Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Increase capillary effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

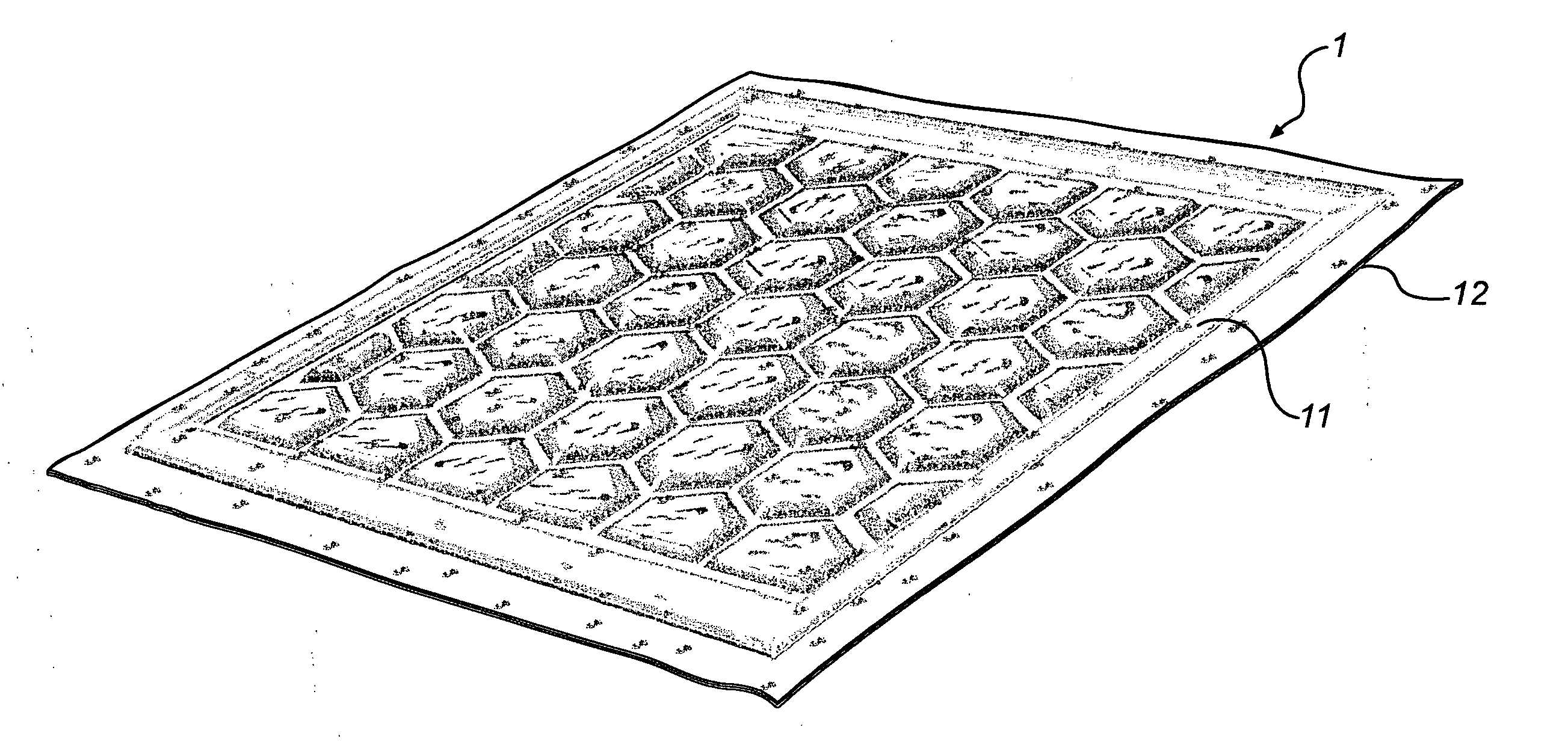

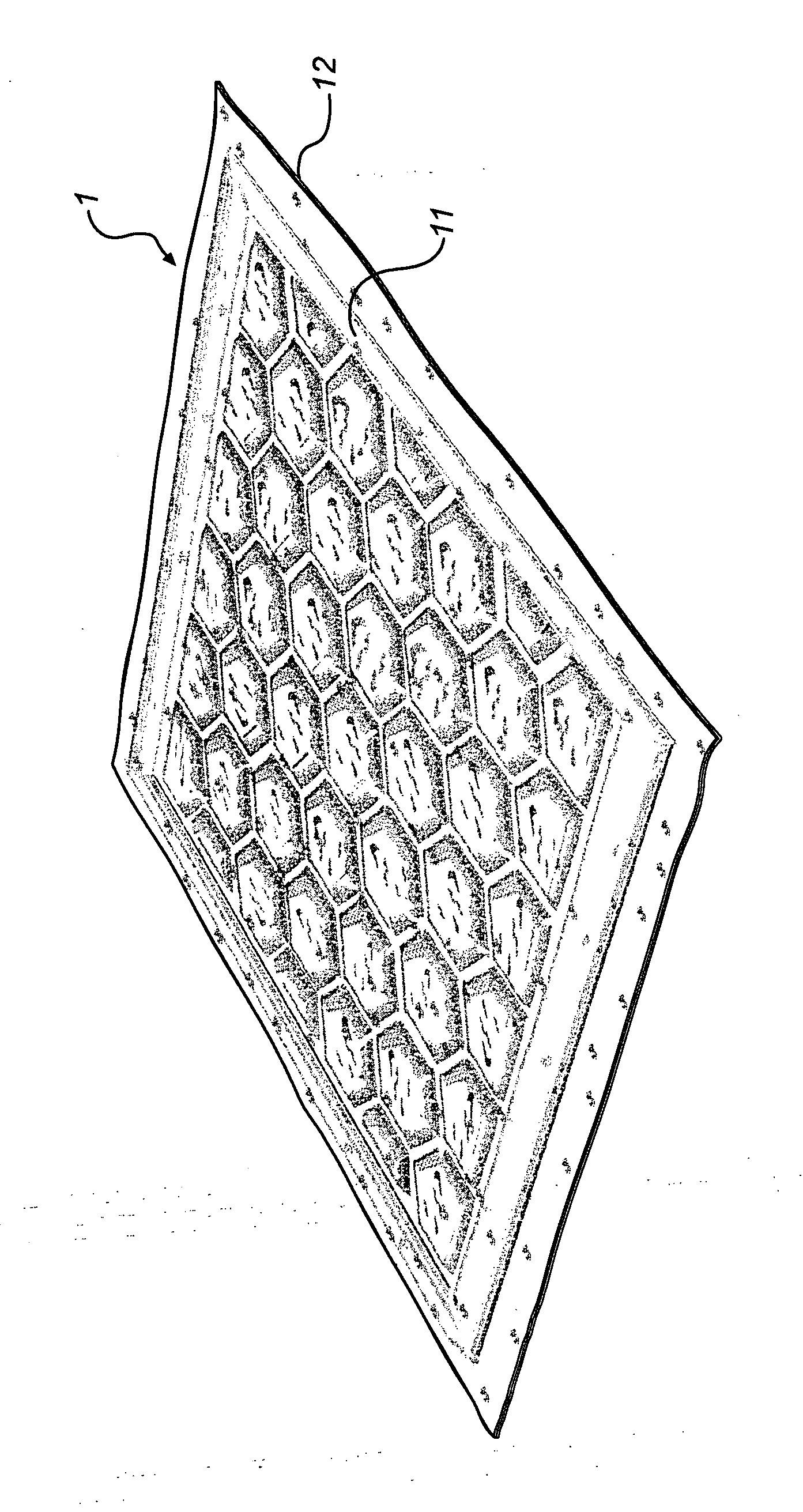

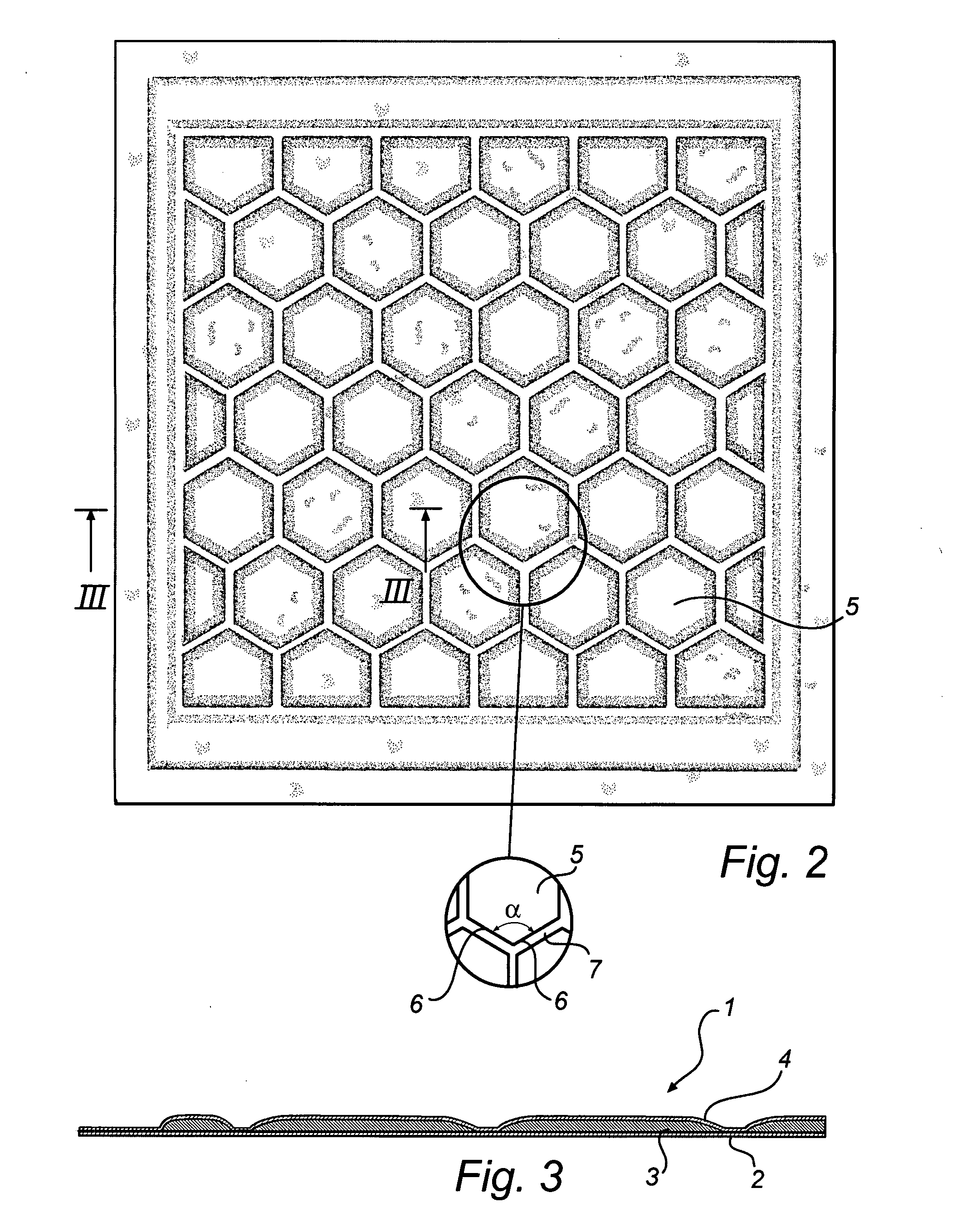

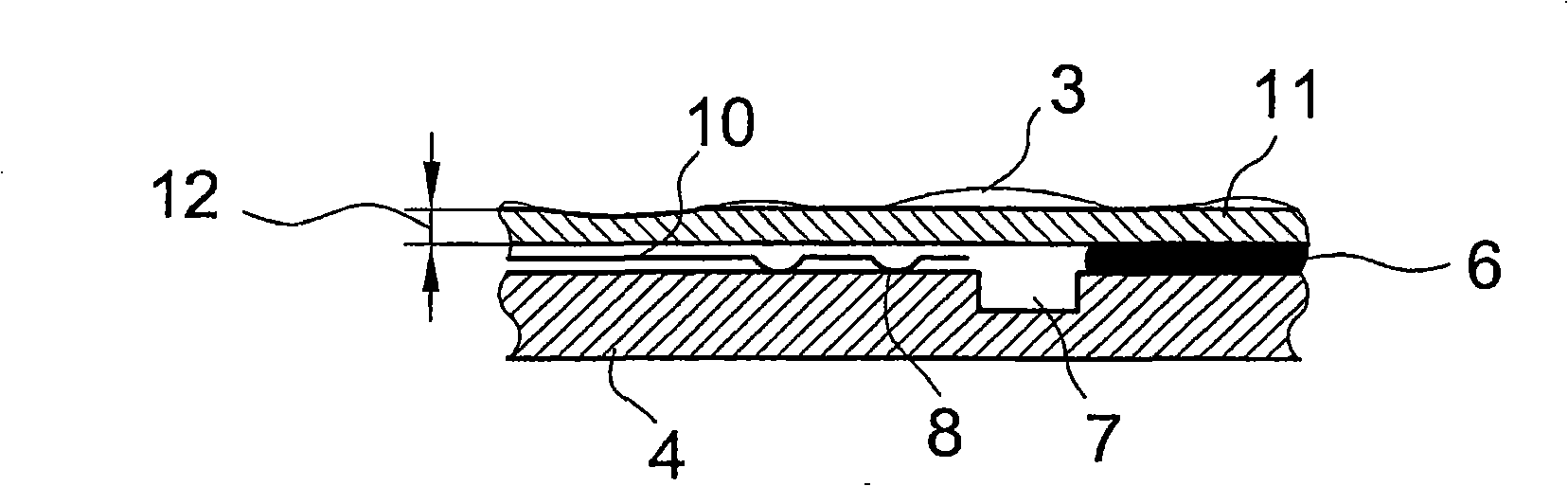

Absorbent pad

InactiveUS20070219523A1Improve characteristicEasy and inexpensive to manufactureBaby linensTamponsAbsorbent PadsBiomedical engineering

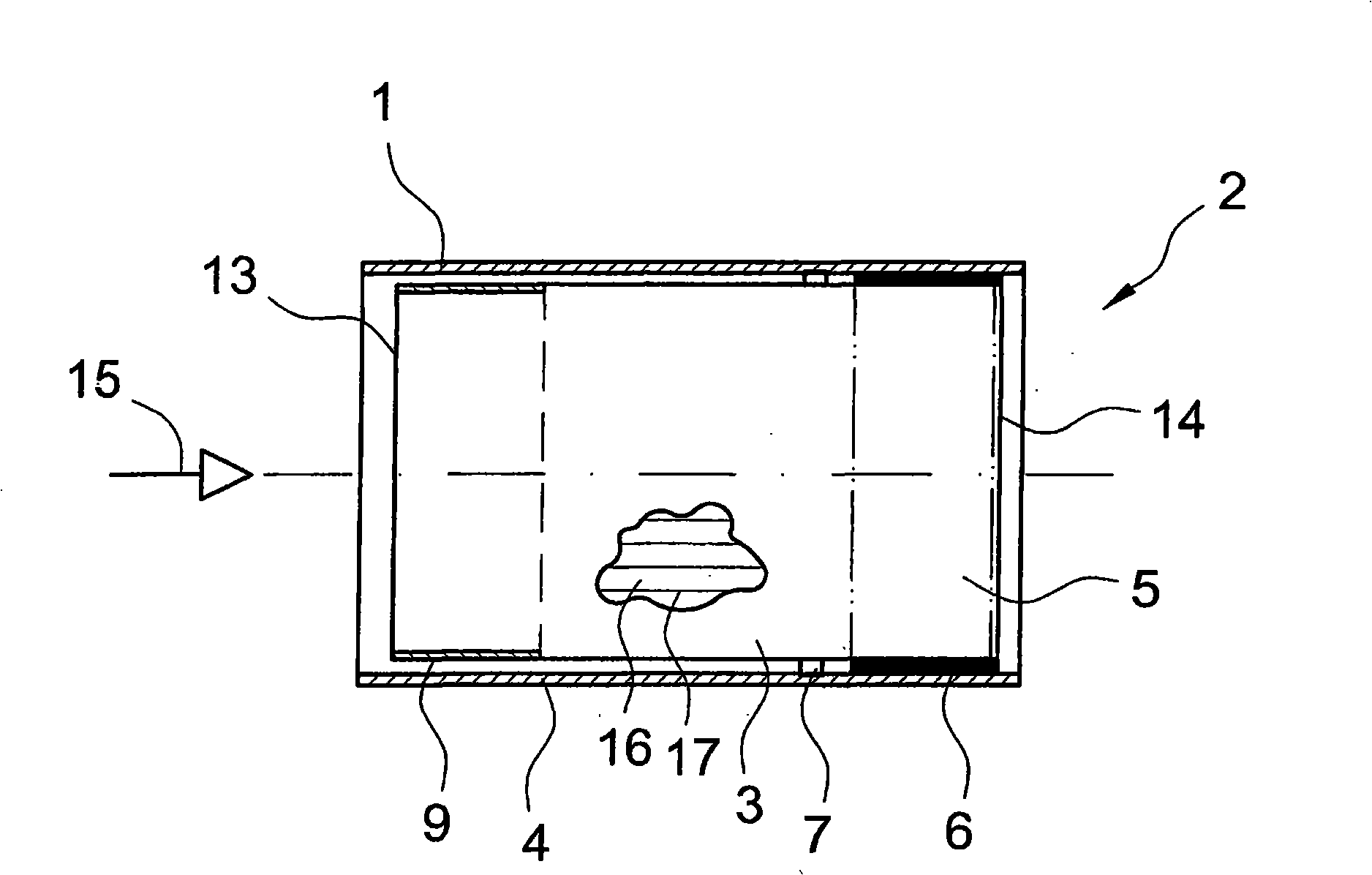

According to the invention it is disclosed an absorbent pad (1) comprising a liquid-impervious back sheet (2), a plurality of bodies (3) of liquid-absorbent material disposed on one surface of the back sheet (2), and a liquid-pervious cover sheet (4) covering said bodies (3) of absorbent material and secured to the back sheet (2) along channels (7) which separate said bodies (3) of absorbent material. The channels (7) progresses in a channel-pattern in which three channels (7), meeting in a joint, form respective edges (6) of said whole bodies (3) and said channels (7) being substantially free from absorbent material. A method for the manufacturing of such absorbent pad (1) is also disclosed.

Owner:ATTENDS HEALTHCARE

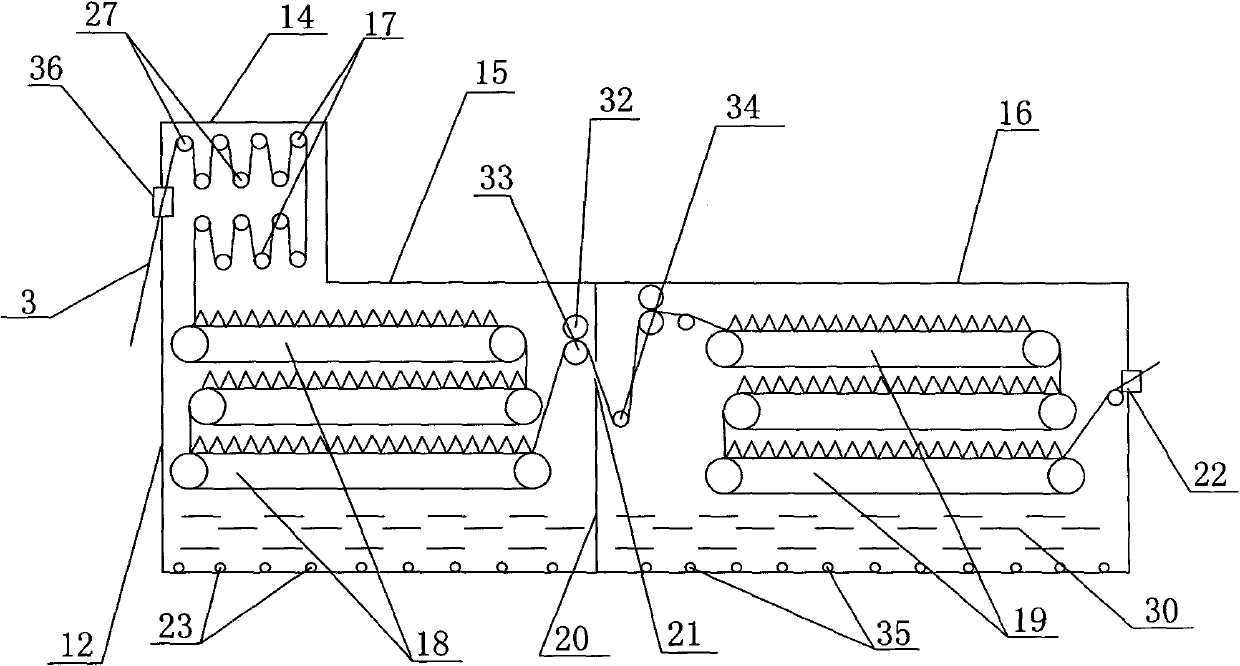

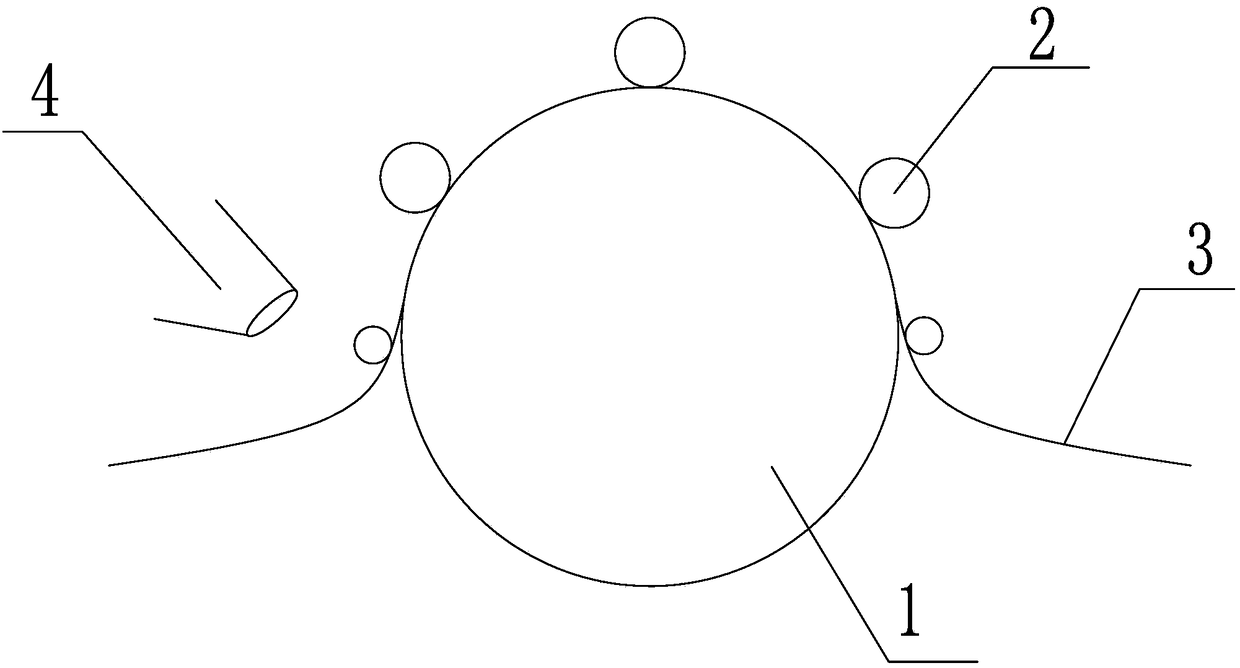

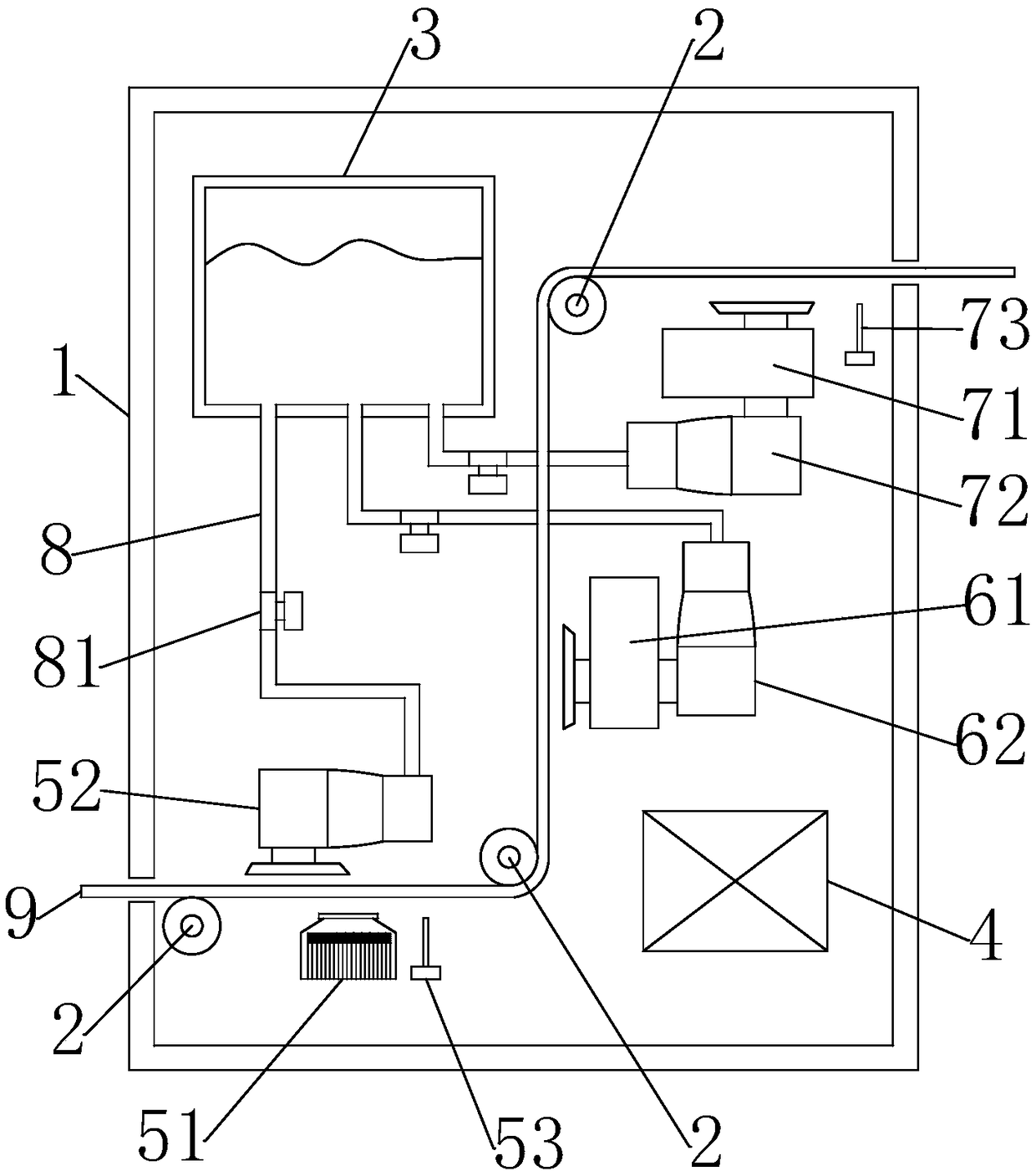

Crease prevention device for scouring and bleaching equipment, scouring and bleaching equipment and crease prevention method

ActiveCN101768845ALess chance of wrinklingImprove processing efficiencyTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentEngineeringTextile

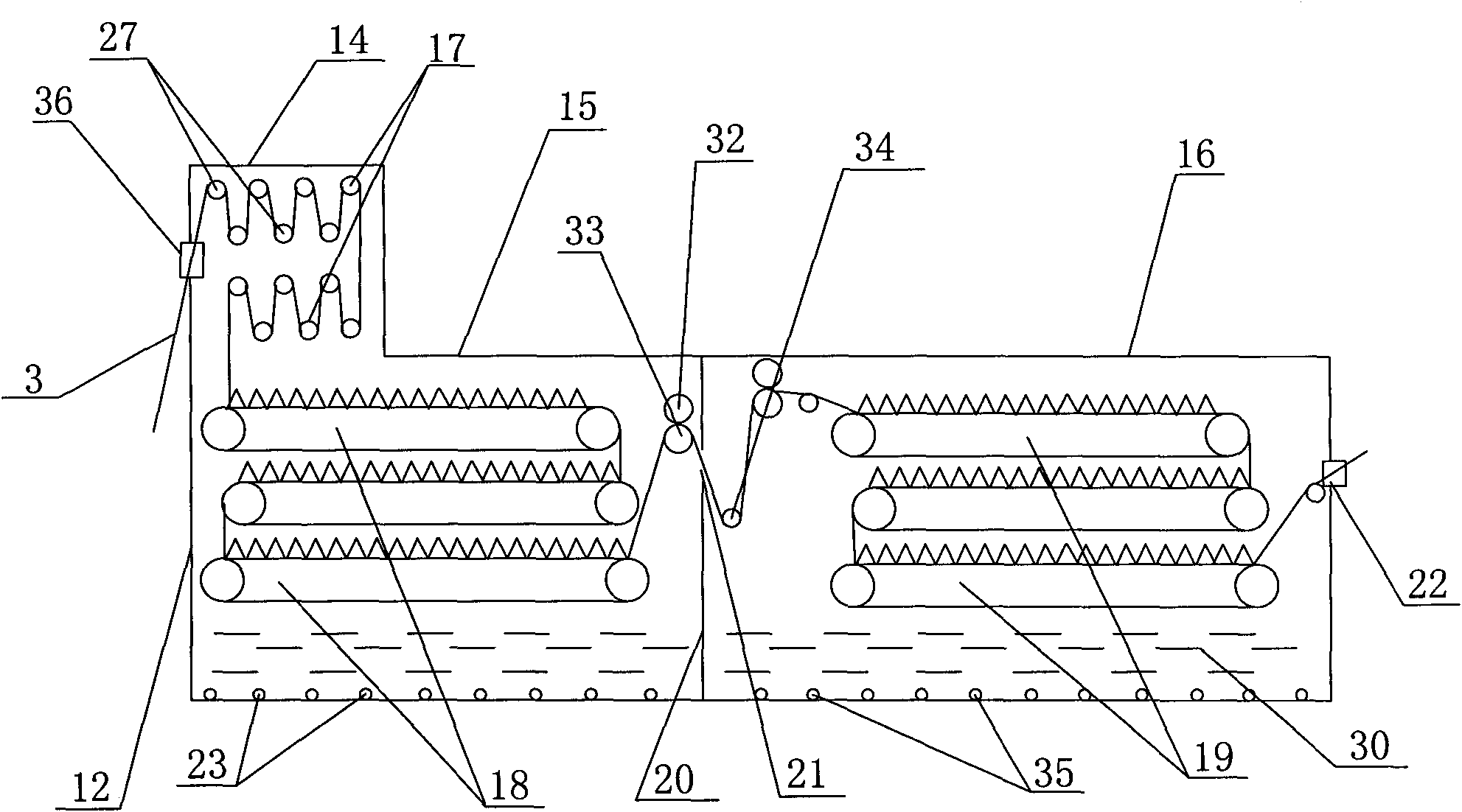

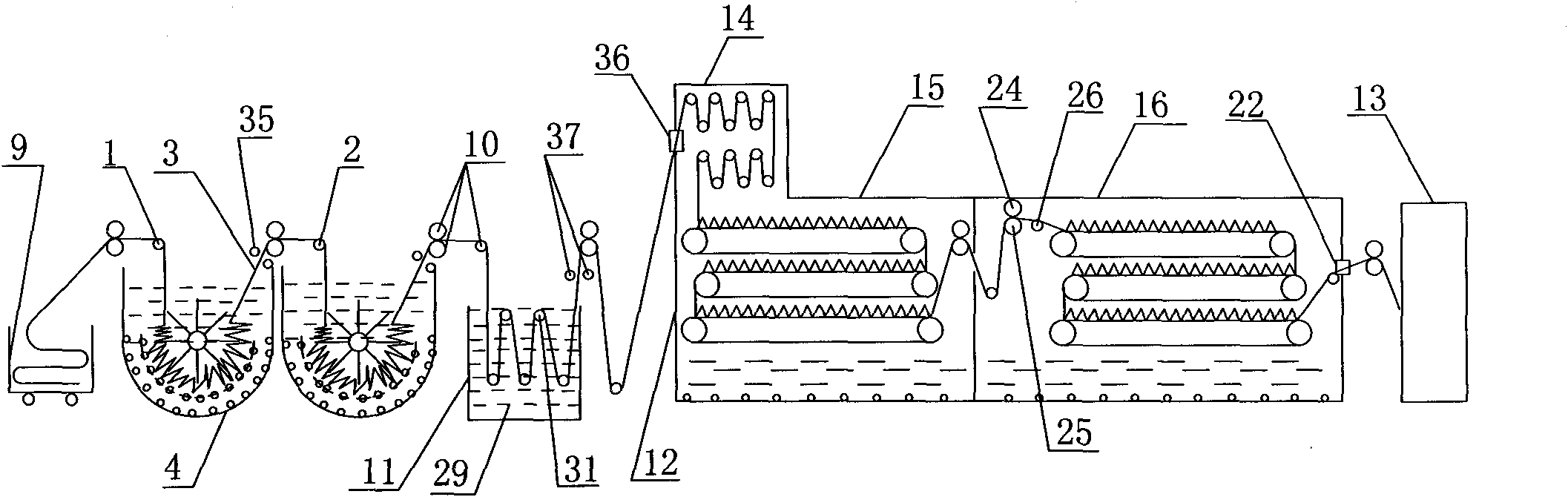

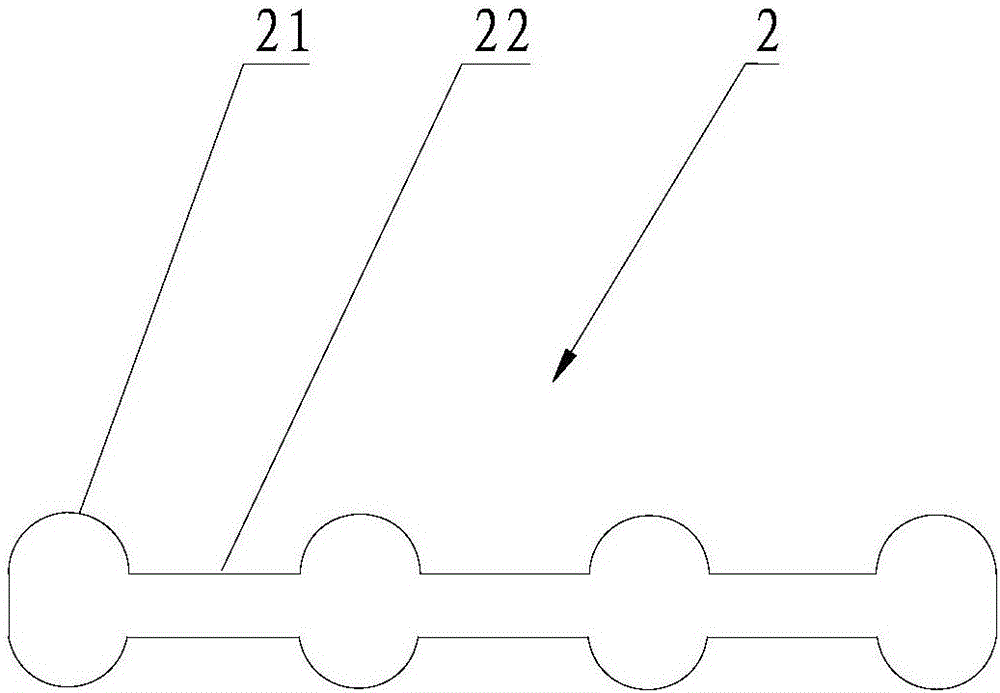

The invention discloses a crease prevention device for scouring and bleaching equipment, scouring and bleaching equipment and a crease prevention method; a fabric is led in a fabric soaking vessel by a fabric lead-in roller; the fabric enters in hot water of the fabric soaking vessel and hot water flows through the fabric continuously under the condition that the fabric is in a loose state; the fabric in the fabric soaking vessel is led out to the next procedure by a fabric lead-out roller; the crease prevention device is arranged in the scouring and bleaching equipment, and the fabric is processed according to the process flows; in the invention, the fabric is fully self-swelled in the crease prevention device, the crease ratio of cotton knitted textile is reduced, the flatness of the cotton knitted textile is kept; in addition, the crease prevention device and a steam box in the scouring and bleaching equipment are improved, the fabric passes through a fabric trolley, an immersion device, the steam box and a rinsing machine sequentially by a delivery mechanism, so as to realize continuous processing and greatly improve the processing efficiency; under the condition of low cost operation, the fabric with no crease, high planeness, high whiteness and high capillary effect can be processed continuously.

Owner:QINGDAO UNIV

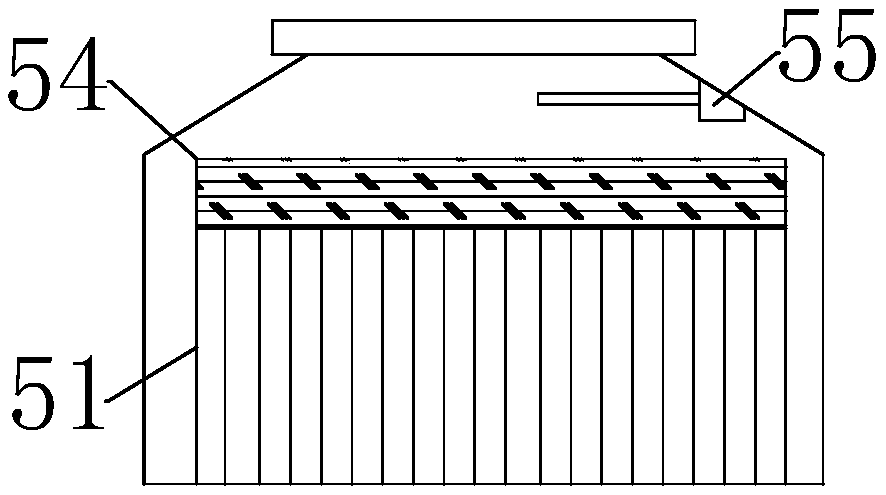

Steam box used for scouring and bleaching equipment, scouring and bleaching equipment and steaming method

ActiveCN101781837AImprove flatnessHigh whitenessTextile treatment containersTextile treatment machine arrangementsEngineeringStretch rate

The invention discloses a steam box used for scouring and bleaching equipment, scouring and bleaching equipment and a steaming method. The steam box comprises a preheating zone, a first temperature zone and a second temperature zone; a steam box guide roller used for transmitting fabrics is arranged in the preheating zone; a first crawler belt set and a second crawler belt set are respectively arranged in the first temperature zone and the second temperature zone; the transmission directions of adjacent crawler belts in the first crawler belt set and the second crawler belt set are opposite; the crawler belts are staggered in parallel to form the continuous transmission of the fabrics, thereby enabling the fabrics to be stacked on the crawler belts and continuously transmitted; the steam box is arranged in the scouring and bleaching equipment and treats the fabrics according to certain process flows. The invention thoroughly solves the problems that the scouring and bleaching effect is not ideal, the cloth cover evenness of the fabrics is poorer, the dimensional stability is poor because the textile stretch rate is overlarge, the effects of energy saving and consumption reducing are not ideal and the like, thereby continuously producing the fabrics with high evenness, high whiteness and high capillary effect but without creases.

Owner:QINGDAO UNIV

Spinneret plate, profiled nylon 6 fiber and making method thereof

InactiveCN106120003ALarge specific surface areaHigh glossFilament/thread formingMonocomponent polyamides artificial filamentFiberNylon 6

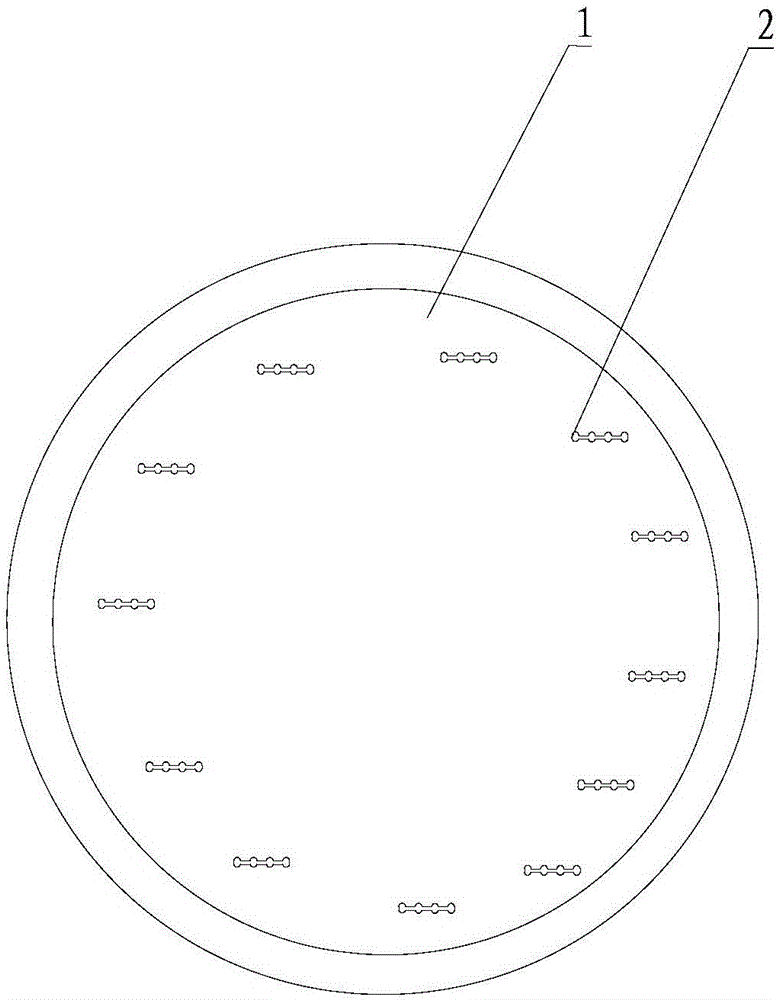

The invention relates to a spinneret plate which comprises a base plate and at least one spinneret micro-hole. The spinneret micro-hole is formed in the base plate, a cross section of the spinneret micro-hole is of a sawtooth structure, the sawtooth structure comprises two sawtooth portions, each sawtooth portion comprises four semi-circular arcs identical in radius, the four semi-circular arcs are sequentially arranged, the adjacent two semi-circular arcs are connected linearly, the two sawtooth portions are mutually connected to form a symmetrical closed structure, and the four semi-circular arcs at one sawtooth portion correspond to the four semi-circular arcs at the other sawtooth portion in a one-to-one mode. The invention further relates to a profiled nylon 6 fiber and a making method thereof. The profiled nylon 6 fiber has good luster and moisture absorption and sweat releasing functions, and a fabric made from the fiber has the soft and exquisite hand feeling of cashmere and also has good dyeing properties, rapid moisture absorption and guidance properties and other excellent characteristics.

Owner:FUJIAN JINJIANG TECH

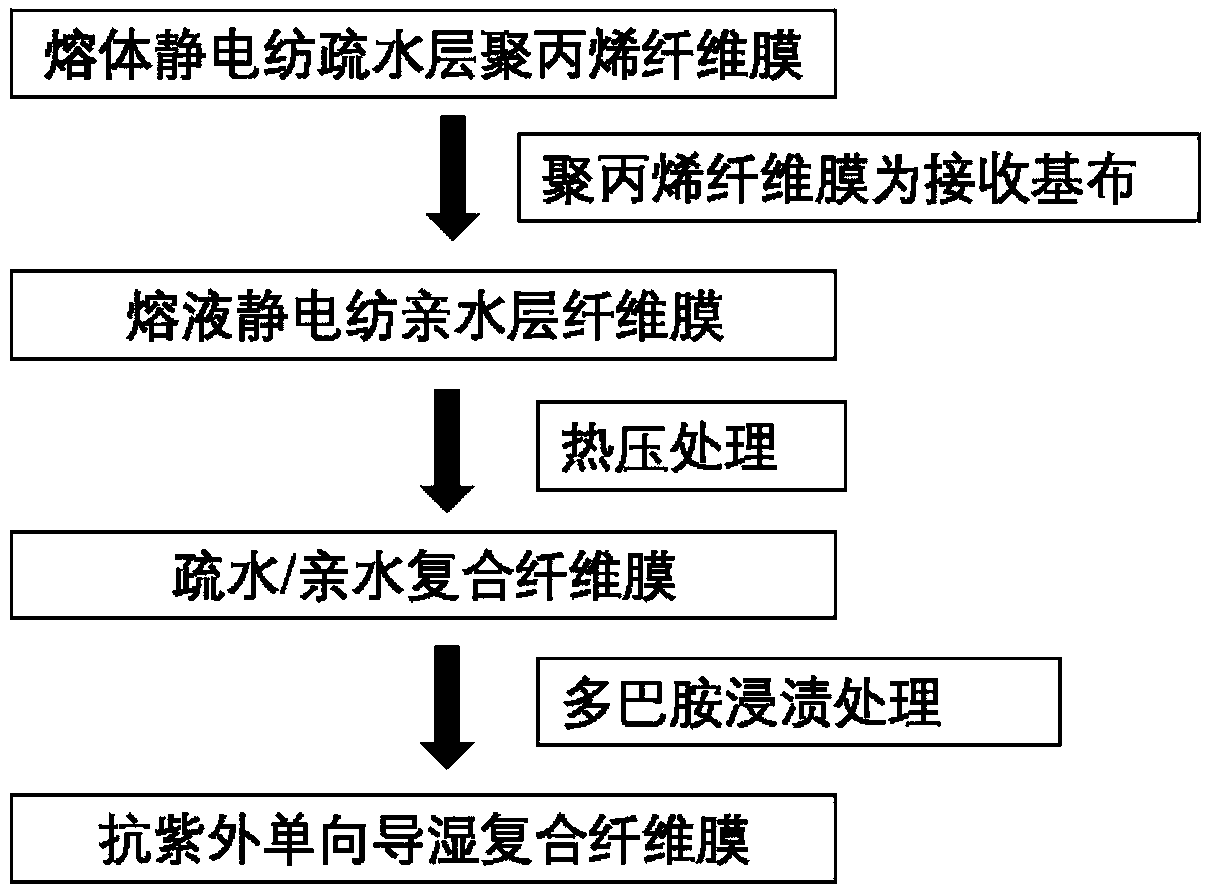

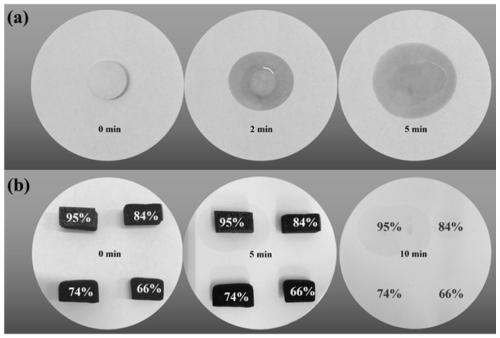

Anti-ultraviolet unidirectional-moisture-permeable fiber composite and preparing method thereof

InactiveCN109322058AGood one-way moisture transferFunction increaseArtificial filaments from cellulose derivativesNon-woven fabricsMicro nanoPolymer science

The invention belongs to the field of functional micro-nano fiber composites, and particularly relates to an anti-ultravoilet unidirectional-moisture-permeable fiber composite and a preparing method thereof. The fiber composite comprises a polypropylene layer and a hydrophilic polymer and ultraviolet absorber mixture layer which are integrally combined. Polydopamine deposits on and adheres to thesurfaces and the interiors of the polypropylene layer and the hydrophilic polymer and ultraviolet absorber mixture layer. The preparing method includes the steps of dissolving an ultraviolet absorberand a hydrophilic polymer in an organic solvent to form a spinning solution, conducting static spinning and then hot-pressing treatment with a melt static spinning polypropylene fiber material as thereceiving substrate, and placing the material in a Tris-HCl buffer solution with dissolved dopamine for impregnation modification to prepare the anti-ultravoilet unidirectional-moisture-permeable fiber composite. The material has good unidirectional moisture-permeable and anti-ultraviolet functions and is stable in integration structure, simple in composition and structure, simple in preparing process and wide in application prospect.

Owner:SHANGHAI UNIV OF ENG SCI

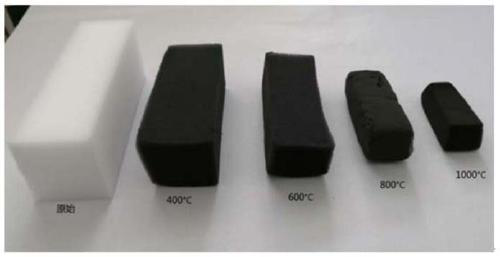

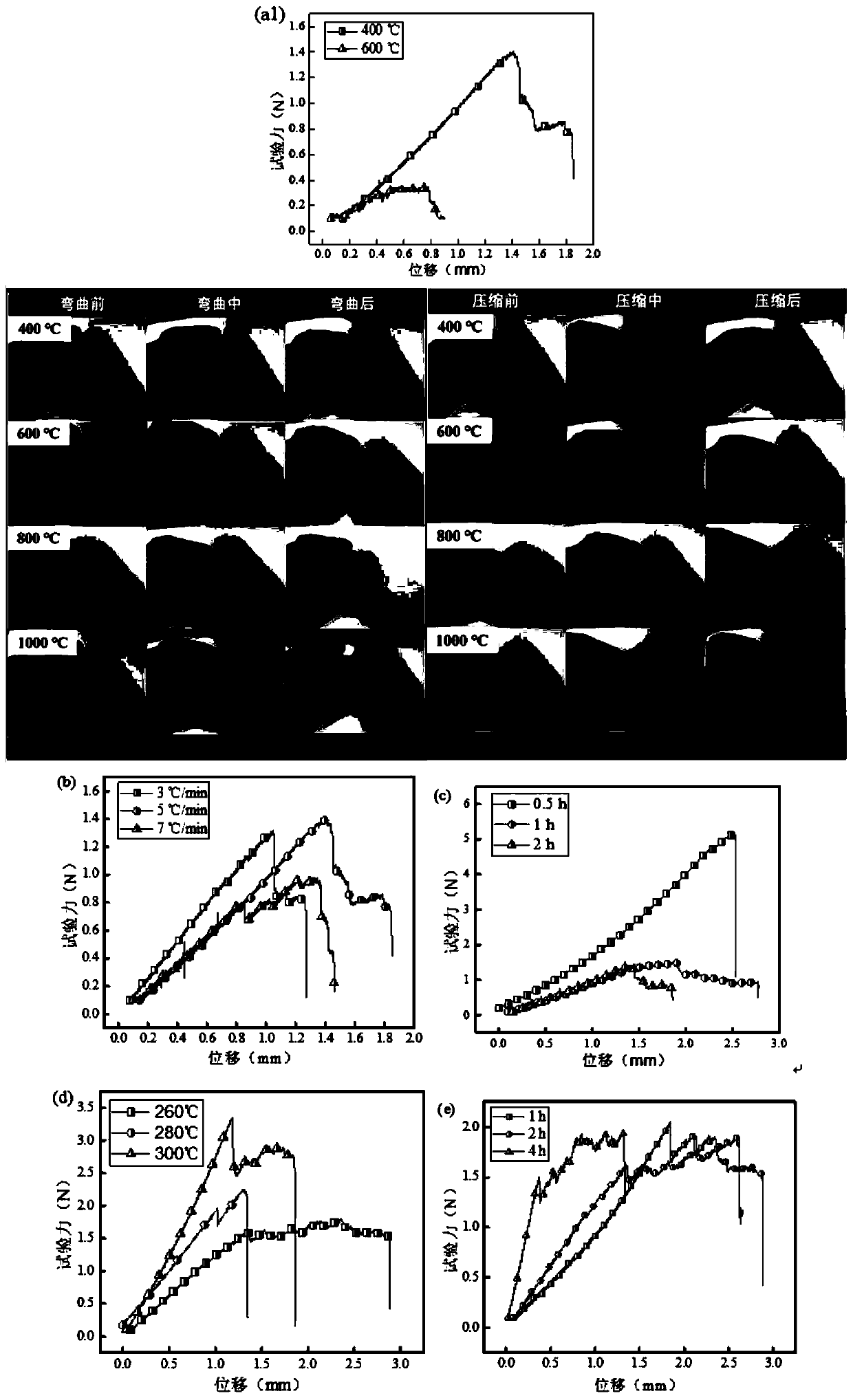

Phase-change composite material with photo-thermal conversion function and preparation method thereof

ActiveCN110257019AGood size controlEasy to processSolar heating energyOther chemical processesDecoyThermal energy storage

The invention discloses a phase-change composite material with a photo-thermal conversion function and a preparation method thereof, and belongs to the cross field of phase-change energy storage and energy conversion. The multifunctional phase change composite material is prepared by combining Ti2O3 nano particles with a heat storage phase change material for the first time, so that a photo-thermal conversion function is expected to be provided on the basis of phase-change heat storage and temperature control functions, and the carbon foam-based phase-change composite material which is is easy to cut and process, has a controllable appearance size, has light weight and flexibility, and has photo-thermal conversion performance is provided. Due to the three-dimensional porous carbon foam matrix of the phase change composite material, the phase-change material can be stably stored, and the storage capacity can be regulated and controlled. The phase-change composite material has excellent photo-thermal conversion and temperature adjusting functions and can be used in the aspects of heat energy storage and release, thermal insulation, photo-thermal conversion, infrared stealth and infrared decoy of military equipment, and the like.

Owner:JIANGNAN UNIV

Technique for preparing returnable bottle piece spinning hollow fiber

InactiveCN101270504AGuaranteed uptimeEfficient removalFilament/thread formingFilament-forming treatmentFiberEngineering

The invention relates to a manufacture technique for spinning hollow fiber by recycling bottle chips. The method is characterized in that the manufacture steps includes filtering bottle chip, drying bottom chip, melting with high temperature, screw rod extrusion, spraying silk spray plate, cooling and oiling, shaping and winding, balancing, stretching, deforming, network and finished product. The silk spraying holes of the adopted silk spray plate are combined by ''C''-shaped holes arranged in a concentric circle, and the numbers of the ''C''-shaped holes are the same as that of special-shaped fiber singles to lead the section shape of the special-shaped fiber sprayed by the silk spray plate and formed by a subsequence working procedure to be ''C''-shaped; a bottle chip drying tower the upper part of which adopts a variable diameter form and the inside is added three rectangle cones; a melt filter device is a three grade vertical filter. The invention is used very broadly.

Owner:邹军

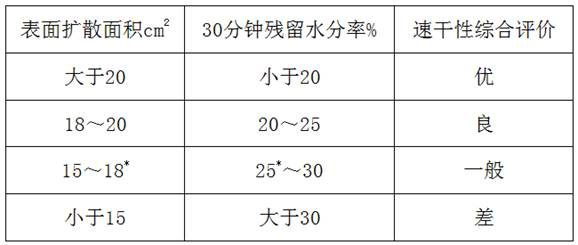

Anti-ultraviolet and moisture-absorption quick-dry yarn, and production technology and application thereof

ActiveCN109112688AIncreased durabilityReduce finishing processYarnMonocomponent polyesters artificial filamentFiberYarn

The invention relates to the production technology of an anti-ultraviolet and moisture-absorption quick-dry fabric. The technology is characterized by firstly, adopting a polyester resin and an addition agent to melt, extruding, and pelletizing to make polyester chips; then, through a spinning technology, forming a fine denier polyester staple fiber; and then, through siro spinning and weaving technologies, an alkali decrement technology and the like, making a finished product. The anti-ultraviolet and moisture-absorption quick-dry fabric has advantages that a lot of micropores and channels are distributed on a surface so that the fabric has a high capillary effect; sweat can be quickly transferred to an outer groove through the micropores so as to form a moisture-absorption quick-dry effect; and an environment-friendly ultraviolet absorbent, a shielding agent and the polyester chips are fused, and a high-performance anti-ultraviolet and moisture-absorption quick-dry fabric after a special spinning technology is formed.

Owner:ZHEJIANG LANTIANHAI FAB TECHNOLAGY CO LTD

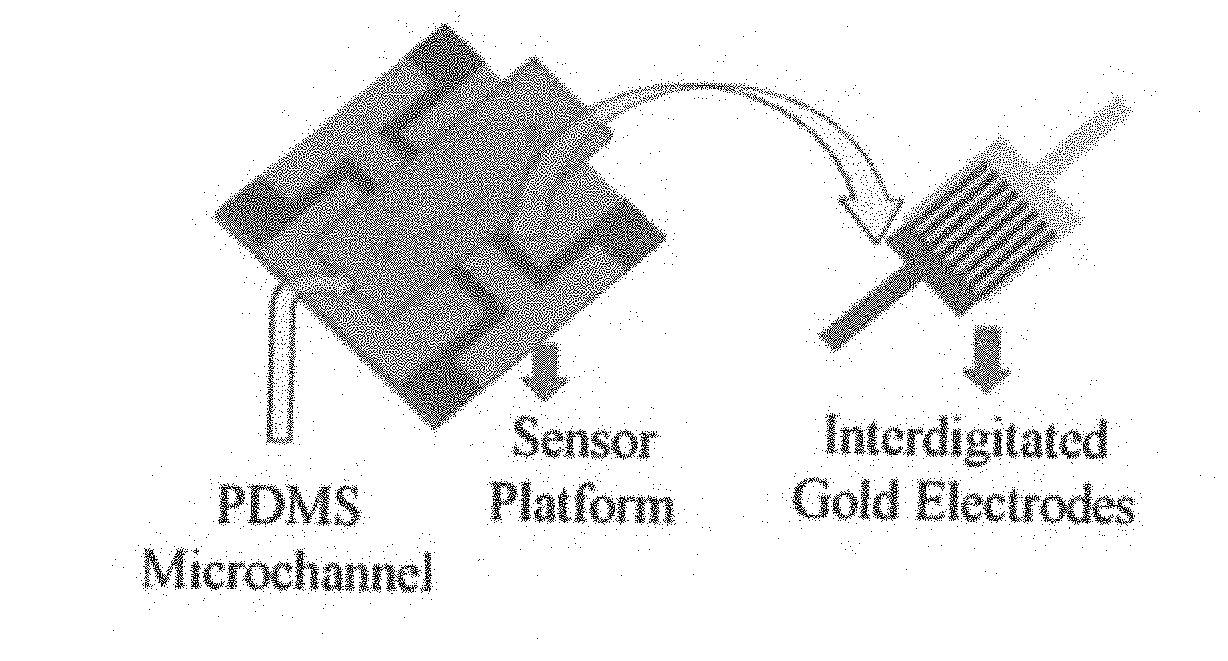

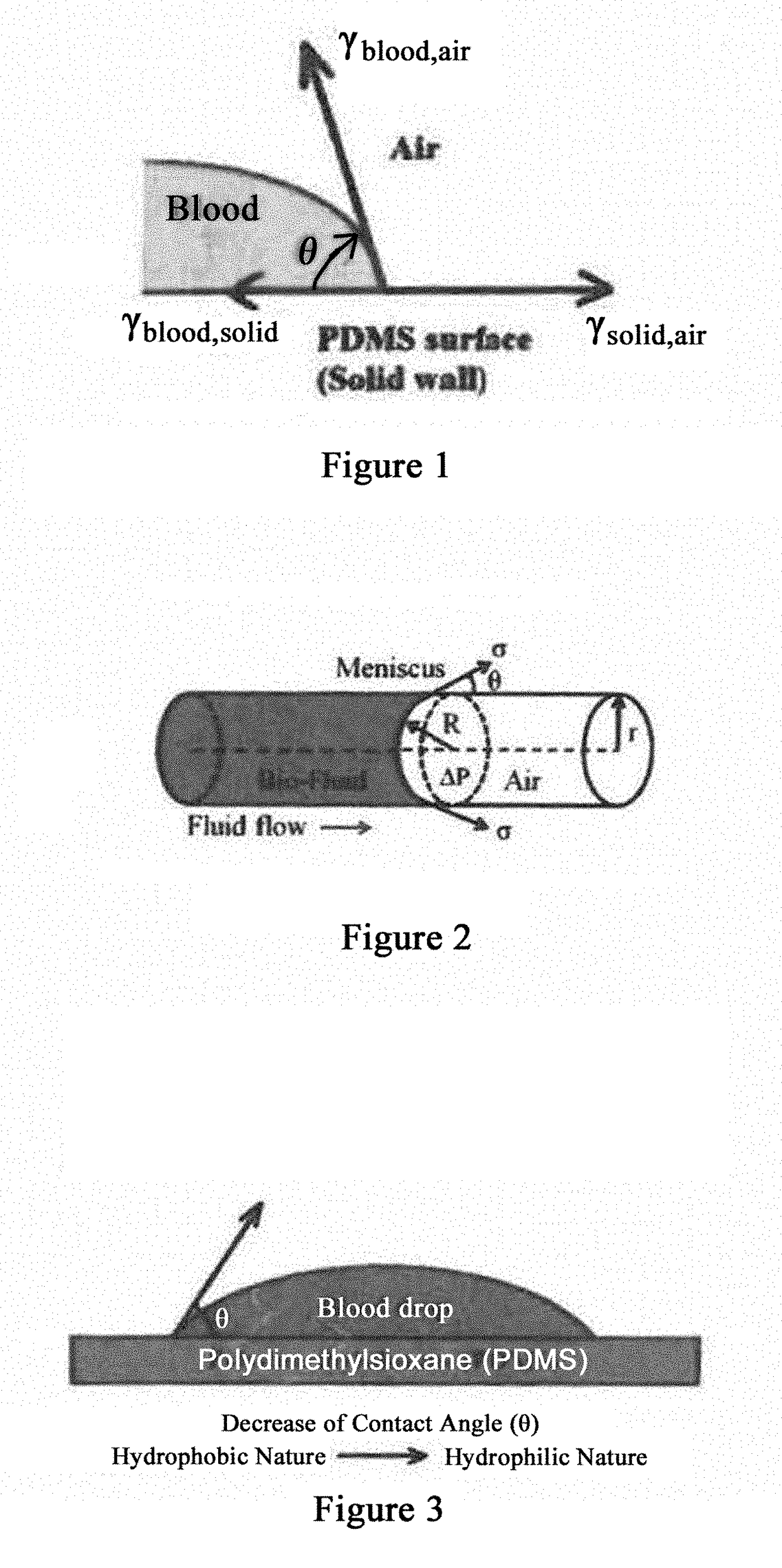

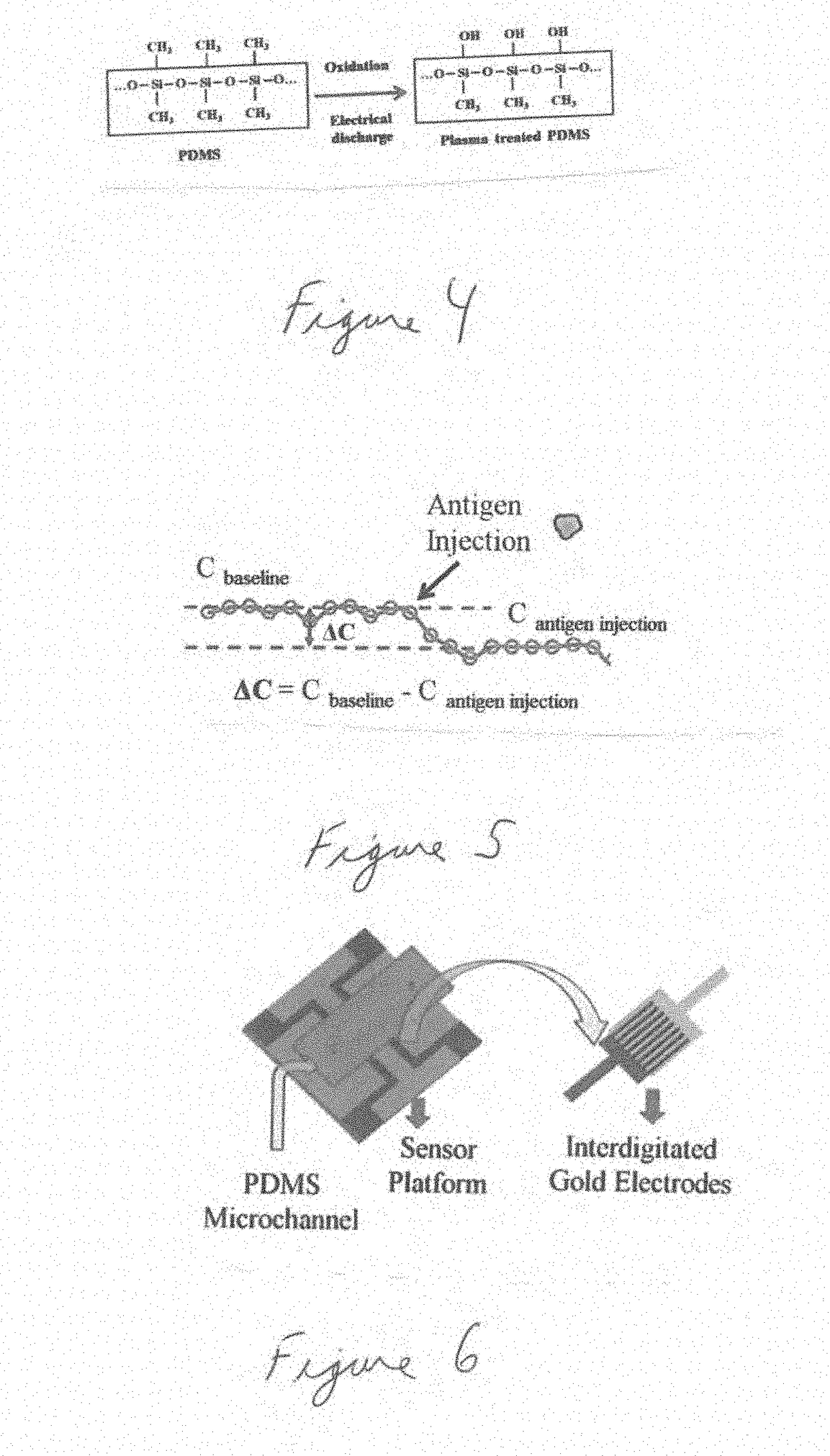

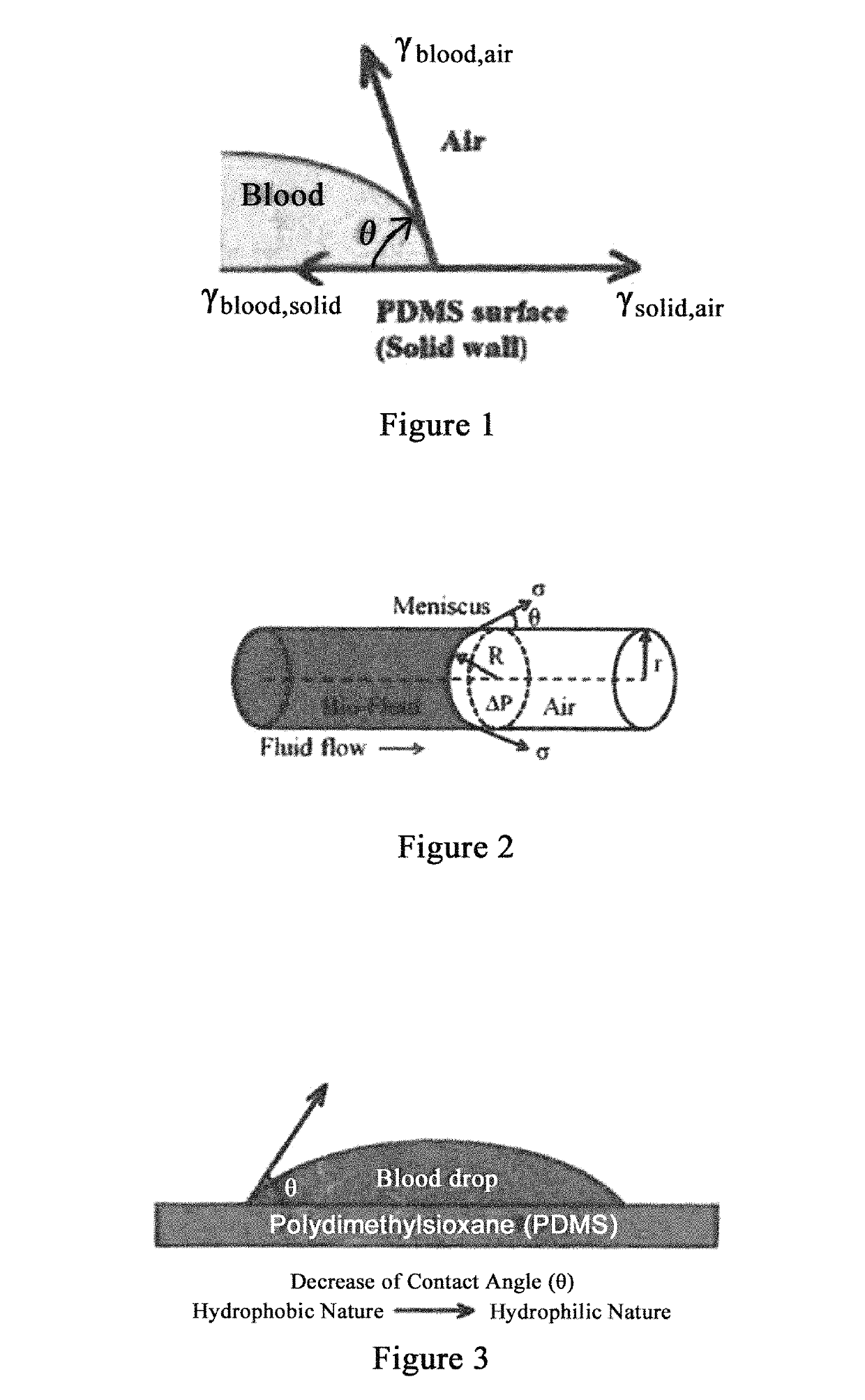

Biomarker detection and self-separation of serum during capillary flow

ActiveUS20180128823A1Reduce effortReduce man powerBiological material analysisLaboratory glasswaresAntigenCapacitance

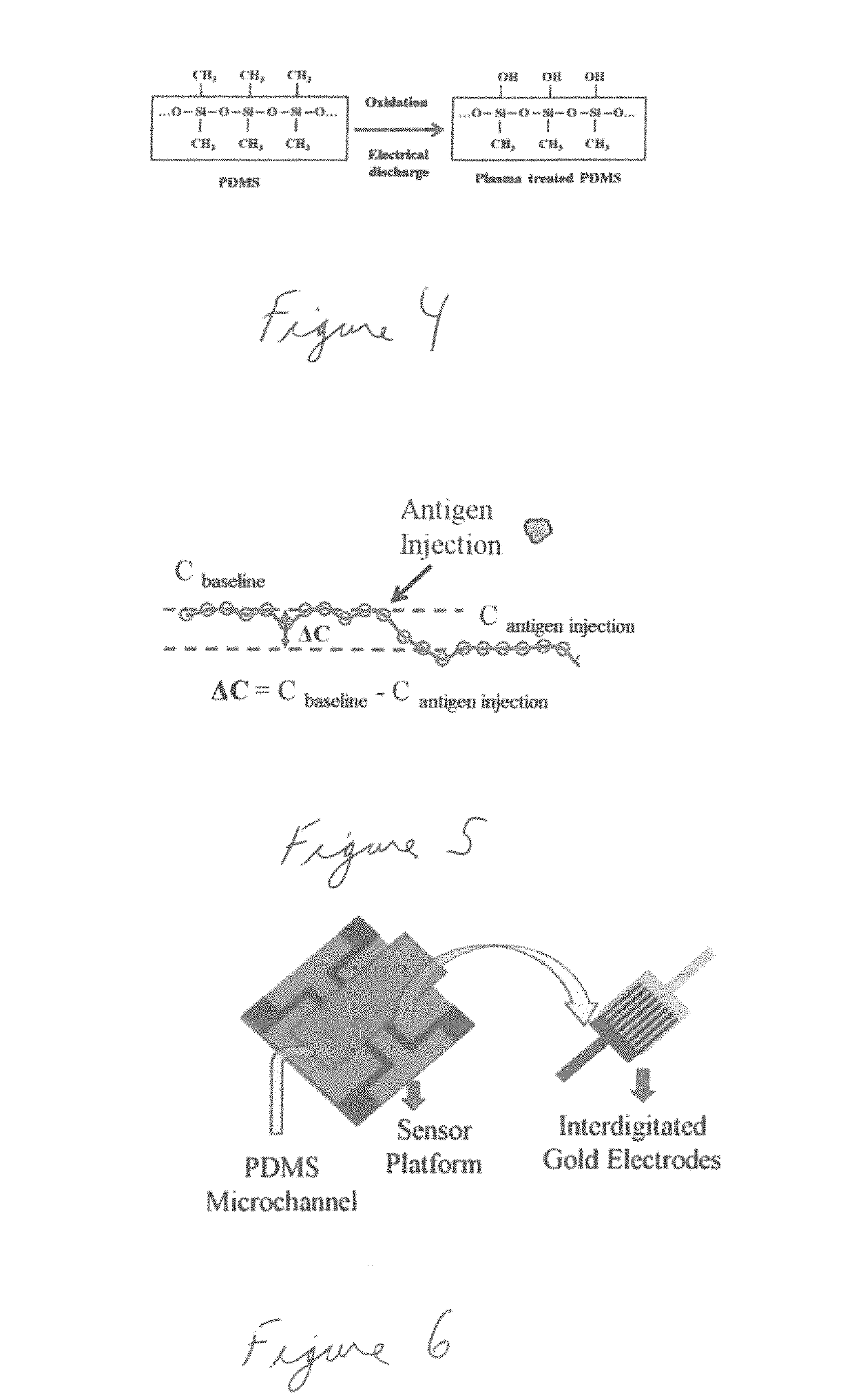

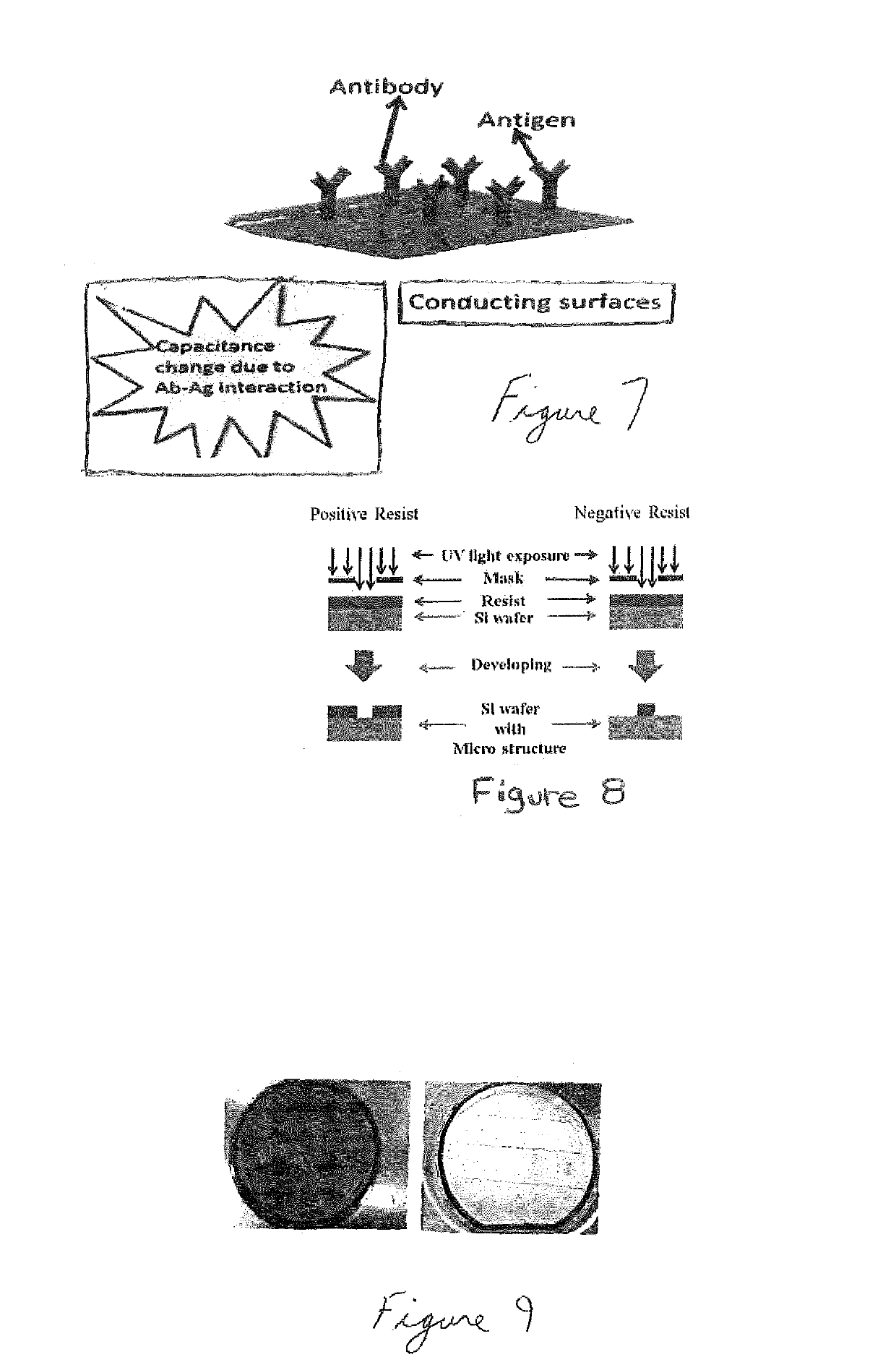

Molecularly Imprinted Polymers (MIPs) are utilized to detect diseases and minimize false negative / positive scenarios. MIPs are implemented on a nano-electric circuit in a biochip where interactions of MIPs and an Antigen / Antibody (AG / AB) are detected, and disease specific biomarkers diagnosed. Biomarker detection is achieved with interdigitated gold electrodes in a biochip's microchannel. Capacitance changes due to biomarker interaction with AG / AB electrode coating diagnose diseases in a microfluidic environment. Biofluid passes through the microchannel and exposed to the nanocircuit to generate a capacitance difference and diagnose any specific disease in the biofluid sample. Blood capillary flow in a microchannel curved section experience centrifugal forces that separate liquid from solid. Various blood densities and segments experience different centrifugal effects while flowing through the curved section so serum is separated from various solid matter without using external devices.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Spinneret plate for producing multi-hollow special-shaped fibers and production method

The invention relates to the technical field of fiber production, in particular to a spinneret plate for producing multi-hollow special-shaped fibers. The spinneret plate comprises a spinneret plate body, a plurality of spinneret orifices are formed in the spinneret plate body, each spinneret orifice comprises a regular porous structure located at the end, close to the raw material input end, of the spinneret plate body and a special-shaped hollow structure located at the end, close to the raw material output end, of the spinneret plate body, and the regular porous structures and the special-shaped hollow structures are communicated and are communicated with the spinneret plate body. A production method for the multi-hollow special-shaped fibers adopting the spinneret plate comprises the specific production steps of raw material screening, raw material drying, high-temperature melting, spiral extruding, spinneret plate spraying-out, cooling and oiling and wind forming. According to thespinneret plate for producing the multi-hollow special-shaped fibers and the production method, the produced multi-hollow special-shaped fibers have the advantages of being high in fluffiness, good in elasticity, high in heat retention property, soft and smooth in hand feeling, good in rebound resilience, good in spreadability and the like.

Owner:新凤鸣集团股份有限公司 +1

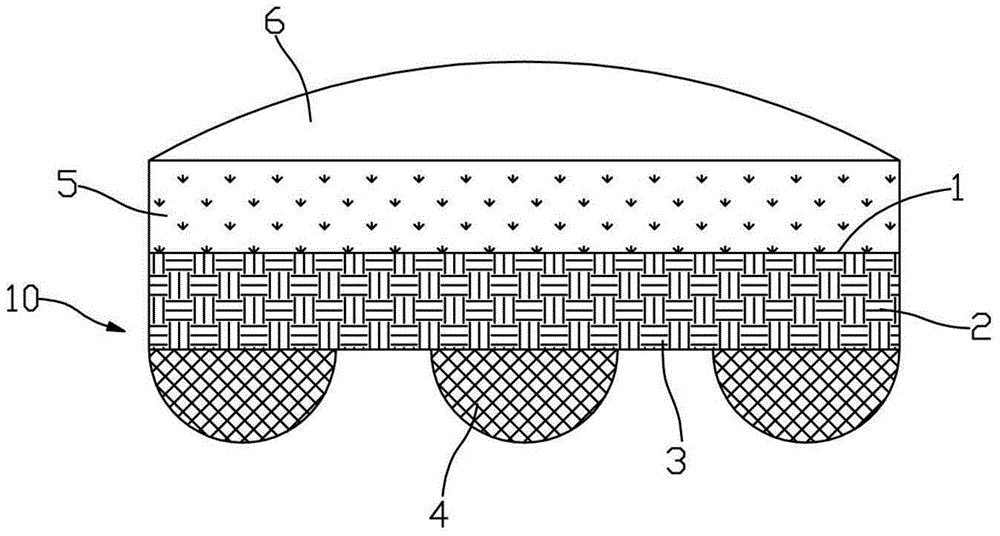

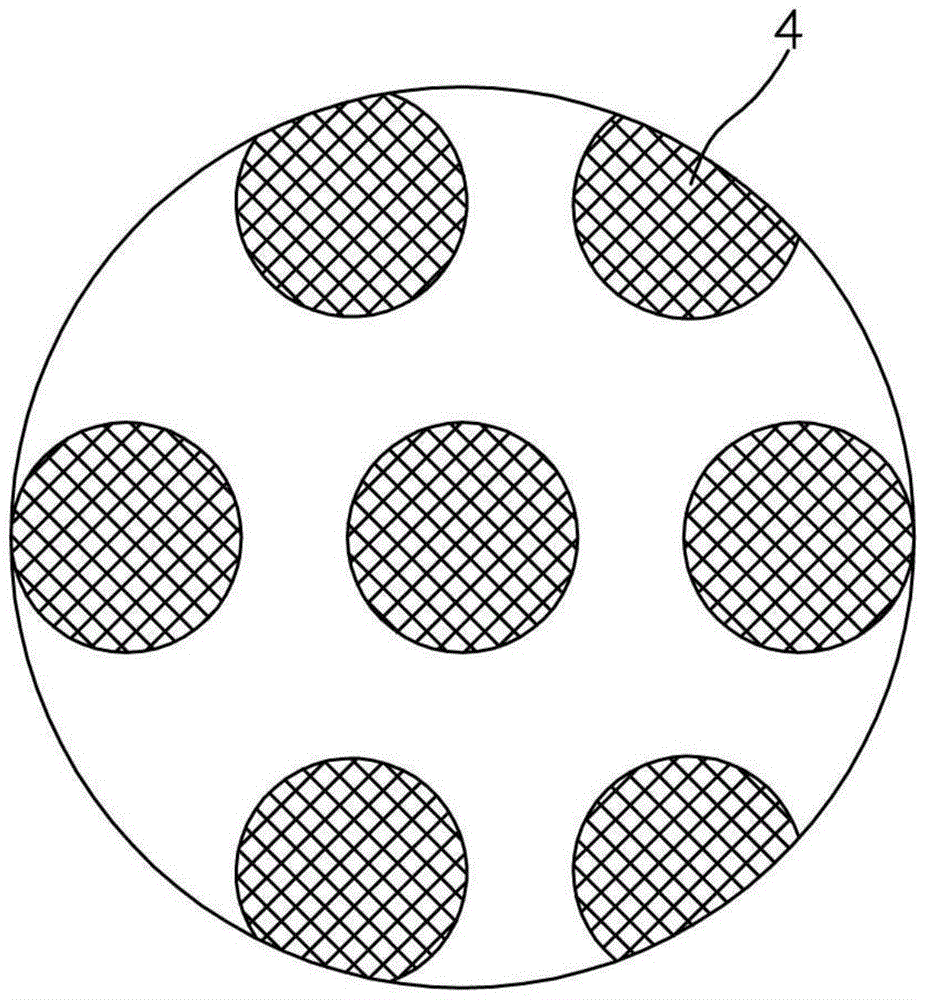

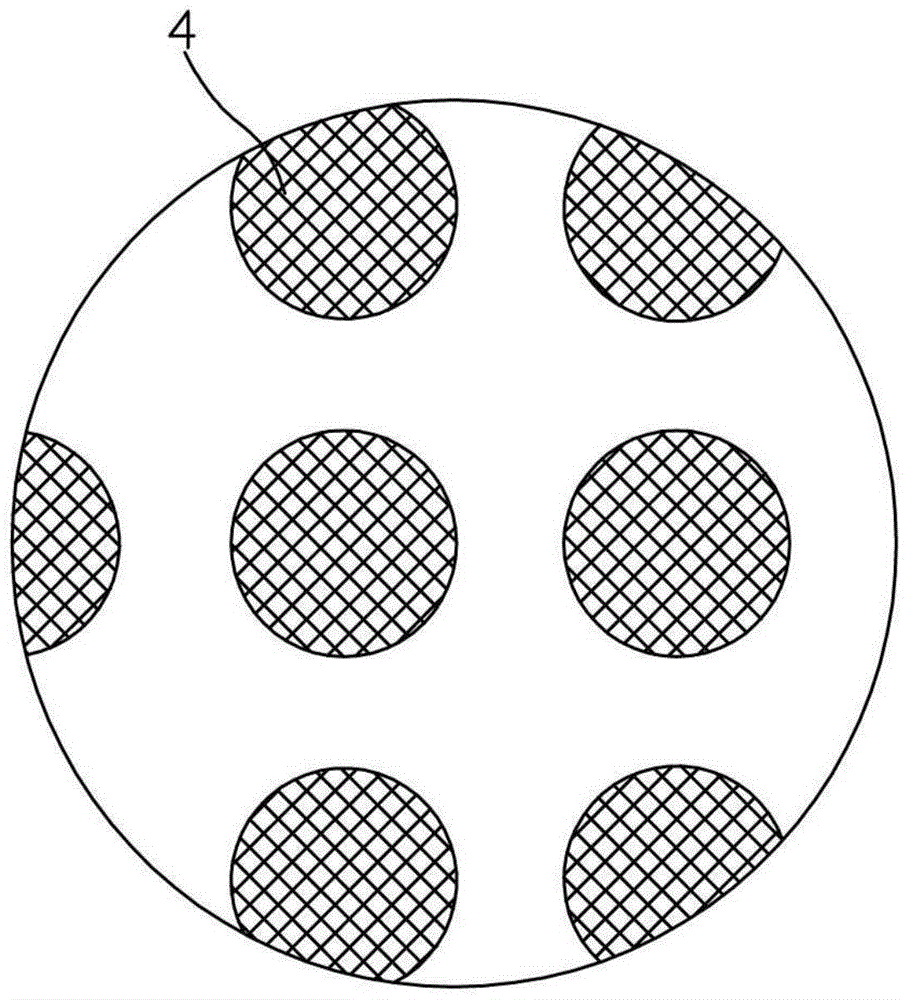

A unidirectional moisture-wicking fabric structure

ActiveCN104786576BHigh speedReduce sticky discomfortGarment special featuresWeft knittingHuman bodySurface layer

Owner:NEWSEGA TEXTILE NANTONG CO LTD

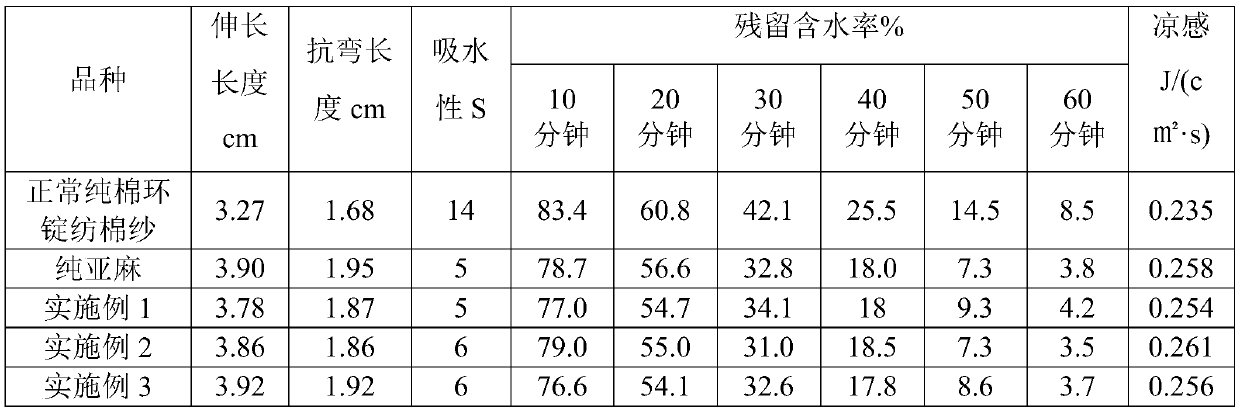

Cotton and hemp blended yarn based imitation pure hemp yarn and spinning method thereof

The invention belongs to the technical field of textiles, and particularly relates to a cotton and hemp blended yarn based imitation pure hemp yarn and a spinning method thereof. The cotton and hemp blended yarn based imitation pure hemp yarn comprises the following raw materials: 40-70% of fine staple cotton carding noil, 30-50% of fine staple cotton and 0-10% of flax loose fibers. According to the cotton and hemp blended yarn based imitation pure hemp yarn and the spinning method thereof, used spun roving contains a large amount of short fibers; in a drafting process of a spinning frame, dueto the fact that the number of floating fibers is increased, irregular and bamboo-joint-like slubs are formed on the surface of the yarn, are just like hemp joints of a hemp yarn and are similar to hemp in appearance and characteristic; and when the twist factor of a cotton yarn is increased, the cotton yarn is reduced in diameter and becomes hard, a gap between the fibers is reduced, the capillary effect is improved, and the characteristics of water absorption and quick drying can appear.

Owner:LUTAI TEXTILE

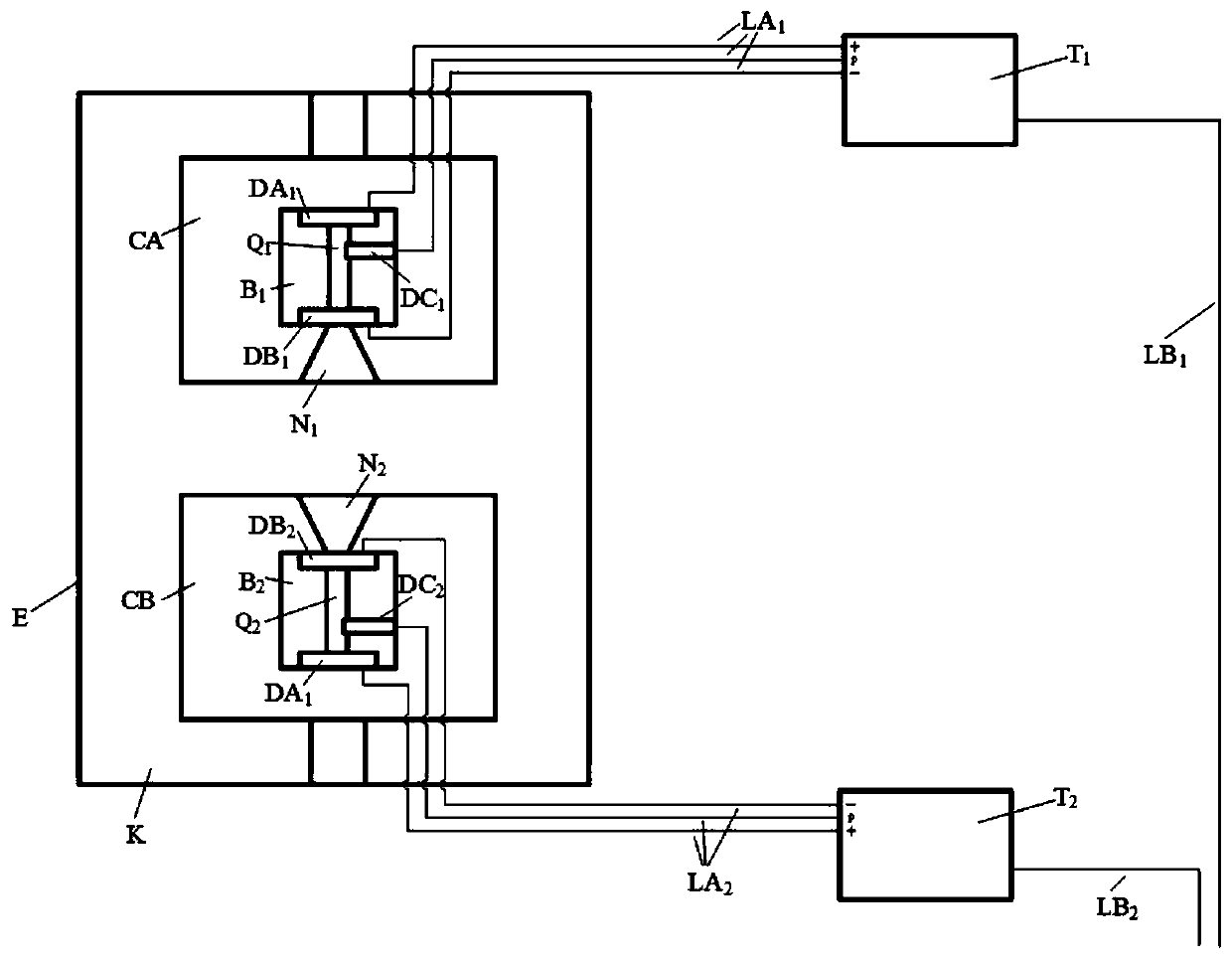

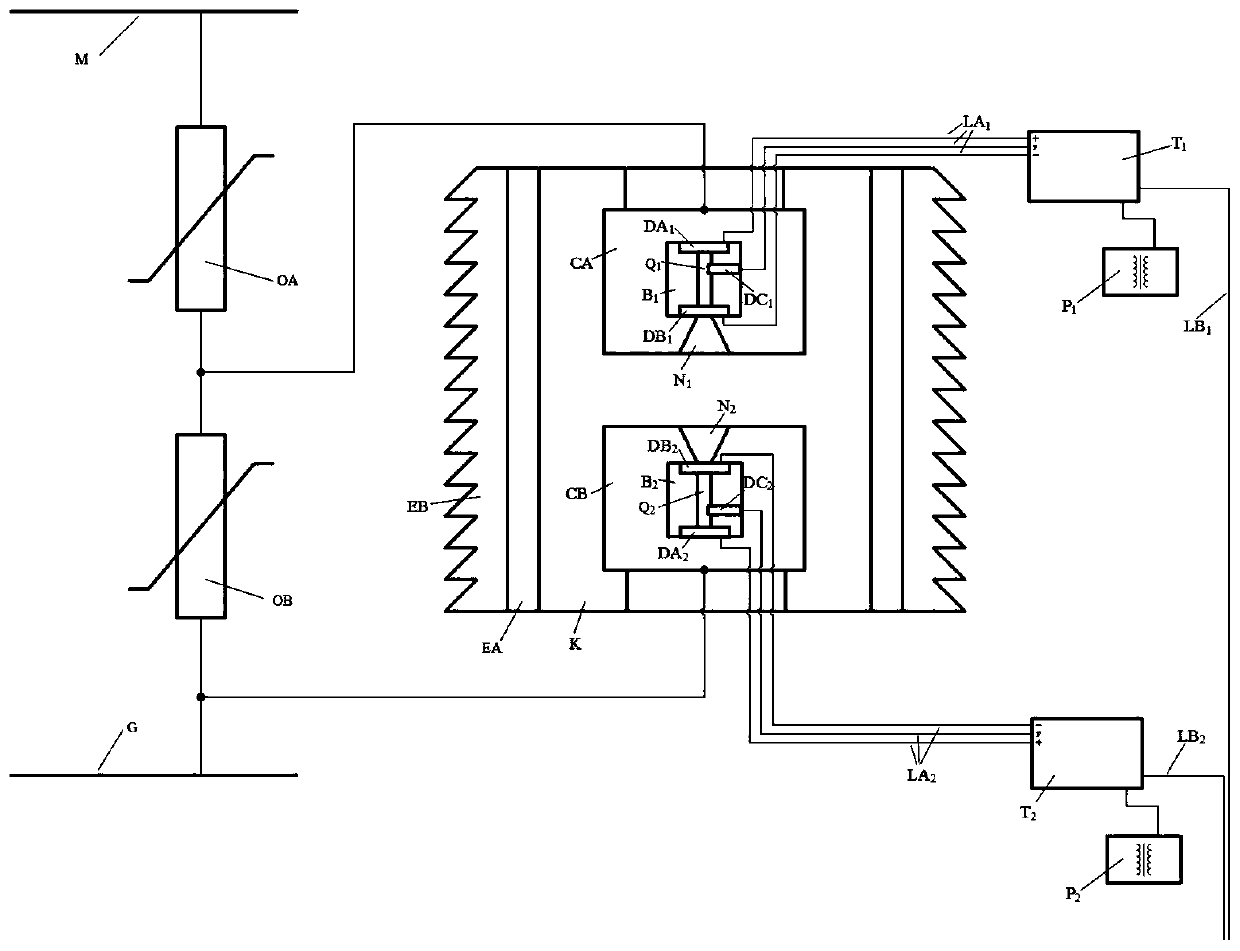

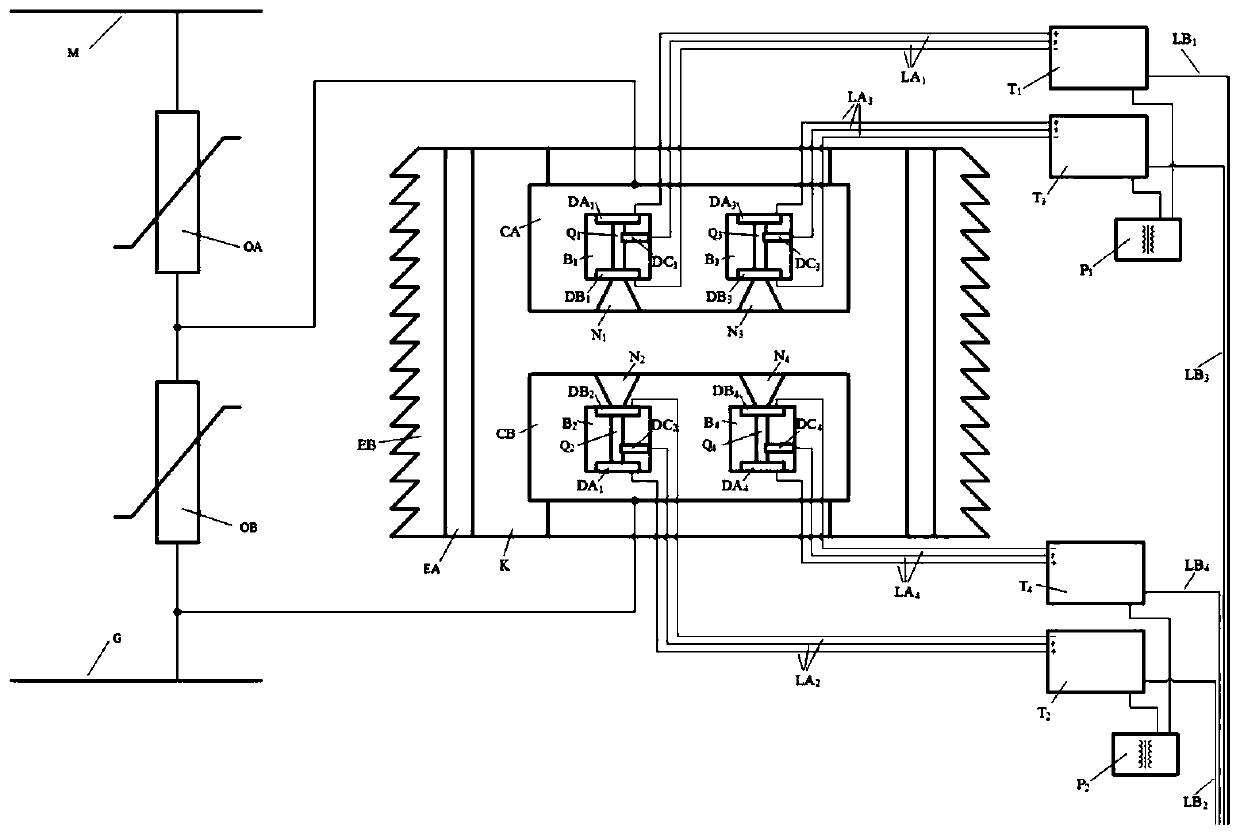

Closed discharge gap triggered by plasma jet and application thereof

PendingCN110430655AReliable actionImprove controlSpark gap detailsPlasma techniquePlasma jetHigh pressure

The invention discloses a closed discharge gap triggered by a plasma jet and an application thereof. The closed discharge gap comprises a plasma spraying unit comprising an injection device and a plasma trigger T, wherein the injection device is arranged in a contact unit, generates plasmas and ablate the ablation materials through pulse voltages and currents and generates a plasma jet by adoptinga capillary action of an elongated cavity, the injection device is connected with a plasma trigger T through the high voltage wire LA, the contact unit is arranged in the cavity unit for tolerance ofarc ablation, the cavity unit is used for providing a closed high-pressure gaseous medium environment. The closed discharge gap can ensure the reliable operation in the low work parameters, improvesthe control performances of the discharge gap, increases the work range and service life of the discharge gap, solves the problems that the arc is extinguished due to the small gap current, avoids thegap breaking, and replaces the complex and high-cost energy storage and freewheeling device.

Owner:西安西交瑞力电气研究院有限公司

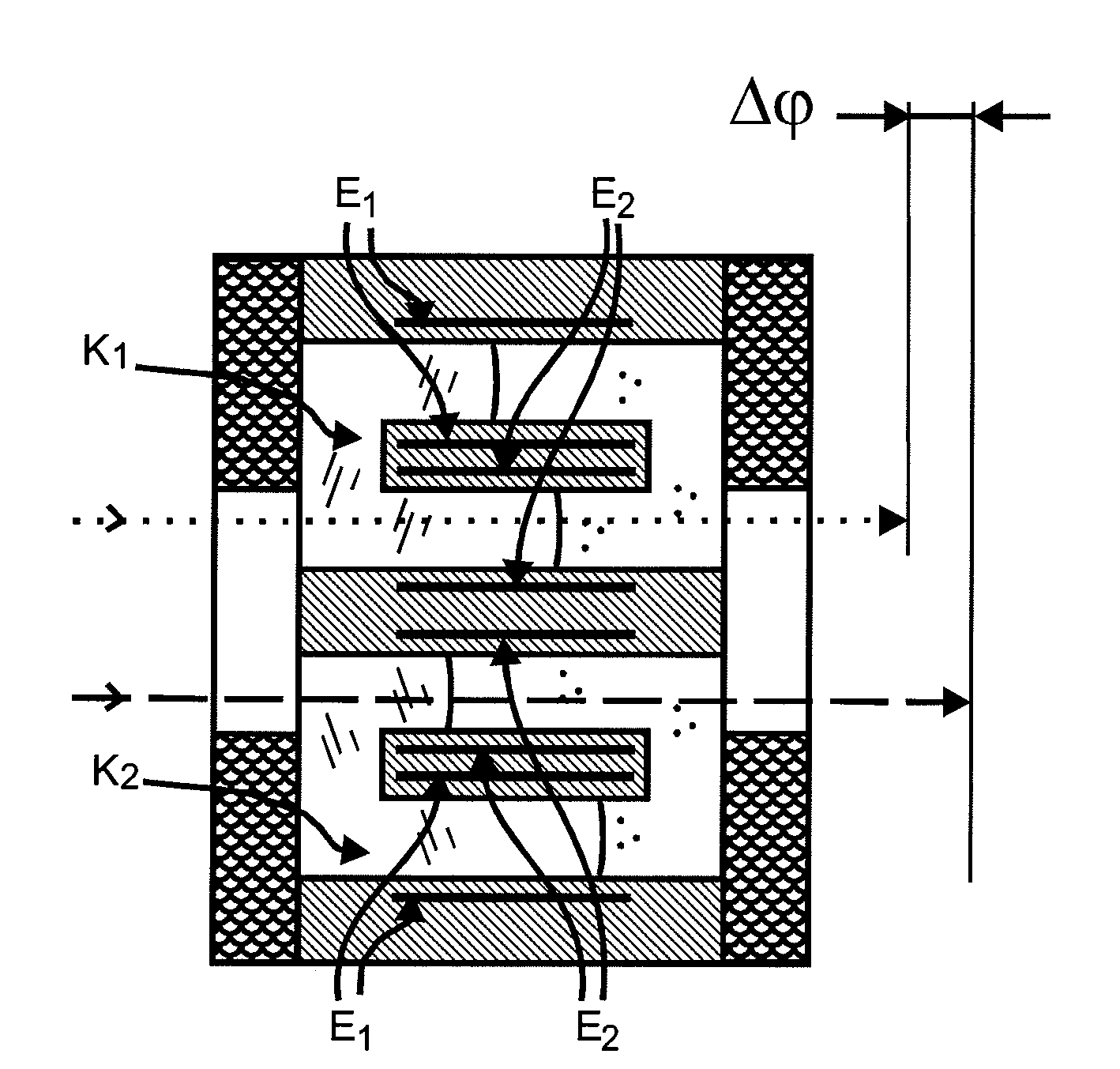

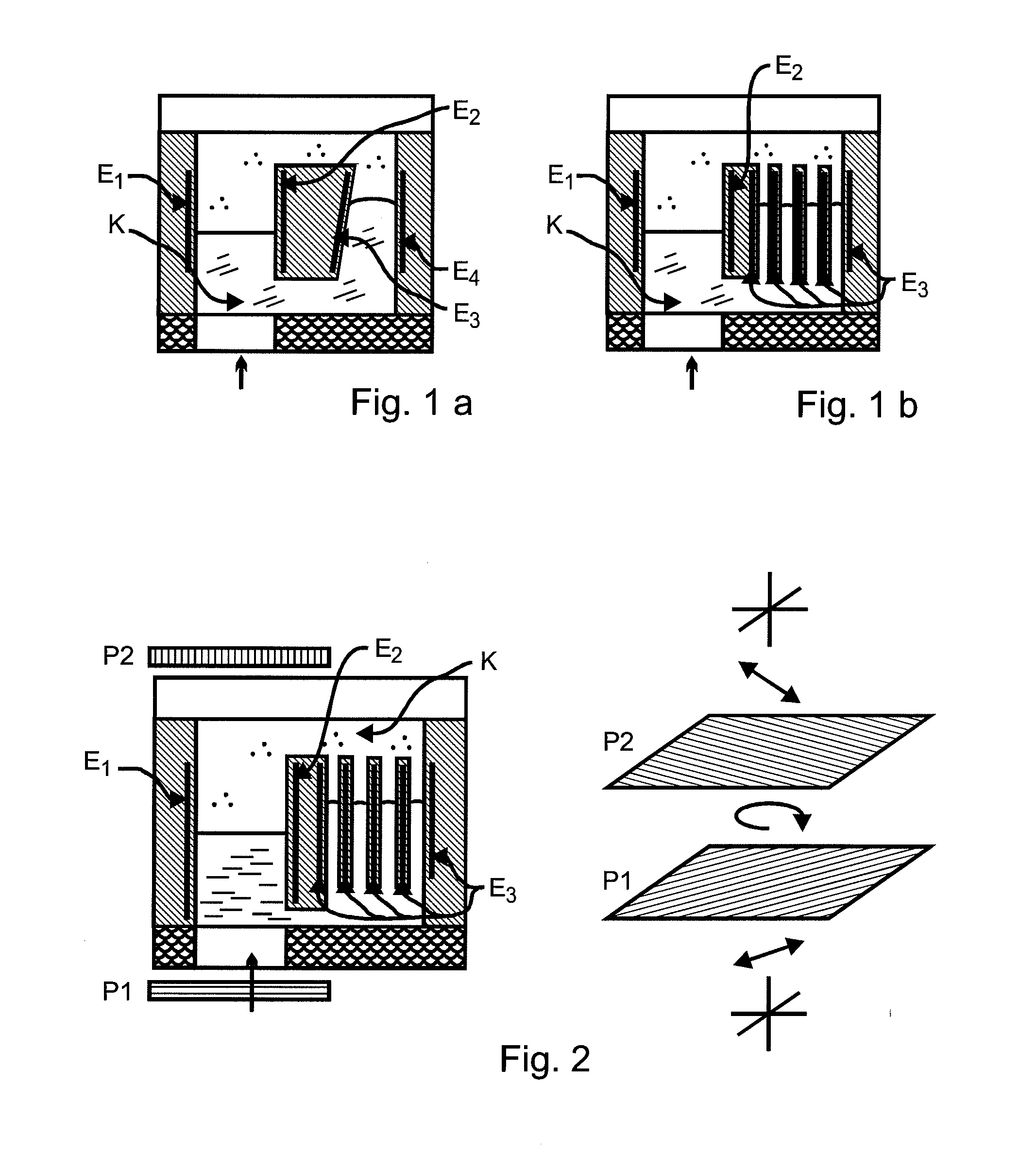

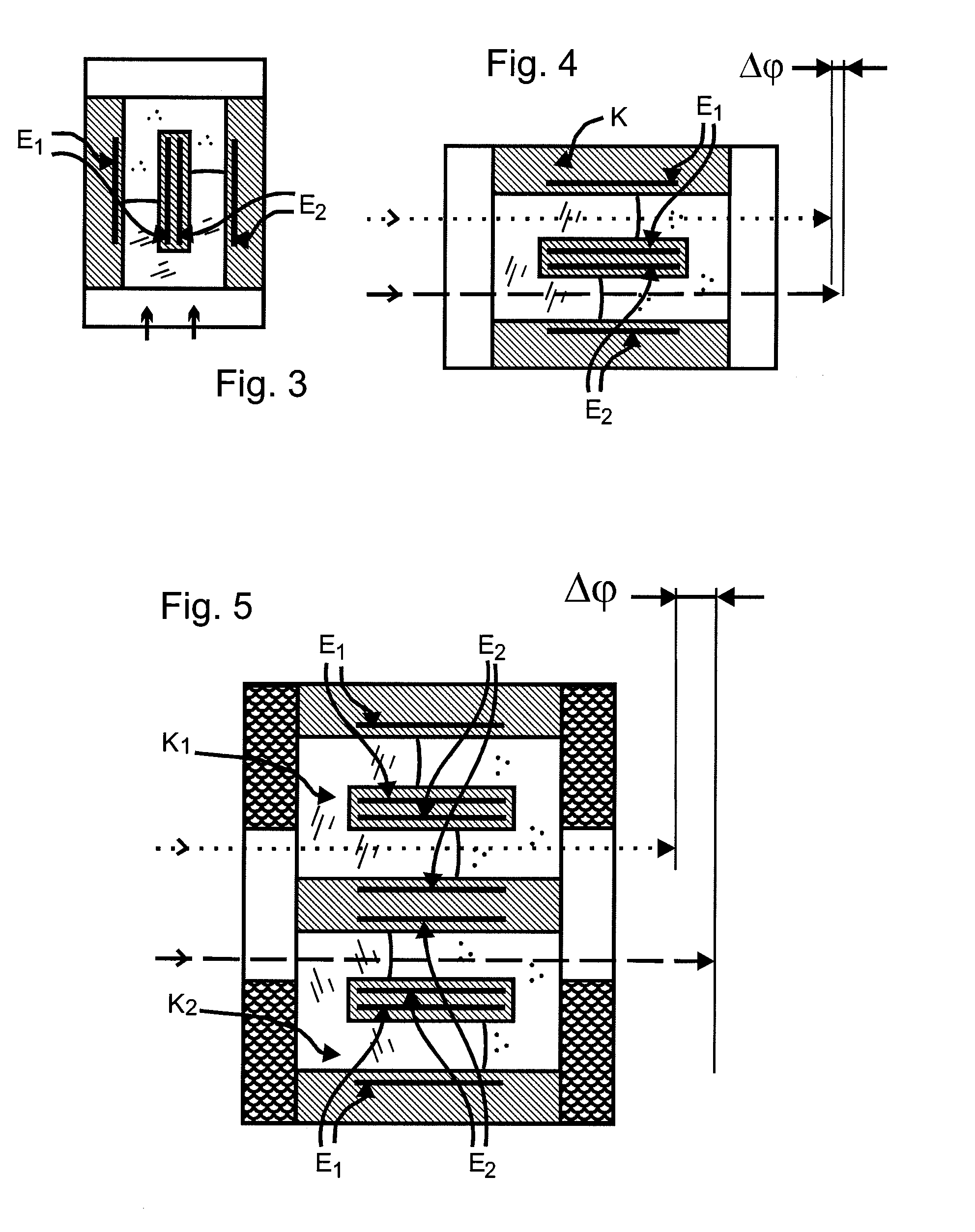

Light Modulation Device

A modulation device based on electrowetting cells (EW cells), phase or amplitude or both simultaneously as a complex value of incident light is modulated in each EW cell. An EW cell includes at least one chamber with at least two fluids which are separated by an interface, external and internal electrodes which form electrode pairs activatable by control means, where at least one electrode pair controls the level of the interfaces in the chamber. The internal, mutually functionally independent electrodes inside the chamber are disposed parallel to each other such that the chamber is divided into two communicating sections with two controllable interfaces, where at least one section is transparent and forms the optical path. When at least one electrode pair is activated, the interfaces are mutually displaced such that the path length of the pencils of rays is changed compared with an initial value.

Owner:SEEREAL TECHNOLOGIES

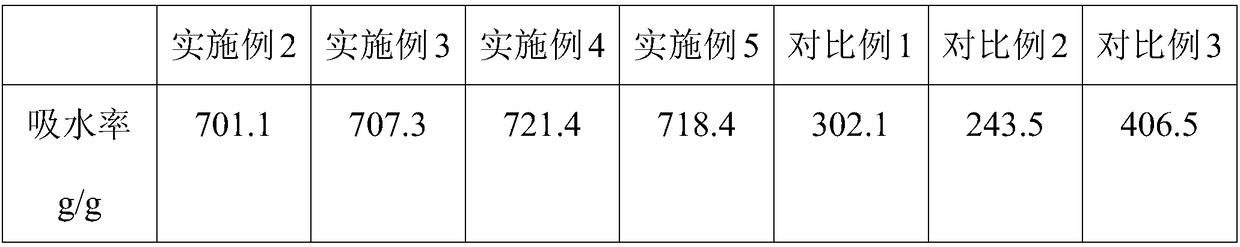

Culture medium of needle mushrooms and preparation method thereof

InactiveCN108975968AFull of nutritionPromote growthCalcareous fertilisersBio-organic fraction processingNutritionEdible mushroom

The invention discloses a culture medium of needle mushrooms and a preparation method thereof, and relates to the technical field of culturing of edible mushrooms. The culture medium is prepared fromthe following raw materials in parts by weight: 20 to 30 parts of peony seed husks, 35 to 45 parts of wood chips, 15 to 25 parts of sweet corn cobs, 6 to 12 parts of sweet potato residues, 5 to 10 parts of grape skin, 3 to 7 parts of vinasse, 5 to 10 parts of bran, 3 to 7 parts of tea residues, 1.6 to 2.4 parts of limes, 0.2 to 1 part of peanut shell based water retaining agent, 0.3 to 0.7 part ofpotassium dihydrogen phosphate and 0.2 to 0.6 part of zinc sulfate. The culture medium of the needle mushrooms prepared by the method disclosed by the invention contains many carbon nitrides and trace elements, so that growth of mycelium and fruiting of the mushrooms can be promoted; by adding the peanut shell based water retaining agent, a wet environment is provided for growth of the needle mushrooms for a long time, influence on growth of the mycelium and a fruiting body by dehydration or lack of water of the culture medium is avoided; moreover, the culture medium is used for culturing theneedle mushrooms, so that the output and quality of the needle mushrooms can be obviously improved; the obtained needle mushrooms are rich in nutrition, and the content of the contained saccharide, crude proteins, amino acid and the like is higher.

Owner:铜陵盛牛菌业有限责任公司

Preparation method of woven carpet without gumming process

ActiveCN108411460AEnhanced shape retention and dimensional stabilityOmit the adhesive processHeating/cooling textile fabricsWoven fabricsCopolyesterWeft yarn

The invention discloses a preparation method of a woven carpet without a gumming process. A second coating layer is a hot-melt fiber-formed filament or a staple fibre yarn, a first coating layer is apolyester fiber filament or a staple fibre yarn, the second coating layer accounts for 20%-50% of the total mass of a composite yarn, the first coating layer accounts for 10%-15% of the total mass ofthe composite yarn, the balance is a core yarn, and a pile weft yarn is obtained by adopting the manner. When the non-adhesive carpet is produced by using a hot-melt copolyester fiber as a bonding material in combination with the pile yarn made of a polyester fiber, the melting occurs when the hot-melt copolyester fiber is heated to be higher than the melting point in a hot pressing process, the conformation of a fiber macromolecular chain is changed, the whole macromolecular chain slips through the transition of chain segments, viscous flow occurs, the pile and weft yarns as well as the weftyarns and warp yarns are effectively solidified after curing, and the pull strength of the pile and the shape retention and dimensional stability of the carpet are enhanced, so that the gumming process in the carpet preparation process is omitted, and the produced carpet is more environmentally friendly.

Owner:QINGDAO UNIV

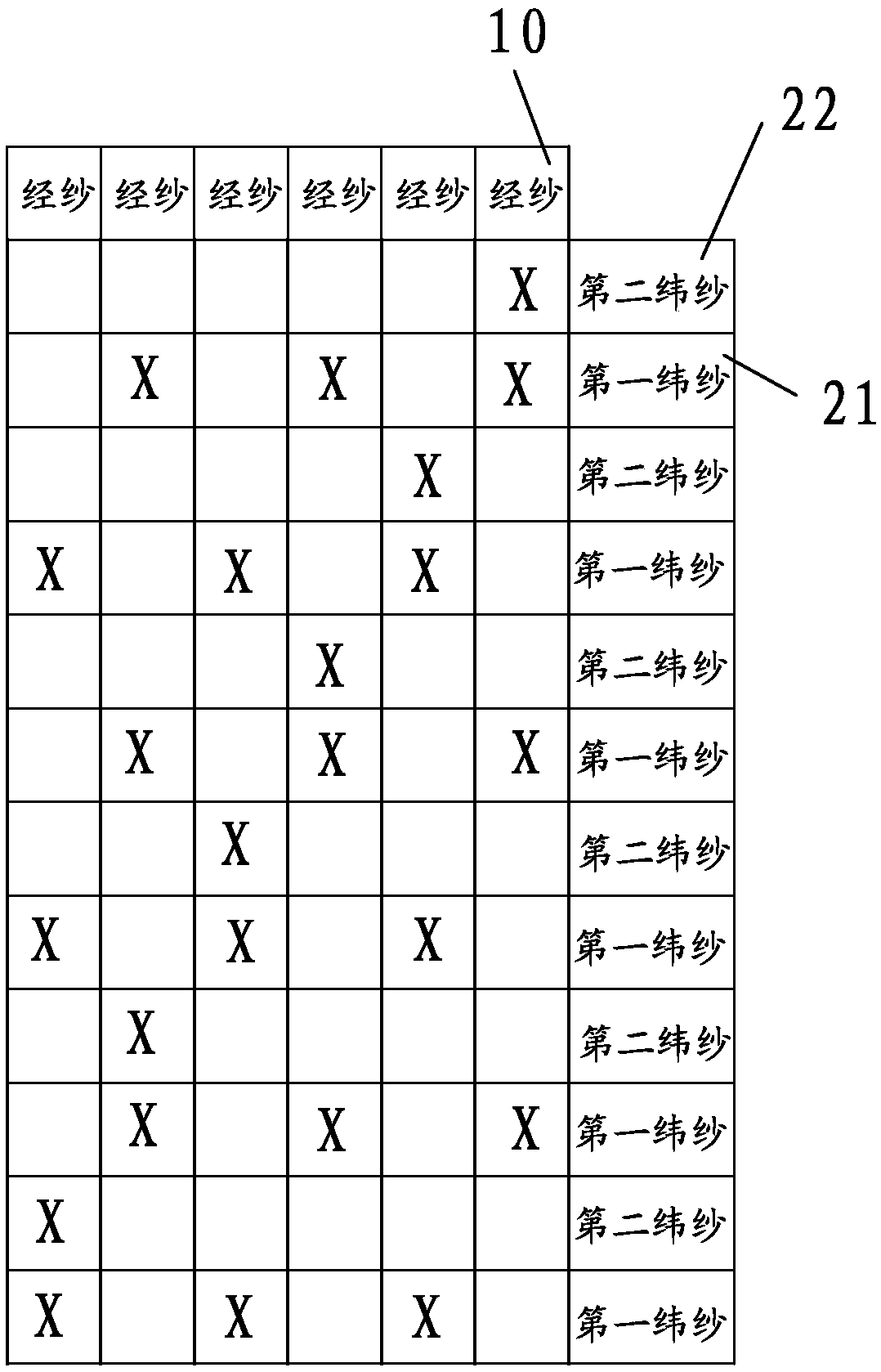

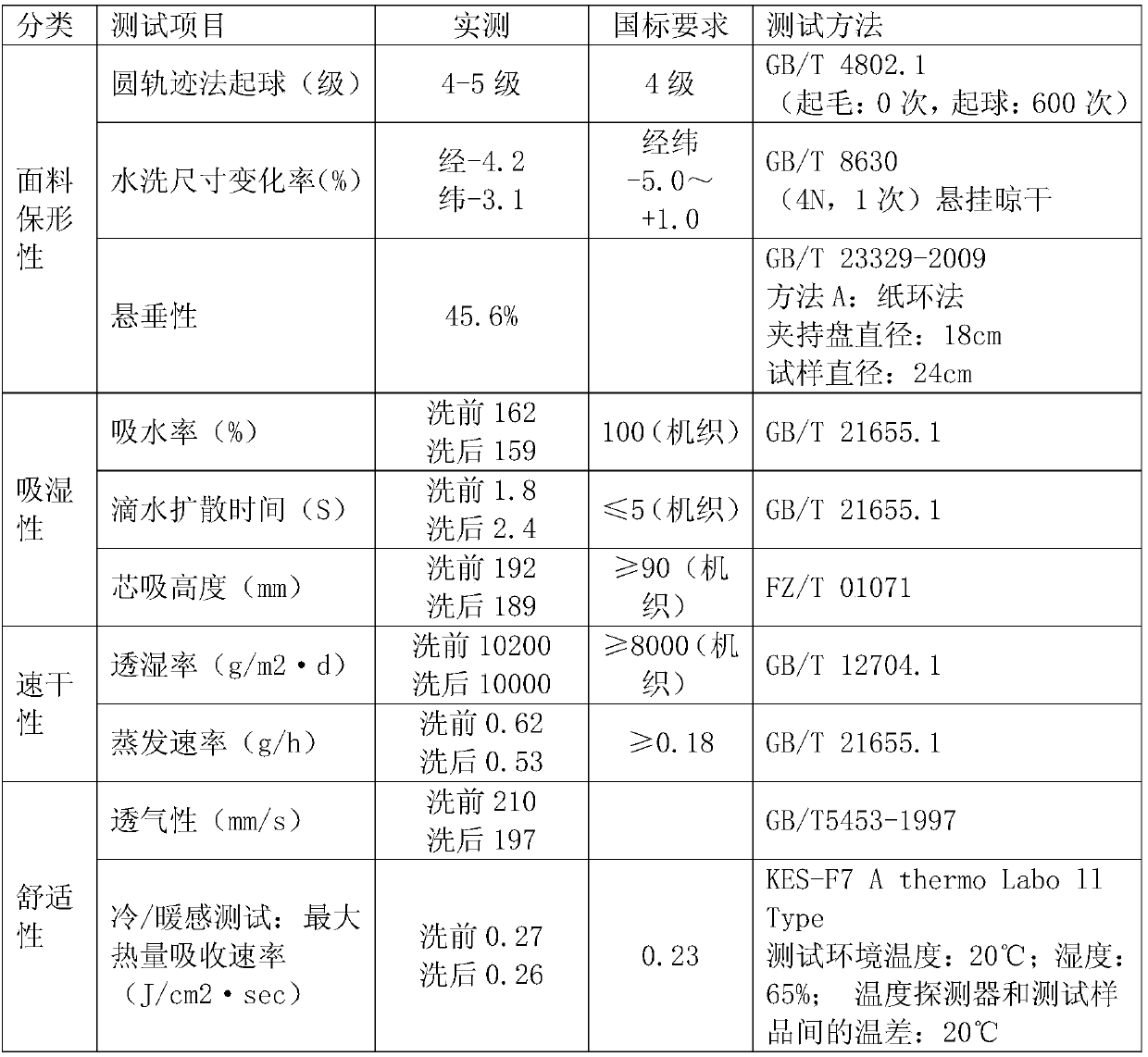

Fabric with excellent temperature, humidity, freedom degree and touch control

ActiveCN109667040ASoft touchEnsure freedom of movementWoven fabricsMonocomponent polyesters artificial filamentPolyamideWeft yarn

The invention relates to a fabric with excellent temperature, humidity, freedom degree and touch control. The fabric comprises a fabric body which is formed by interweaving warp yarns and weft yarns;the warp yarns are polyamide core-spun yarns; the weft yarns comprises first weft yarns and second yarns; the first weft yarns are the polyamide core-spun yarns; the polyamide core-spun yarns are thecore-spun yarns which are formed by coating 20D spandex yarns with 30D / 34F matt DTY polyamide yarns; the second weft yarns are 50D / 72F modified matt DTY terylene; the fabric body comprises 71 mass percent of the polyamide, 17 mass percent of the modified matt DTY terylene, and 12 mass percent of a spandex; the first weft yarns and the second weft yarns are arranged alternatively in the weft direction; the first weft yarns are protruded from the upper surface of the fabric body; and the second weft yarns are protruded from the lower surface of the fabric body. The fabric has excellent skin affinity, has good elasticity on freedom degree, has excellent air permeability on temperature control, has excellent moisture absorbing and quick drying functions on temperature control, and also has drapability.

Owner:XTEPCHINA

Biomarker detection and self-separation of serum during capillary flow

ActiveUS10481154B2Increase capillary effectEnhanced specificity and affinityBiological material analysisLaboratory glasswaresAntigenCapacitance

Molecularly Imprinted Polymers (MIPs) are utilized to detect diseases and minimize false negative / positive scenarios. MIPs are implemented on a nano-electric circuit in a biochip where interactions of MIPs and an Antigen / Antibody (AG / AB) are detected, and disease specific biomarkers diagnosed. Biomarker detection is achieved with interdigitated gold electrodes in a biochip's microchannel. Capacitance changes due to biomarker interaction with AG / AB electrode coating diagnose diseases in a microfluidic environment. Biofluid passes through the microchannel and exposed to the nanocircuit to generate a capacitance difference and diagnose any specific disease in the biofluid sample. Blood capillary flow in a microchannel curved section experience centrifugal forces that separate liquid from solid. Various blood densities and segments experience different centrifugal effects while flowing through the curved section so serum is separated from various solid matter without using external devices.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

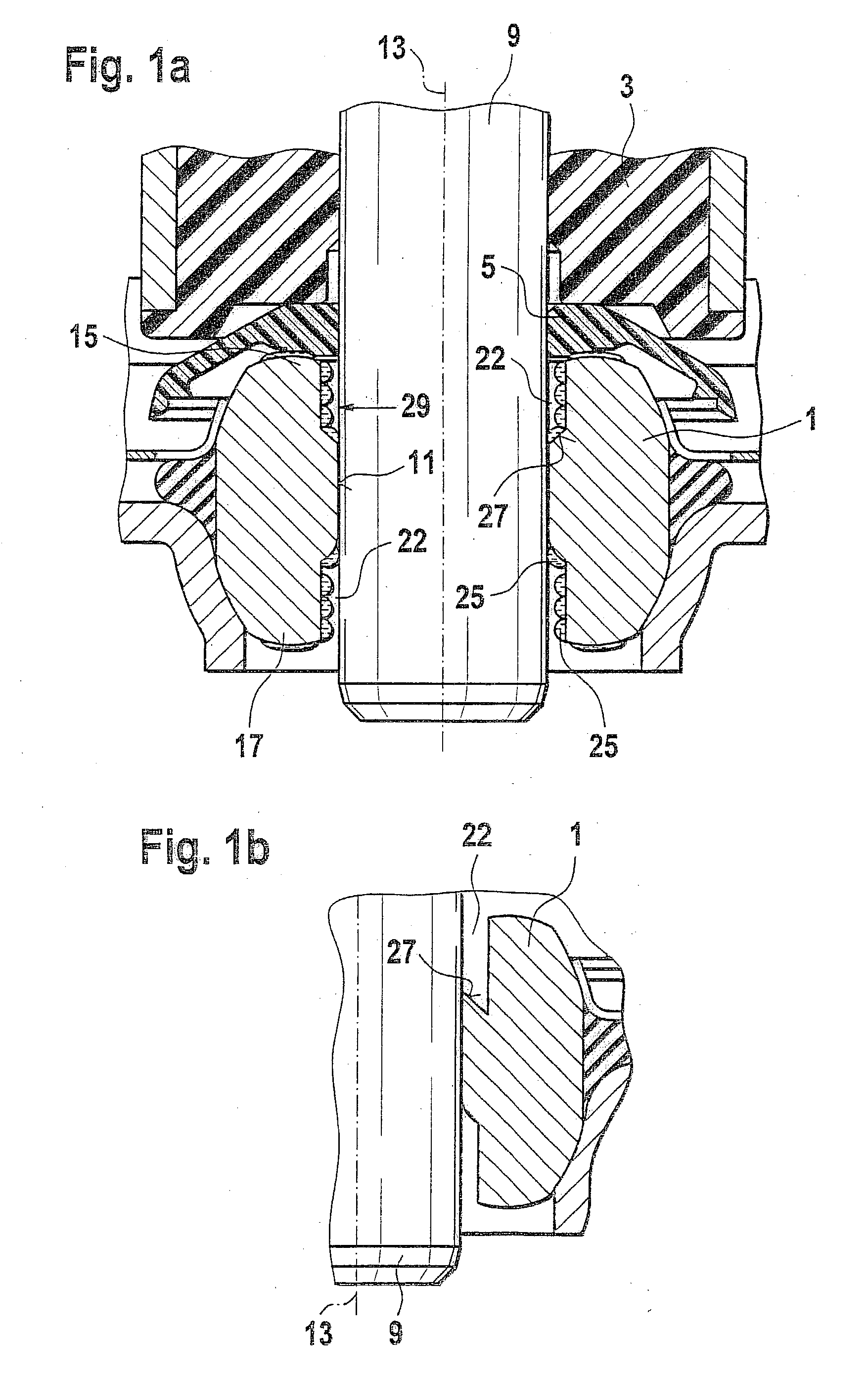

Honeycomb for an exhaust treatment unit

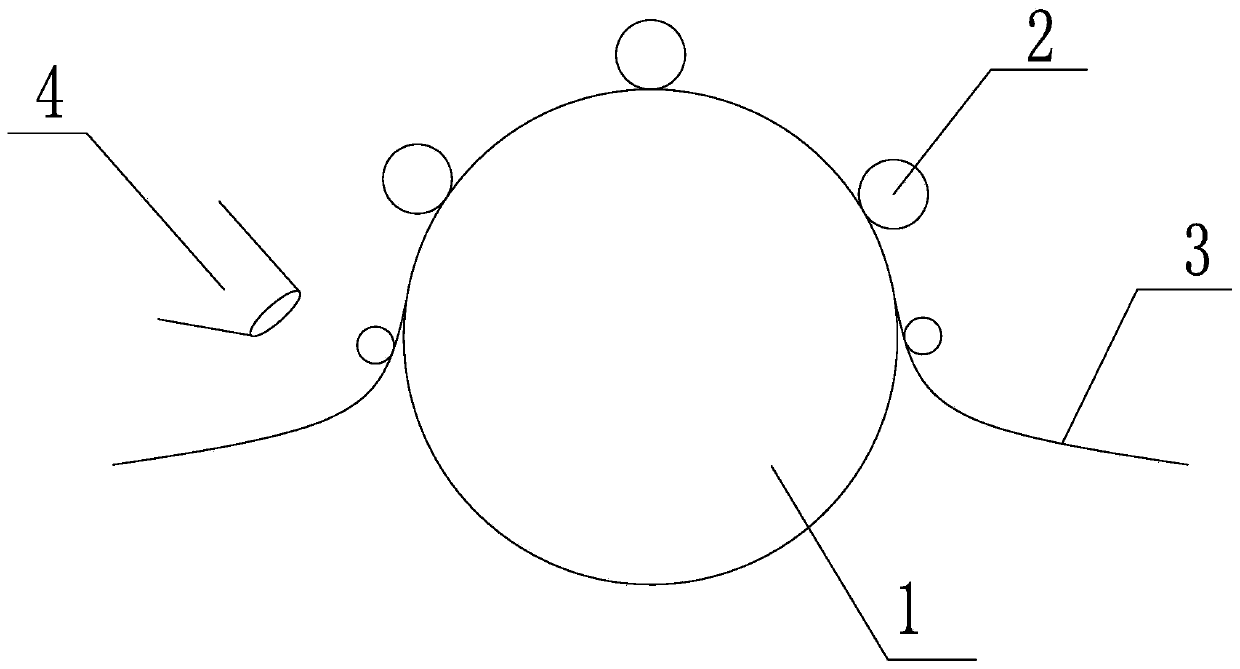

InactiveCN101305170APut an end to the phenomenonIncrease capillary effectExhaust apparatusSoldering apparatusEngineeringHoneycomb structure

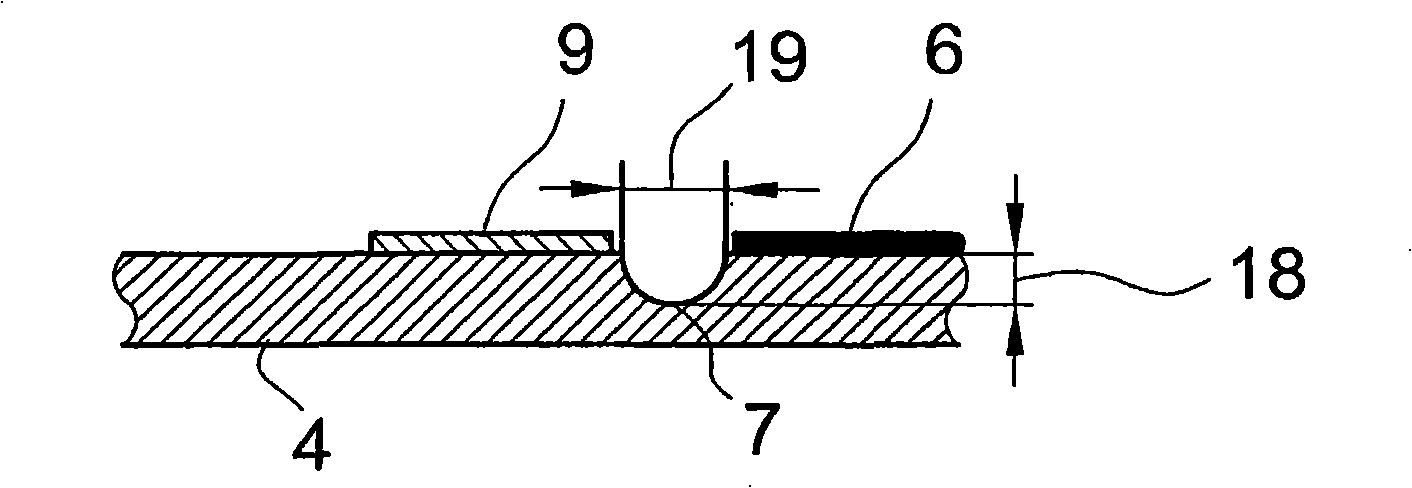

Honeycomb (1) for an exhaust treatment unit (2) having at least one honeycomb structure (3) and a least one housing (4), which at least partially surrounds the at least one honeycomb structure (3), at least one region (5) between the honeycomb structure (3) and the housing (4) being formed with a brazed joint (6), wherein at least two separate means (7, 9) for delimiting the brazed joint (6) are provided. Furthermore, a method for producing a corresponding honeycomb is also proposed.

Owner:EMITEC EMISSIONSTECHNIK

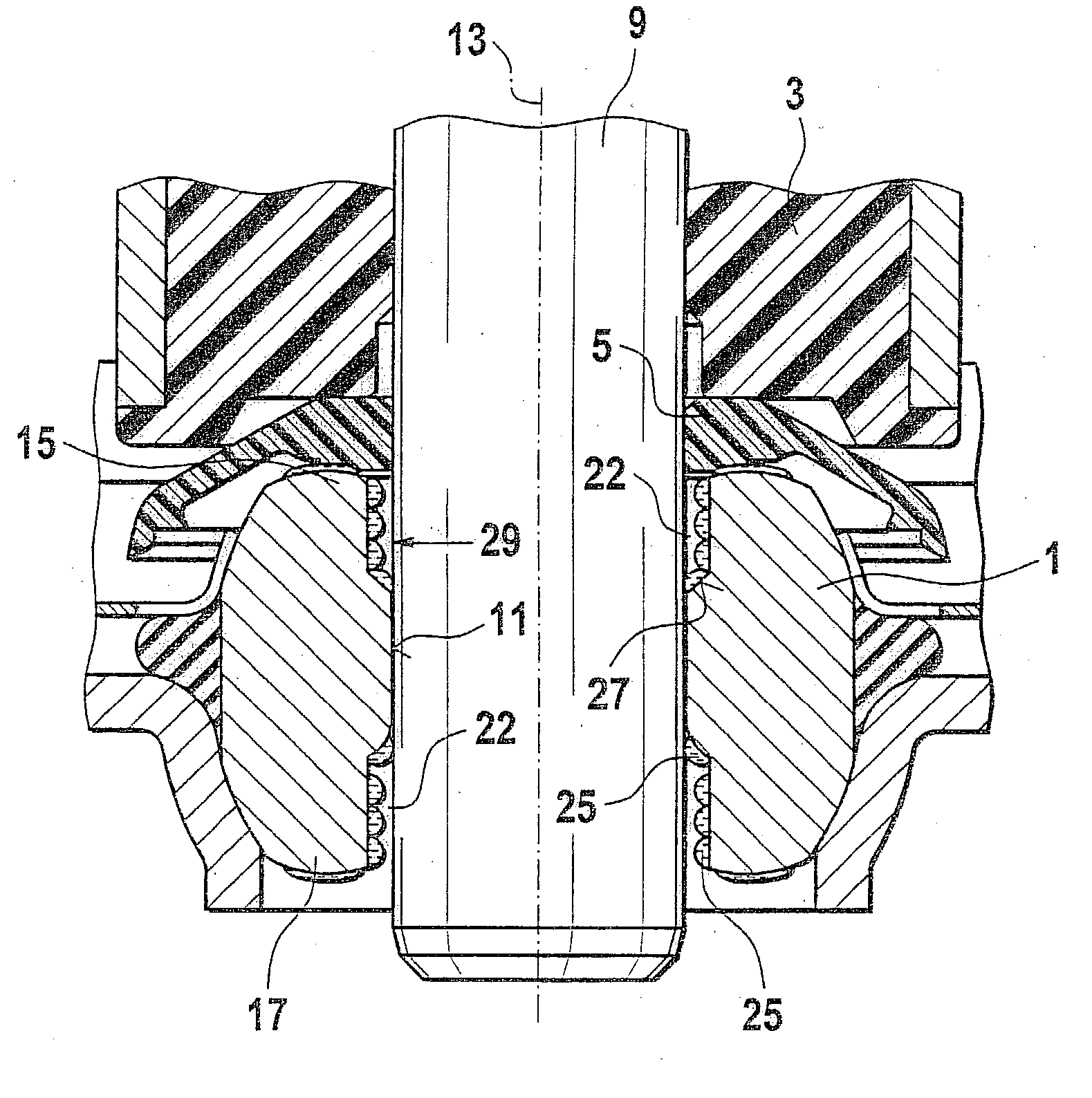

Slide bearing

InactiveUS20030179965A1Increase capillary effectBearing componentsSliding contact bearingsSlider bearingLubricant

In a slide bearing of the prior art, any lubricant present is lost at the two outer axial ends of the bearing. In a slide bearing (1) of the invention, there are hollow chambers (22) at both outer axial ends (15, 17), which by the capillary effect cause escaping lubricant (25) to be stored in the hollow chamber (22).

Owner:ROBERT BOSCH GMBH

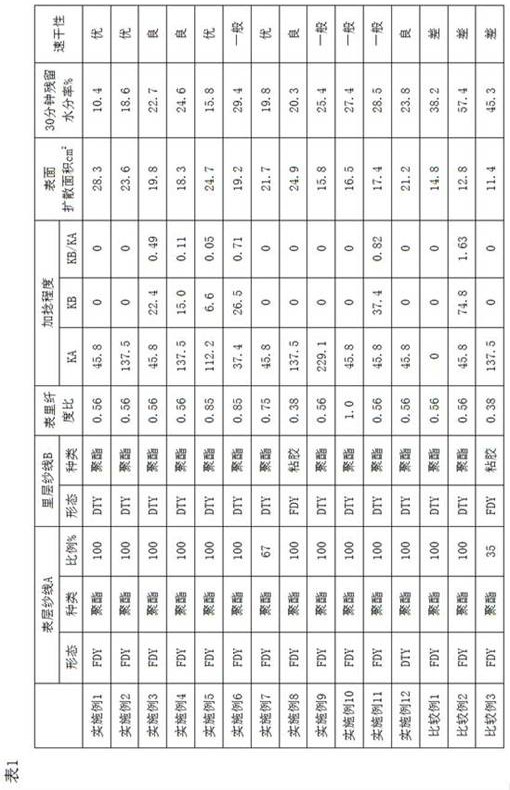

Water-absorbing and quick-drying fabric

ActiveCN111607875ASimple production processLow costWeft knittingMulti-ply fabricsYarnPolymer science

The invention discloses a water-absorbing and quick-drying fabric. The fabric is at least formed by yarn A and yarn B, a surface layer is formed by 50% or above, by weight, of the yarn A, an inner layer is formed by the yarn B, and a twisting degree KA of the yarn A and a twisting degree KB of the yarn B meet the following relational expression: 0=<KB / KA<1, wherein KA and KB are yarn twisting coefficients, and KA is greater than 0. The fabric has a superior drying speed and is suitable for making T-shirts or pants.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Textile cloth wetting device

InactiveCN109208204AImprove wettabilityImprove gross effectFibre treatmentTextile treatment by spraying/projectingWater storage tankMoisture sensor

The invention provides a textile cloth wetting device, which comprises a box body, and is characterized by further comprising a driving motor, cloth conveying rollers, a wetting device, a water storage tank and a controller which are arranged in the box body, wherein the wetting device includes a first wetting device, a second wetting device and a third wetting device, the first wetting device includes a low-temperature plasma generator, a first atomizer and an ion sensor, the second wetting device includes a rare earth auxiliary agent bag and a second atomizer, the third wetting device includes a redox agent bag, a third atomizer and a humidity sensor, the driving motor, the ion sensor and the humidity sensor are in signal connection with the controller, and the first atomizer, the secondatomizer and the third atomizer are communicated with the water storage tank through pipelines. The textile cloth wetting device provided by the invention is good in textile cloth wetting effect, effectively improves the tensile strength of the textile cloth, and improves the subsequent production efficiency and product quality.

Owner:赵芳华

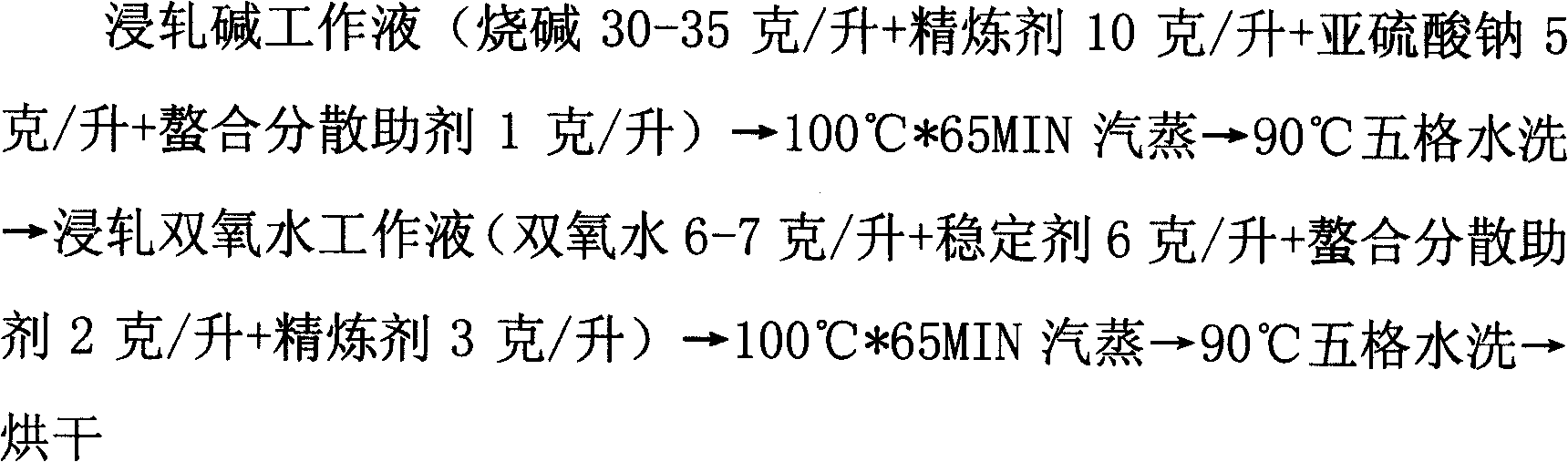

Fore treatment method of polyester-cotton fabric by high efficiency refining enzyme one-step and one-bath method

InactiveCN101457477BAvoid damageEfficient removalBiochemical fibre treatmentDry-cleaning apparatus for textilesPolyesterGram

The invention relates to a manufacturing method of fabrics. Highly active refined enzyme one-step-one-bath preprocessing method is adopted for a polyester-cotton fabric, the method has the following steps: following solutions are adopted, a chemical of 50-60 DEG C is heated up, a piece of dry fabric cloth to be processed is sent to working solutions for padding with dispersed phase holdup of 80-100%, then the dry fabric cloth is steamed for 60-75 min under the temperature of 98-102 DEG C, dried after being washed by hot water under the temperature of 95 DEG C to 98 DEG C at first and then by water under the temperature of 60 DEG C to 65 DEG C, thus the one-step-one-bath preprocessing method is competed. The working solutions used in the method has mixture ratio as follows: hydrogen peroxide (100%) 12-14 gram / liter; highly active refined enzyme 25-30 gram / liter; refined osmotic agent 5-8 gram / liter. The highly active refined enzyme preprocessing method combines refining, stabilizing, infiltrating, emulsificating, chelating into a whole, hydrogen peroxide stabilizer and alkali and the like are not needed to be added, thus ensuring stability and uniformity of preprocessing, not only saving sewage treatment expense but also reducing sewage treatment pressure.

Owner:辽宁宏丰印染有限公司 +2

Moisture absorption and sweat releasing anti-stain work suit

InactiveCN104082881AFree from pollutionReduce cleaning timesSynthetic resin layered productsProtective garmentYarnFiber

The invention relates to a moisture absorption and sweat releasing anti-stain work suit. The moisture absorption and sweat releasing anti-stain work suit is composed of a fabric layer (1) and a waterproof fabric layer (2), the waterproof fabric layer (2) is formed by a polytetrafluoroethylene film and cloth in a compound mode, the surface of the waterproof fabric layer (2) is coated with a waterproof coating (3), and the waterproof coating (3) is a plastic modified asphalt coating layer. The fabric layer is formed by interweaving warps and wefts, the warps are environment-friendly yarns, the wefts are hollow fibers, the surfaces of the fibers are of a cellular structure, and the cross section of the fibers is in a four-tube shape. Under joint protection of the waterproof fabric layer and the waterproof coating, the anti-stain work suit will not be stained with sewage, liquid and other sundries, and therefore it is ensured that the anti-stain work suit is prevented from being stained. The fabric of the anti-stain work suit has the moisture absorption and sweat releasing functions.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

Method for preparing corn bract leaf fiber from bio-enzymes

The invention belongs to the technical field of renewable resource utilization, and particularly relates to a method for preparing corn bract leaf fiber from bio-enzymes. The method comprises the following steps of (1) performing pretreatment on corn bract leaves to obtain pretreated corn bract leaves; (2) performing bio-enzyme treatment on the corn bract leaves pretreated in the step (1) to obtain the corn bract leaf fiber subjected to enzyme treatment; (3) performing softening treatment on the corn bract leaf fiber subjected to enzyme treatment in the step (2); performing drying. The low-concentration sodium hydroxide, sodium carbonate and sodium polyphosphate mixed water solution is used for pretreating the corn bract leaves so that the corn bract leaves generate lubrication swelling effects; the fiber capillary effect is enhanced; the seepage effect of the bio-enzyme liquid in the subsequent step is promoted; the damage to the fiber is small; the high-intensity can be favorably obtained; the bio-enzymes can be used for favorably decomposing gum impurities in the corn bract leaves; the damage to the fiber is avoided; the bio-enzymes can decompose most lignin, so that the obtained fiber is softer.

Owner:QIQIHAR UNIVERSITY

A kind of method utilizing biological enzyme to prepare corn bract fiber

The invention belongs to the technical field of application of renewable resources, and in particular relates to a method for preparing corn bract fiber by using biological enzymes. The method includes the following steps: (1) Pretreating corn bracts to obtain pretreated corn bracts leaves; (2) performing biological enzyme treatment on the pretreated corn bracts in step (1) to obtain enzyme-treated corn bract fibers; (3) softening the enzyme-treated corn bract fibers in step (2) , dry it. The present invention pretreats corn husks with a mixed aqueous solution of sodium hydroxide, sodium carbonate and sodium polyphosphate at a low concentration, so that the corn husks are swelled, the capillary effect of fibers is increased, and the biological enzyme liquid is promoted in subsequent steps. Osmosis, less damage to fibers, is conducive to obtaining high-strength fibers; using biological enzymes to effectively decompose glue impurities in corn bracts to avoid damage to fibers; biological enzymes can decompose most of the lignin, and the obtained fibers are more soft.

Owner:QIQIHAR UNIVERSITY

A composite desizing aid

ActiveCN103422337BHigh desizing rateIncrease capillary effectDry-cleaning apparatus for textilesHydrophobeMaterials science

The invention discloses a composite desizing aid. The components are in parts by weight, 20-25 parts of hydroxypropyl acrylate, 10-18 parts of silicate, 5-7 parts of chelating dispersant, 6- 10 servings. The composite desizing aid of the present invention adopts the combination of chelating agent, hydroxypropyl acrylate and silicate, etc., which can not only consume the metal ions produced in the desizing process, but also avoid the formation of precipitates. It can also remove the pectin in the desizing solution. The desizing rate and capillary effect of the fabric have been improved, and with the removal of metal ions in the pectin, the binding force of other impurities in the hydrophobic network layer of the pectin skeleton has decreased, and it has been successively processed. , which can be further removed by washing with water, so as to obtain the ideal finishing effect.

Owner:广东先骏新材料科技有限公司

A phase-change composite material with light-to-heat conversion function and its preparation method

ActiveCN110257019BGood size controlEasy to processSolar heating energyOther chemical processesTemperature controlThermal insulation

The invention discloses a phase-change composite material with a photo-thermal conversion function and a preparation method thereof, and belongs to the cross field of phase-change energy storage and energy conversion. The multifunctional phase change composite material is prepared by combining Ti2O3 nano particles with a heat storage phase change material for the first time, so that a photo-thermal conversion function is expected to be provided on the basis of phase-change heat storage and temperature control functions, and the carbon foam-based phase-change composite material which is is easy to cut and process, has a controllable appearance size, has light weight and flexibility, and has photo-thermal conversion performance is provided. Due to the three-dimensional porous carbon foam matrix of the phase change composite material, the phase-change material can be stably stored, and the storage capacity can be regulated and controlled. The phase-change composite material has excellent photo-thermal conversion and temperature adjusting functions and can be used in the aspects of heat energy storage and release, thermal insulation, photo-thermal conversion, infrared stealth and infrared decoy of military equipment, and the like.

Owner:JIANGNAN UNIV

A kind of preparation method of latex-free machine-woven carpet

ActiveCN108396397BGuaranteed pull-out forceReduce dosageCarpetsWoven fabricsPolymer scienceLatex rubber

The invention discloses a method for preparing a latex-free woven carpet. The second coating layer is filament or spun yarn formed of hot-melt fibers, and the first coating layer is fiber long yarn formed of nylon 6 or nylon 66. Silk or spun yarn, the second covering layer accounts for 20%-50% of the total mass of the composite yarn, the first covering layer accounts for 10%-15% of the total mass of the composite yarn, and the rest is the core yarn. Pile weft. When hot-melt copolyamide fibers are used as bonding materials to produce adhesive-free carpets, and pile yarns made of nylon or wool fibers, when the hot-melt copolyamide fibers are heated above their melting point in the hot-pressing process, they melt, and the fibers The conformation of the macromolecular chain changes, and through the transition of the chain segment, the entire macromolecular chain slips and viscous flow occurs. After curing, the pile and weft yarn as well as the weft and warp yarn are effectively consolidated, which enhances the pull-out strength of the carpet pile and The shape retention and dimensional stability of the carpet, thereby omitting the back glue process in the carpet preparation process, makes the prepared carpet more environmentally friendly.

Owner:BINZHOU COC CARPET

A kind of preparation method of machine-woven carpet without back glue process

ActiveCN108411460BGuaranteed pull-out forceReduce dosageHeating/cooling textile fabricsWoven fabricsFiberPolymer science

The invention discloses a preparation method of a machine-woven carpet without adhesive backing process. The second coating layer is filament or staple fiber yarn formed by hot-melt fibers, and the first coating layer is polyester fiber filament or staple yarn. Fiber yarn, the second covering layer accounts for 20%-50% of the total mass of the composite yarn, the first covering layer accounts for 10%-15% of the total mass of the composite yarn, and the rest is the core yarn to obtain the pile weft yarn . When hot-melt copolyester fibers are used as bonding materials to produce adhesive-free carpets, and pile yarns made of polyester fibers, when the hot-melt copolyester fibers are heated above their melting point in the hot-pressing process, they melt, and the fibers The conformation of the macromolecular chain changes, and through the transition of the chain segment, the entire macromolecular chain slips and viscous flow occurs. After curing, the pile and weft yarn as well as the weft and warp yarn are effectively consolidated, which enhances the pull-out strength of the pile and the carpet Excellent shape retention and dimensional stability, thereby omitting the back glue process in the carpet preparation process, making the prepared carpet more environmentally friendly.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com