A device for treating waste gas based on dielectric barrier discharge plasma

A dielectric barrier discharge and plasma technology, used in gas treatment, separation methods, dispersed particle separation, etc., can solve the problems of low expected effect and short life of plasma products, and achieve good uniformity, abundant active products, and effective increase. Effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

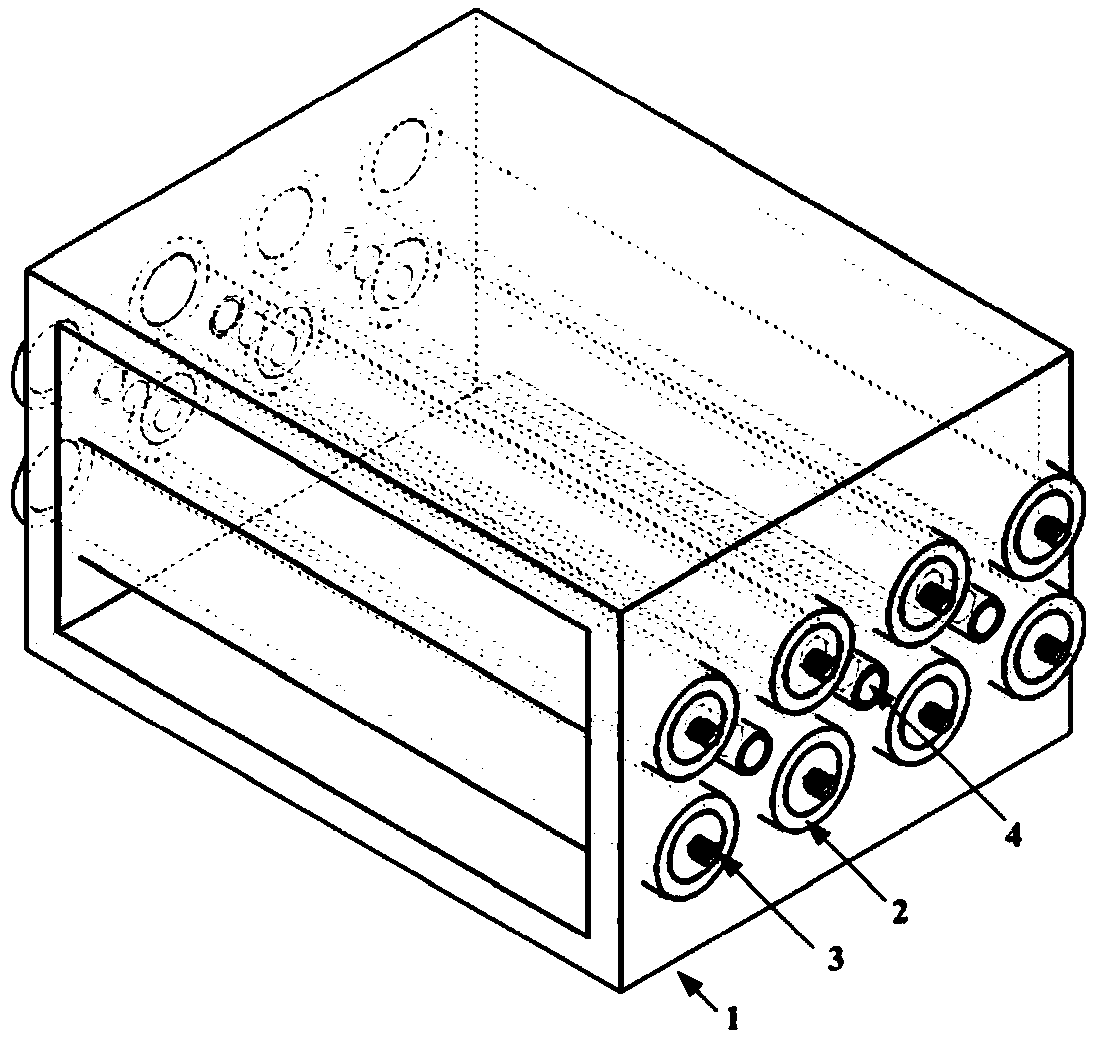

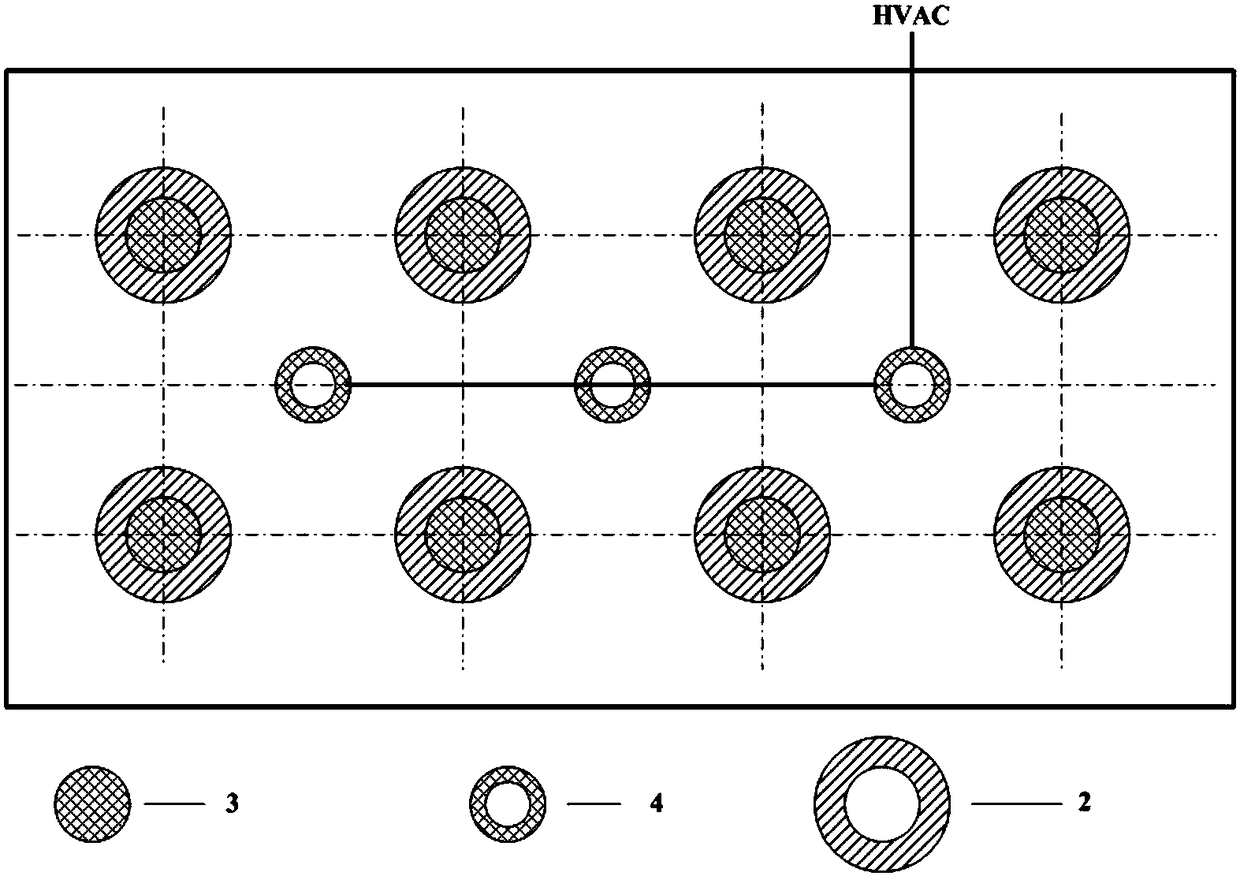

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] The device for treating exhaust gas based on dielectric barrier discharge plasma provided by the present invention, the device is according to the attached Figure 4 Install it into the treatment system, connect it to the waste gas treatment pipeline 1, turn on the driving power, and start the treatment.

[0032] see Figure 4 , the exhaust gas that needs to be processed physically filters larger-sized particles through the filter screen 5, and after the exhaust gas enters the photocatalytic treatment section 6 for treatment, it enters the plasma treatment section 7 designed by the present invention, and the catalyst treatment section 8 and activated carbon treatment are designed downstream Segment 9 is purified again.

[0033] According to the needs of waste gas treatment, the HV high-voltage power supply provides an external voltage amplitude of 4.5kV-10kV (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com