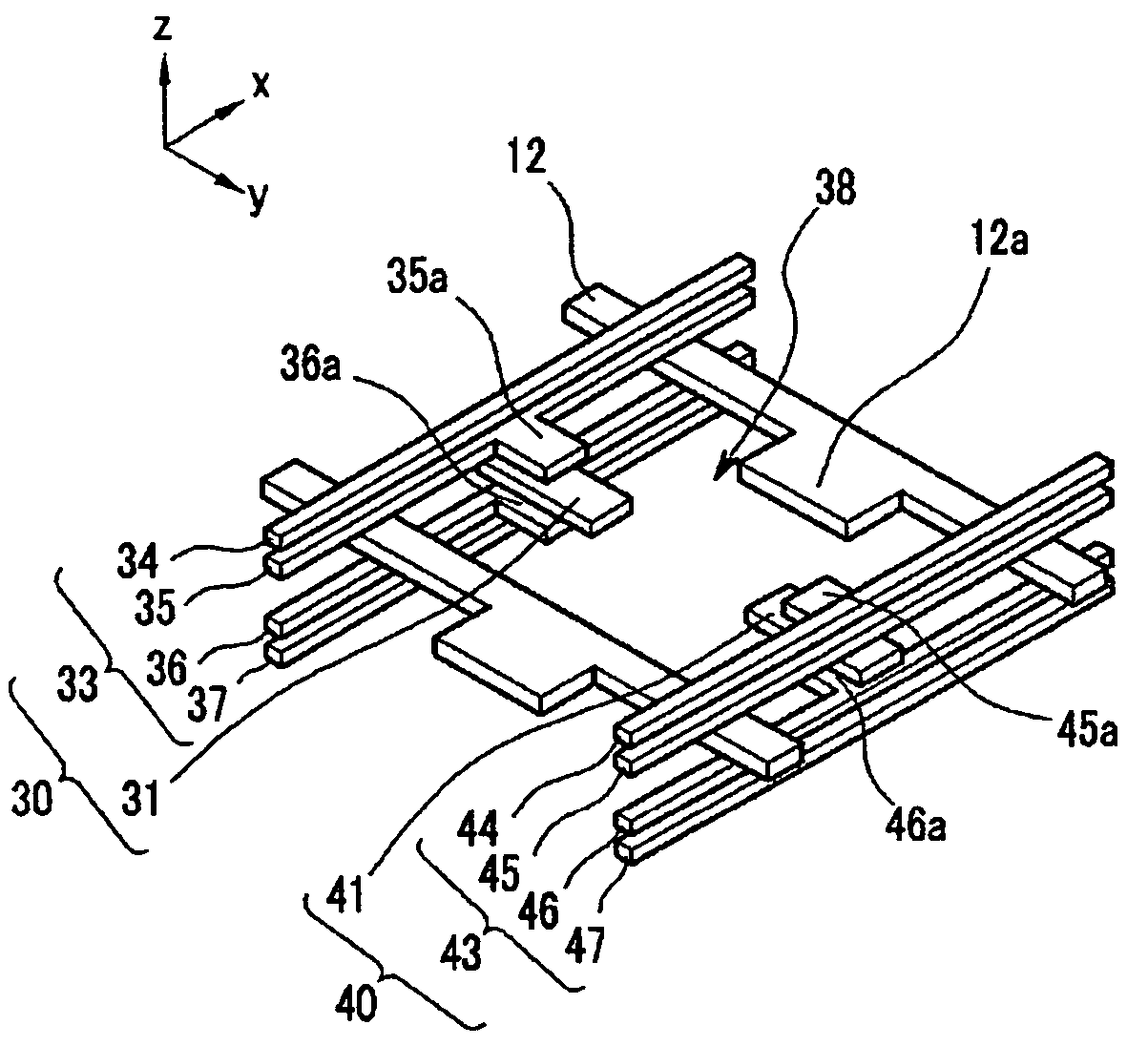

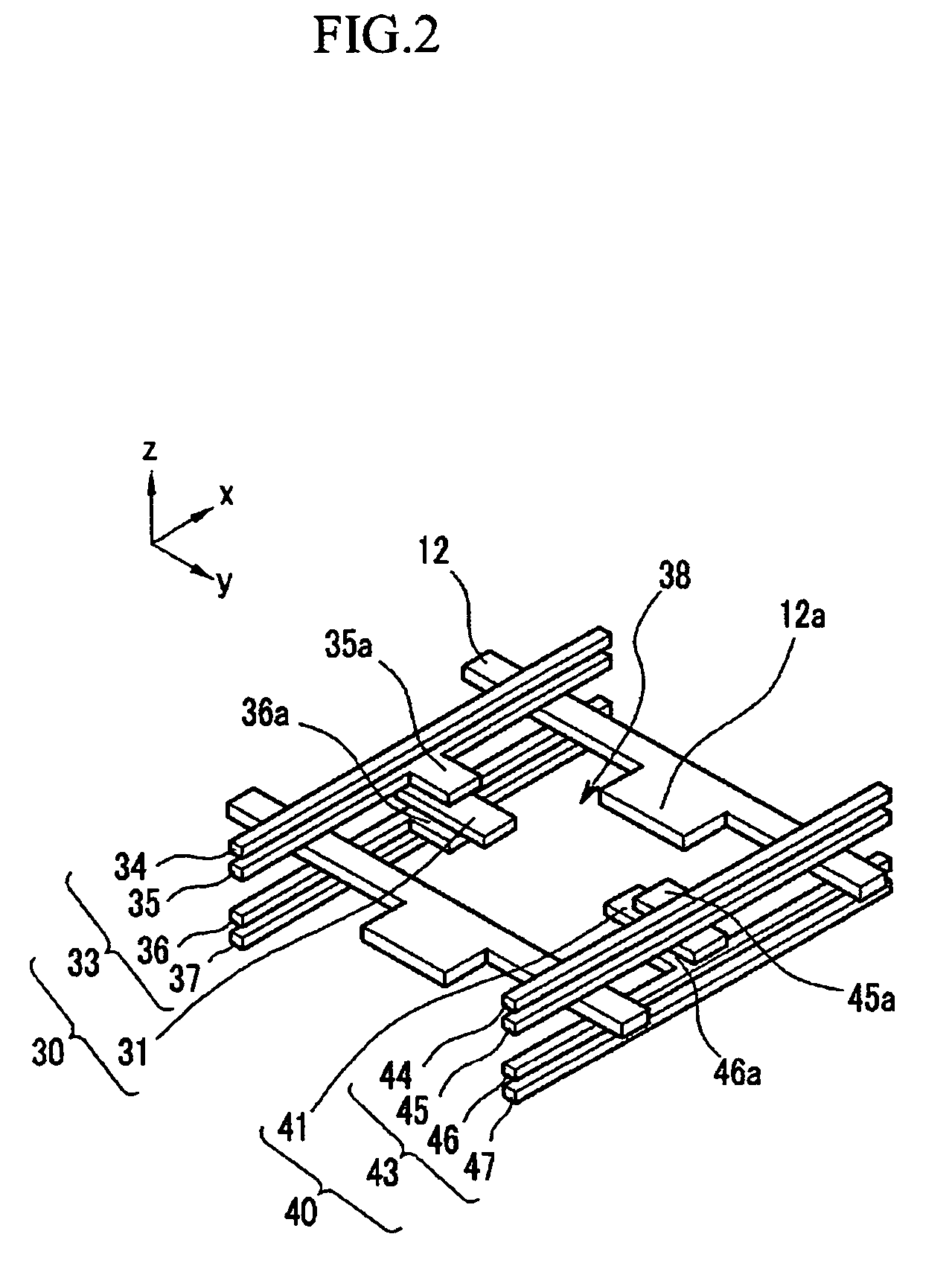

Plasma display panel and manufacturing method thereof

InactiveCN101685746AHigh strengthImprove luminous brightnessSustain/scan electrodesAlternating current plasma display panelsEngineeringUnit structure

The invention discloses a plasma display panel. The plasma display panel comprises a front substrate and a back substrate sealed with the front substrate together, wherein the front substrate is provided with a maintenance discharge electrode X and a scanning / maintenance discharge electrode Y; a discharge part of a transparent electrode of the maintenance discharge electrode X is convexly and concavely opposite to a discharge part of a transparent electrode of the scanning / maintenance discharge electrode Y to form an arc discharge space. The invention also provides a method for manufacturing the plasma display panel. In the invention, the unit structure of the transparent electrodes can be improved to improve the brightness and the luminous efficiency of the plasma display panel.

Owner:四川世纪双虹显示器件份有限公司

Plasma display panel and manufacturing method thereof

InactiveCN101685746BHigh strengthImprove luminous brightnessSustain/scan electrodesAlternating current plasma display panelsEngineeringUnit structure

The invention discloses a plasma display panel. The plasma display panel comprises a front substrate and a back substrate sealed with the front substrate together, wherein the front substrate is provided with a maintenance discharge electrode X and a scanning / maintenance discharge electrode Y; a discharge part of a transparent electrode of the maintenance discharge electrode X is convexly and concavely opposite to a discharge part of a transparent electrode of the scanning / maintenance discharge electrode Y to form an arc discharge space. The invention also provides a method for manufacturing the plasma display panel. In the invention, the unit structure of the transparent electrodes can be improved to improve the brightness and the luminous efficiency of the plasma display panel.

Owner:四川世纪双虹显示器件份有限公司

Plasma display panel (PDP) having improved electrodes structure

InactiveUS7602124B2Improve efficiencyIncrease discharge gapAddress electrodesSustain/scan electrodesPhosphorPlasma display

Owner:SAMSUNG SDI CO LTD

Reaction device and method for activation of carbon dioxide by disturbance-enhanced dielectric barrier discharge

ActiveCN109663556BStrengthen the degree of disturbanceExtended stayGas treatmentDispersed particle separationFully developedDecomposition

The invention discloses a reaction device and a method for activation of carbon dioxide by disturbance enhanced dielectric barrier discharge, wherein the device comprises a dielectric barrier discharge reactor, a high-voltage pulse power source and an online infrared analyzer. The dielectric barrier discharge reactor mainly comprises a tangential inlet, an inner electrode, an outer electrode, a quartz tube and the like. The inner electrode is an integral shape of the lower round table and the upper cone. The outer electrode is arranged around the outer wall of the quartz tube. The carbon dioxide forms a spiraling airflow through the two-way tangential flow. A filament discharge formed between the inner and outer electrodes is violently disturbed under the impetus of the spiral airflow, fully develops toward the increase direction of the pole gap, and forms a large-area, disturbance-enhancing discharge region. The carbon dioxide is efficiently activated and decomposed by high energy electrons and active particles. The reaction device and the method for activation of carbon dioxide by disturbance enhanced dielectric barrier discharge have the advantages that the gas residence time ofis long, the reaction zone is highly disturbed, the high-efficiency vibration excitation decomposition is fully developed, and the carbon dioxide activation effect is optimized.

Owner:ZHEJIANG UNIV

EDM Method in Atmospheric Pressure Cooled Plasma Jet

The invention relates to a method for electrosparking in an atmospheric pressure cold plasma jet, and belongs to the field of machining and tools. The macroscopic temperature of the atmospheric pressure cold plasma jet is lower than the room temperature or slightly higher than the room temperature, and any heat injury to a surface to be machined is avoided. During work, a work gas source enters a cold plasma jet generator through a pressure reducing valve and a gas flow and quality controller; and the flow of the work gas source and the output voltage of a high-voltage power source are adjusted, and therefore the cold plasma jet generator can generate the stable cold plasma jet. The position of the cold plasma jet generator is adjusted, and therefore the end of an electrode and to-be-machined areas of workpieces can be completely immersed in the cold plasma jet. According to the method for carrying out electrosparking in the atmospheric pressure cold plasma jet, under the same machining condition, the surface roughness and the electrode consumption lower than those in deionized water and the surface quality better than that in gas can be obtained.

Owner:DALIAN UNIV OF TECH

High instantaneous energy density electric discharge high speed milling power supply device

ActiveCN103008803BIncrease energy densityReduce relative lossElectric circuitsVoltage pulseHigh peak

The invention relates to an electric spark machining power supply device, i.e., a high-instantaneous-energy-density electric spark high-speed milling power supply device, in the field of machining. The device comprises a high-power rectifying and filtering circuit 1, a breakdown voltage regulating circuit 2, a high-power low-voltage pulse conversion circuit 3, an isolator 4, a current and voltage detection circuit 6 and a control circuit 7. According to the power supply device, on one hand, higher breakdown voltage can be provided for a discharge gap to increase the discharge gap and reduce collision probability of machining chips and a tool electrode, so as to reduce relative loss of the tool electrode, and on the other hand, the power supply device can also provide higher peak current for a discharge passage, so that the energy density of a discharge passage acting on the surface of a workpiece is guaranteed, and the machining efficiency can be greatly increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com