Crease prevention device for scouring and bleaching equipment, scouring and bleaching equipment and crease prevention method

A technology for refining, bleaching and equipment, which is applied in the direction of processing textile material equipment configuration, textile material processing, textile and papermaking, etc. Efficiency, reduced wrinkle probability, reduced processing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

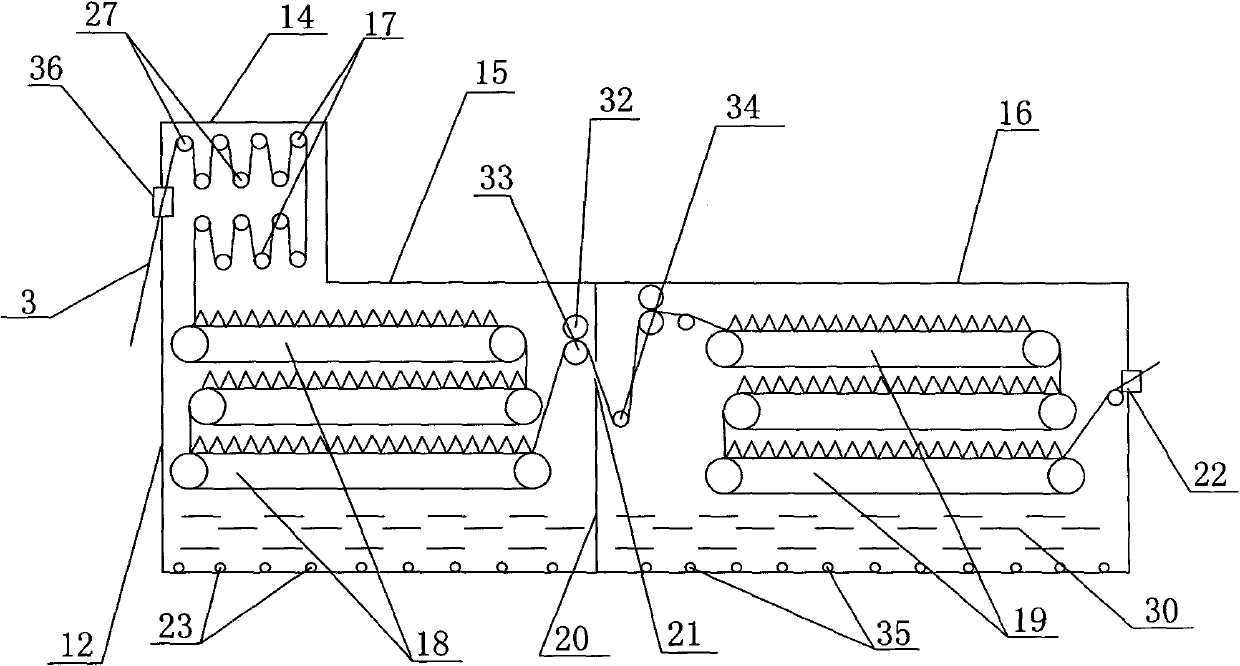

[0035]The present invention provides an anti-folding device for scouring and bleaching equipment, scouring and bleaching equipment and an anti-folding method. In order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the following will be combined with the accompanying drawings and embodiments to describe this The invention is further described in detail.

[0036] The invention provides an anti-folding device for scouring and bleaching equipment. Through structural restrictions, fabrics are accumulated between the blades of the rotary impeller and fully swell by themselves in a relaxed state, providing excellent raw materials for the production of high-flatness fabrics. Its basic structure is as figure 1 As shown, the fabric 3 is guided into the following fabric soaking container 4 by the fabric import roller 1; the fabric 3 enters the hot water 28 of the fabric soaking container 4, and passes through the hot water 28 continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com