Plasma display panel and manufacturing method thereof

A plasma display screen and combined technology, applied in the direction of alternating current plasma display panel, cold cathode manufacturing, electrode system manufacturing, etc., can solve the problems of low luminous brightness and luminous efficiency, small discharge area between electrodes, etc., and achieve luminous brightness and luminous efficiency. Effect of increase, increase in effective area, increase in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

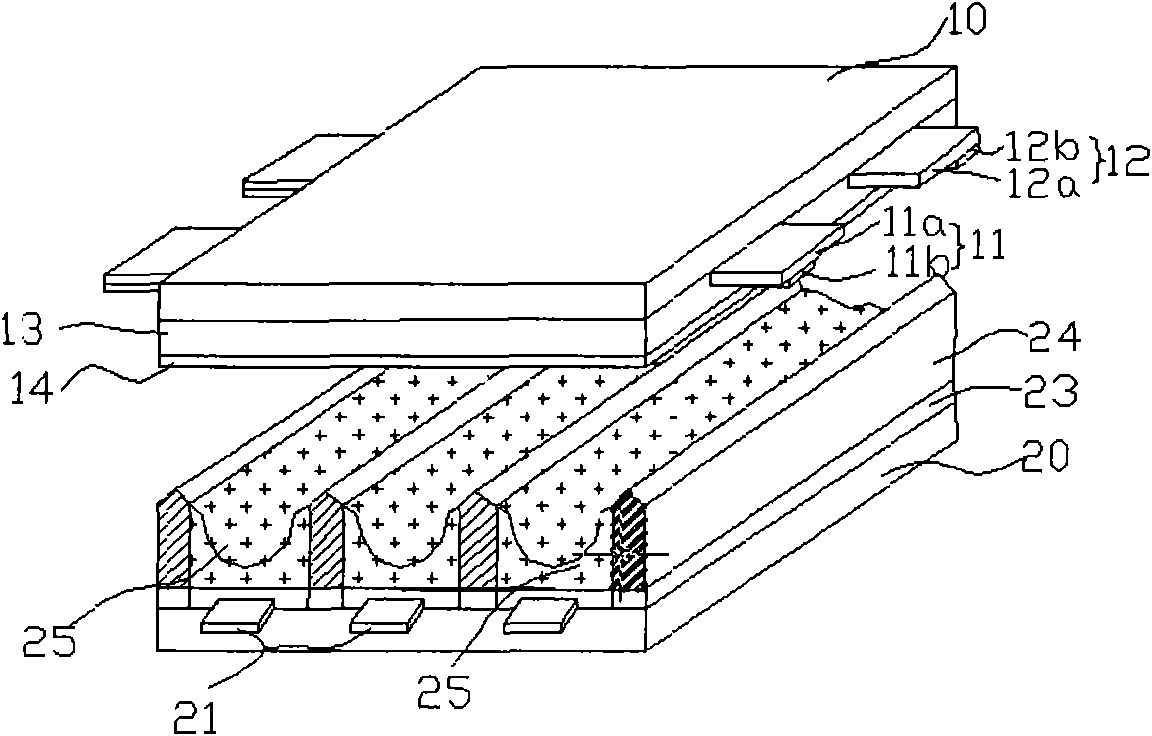

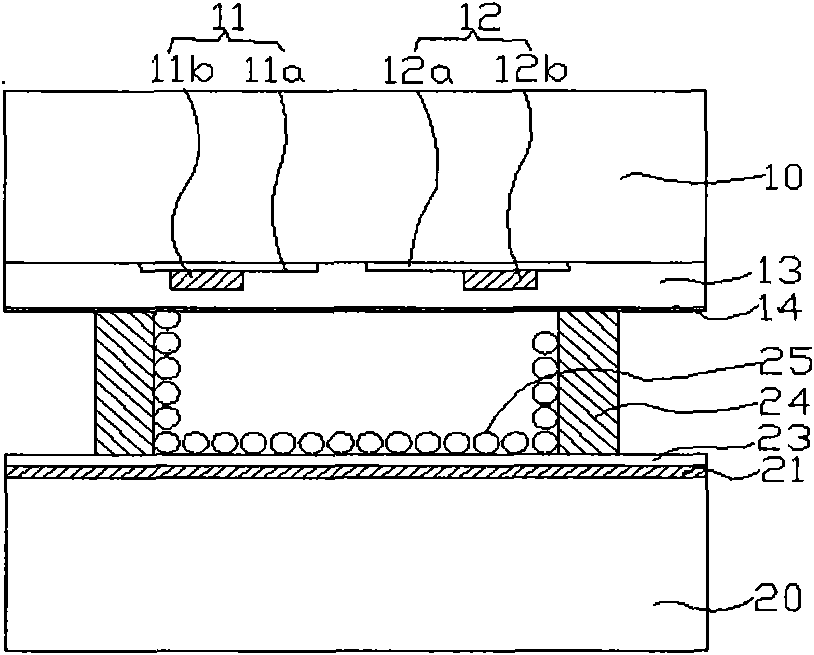

[0026] The present invention will be described below with reference to the drawings and preferred embodiments.

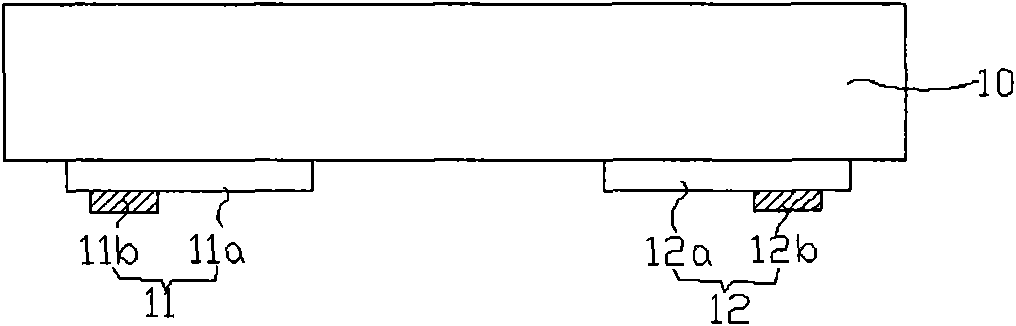

[0027] Figure 7 Shows the new transparent electrode structure of the front substrate of the AC gas discharge plasma display screen according to the present invention, Figure 8 show Figure 7 The transparent electrode structure. Combined reference Figure 7 with Figure 8 The discharge part 111 of the transparent electrode 11a and the discharge part 121 of the transparent electrode 12a face each other to form an arc-shaped discharge space.

[0028] Among them, the arc-shaped discharge space is preferably a semicircular annular discharge space. The discharge part 121 of the transparent electrode 12a of the scan discharge electrode X is in a protruding arc shape, and the discharge part 111 of the transparent electrode 11a of the sustain discharge electrode Y is in the shape of a concave arc, and the inner diameter of the arc is 75um-100um.

[0029] In other embodiments, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com