A multi-channel electrical discharge machining device based on ultrasonic vibration and its application method

A technology of electrical discharge machining and ultrasonic vibration, which is applied in the direction of electric processing equipment, electrochemical processing equipment, and auxiliary devices, can solve the problems of increasing the difficulty of breakdown and reducing processing efficiency, and achieves easy manufacturing, increased chip removal, and improved discharge. gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

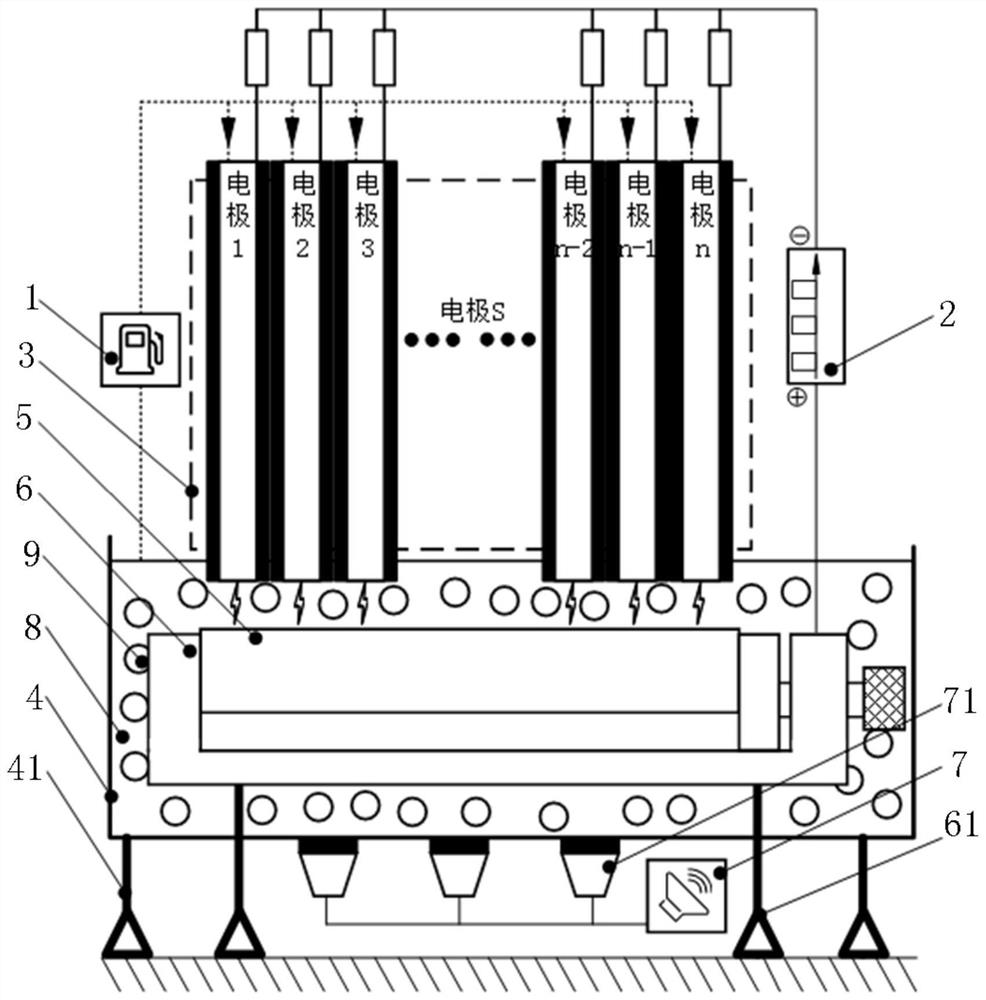

[0028] This embodiment provides a multi-channel electrical discharge machining device based on ultrasonic vibration, which includes a discharge circuit and a working fluid circulating pump 1. The discharge circuit is provided with a pulse power supply 2, and the negative pole of the pulse power supply 2 is connected in parallel with several pull-up resistors. The pull-up resistors are respectively connected with sub-electrodes, all the sub-electrodes are fixed in parallel as a multi-channel electrode 3, the sub-electrodes are copper tubes, and the copper tubes are used as electrodes, which have superior performance and are convenient for procurement and production; The discharge end is on the same plane, which can ensure the processing effect of multi-channel electrical discharge machining. The upper end of the multi-channel electrode 3 is the liquid inlet end, and the lower end is the discharge end. The positive pole of the pulse power supply 2 is connected with a metal fixtur...

Embodiment 2

[0031] This embodiment provides a multi-channel electrical discharge machining device based on ultrasonic vibration, which includes a discharge circuit and a working fluid circulating pump 1. The discharge circuit is provided with a pulse power supply 2, and the negative pole of the pulse power supply 2 is connected in parallel with several pull-up resistors. The pull-up resistors are respectively connected with sub-electrodes, the sub-electrodes are copper tubes, and the copper tubes are used as electrodes, which have superior performance and are convenient for procurement and production. All sub-electrodes are parallel and integrally fixed as multi-channel electrodes 3. The liquid inlet end, the lower end is the discharge end, the suction port of the working liquid circulating pump 1 is connected with the working liquid tank 4, the outlet is connected with the liquid inlet end, the positive electrode of the pulse power supply 2 is connected with a metal fixture 6 for fixing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com