Measurement method of ultra-high water-cut oil-water holdup based on thermal tracer

A technology of ultra-high water content and measurement method, which is applied in construction and other fields, can solve the problems of large influence on measurement accuracy and complex fluid distribution, and achieve the effects of solving the influence of measurement accuracy, improving measurement accuracy, and stabilizing measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0064] This embodiment is a further description of Embodiment 1. The internal resistance of the heat source generator 4 is R and the heating voltage value U, and the heat Q dissipated when the heat source generator is heated per unit time is calculated. san , whose expression is as follows:

[0065]

[0066] Among them, i is the serial number of the heating voltage, i=1,2,...,n, the expression of the heating voltage vector U of the heat source generator is as follows:

[0067] U={U 1 ,U 2 ,...,U i ,...,U n} T .

specific Embodiment approach 3

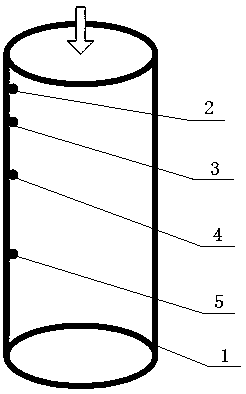

[0069] This embodiment is a further description of Embodiment 2. In step 2, the initial temperature of the water phase and oil phase in the fluid to be measured is detected by the first temperature sensor 3, and the initial temperature value is denoted as T 0 , because the wellbore of the oil well adopts a small pipe diameter, the temperature field of the entire cross-section is regarded as a uniform distribution, and the temperature of the fluid to be measured is detected by the second temperature sensor 5 after heating, and the temperature data of the fluid after heating is recorded as a vector T 1 ,T 1 Expressed as:

[0070] T 1 ={T 11 , T 12 ,...,T 1i ,...,T 1n} T

[0071] Among them, T 1i is the fluid temperature value obtained by the temperature sensor at the i-th heating voltage.

specific Embodiment approach 4

[0073] This embodiment is a further description of Embodiment 3. In step 3, the theoretical value Q of the heat absorbed by the oil phase in the fluid to be measured in the thermal pulse marked after being heated by the heat source generator 4 per unit time is obtained. xio The theoretical value of heat absorbed by the water phase Q xiw , which is expressed as follows:

[0074]

[0075] Among them, q mw is the mass flow rate of water phase per unit time, c w is the specific heat capacity of water, ρ w is the water phase density, q vw is the volumetric flow rate of the water phase;

[0076]

[0077] Among them, q mo is the mass flow rate of oil phase per unit time, c o is the specific heat capacity of oil, ρ o is the oil phase density, q vo is the volumetric flow rate of the oil phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com