Process for charging and packing industrial powder explosive cartridge and vibratory charging machine

A packaging technology, vibration-type technology, applied in the field of industrial powder explosive cartridge charging packaging technology and vibration-type charging machine, can solve the problem that the charging and packaging cannot be effectively combined, and achieve a high degree of intrinsic safety , high safety performance, and the effect of reducing cartridge damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0043] Industrial powdery explosive cartridge charge packaging process of the present invention is characterized in that it comprises the following operations:

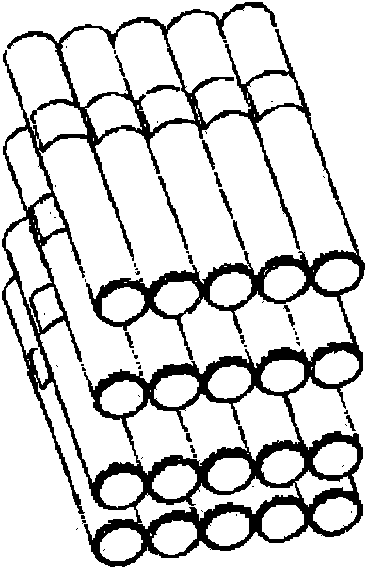

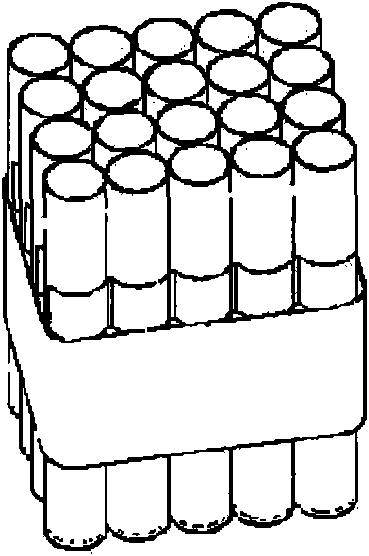

[0044] (1) Cartridge sorting and fixing process, using a fixed connector, sorting a number of single cartridges that are not charged into a cartridge with the mouth of the cartridge upwards, the gap between the cartridges is relatively small, relatively fixed, and fixed into an integrated structure barrel group;

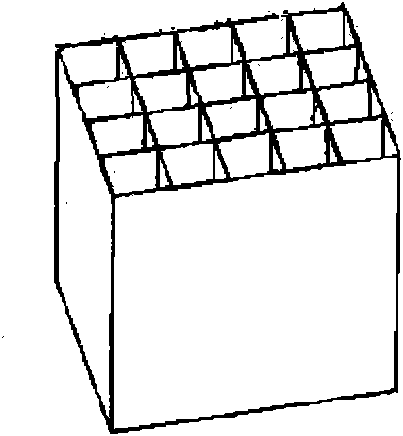

[0045] (2) Cartridge charging process, using a vibrating charging machine, the charging port of the vibrating charging machine is socketed on several charging openings provided on the bottom surface of the drug box, and the supporting plate lifts the cartridge upward to make the cartridge mouth open. The vibrating device drives the supporting plate and the cartridge to vibrate togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com