Plane fluorescent lamp

A fluorescent lamp and flat technology, applied in the field of fluorescent lamps and flat fluorescent lamps, can solve the problems of limiting the size of the discharge gap, difficult to improve the luminous efficiency, and reducing the brightness of the backlight source, so as to increase the discharge gap, improve the brightness and luminous efficiency, and achieve uniform brightness. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

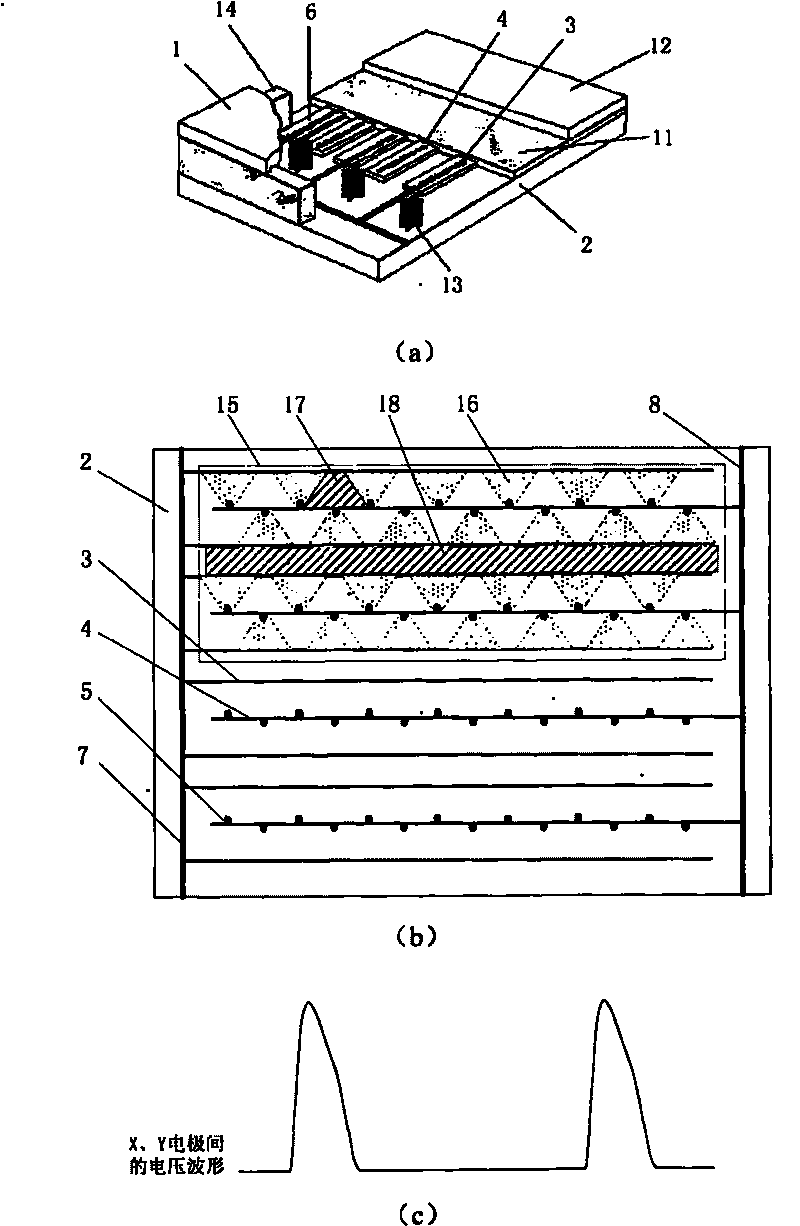

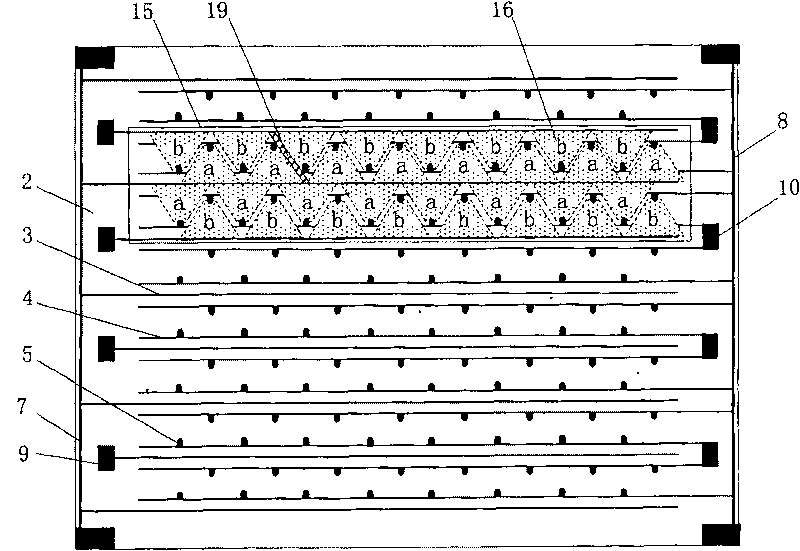

[0033] figure 2 It is the top view and driving voltage waveform diagram of the flat fluorescent lamp of the present invention. The flat fluorescent lamp includes a front glass substrate 1 and a rear glass substrate 2, the inner surface of the front glass substrate 1 is covered with a phosphor layer, and the inner surface of the rear glass substrate 2 is provided with two sets of strip electrodes——X electrodes 3 and Y electrodes 4, Protrusions 5 with a certain interval are arranged on the side of the Y electrode 4, the X electrode 3 and the Y electrode 4 are covered with a dielectric layer 6, and the surface of the dielectric layer 6 and the inner side of the rear glass substrate 2 not covered by the dielectric layer 6 are covered. There is a phosphor layer. After the two substrates are aligned, they are sealed together with low-melting glass around them, and the interior is filled with inert gas. All the discharges between the X electrodes 3 and the Y electrodes 4 are divid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com