Oil gas water three-phase plugged dispersed flow velocity measuring method

A technology of flow velocity measurement and dispersed flow, which is applied in fluid velocity measurement, velocity/acceleration/impact measurement, measuring devices, etc. It can solve the problems of reducing the success rate of related calculations, and achieve the effects of fast speed, low cost and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The calculation method of the present invention will be described in detail below in conjunction with the accompanying drawings.

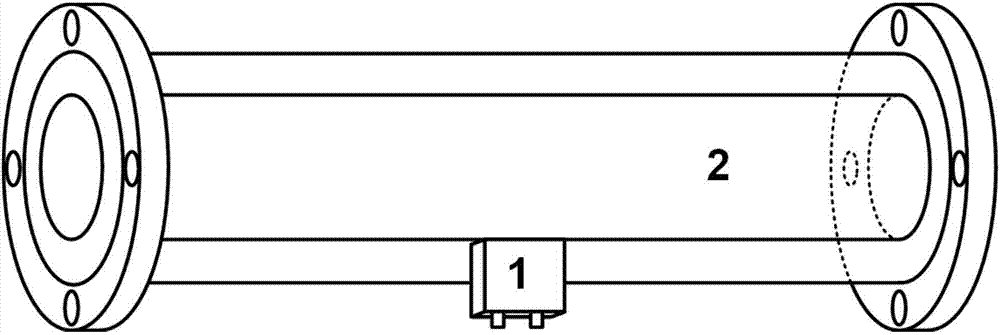

[0027] figure 1 Schematic diagram of an ultrasonic Doppler sensor in the measurement method of the present invention; a dual-crystal probe 1 is installed at the bottom of a pipeline 2 .

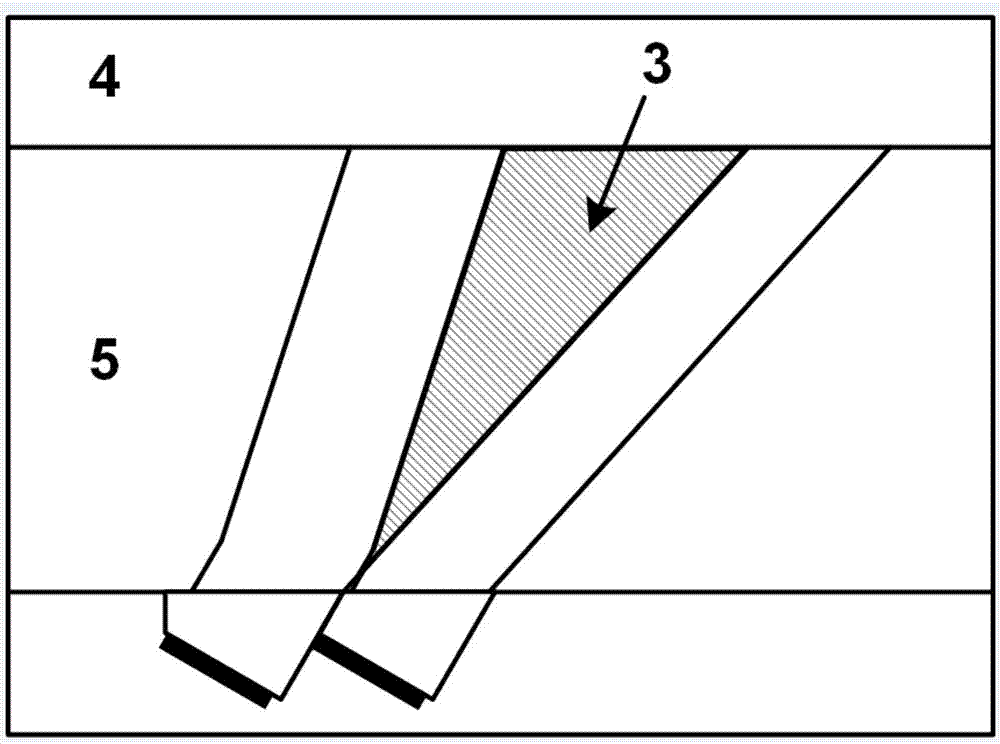

[0028] figure 2 It is a schematic diagram of ultrasonic Doppler measurement space in the measurement method of the present invention; the dual crystal probe is installed at the bottom of the pipeline and embedded in the 4 pipe walls. The CW Doppler measurement space is defined as the overlapping area of the sound field where the sound waves are transmitted and received. Inside the pipe 5 area, the overlapping area of the two parts of the sound field is the shaded area 3, which is the measurement space. The velocity information of the discrete phases in the fluid flowing through this region can be obtained by ultrasonic Doppler sensors. The projecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com