Machine vision-based slag salvaging method and robot system

A machine vision and robot technology, applied in the field of robot systems, can solve problems such as low efficiency of blind fishing and low accuracy of slag fishing, and achieve the effects of reducing fishing frequency, improving autonomy, and low power consumption/efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

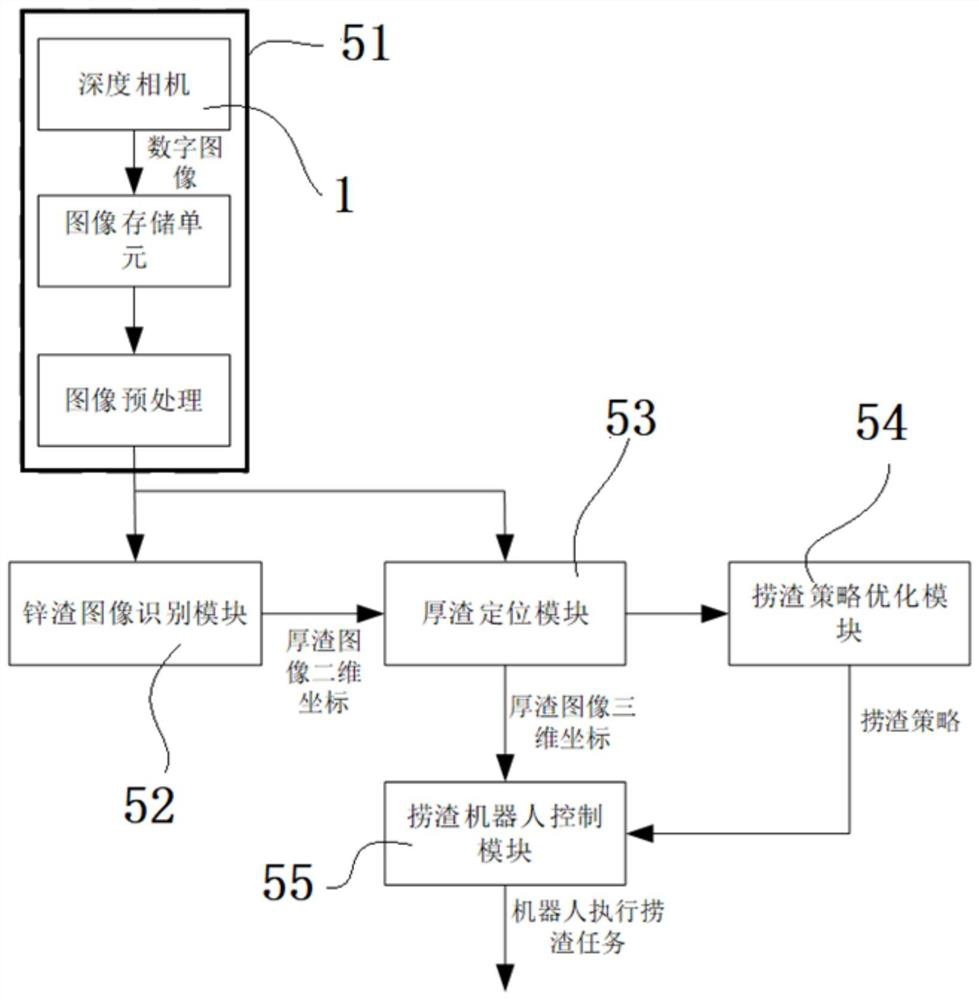

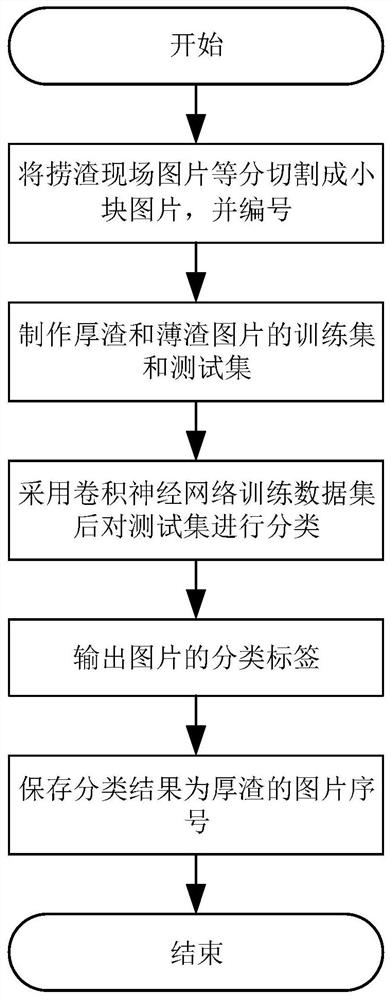

[0052] The slag removal method and robot system based on machine vision implemented according to the present invention, such as Figure 1-6 As shown, the problem of low efficiency of the slag removal robot in the related art is solved.

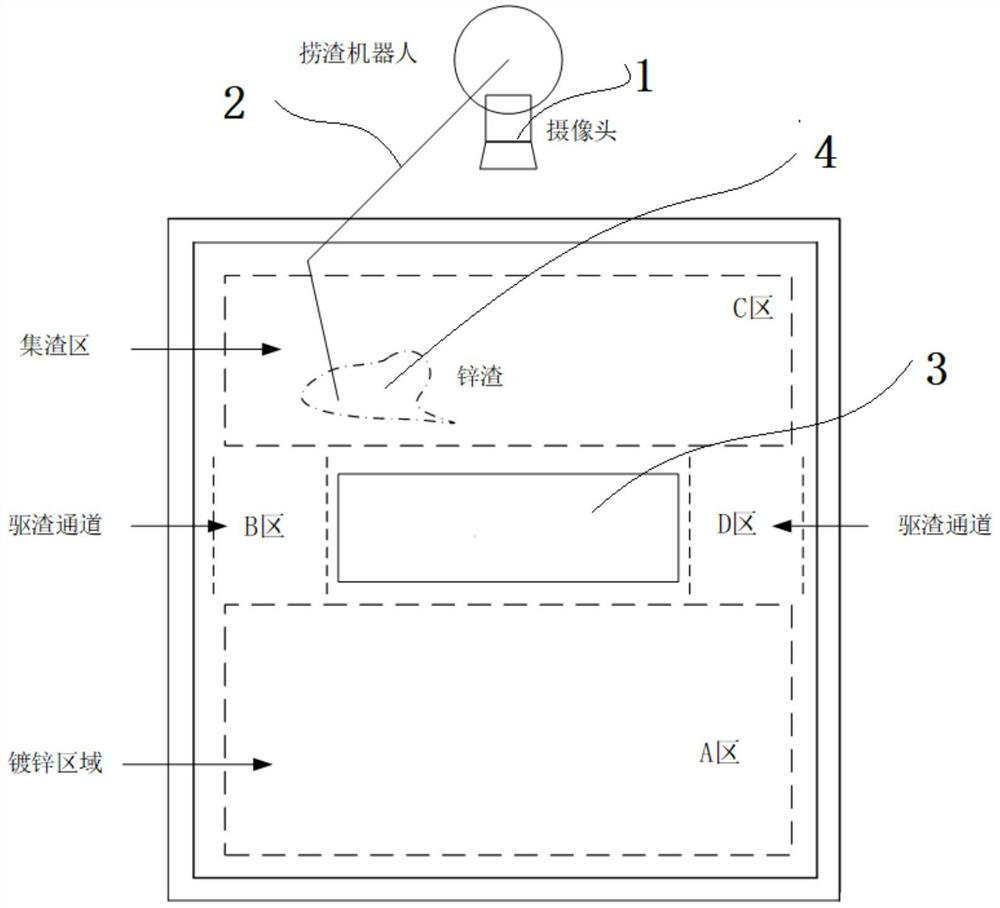

[0053] The slag removal robot system based on machine vision provided by the present invention, the system flow chart is as follows Figure 1-2 As shown, the plane structure diagram of the slag removal system is shown in figure 2 As shown, the slag removal robot system includes the camera of the depth camera 1, the robot arm 2 of the slag removal robot, and the PLC controller 5. The working range of the robot arm 2 extends to the slag removal area C, and the depth camera 1 is arranged in the slag collection area C. The upper part of the district, the slag removal area C area is located at the rear of the furnace nose 3. Area A is the galvanized area, where zinc slag 4 is mainly generated, areas B and D are slag removal channels, zinc slag i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com