An Atmospheric Pressure Cooled Plasma Jet Electric Discharge Machining Device

A cold plasma and spark machining technology, applied in the field of machining and tools, can solve problems such as unreported, achieve the effect of low cost, improve the state between the poles, and accelerate the discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

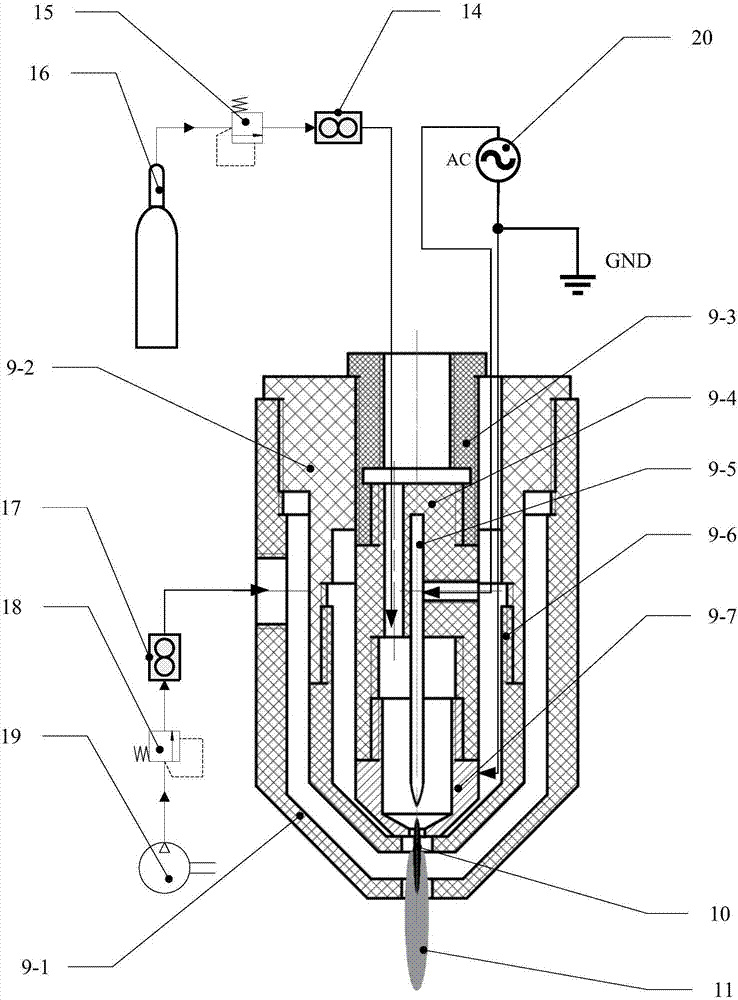

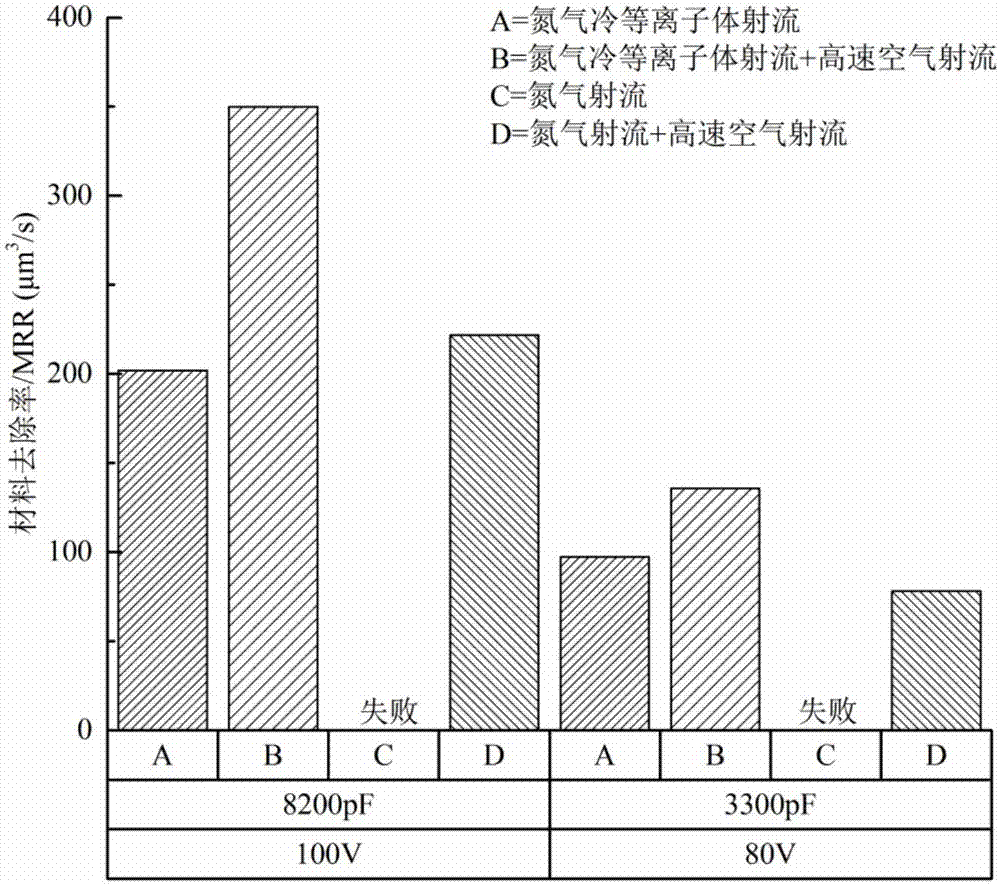

[0034] The influence of the present invention on the characteristics of electric discharge machining in cold plasma jets will be illustrated in conjunction with an example of an electric discharge milling micro-groove experiment. First, the experimental equipment is figure 1 , figure 2 connection shown. The material of the tool electrode 8 in this embodiment is tungsten, the material of the workpiece 12 is H62 brass, the high-purity working gas source 16 adopts high-purity nitrogen with a purity of 99.999%, and the high-pressure gas source 19 adopts an air compressor, which is used in the experiment The coaxial high-speed jet is a compressed air jet. The EDM medium is respectively nitrogen-cooled plasma jet, nitrogen-cooled plasma jet and coaxial high-speed air jet mixed medium, nitrogen jet, nitrogen jet and coaxial high-speed air jet mixed medium. The pulse power supply type is selected as RC pulse power supply. The processing energy is respectively set to 8200pF for a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com