Air blast electric spark processing method in liquid

A processing method, electric spark technology, applied in the direction of electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve the problems that molten metal is difficult to cool and solidify in time, it is difficult to process peak current, and the cooling effect is not as good as that of liquid, etc., to improve Material removal rate, processing short circuit rate is low, and the effect of increasing the explosive force of discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

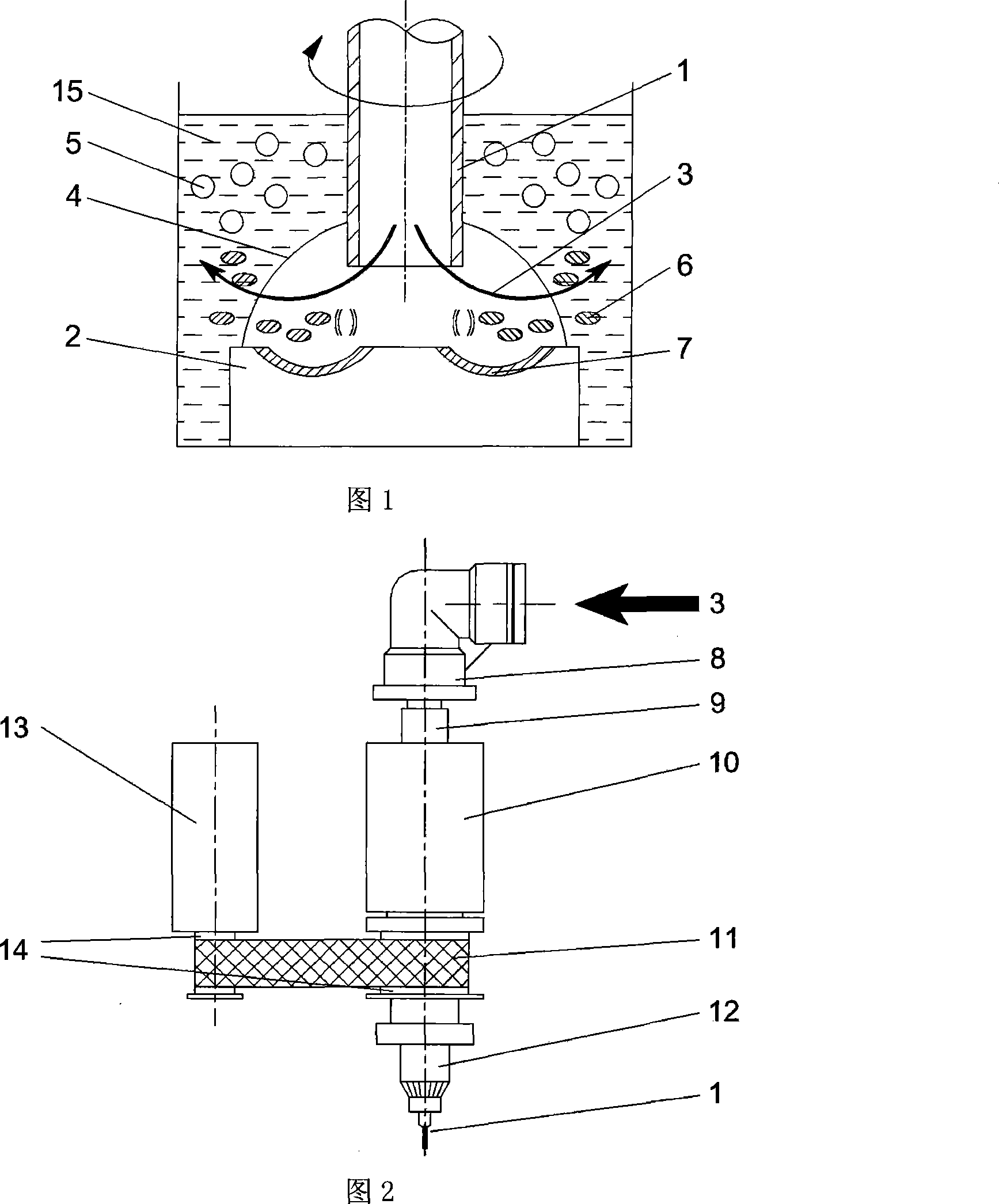

Method used

Image

Examples

example 1

[0031] The processing conditions in this example are shown in the table below:

[0032] Pulse width (μs)

[0033] The material removal rate obtained by processing: 0.17mm 3 / min, electrode relative loss rate: 0.75%

example 2

[0035] The processing conditions in this example are shown in the table below:

[0036] Pulse width (μs)

[0037] The material removal rate obtained by processing: 0.453mm 3 / min, electrode relative loss rate: 0.75%

example 3

[0039] The processing conditions in this example are shown in the table below:

[0040] Pulse width (μs)

[0041] Material removal rate obtained by machining: 1.135mm 3 / min, electrode relative loss rate: 1.01%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com