Discharge plasma vehicle exhaust gas treatment device with rotating spiral electrode and treatment method thereof

A discharge plasma and tail gas treatment technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve problems such as low purification efficiency and uneven plasma, and achieve high purification efficiency, no secondary pollution, Solve the effect of high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

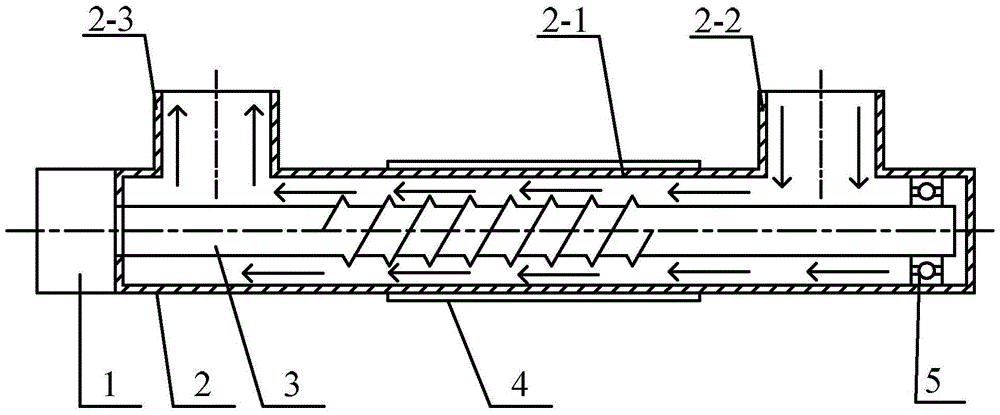

[0019] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the discharge plasma vehicle exhaust treatment device with rotating spiral electrode described in this embodiment, it comprises motor 1, tail gas plasma processing tube 2, spiral electrode 3 and copper tube 4,

[0020] Tail gas plasma treatment tube 2 is composed of horizontal tail gas treatment section 2-1, tail gas inlet section 2-2 and tail gas outlet section 2-3, tail gas inlet section 2-2 is at the head end side of horizontal tail gas treatment section 2-1 It is vertically connected with the horizontal tail gas treatment section 2-1, the tail gas outlet section 2-3 is vertically connected with the horizontal tail gas treatment section 2-1 at the end side of the horizontal tail gas treatment section 2-1, and the tail gas inlet section 2-2 Located on the same side as the tail gas outlet section 2-3 on the same side as the horizontal tail gas treatment section 2-1;

[0021]...

specific Embodiment approach 2

[0023] Specific implementation mode two: the following combination figure 1 Describe this embodiment, this embodiment will further explain the first embodiment, it also includes a positioning bearing 5, the head end of the spiral electrode 3 and the head end of the horizontal tail gas treatment section 2-1 are rotatably connected through the center hole of the positioning bearing 5 .

[0024] The positioning bearing 5 is used for positioning the spiral electrode 3 , and the motor 1 is used for controlling the rotation of the spiral electrode 3 . Positioning bearing 5 is made of non-metallic material.

specific Embodiment approach 3

[0025] Specific implementation mode three: the following combination figure 1 This embodiment will be described. This embodiment will further describe Embodiment 1 or 2. The middle section of the outer surface of the spiral electrode 3 has a dense thread distribution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com