Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Improve the pass rate of product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

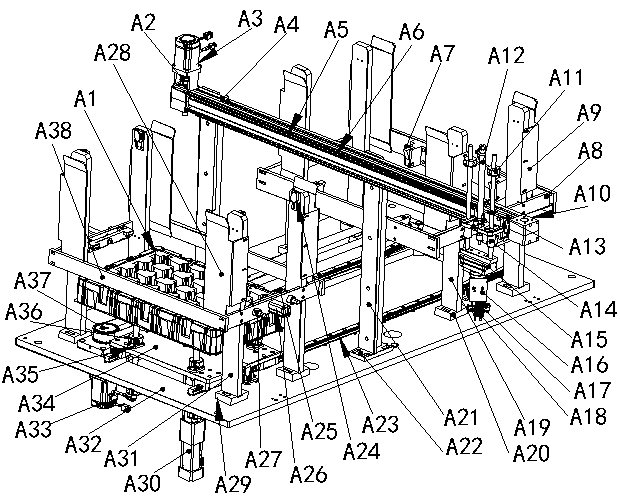

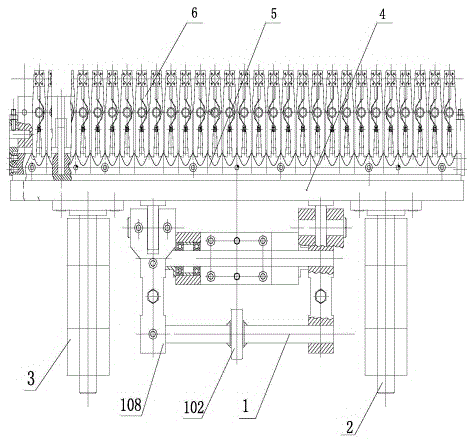

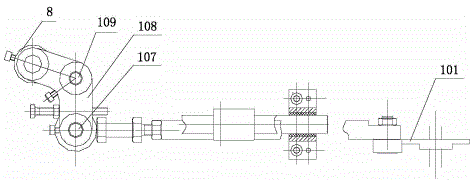

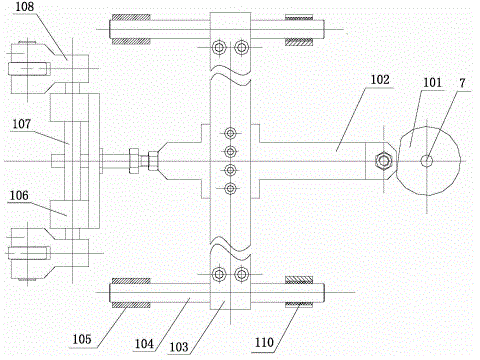

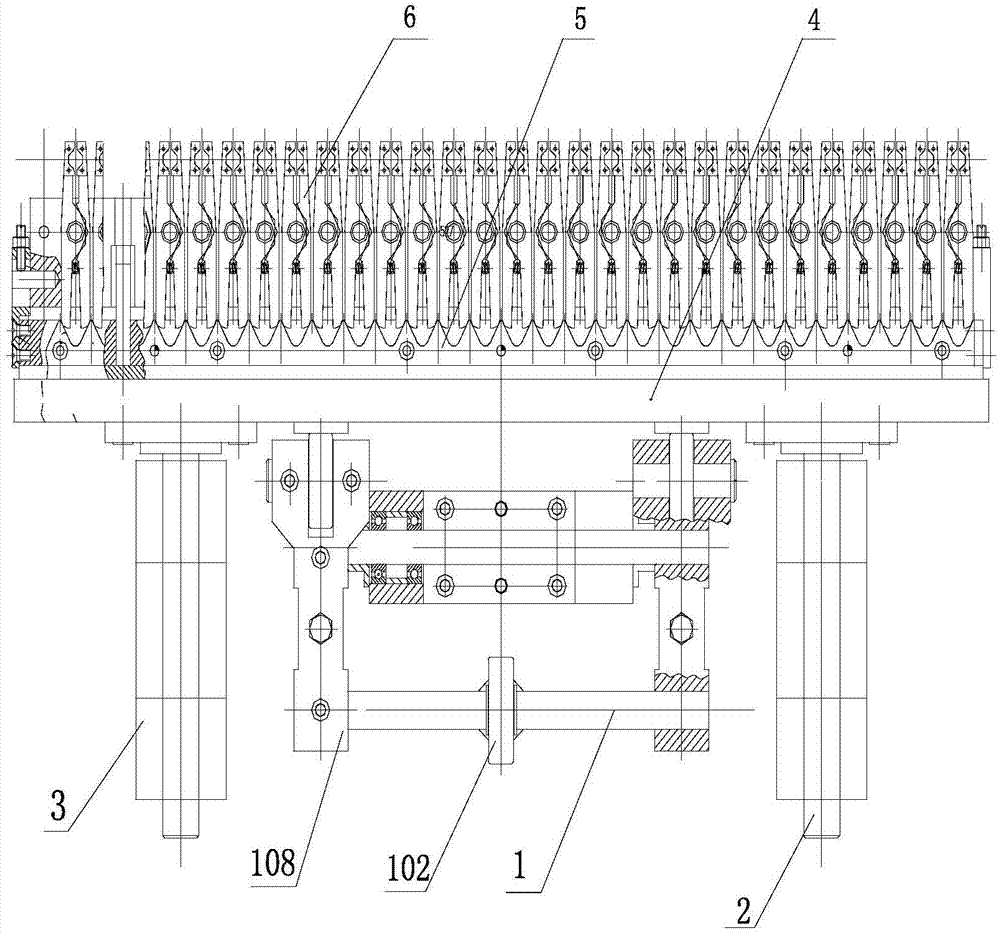

Process for charging and packing industrial powder explosive cartridge and vibratory charging machine

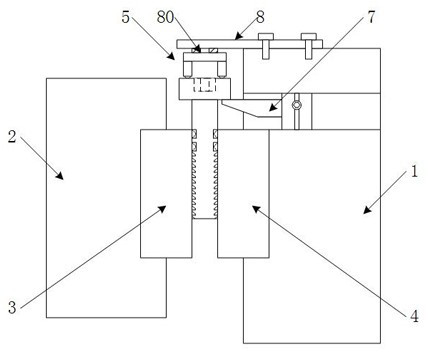

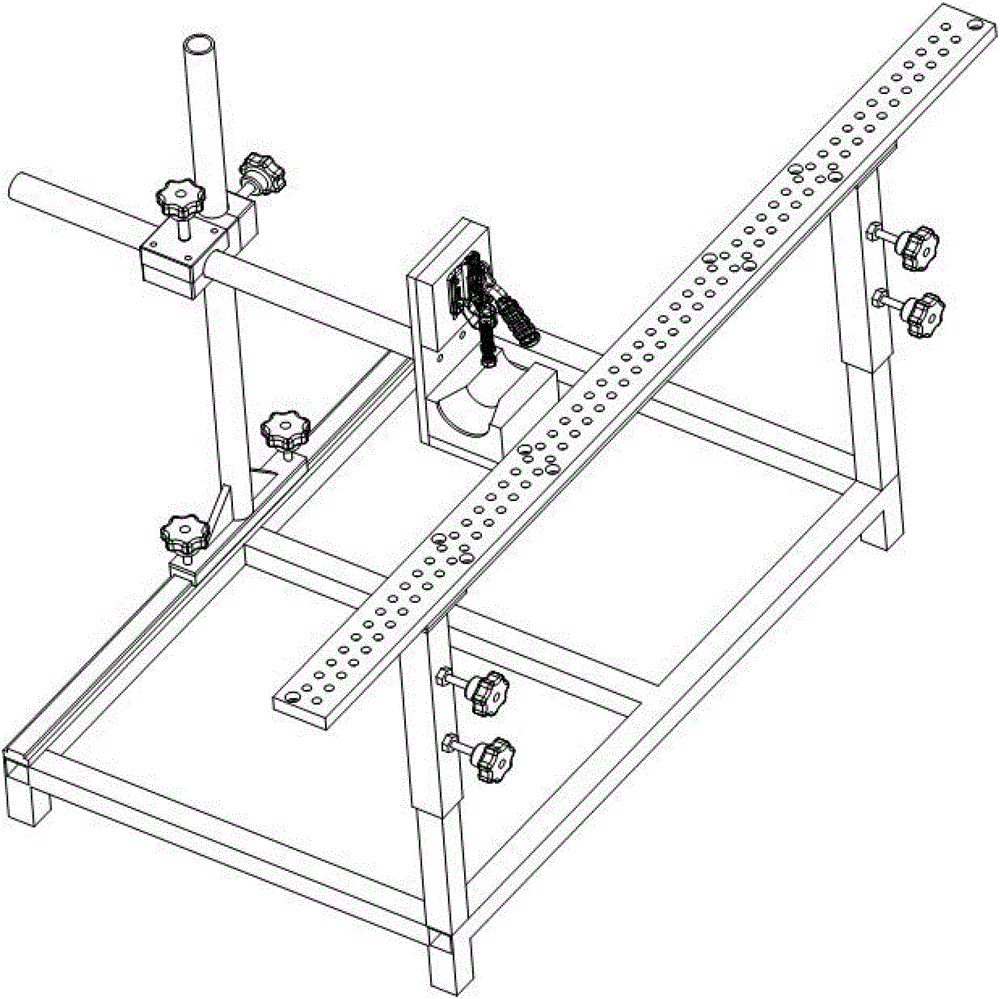

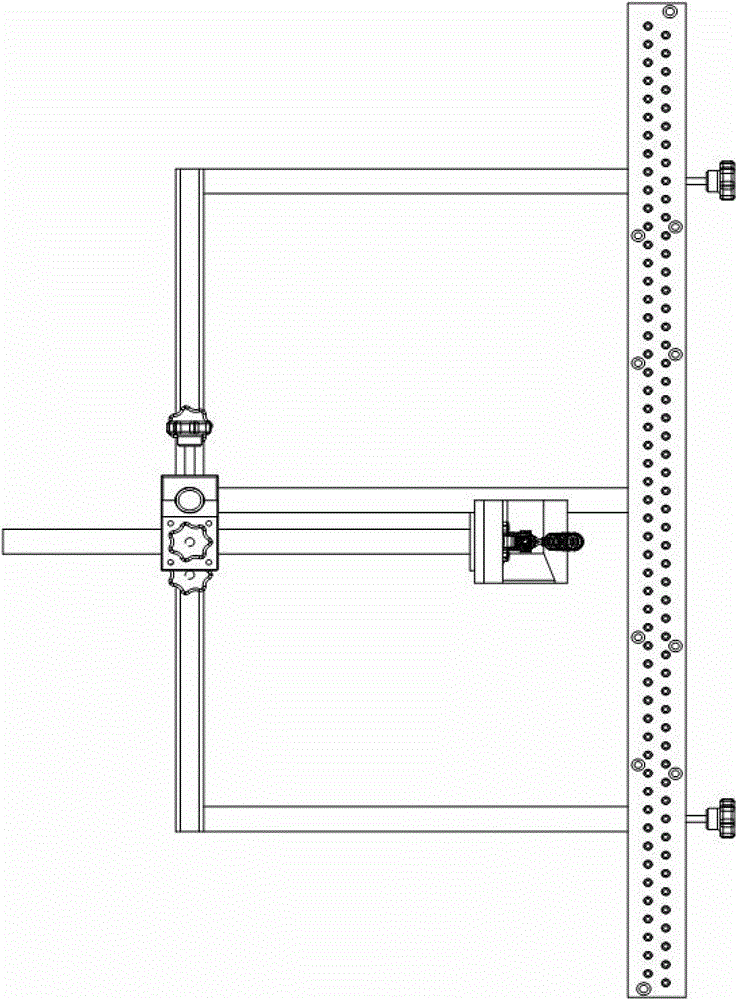

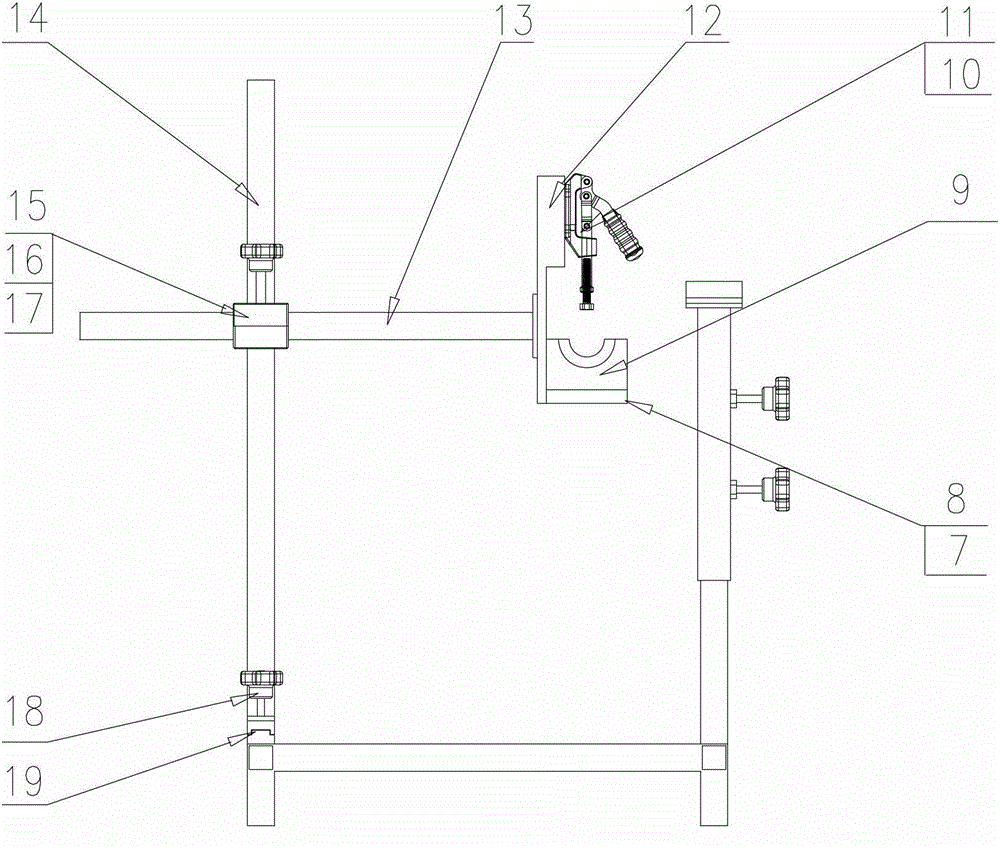

The invention relates to the technical field of explosives, in particular to a process for charging and packing an industrial powder explosive cartridge and a vibratory charging machine. The process for charging and packing the industrial powder explosive cartridge is characterized by comprising a cartridge finishing and fixed connecting process, a cartridge charging process and a cartridge sealing process. The vibratory charging machine is characterized by comprising a stander; the stander is provided with a frame conveying mechanism, a charging station and a sealing station; the charging station is provided with a charging ramming mechanism and a compaction mechanism; and the sealing station is provided with a sealing mechanism. The process has the advantages of short flow, high safety performance, high working efficiency, good charging quality, and the like; and the vibratory charging machine has the advantages of high essential safety level, high product quality qualification rate, high automation degree, large capacity, compact and reasonable structure, little occupied area, few operation personnel at a dangerous area, and the like.

Owner:蒙宝林

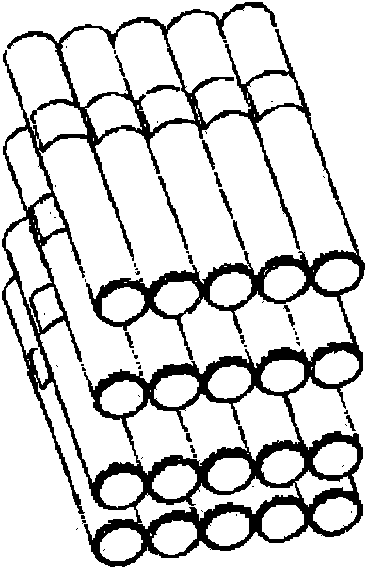

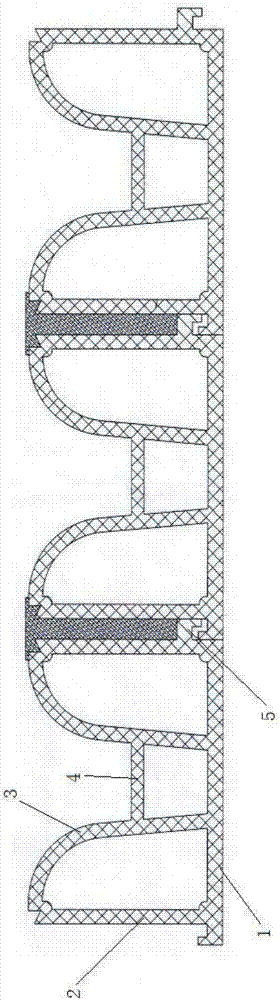

Double-layer hollow capsule and multi-layer enteric hollow capsule

InactiveCN102552209AReduce processReduce production processCapsule deliveryAlkalinityIsolation layer

A double-layer hollow capsule comprises a gelatine layer and is characterized in that a stomach soluble hollow capsule formed by an isolation layer made of stomach soluble membrane forming materials is arranged on the inner wall of the gelatine layer. A multi-layer enteric hollow capsule comprises a gelatine layer and is characterized in that an enteric hollow capsule formed by an isolation layer made of enteric membrane forming materials is arranged on the inner wall of the gelatine layer. The isolation layers can be resistant to acidity and alkalinity of medicines to protect the gelatine layers and ensure that the capsules do not deteriorate during storage periods.

Owner:ANHUI HUANGSHAN CAPSULE CO LTD

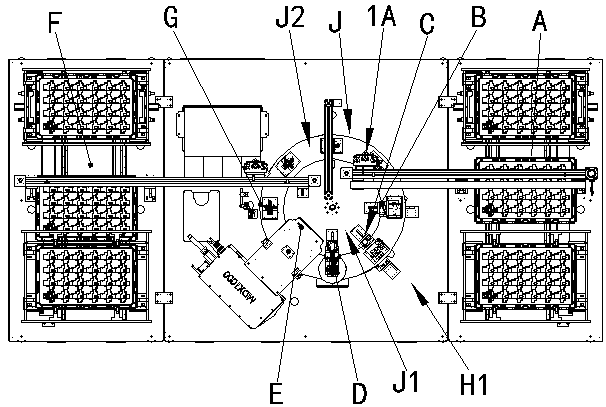

Automobile connector PIN needle detecting machine and detecting method thereof

PendingCN108387825AFast trackImprove detection efficiencyTesting dielectric strengthCo-operative working arrangementsEngineeringConnector Pin

The invention discloses an automobile connector PIN needle detecting machine and a detecting method thereof. A feeding station, an electrical characteristic detecting station, a high and low needle detecting station, an image detecting station, a laser marking station, a code scanning station and a material discharging station are respectively located on corresponding detection or operation stations on an externally-rotary index dial; a feeding jaw of the feeding station is oppositely matched with a loading station on the index dial, and the electrical characteristic detecting station includesan electrical characteristic upper detecting component and an electrical characteristic lower detecting component; the high and low needle detecting station comprises a high and low needle upper detecting component and a high and low needle lower detecting component; the image detecting station comprises an image detecting upper component and an image detecting lower component; the laser markingstation is arranged above the index dial; the code scanning station is located above the index dial, and the discharge jaw of the material discharging station is oppositely matched with a discharge station on the index dial. Automatic feeding and discharging detection is achieved, the detection efficiency and accuracy are improved, the manual operation intensity is lowered, the detection quality is improved, and the quality pass rate is increased.

Owner:HANGZHOU TAISHANG MACHINERY CO LTD

Two-stage treating method for accretion in carbon jacket hearth roll of continuous annealing furnace

ActiveCN102776351AFast online processingImprove work rateFurnace typesHeat treatment process controlControl switchContinuous annealing

The invention discloses a two-stage treating method for accretion in a carbon jacket hearth roll of a continuous annealing furnace. According to the invention, moisture inlets and hand-operated valve control switches are additionally installed at a second radiant tube heating zone and a second soaking zone, and when accretion occurs in the carbon jacket hearth roll, the hand-operated valve control switch is opened and moisture is directly blown in for roll grinding of the carbon jacket hearth roll. The method provided by the invention has the advantages of a simple and practical process, convenient operation and controlling and capacity of effectively controlling accretion in a carbon jacket of the hearth roll and realizing rapid on-line treatment of the accretion in the carbon jacket hearth roll; therefore, an operating rate of a unit and surface quality of products are improved, a life cycle of the carbon jacket hearth roll is prolonged, energy consumption is reduced, and the qualified rate of the products is greatly enhanced.

Owner:ANGANG STEEL CO LTD

Industrial pleurotus erygii cultivation method adopting temperature-controlled fruiting management technique

InactiveCN105379556AProduction process streamlinedImprove labor productivityCultivating equipmentsMushroom cultivationBiotechnologyEngineering

The invention discloses an industrial pleurotus erygii cultivation method adopting a temperature-controlled fruiting management technique. The cultivation method comprises the following steps: material-loading, sterilizing, cooling, inoculating, culturing, fruiting, harvesting and packaging; the fruiting management comprises the managements of the following stages: a stage of primordium formation promotion, a stage of mushroom bud formation, a stage of elongation and a stage of maturation; the temperature of the stage of primordium formation promotion is controlled at 15-18 DEG C; the temperature of the stage of mushroom bud formation is controlled at 14-17 DEG C; the temperature of the stage of elongation is controlled at 13-16 DEG C; and the temperature of the stage of maturation is controlled at 12-15 DEG C. The industrial pleurotus erygii cultivation method adopting the temperature-controlled fruiting management technique designed by the invention is simple in process and greatly improved in labor productivity, product-quality qualification rate and biological conversion rate; the industrial pleurotus erygii cultivation method has the effects of reducing pollution, lowering cost and raising economic performance of the pleurotus erygii cultivation.

Owner:江苏久禾生物科技发展有限公司

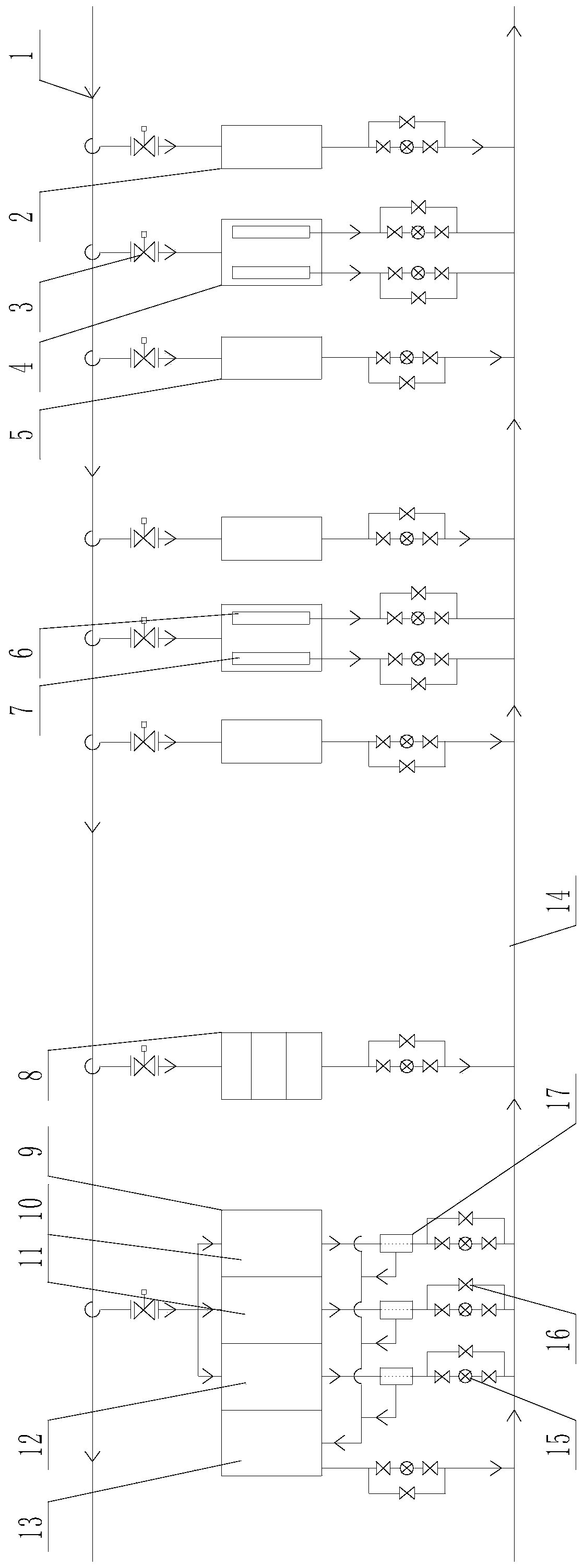

Forming method of large-scale metal storage tank with high bonding strength inner wall anticorrosive layer

InactiveCN103318578AIncrease contact areaImprove physical bindingLarge containersSilanizationUltimate tensile strength

The invention discloses a forming method of a large-scale metal storage tank with a high bonding strength inner wall anticorrosive layer. The forming method is suitable for machining of large-scale polyethylene steel-plastic composite storage tanks. The forming method is characterized by including: (1) laser texturing of the surface, a micro concave-convex structure is machined on the surface of a steel plate through laser, and the bonding area of a steel substrate and a coating layer is improved; (2) silylanization, a KH560 silicane film bonding layer is formed on the surface of the steel substrate, and the KH560 silicane film bonding layer is bonded with a polyethylene coating layer through chemical bond. The forming method combining the laser texturing and the silylanization is adopted, the contact area is increased, meanwhile the chemical bond is led in, the bonding capacity of the steel substrate and the coating layer is improved, and quality of the storage tanks is guaranteed.

Owner:无锡新开河储罐有限公司 +1

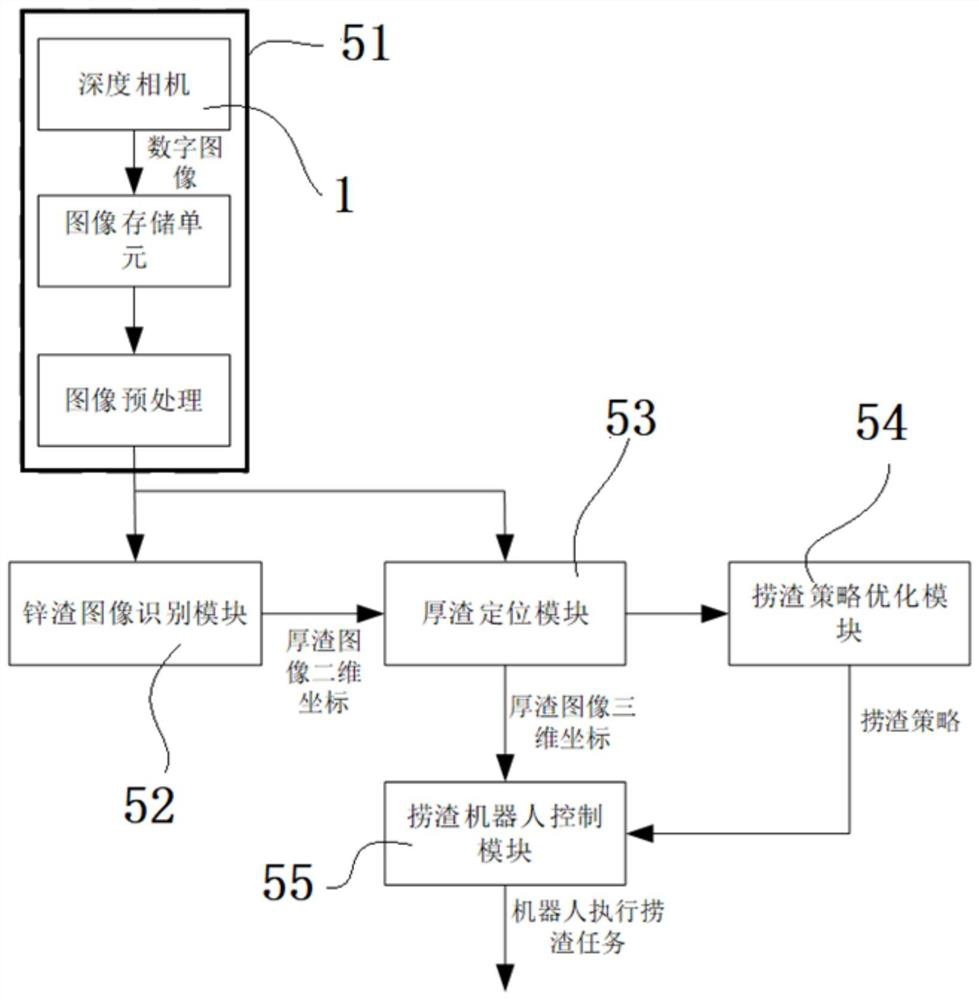

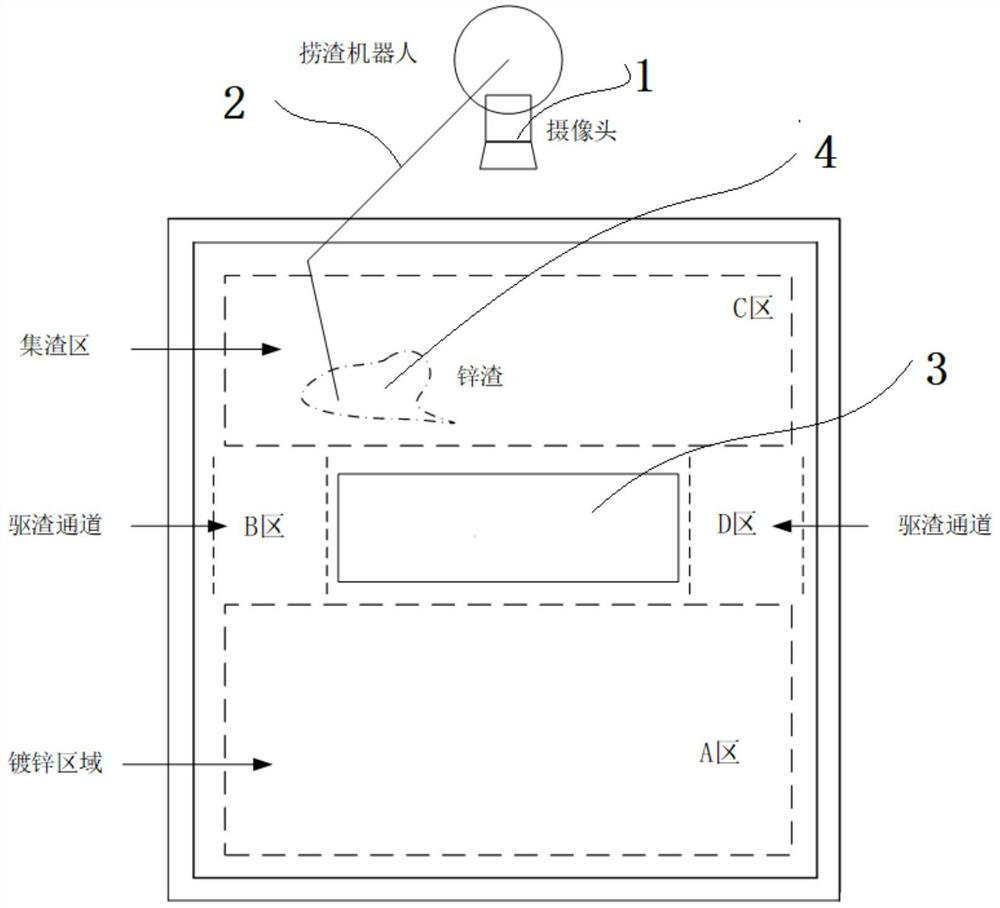

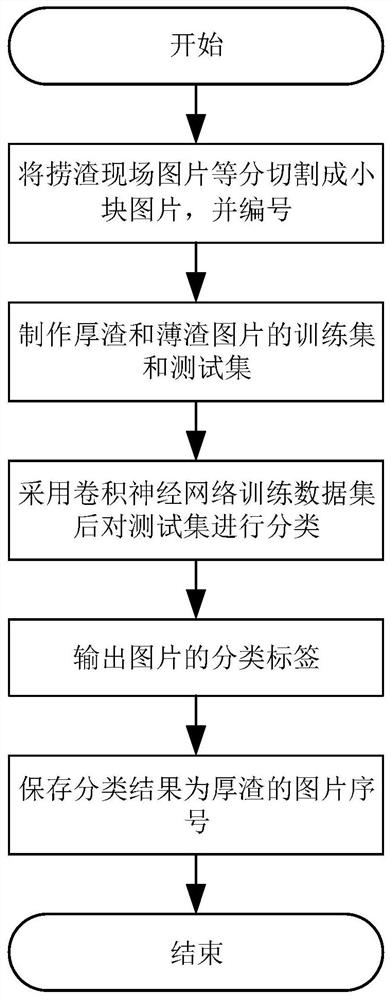

Machine vision-based slag salvaging method and robot system

ActiveCN112011750AIncrease autonomyReduce fishing frequencyHot-dipping/immersion processesProgramme-controlled manipulatorRobotic systemsMachine vision

The invention discloses a machine vision-based slag salvaging method and robot system. A thick slag area influencing the quality of a galvanized plate is identified and positioned through a vision technology, then, a slag salvaging sequence is obtained according to a slag salvaging area priority rule, and finally, a slag salvaging robot is controlled to salvage all thick slag and pour the thick slag into a nearby slag hopper. Compared with a traditional robot slag salvaging system, the machine vision-based slag salvaging scheme is provided, the optimal slag salvaging sequence is optimized anddetermined according to zinc slag distribution characteristics and a slag salvaging strategy, zinc consumption and power consumption caused by unnecessary slag salvaging times are reduced, the autonomy of the slag salvaging robot is remarkably improved, and the operation efficiency is improved.

Owner:WUHAN UNIV OF SCI & TECH

Factory-like cultivation method for agrocybe cylindracea

InactiveCN104255290ACultivation process flowUniform product qualityCultivating equipmentsMushroom cultivationEconomic benefitsEngineering

The invention discloses a factory-like cultivation method for agrocybe cylindracea. The factory-like cultivation method for the agrocybe cylindracea sequentially comprises the following steps of batching, packaging, sterilizing, inoculating, cultivation and agrocybe cylindracea yielding management operation. Mixed compost comprises the following raw materials in percentage by weight: 50-85% of cotton-seed hulls, 10-30% of bran and 10-25% of auxiliary materials. A step of secondary sterilization before putaway is added between the step of cultivation and the step of agrocybe cylindracea yielding management operation. By the factory-like cultivation method for the agrocybe cylindracea, a cultivation process can be processized, a production technology is standard, the quality of products is balanced, production of the agrocybe cylindracea is annual, the labor productivity, the quality qualified ratio of the products and the biological conversion rate are greatly improved, pollution is reduced, the cost is also reduced, and the agrocybe cylindracea cultivation economic benefit is further improved.

Owner:SHUYANG SU HE AGRI PROD SALES PROFESSIONAL COOP ASSOC

Program control smoking and roasting betelnut production line

InactiveCN104664568ASolve the pollution of the environmentSolve labor intensityFruit and vegetables preservationFood treatmentProduction lineHeating oil

The invention discloses a program control smoking and roasting betelnut production line, which comprises a smoking and roasting oven, a smoke generator, a heat conducting oil boiler, a drier, a fruit ripening machine, a bucket elevator and a conveyor, wherein a sensor, a smoking and roasting pipe and a first heating oil pipe are arranged in the smoking and roasting oven, an exhaust fan and a blast blower are arranged in positions, near the smoking and roasting box, on a flue, the smoking and roasting pipe is connected with the smoke generator through the flue, a second heating oil pipe is arranged in the fruit ripening machine, the first heating oil pipe and the second heating oil pipe are connected with the heat conducting oil boiler through an oil path, the sensor connects and controls a special control valve and the exhaust machine, a smoke inlet of the smoke generator is connected with the drier, and smoke exhausted by each exhaust fan is gathered in the drier. The program control smoking and roasting betelnut production line has the advantages and positive effects that the three-waste discharge of the production line conforms to national environment-protection discharge standards, the zero discharge is basically realized, the problems caused by the adoption of manual control on smoke degree, temperature, humidity and the like of the existing production equipment are solved, and the product quality qualification rate and the economic benefits are improved.

Owner:张锡来

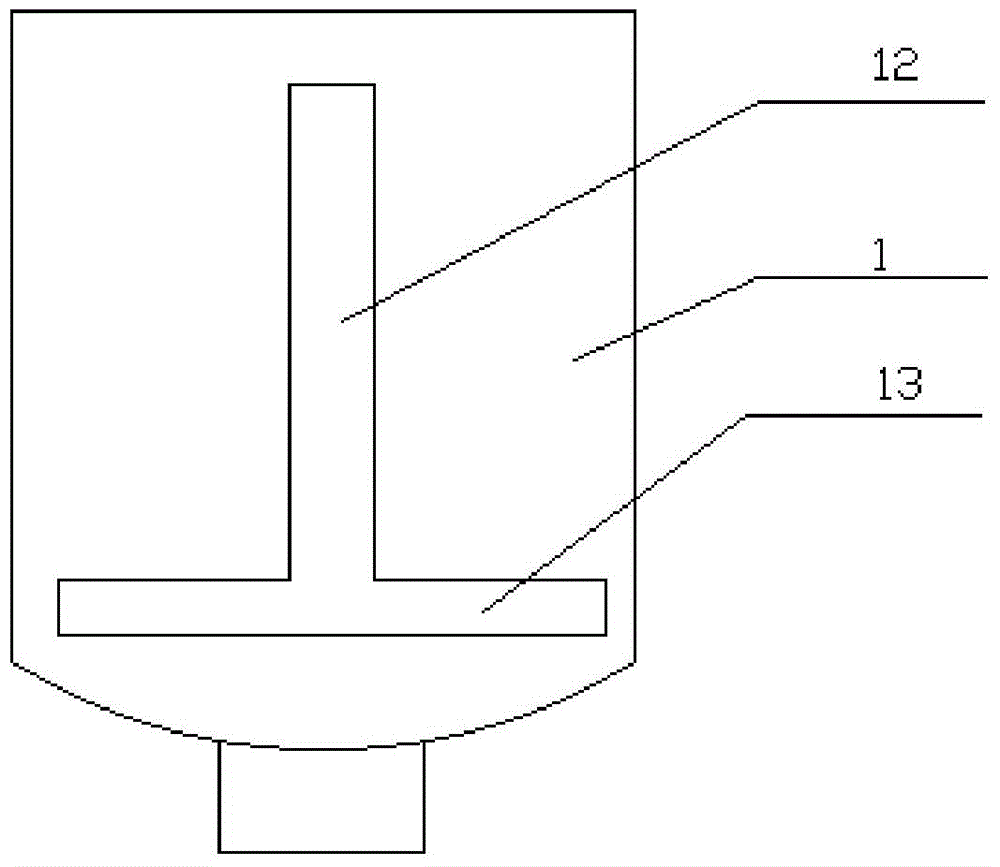

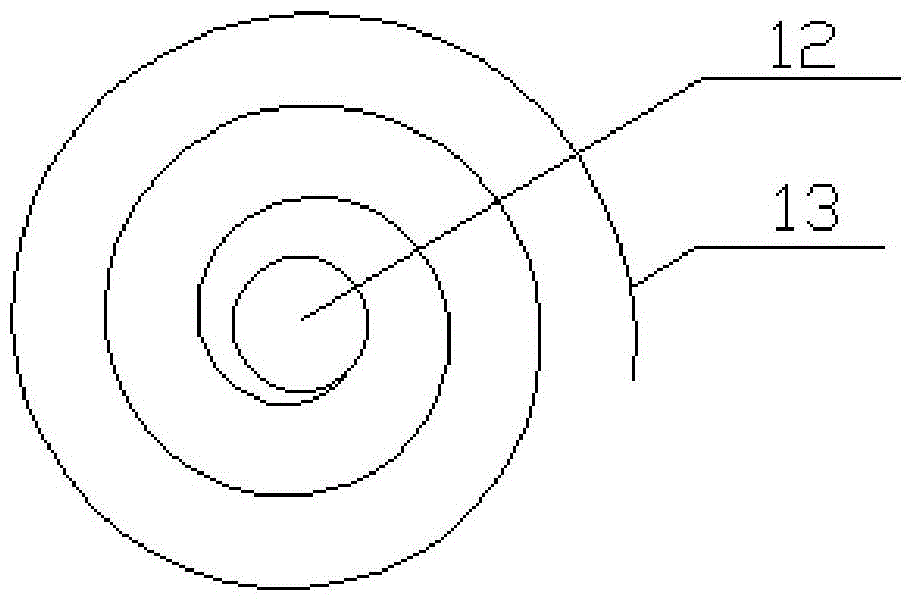

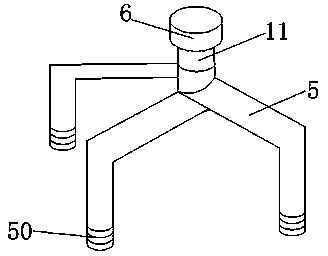

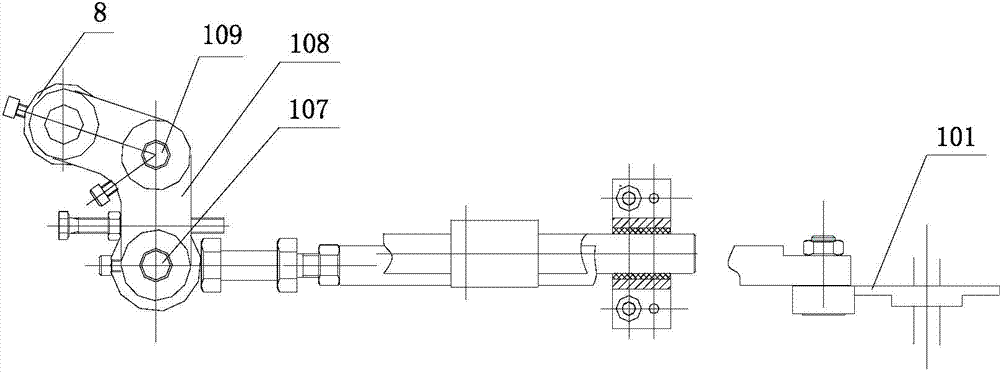

Lifting mechanism used for capsules

InactiveCN104890172AImprove the pass rate of product qualityDomestic articlesCoatingsCamContact Transmission

The invention relates to a lifting mechanism used for capsules. The lifting mechanism used for the capsules is characterized in that a clamp transmitting mechanism comprises a cam, a push rod, connection plates, a slide guiding device, a connection rod, a rotating shaft, an oscillating rod shaft and two oscillating rods, wherein the cam is fixed on a driving spindle and in contact transmission with one end of the push rod, the other end of the push rod is connected with the oscillating rod shaft via the connection rod, two ends of the oscillating rod shaft are connected with the oscillating rods respectively, the two oscillating rods are in contact transmission with a V-shaped base, and the rotating shaft is connected between the two oscillating rods. By the aid of the clamp transmission mechanism and the oscillating rod structures thereof, the V-shaped base can be lifted up timely, a clamp jaw is opened maximally to enable a clamp not to contact with one capsule on a mould pin, when the clamp moves forwards in position, the V-shaped base can fall immediately to close the clamp jaw to clamp the capsule for the convenience of capsule removing, and accordingly, the produced capsules are high in quality yield.

Owner:XINCHANG WUPENG MACHINERY

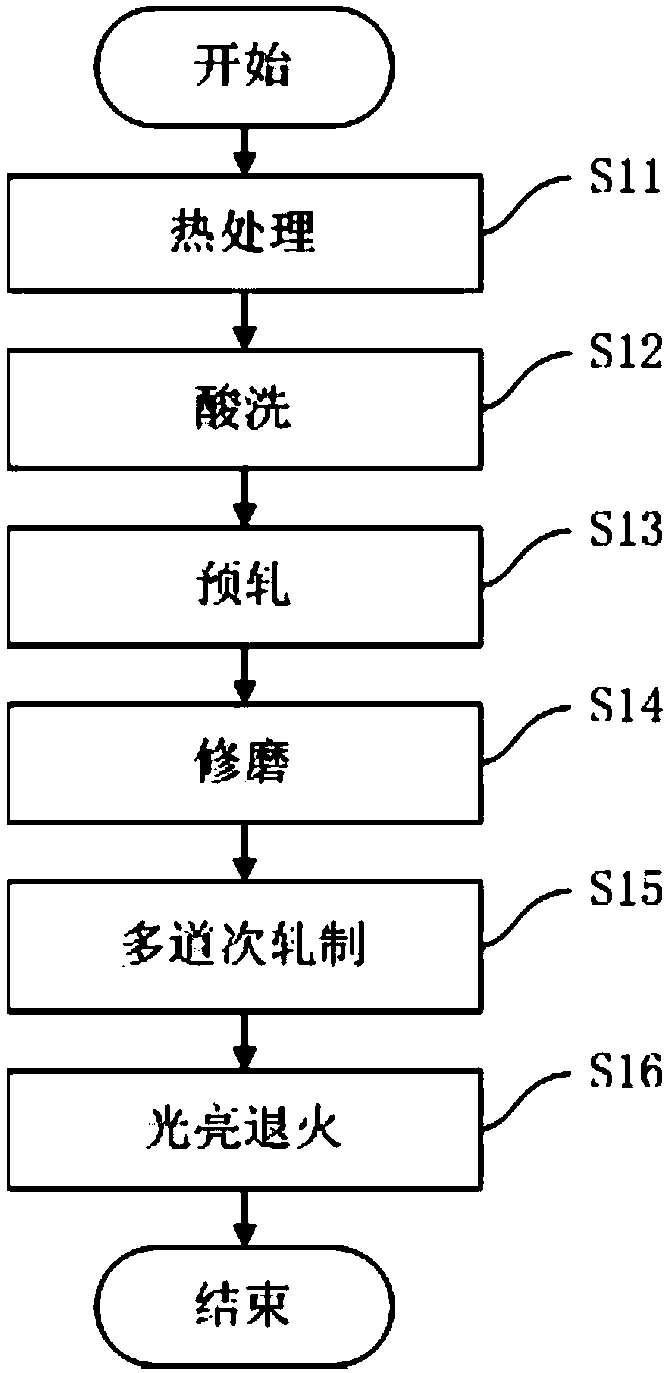

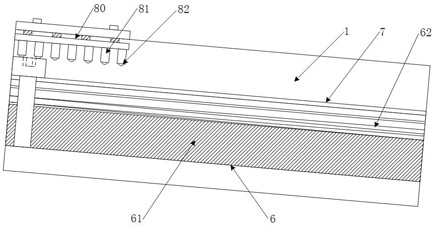

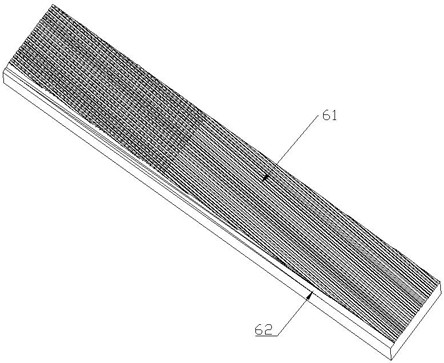

Process used for improving surface grade of 300-series stainless steel BA plate

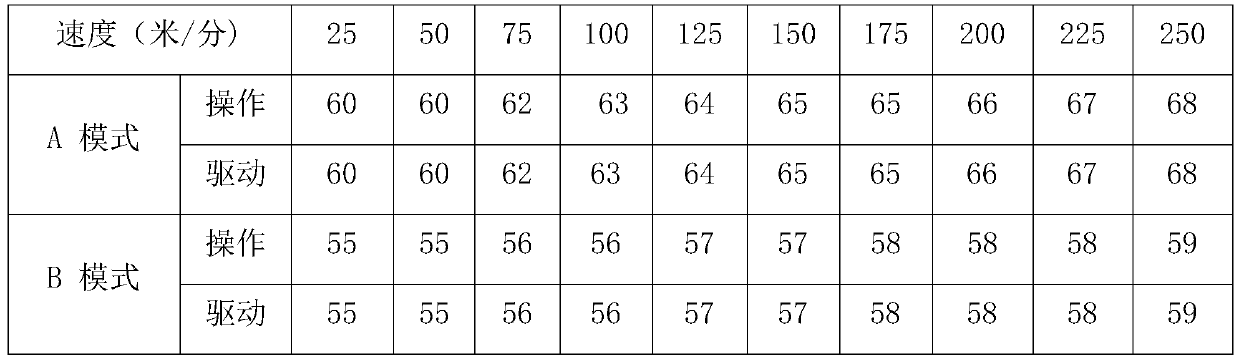

InactiveCN109332418AImprove surface gradeReduce surface defect rateRoll speed control deviceStrip steelHeat treated

The invention discloses a process used for improving the surface grade of a 300-series stainless steel BA plate. The method includes the sequentially-executed steps that eleventhly, on a heat treatment line, low shot blasting, repainting and flattening processing are conducted on strip steel; twelfthly, acid cleaning is conducted on the strip steel; thirteenthly, 20%-30% of pre-rolling is conducted on the strip steel through a rolling mill; fourtheenthly, on a grinding unit, grinding is conducted on the strip steel through multiple different abrasive belts with the gradually-decreasing roughness in sequence; fifteenthly, multi-pass rolling is conducted on the strip steel, and the deformation amount of the last three passes is controlled to be within 18%; and sixteenthly, bright annealing treatment is conducted on the strip steel. According to the method for improving the surface grade of the 300-series stainless steel BA plate, by adopting the processing method of heat treatment, pre-rolling, different-roughness grinding, multi-pass rolling and bright annealing for the strip steel, the surface defect rate of the BA plate in the production process can be decreased, resolution, whitedimness and colorization of the surface of the strip steel are effectively improved, and therefore the surface grade of the BA plate is improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

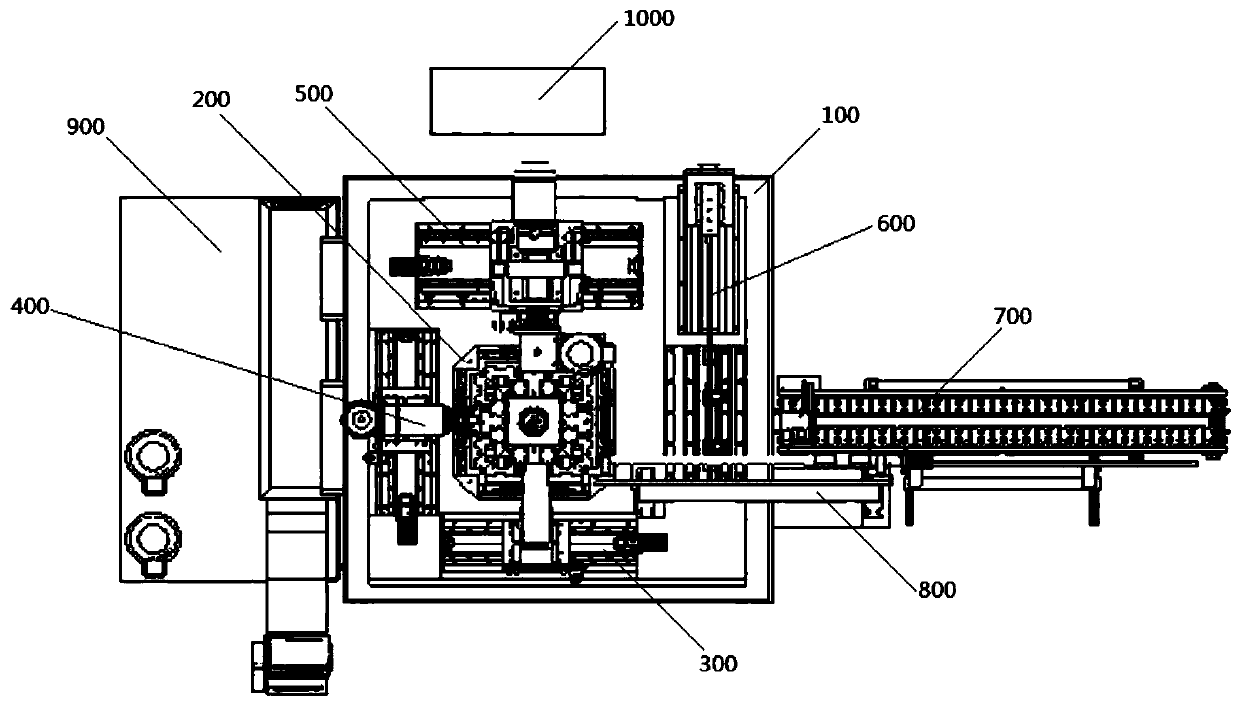

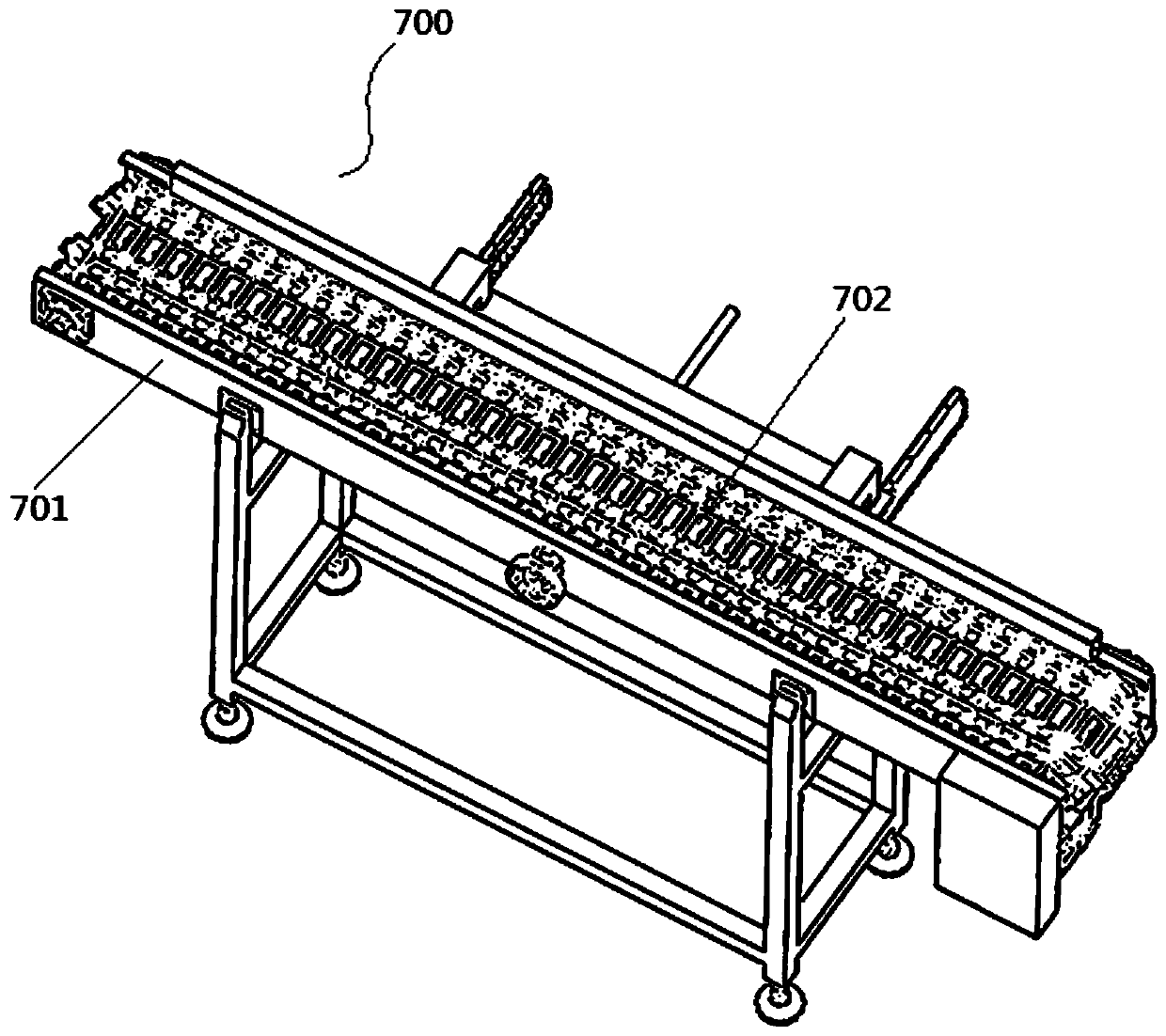

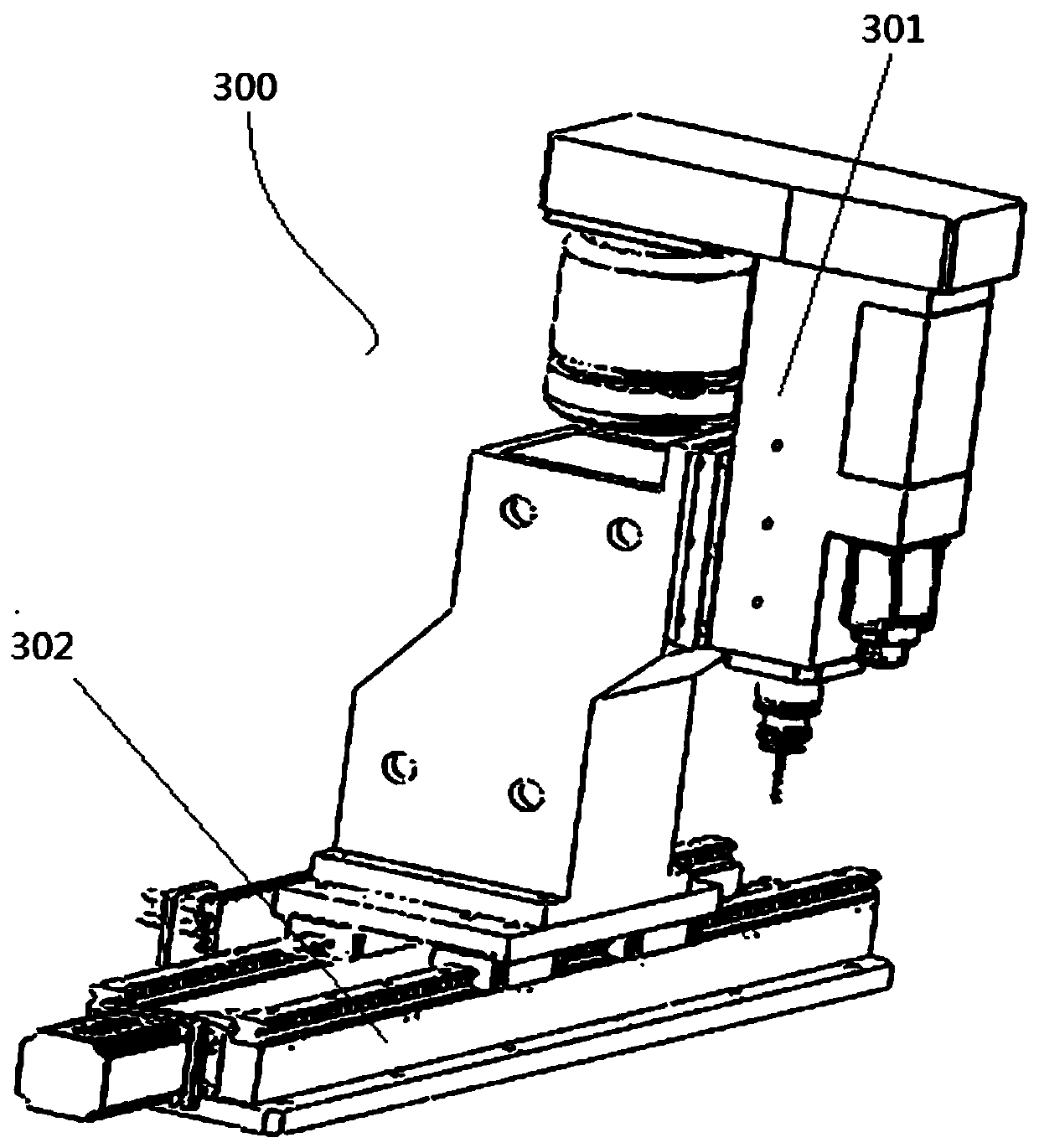

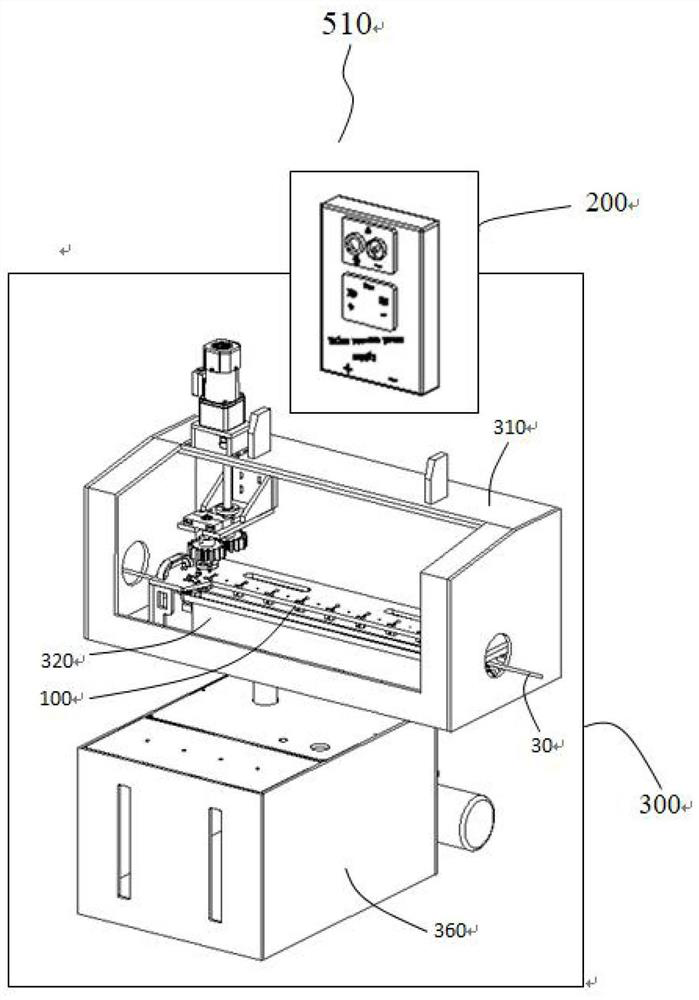

Numerical control servo machining system for gas separation pipes of combustor

PendingCN110653615AEfficient processingImprove processing productivityOther manufacturing equipments/toolsMetal working apparatusNumerical controlCombustor

Owner:SHANGHAI HESEN ELECTRO MACHINERY

Bead stringing machine with manipulators and operating method of bead stringing machine

InactiveCN104223622AAvoid collision damageIntegrity guaranteedJewelleryPulp and paper industryManipulator

The invention discloses a bead stringing machine with manipulators. The bead stringing machine comprises a bracket, a supporting table above the bracket, a fixed disk above the supporting table, a rotating disk in the fixed disk, a supporting column on the right side of the fixed disk, a fixed block at the end part of the supporting column, a telescopic rod below the fixed block, manipulators on the telescopic rod, fixed rod disks at the end parts of the manipulators, a main shaft penetrating through the supporting table and a motor below the main shaft, wherein threads are formed at the end parts of the manipulators; the fixed rod disks comprise fixed rod walls, first through holes formed in the middle parts of the fixed rod walls, second through holes running through the fixed rod walls, buckles positioned in the second through holes and bead stringing rods; one end of each bead stringing rod is positioned in the corresponding second through hole; a threading hole is formed in one end of each bead stringing rod; the other end of each bead stringing rod is of a rhombic structure; wires are arranged between the motor and the manipulators. The bead stringing machine with the manipulators has the advantages of high product quality, high product yield, low labor intensity and high processing quality, and can operate continuously.

Owner:ZHONGSHAN JUCHANG AUTOMATION EQUIP TECH CO LTD

Low-density large-pore ceramic grinding wheel and preparation method thereof

ActiveCN112677059APrevent defects such as cracksCracks and other defects to avoidAbrasion apparatusGrinding devicesCrazingGrinding wheel

The invention relates to a low-density large-pore ceramic grinding wheel. The low-density large-pore ceramic grinding wheel comprises 100 parts of grinding materials, 10-30 parts of ceramic bond, 5-15 parts of pore forming agent, and 2-5 parts of resin binder, wherein the resin binder is a mixture of a resin solution and a diluent, and the ratio of the resin solution to the diluent is 1: 1-1: 4. According to the low-density large-pore ceramic grinding wheel provided by the invention, the modulated resin binder is adopted to replace a temporary binder and a wetting agent in the prior art, so that when the low-density large-pore ceramic grinding wheel is prepared, the strength of a grinding wheel green body is improved, the morphology defect rate generated in the production process is reduced, and the percent of pass of the product quality is increased; and meanwhile, walnut shells subjected to surface treatment reduce the defects of cracks and the like of the ceramic grinding wheel caused by inconsistent and non-uniform volatilization in the drying and sintering process. The pressed grinding wheel green body can be directly cured, the drying time is shortened, and the production efficiency is improved.

Owner:SUZHOU FAR EAST ABRASIVES

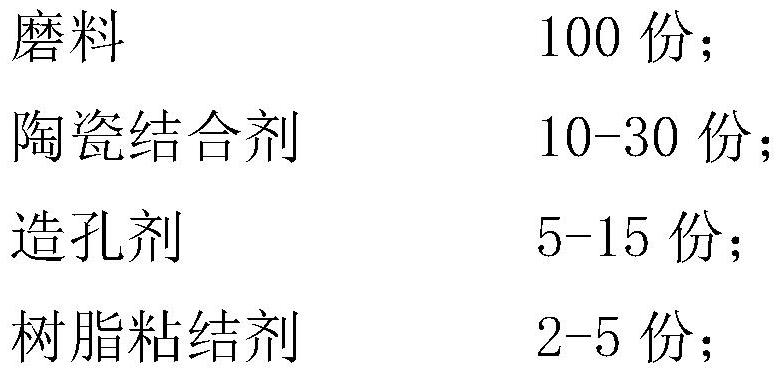

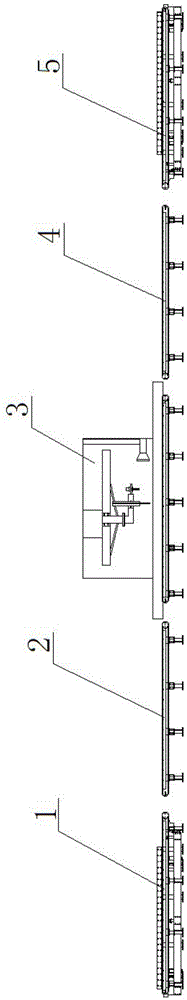

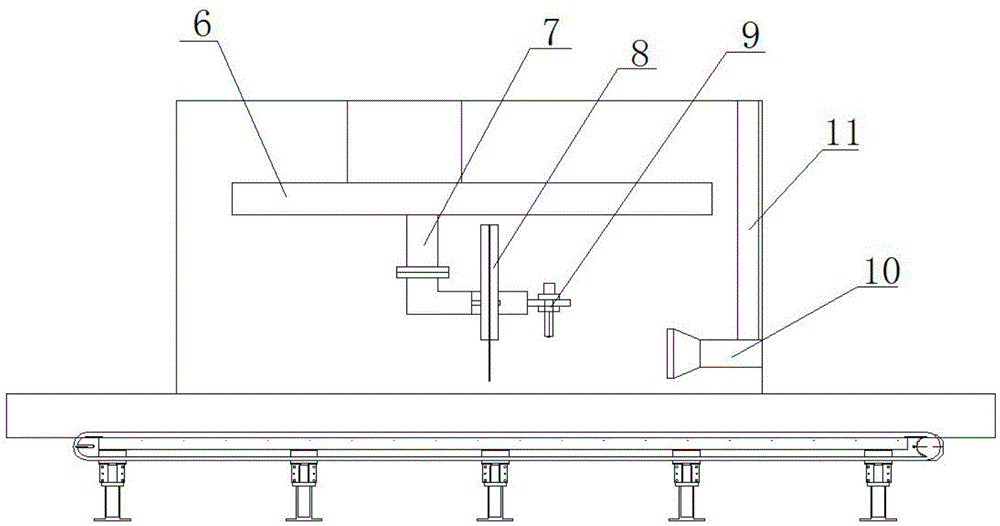

Low temperature production method for high speed corrugated board line, and steam system

PendingCN110281594ARealize energy-saving productionSave energyMechanical working/deformationPipeline systemsFiberEngineering

The invention discloses a low temperature production method for a high speed corrugated board line, and a steam system, and belongs to the field of corrugated board production. The low temperature production method mainly comprises the following steps that (1), making preparations; (2), setting base paper wrapping angles; (3), pressing a single-face corrugated board; (4), forming the single-face corrugated board; (5), regulating the clearance between a spreading roller and a scraping roller of a double-face machine and the clearance between contact rods; (6), setting the temperature of multiple preheaters; (7), regulating the spreading roller speed and spreading clearance of the double-face machine; (8), wrapping corners of a multilayered corrugated board; and (9), forming the multilayered corrugated board. According to the low temperature production method, the high speed production of the corrugated board line is achieved by adopting low temperature primary saturated steam, and meanwhile damage to base paper fibers is reduced; and the physical index of the corrugated board is ensured, and the warpage deformation of the produced corrugated board is avoided. The low temperature production method is mainly used for low temperature, low pressure and high speed production of the corrugated board.

Owner:LINYI XINGHUA PACKAGING

Two-stage treating method for accretion in carbon jacket hearth roll of continuous annealing furnace

ActiveCN102776351BFast online processingImprove work rateFurnace typesHeat treatment process controlHearthControl switch

Owner:ANGANG STEEL CO LTD

Wood-wool cement board processing and trimming equipment

The utility model provides wood-wool cement board processing and trimming equipment which comprises a feeding device, a first conveying device, a processing and trimming device, a second conveying device and a discharging device, wherein the five devices are arranged in sequence; the processing and trimming device comprises an adjusting arm and an operating arm which are connected in sliding manner in the longitudinal direction; a cutting saw blade and a cutting tool bit are arranged at the front end of the operating arm; and the cutting saw blade and the cutting tool head are connected with the operating arm in a sliding manner in the transverse direction. According to the wood-wool cement board processing and trimming equipment, the manpower, material resources and time are saved, the product processing and trimming speed is increased, and the pass percentage of the product quality is increased at the same time.

Owner:WUXI PAN ASIA ENVIRONMENTAL PROTECTION TECH LTD

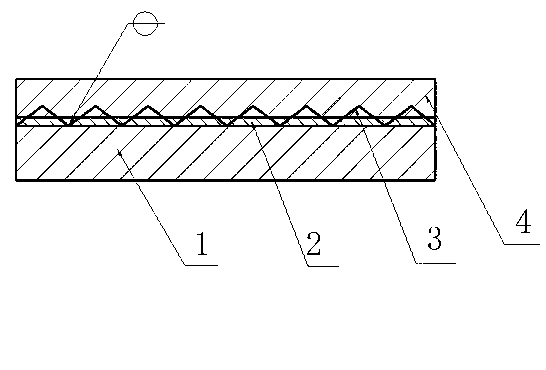

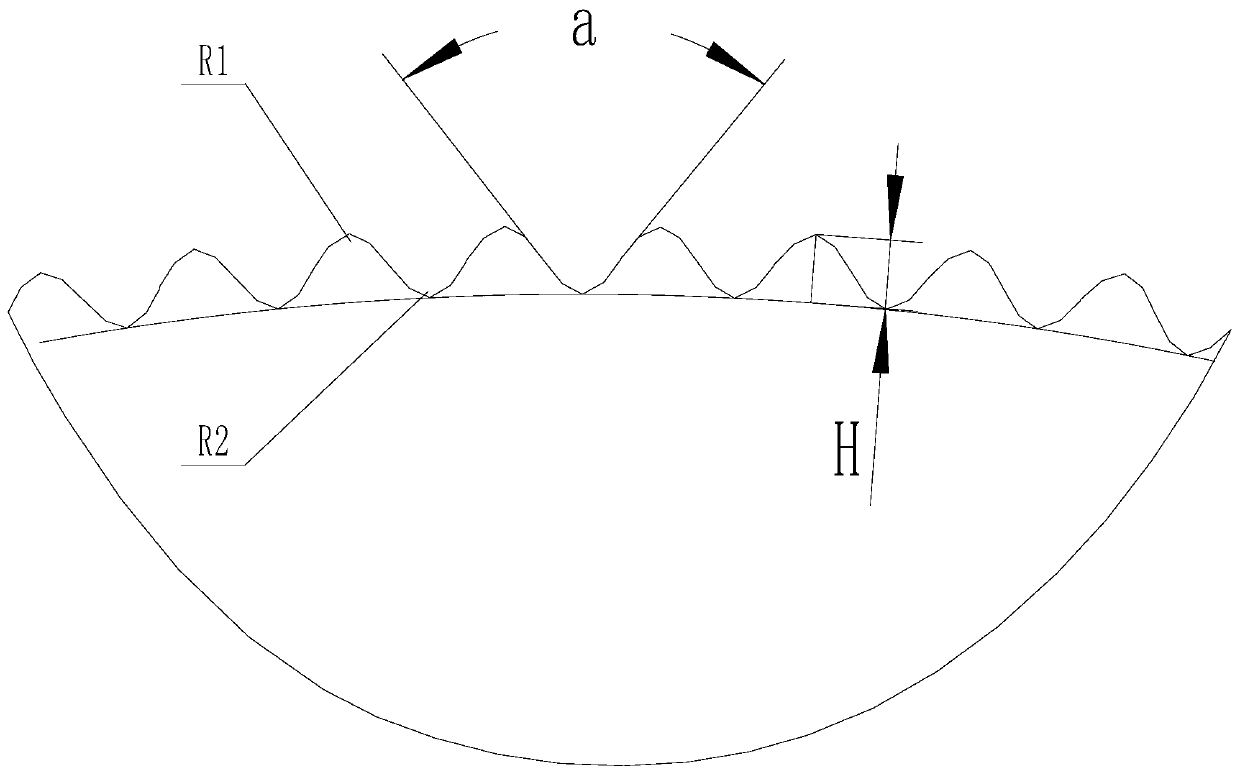

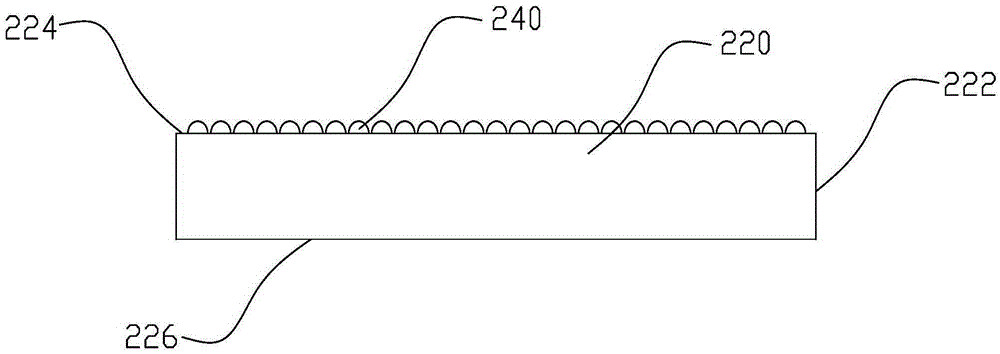

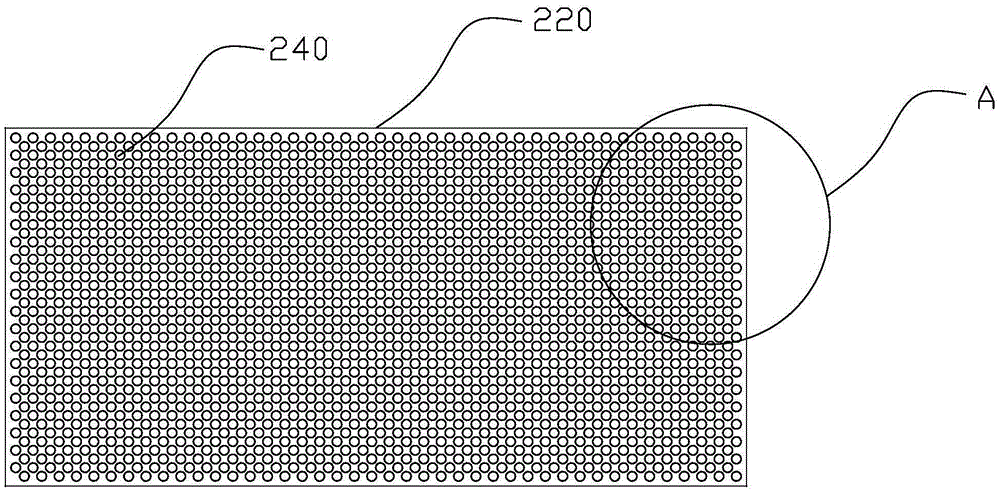

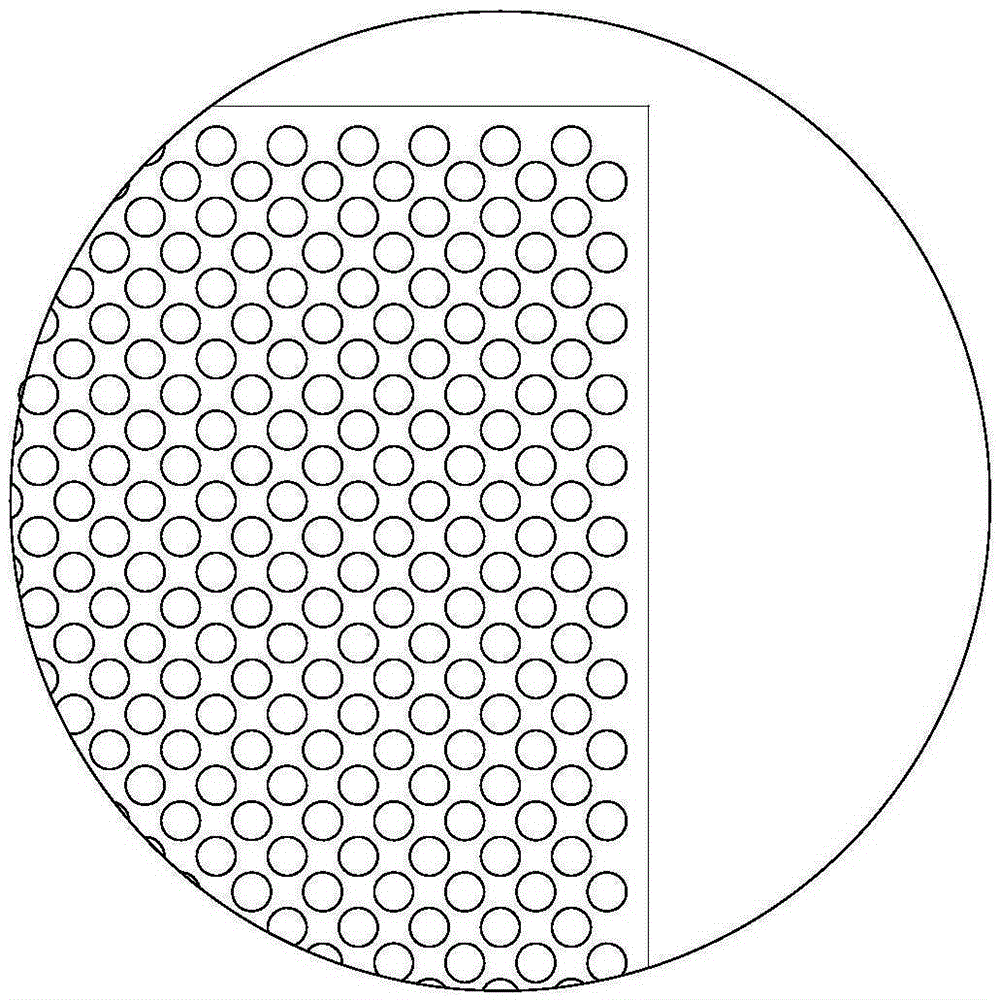

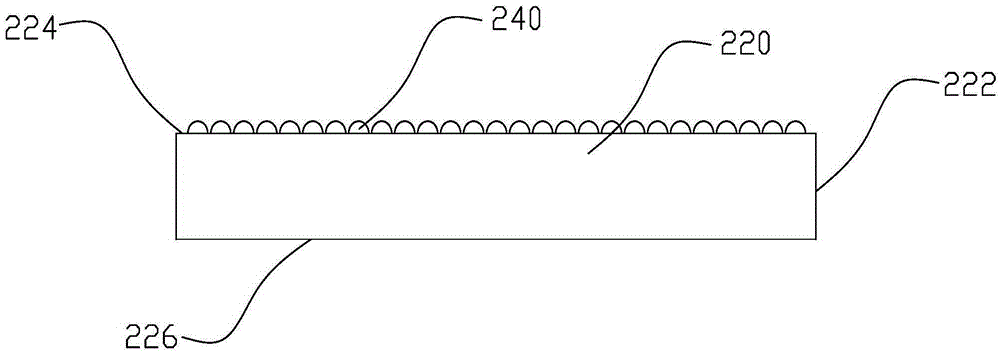

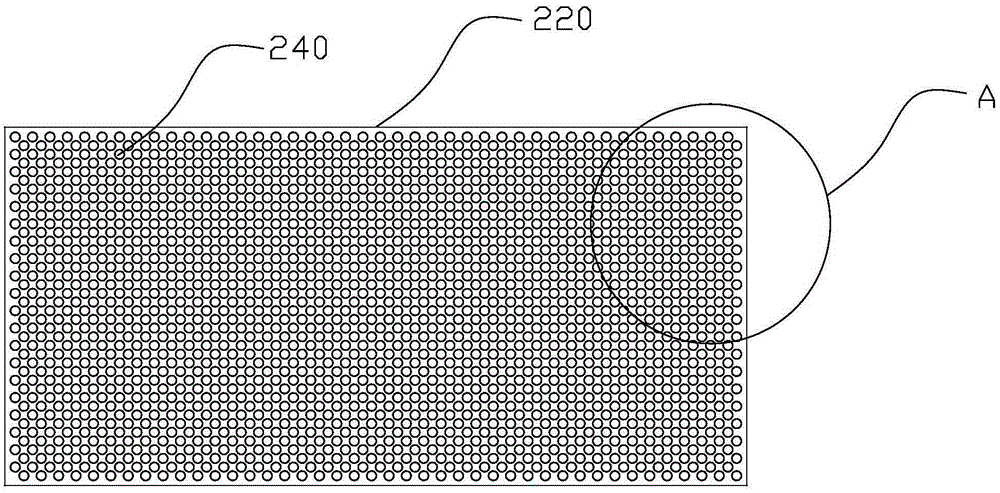

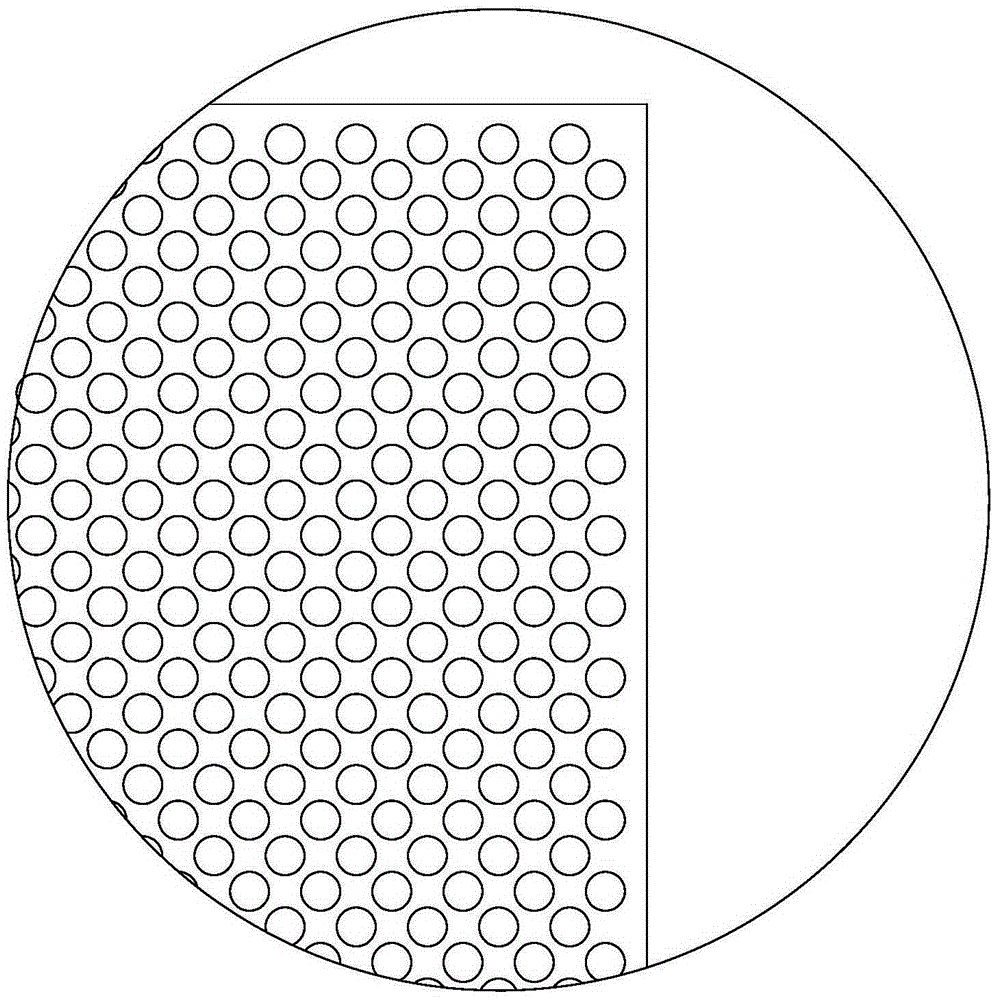

Light guide plate of PS material and with projection structures

InactiveCN105353442ASimple processing technologyHigh refractive indexOptical light guidesNon-linear opticsLight guideLight beam

The invention provides a light guide plate of a PS material and with projection structures. The light guide plate comprises a light guide plate body; the light guide plate body includes a light input surface, a light output surface and a bottom surface, wherein a light beam is guided into the light guide plate body via the light input surface, the light input surface is placed in the lateral portion of the light guide plate body, the light beam is guided out of the light guide plate body via the light output surface, and the bottom surface of a planar structure is opposite to the light output surface; multiple spherical projections which are molded with the light guide plate body in an integrated manner are arranged at the light output surface in an array, the spherical projections in the array are arranged in rows and columns in a staggered manner, and the spherical projections are made of the PS material; and the diameter of each spherical projection ranges from 240-265 micron, the height of the spherical projection ranges from 175 to 200 micron, and the spacing between the adjacent spherical projections in each row / column ranges from 295 to 330 micron.

Owner:CHONGQING LINGCHUANGFU PHOTOELECTRIC TECH

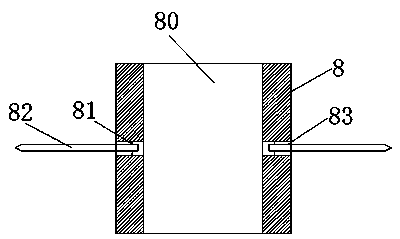

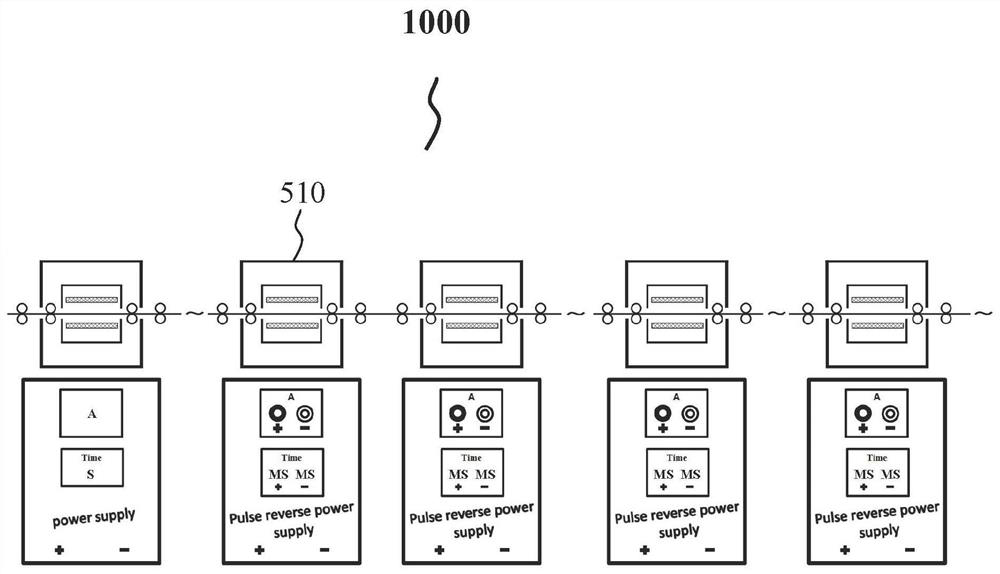

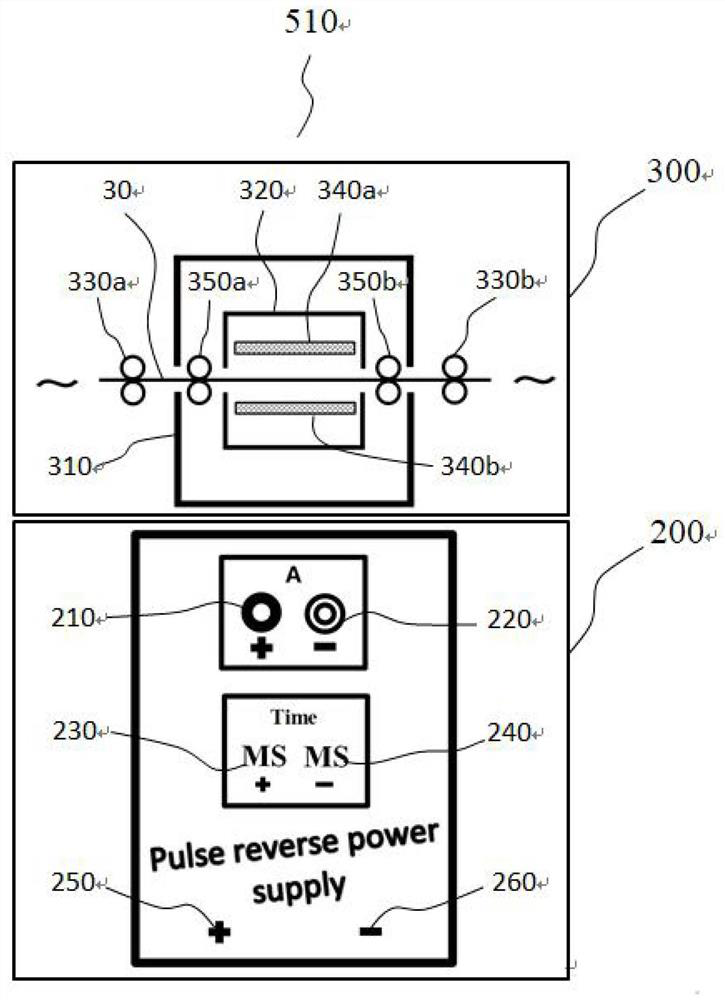

Electrolysis method of continuous terminal

ActiveCN112323111AImprove the pass rate of product qualitySolve the problem that the local part of one side of the strip cannot be processed effectivelyElectrolysisConveyor belt

The invention relates to the technical field of electrolytic surface treatment, in particular to an electrolysis method of a continuous terminal. Through fully shielding one surface of a material beltthrough a first conveyor belt, and partially shielding the other surface of the material belt through a second conveyor belt, the part, extending out of the outer periphery of the second conveyor belt, of the material belt can be processed, so that the purpose of local processing is realized, and the problem that the existing equipment cannot effectively process the local part of the single surface of the material belt is solved; and the pulse periodic reverse current is applied to the local surface of a continuous terminal material for electrolysis, so that electrolytic precious metal on thesurface of the continuous terminal material is adjusted and controlled to have required uniform precious metal film thickness distribution and excellent corrosion resistance.

Owner:KUNSHAN YIDING IND TECH CO LTD

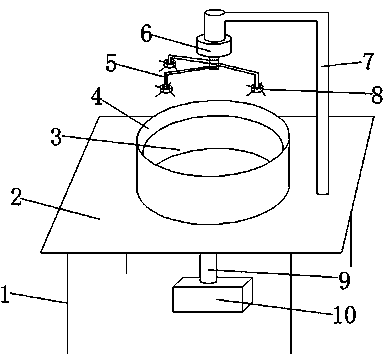

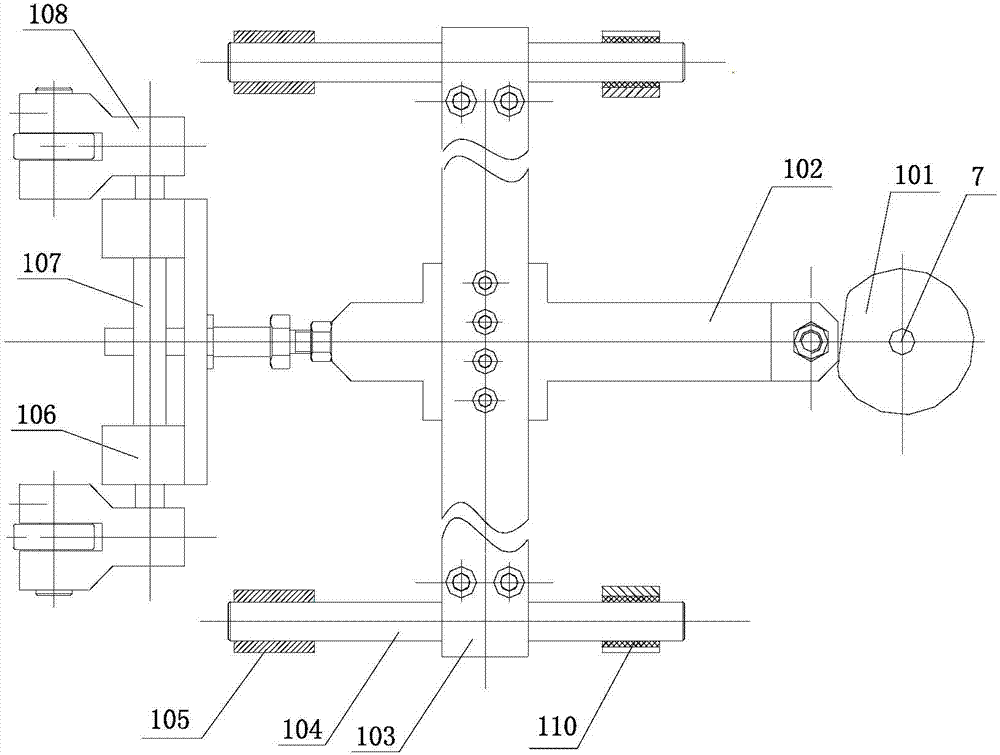

V-type device lifting mechanism in capsule production system

InactiveCN103705384BUnanimous actionHigh decapsulation efficiencyCapsule deliveryProduction lineProduction rate

The invention discloses a V-type device lifting mechanism in a capsule production system, and belongs to the technical field of capsule manufacturing production lines. The V-type device lifting mechanism in the capsule production system is connected to an automatic machine of the capsule preparing system and comprises a driving main shaft connected with the automatic machine, a clamp transmission mechanism, a V-type device base, a plurality of V-type devices and a plurality of clamps, wherein the V-type devices are arranged side by side to form an integrated structure, the clamps are arranged on the V-type devices respectively, the integrated V-type devices are fixed to the V-type device base, a guide shaft is connected to the V-type device base and connected to a rack of the automatic machine through a linear bearing, one end of the clamp transmission mechanism is connected with driving main shaft, the other end of the clamp transmission mechanism is a working end and makes contact with the V-type device base, and the V-type device base is pushed to move back and forth. The V-type device lifting mechanism in the capsule production system is simple in structure, easy to transform, high in operability and low in cost, and the productivity of the V-type device lifting mechanism can be improved substantially.

Owner:DANDONG JINWAN GRP

Bolt thread rolling forming device

PendingCN114700450AAccurate and reliableAccurate and reliable relative position accuracyScrew-threads articlesScrew threadMoulding device

The invention discloses a bolt thread rolling forming device which comprises a fixed die holder and a thread rolling movable die holder, a first thread rolling module is arranged on the thread rolling movable die holder, a second thread rolling module and a bolt head positioning mechanism are arranged on the fixed die holder, and machining die surfaces matched with each other are arranged on the first thread rolling module and the second thread rolling module respectively. The machining die face is provided with a thread forming die part and at least one annular concave extrusion forming die part. According to the invention, synchronous forming of the thread and the ring recess can be realized, the relative position precision of the thread and the ring recess is accurate and reliable, secondary forming of the ring recess is not needed, the production cost is reduced, and the product forming precision is improved. The bolt head positioning mechanism is arranged, so that the relative position precision of the bottom wall of the bolt head, the thread and the annular concave part is guaranteed, the carrying quality of the rear-end locking sleeve is controllable and stable, meanwhile, the rear-end assembling precision of the bolt assembly is guaranteed, and the qualified rate of the product quality is remarkably improved. And the machining die surface is skillful in design, and the gradual transition design enables the twisting stress to be more uniform.

Owner:斯塔比奥紧固件(昆山)有限公司

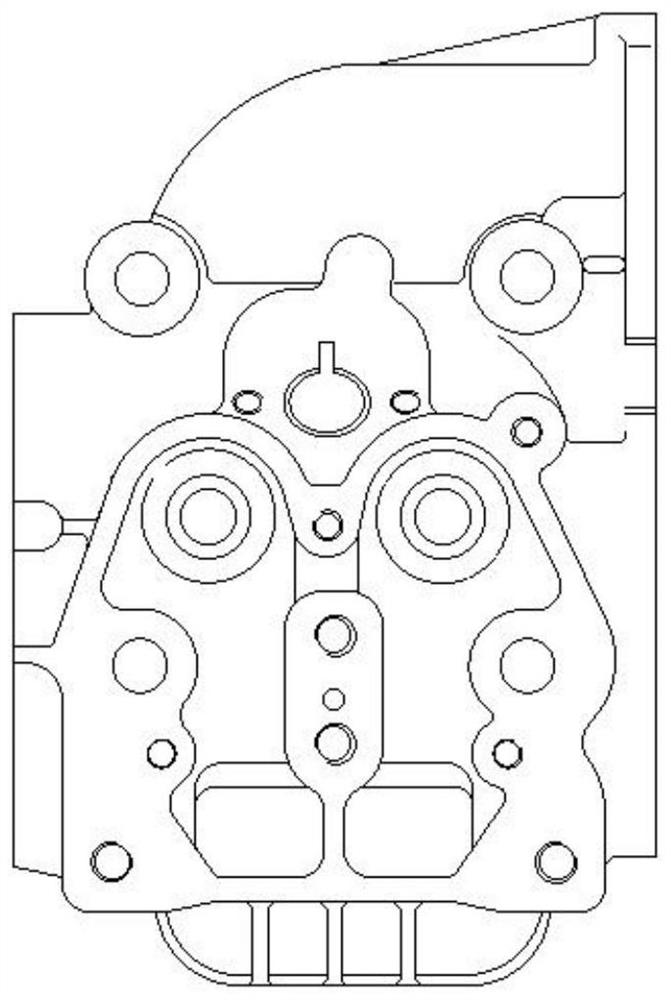

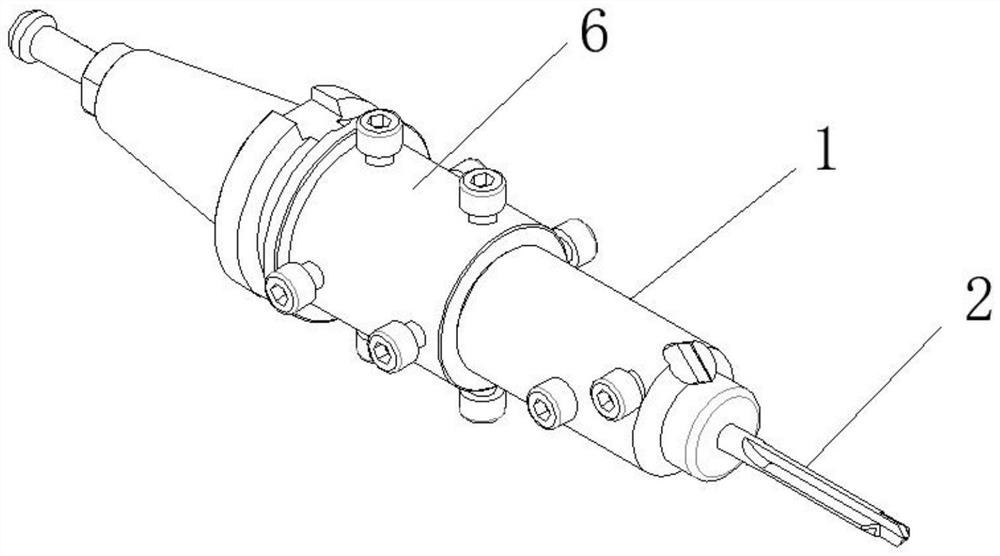

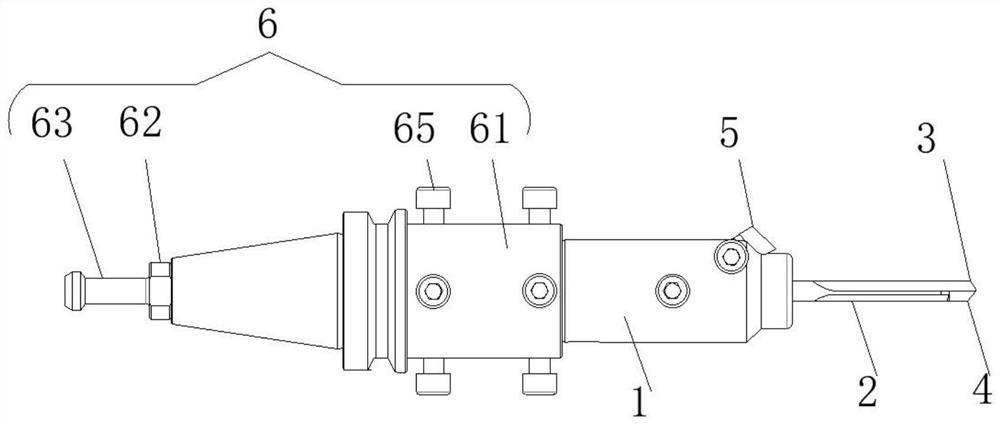

Composite cutter for machining guide pipe hole and seat ring chamfer of aluminum cylinder cover

PendingCN114871459AImprove roundnessHigh coaxial precisionInternal combustion piston enginesTurning toolsStructural engineeringMechanical engineering

A composite cutter for machining a guide pipe hole and a seat ring chamfer of an aluminum cylinder cover comprises a main cutter rod, a fine boring and fine reaming composite cutter is arranged at one end of the main cutter rod, and a fine boring blade and a fine reaming blade are arranged on the two sides of the end, away from the main cutter rod, of the fine boring and fine reaming composite cutter respectively. The transverse distance between a tool nose of the fine boring tool edge and the main tool bar is larger than that between a tool nose of the fine reaming tool edge and the main tool bar, the fine boring tool edge is made to feed before the fine reaming tool edge, and a seat ring chamfering tool is installed on the outer surface of the end, facing the fine boring and fine reaming composite tool, of the main tool bar. A fine boring blade of the fine boring and fine reaming compound cutter is fed in the front, a fine reaming blade of the fine boring and fine reaming compound cutter is fed in the rear, boring and reaming are combined, the roundness of a hole is improved, after a boring and reaming guide pipe hole cutter point goes out of the hole, a seat ring chamfering cutter chamfers a cylinder cover seat ring orifice by 0.8 * 45 degrees, one-time machining forming is achieved, secondary clamping is reduced, repeated positioning and accumulative errors are reduced, and the machining efficiency is improved. And the coaxial precision of the guide pipe hole and the seat ring chamfer is improved.

Owner:ANHUI HIGH TECH POWER TECH

Process for charging and packing industrial powder explosive cartridge and vibratory charging machine

InactiveCN101592462BImprove intrinsic safetyImprove the pass rate of product qualityAmmunition storageExplosive AgentsProcess engineering

Owner:蒙宝林

Printing-free light guide plate structure

InactiveCN105353444ASimple processing technologyHigh refractive indexOptical light guidesLight guideLight beam

The invention provides a printing-free light guide plate structure. The structure comprises a light guide plate body; the light guide plate body includes a light input surface, a light output surface and a bottom surface, wherein a light beam is guided into the light guide plate body via the light input surface, the light input surface is placed in the lateral portion of the light guide plate body, the light beam is guided out of the light guide plate body via the light output surface, and the bottom surface of a planar structure is opposite to the light output surface; multiple spherical projections which are molded with the light guide plate body in an integrated manner are arranged at the light output surface in an array, the spherical projections in the array are arranged in rows and columns in a staggered manner, and the spherical projections are made of a PMMA material; and the diameter of each spherical projection ranges from 180 to200 micron, the height of the spherical projection ranges from 135 to 150 micron, and the spacing between the adjacent spherical projections in each row / column ranges from 225 to 250 micron.

Owner:CHONGQING LINGCHUANGFU PHOTOELECTRIC TECH

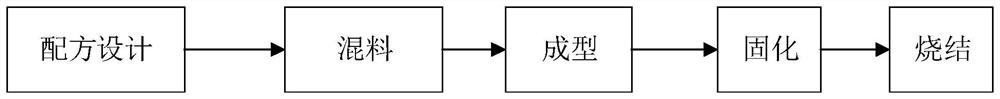

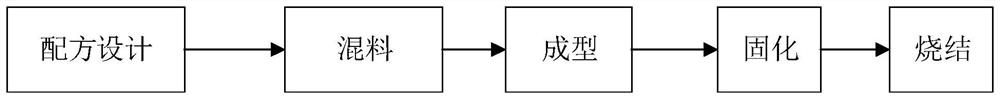

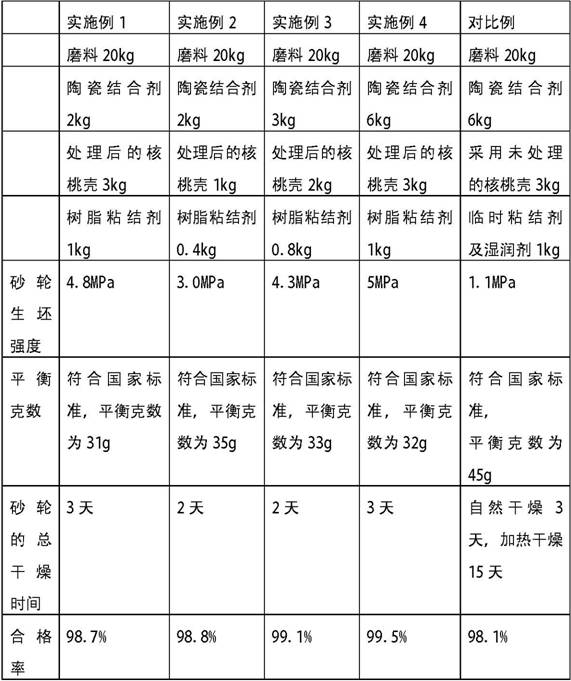

A kind of preparation method of low-density macroporous ceramic grinding wheel

ActiveCN112677059BPrevent defects such as cracksCracks and other defects to avoidAbrasion apparatusGrinding devicesPorosityCrazing

The invention relates to a low-density macroporous ceramic grinding wheel, comprising 100 parts of abrasive material; 10-30 parts of vitrified bond; 5-15 parts of pore-forming agent; 2-5 parts of resin binder; wherein the resin binder is resin liquid Mixture with diluent, the ratio of resin liquid to diluent is 1:1 to 1:4. The low-density macroporous ceramic grinding wheel provided by the present invention adopts the modulated resin binder to replace the temporary binder and wetting agent in the prior art. When preparing the low-density macroporous grinding wheel, the strength of the green body of the grinding wheel is improved and the The appearance defect rate produced in the production process is improved, and the qualified rate of product quality is improved; meanwhile, the surface-treated walnut shell reduces defects such as cracks on the ceramic grinding wheel caused by inconsistency and inhomogeneity in volatilization during the drying and sintering process; The grinding wheel blank can be solidified directly, which shortens the drying time and improves the production efficiency.

Owner:SUZHOU FAR EAST ABRASIVES

Process for charging and packing pasty emulsified explosive cartridge and charging machine

InactiveCN101592461BImprove intrinsic safetyImprove the pass rate of product qualityAmmunition storageExplosive AgentsProcess engineering

The invention relates to the technical field of explosives, in particular to a process for charging and packing a pasty emulsified explosive cartridge and a charging machine. The process for charging and packing the pasty emulsified explosive cartridge is characterized by comprising a cartridge finishing and fixed connecting process, a cartridge charging process and a cartridge sealing process. The charging machine is characterized by comprising a stander; the stander is provided with a frame conveying mechanism, a charging station and a sealing station; the charging station is provided with a charging mechanism; and the sealing station is provided with a sealing mechanism. The process has the advantages of short flow, high safety performance, high working efficiency, good charging quality, and the like; and the charging machine has the advantages of high essential safety level, high product quality qualification rate, high automation degree, large capacity, high efficiency, compact and reasonable structure, little occupied area, low energy consumption, low cost, few operation personnel at a dangerous area, and the like.

Owner:蒙宝林

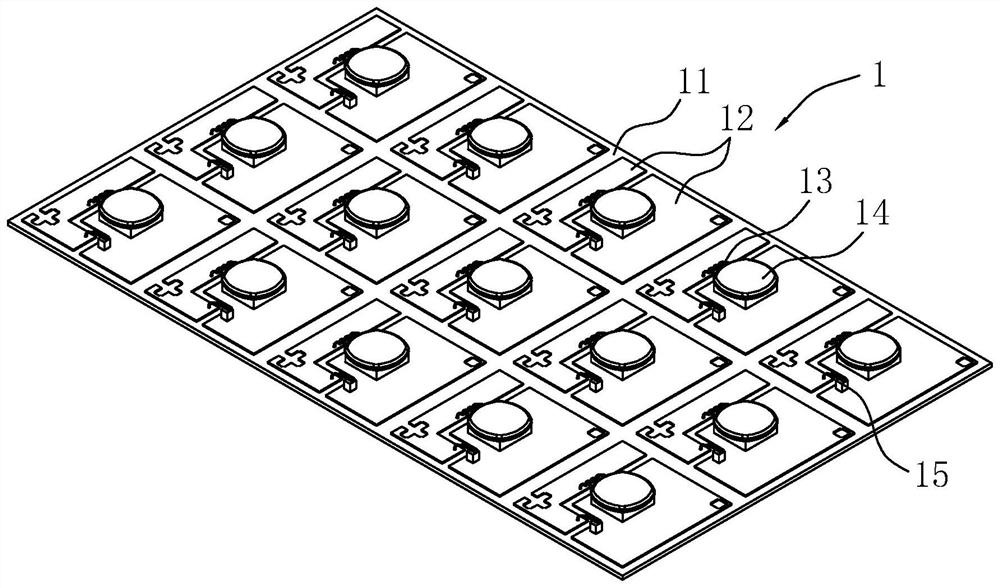

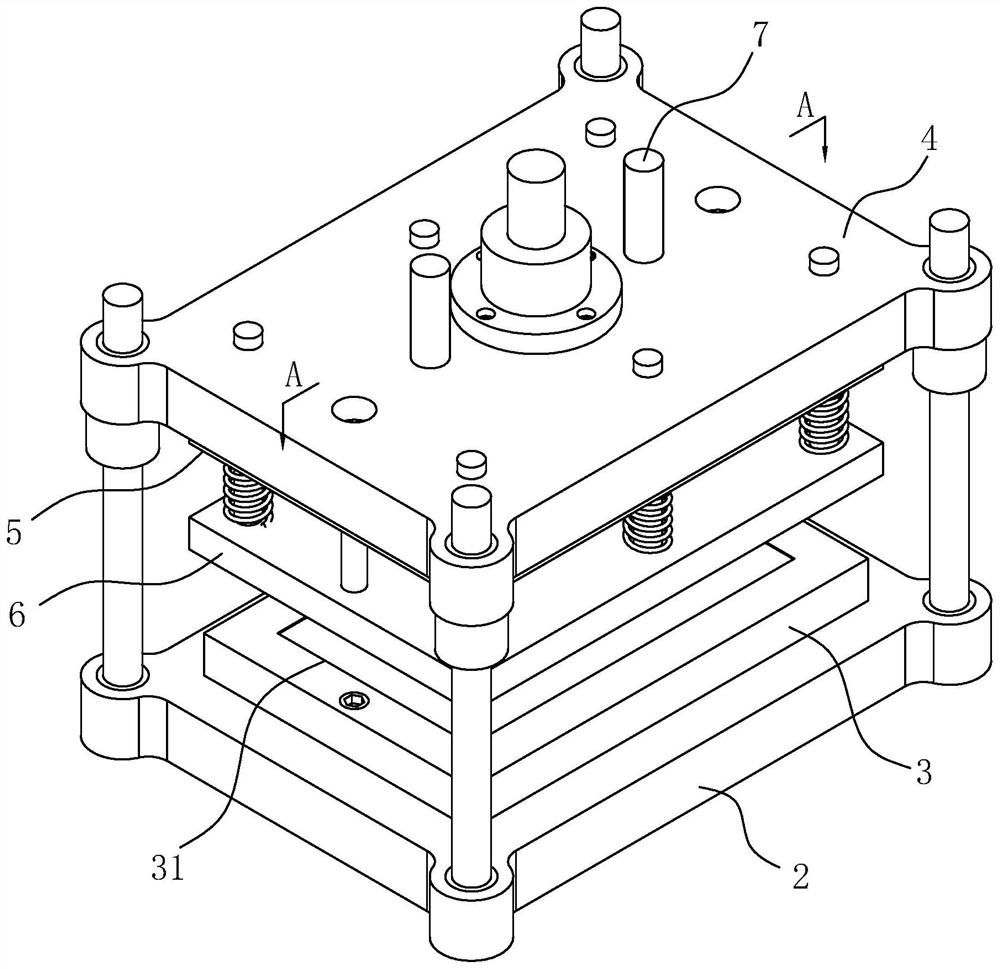

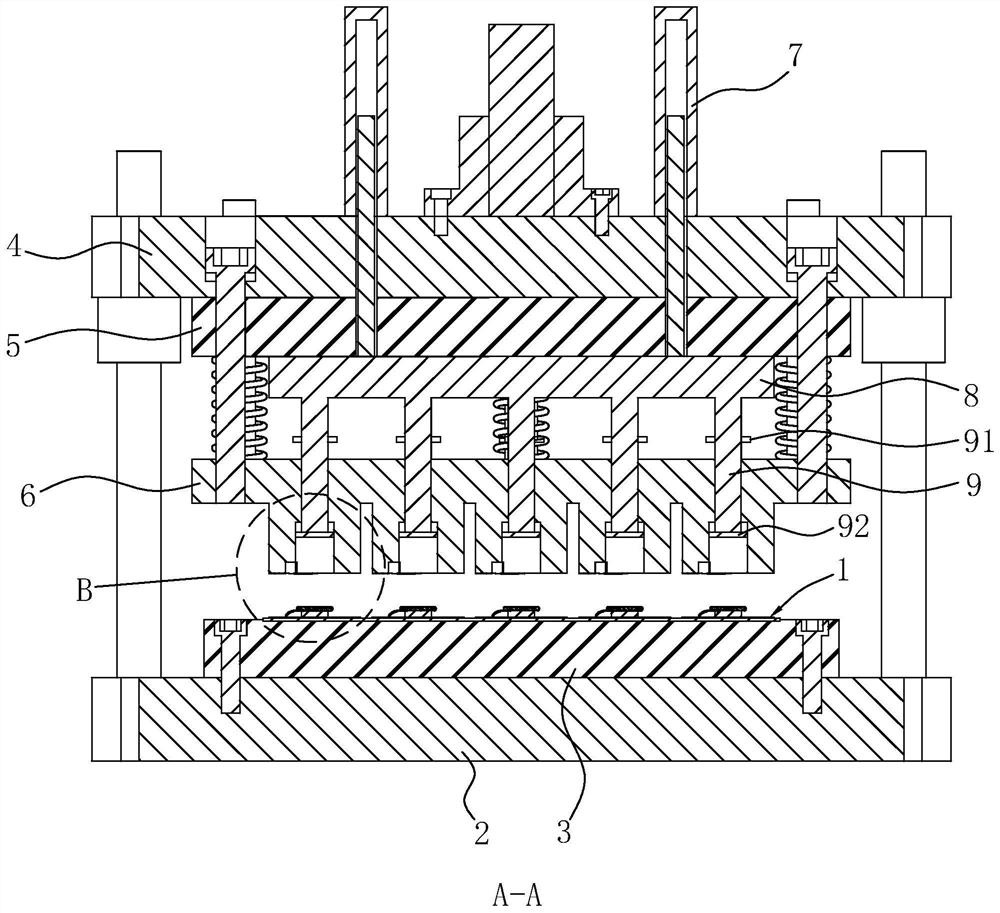

Mould pressing device for fluorescent glue for illumination and illumination production process

PendingCN114141662AQuality improvementImprove the pass rate of product qualitySemiconductor/solid-state device manufacturingSemiconductor devicesFluorescenceEngineering

The invention relates to a fluorescent glue mold pressing device for illumination and an illumination production process, and relates to the technical field of illumination production, the mold pressing device comprises an upper mold base and a lower mold base, and the fluorescent glue mold pressing device further comprises a lower mold plate fixed to the lower mold base and provided with a positioning groove used for installing a bottom plate; the upper mold plate is installed on the upper mold base, one face, away from the upper mold base, of the upper mold plate is provided with at least one mold cavity matched with the outline of the fluorescent glue layer, the face, away from the upper mold base, of the upper mold plate is further provided with a pin receding groove, and the pin receding groove is communicated with the mold cavity; the pressing column is located in the die cavity and can slide along the axis relative to the upper die plate; the power piece is connected between the pressing column and the upper die base and used for driving the pressing column to move relative to the upper die plate. According to the production process, hemispherical fluorescent glue is flattened into a fluorescent glue layer by applying the fluorescent glue mould pressing device for illumination. The method has the advantage that the chip pins are protected from being crushed during fluorescent glue mold pressing.

Owner:深圳市中美欧光电科技有限公司

Correction equipment for liquid collecting pipe of air conditioning condenser

ActiveCN102658310BFast windingReduce operating intensityMetal-working feeding devicesPositioning devicesFailure rateEngineering

The invention discloses correction equipment for a liquid collecting pipe of an air conditioning condenser, which is used for winding and installing an air conditioning condenser part, namely the liquid collecting pipe. The equipment comprises a bottom frame and a liquid collecting pipe winding die arranged on the bottom frame, wherein a winding hole which is the same as a liquid collecting pipe coiling hole in an air conditioning condenser part, namely a condenser side plate is formed in the liquid collecting pipe winding die. By the correction equipment for the liquid collecting pipe of the air conditioning condenser, the liquid collecting pipe winding die is designed to replace the condenser according to drawings of the condenser side plate and a small bend, the site can be independently arranged during operation, operation is not required to be performed on a lower line of the condenser, and the operating environment is improved; by using the liquid collecting pipe winding die, operation is simply performed, a liquid collecting pipe component can be quickly wound, the operating intensity of workers is reduced, and action waste is reduced, so that production efficiency is improved; and meanwhile, the quality hidden danger in the operation process is eliminated, the quality yield of a product is improved, and the after-sales failure rate is reduced.

Owner:GREE ELECTRIC APPLIANCES INC +1

High-performance ceramic surface metallization process

The invention relates to a high-performance ceramic surface metallization processing technique comprising ultrasonic cleaning, calcining, infrared heating, automatic coating and printing, metalized agglutination, and galvanization and nickel agglutination. The invention is a technique that carries infrared pre-heating treatment on the ceramic surface to be metalized, automatically coats and prints the metal ointment to form an evenly dense flat metallization layer. The invention belongs to one of the techniques for improving the surface function of the high-performance compound ceramics. The metal ceramics which is produced with the technique can be welded with metal to form the high-performance compound ceramic ware which is featured by firm connection, good airproof and reliable quality and is widely applied in the fields of vacuum electronic devices, spaceflight, aviation, broadcast TV, communication, metallurgy, medicine, high energy physics, etc. The technique is easily operated and controlled, and the product has high good yield, thereby greatly reducing the loss cost of the noble metal and significantly improving the production efficiency.

Owner:湖南湘瓷科艺有限公司

HDPE (high-density polyethylene) hollow wall winding drainage pipe with inner fins

PendingCN107166108ASimple structureIncrease productivityRigid pipesLow-density polyethyleneEngineering

The invention relates to an HDPE (high-density polyethylene) hollow wall winding drainage pipe with inner fins. The HDPE hollow wall winding drainage pipe comprises a draining pipe body and a reinforcing outer wall, wherein the reinforcing outer wall covers the outer surface of the draining pipe body, the reinforcing outer wall is provided with two reinforcing inner fins which are vertically arranged and are perpendicular to the reinforcing outer wall, the bottoms of the reinforcing inner fins are fused with the surface of the reinforcing outer wall, two arc-shaped reinforcing ribs are inwards arranged on the two reinforcing inner fins, the bottoms of the arc-shaped reinforcing ribs are also fused with the surface of the reinforcing outer wall, a transverse reinforcing rib is arranged between the two arc-shaped reinforcing ribs, both ends of the transverse reinforcing rib are separately fused with the two arc-shaped reinforcing ribs, a V-shaped buckle is arranged between both ends of the outer wall, the space above the V-shaped buckle is filled with PP modified materials which are used for increasing the bearing capacity, the transverse reinforcing rib is used for increasing the stability of the draining pipe, a protective layer is additionally arranged, and the pressure resistance, the impact resistance and the seam stretching capacity are increased. According to the HDPE hollow wall winding drainage pipe, the production efficiency can be greatly improved, the production cost is reduced, and the quality passing percent of products is increased.

Owner:高其容

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com