Printing-free light guide plate structure

A light guide plate, printing-free technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of difficult groove structure processing, complex processing technology of light guide plate, printing light guide ink dots, etc., to improve the brightness of light source, The effect of simple structure and high qualified rate of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

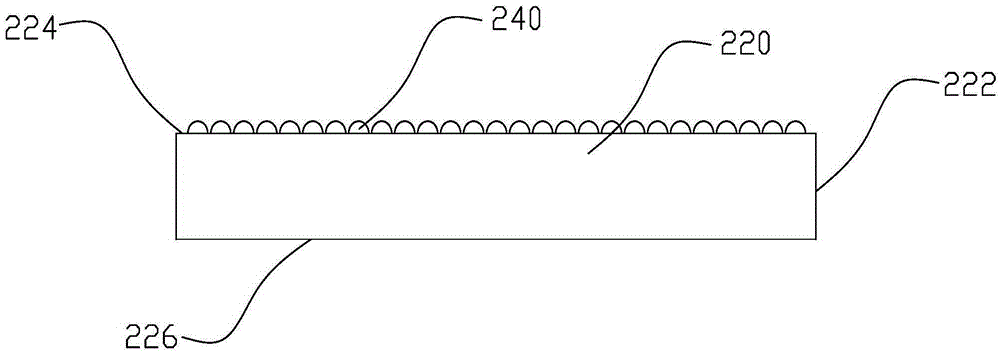

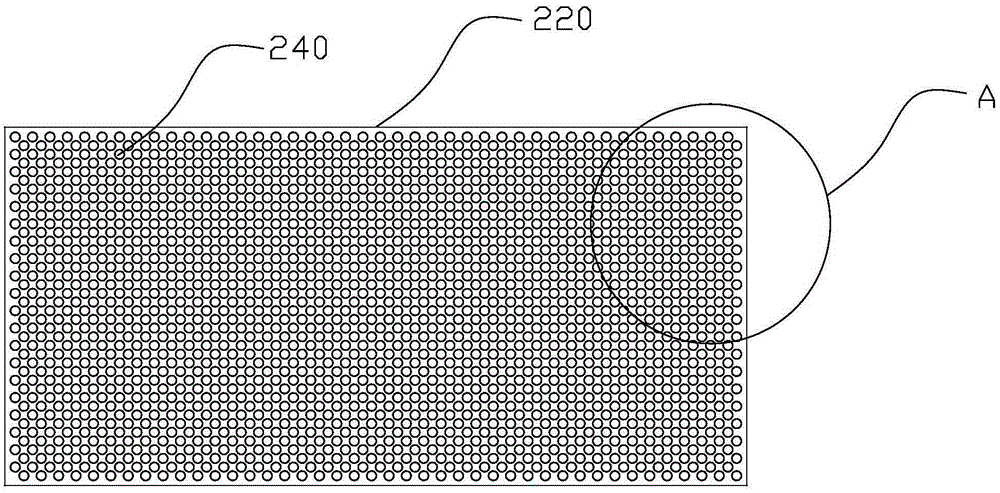

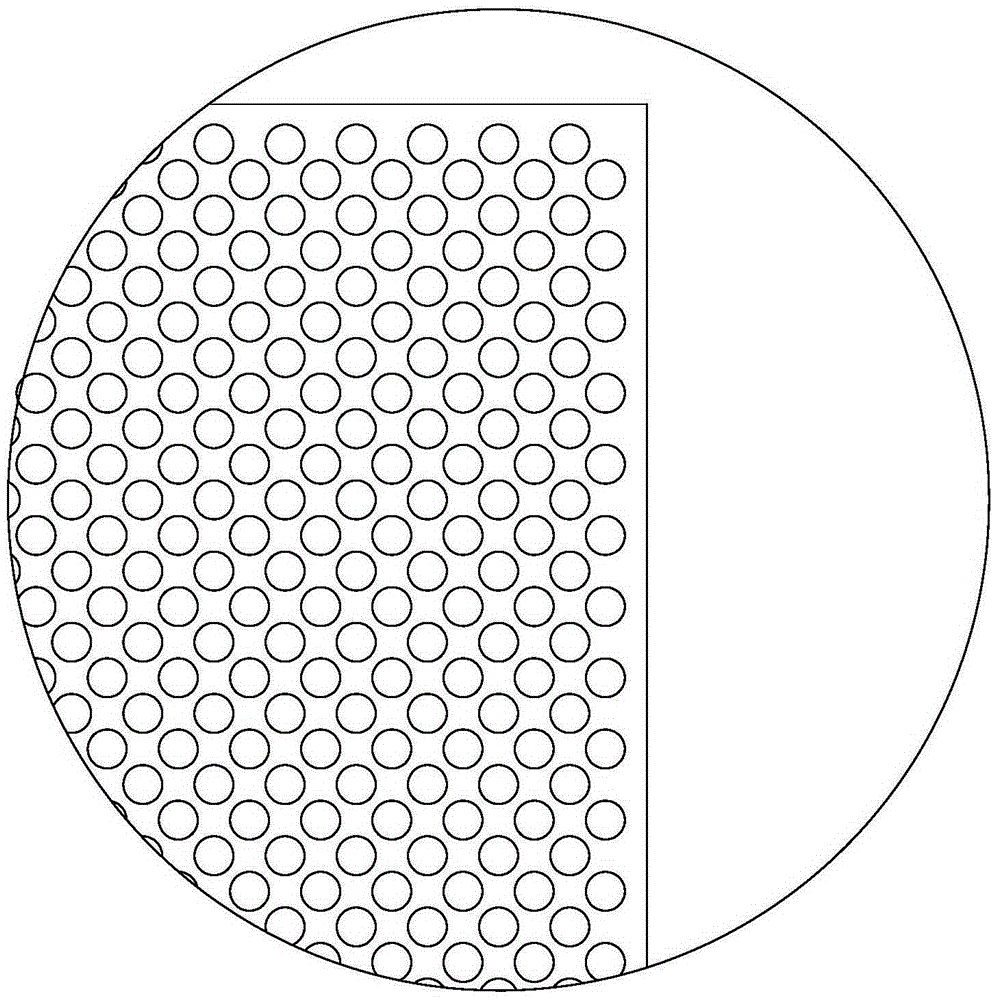

[0018] see Figure 1 to Figure 4 , a non-printing light guide plate structure, including a light guide plate body 220, the light guide plate body 220 includes a light incident surface 222 that guides a light beam 300 into the light guide plate body 220 and is located at the side of the light guide plate body 220, and guides the light beam 300 from the light guide plate body 220 The light exit surface 224 derived from the light plate body 220 and the bottom surface 226 opposite to the light exit surface 224, the bottom surface 226 is a smooth planar structure, a kind of non-printing light guide plate structure, including the light guide plate body, the light guide plate body 220 includes The light beam is introduced into the light guide plate body 220 and is located at the light incident surface 222 on the side of the light guide plate body 220, the light exit surface 224 that guides the light beam from the light guide plate body 220, and the bottom surface 226 opposite to the l...

Embodiment 2

[0025] The structure of this embodiment is the same as that of Embodiment 1, except that the diameter of the spherical protrusion 240 is 190um, the height of the spherical protrusion 240 is 136.8um, and the distance between adjacent spherical protrusions 240 in each row and column is 237.5um, and the thickness of the light guide plate body 220 is 2.5mm.

Embodiment 3

[0027] The structure of this embodiment is the same as that of Embodiment 1, the difference is that the diameter of the spherical protrusion 240 is 200um, the height of the spherical protrusion 240 is 150um, and the distance between adjacent spherical protrusions 240 in each row is 250um. , the thickness of the light guide plate body 220 is 3.0 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com