Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Phase holdup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

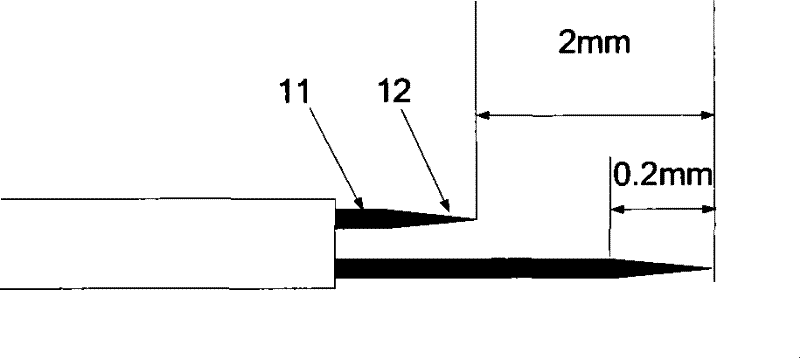

Method and device for measuring two-phase flow parameter based on double-end capacitance probe

InactiveCN101413911ANo electrolysisNo polarization problemFluid speed measurementMaterial capacitanceMeasurement deviceEngineering

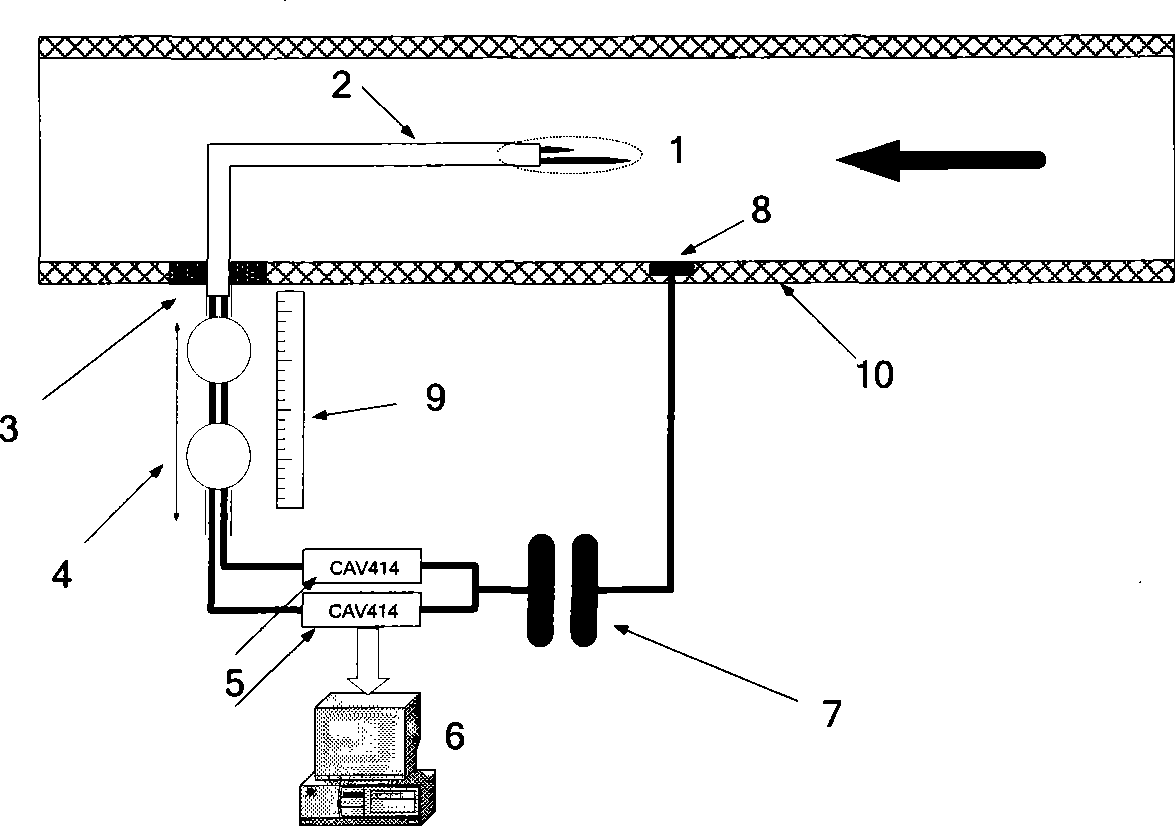

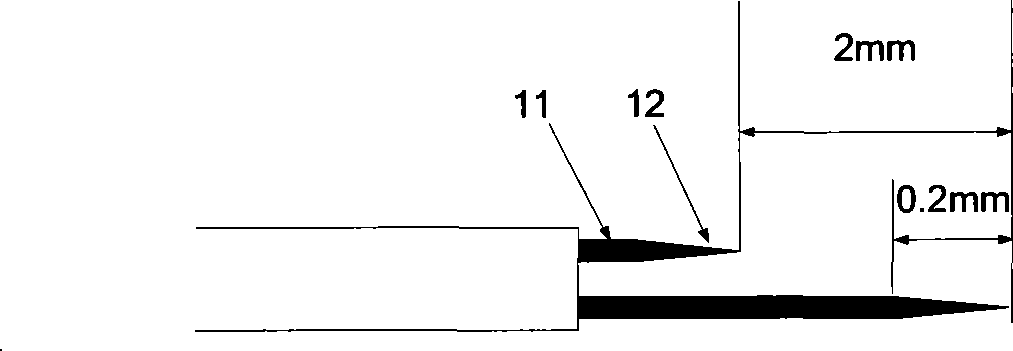

The invention provides a two-phase flow parameter measurement method based on a dual-head capacitance probe and a device thereof, belonging to the field of multi-phase flow testing technology. The device comprises the dual-head capacitance probe, a probe driving mechanism, two capacitance measurement circuits, a fixed capacitor, a slab electrode and a computer system; wherein, the dual-head capacitance probe system consists of two independent single-point capacitance probes and can carry out one-dimensional motion on the section of a pipeline. The method comprises the steps as follows: each single-point capacitance probe is used for recognizing fluid property; when the fluid passing through the head of the probe is conducted, the circuit is connected and the capacitance measurement device outputs high level, otherwise the circuit is cut off and the capacitance measurement device outputs low level. The level signal can obtain local phase holdup; the measurement result of the method is not affected by the conductivity of the fluid and the spacing of the probes. The local phase holdup and the flowing speed can be obtained by processing the two single-point capacitance probe signals by the threshold method and the correlation method; the flowing pattern information can be obtained by combining with two-phase flow knowledge, thus achieving the recognition of flow pattern on line.

Owner:SHANGHAI JIAO TONG UNIV

Device for measuring oil, gas, water three phase flow containing rate

ActiveCN101324186AUniform electric fieldReduce mistakesSurveyConstructionsCapacitanceMeasurement device

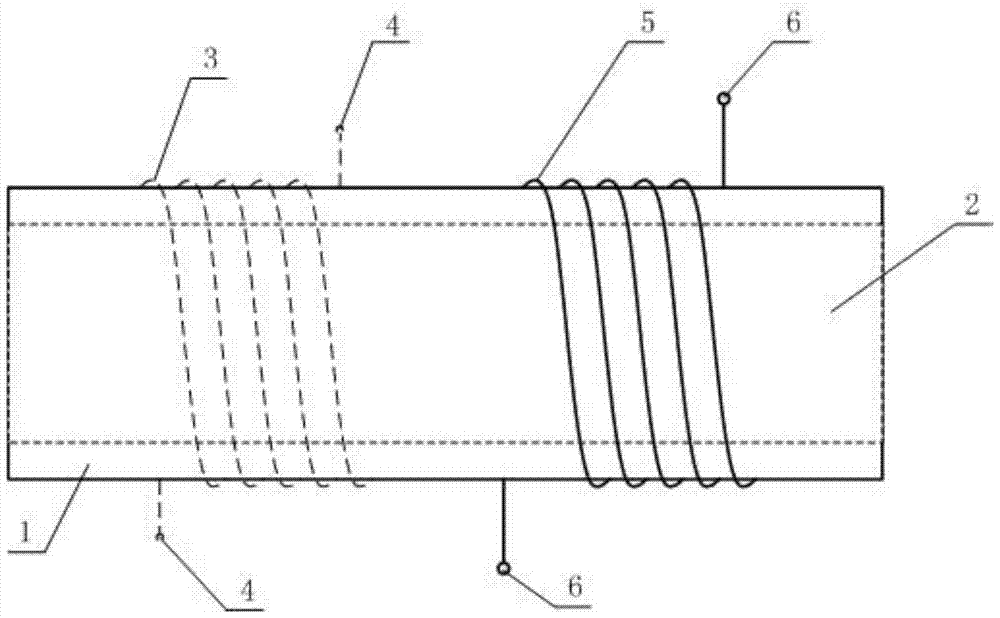

The invention belongs to the multiphase flow measurement field, which mainly relates to the multiphase flow phase holdup measurement field and particularly discloses an oil-gas-water three-phase flow phase holdup measurement device which is based on an double helix capacitive sensor and can carry out precise measurement of the oil-gas-water three-phase flow holdup. The measurement device comprises at least one double helix capacitive sensor, a signal processing circuit, a weak capacitance measurement circuit and a moisture content measurement circuit which are respectively connected with the signal processing circuit, wherein, the double helix capacitive sensor is connected with the weak capacitance measurement circuit or the moisture content measurement circuit selectively; when a pipeline is filled with oil gas, the double helix capacitive sensor is connected with the weak capacitance measurement circuit, the signal processing circuit outputs the phase holdup of the oil; when the pipeline is filled with water, the double helix capacitive sensor is connected with the moisture content measurement circuit, and the signal processing circuit outputs the phase holdup of the water.

Owner:XI AN JIAOTONG UNIV

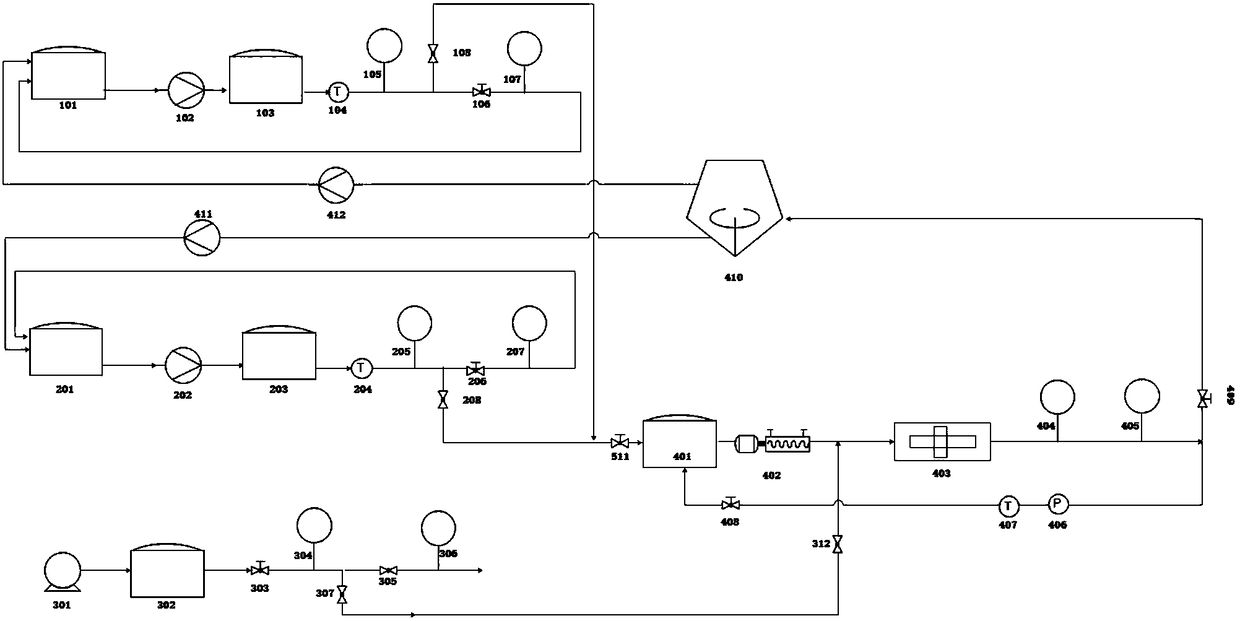

Oil-gas-water multi-phase flow online metering calibration device

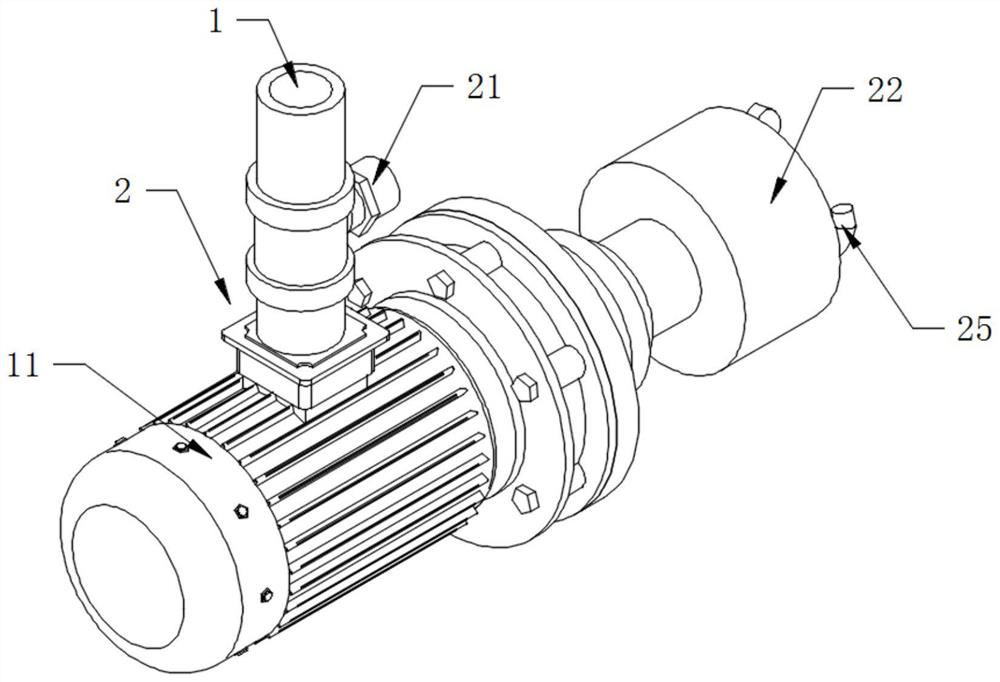

ActiveCN108592978AImplement modular managementRealize fully automated operationNuclear energy generationTesting/calibration for volume flowEngineeringScrew pump

The invention discloses an oil-gas-water multi-phase flow online metering calibration device which comprises a single-phase oil calibration system, a single-phase water flow calibration system, a single-phase gas flow calibration system, a heating buffer tank, a screw pump, a static mixer, a standard meter, a to-be-detected meter, a pressure sensor, a first temperature sensor, a first adjusting valve, a first ball valve, a separator, a first quantitative plunger pump and a second quantitative plunger pump. The device achieves the modular management and full-automatic operation, and is used forsimulating the flow type, the flow state, and the flow rate of the oil-gas-water three-phase flow of an oil-gas wellhead and the proportion of the flow type, the flow state, and the flow rate; the calibration function of the single-phase oil flow, the single-phase water flow, the single-phase gas flow, the gas-liquid two-phase flow, the oil-water two-phase flow, the oil-gas-water three-phase flow, the oil-water two-phase flow split-phase holdup rate, and the oil-gas-water three-phase flow split-phase holdup rate can be achieved, the working condition of a real oil well is simulated, and an experimental support is provided for research and development of a multi-phase flow metering instrument.

Owner:ANHUI FIRSTCON INSTR +1

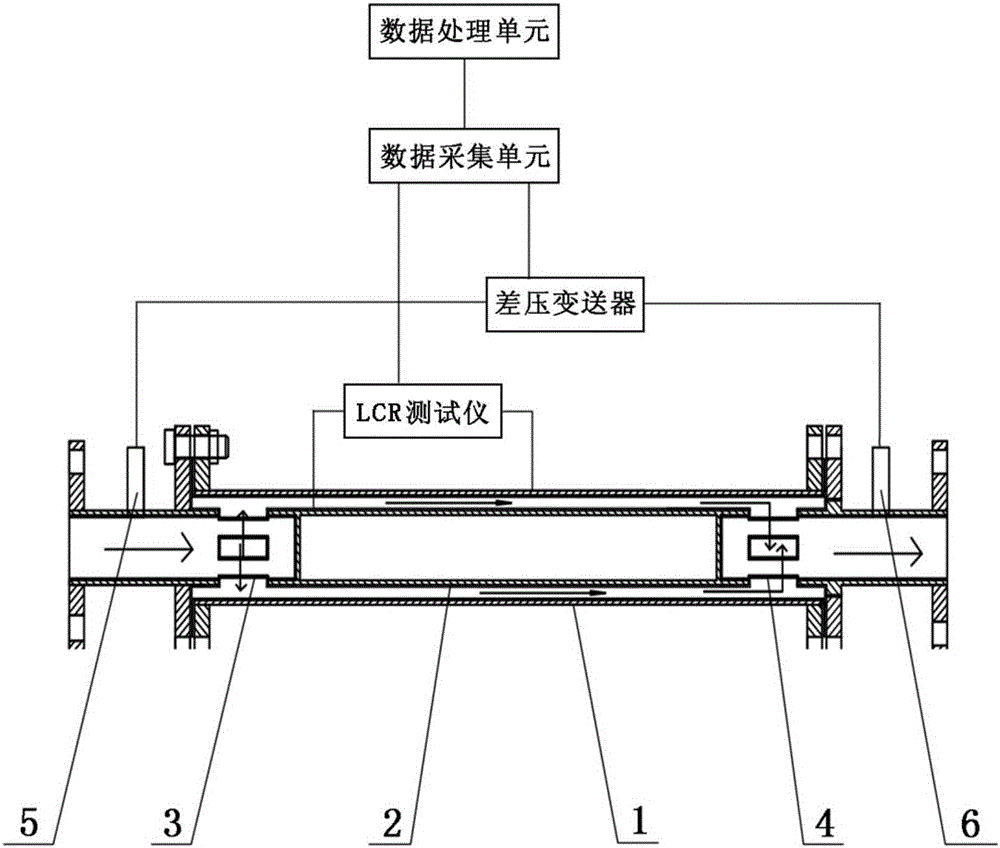

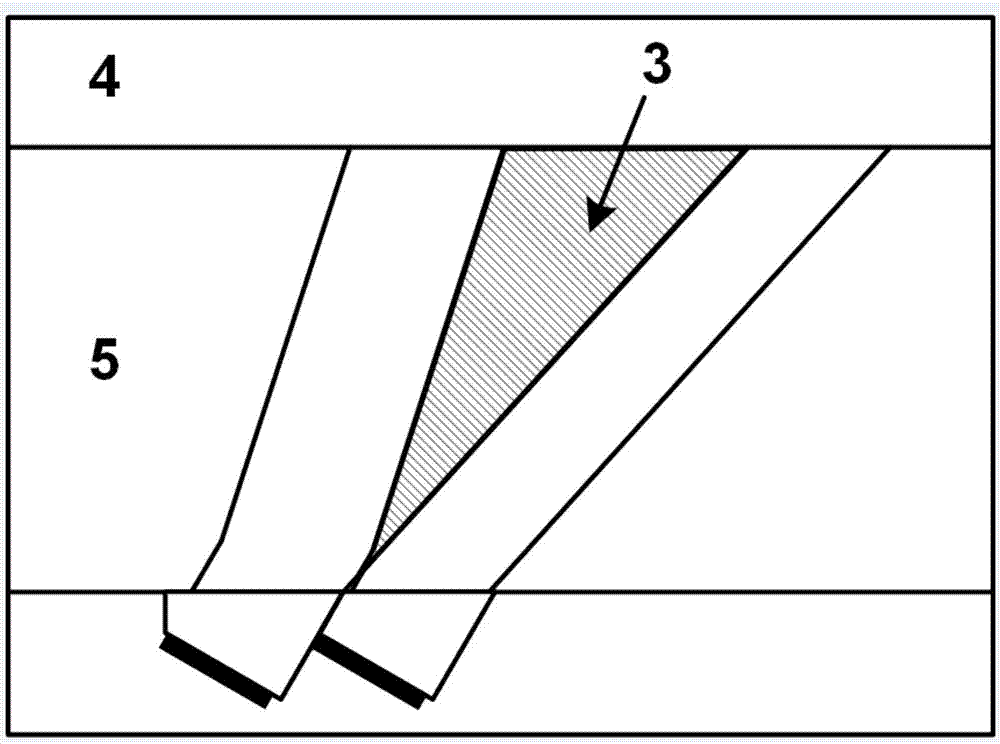

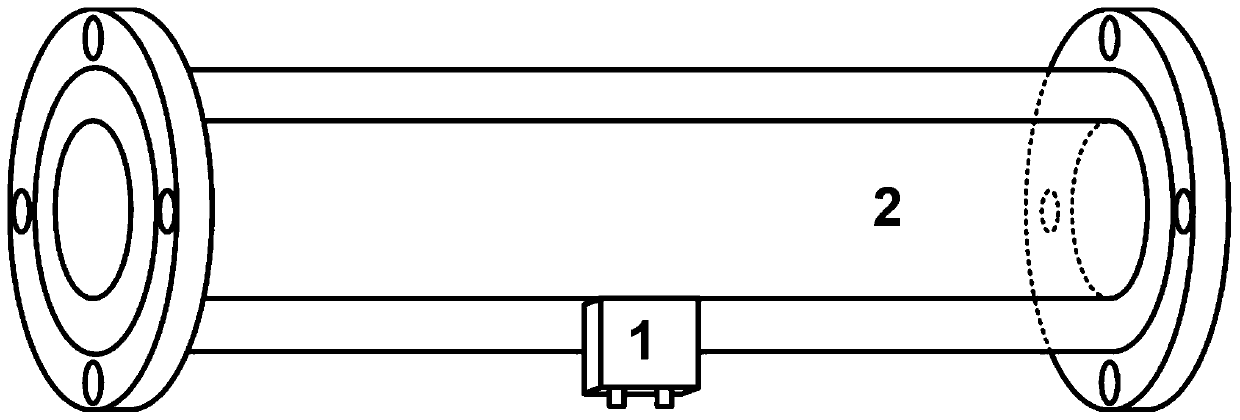

Gas-liquid two-phase flow phase holdup and separate phase flow rate detection device and detection method

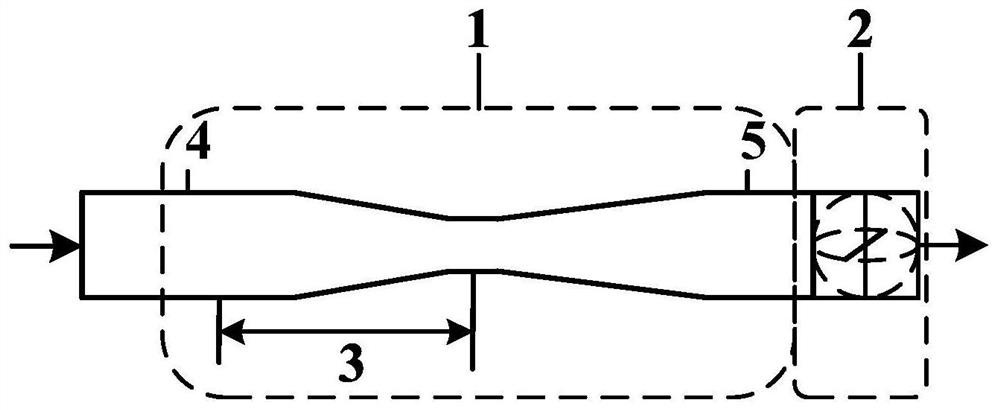

ActiveCN105890693AReduce measurement impactReduce the impactVolume flow measuring devicesMaterial capacitanceCapacitanceDifferential pressure

The invention provides a gas-liquid two-phase flow phase holdup and a separate phase flow rate detection device and detection method. The device comprises an outer tube, an inner tube, a differential pressure transmitter, an LCR tester, a data collection unit and a data processing unit. The inner tube is connected in the outer tube in a sleeved mode, the middle of the inner tube is a baffle area, the two ends of the inner tube are circulation areas, fluid outlet holes and fluid inlet holes are formed in the side walls of the circulation areas at the two ends of the inner tube respectively, a to-be-tested fluid enters the inner tube from one circulation area of the inner tube, enters an annular space between the inner tube and the outer tube through the fluid outlet holes and then flows to the other circulation area through the fluid inlet holes, and the phase holdup of two-phase flow can be obtained by measuring a capacitance value of an annular capacitor and combing correlation operation; by combining pressure differences of the fluid at the two ends of the inner tube, the fluid total flow can be obtained, and the separate phase flow rate can be obtained finally. According to the gas-liquid two-phase flow phase holdup and the separate phase flow rate detection device and detection method, the inner tube and the outer tube and a middle fluid forms capacitance, the capacitance value is only related to an intermediate medium, and therefore an influence of flow pattern changes to measurement of the two-phase flow holdup can be weakened.

Owner:HEBEI UNIVERSITY

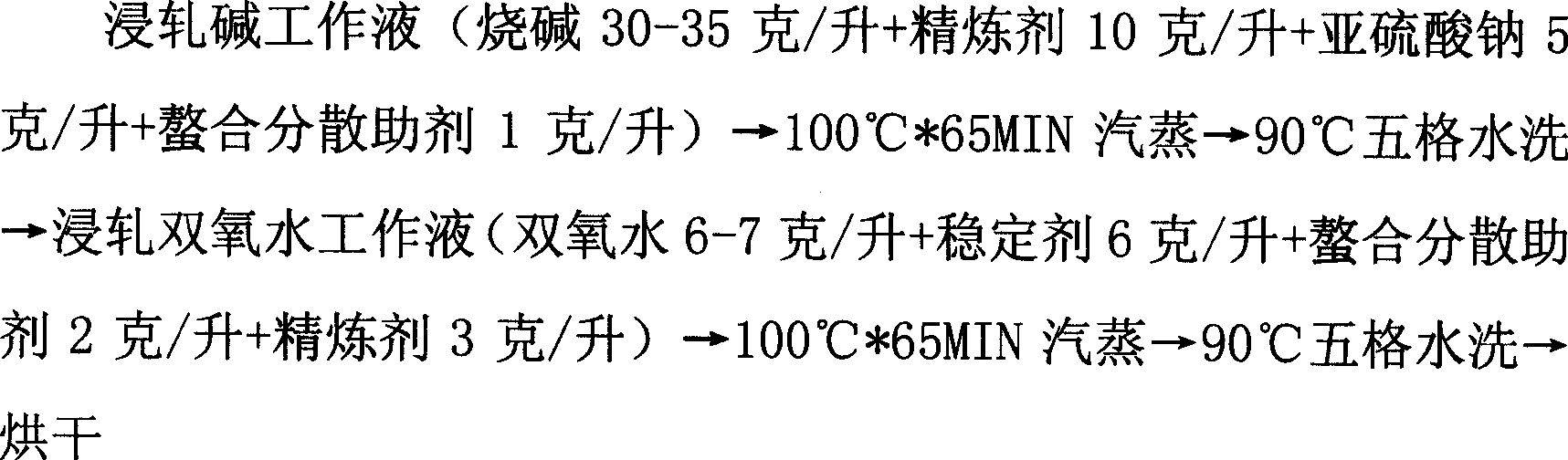

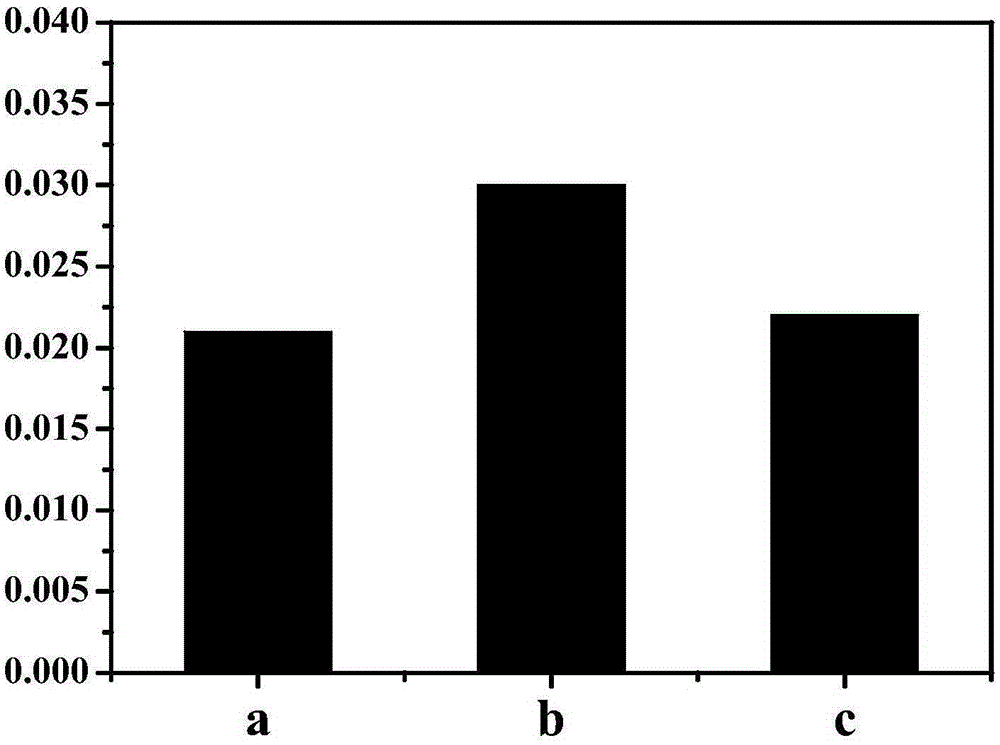

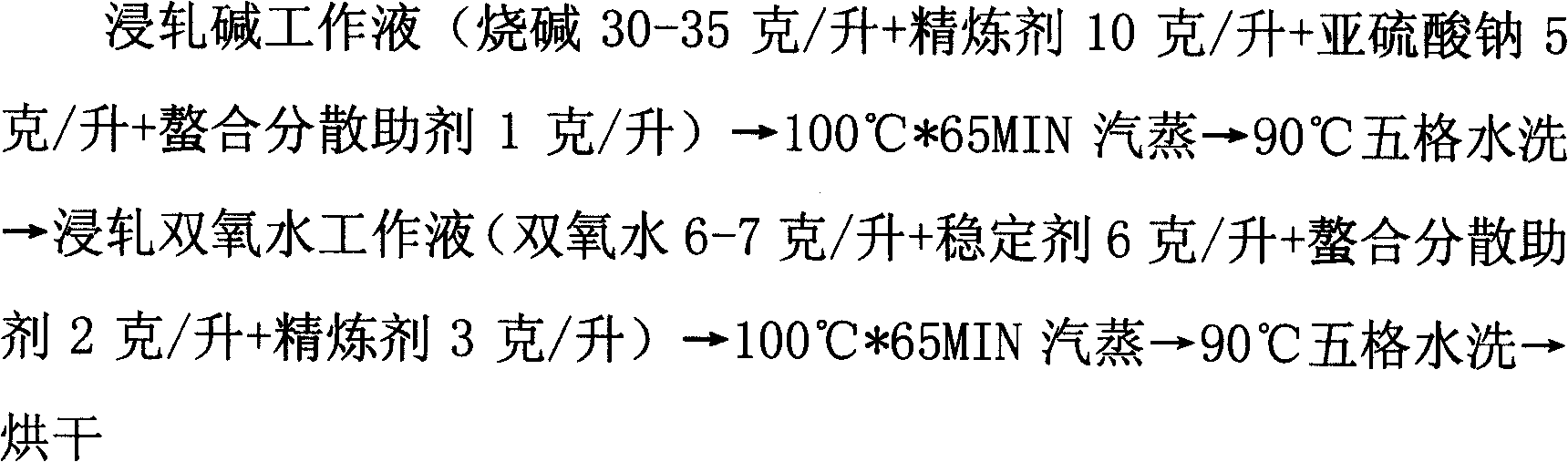

Fore treatment method of polyester-cotton fabric by high efficiency refining enzyme one-step and one-bath method

InactiveCN101457477AAvoid damageEfficient removalBiochemical fibre treatmentDry-cleaning apparatus for textilesPolyesterGram

The invention relates to a manufacturing method of fabrics. Highly active refined enzyme one-step-one-bath preprocessing method is adopted for a polyester-cotton fabric, the method has the following steps: following solutions are adopted, a chemical of 50-60 DEG C is heated up, a piece of dry fabric cloth to be processed is sent to working solutions for padding with dispersed phase holdup of 80-100%, then the dry fabric cloth is steamed for 60-75 min under the temperature of 98-102 DEG C, dried after being washed by hot water under the temperature of 95 DEG C to 98 DEG C at first and then by water under the temperature of 60 DEG C to 65 DEG C, thus the one-step-one-bath preprocessing method is competed. The working solutions used in the method has mixture ratio as follows: hydrogen peroxide (100%) 12-14 gram / liter; highly active refined enzyme 25-30 gram / liter; refined osmotic agent 5-8 gram / liter. The highly active refined enzyme preprocessing method combines refining, stabilizing, infiltrating, emulsificating, chelating into a whole, hydrogen peroxide stabilizer and alkali and the like are not needed to be added, thus ensuring stability and uniformity of preprocessing, not only saving sewage treatment expense but also reducing sewage treatment pressure.

Owner:辽宁宏丰印染有限公司 +2

Gas-liquid two-phase flow distribution control apparatus and gas-liquid two-phase flow distribution control method

PendingCN110180220AEvenly distributedHomogeneous fractionDispersed particle separationLiquid degasification regulation/controlDistribution controlEngineering

The invention discloses a gas-liquid two-phase flow distribution control apparatus and a gas-liquid two-phase flow distribution control method. The apparatus comprises a center pipe, swirling flow blades installed inside the center pipe, a gas-liquid flow dividing outer pipe, a first resistance control valve, a second upper resistance control valve, a second lower resistance control valve, a thirdresistance control valve and a phase holdup control device, wherein the phase holdup control device and the third resistance control valve are both arranged inside the center pipe, the phase holdup control device is positioned below the swirling flow blades, the third resistance control valve is positioned below the phase holdup control device, the gas-liquid flow dividing outer pipe is sleeved on the outer portion of the center pipe, a buffer annulus is formed between the gas-liquid flow dividing outer pipe and the center pipe, and the second upper resistance control valve and the second lower resistance control valve are arranged in the buffer annulus. According to the present invention, with the apparatus and the method, the influence of the different resistance characteristics of various distribution branches on the distribution is fundamentally overcome, and the uniform or non-uniform holdup distribution of the gas-liquid two-phase fluid under different flow rates is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil gas water three-phase plugged dispersed flow velocity measuring method

ActiveCN106996988AEasy to measureAccurate measurementFluid speed measurementUltrasonic sensorGas phase

The invention relates to an oil gas water three-phase plugged dispersed flow velocity measuring method. The oil gas water three-phase plugged dispersed flow velocity measuring method comprises steps that 1) a phase holdup measuring device is used to acquire various phase holdup information; 2) a continuous phase and dispersed phases of a three-phase plugged dispersed flow are determined according to the phase holdup; 3) receiving signals acquired by an ultrasonic transducer are demodulated, and Doppler frequency shift is acquired; 4) drag force between the continuous phase and a dispersed gas phase is calculated; 5) the drag force between the continuous phase and a dispersed liquid phase is calculated; 6) shearing force of a tube wall applied to the continuous liquid phase is calculated; 7) ternary non-linear equations related to uc, ug, ud are established; 8) by adopting a numerical iteration type algorithm for solution, the optimal estimations of the uc, the ug, and the ud are acquired; 9) a three-phase flow split phase apparent velocity is calculated.

Owner:TIANJIN UNIV

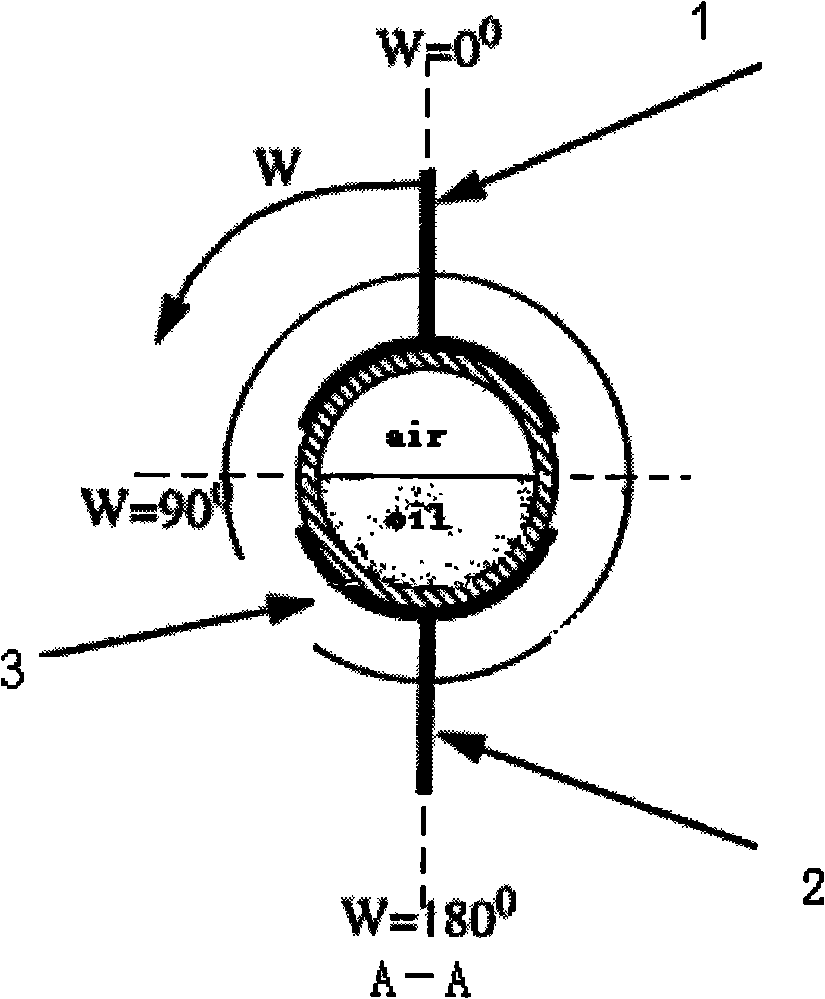

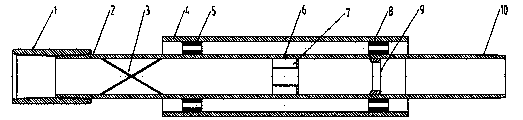

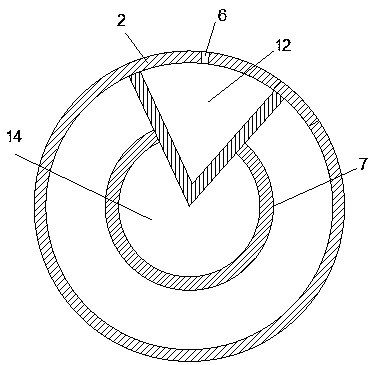

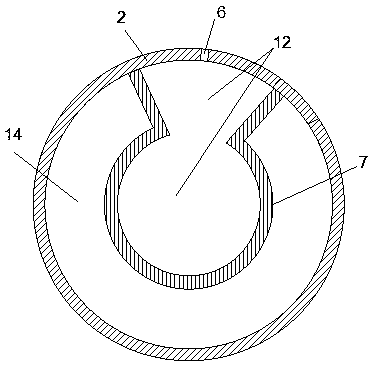

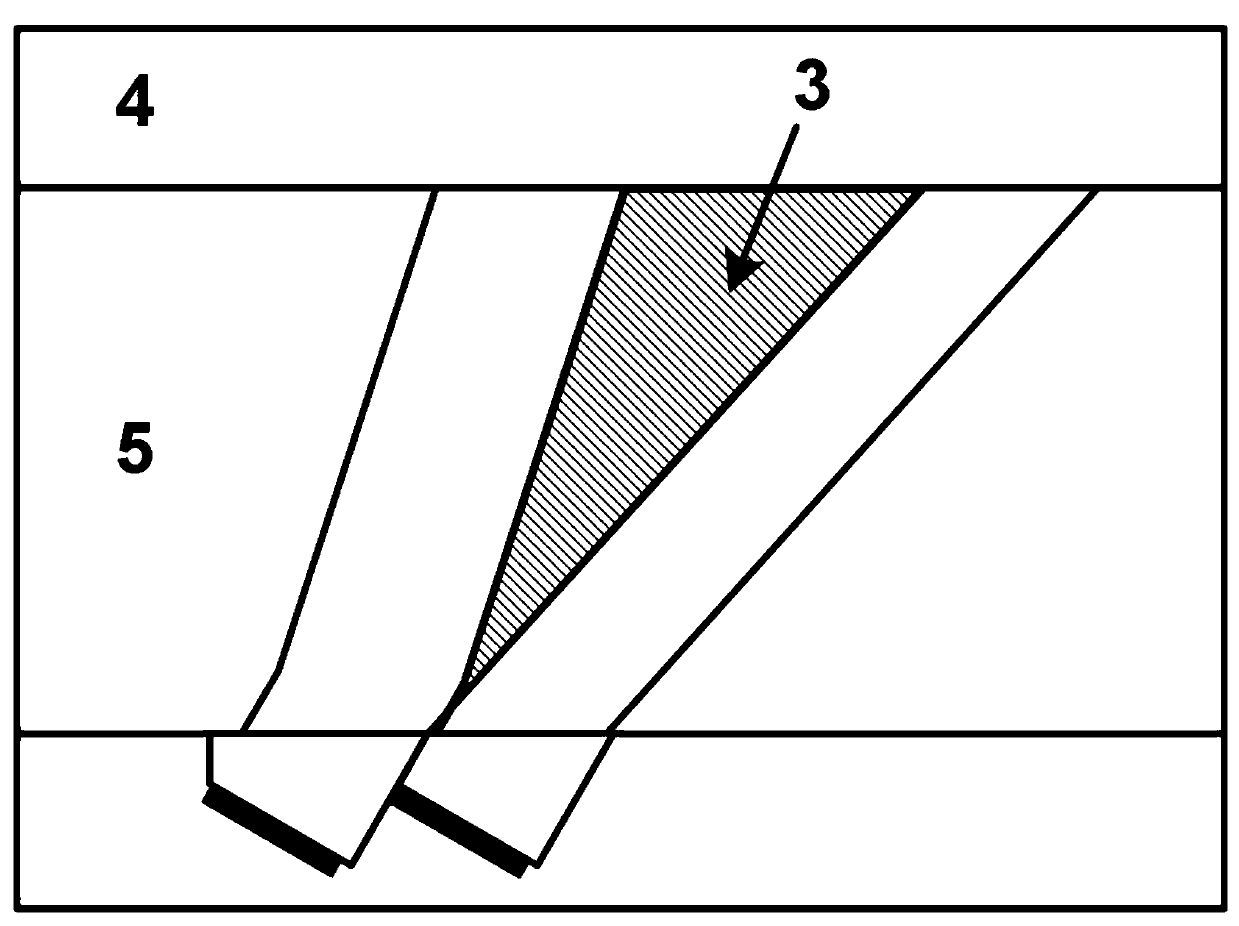

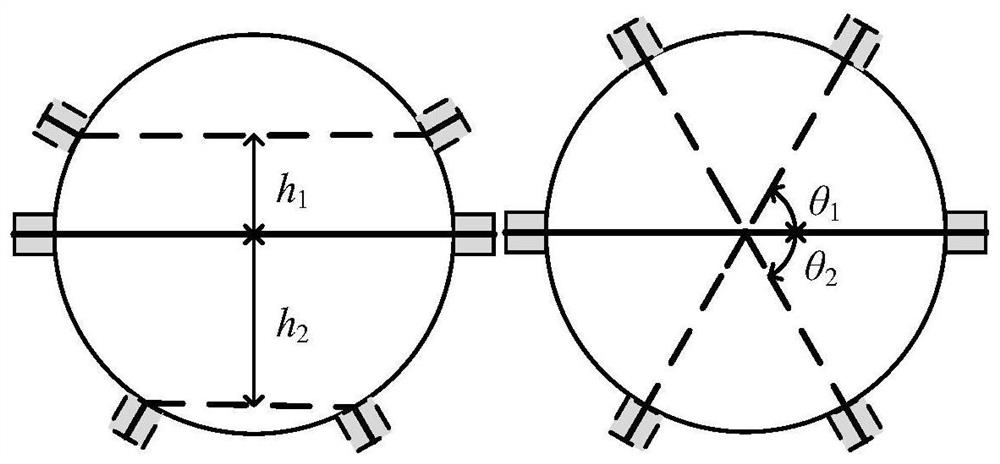

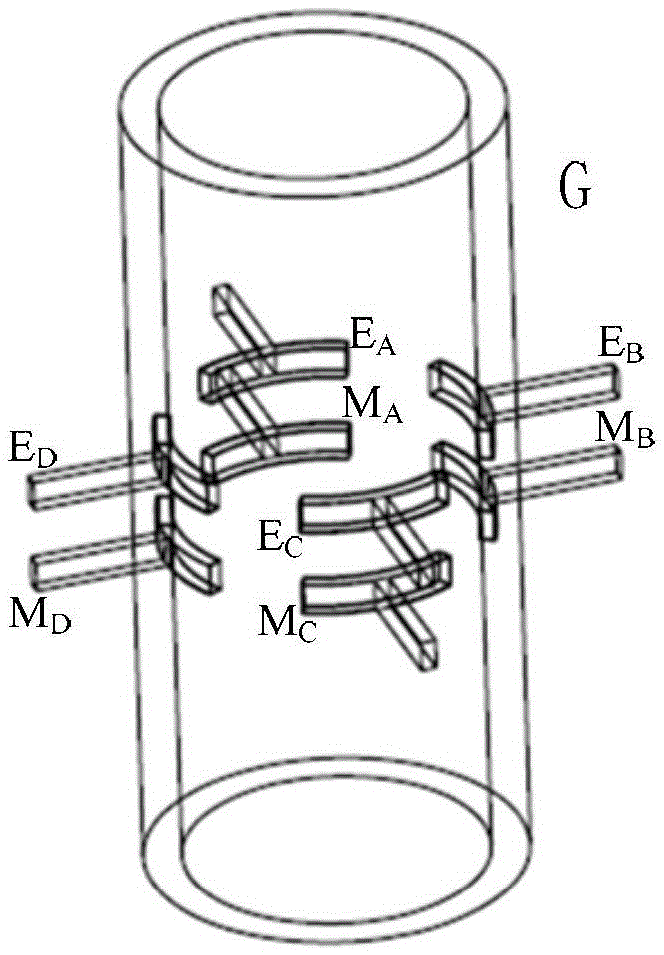

Annular space double-sensor conducting probe for flow parameter measurement of two-phase flow

InactiveCN105486360AEffective use of high-resolution featuresImplement relative velocity measurementsVolume/mass flow by electric/magnetic effectsEngineeringPhase holdup

The present invention relates to an annular space double-sensor conducting probe for flow parameter measurement of two-phase flow. The annular space double-sensor conducting probe is composed of three portions including a pipeline center variable diameter insulation insertion body, annular space split-phase holdup sensors, and annular space correlation velocity measurement sensors. The pipeline center variable diameter insulation insertion body is fixed in the center of a vertical measurement pipeline to force the two-phase flow fluid to flow in annular space between an external surface of the pipeline center variable diameter insulation insertion body and an inner wall of the vertical measurement pipeline, and the variable diameter insulation insertion body is formed by three sections of a small-diameter section, a transition section and a large-diameter section successively from bottom to top. The split-phase holdup sensors are formed by four pairs or more than four pairs of arc-shaped electrodes, and each pair of arc-shaped electrodes is uniformly distributed on the periphery of the inner wall of the vertical measurement pipeline. The annular space correlation velocity measurement sensors are formed by two pairs of annular electrodes fixed on the surface of the small-diameter section of the variable diameter insulation insertion body. The annular space double-sensor conducting probe is advantaged by high measuring sensitivity.

Owner:TIANJIN UNIV

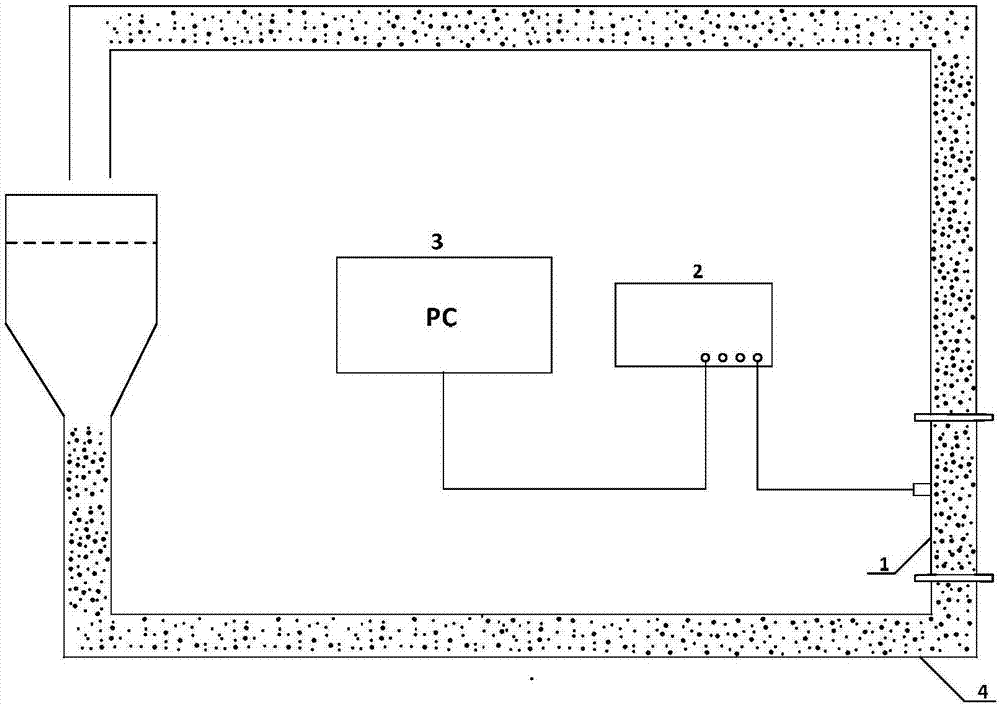

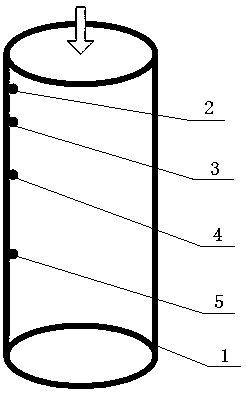

Device and method for measuring phase holdups of solid-liquid two-phase flow

InactiveCN106932476AAccurate measurementEasy to detectMaterial analysis using sonic/ultrasonic/infrasonic wavesUltrasound attenuationTransceiver

The invention discloses a device and a method for measuring phase holdups of solid-liquid two-phase flow. The device comprises a pipeline, an ultrasonic transceiver and a computer. With the phase holdups of the solid-liquid two-phase flow inside the pipeline unchanged, supersonic wave is transmitted into the pipeline to obtain an echo signal; through FFT conversion, ultrasonic echo power spectrums are obtained; multiple ultrasonic echo power spectrums fit corresponding phase holdups so as to obtain a echo power spectrum-phase holdup curve; echo attenuation is calculated to obtain an echo attenuation-phase holdup curve; and fitting curves are compared to obtain the phase holdups of the solid-liquid two-phase flow. The method is accurate and convenient in measurement; transmittance and conductivity of the two-phase flow will not affect the measurement accuracy; and the method has a wider application range.

Owner:CHINA JILIANG UNIV

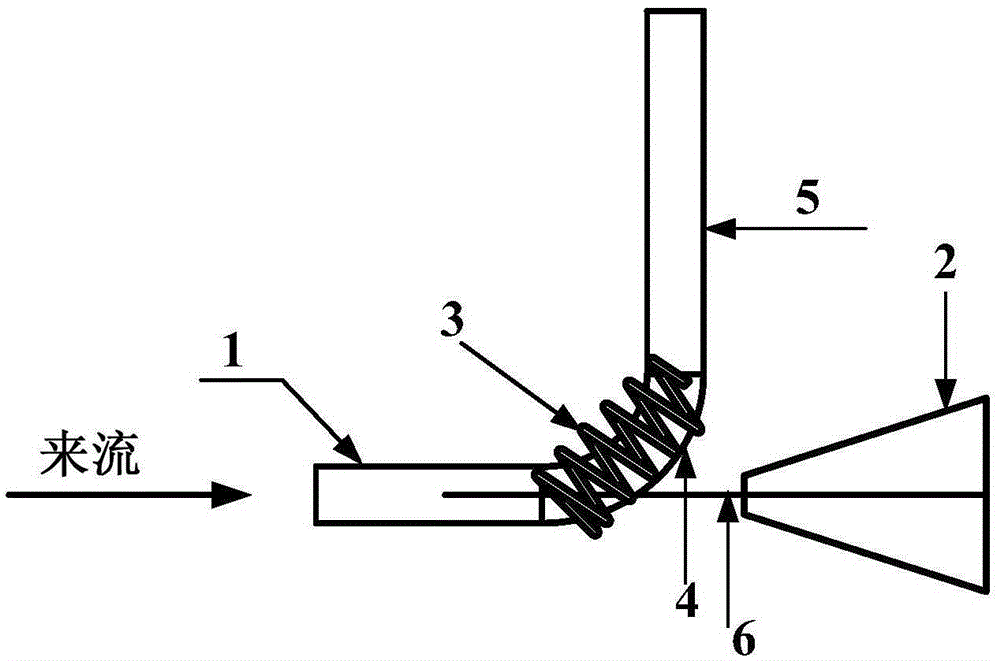

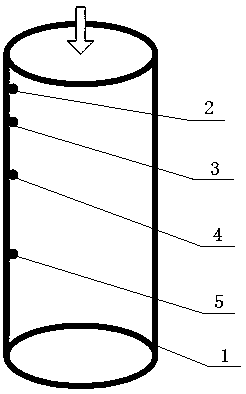

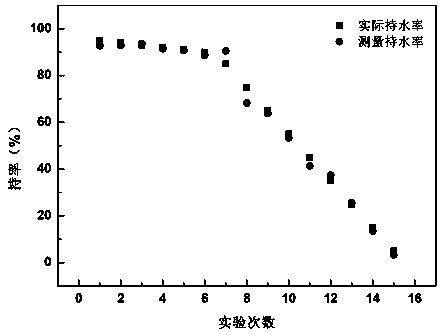

Sampler and method for measuring multi-phase-flow phase holdup distribution

ActiveCN105372099AImprove accuracySimple method for measuring holdup distribution of multiphase fluidWithdrawing sample devicesMeasurement pointEngineering

The invention provides a sampler and method for measuring multi-phase-flow phase holdup distribution. The sampler comprises a front end sampling pipe, a connecting pipe capable of conducting free steering, a rear end sampling pipe, and an adjustor for adjusting the direction of a pipe opening of the front end sampling pipe. The front end sampling pipe is connected with the rear end sampling pipe through the connecting pipe. The adjustor comprises an adjusting rod and an adjusting piece installed at one end of the adjusting rod. The other end of the adjusting rod is connected with the front end sampling pipe. When the adjusting piece bears unbalanced force in the multi-phase-flow fluid, the adjusting piece drives the front end sampling pipe to rotate through the adjusting rod under the effect of unbalanced force till the adjusting piece bears balanced force; at the moment, the pipe opening of the front end sampling pipe just faces the multi-phase-flow incoming direction. By means of the sampler, the self-adaption can be achieved in the flowing direction of fluid at the measurement point, the flowing direction of fluid at the sampling point can be automatically sensed, the pipe opening can be automatically adjusted to just face the incoming direction, and therefore the sampling and measuring accuracy is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Fore treatment method of polyester-cotton fabric by high efficiency refining enzyme one-step and one-bath method

InactiveCN101457477BAvoid damageEfficient removalBiochemical fibre treatmentDry-cleaning apparatus for textilesPolyesterGram

The invention relates to a manufacturing method of fabrics. Highly active refined enzyme one-step-one-bath preprocessing method is adopted for a polyester-cotton fabric, the method has the following steps: following solutions are adopted, a chemical of 50-60 DEG C is heated up, a piece of dry fabric cloth to be processed is sent to working solutions for padding with dispersed phase holdup of 80-100%, then the dry fabric cloth is steamed for 60-75 min under the temperature of 98-102 DEG C, dried after being washed by hot water under the temperature of 95 DEG C to 98 DEG C at first and then by water under the temperature of 60 DEG C to 65 DEG C, thus the one-step-one-bath preprocessing method is competed. The working solutions used in the method has mixture ratio as follows: hydrogen peroxide (100%) 12-14 gram / liter; highly active refined enzyme 25-30 gram / liter; refined osmotic agent 5-8 gram / liter. The highly active refined enzyme preprocessing method combines refining, stabilizing, infiltrating, emulsificating, chelating into a whole, hydrogen peroxide stabilizer and alkali and the like are not needed to be added, thus ensuring stability and uniformity of preprocessing, not only saving sewage treatment expense but also reducing sewage treatment pressure.

Owner:辽宁宏丰印染有限公司 +2

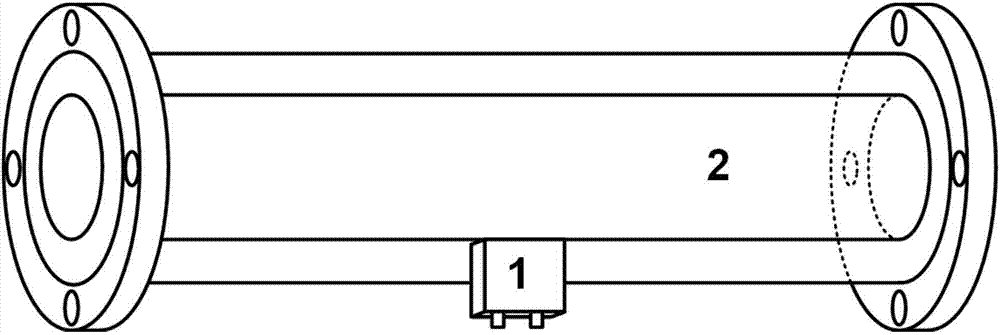

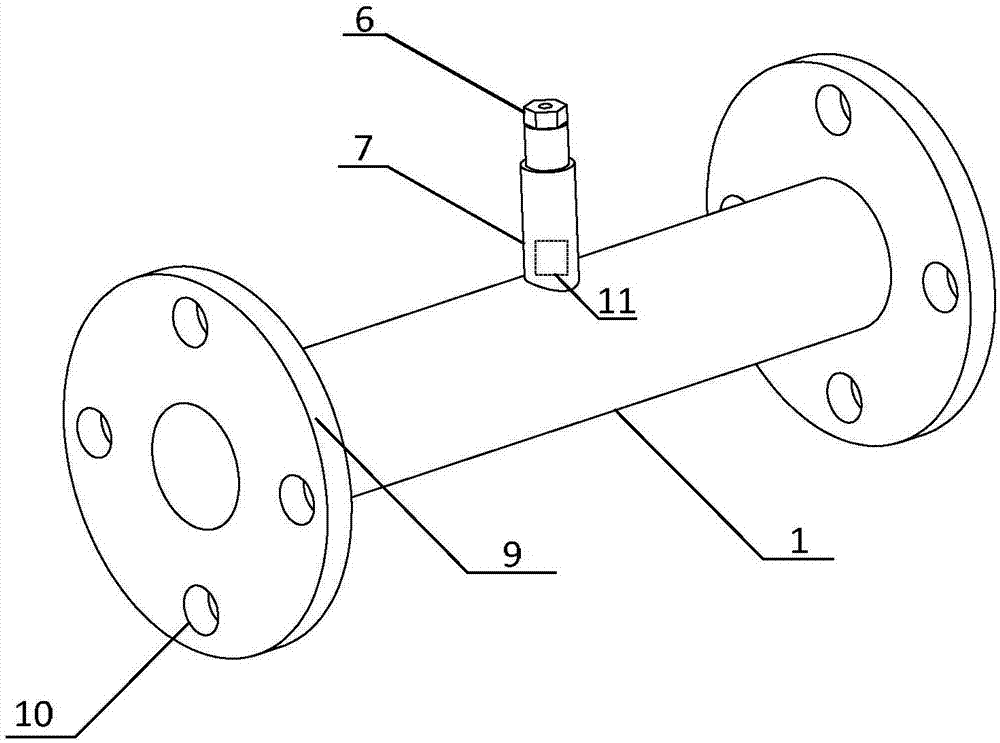

Method and device for online measurement of multiphase wet gas flow and phase holdup

ActiveCN104266702BCompact structureFlexible useVolume flow measuring devicesMaterial analysisData processing systemMeasurement device

The invention discloses a multiphase wet air flow and phase content online measurement method and device. The multiphase wet air flow and phase content online measurement device comprises a cylindrical V cone throttling device; a throttling cone body and a temperature sensor are arranged in an inner chamber of the V cone throttling device along the wet air flow direction in turn; the throttling cone body is connected with a retraction section differential pressure sensor and an expansion section differential pressure sensor through a pressure taking pipe; a pressure sensor, the retraction section differential pressure sensor, the expansion section differential pressure sensor and the temperature sensor are connected with a data processing system; a wet air flow inlet of the V cone throttling device is connected with a capacitance probe device through a flange. According to the multiphase wet air flow and phase content online measurement method and device, the wet gas passes through the V cone throttling device which is provided with the pressure sensor, the differential pressure sensors and the temperature sensor and statistical data are transmitted to the data processing system through the pressure sensor, the differential pressure sensors and the temperature sensor to be processed.

Owner:XI AN JIAOTONG UNIV

Method and device for measuring two-phase flow parameter based on double-end capacitance probe

InactiveCN101413911BMeasurement results have no effectImprove general performanceFluid speed measurementMaterial capacitanceMeasurement deviceFixed capacitor

The invention provides a two-phase flow parameter measurement method based on a dual-head capacitance probe and a device thereof, belonging to the field of multi-phase flow testing technology. The device comprises the dual-head capacitance probe, a probe driving mechanism, two capacitance measurement circuits, a fixed capacitor, a slab electrode and a computer system; wherein, the dual-head capacitance probe system consists of two independent single-point capacitance probes and can carry out one-dimensional motion on the section of a pipeline. The method comprises the steps as follows: each single-point capacitance probe is used for recognizing fluid property; when the fluid passing through the head of the probe is conducted, the circuit is connected and the capacitance measurement deviceoutputs high level, otherwise the circuit is cut off and the capacitance measurement device outputs low level. The level signal can obtain local phase holdup; the measurement result of the method is not affected by the conductivity of the fluid and the spacing of the probes. The local phase holdup and the flowing speed can be obtained by processing the two single-point capacitance probe signals by the threshold method and the correlation method; the flowing pattern information can be obtained by combining with two-phase flow knowledge, thus achieving the recognition of flow pattern on line.

Owner:SHANGHAI JIAOTONG UNIV

A dual-nozzle-based on-line measurement method for oil well multiphase fluid fractional holdup

ActiveCN110411521BHarm reductionSimple structureMaterial testing goodsVolume/mass flow by differential pressureDifferential pressureRadio frequency

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Velocity Measurement Method for Oil-Gas-Water Three-Phase Plug Dispersed Flow

ActiveCN106996988BDisturbance generationEasy to measureFluid speed measurementMeasurement deviceUltrasonic sensor

The invention relates to an oil gas water three-phase plugged dispersed flow velocity measuring method. The oil gas water three-phase plugged dispersed flow velocity measuring method comprises steps that 1) a phase holdup measuring device is used to acquire various phase holdup information; 2) a continuous phase and dispersed phases of a three-phase plugged dispersed flow are determined according to the phase holdup; 3) receiving signals acquired by an ultrasonic transducer are demodulated, and Doppler frequency shift is acquired; 4) drag force between the continuous phase and a dispersed gas phase is calculated; 5) the drag force between the continuous phase and a dispersed liquid phase is calculated; 6) shearing force of a tube wall applied to the continuous liquid phase is calculated; 7) ternary non-linear equations related to uc, ug, ud are established; 8) by adopting a numerical iteration type algorithm for solution, the optimal estimations of the uc, the ug, and the ud are acquired; 9) a three-phase flow split phase apparent velocity is calculated.

Owner:TIANJIN UNIV

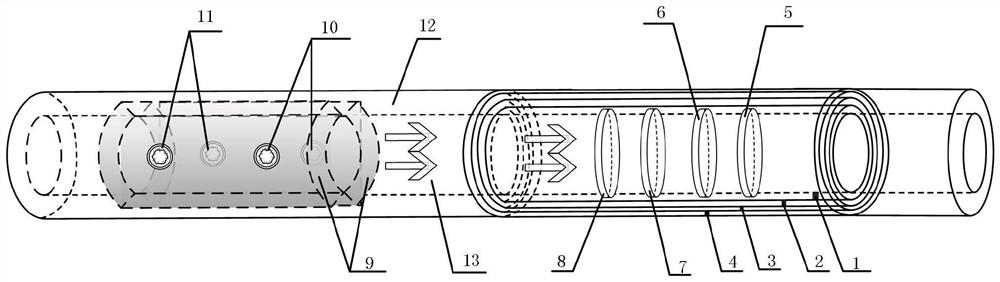

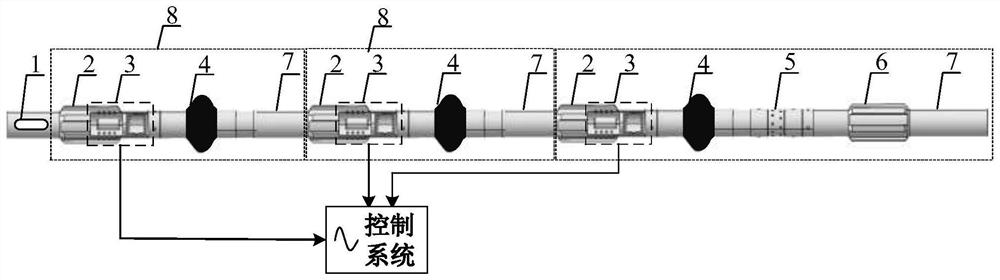

An unimpeded oil-gas-water multiphase flow parameter oil production combination logging tool

ActiveCN111946325BNo moving partsAccurate measurementSurveyFluid removalThermodynamicsControl system

The invention discloses an unobstructed oil-gas-water multiphase flow parameter petroleum production combined well logging instrument. Including an integrated measurement sensor and a control system; the integrated measurement sensor includes a measurement pipeline, a capacitance measurement module, an electromagnetic correlation flow measurement module and an impedance measurement module; the electromagnetic correlation flow measurement module is arranged in the insulation area of the measurement pipeline The impedance measurement module is arranged in the inner insulating layer of the capacitance measurement module, and the inner surface of the impedance measurement module is exposed in the measurement pipeline; the upper and lower ends of the capacitance measurement module are connected to the insulation area; the control The system provides circuits and measurement methods, and controls the corresponding modules to measure and calculate the water phase flow and oil phase flow according to the internal fluid state of the integrated sensor. The invention realizes the accurate real-time measurement of the oil-water two-phase flow parameters (flow rate and phase separation holdup) at the wellhead, and has the characteristics of compact structure, low cost, no moving parts, no obstructed flow, high reliability and the like.

Owner:YANSHAN UNIV

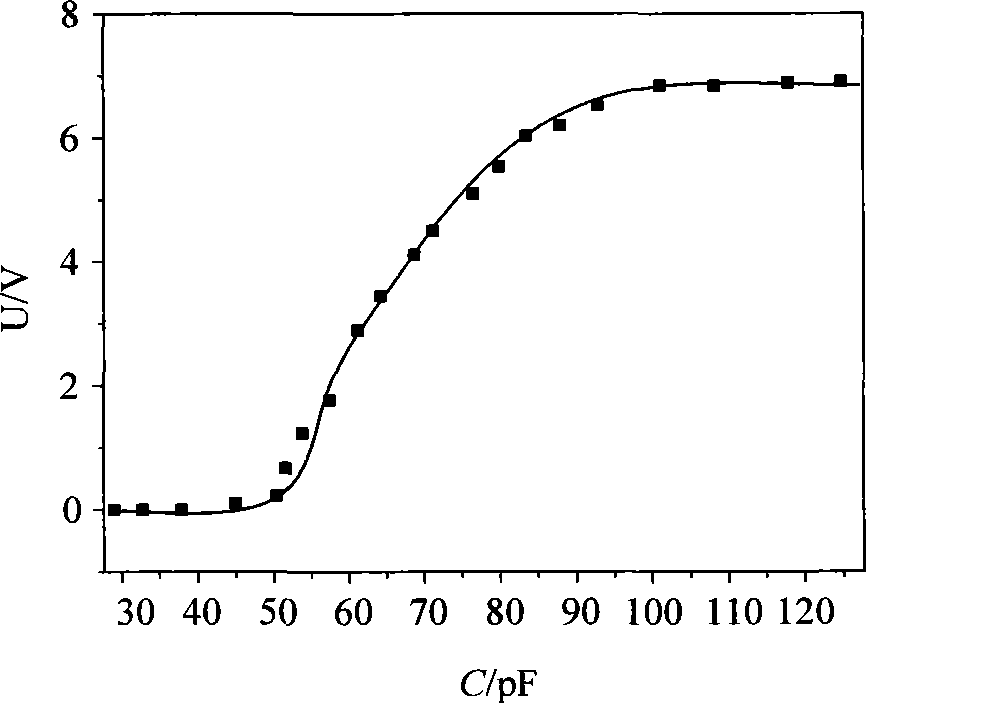

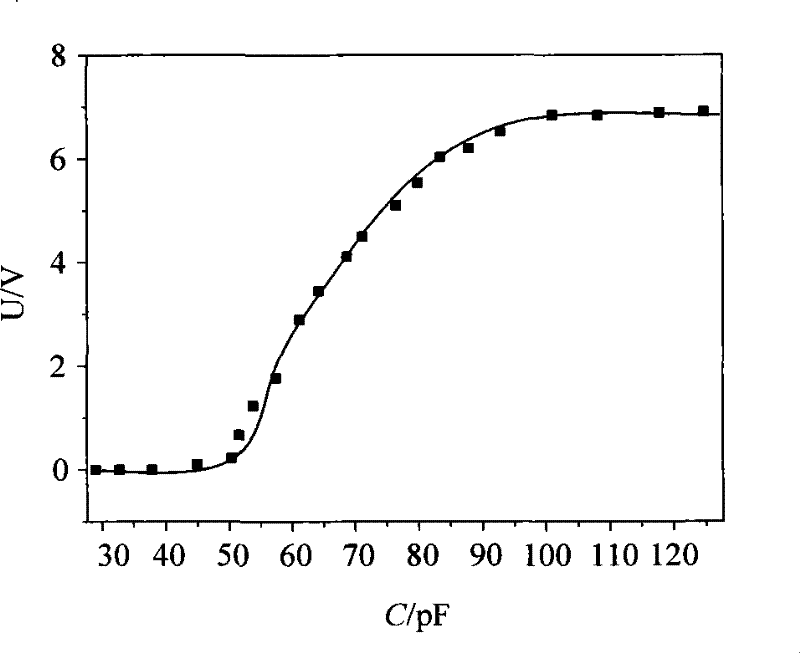

A gas-liquid two-phase flow phase holdup real-time capacitance measurement system and its measurement method

ActiveCN103884747BUnaffected by inhomogeneous phase distributionSignificant difference in output voltage valuesMaterial capacitanceAir interfaceFilling materials

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

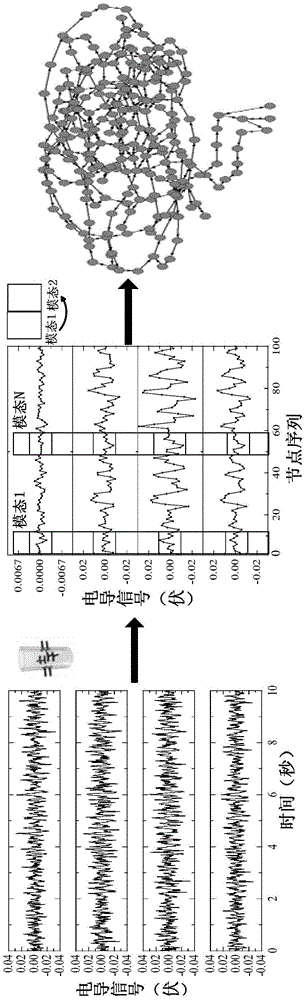

Two-phase flow instantaneous split-phase holdup prediction method based on phase space topology causality

ActiveCN111189882AOvercome the soft field effectImprove forecast accuracyMaterial analysis by electric/magnetic meansData segmentAlgorithm

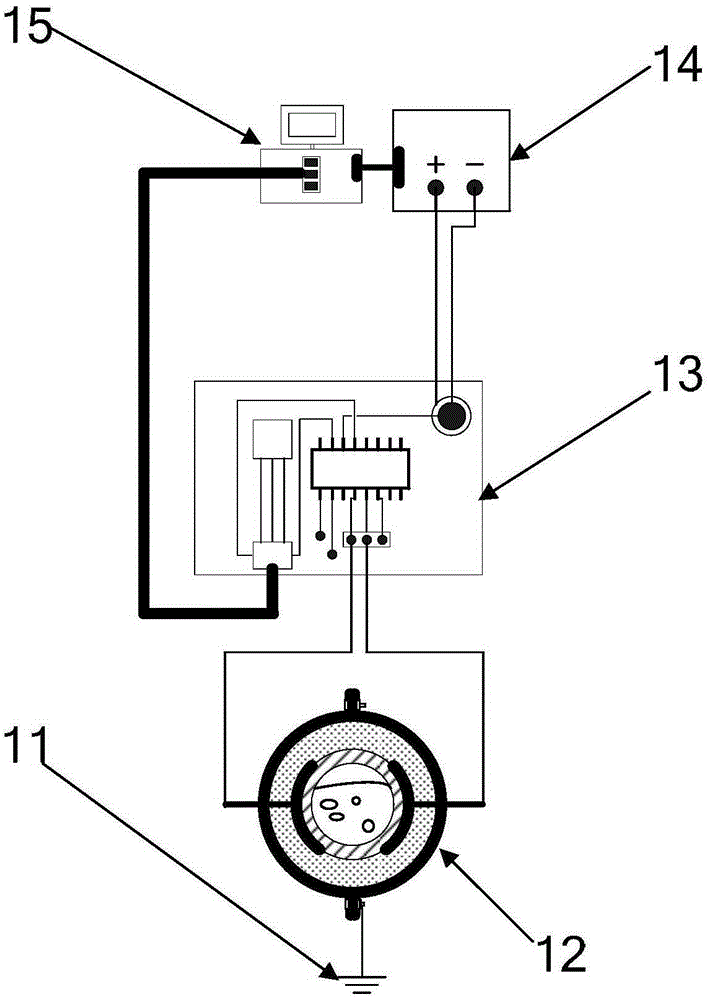

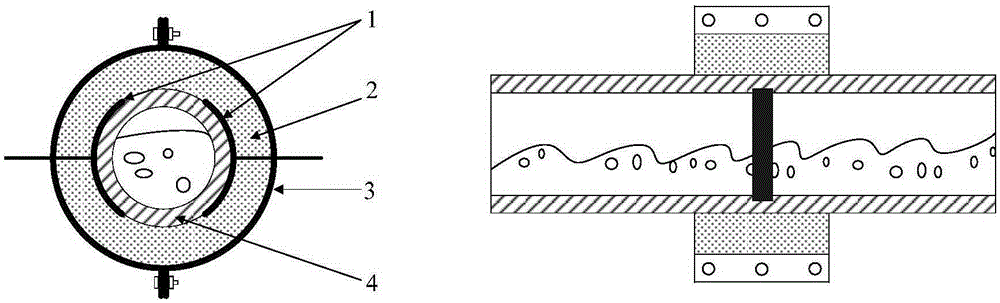

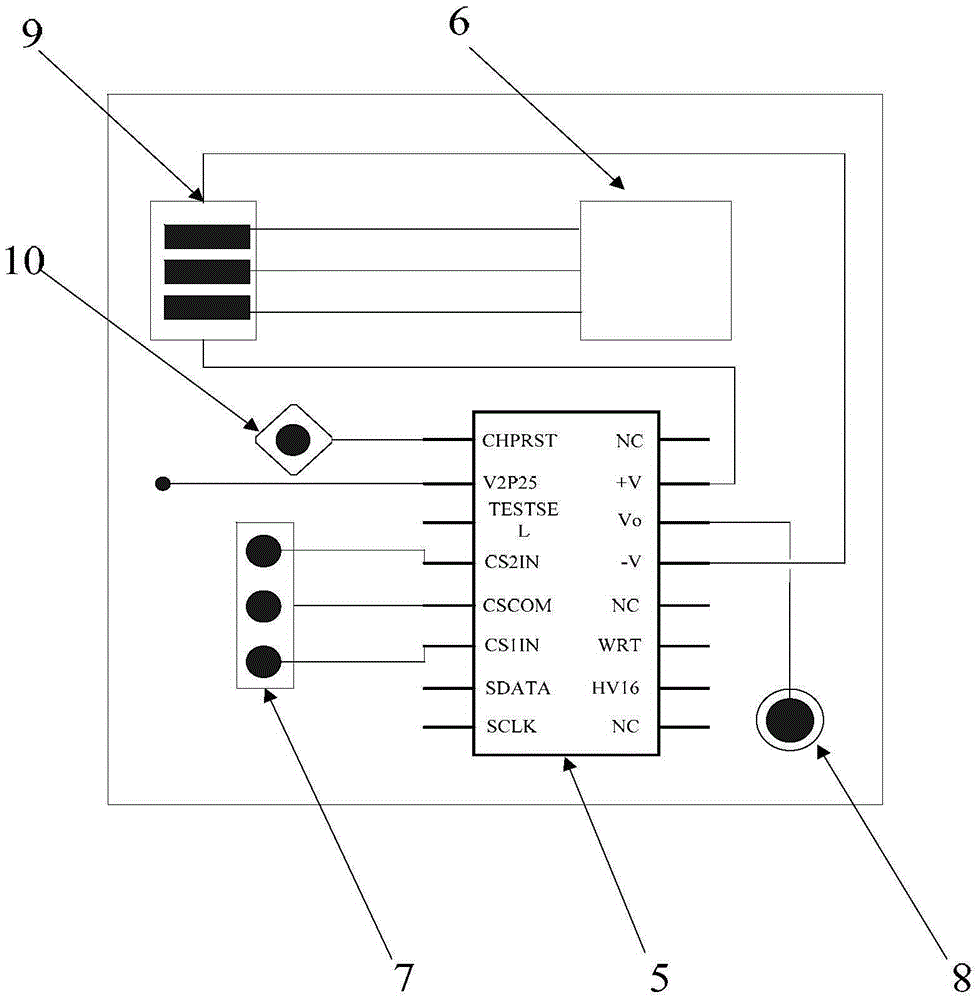

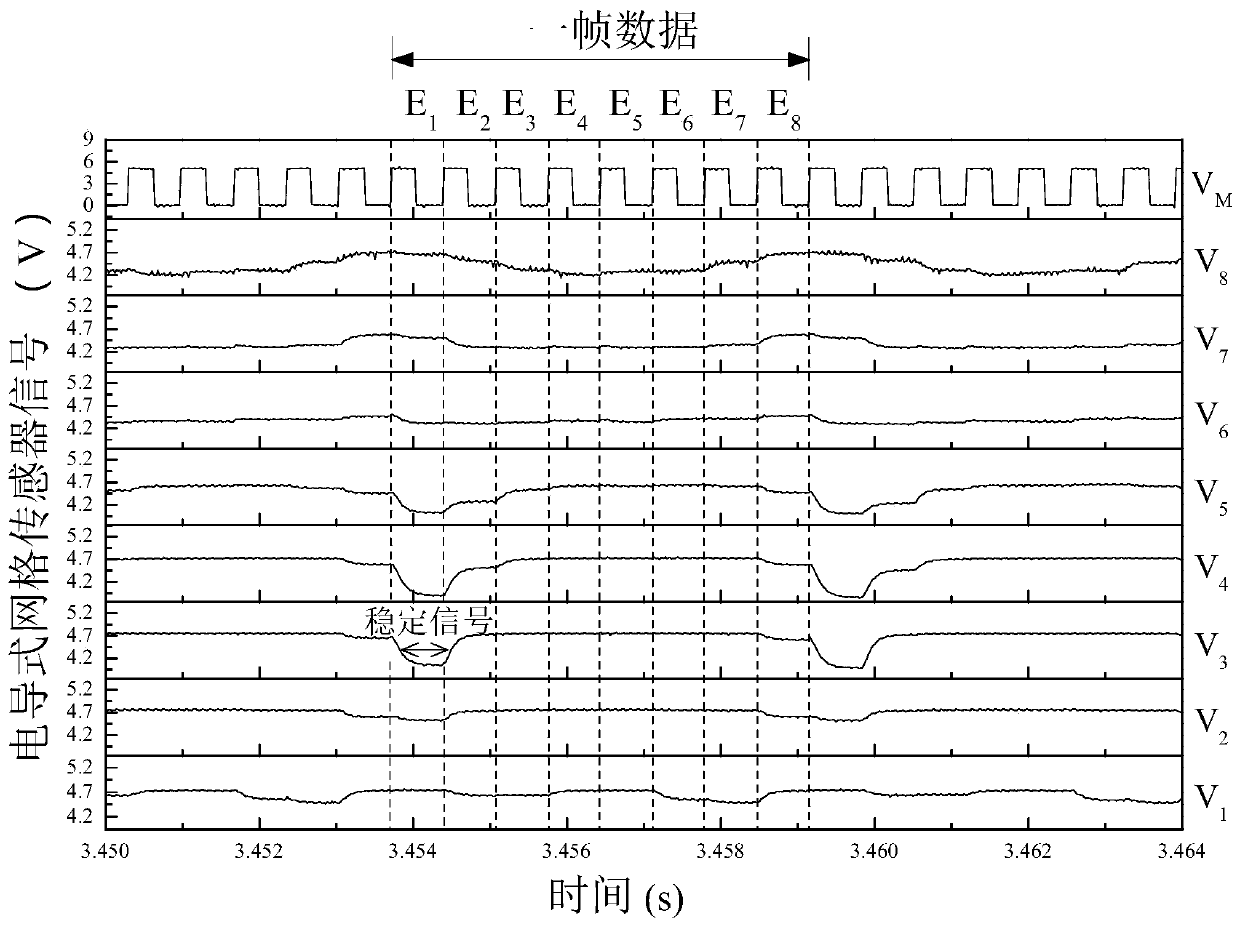

The invention relates to a two-phase flow instantaneous split-phase holdup prediction method based on phase space topology causality, and the method comprises the steps: designing a conductive grid sensor which is an 8 * 8 conductive grid sensor formed by two layers of parallel metal fine lines perpendicular to each other and making no contact with each other, and installing the conductive grid sensor on a circular pipeline; extracting each frame of data of the conductive grid sensor; constructing a one-dimensional data sequence according to normalized values of the measurement data distributed on the intersection points of the conductive grid sensors; according to a phase space embedding theory, embedding each data segment of the one-dimensional data sequence S into a phase space, and establishing mapping phi between adjacent phase spaces; training a radial basis function neural network to estimate the mapping phi, and calculating a causality index according to an estimation error; calculating a causal index between any two adjacent phase spaces; obtaining a causal index sequence R; and predicting the instantaneous water holdup of the two-phase flow by using the causal index sequence R.

Owner:TIANJIN UNIV

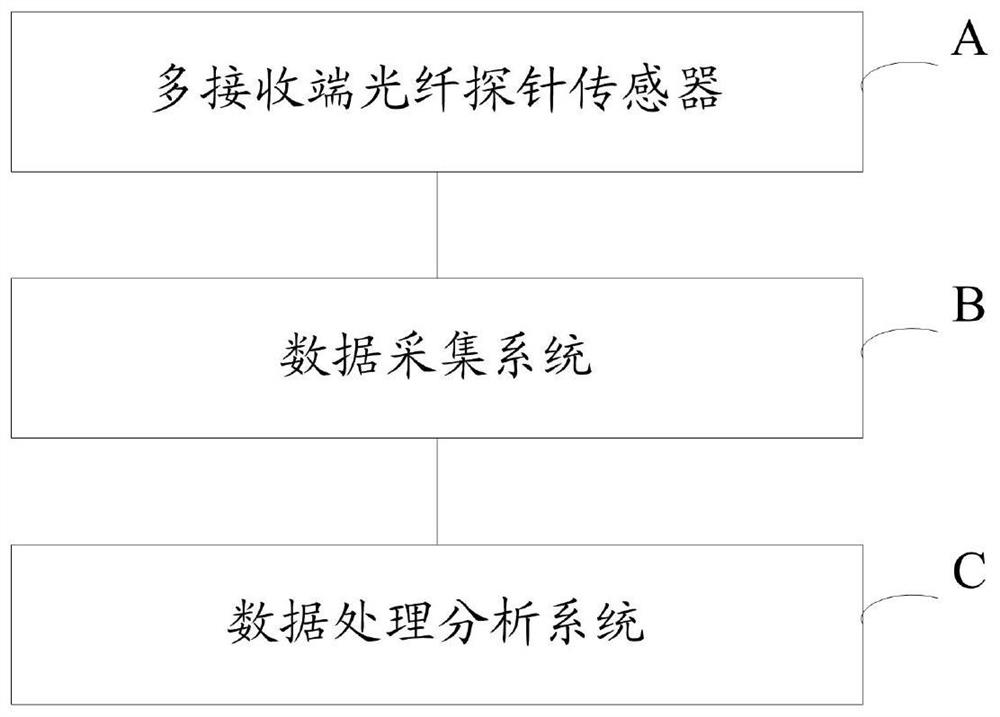

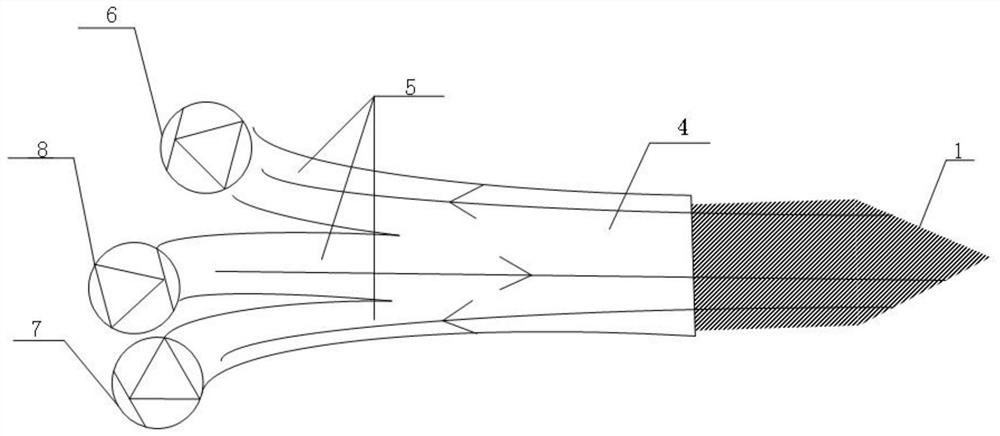

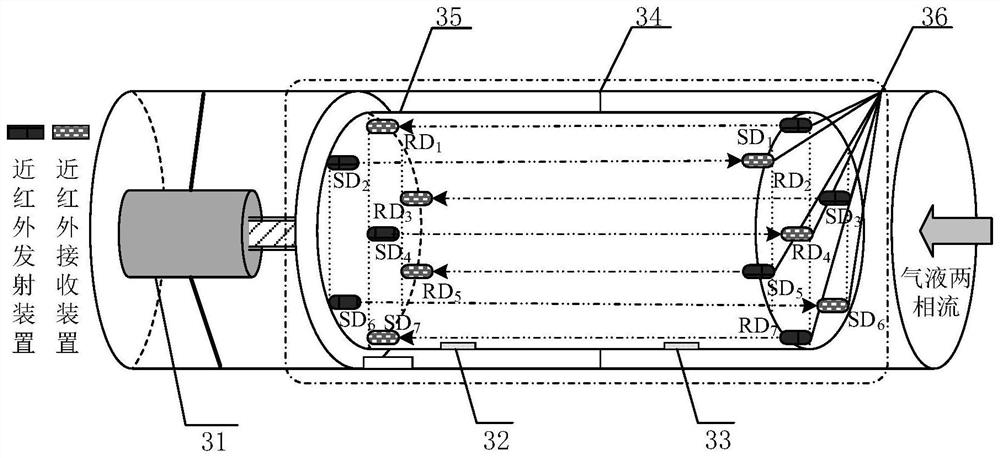

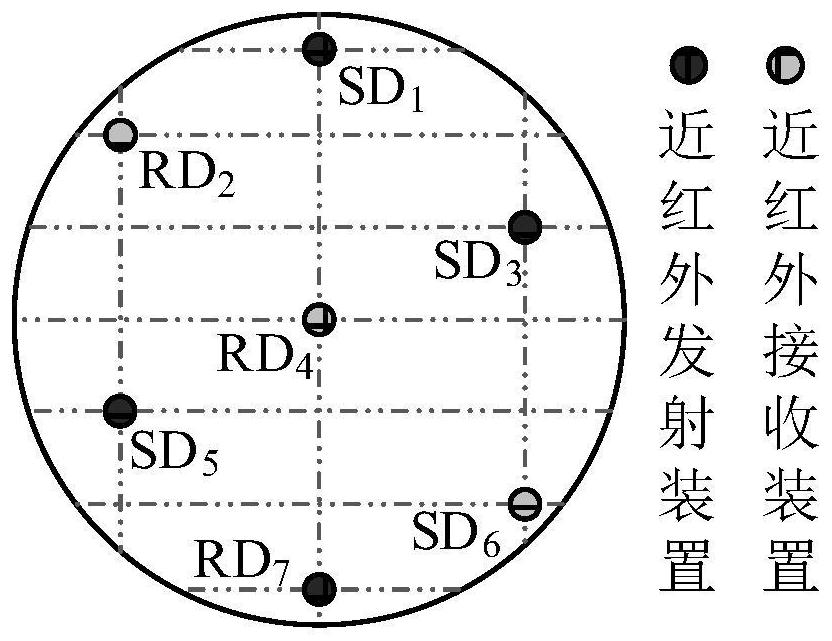

System and method for measuring phase separation holdup of oil-gas-water multiphase fluid in oil production logging

ActiveCN110273681BOvercome the technical defect that oil-water detection cannot be realizedReduce measurement errorConstructionsBorehole/well accessoriesWell loggingData acquisition

The invention provides a system and method for measuring split-phase volume fraction of oil-gas-water multi-phase fluid in oil production well logging. According to the system for measuring the split-phase volume fraction of the oil-gas-water multi-phase fluid in oil production well logging, a light signal reflected by oil well underground petroleum is converted to an electric signal through a multi-receiving-end optical fiber probe sensor, and the electric signal is transmitted to a data processing analysis system through a data collection system. According to the data processing analysis system, through a clustering network model from comprehensive feature parameters to the oil-gas-water multi-phase fluid, according to the comprehensive feature parameters obtained by feature extraction and normalization processing carried out on a voltage signal detected by the multi-receiving-end optical fiber probe sensor, split-phase volume fraction information of the oil well underground oil-gas-water multi-phase fluid is obtained, measurement error of split-phase volume fraction of the oil well underground oil-gas-water multi-phase fluid is reduced, and the technical defect that an optical fiber method cannot realize oil-water detection is overcome.

Owner:YANSHAN UNIV

A gas-liquid two-phase flow phase holdup and phase separation flow detection device and detection method

ActiveCN105890693BRealize measurementDo not disturb the flow fieldVolume flow measuring devicesMaterial capacitanceCapacitanceEngineering

The invention provides a gas-liquid two-phase flow phase holdup and a separate phase flow rate detection device and detection method. The device comprises an outer tube, an inner tube, a differential pressure transmitter, an LCR tester, a data collection unit and a data processing unit. The inner tube is connected in the outer tube in a sleeved mode, the middle of the inner tube is a baffle area, the two ends of the inner tube are circulation areas, fluid outlet holes and fluid inlet holes are formed in the side walls of the circulation areas at the two ends of the inner tube respectively, a to-be-tested fluid enters the inner tube from one circulation area of the inner tube, enters an annular space between the inner tube and the outer tube through the fluid outlet holes and then flows to the other circulation area through the fluid inlet holes, and the phase holdup of two-phase flow can be obtained by measuring a capacitance value of an annular capacitor and combing correlation operation; by combining pressure differences of the fluid at the two ends of the inner tube, the fluid total flow can be obtained, and the separate phase flow rate can be obtained finally. According to the gas-liquid two-phase flow phase holdup and the separate phase flow rate detection device and detection method, the inner tube and the outer tube and a middle fluid forms capacitance, the capacitance value is only related to an intermediate medium, and therefore an influence of flow pattern changes to measurement of the two-phase flow holdup can be weakened.

Owner:HEBEI UNIVERSITY

Optical path adjustable pipe phase holdup detection system and method

ActiveCN110441239AIncrease the optical pathAccurate measurementColor/spectral properties measurementsSignal-to-noise ratio (imaging)Light guide

Owner:HEBEI UNIVERSITY

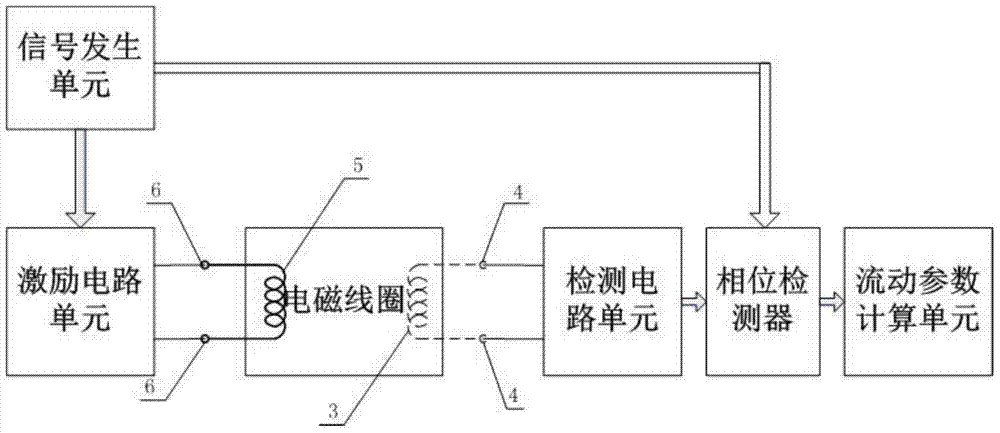

Two-phase flow holdup measurement method based on electromagnetic eddy current detection

ActiveCN104820013BEasy to measureHigh speedMaterial magnetic variablesPhase differenceAlternating current

The invention provides a method for measuring phase holdup of two-phase flow based on electromagnetic eddy current detection. The device used includes an electromagnetic coil, a signal generating unit, an excitation circuit unit, a detection circuit unit, a phase detector and a flow parameter calculation unit; the electromagnetic coil It includes an excitation coil and a detection coil wound on the outer wall of the pipeline; the signal generating unit is used to generate an alternating sinusoidal current signal, and the signal generated by it excites the excitation coil through the excitation circuit unit; the detection circuit unit uses It is used to measure the voltage signal at both ends of the detection coil; the phase detector is used to detect the phase difference between the excitation signal of the excitation coil and the voltage signal of the detection coil obtained by the detection circuit unit, and the detection result is sent to the flow parameter calculation unit; the flow parameter calculation The unit calculates the phase holdup of the two-phase flow according to the phase difference detection result of the phase detector. The invention obtains the two-phase fluid phase holdup in a non-invasive manner without pre-separation or mixing of the measurement fluid.

Owner:TIANJIN UNIV

Device for measuring oil, gas, water three phase flow containing rate

ActiveCN101324186BUniform electric fieldReduce mistakesConstructionsMaterial capacitanceCapacitanceSignal processing circuits

The invention belongs to the multiphase flow measurement field, which mainly relates to the multiphase flow phase holdup measurement field and particularly discloses an oil-gas-water three-phase flow phase holdup measurement device which is based on an double helix capacitive sensor and can carry out precise measurement of the oil-gas-water three-phase flow holdup. The measurement device comprises at least one double helix capacitive sensor, a signal processing circuit, a weak capacitance measurement circuit and a moisture content measurement circuit which are respectively connected with the signal processing circuit, wherein, the double helix capacitive sensor is connected with the weak capacitance measurement circuit or the moisture content measurement circuit selectively; when a pipeline is filled with oil gas, the double helix capacitive sensor is connected with the weak capacitance measurement circuit, the signal processing circuit outputs the phase holdup of the oil; when the pipeline is filled with water, the double helix capacitive sensor is connected with the moisture content measurement circuit, and the signal processing circuit outputs the phase holdup of the water.

Owner:XI AN JIAOTONG UNIV

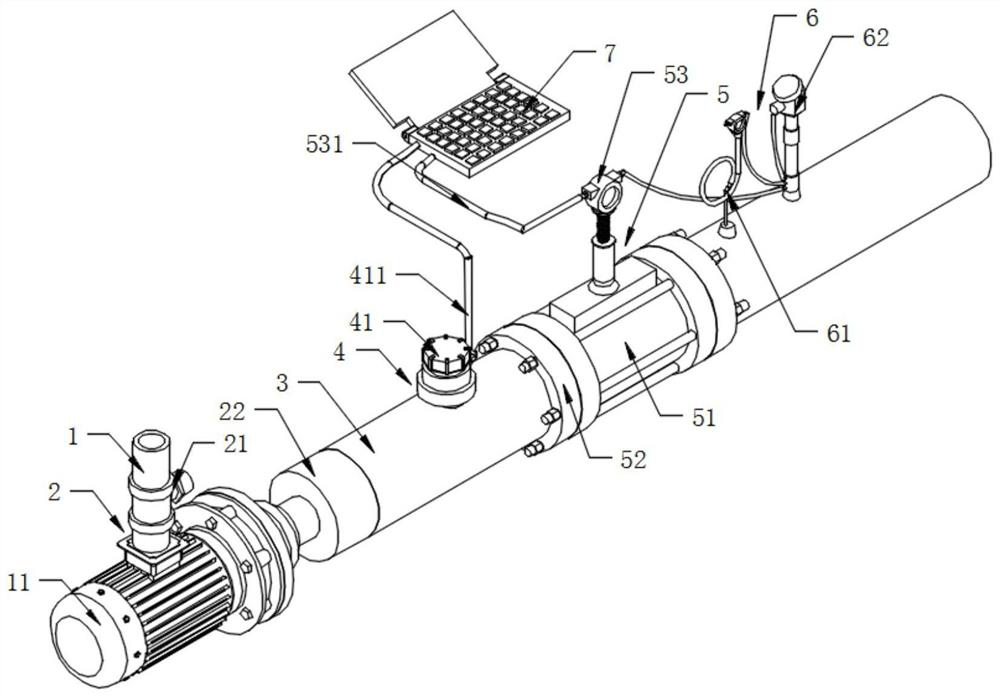

A Multiphase Fluid Measurement System

ActiveCN113389540BEasy to adjustRapid Metrology Test ResultsSurveyConstructionsThermodynamicsStream flow

The application belongs to the technical field of flow measurement, and in particular relates to a multiphase flow fluid measurement system. The existing oil-gas-water three-phase flowmeter is harmful to the environment and the human body, and the subsequent cost is relatively high. The application provides a multiphase flow fluid measurement system, including a flowmeter module, a water cut module and a data acquisition and processing module, wherein the flowmeter module is connected to the water cut module, and the flowmeter module is connected to the data The collection and processing module is connected, and the water content module is connected with the data collection and processing module; the flowmeter module is used to measure the virtual high flow rate of the fluid; the water content module is used to measure the phase holdup of water; The data acquisition and processing module is used to calculate the flow of each phase after collecting data. The modular design of the sensor is convenient for adjusting the position of the sensor according to different measurement requirements, and can provide fast, stable and reliable measurement and detection results for oil and gas wells under different working conditions.

Owner:深圳市联恒星科技有限公司

Method for simultaneously monitoring oil-gas-water three-phase flow

PendingCN113324597APrevent influence of measurement resultsLow costAnalysing fluids using sonic/ultrasonic/infrasonic wavesVolume variation compensation/correction apparatusFlow transducerCapacitance

The invention belongs to the technical field of oil-gas-water three-phase flow, and particularly relates to a method for simultaneously monitoring oil-gas-water three-phase flow, wherein the method comprises a liquid inlet pipeline and a monitoring pipeline, a liquid inlet mechanism is arranged below the liquid inlet pipeline, and the liquid inlet mechanism controls the flow of fluid in the liquid inlet pipeline; and the monitoring pipeline is arranged on one side of the liquid inlet mechanism, monitoring components are arranged in the monitoring pipeline and on the surface of the monitoring pipeline, and the monitoring components monitor the oil-gas-water content of fluid flowing into the monitoring pipeline. According to the method for simultaneously monitoring the oil-gas-water three-phase flow, monitoring of oil-gas-water three-phase holdup is achieved through an oil-gas-water three-phase holdup sensor by means of capacitance conductivity and an ultrasonic sensing technology, and the overall flow in a monitored pipeline is obtained through a flow sensor which is a vortex street sensor. The oil-gas-water three-phase holdup sensor and the flow sensor are connected to a host through an oil-gas-water three-phase holdup sensing signal line and a flow sensing signal line, and the flow of the oil phase, the flow of the gas phase and the flow of the water phase can be obtained through analysis software on the host.

Owner:TIANJIN NEW STAR ENERGY TECH CO LTD

Measurement method of ultra-high water-cut oil-water holdup based on thermal tracer

ActiveCN109838228BResolve failureAccurate measurementConstructionsMathematical modelInternal resistance

The invention relates to method for measuring the water retention rate of extra high water-containing oil based on heat trace. The method for measuring the water retention rate of extra high water-containing oil based on heat trace comprises the steps that heat quantity dissipated during heating of a heat generator in unit time is calculated according to internal resistance and a heating voltage value of the known heat generator; the initial temperature and the temperature after heating in a fluid is measured; the theoretical values of the oil phase heat absorption and the water phase heat absorption in a thermal pulse to-be-tested fluid per unit time are calculated; actual heat quantities absorbed by oil and water are calculated; the sum of volume low rates of each phase fluid per unit time is calculated; measurement models between a heat source heating voltage and the initial temperature, the temperature after heating, a water phase mass flow quantity, and an oil phase mass flow quantity are established; establish a mathematical model of the water phase mass flow quantity and the oil phase mass flow quantity is established; a mathematical model of a water phase holdup rate and anoil phase holdup rate is established. According to the method for measuring the water retention rate of extra high water-containing oil based on heat trace, measurement accuracy is only affected by the sensitivity of a temperature sensor, the influence on the measurement accuracy due to unknown fluid distribution during an extra high water retaining development period is effectively solved, and the measurement accuracy of oil and water holdup rates is improved.

Owner:湖州信倍连网络科技有限公司

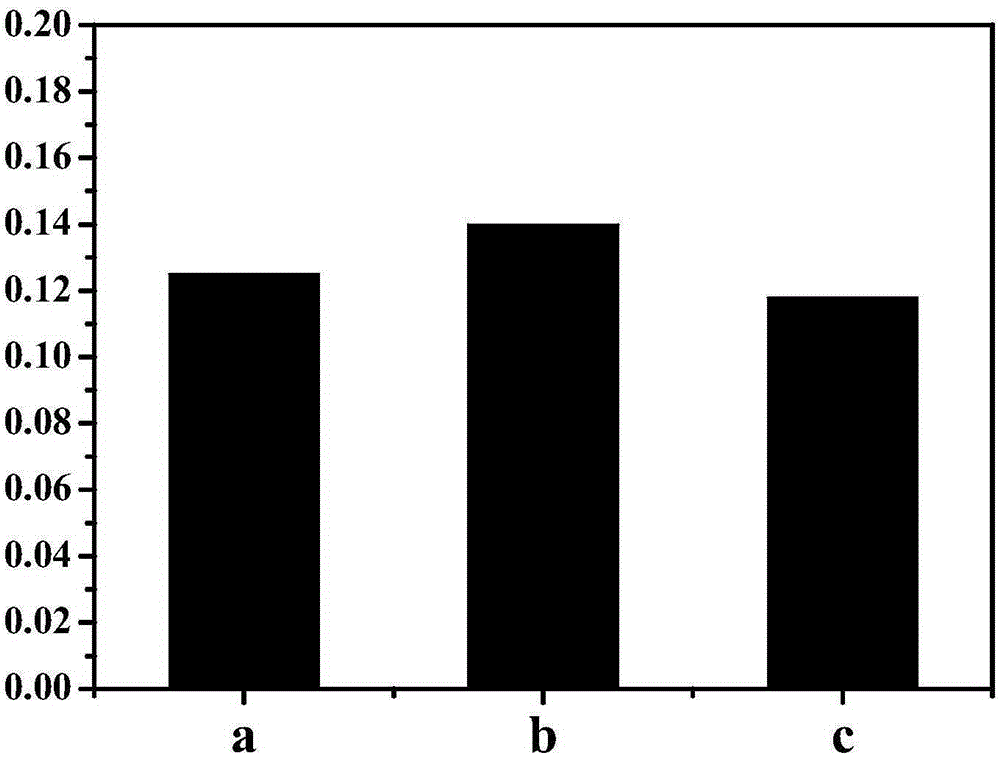

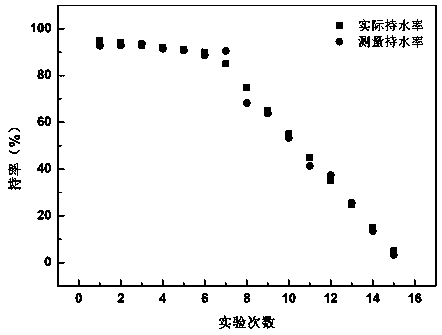

Gas-liquid phase holdup measurement and verification method based on modal transfer complex network

ActiveCN104049000BEfficient identificationGood phase holdup measurementMaterial resistanceWeight coefficientValidation methods

A gas-liquid phase holdup measurement and verification method based on modal migration complex network: constructing modal migration complex network; calculating gas-liquid two-phase flow parameter measurement information; drawing directional weighted aggregation coefficient, local betweenness and average shortest The measurement chart of the linear relationship between path and phase holdup realizes the measurement of phase holdup of gas-liquid two-phase flow; according to the drawn measurement chart, analyze the directional weighted aggregation coefficient, local betweenness and average shortest path and flow pattern evolution dynamics relationship, revealing the dynamic mechanism of gas-liquid two-phase flow flow regime evolution. The verification method is to use four-sector distributed conductance sensors for verification. The present invention proposes a multivariate time series modal migration complex network method for information fusion of two-phase flow distributed conductance sensor measurement signals; the multivariate time series modal migration complex network information fusion method can effectively identify different gas-liquid two-phase flows type; the verification of multivariate time series modal migration complex network information fusion method can obtain good phase inclusion rate measurement results.

Owner:TIANJIN UNIV

Method for measuring water retention rate of extra high water-containing oil based on heat trace

ActiveCN109838228AResolve failureAccurate measurementConstructionsMathematical modelInternal resistance

The invention relates to method for measuring the water retention rate of extra high water-containing oil based on heat trace. The method for measuring the water retention rate of extra high water-containing oil based on heat trace comprises the steps that heat quantity dissipated during heating of a heat generator in unit time is calculated according to internal resistance and a heating voltage value of the known heat generator; the initial temperature and the temperature after heating in a fluid is measured; the theoretical values of the oil phase heat absorption and the water phase heat absorption in a thermal pulse to-be-tested fluid per unit time are calculated; actual heat quantities absorbed by oil and water are calculated; the sum of volume low rates of each phase fluid per unit time is calculated; measurement models between a heat source heating voltage and the initial temperature, the temperature after heating, a water phase mass flow quantity, and an oil phase mass flow quantity are established; establish a mathematical model of the water phase mass flow quantity and the oil phase mass flow quantity is established; a mathematical model of a water phase holdup rate and anoil phase holdup rate is established. According to the method for measuring the water retention rate of extra high water-containing oil based on heat trace, measurement accuracy is only affected by the sensitivity of a temperature sensor, the influence on the measurement accuracy due to unknown fluid distribution during an extra high water retaining development period is effectively solved, and the measurement accuracy of oil and water holdup rates is improved.

Owner:湖州信倍连网络科技有限公司

A two-phase flow split-phase holdup conductivity sensor and its structure parameter optimization method

InactiveCN101419180BPrevent floatingLarge measuring rangeMaterial resistanceFast measurementConductive materials

The invention provides a two-phase flow separation phase holdup conductivity sensor. The sensor is composed of a conductive ring layer and an excitation electrode pair and a measurement electrode pair attached to it. The excitation electrode and the measurement electrode are on the upper diameter of the pipe wall of the conductive ring layer. Symmetrically distributed in a spiral at an angle of 180 degrees. At the same time, a structural parameter optimization method based on the above-mentioned sensor structure is also provided. The beneficial effects of the present invention are aimed at the real-time measurement of the phase holdup of two-phase flow, which overcomes the shortcoming that the measurement electrode is in contact with the non-conductive substance in the traditional conductivity sensor, which causes the measurement electrode to float, and provides a conductivity type electrical sensor based on its analysis The model gives the expression of the sensitivity distribution at any point on the two-dimensional sensor cross-section, which can quickly optimize the structural parameters. Belonging to non-invasive rapid measurement, the measurement range is widened, and the cost is low.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com