Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Improve optical precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

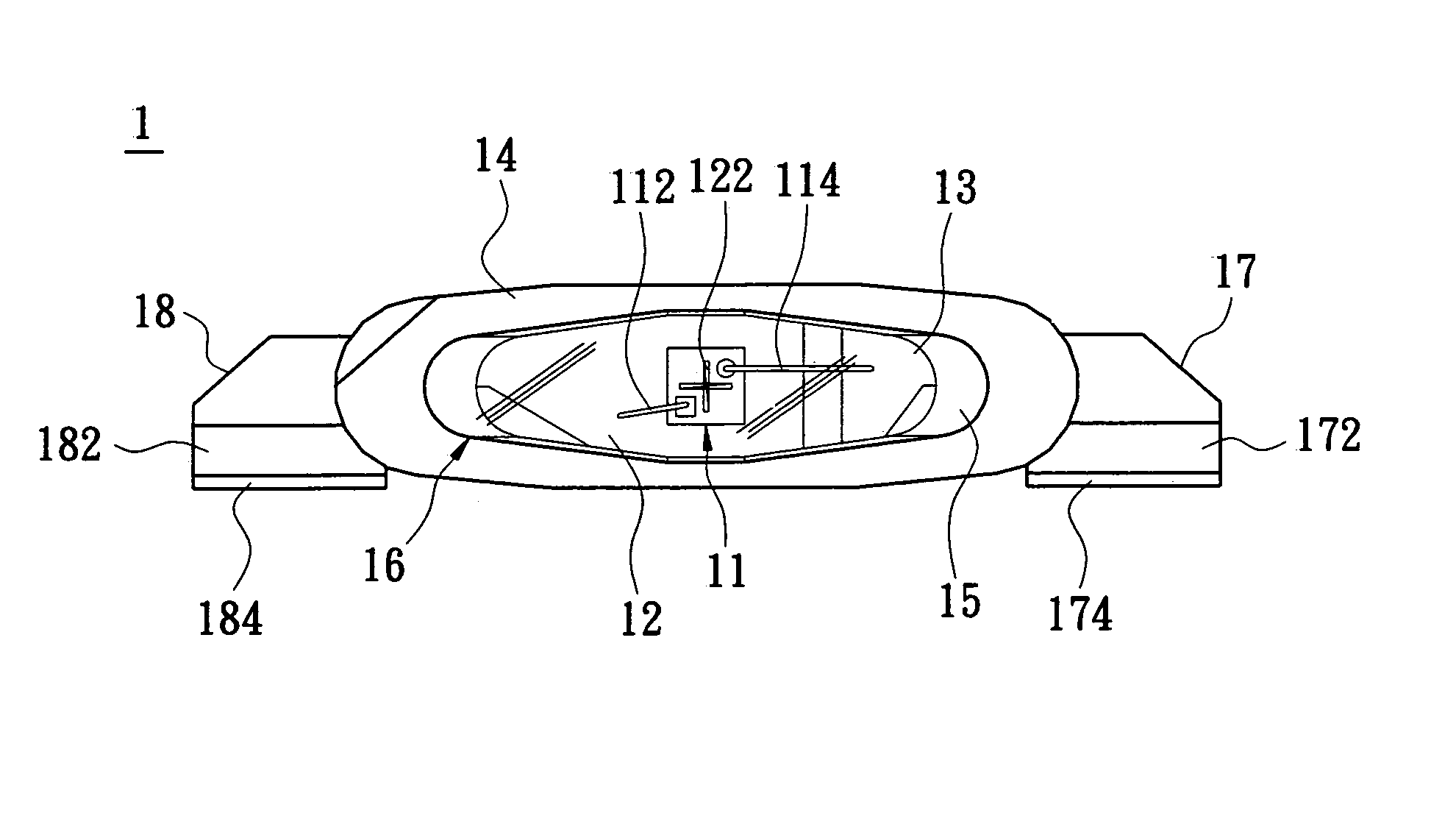

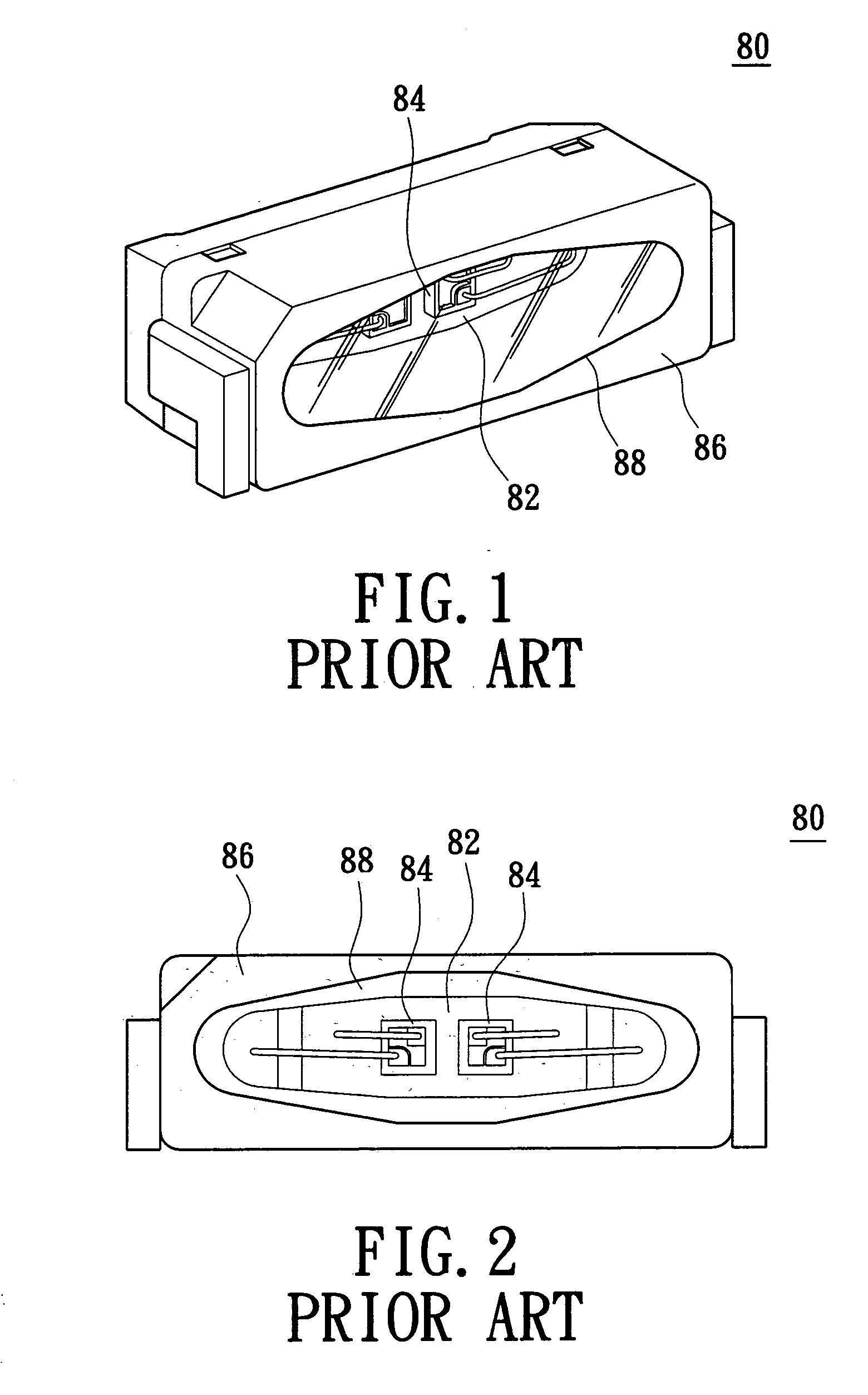

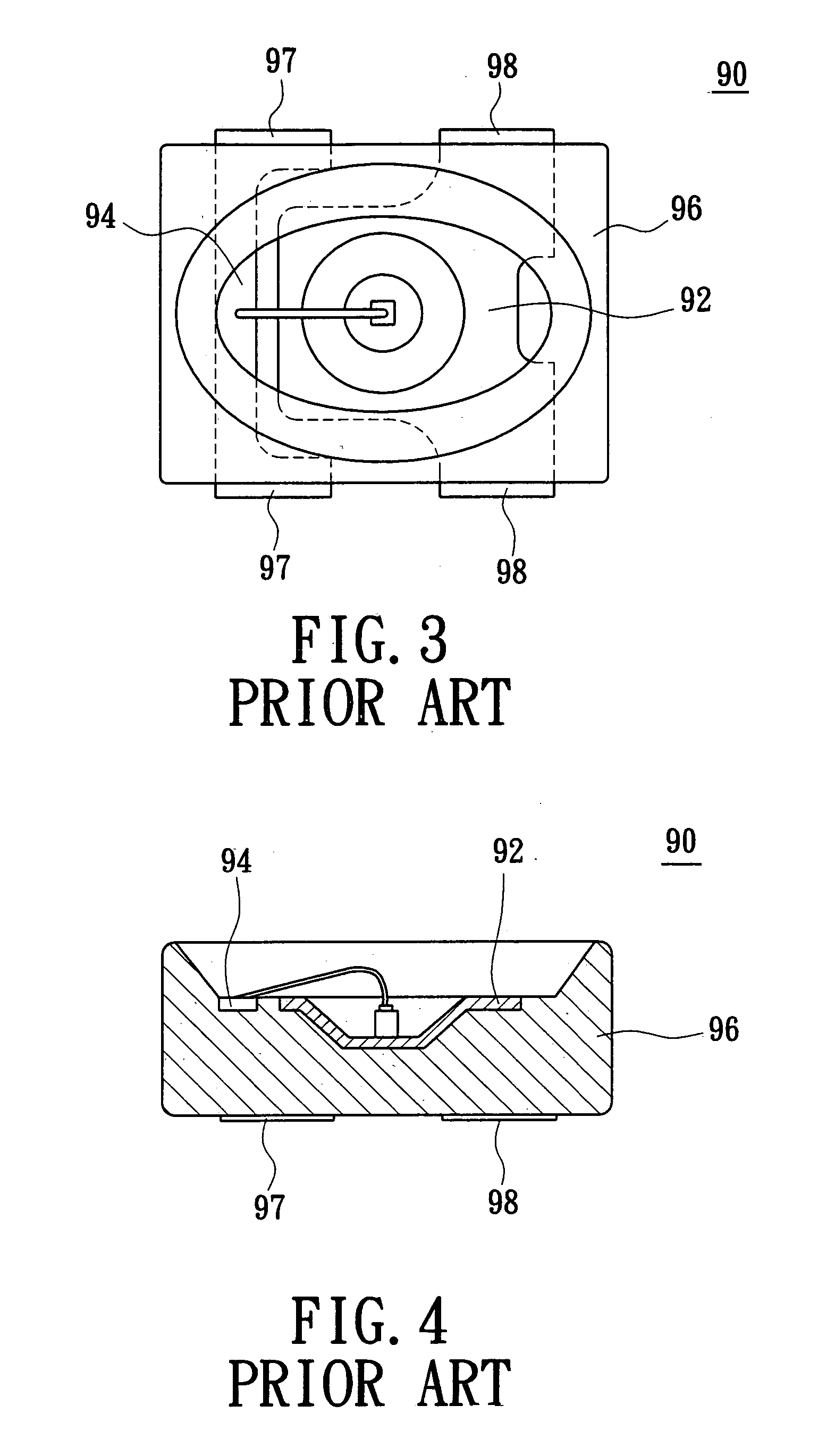

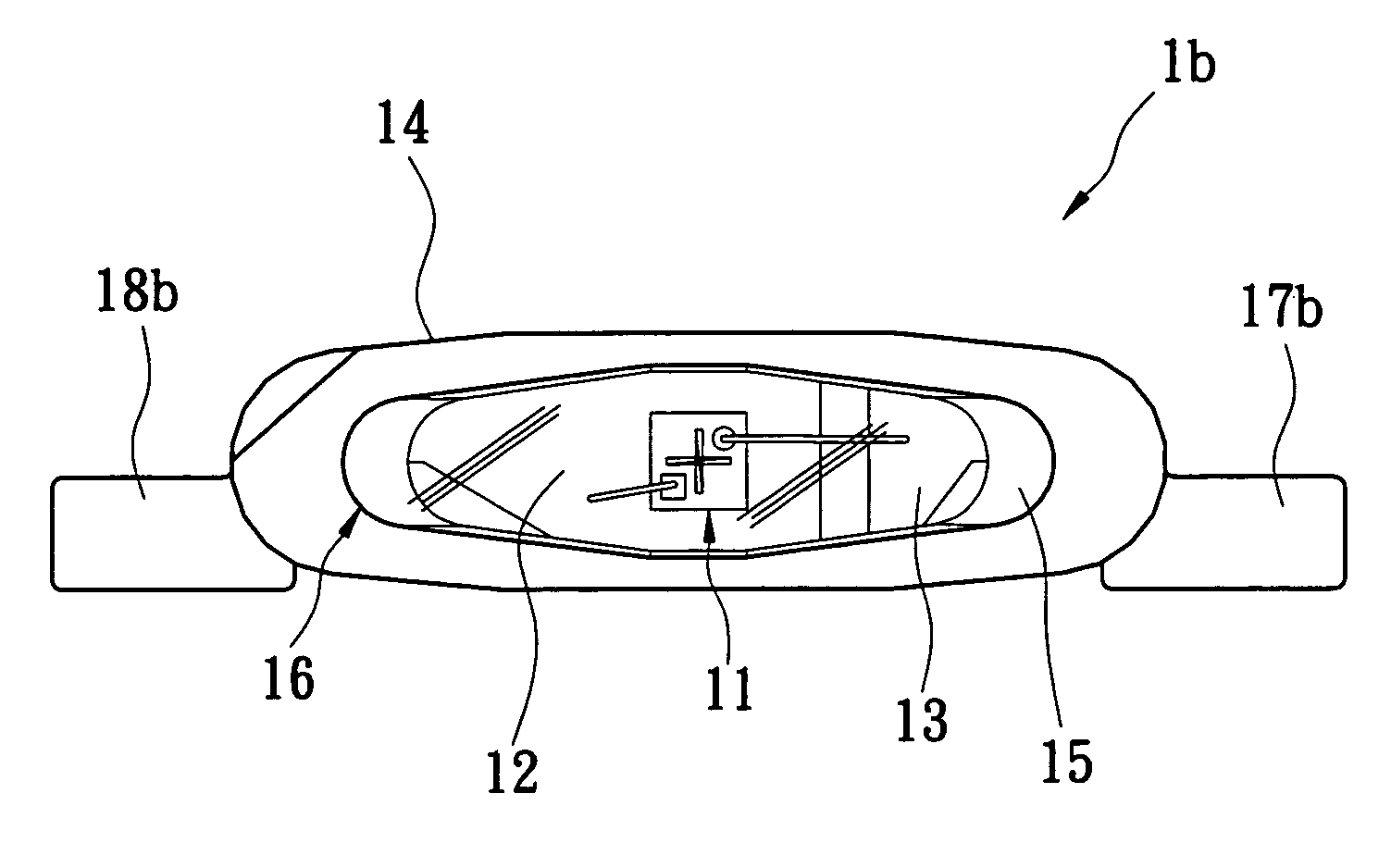

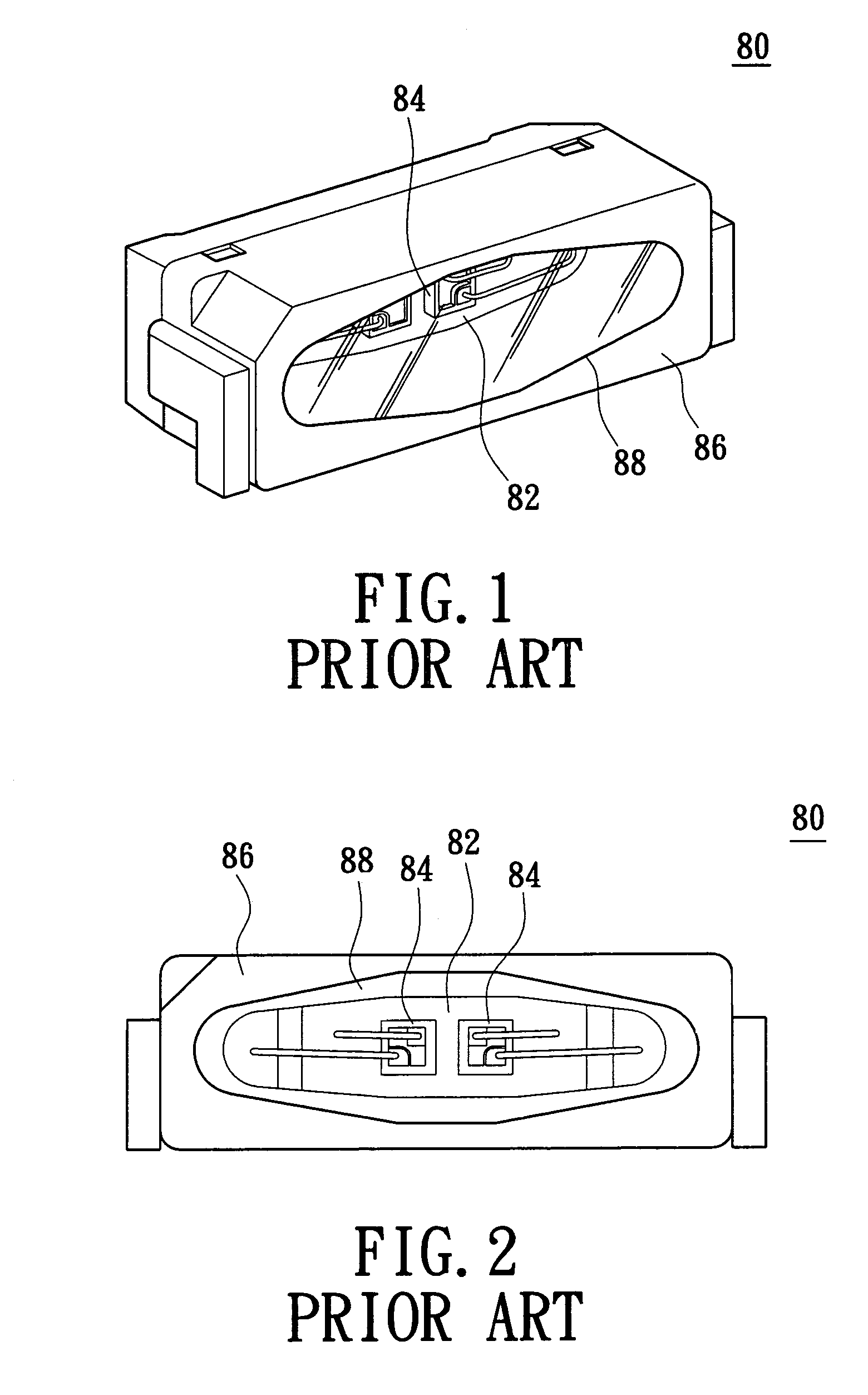

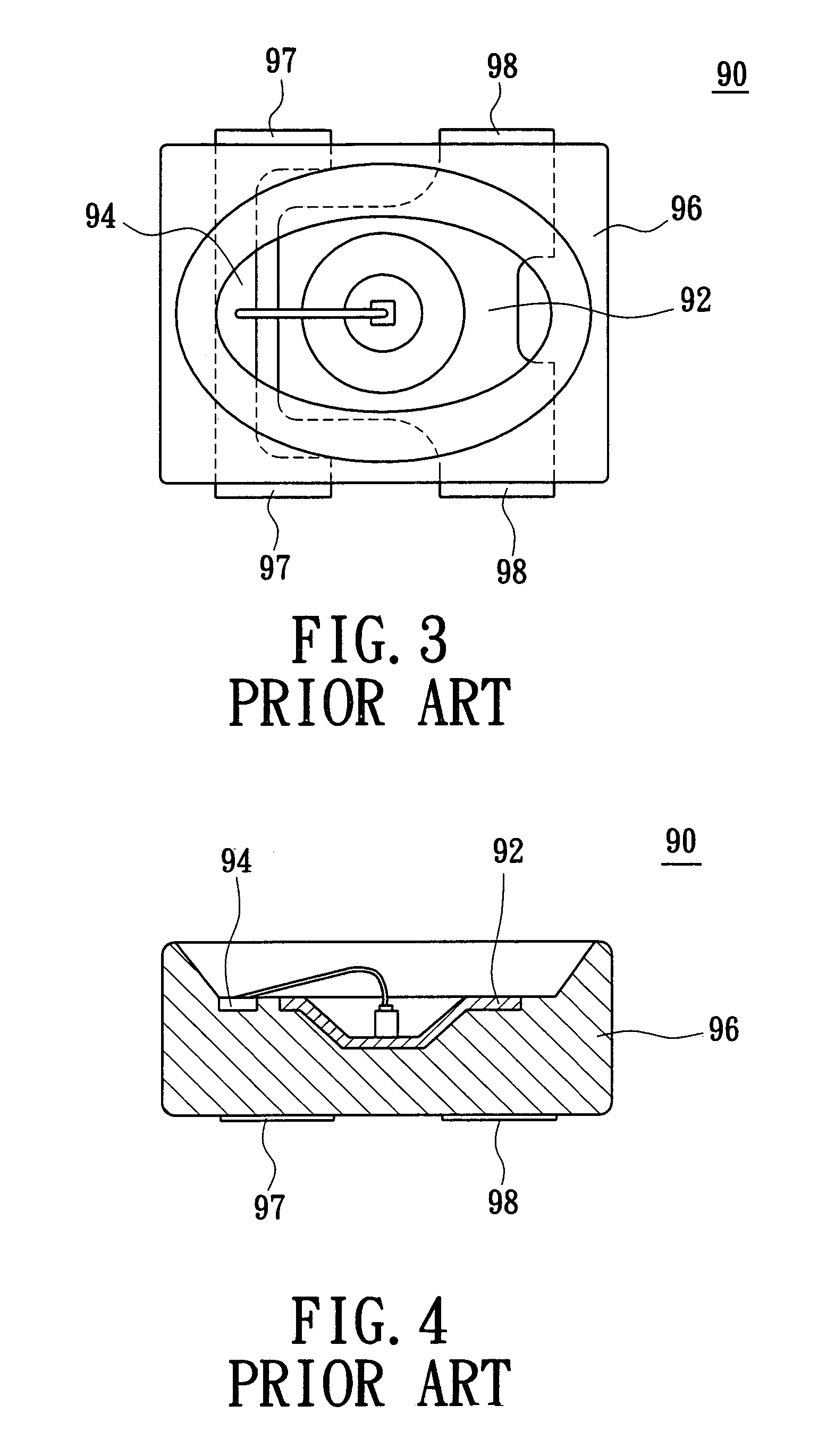

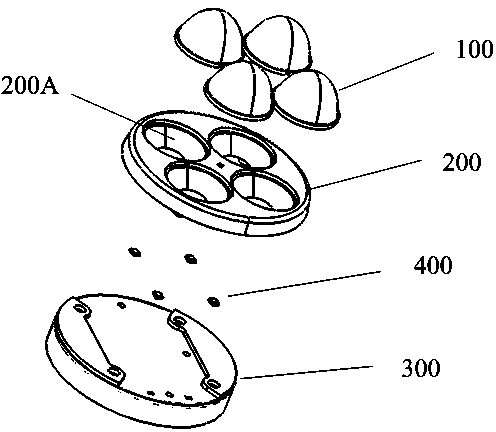

Optoelectronic semiconductor component

InactiveUS20050205974A1Easy to packRelieve pressureSemiconductor/solid-state device detailsSolid-state devicesSurface mountingSemiconductor chip

An optoelectronic semiconductor component applies to a surface mount component of an optoelectronic semiconductor. The optoelectronic semiconductor component has one or more semiconductor chip secured on a chip carrier. The chip carrier is a part of a lead frame, and another part of the lead frame is formed with an independent connection part as a contact of the semiconductor chip. An encapsulation body centers on the semiconductor chip and encircles part of the chip carrier and the independent connection part to form an annular ellipsoid for reflecting or receiving radiation of the semiconductor chip. The encapsulation body has a recess and a window part filling the recess. The window part is composed of materials for transforming the optical characteristics of the semiconductor chip. Part of the chip carrier and the independent connection part extend out the encapsulation body to form outside contacts as a SMT component.

Owner:LITE ON TECH CORP

Optoelectronic semiconductor component

InactiveUS7009285B2Easy to packRelieve pressureSemiconductor/solid-state device detailsSolid-state devicesSurface mountingSemiconductor chip

An optoelectronic semiconductor component applies to a surface mount component of an optoelectronic semiconductor. The optoelectronic semiconductor component has one or more semiconductor chip secured on a chip carrier. The chip carrier is a part of a lead frame, and another part of the lead frame is formed with an independent connection part as a contact of the semiconductor chip. An encapsulation body centers on the semiconductor chip and encircles part of the chip carrier and the independent connection part to form an annular ellipsoid for reflecting or receiving radiation of the semiconductor chip. The encapsulation body has a recess and a window part filling the recess. The window part is composed of materials for transforming the optical characteristics of the semiconductor chip. Part of the chip carrier and the independent connection part extend out the encapsulation body to form outside contacts as a SMT component.

Owner:LITE ON TECH CORP

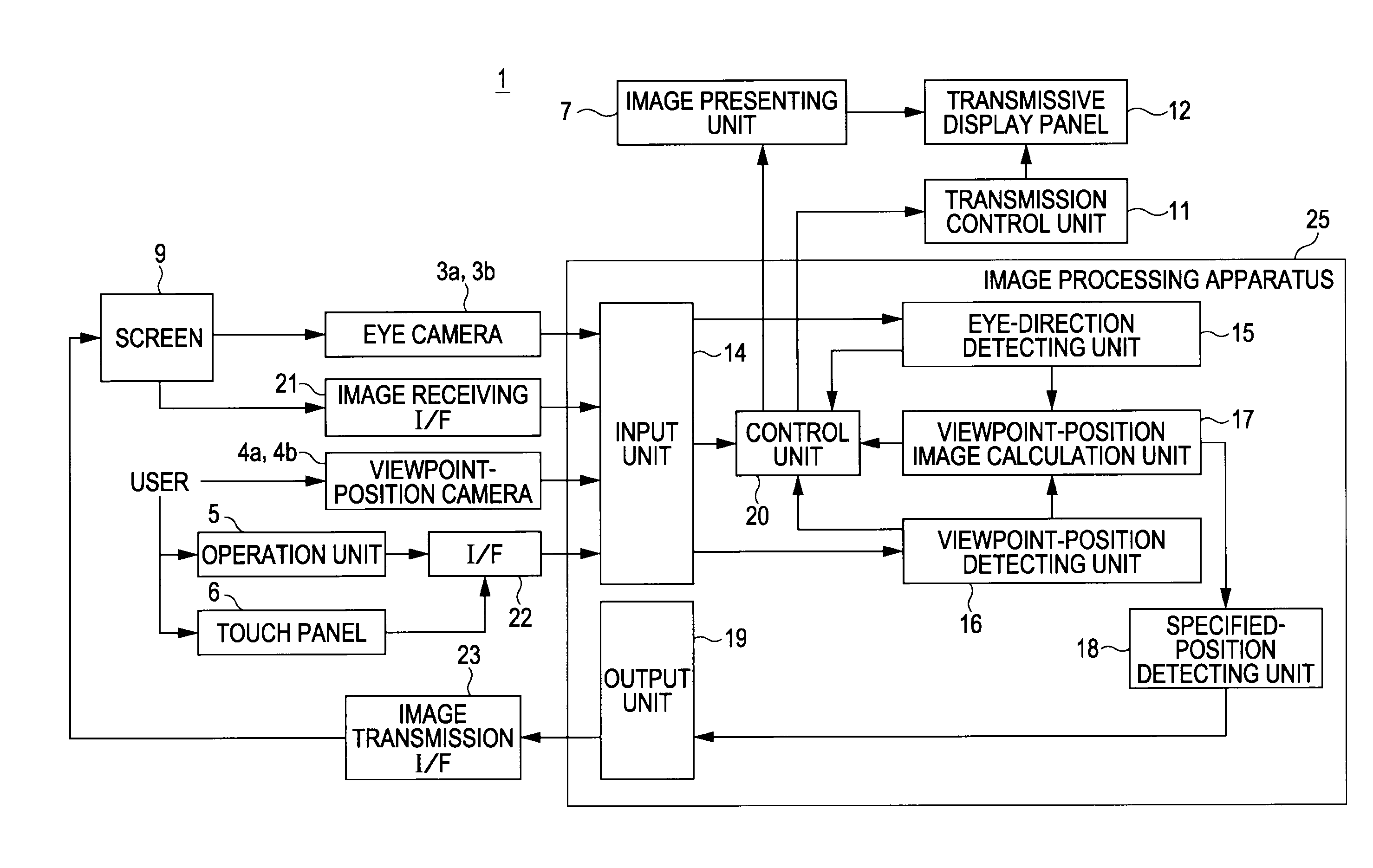

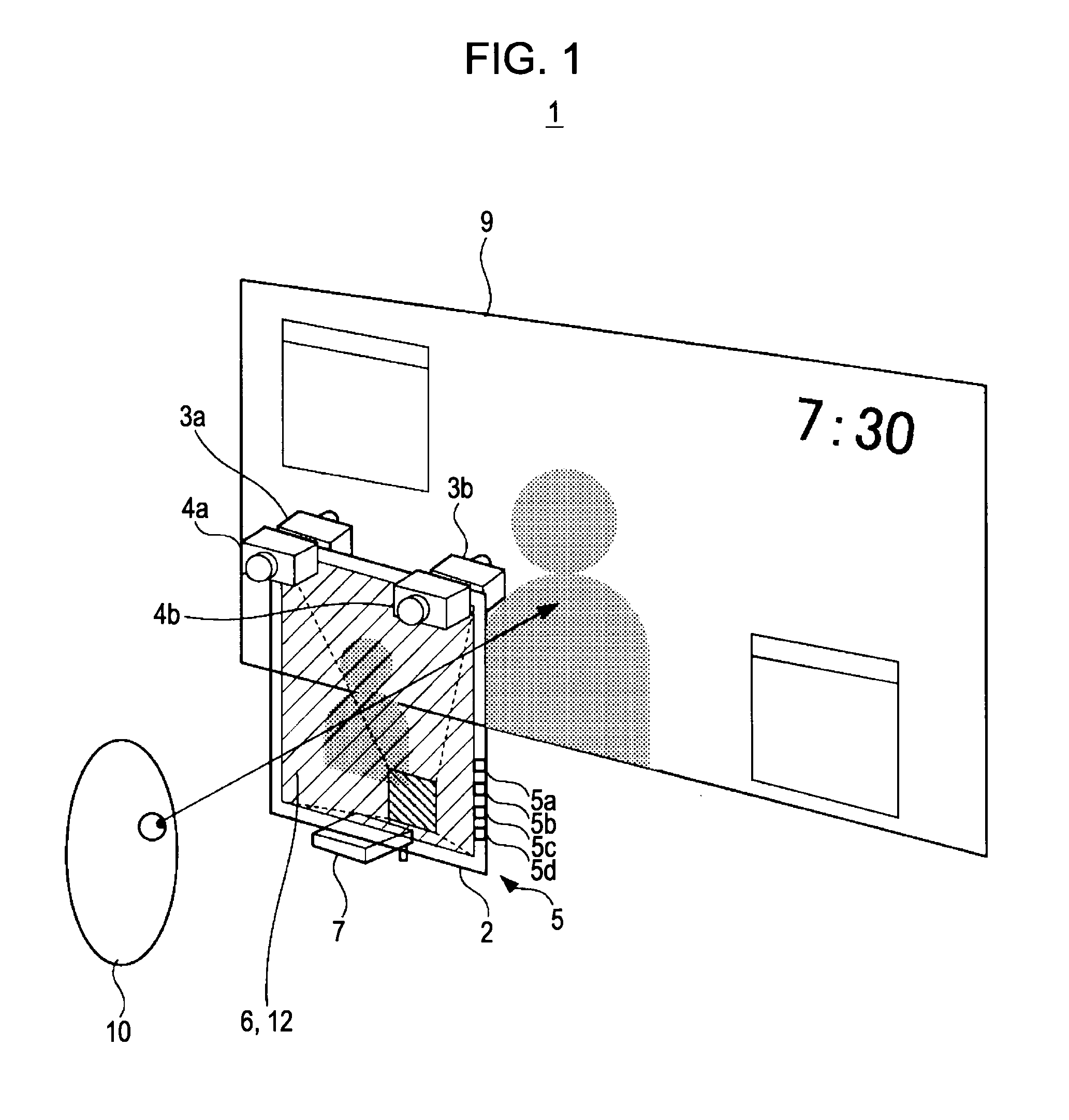

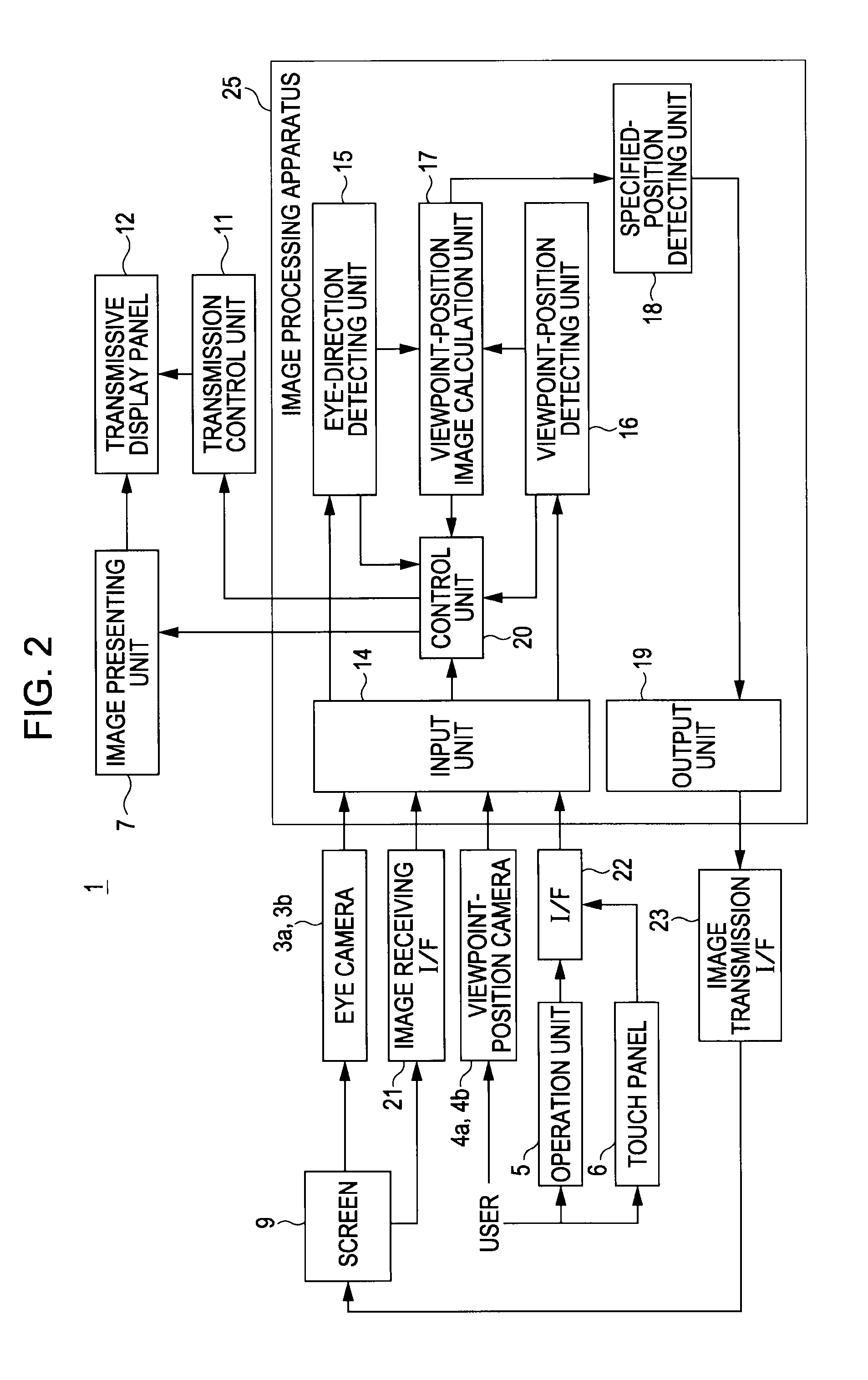

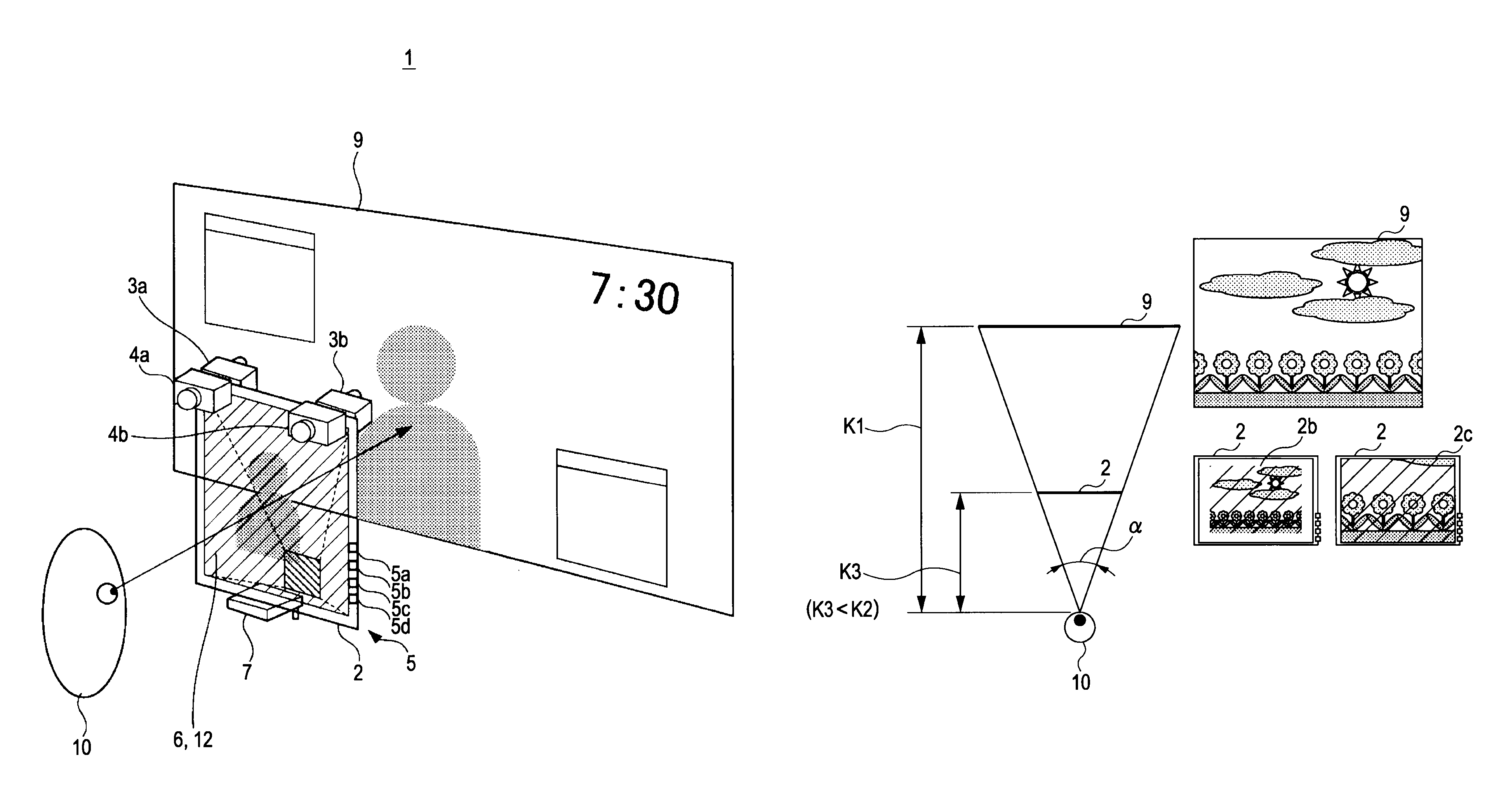

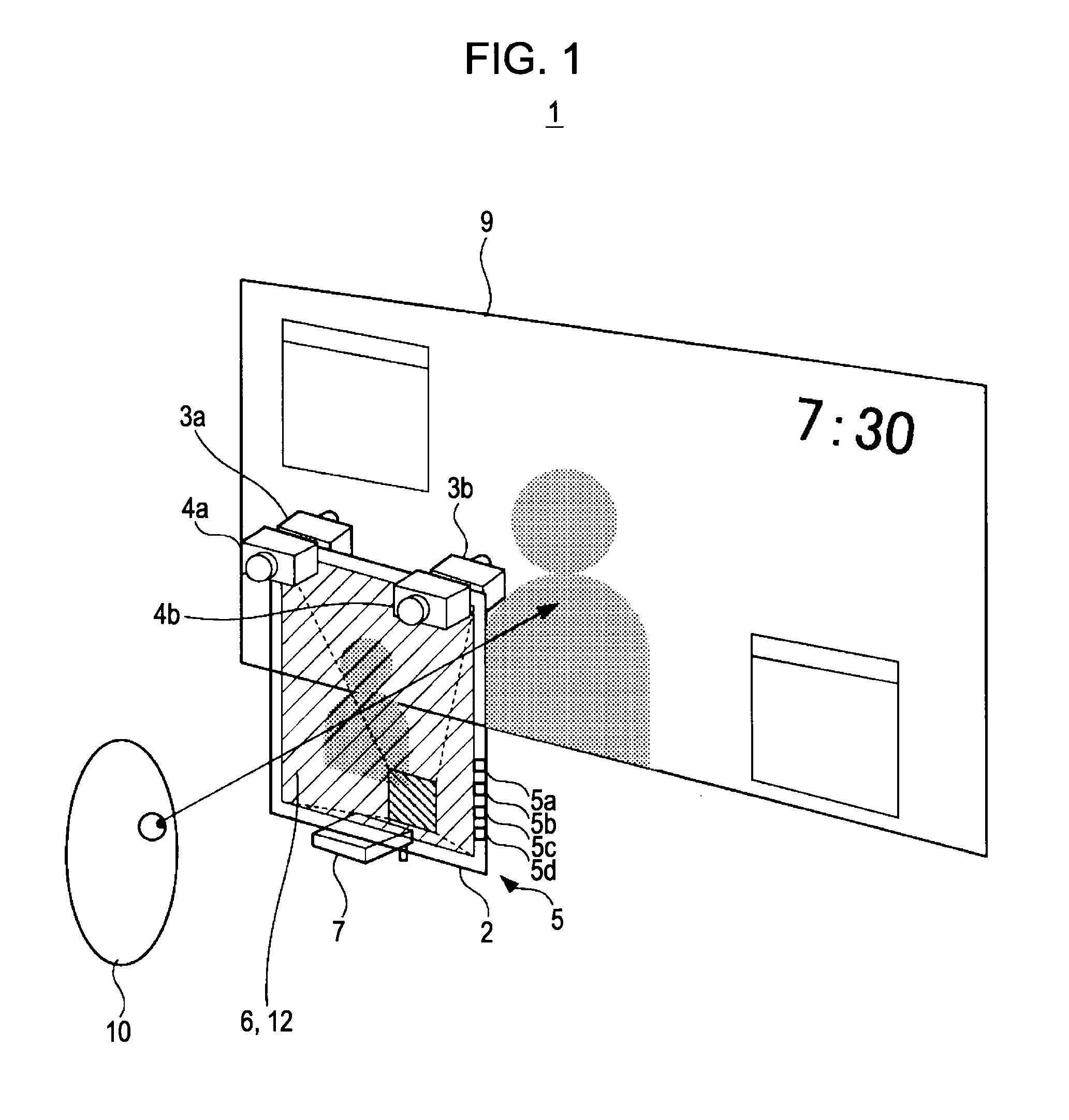

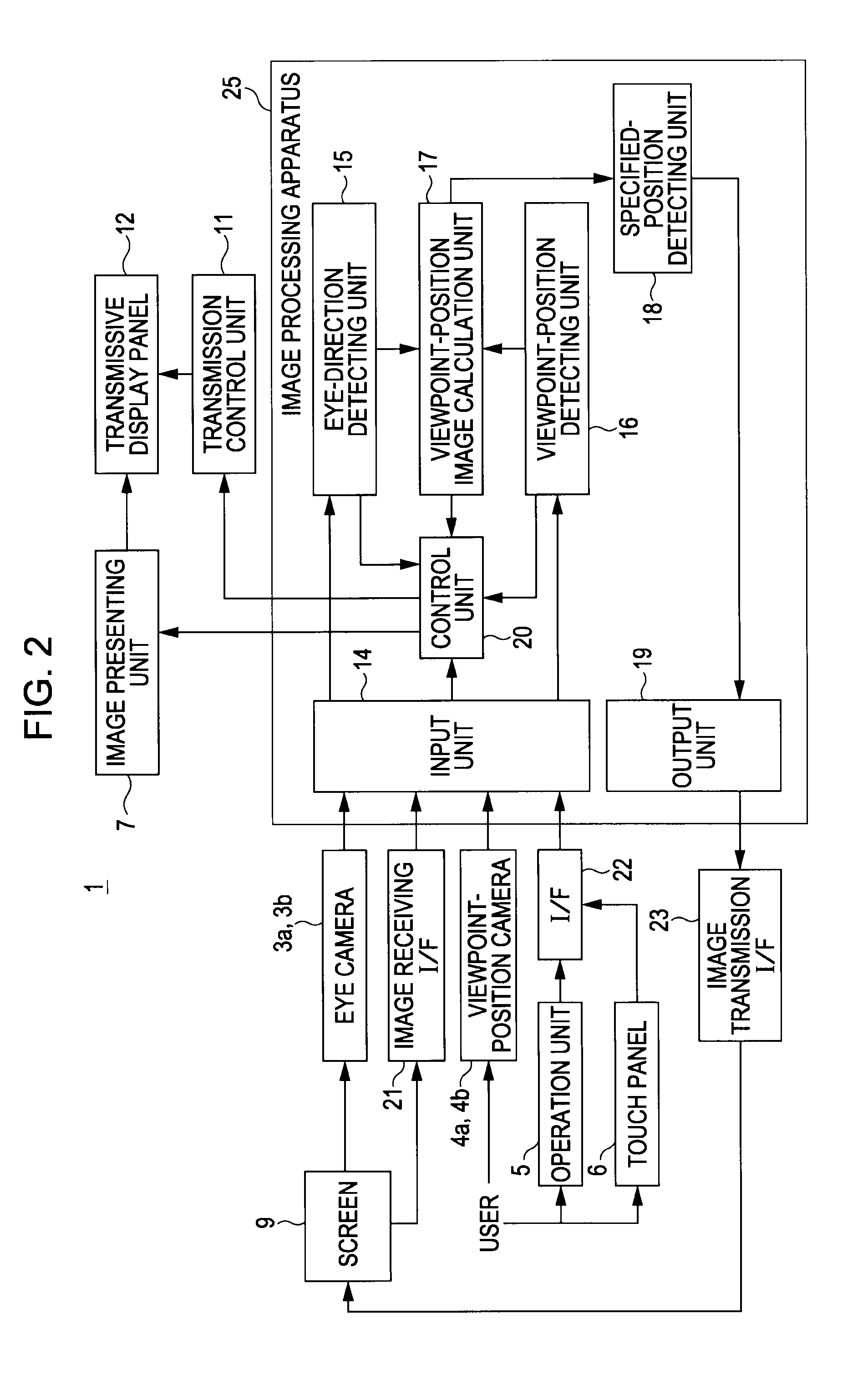

Image processing apparatus, image processing method, program, and recording medium

InactiveUS20090271732A1Wide viewing angleEasy to getImage analysisCathode-ray tube indicatorsImaging processingComputer graphics (images)

An image processing apparatus includes an input unit to which an image of an object picked up by an image pickup device is input, a display device on which the image is presented, an image presenting unit configured to present the image on the display device; a viewpoint detecting unit configured to detect a viewpoint position of a user, and a control unit configured to supply, to the image presenting unit, the image in an area extracted corresponding to an image frame of a display surface of the display device when the image is viewed through the display surface from the viewpoint position of the user detected by the viewpoint detecting unit.

Owner:SONY CORP

Optical signal quality monitoring method and apparatus using a software-based synchronized amplitude histogram

InactiveUS20140308034A1Monitor quality of opticalAccurate synchronizationTransmission monitoringTransmission monitoring/testing/fault-measurement systemsSignal qualityAmplitude histogram

An optical signal quality monitoring apparatus includes an optical detector for directly receiving an optical signal modulated in an optical path and converting the optical signal to an electric signal, an asynchronous sampling unit for asynchronously sampling the electric signal of the optical detector at a reduced speed, and a digital signal processor for monitoring an optical signal quality by finding a synchronized amplitude histogram of data sampled in the asynchronous sampling unit. An optical signal quality monitoring method includes (a) a step of allowing an optical detector to directly receive a modulated optical signal and to convert the optical signal to an electric signal; (b) a step of allowing an asynchronous sampling unit to asynchronously sample the electric signal; and (c) a step of allowing a digital signal processor to monitor an optical signal quality by generating a synchronized amplitude histogram of sampled data.

Owner:KOREA ADVANCED INST OF SCI & TECH

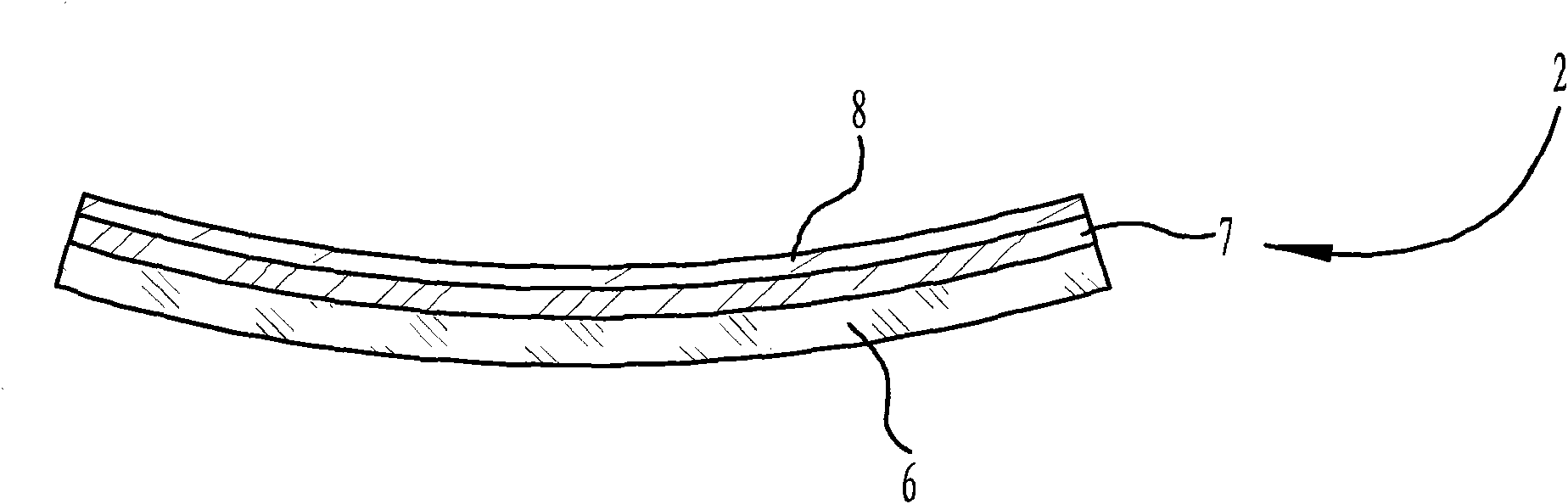

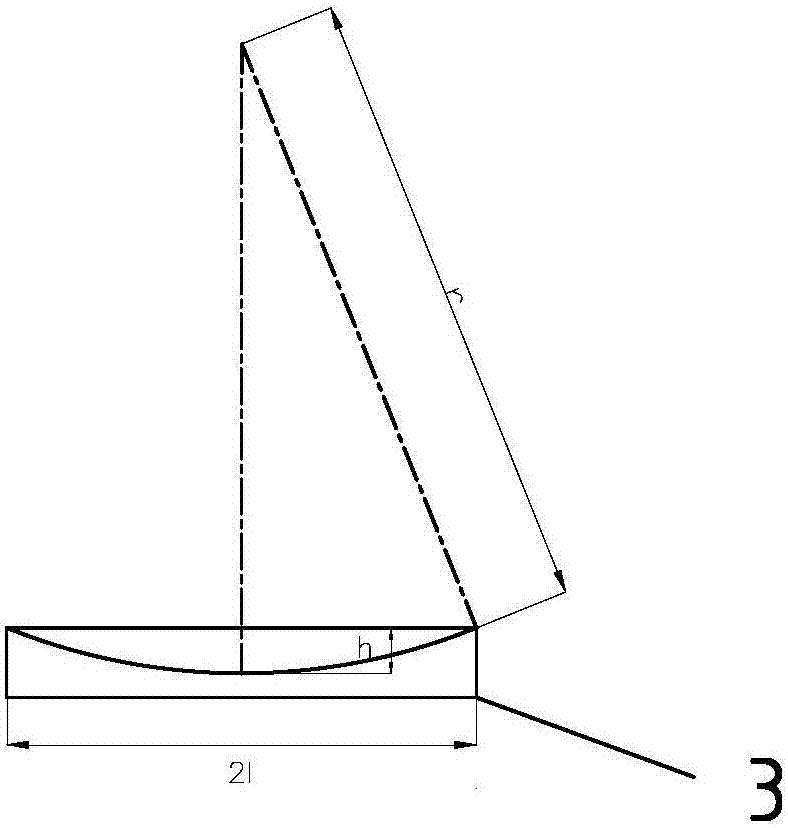

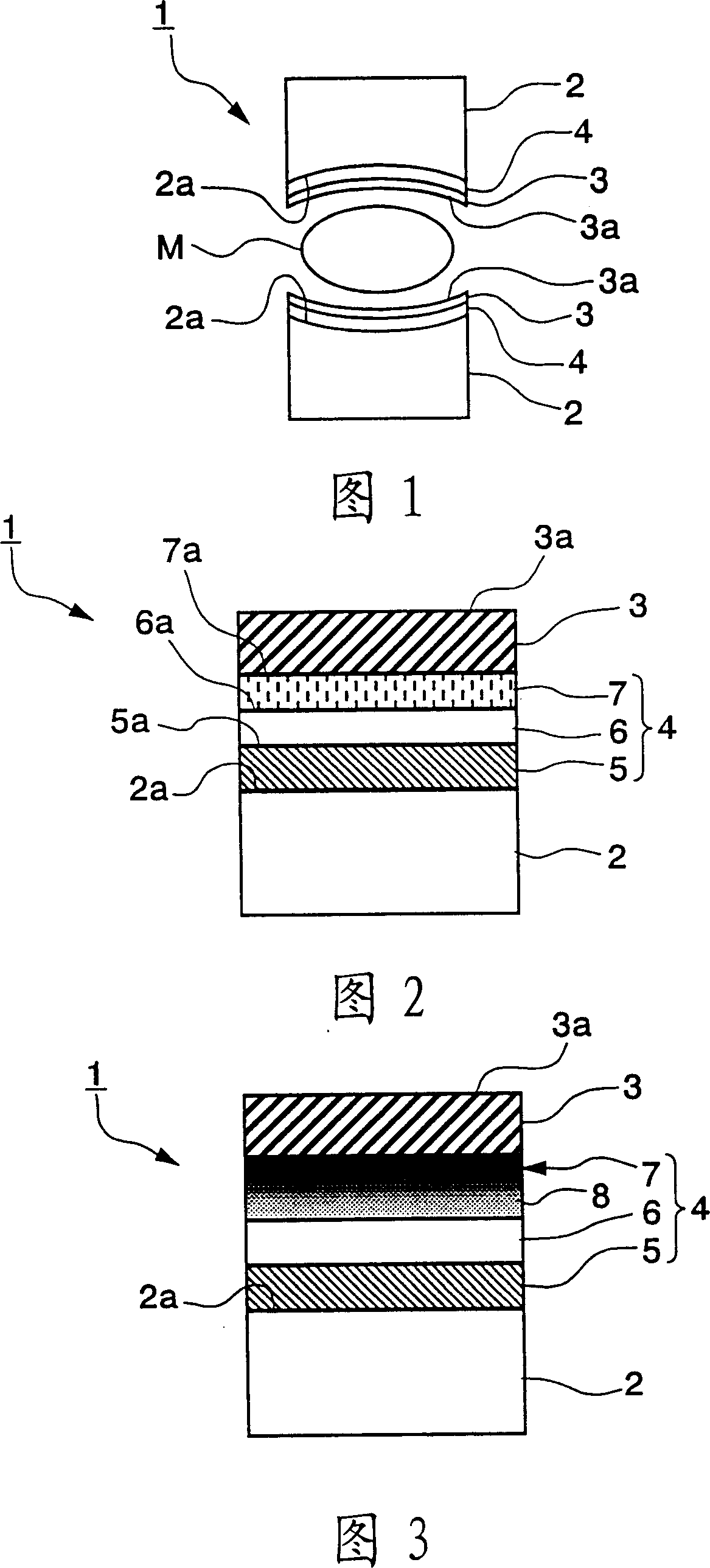

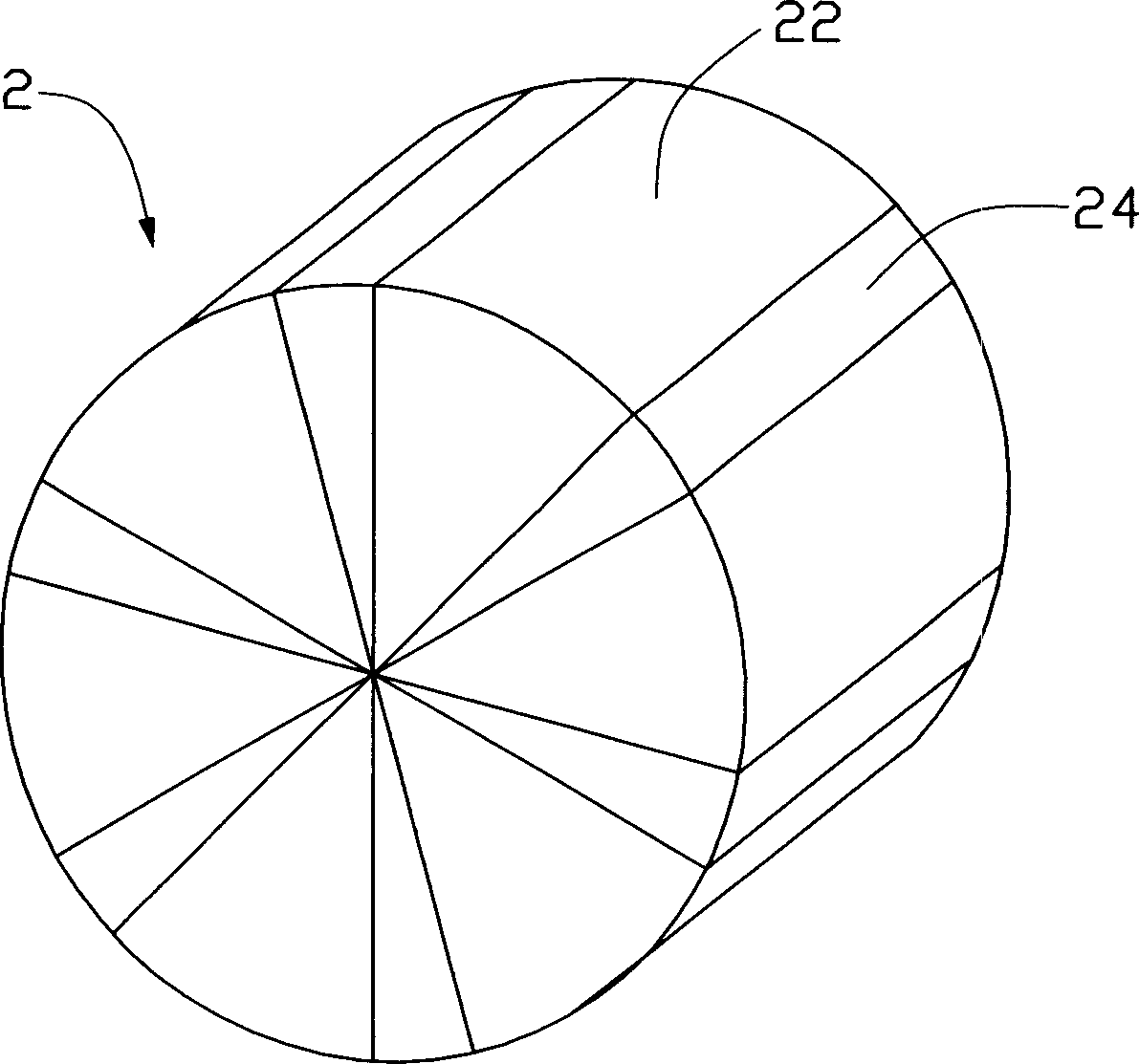

Curved mirror reflector and production method thereof

ActiveCN102759765AStable structureCombine tightly and evenlyMirrorsLayered productsOptoelectronicsFlat glass

The invention provides a curved mirror reflector (2), which comprises a flat glass structure (6), a middle bonding layer (7) and a flat glass mirror (8), wherein the flat glass structure (6) and the flat glass mirror (8) are processed by non-edging and / or non-tempered common glass; the middle bonding layer (7) is located between the flat glass structure (6) and the flat glass mirror (8), and is bent and deformed under support of a mould through a mechanical manner, and the bent and deformed flat glass structure (6), the middle bonding layer (7) and the flat glass mirror (8) are solidified and bonded to a composite curved surface structure through a heating and / or normal-temperature solidification manner. The curved mirror reflector (2), provided by the invention, can be widely applied in all kinds of fields of solar thermal collection and focus and solar thermal power generation.

Owner:BEIJING TERASOLAR PHOTOTHERMAL TECH CO LTD

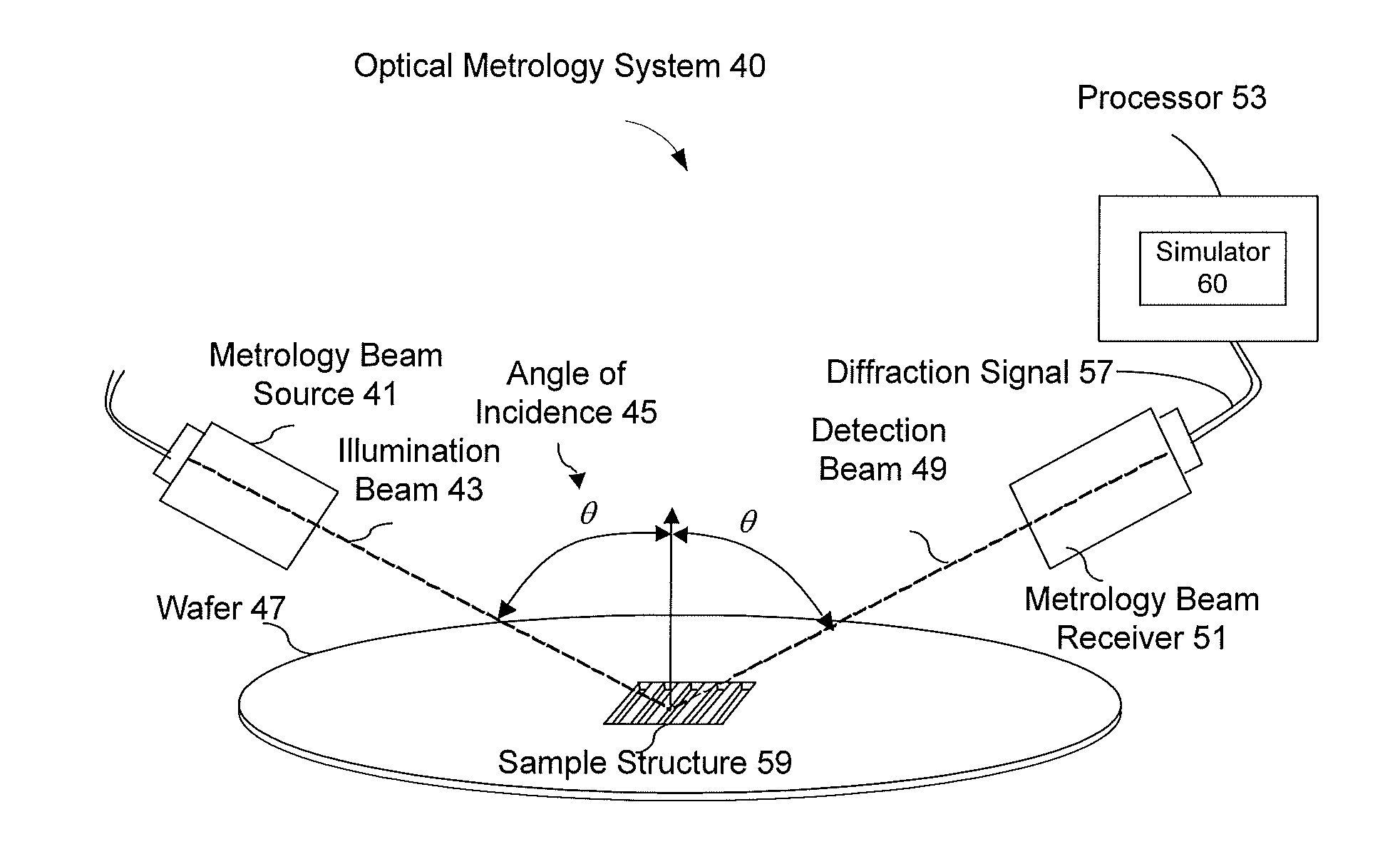

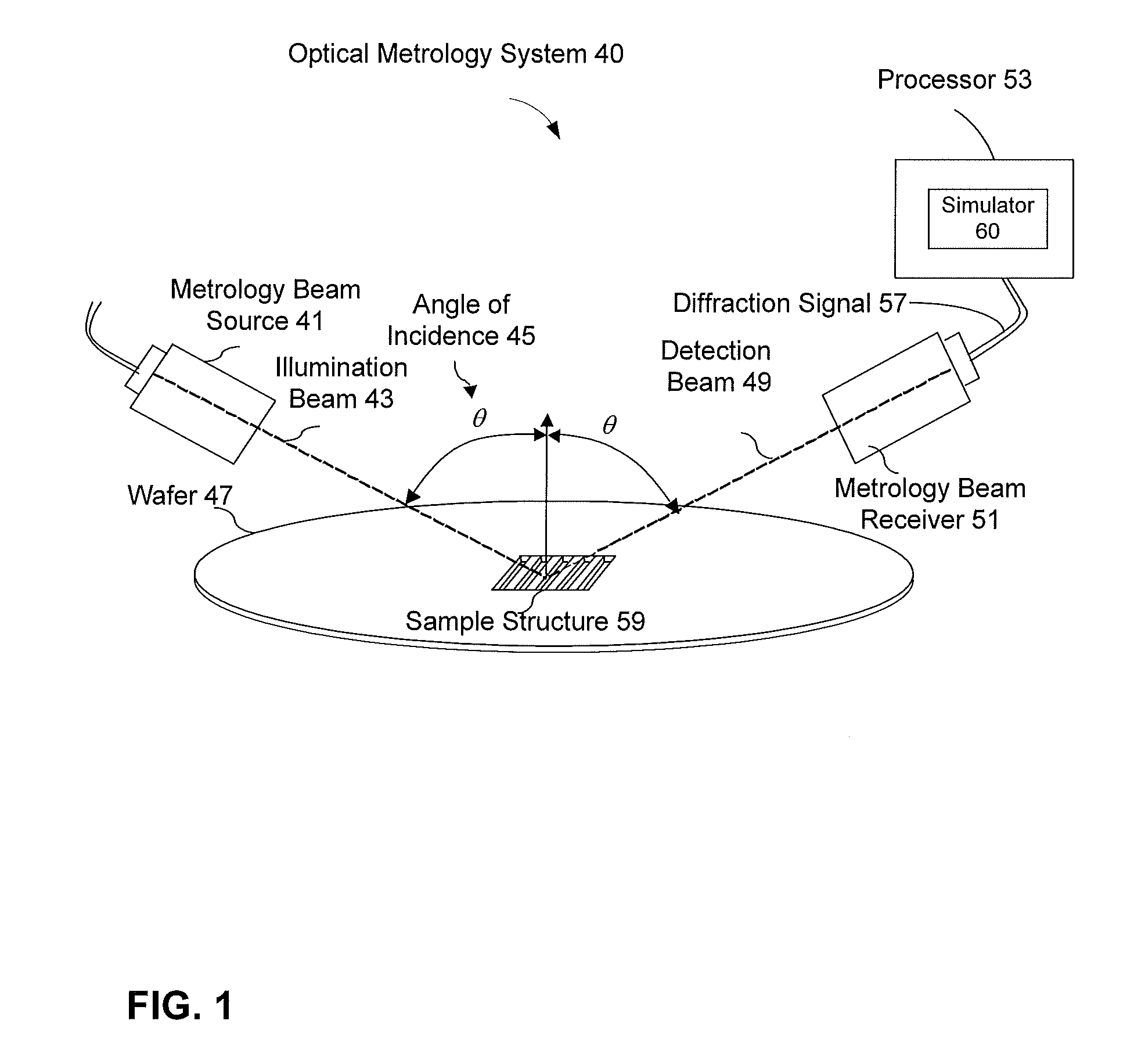

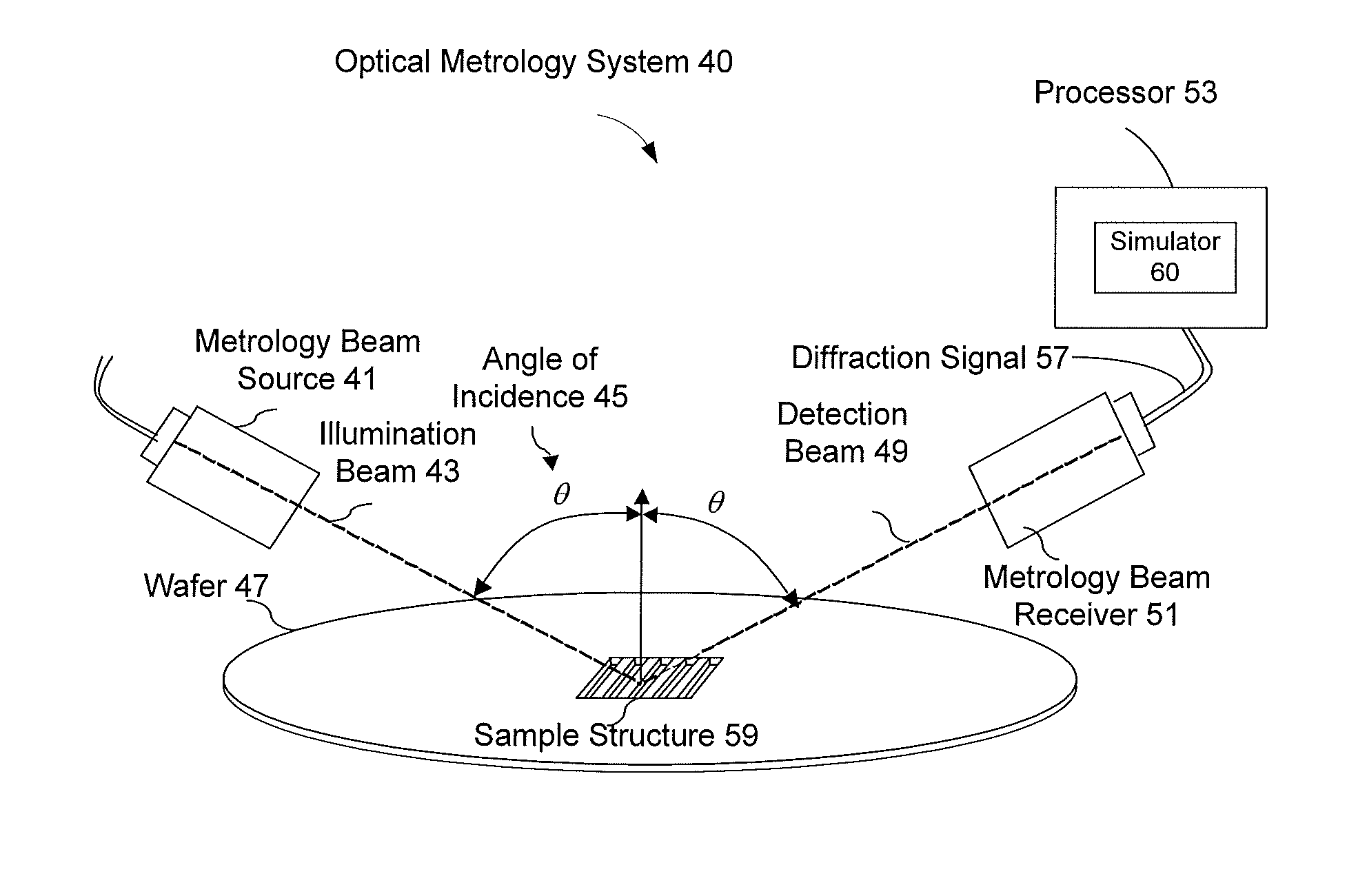

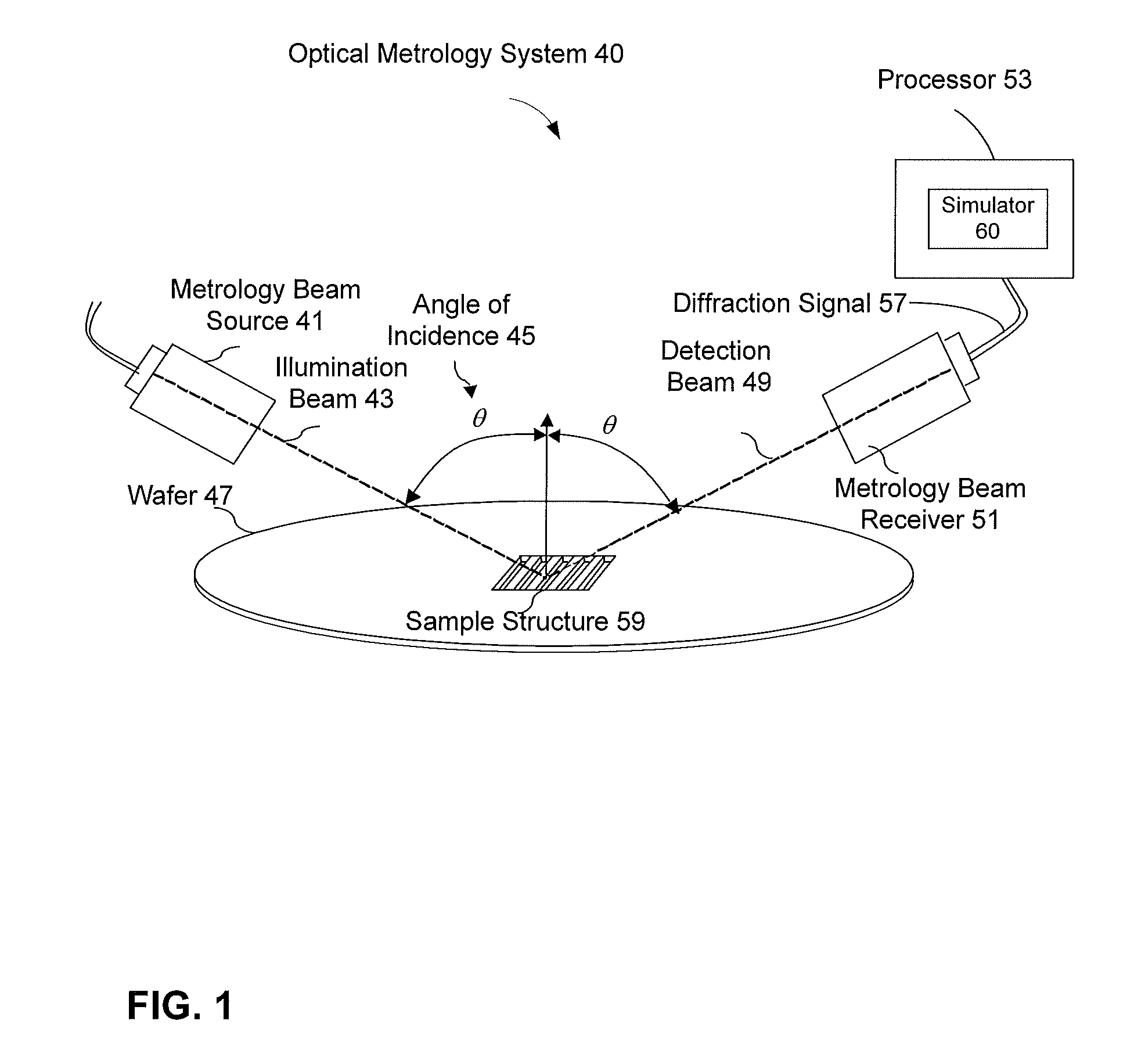

Method of regenerating diffraction signals for optical metrology systems

InactiveUS20130151440A1Improve optical precisionMaterial analysis by optical meansDigital computer detailsLight beamComputational physics

Provided is a method for enhancing accuracy of an optical metrology system that includes a metrology tool, an optical metrology model, and a profile extraction algorithm. The optical metrology model includes a model of the metrology tool and a profile model of the sample structure, the profile model having profile parameters. A library comprising Jones and / or Mueller matrices and / or components (JMMOC) and corresponding profile parameters is generated using ray tracing and a selected range of beam propagation parameters. An original simulated diffraction signal is calculated using the optical metrology model. A regenerated simulated diffraction signal is obtained using the regenerated JMMOC, integrated for all the rays of the optical metrology model. If an error and precision criteria for the regenerated simulated diffraction signal compared to the original simulated diffraction signal are met, one or more profile parameters are determined from the best match regenerated simulated diffraction signal.

Owner:TOKYO ELECTRON LTD

LED car high beam

ActiveCN103629614AImprove optical precisionSuitable for high beam lightingPoint-like light sourceSemiconductor devices for light sourcesExit planeLight energy

The invention discloses an LED car high beam. The LED car high beam comprises a plurality of LED light sources, a plurality of free-form surface optical lenses, a lens support and a base plate. The lens support and the LED light sources are fixed to the base plate, and a plurality of holes for emergent light of the LED light sources to pass through are correspondingly formed in the lens support. One free-form surface optical lens is arranged at each hole in the lens support, and the distance between light-emitting faces of the LED light sources and incident planes of the free-form surface optical lenses is fixed according to the height of the lens support. The LED car high beam is simple in structure, high in light energy utilization efficiency, simple and stable in structure, convenient to assemble, low in cost, long in service life, good in light distribution performance and capable of meeting GB25991-2010 light distribution requirements. According to the LED car high beam, exit planes of the lenses are free-form surfaces, so that the appearance of the whole car high beam can be more flexible and meet requirements for beautification and streamline of modern car high beam design.

Owner:SOUTH CHINA UNIV OF TECH

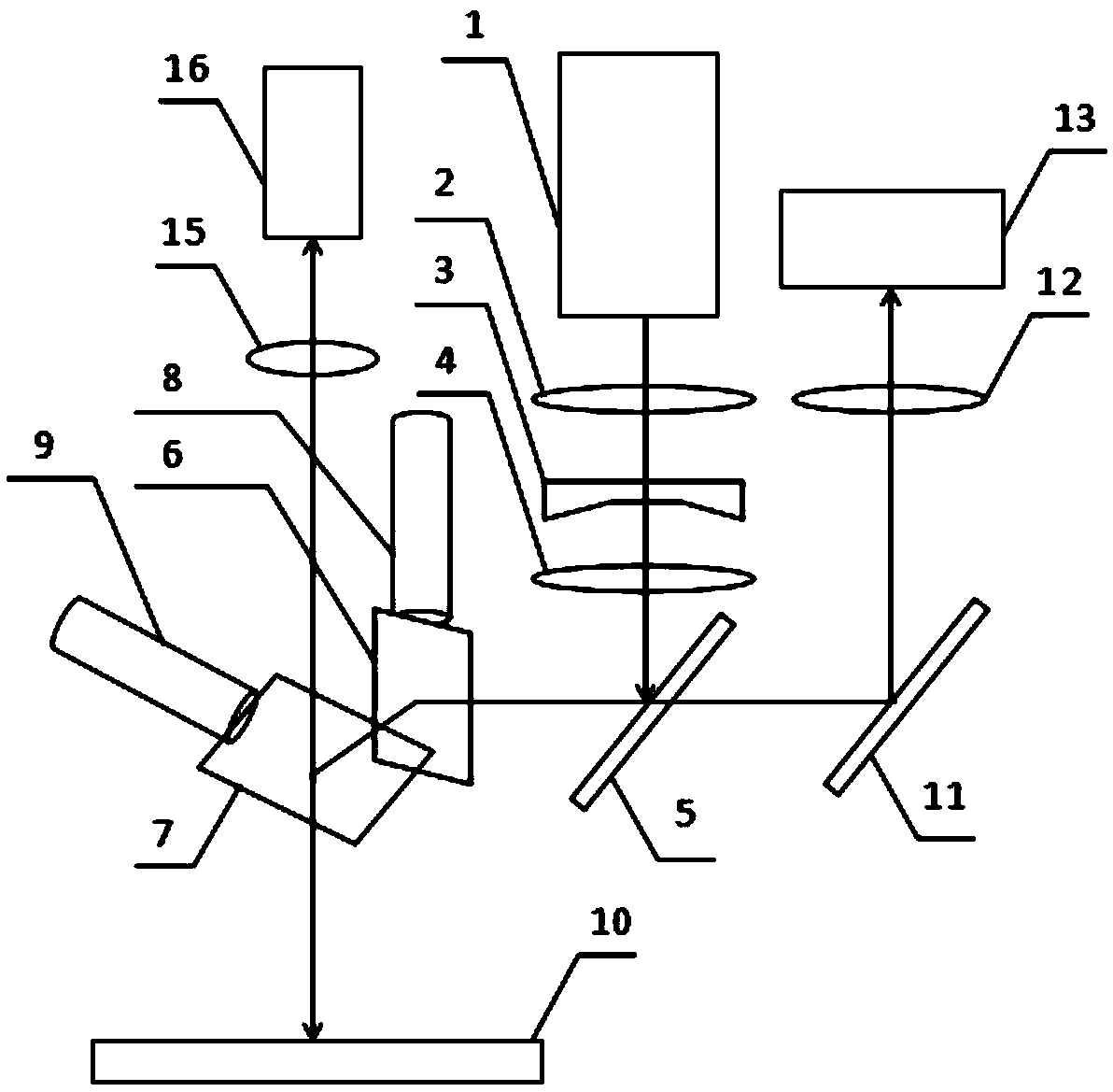

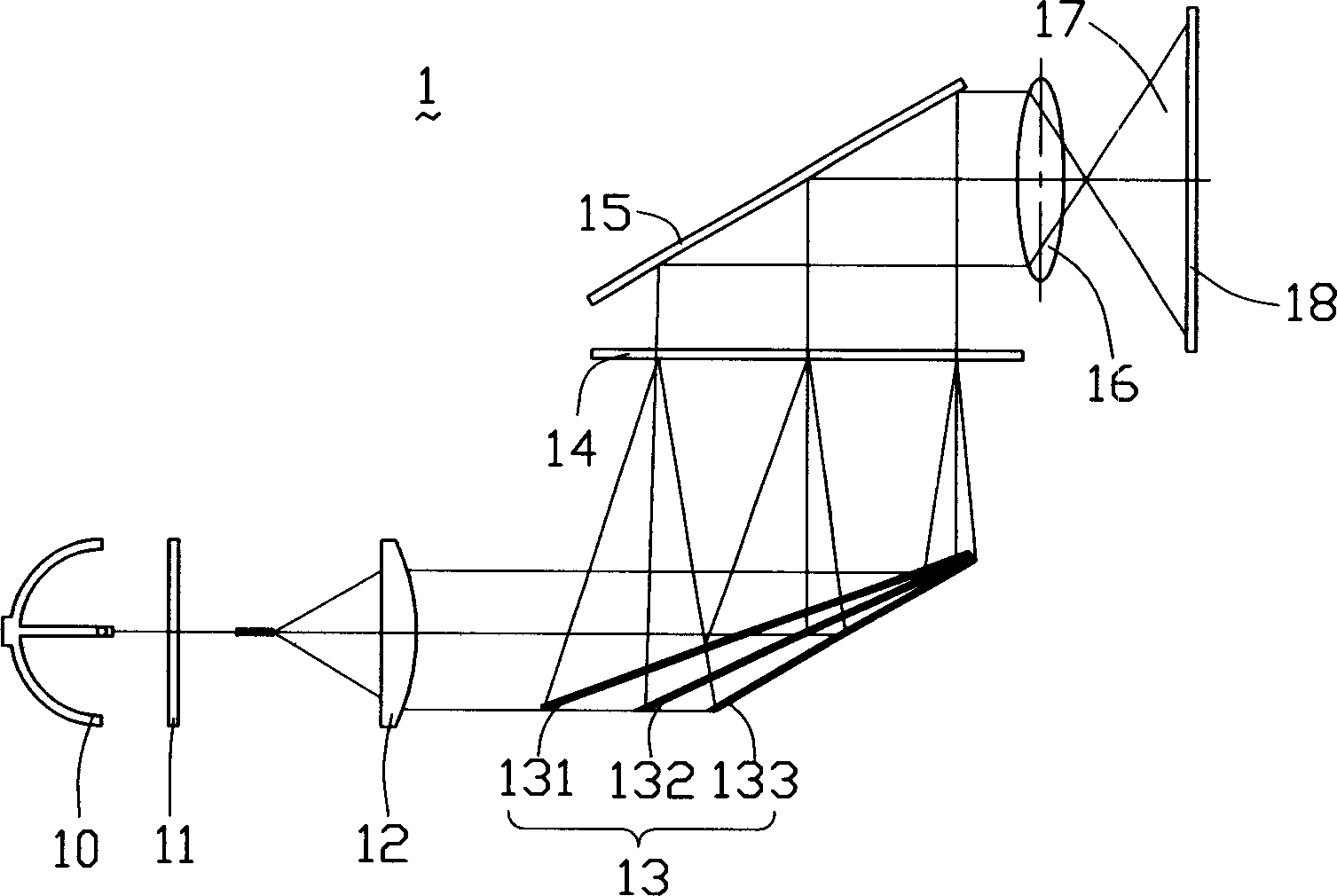

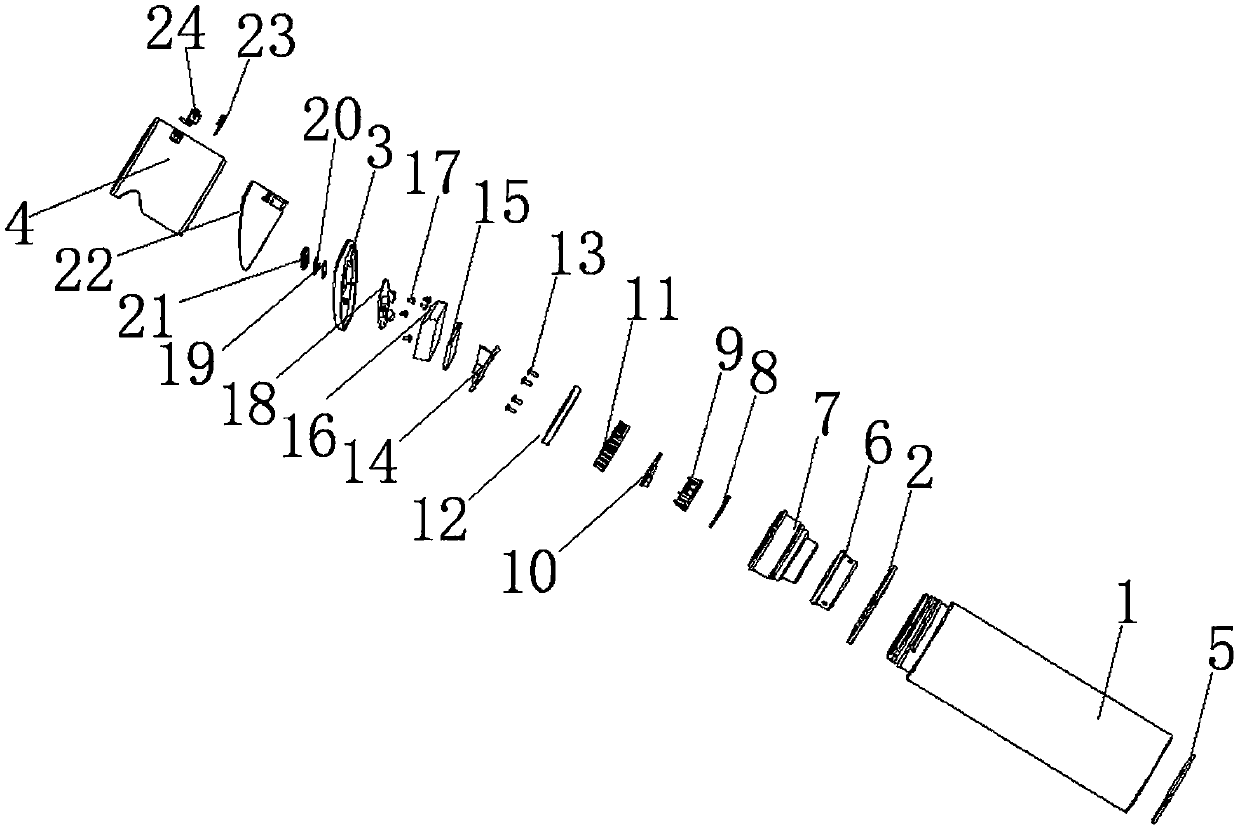

Integrated laser cleaning photoelectric system

PendingCN108723012AEasy to controlHigh precisionColor/spectral properties measurementsCleaning processes and apparatusLaser beam guideOpto electronic

The invention relates to an integrated laser cleaning photoelectric system. The system comprises a laser device used for emitting a laser beam for cleaning, an online monitoring assembly used for monitoring the laser cleaning process online, a spectral analysis assembly used for analyzing product components in the laser cleaning process, and an optical assembly used for guiding the laser beam of the laser device to be emitted to the surface of a to-be-cleaned sample. The optical assembly can simultaneously guide spectral signals radiated outwards from the surface of the to-be-cleaned sample tobe emitted to the online monitoring assembly and the spectral analysis assembly. The integrated laser cleaning photoelectric system can be used for online monitoring of the laser cleaning process andonline analysis of additional products, so that accurate control over the laser cleaning process is achieved, and the purpose of high-precision and high-efficiency laser cleaning is achieved.

Owner:深圳市汇泽激光科技有限公司

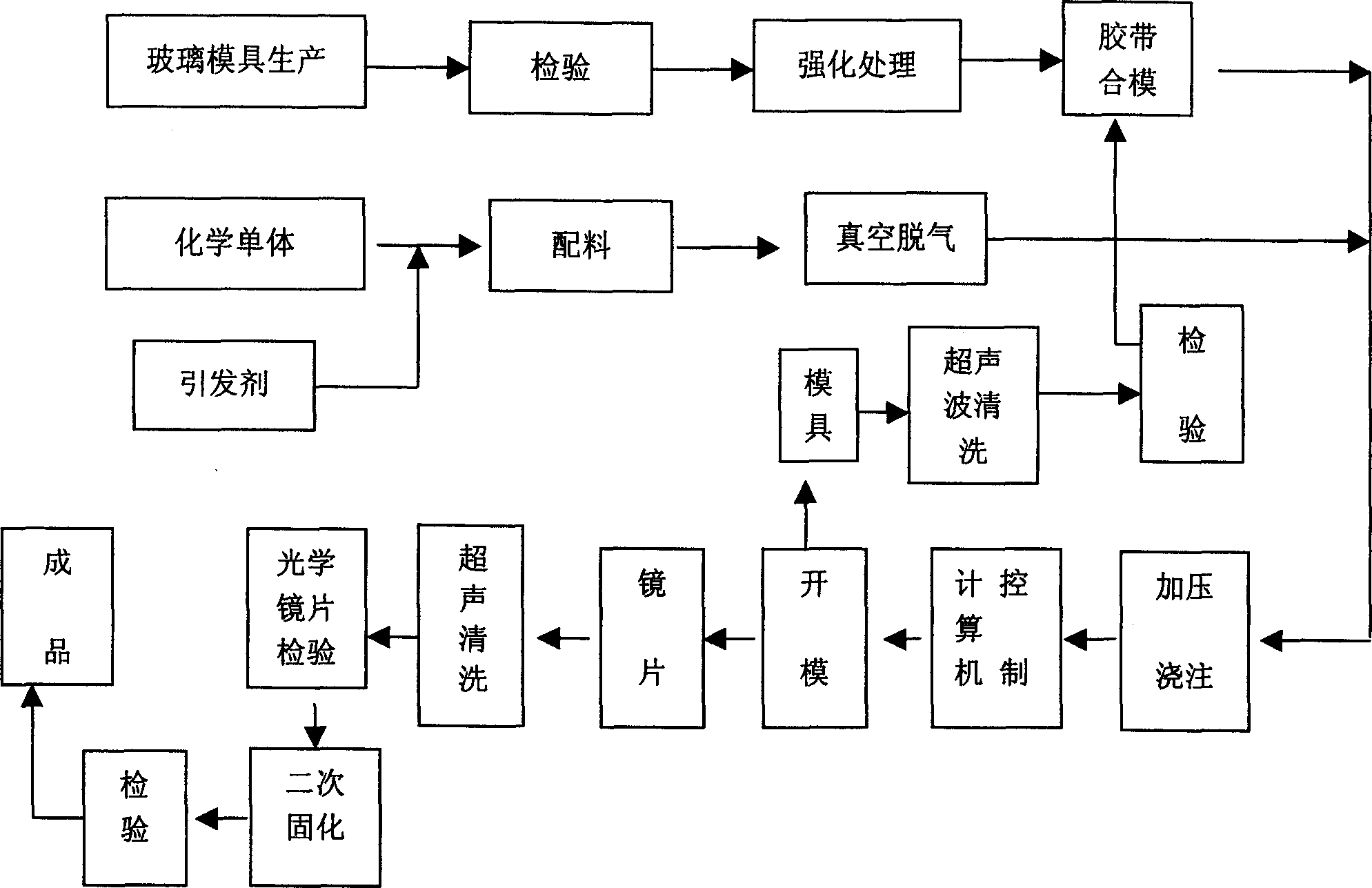

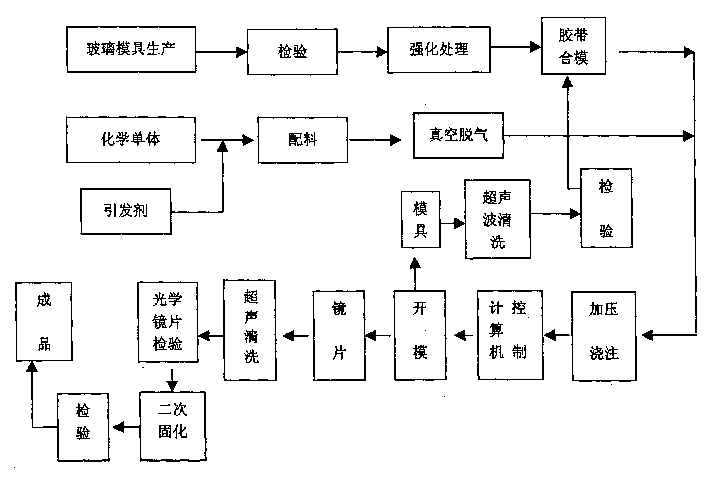

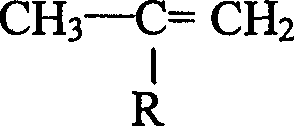

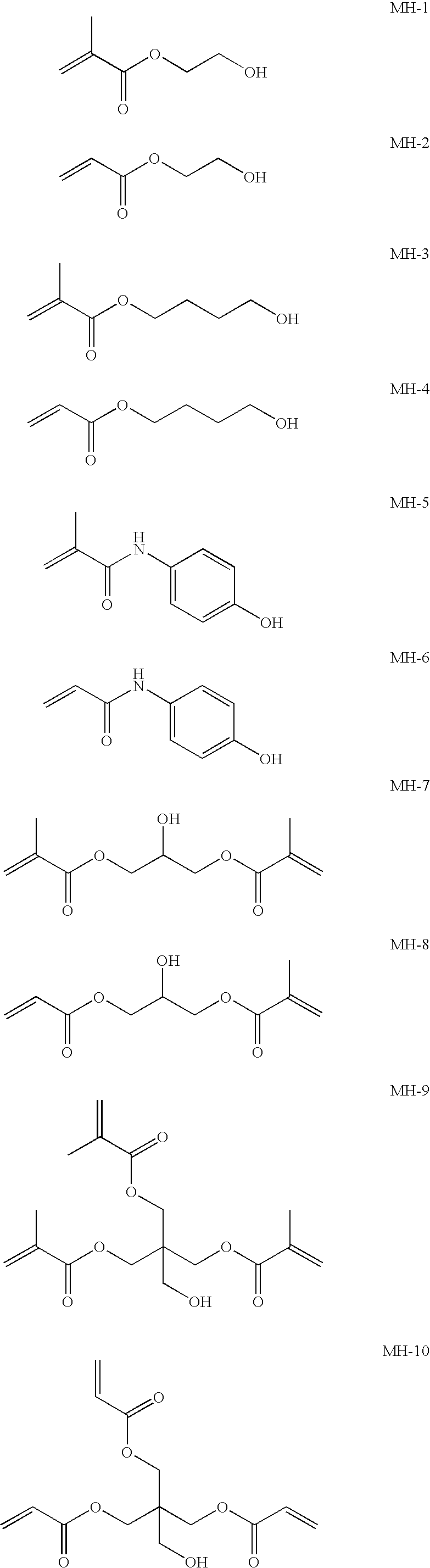

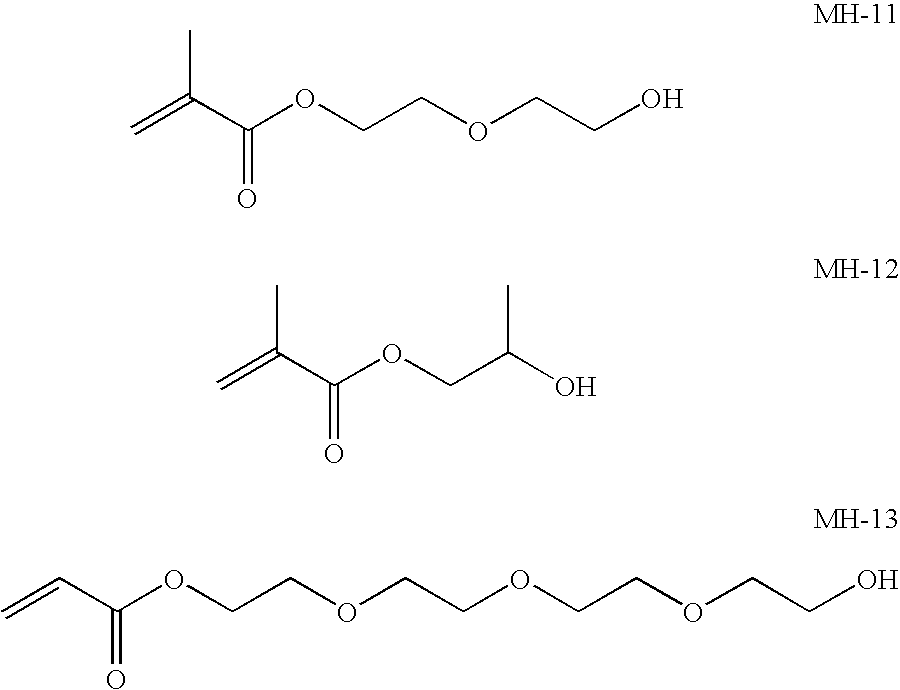

Manufacture of superthin high-refractivity optical resin lens

InactiveCN1548285AAvoid thermal effectsSolve the error of optical surface shape variationOptical articlesTemperature controlRefractive index

The manufacture process of superthin high-refractivity optical resin lens includes the following steps: making mold, reinforcing treatment and closing mold with tape machine; weighing chemical monomer and initiator, mixing and vacuum deairing; depositing the mixture in the mold, curing to form, demolding and cleaning. The present invention features the chemical monomer with one kind of alkenyl radical containing organic compound additive, the initiator being tert-butyl peroxide, the ratio among the chemical monomer, the additive and the initiator of 100 to 0.1-0.3 to 0.7-0.9, computerized temperature control during the polymerization, and the secondary curing of lens after demolding and cleaning. The present invention eliminates the lens profile variation caused by the polymerization and raises the optical precision of the lens.

Owner:SHANGHAI CONANT OPTICS CO LTD

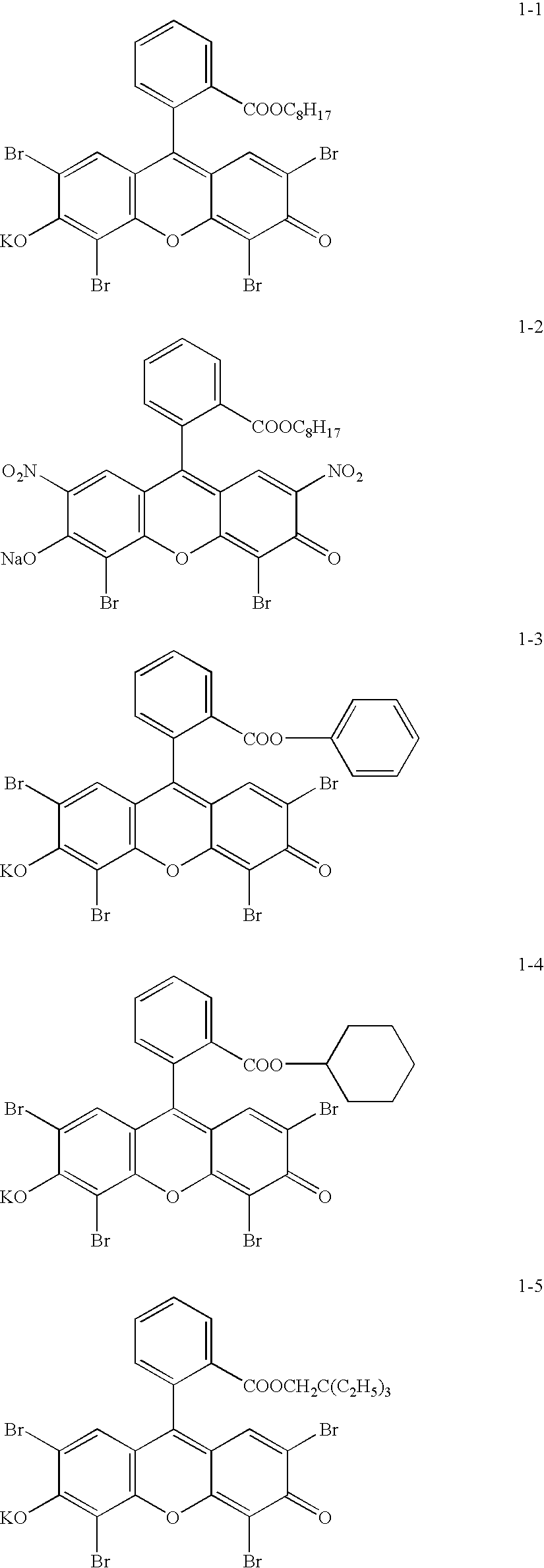

Light sensitive composition and light sensitive planographic printing plate precursor

InactiveUS6890702B2Improve optical precisionHigh density recordingPhotosensitive materialsSemiconductor/solid-state device manufacturingDouble bondPlanographic printing

Disclosed are a light sensitive composition containing A) an addition polymerizable ethylenically double bond-containing monomer, B) a photopolymerization initiator, and C) a polymer binder, wherein the addition polymerizable ethylenically double bond-containing monomer is a reaction product of a tertiary amine having two or more hydroxyl groups in the molecule, a diisocyanate having an aromatic ring in the molecule and a compound having a hydroxyl group and an addition polymerizable ethylenically double bond in the molecule, and a light sensitive planographic printing plate precursor comprising the light sensitive composition.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Method of regenerating diffraction signals for optical metrology systems

InactiveUS8570531B2Improve optical precisionMaterial analysis by optical meansUsing optical meansLight beamComputational physics

Owner:TOKYO ELECTRON LTD

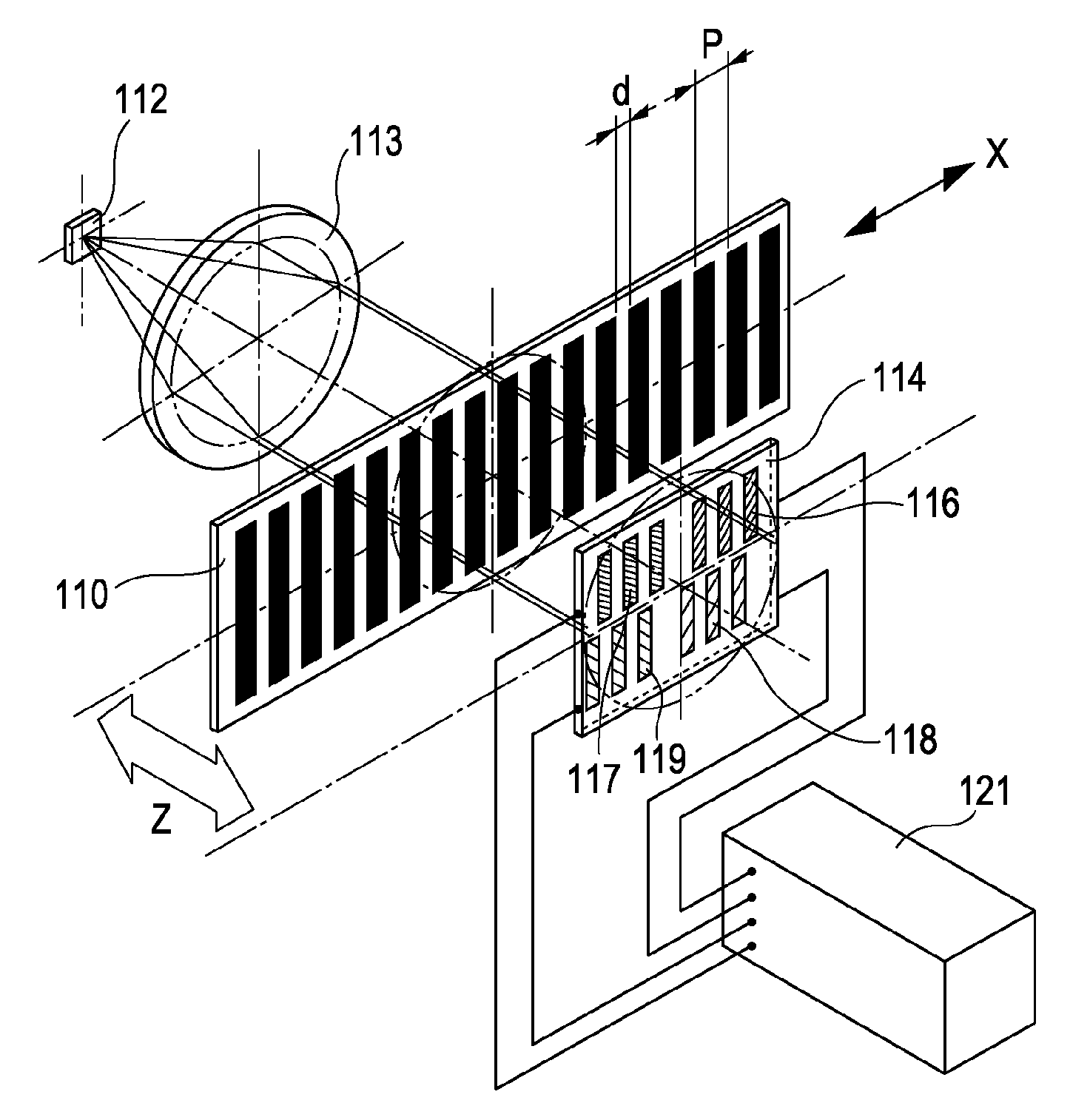

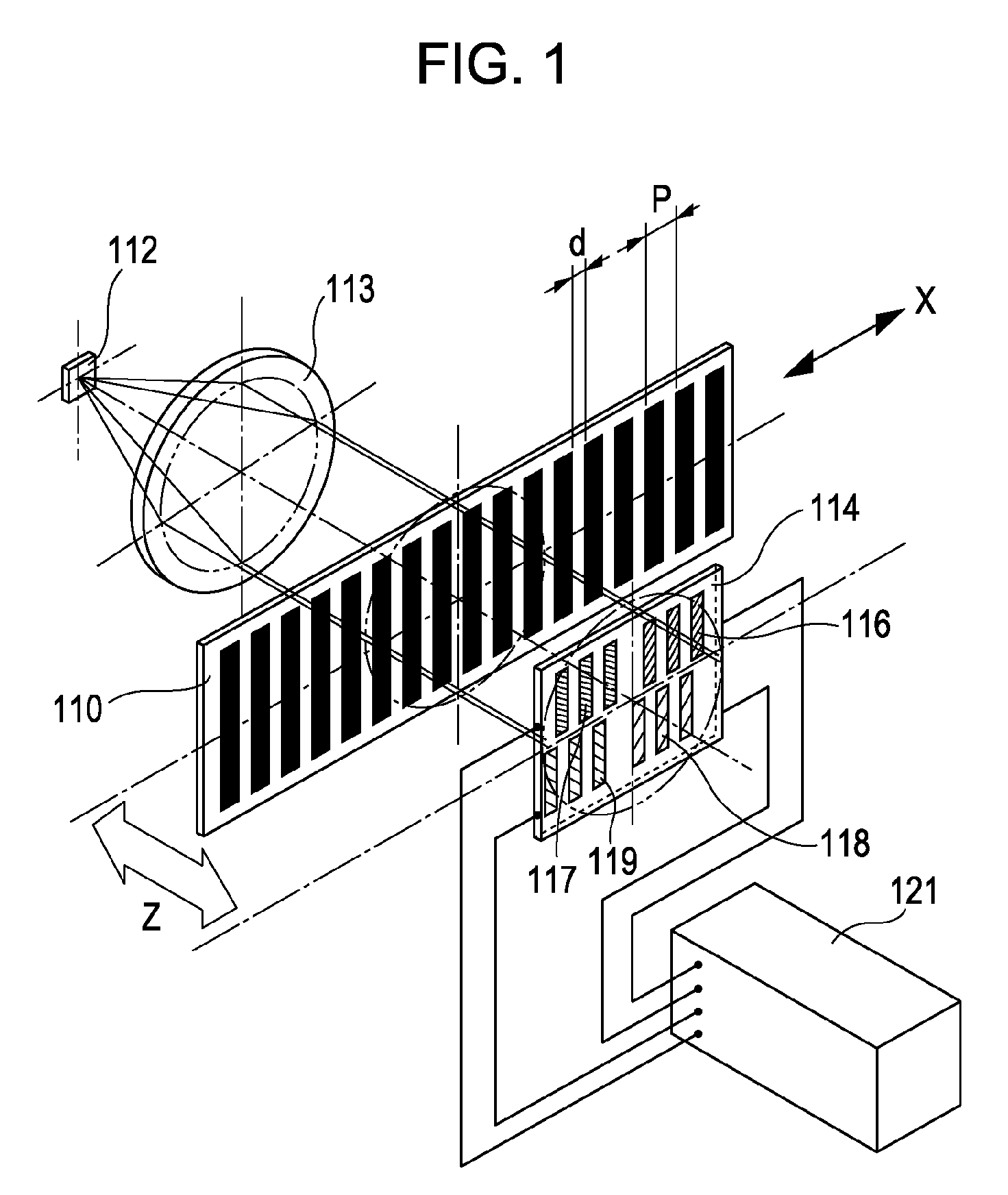

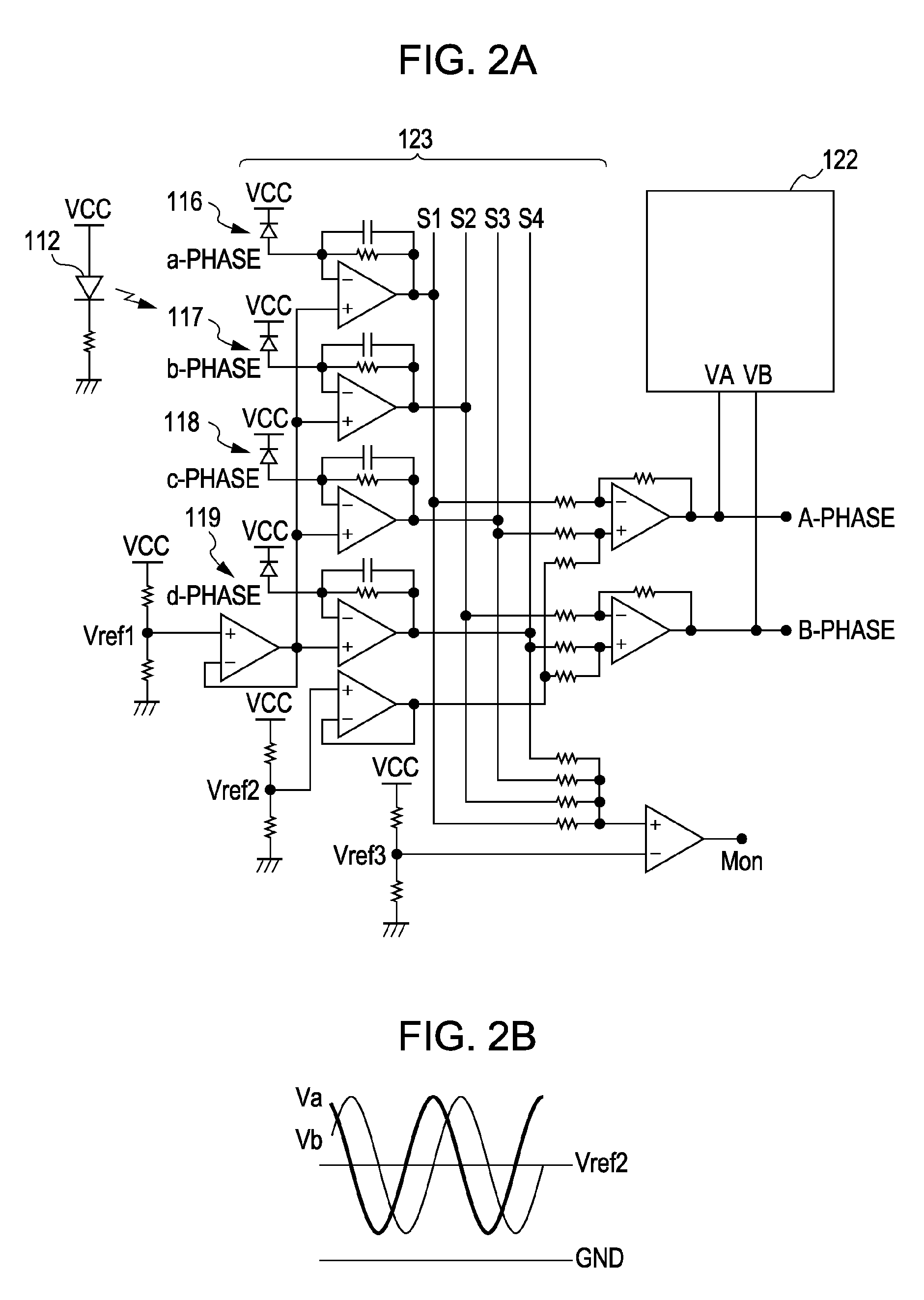

Optical encoder for measuring displacement

InactiveUS7385179B2Reducing high-order harmonic distortion componentImprove optical precisionMaterial analysis by optical meansUsing optical meansAperture ratioSpatial frequency

At least one exemplary embodiment is directed to an optical encoder which includes a first diffraction grating having a desired optical effective aperture ratio at an appropriate gap position so as to eliminate and / or reduce high-harmonic components from the light intensity distribution of interference fringes and reduce high-order spatial frequency components overlapped on a displacement signal of the interference fringes formed by the first diffraction grating.

Owner:CANON KK

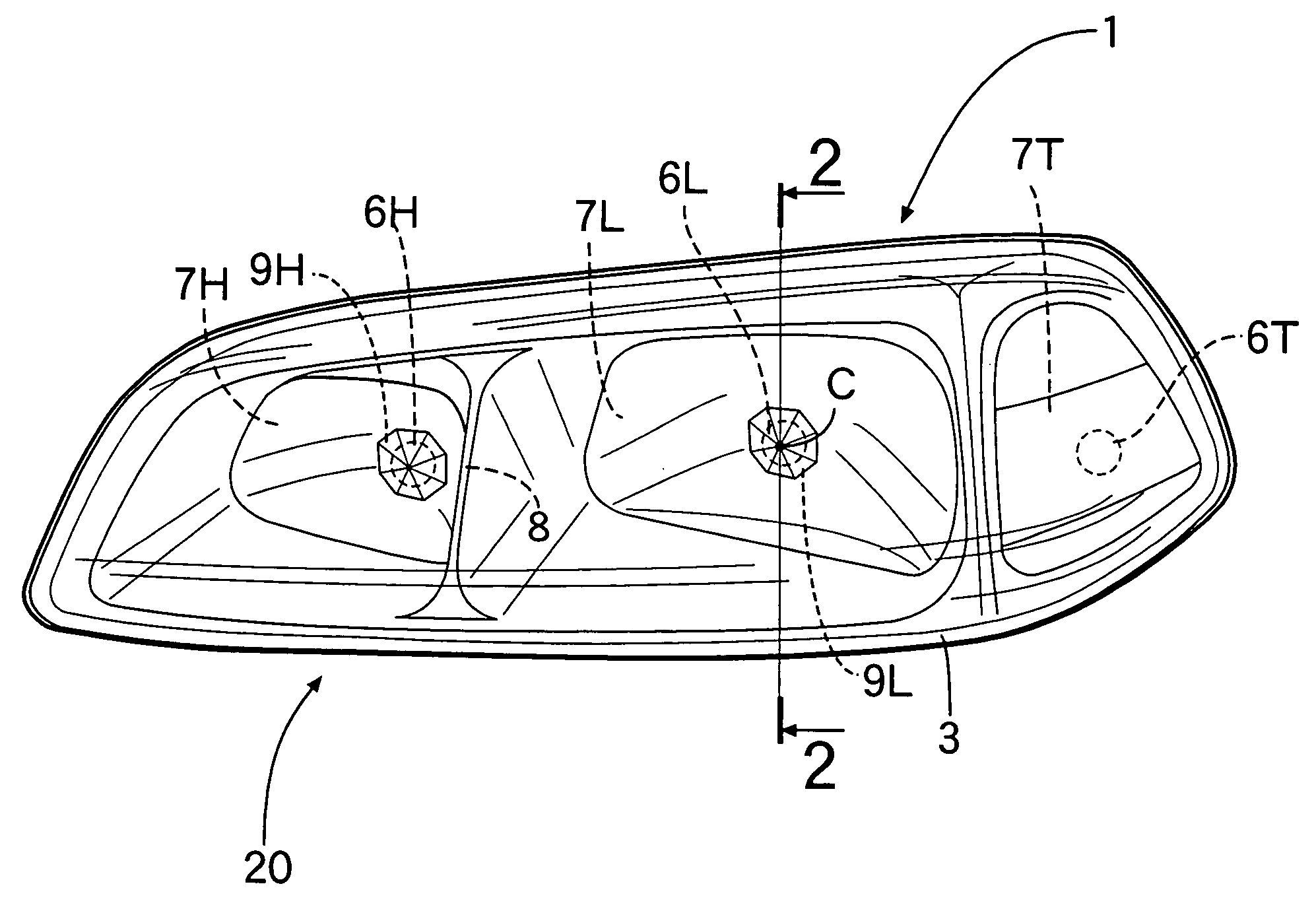

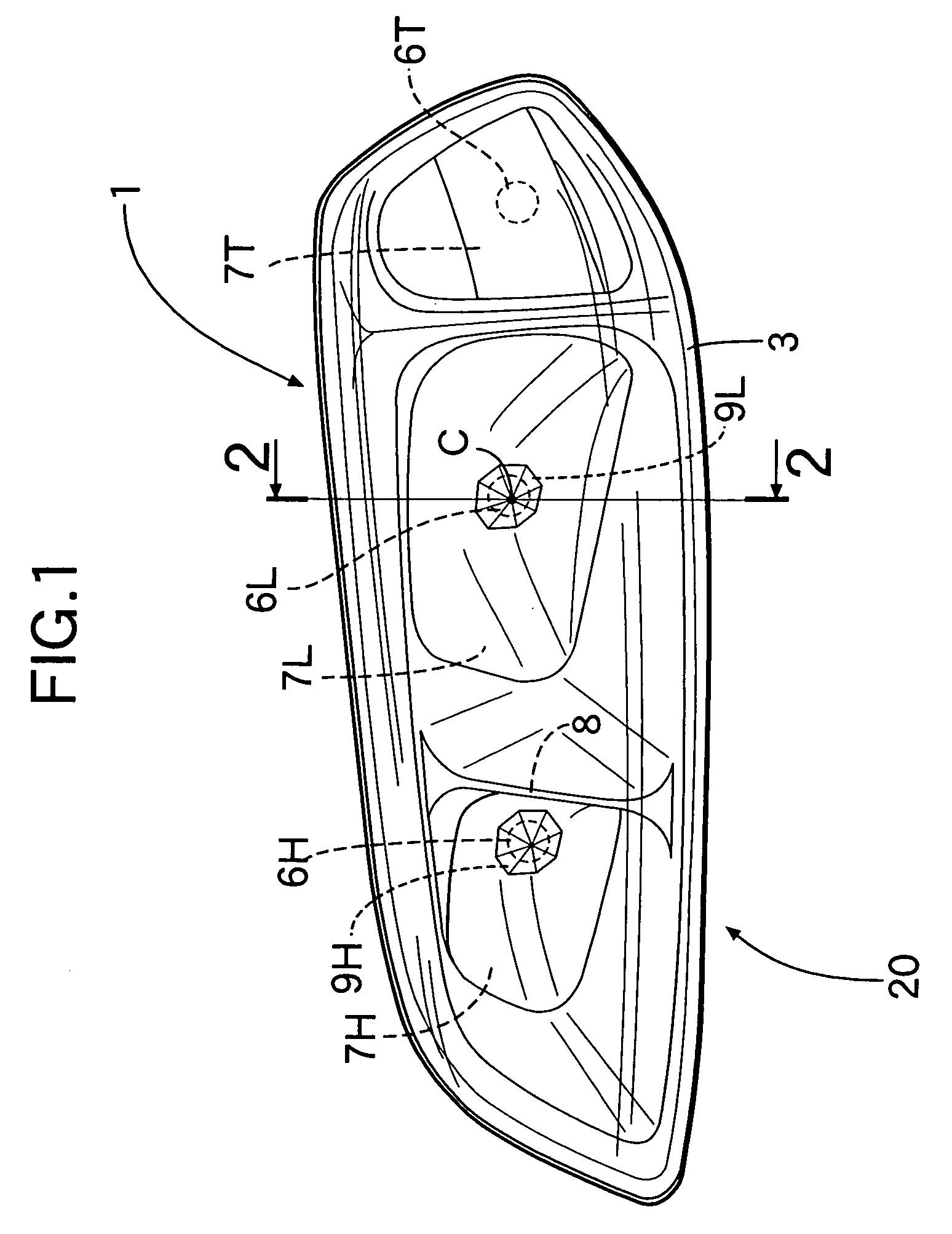

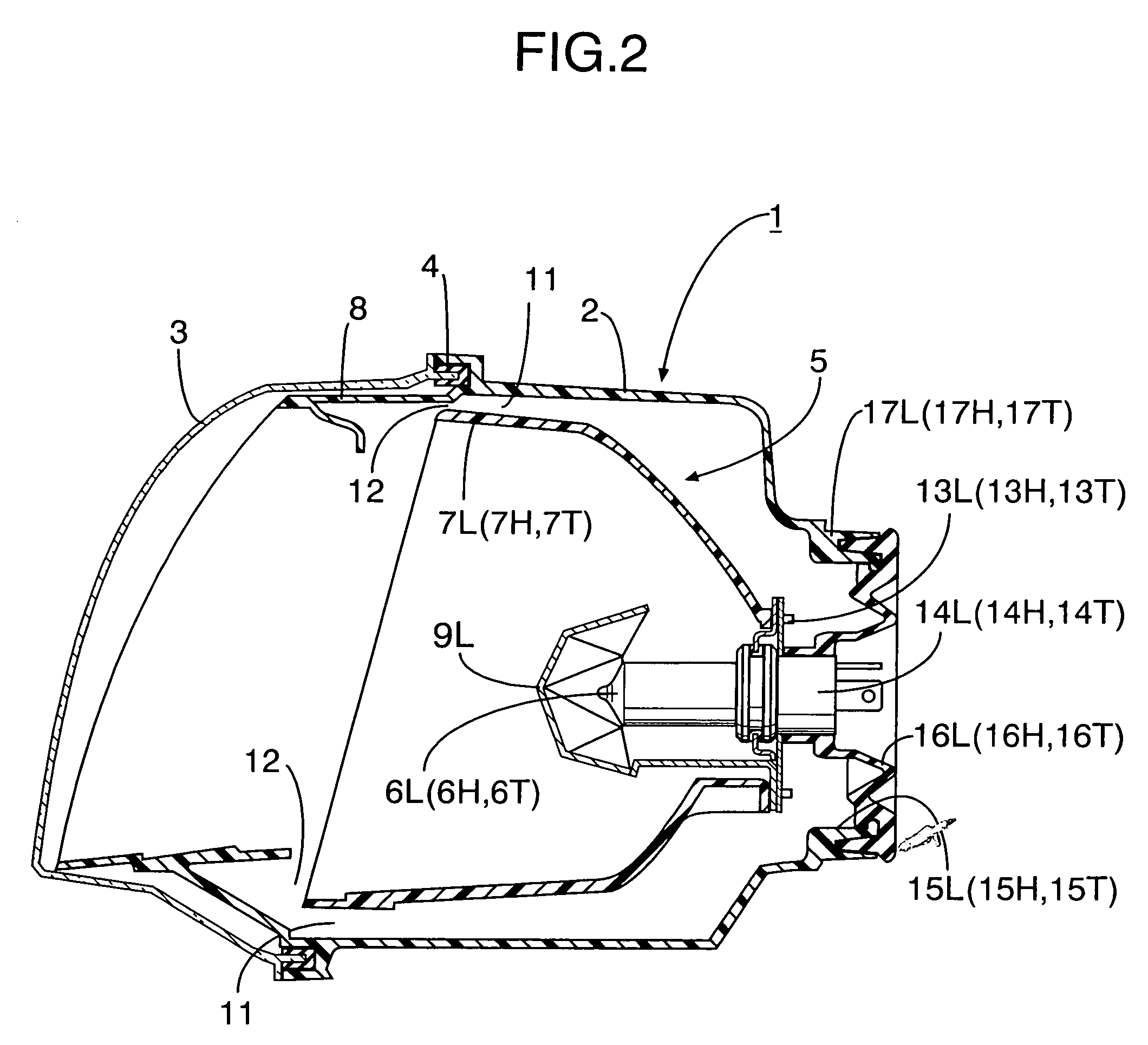

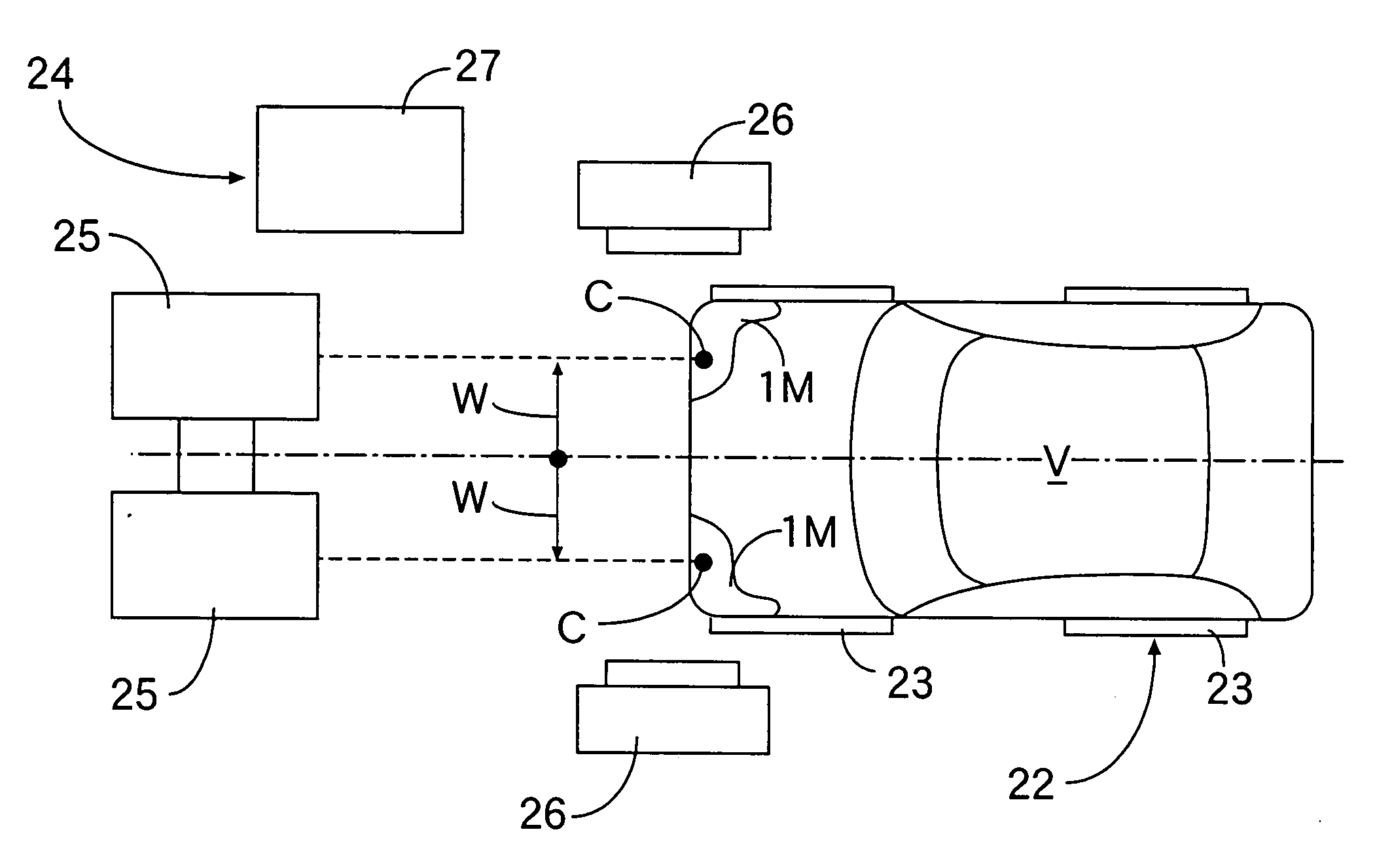

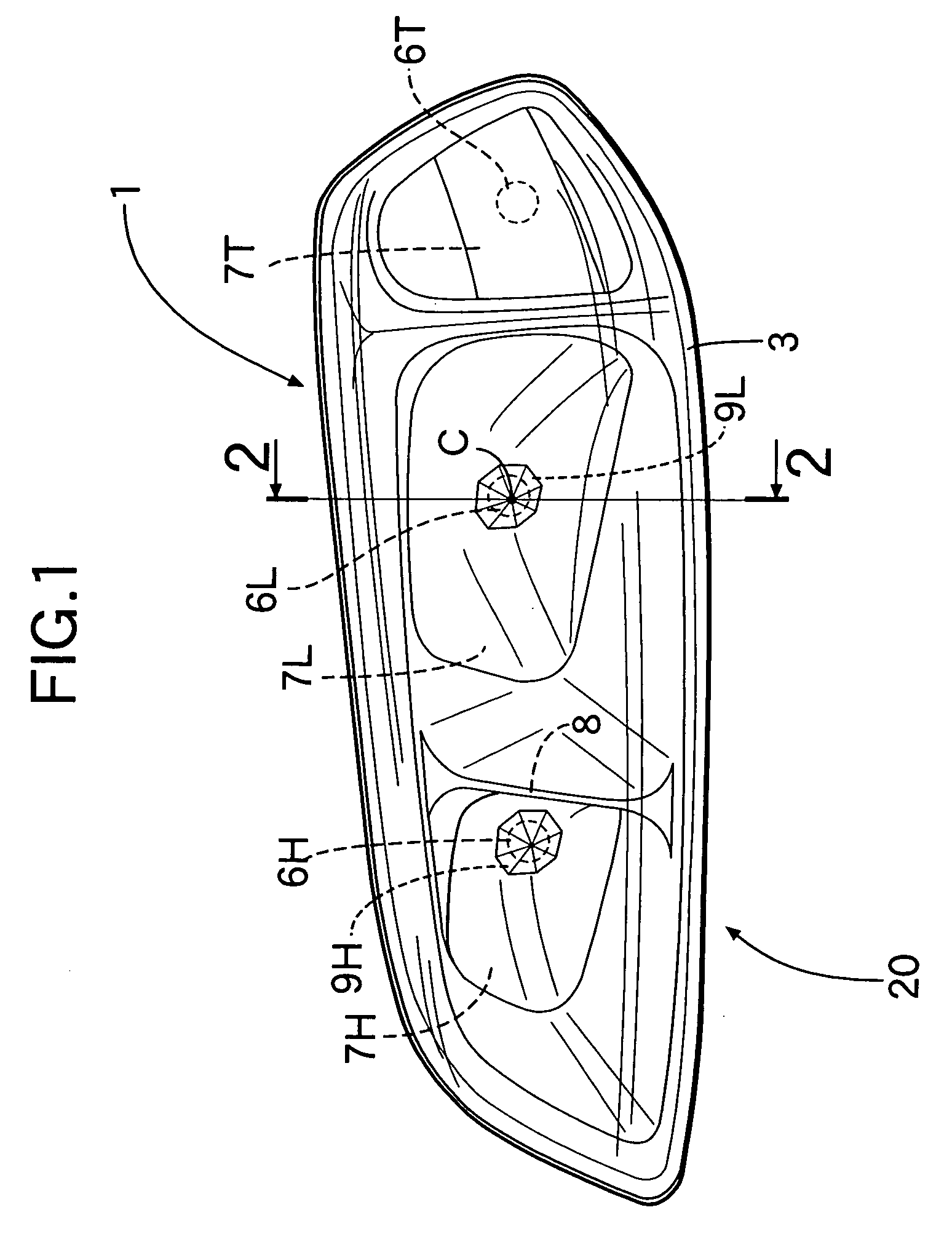

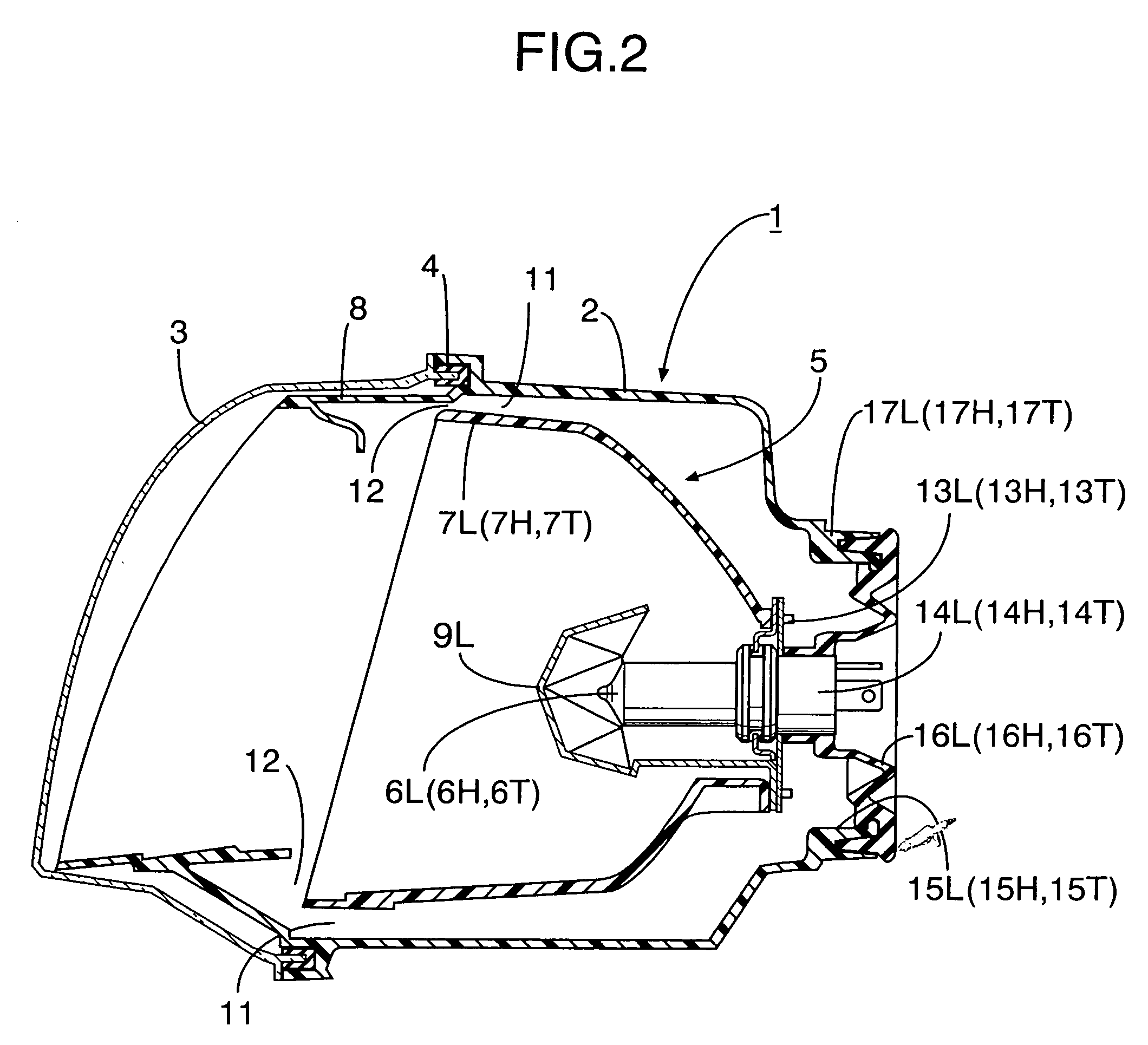

Headlamp optical axis adjusting method

InactiveUS7275847B2High precisionImprove optical precisionNon-electric lightingPoint-like light sourceOptical axisDistribution pattern

A headlight optical axis adjustment method where, on an imaged picture of a light distribution pattern of low beam illumination from a master headlight whose optical axis has been adjusted, a relative positional relationship between a horizontal and oblique line of a light / dark boundary line. A reference point is determined on the imaged picture to correspond to a bulb center. An acceptance frame is set based on an imaged position of an intersection of the horizontal and oblique line. On an imaged picture of a light distribution pattern of low beam illumination from a headlight to be adjusted, a horizontal and oblique line of a light / dark boundary line are detected based on a relative positional relationship with the reference point, and the optical axis of the headlight to be adjusted is adjusted so that an intersection of the detected horizontal and oblique lines is within the acceptance frame.

Owner:HONDA MOTOR CO LTD

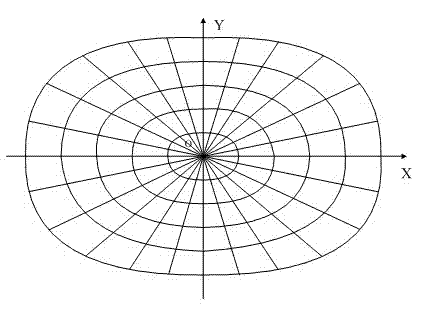

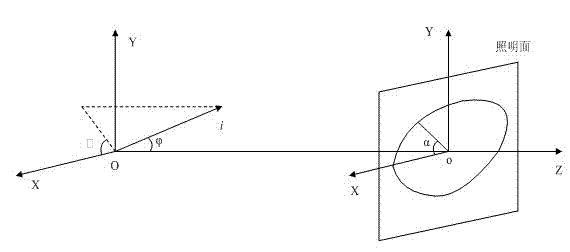

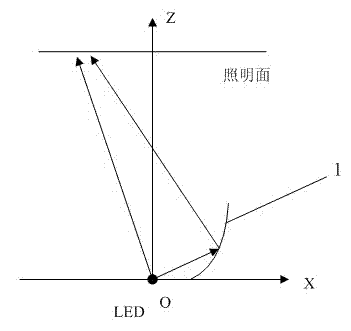

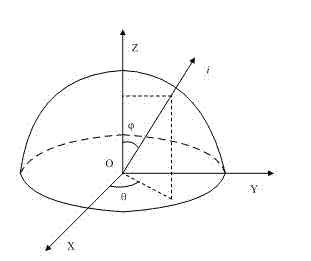

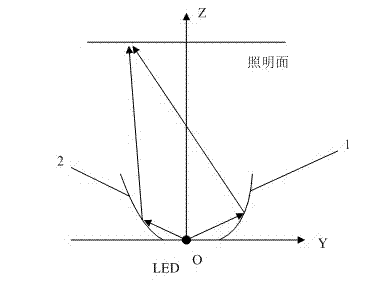

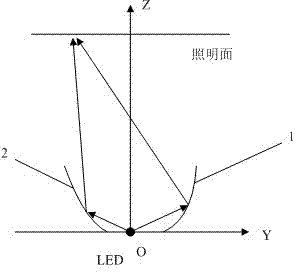

Free-form optical reflector for LED (light-emitting diode) motorcycle high beam

ActiveCN102777857AReduce volumeReduce glare effectsPoint-like light sourceRoad vehiclesOptical reflectionFree form

The invention discloses a free-form optical reflector for an LED (light-emitting diode) motorcycle high beam, wherein an internal surface of the reflector is a free-form surface to form an optical reflecting surface; the bottom surface of the reflector is an opening; an LED light source is installed at the centre of the opening; one end rightly facing the bottom surface is a light exit port of the reflector; the minority of light emitted by the LED light source directly shines on an illuminating surface, and the majority of the light is reflected by the internal surface of the reflector and then is emergent to the illuminating surface. The light energy emitted by the LED light source is emergent after being reflected by the freeform reflector, so that the loss is reduced and the utilization rate of light energy is improved. The reflector is small in size and has a low glare effect and meets the light distribution requirements in GB5948-1998. In addition, a heat-radiating device and the LED light source are conveniently installed, and the heat dissipation efficiency of the overall lamp is favorably improved.

Owner:SOUTH CHINA UNIV OF TECH

Headlamp optical axis adjusting method

InactiveUS20060239019A1Improve optical precisionHigh precisionNon-electric lightingLighting support devicesOptical axisDistribution pattern

A headlight optical axis adjustment method is provided in which, on an imaged picture of a light distribution pattern of low beam illumination from a master headlight whose optical axis has been adjusted, a relative positional relationship between a horizontal line (36a) and an oblique line (30b) of a light / dark boundary line (36), and a reference point (BP) determined on the imaged picture so as to correspond to a bulb center (C) is determined, and an acceptance frame (38) is set based on an imaged position of an intersection point (36c) of the horizontal line (36a) and the oblique line (36b); on an imaged picture of a light distribution pattern of low beam illumination from a headlight to be adjusted, a horizontal line and an oblique line of a light / dark boundary line are detected based on a relative positional relationship with the reference point (BP), and the optical axis of the headlight to be adjusted is adjusted so that an intersection point of the detected horizontal and oblique lines is present within the acceptance frame (38), thus enhancing the precision of the headlight optical axis adjustment.

Owner:HONDA MOTOR CO LTD

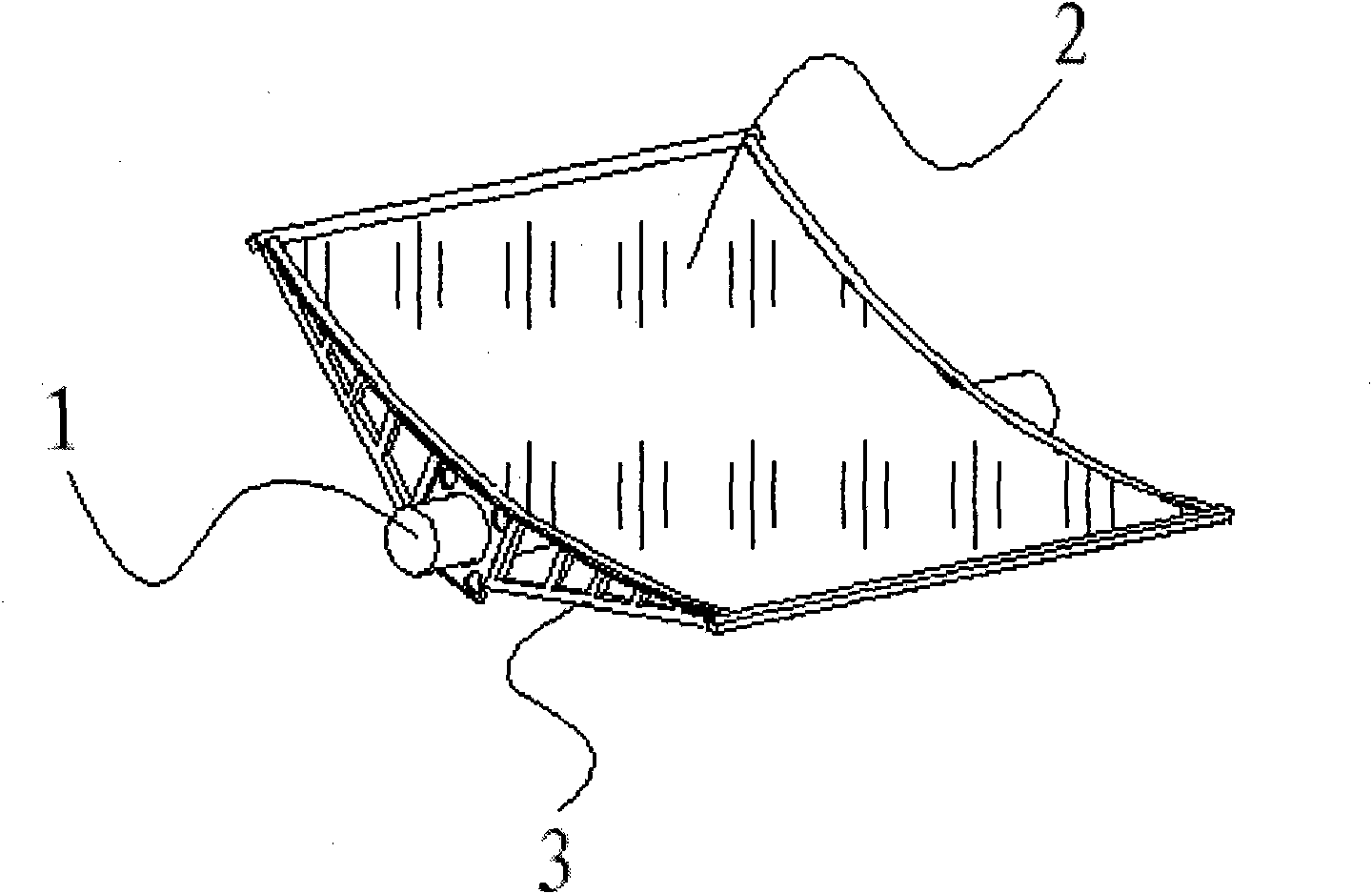

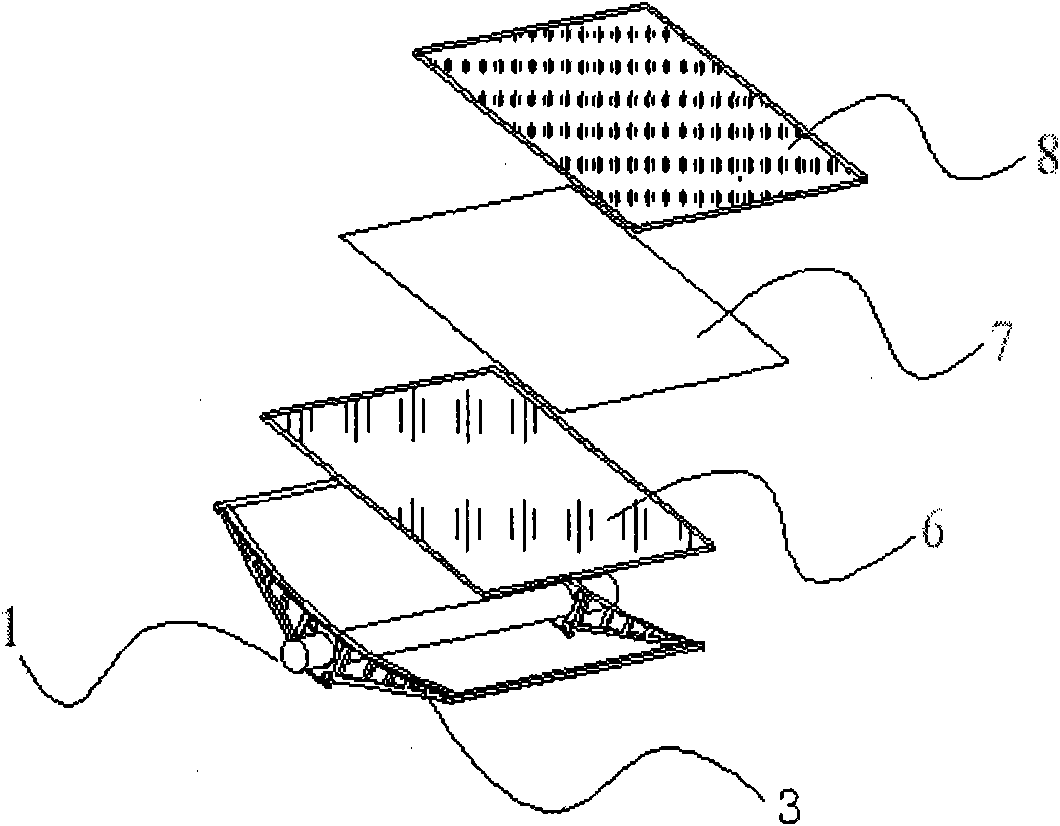

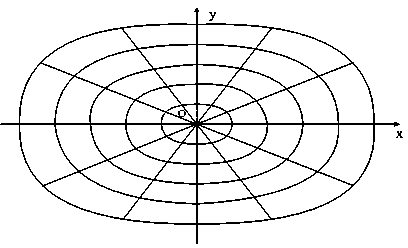

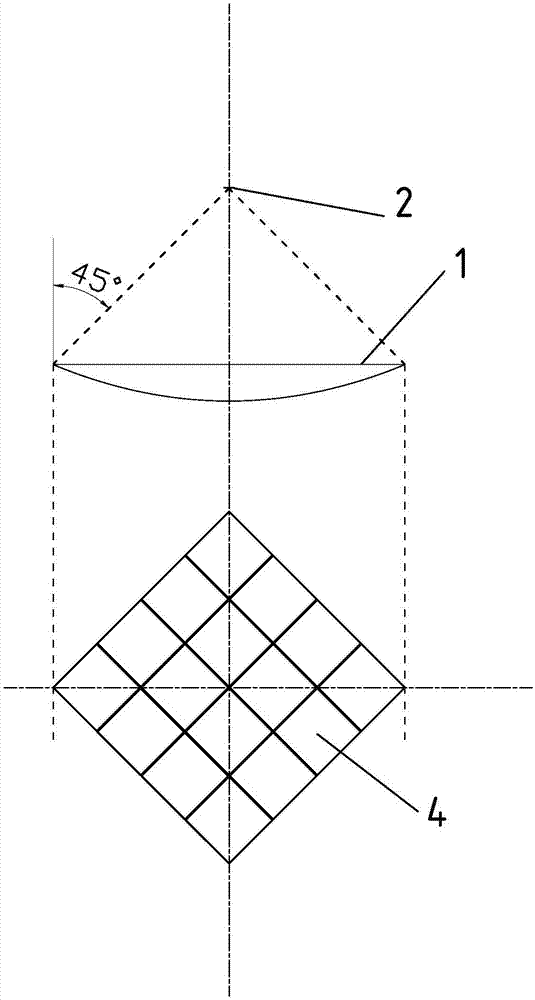

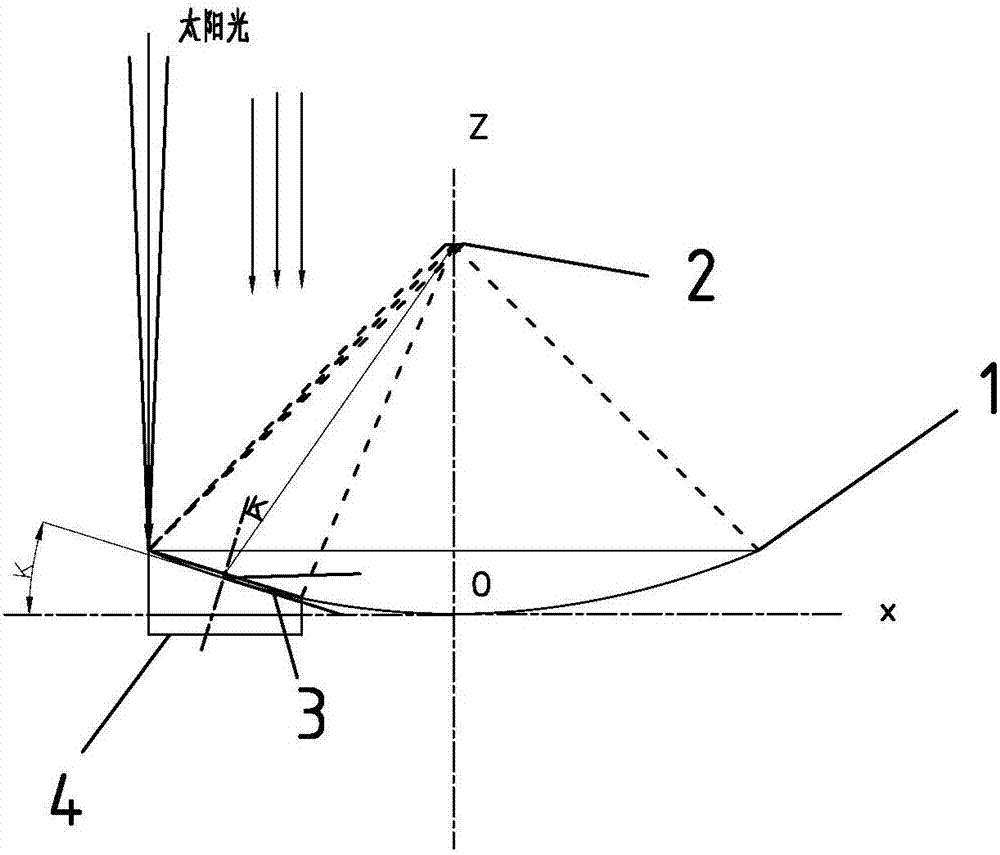

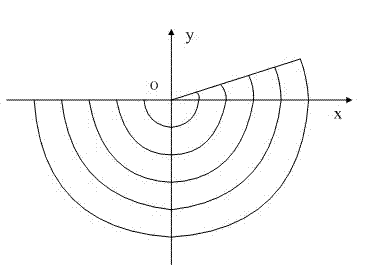

Solar energy disc-type collection lens system and design method thereof

The present invention discloses a solar energy disc-type collection lens system. The system comprises a solar energy disc-type collection lens and a heat absorber located near the focal plane of the solar energy disc-type collection lens, the solar energy disc-type collection lens is formed by splicing M spherical mirrors, the reflection surfaces of the spherical mirrors are quadrangle curved surfaces, the four vertexes of the quadrangle curved surfaces are located at the same paraboloid of revolution, and the orthographic projections of the M spherical mirrors on tangent planes passing through the vertexes of the paraboloid of revolution are square and have the same area. The present invention discloses the method of the solar energy disc-type collection lens system. The spherical mirrors with easy processing are processed to reduce the number of the reflection mirror units and the number of manufacturing dies, reduce the processing and manufacturing cost and improve the optical precision; the deformation errors are little and optics stability is high caused by the environment and other factors; and moreover, the light spot uniformity is high, and the shape is easy to regulate.

Owner:DALIAN GREAT OCEAN NEW ENERGY DEV

Image processing apparatus, image processing method, program, and recording medium

InactiveUS8441435B2Prone to inconsistencyImprove optical precisionImage analysisCathode-ray tube indicatorsViewpointsImaging processing

An image processing apparatus includes an input unit to which an image of an object picked up by an image pickup device is input, a display device on which the image is presented, an image presenting unit configured to present the image on the display device; a viewpoint detecting unit configured to detect a viewpoint position of a user, and a control unit configured to supply, to the image presenting unit, the image in an area extracted corresponding to an image frame of a display surface of the display device when the image is viewed through the display surface from the viewpoint position of the user detected by the viewpoint detecting unit.

Owner:SONY CORP

Mould for forming optical elements and the optical elements

ActiveCN1524813ADoes not increase the roughness of the forming surfacePrevents the roughness of the forming surface from increasingGlass pressing apparatusGlass press-moulding apparatusIridiumRhenium

The die is comprised of a die base material consisting of a sintered hard alloy or silicon carbide, a surface layer formed on the surface of the die base material and brought into contact with a glass material in press molding, and an intermediate layer formed between the die base material and the surface layer. The surface layer is formed from at least one element selected from among platinum, palladium, iridium, osmium, ruthenium, and rhenium or an alloy or compound containing these elements. The intermediate layer has a surface base material layer which consists of at least a substance selected from among tungsten, carbon, tungsten carbide, and silicon carbide, is in an amorphous state or in a crystalline state with a crystal grain diameter smaller than that of the substance constituting the die base material, and is brought into contact with the surface of the die base material.

Owner:OLYMPUS CORP

Free-form optical reflector for LED (light-emitting diode) motorcycle low beam

ActiveCN102777858AReduce volumeHigh precisionPoint-like light sourceRoad vehiclesOptical reflectionLight energy

The invention discloses a free-form optical reflector for an LED (light-emitting diode) motorcycle low beam, wherein an internal surface of the reflector is a free-form surface to form an optical reflecting surface; the bottom surface of the reflector is provided with an opening for installation of an LED; one end rightly facing the bottom surface is a light exit port of the reflector; the majority of light emitted by the LED light source is reflected by the internal surface of the reflector and then is emergent to an illuminating plane, and the other light is directly emergent to the illuminating plane. The reflector is divided into an upper part and a lower part; the free-form surface at the upper part of the internal surface of the reflector is mainly used for reflecting the light above a horizontal plane to the illuminating plane below the horizontal plane; the free-form surface at the lower part of the internal surface of the reflector is mainly used for gathering diffused light below the horizontal plane to the illuminating plane below the horizontal plane. The free-form optical reflector for the LED motorcycle low beam has the characteristics of simple structure, convenience in installation and high utilization rate of light energy; light direction can be effectively controlled and the glare effect can be inhibited; and the free-form optical reflector for the LED motorcycle low beam meets the light distribution requirements in GB5948-1998.

Owner:SOUTH CHINA UNIV OF TECH

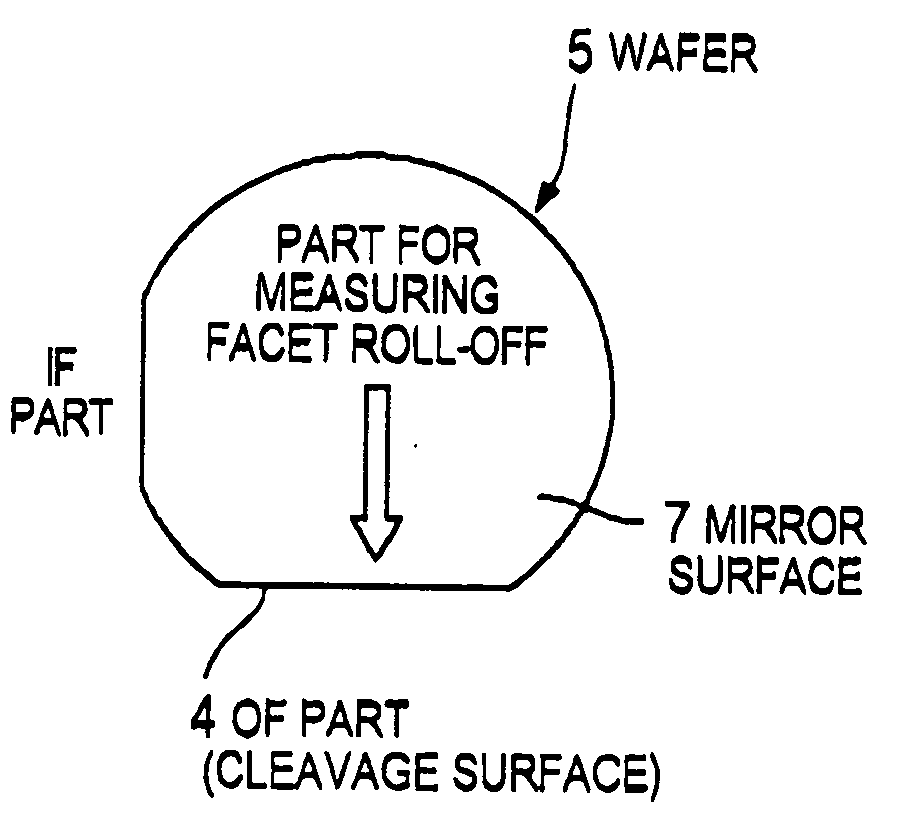

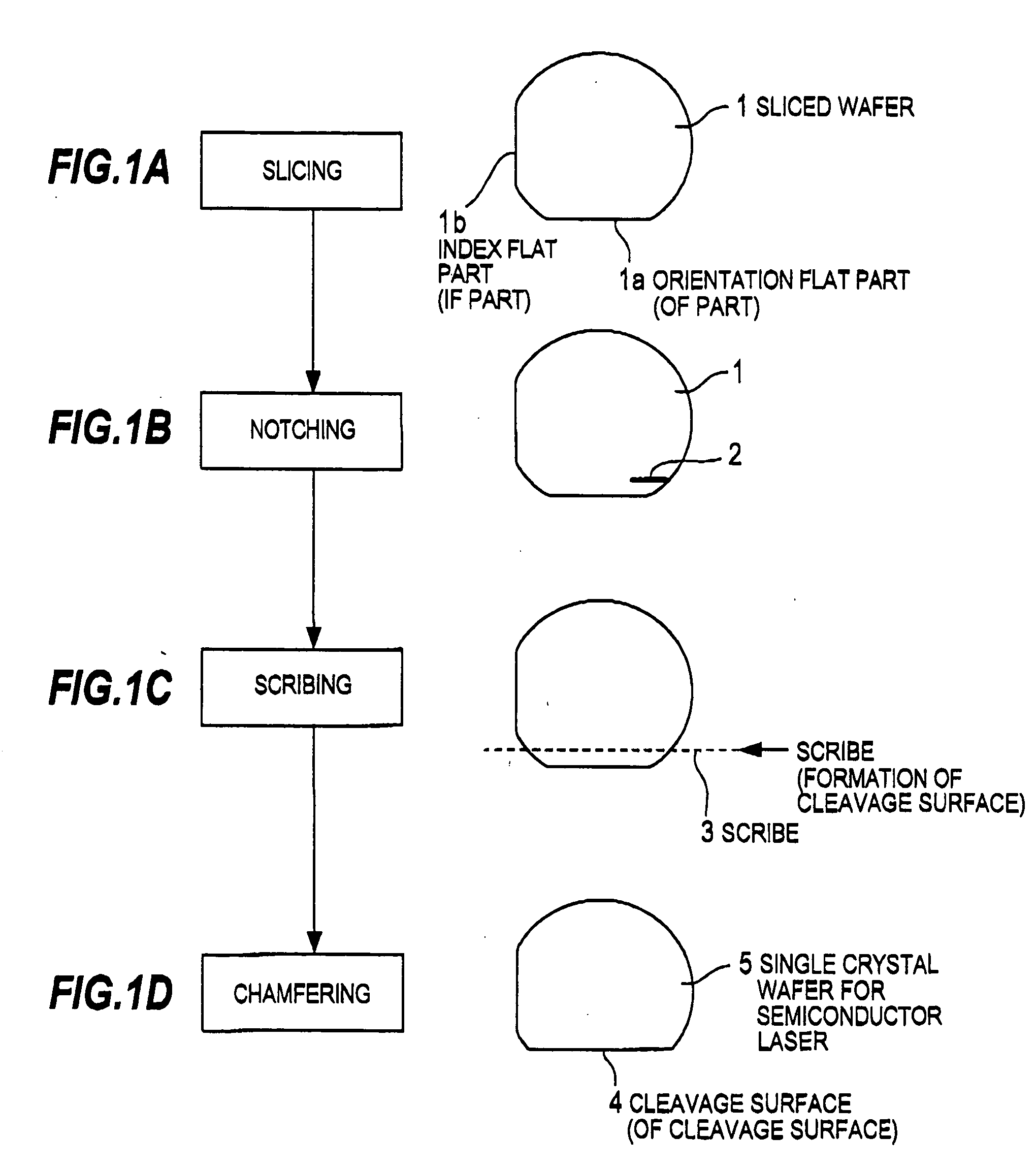

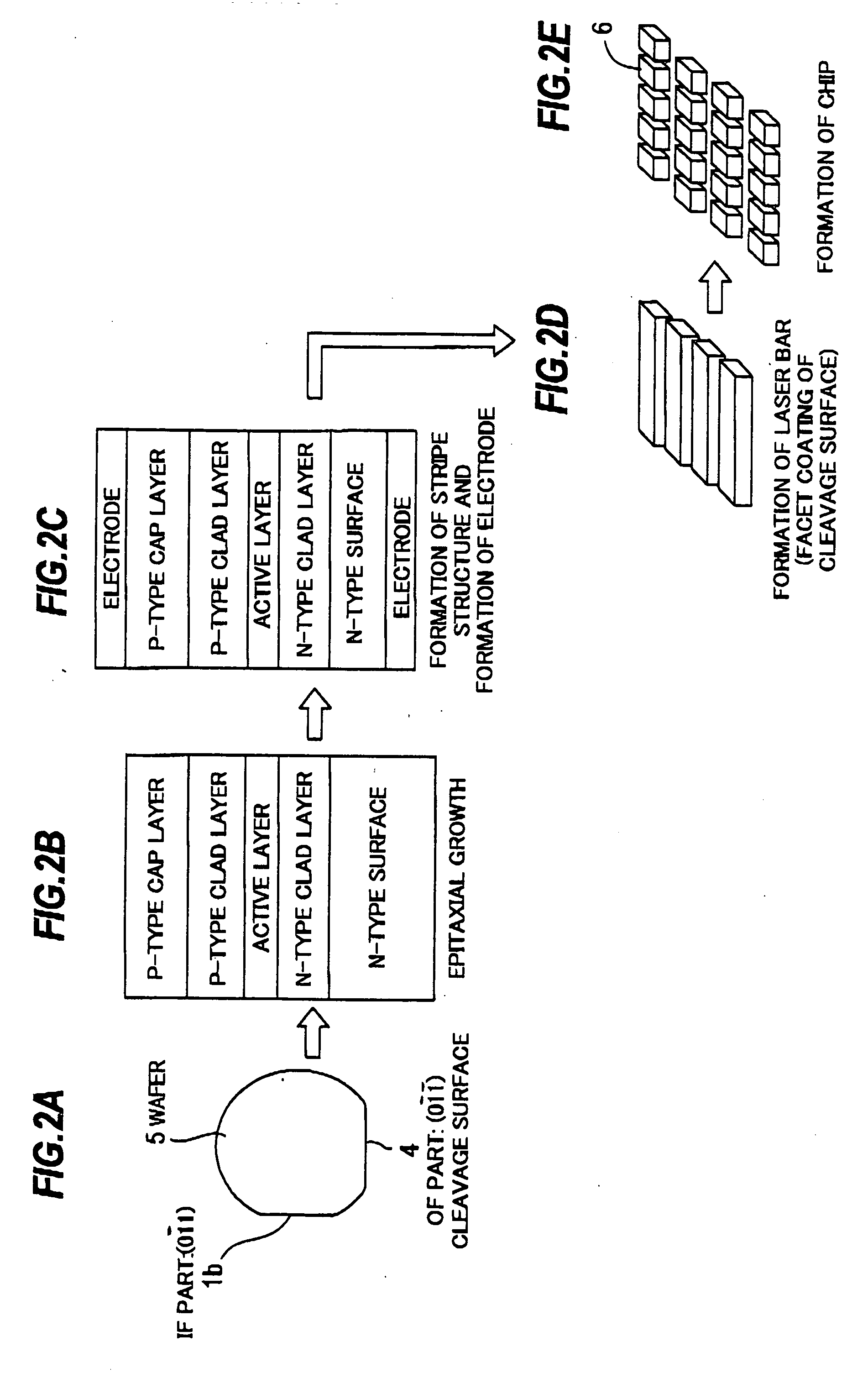

Single crystal wafer for semiconductor laser

InactiveUS20060169988A1Improve alignment accuracyImprove processing yieldAfter-treatment detailsLaser active region structureHardnessSingle crystal

A surface of the single crystal wafer 5 for semiconductor laser having an orientation flat formed by cleaving is polished by using the abrasive cloth 8 with high hardness under the optimized pressure for pushing the wafer and polishing rate, such that the polishing rate on the whole surface of the respective wafer 5 becomes uniform. The facet roll-off D occurred at a ridge of a cleavage surface 4 of the single crystal wafer 5 for semiconductor laser to be equal to or less than 40 μm. The single crystal wafer for a semiconductor laser of the present invention can provide an improvement in a precision of an optical alignment of mask pattern using the cleavage surface as a reference, and an improvement in process yield.

Owner:HITACHI CABLE

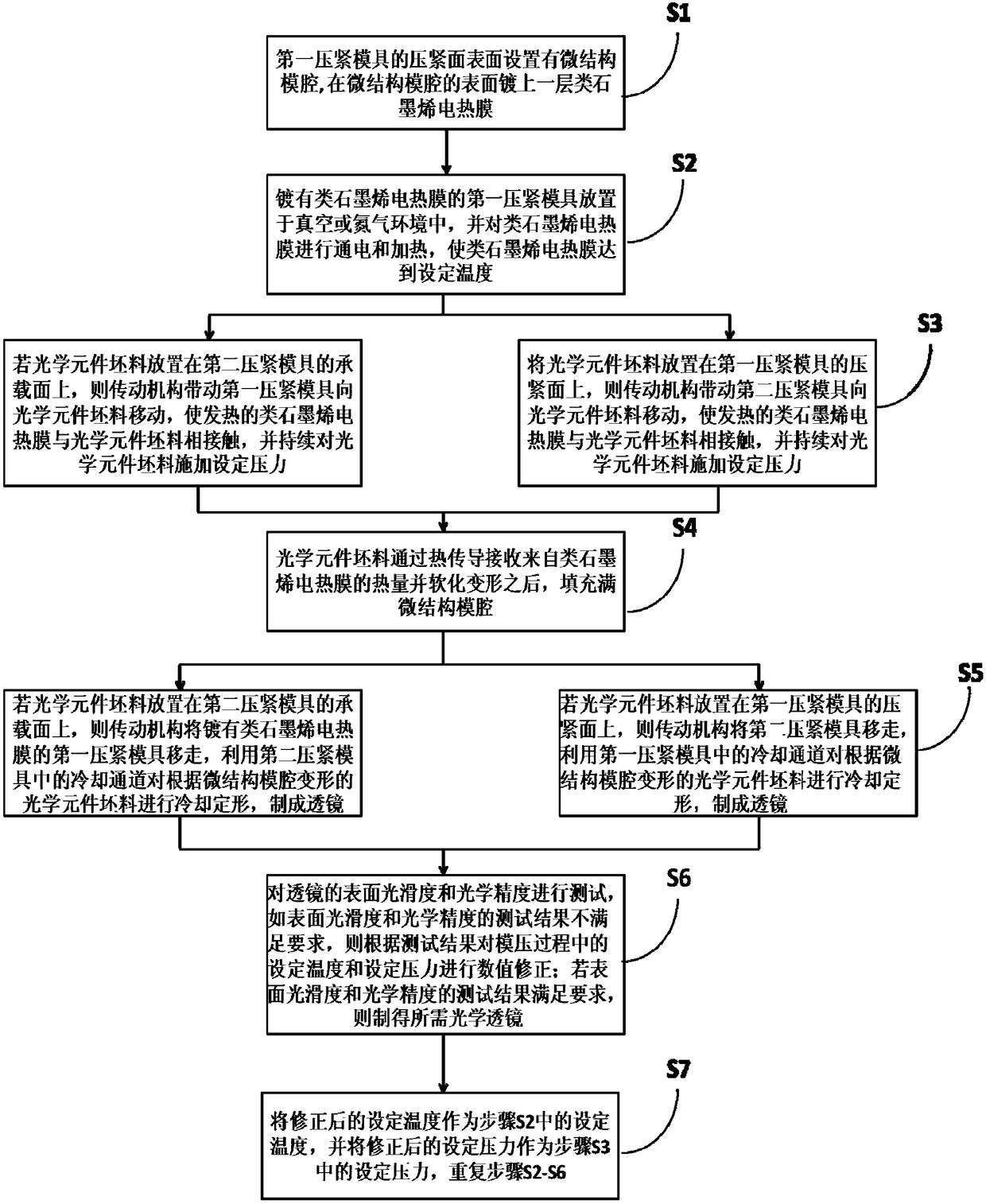

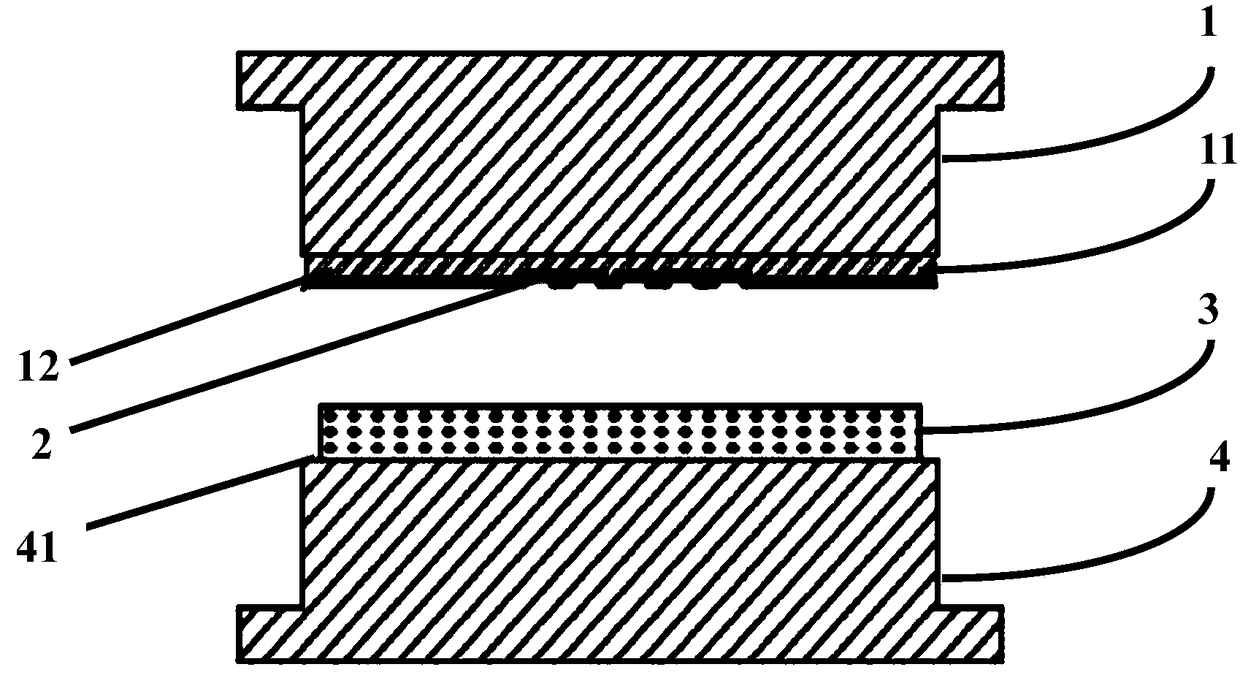

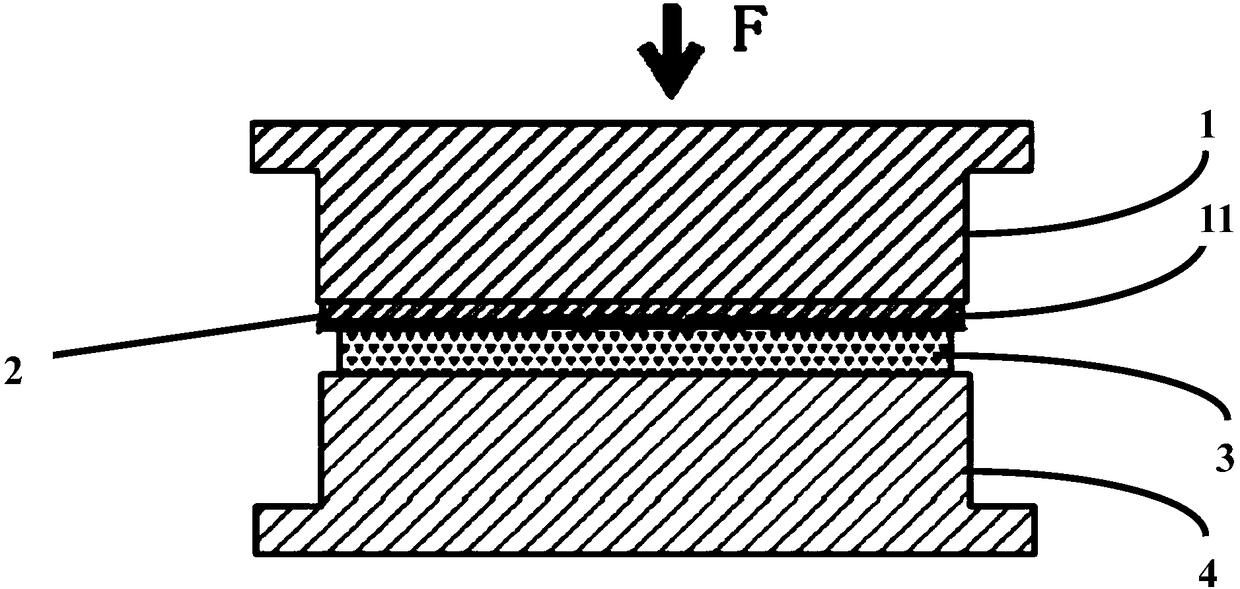

Optical element molding method based on graphene-like electrothermal film

ActiveCN109384372AReduce coefficient of frictionQuality improvementOptical articlesGlass reforming apparatusHigh energyGraphene

The invention provides an optical element molding method based on a graphene-like electrothermal film. The method includes the following steps: a surface of a pressing surface of a first pressing moldis provided with a microstructure mode cavity, and a surface of the microstructure mode cavity is plated with the graphene-like electrothermal film; the graphene-like electrothermal film is energizedand heated; the heat-generating graphene-like electrothermal film and an optical element blank material are contacted; after receiving the heat from the graphene-like electrothermal film by heat conduction and softening and deforming, the micro-structure mode cavity is filled with the optical element blank material; and the optical element blank material deformed according to the microstructure mode cavity is cooled and shaped by a cooling channel in a second pressing mold to form a lens. The method adopts the graphene-like electrothermal film for local heating, has high heating speed and high energy utilization rate, and the graphene-like electrothermal film has a low friction coefficient, can effectively prevent the adhesion between the blank material and the mold, and ensures the high-quality, high optical precision processing of the optical element surface.

Owner:THE HONG KONG POLYTECHNIC UNIV

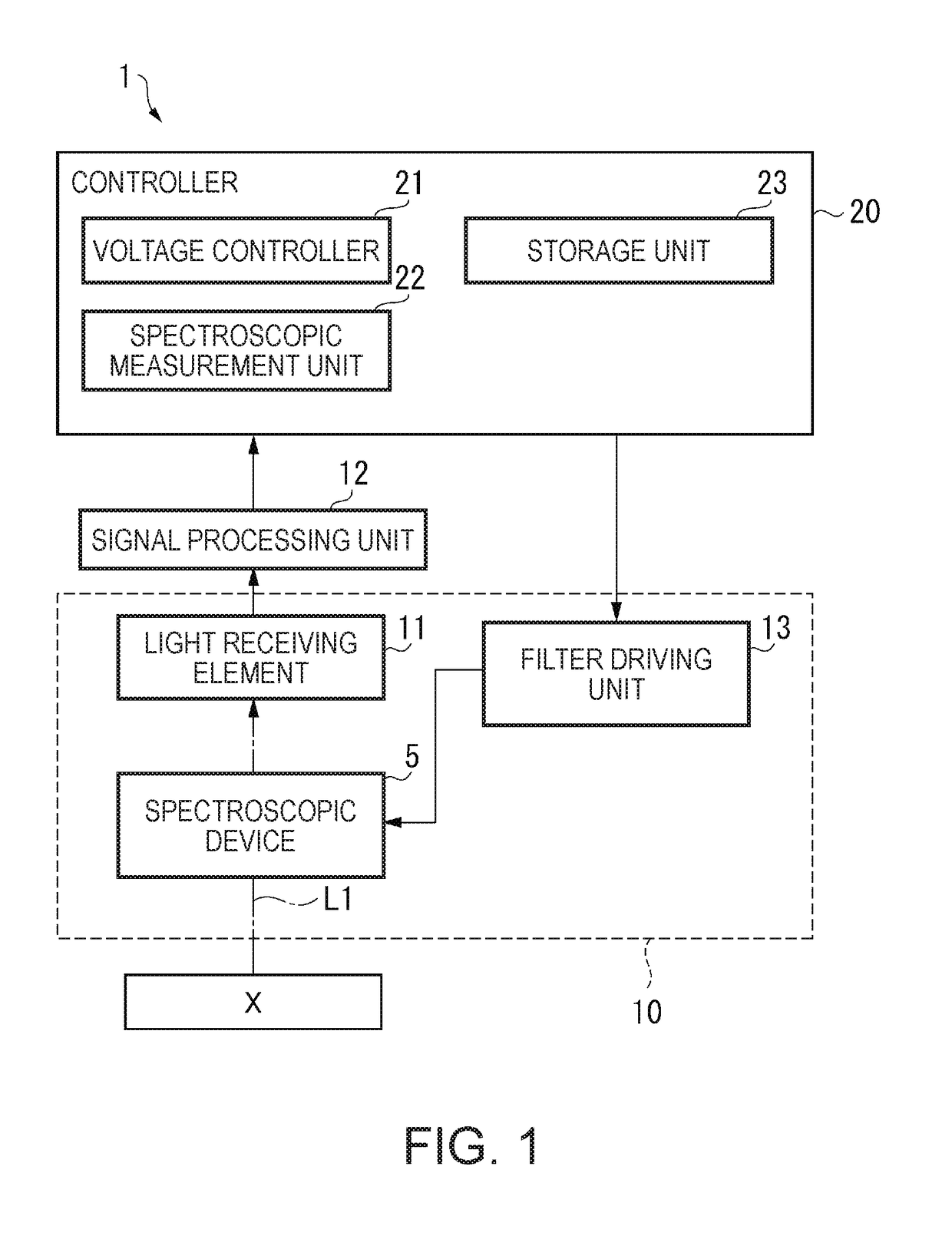

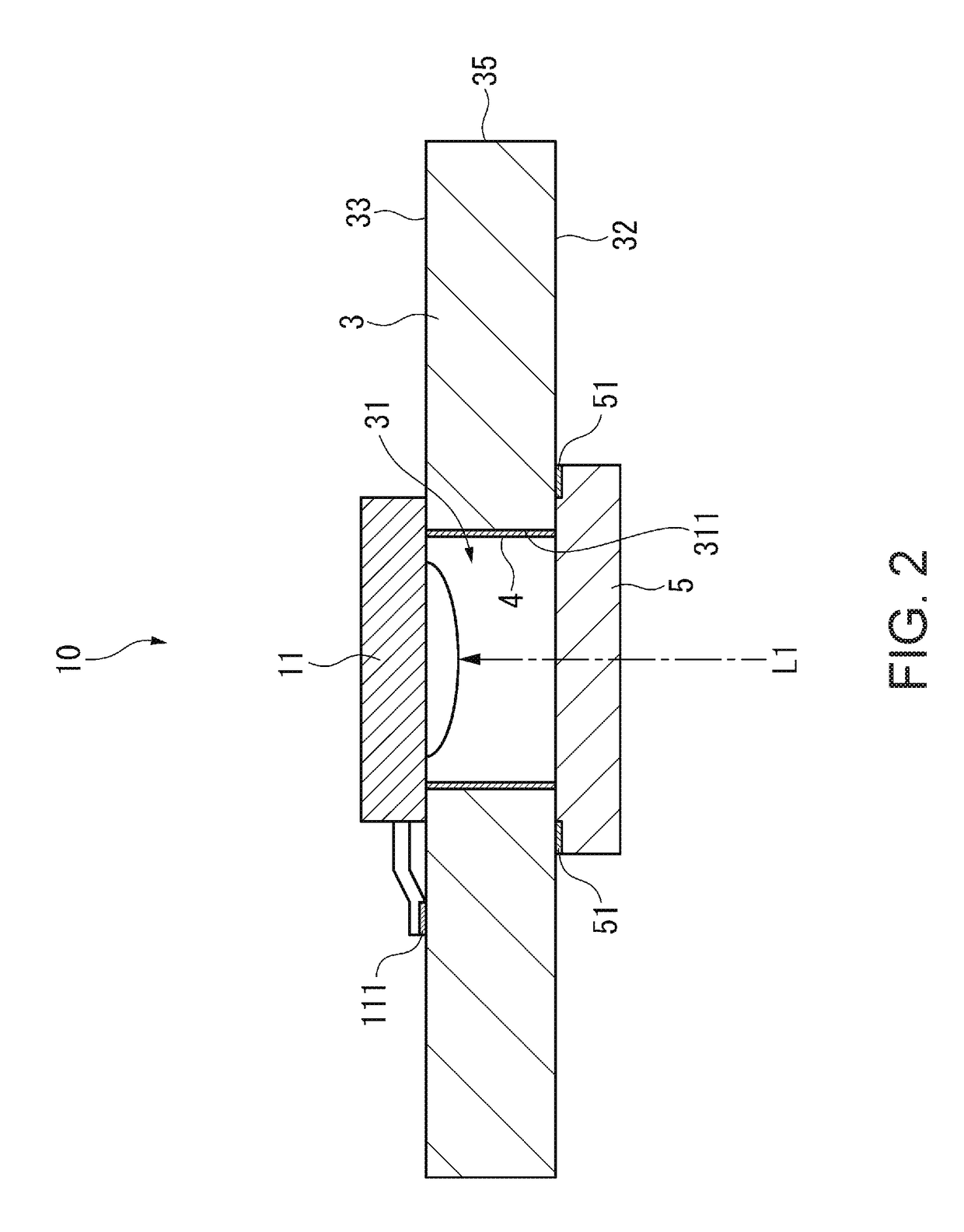

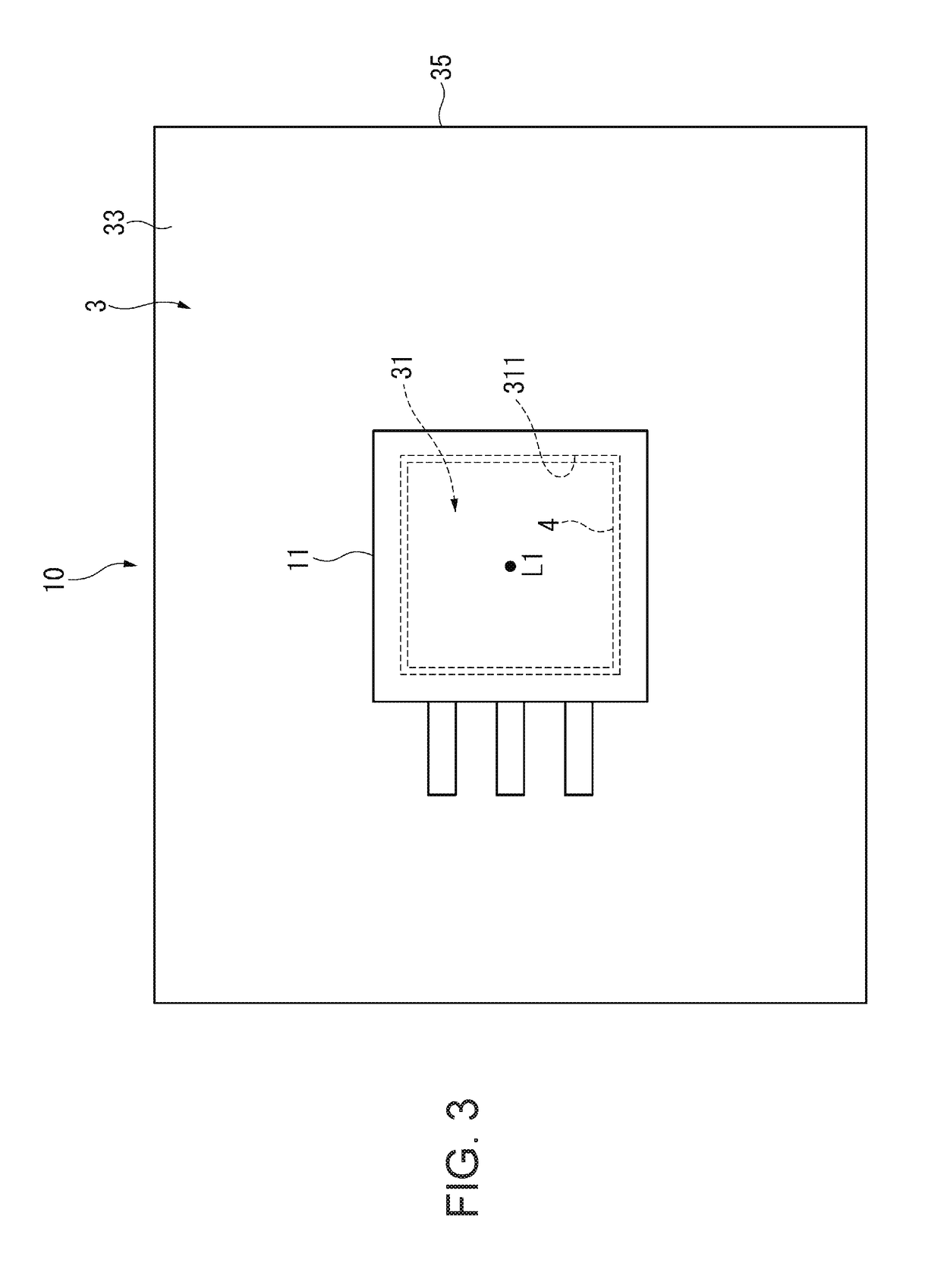

Optical module and electronic apparatus

ActiveUS20190063989A1Improve optical precisionImprove accuracy of variousSpectrum investigationMountingsOptical ModuleOptical axis

An optical module includes a substrate that has a first surface and a second surface opposite to the first surface and provided with a first hole portion having an opening surface on at least the first surface, an optical element that is provided on the substrate, the optical element having an optical axis located along a thickness direction from the first surface toward the second surface and located in the first hole portion, and a first light shielding portion that is provided on an inner peripheral surface which intersects the opening surface of the first hole portion and has a higher light shielding property than the substrate.

Owner:SEIKO EPSON CORP

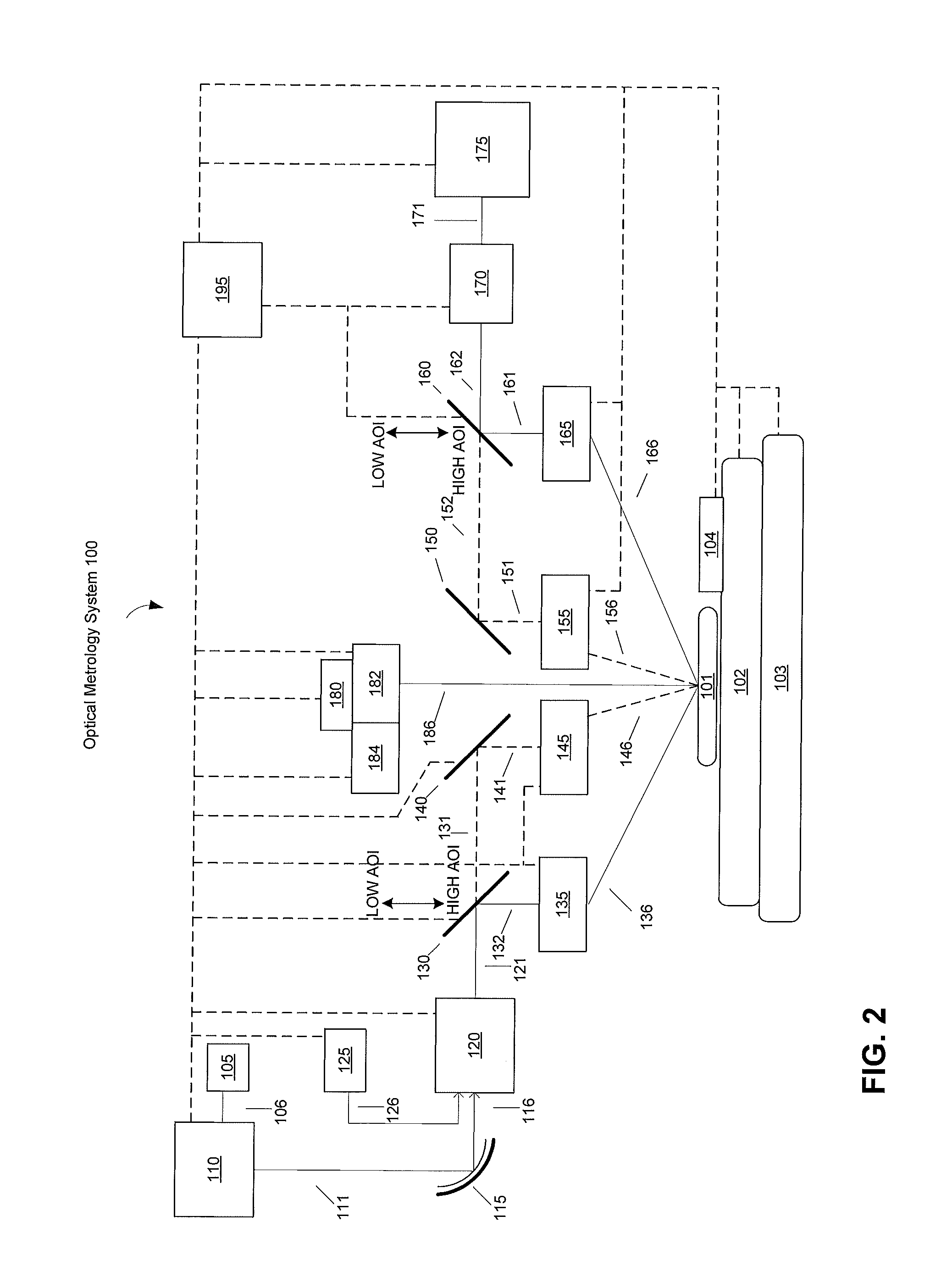

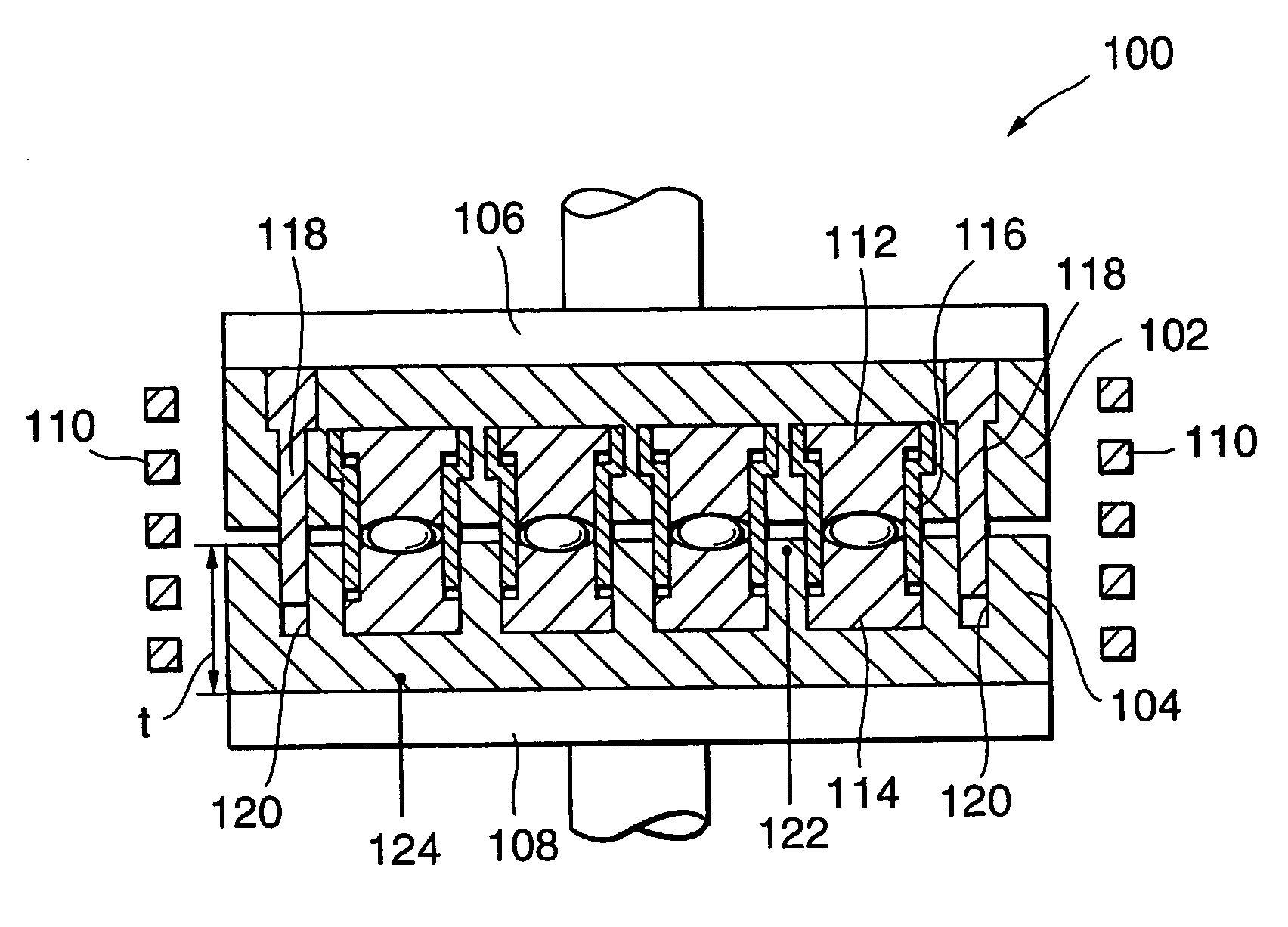

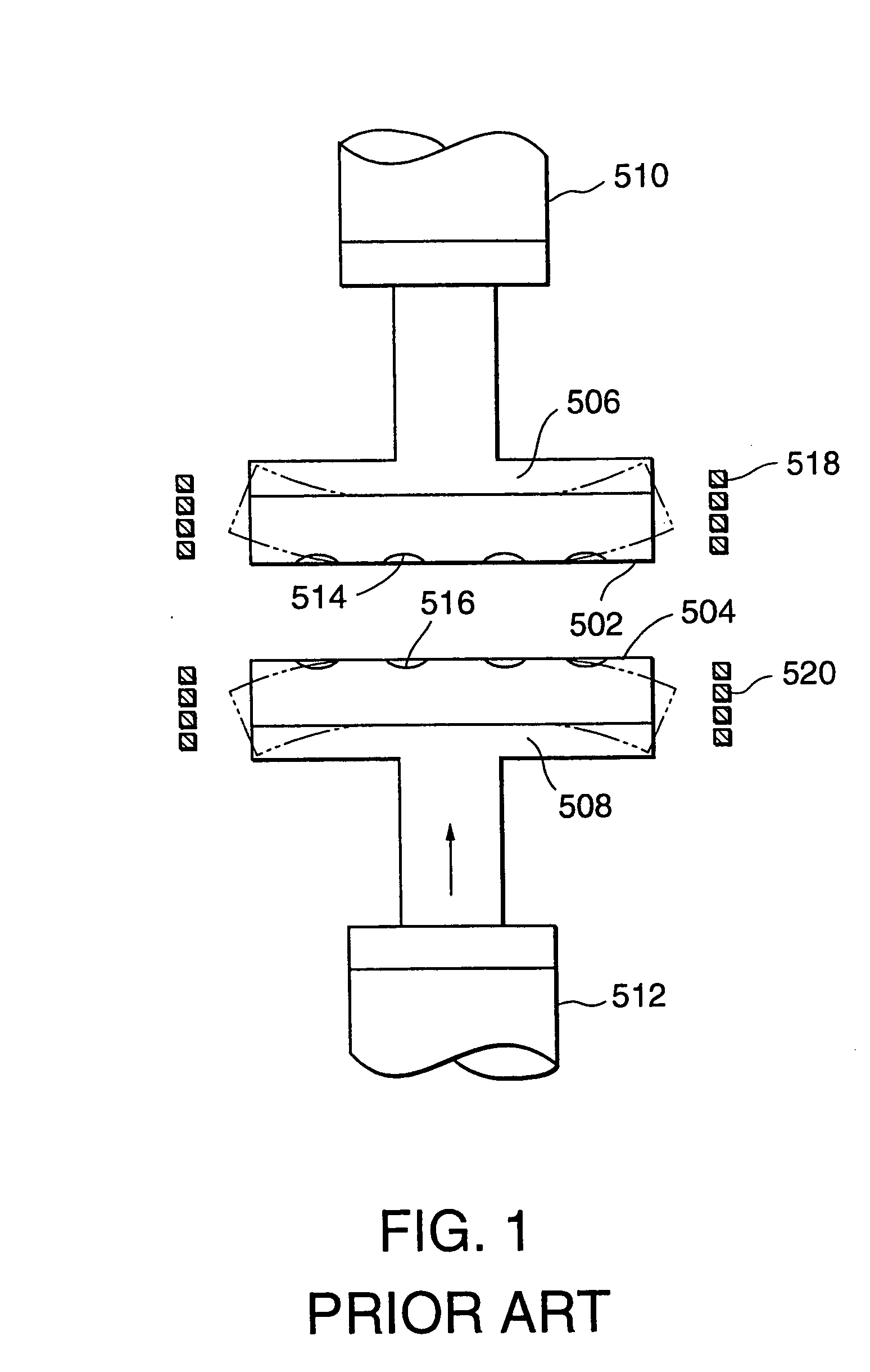

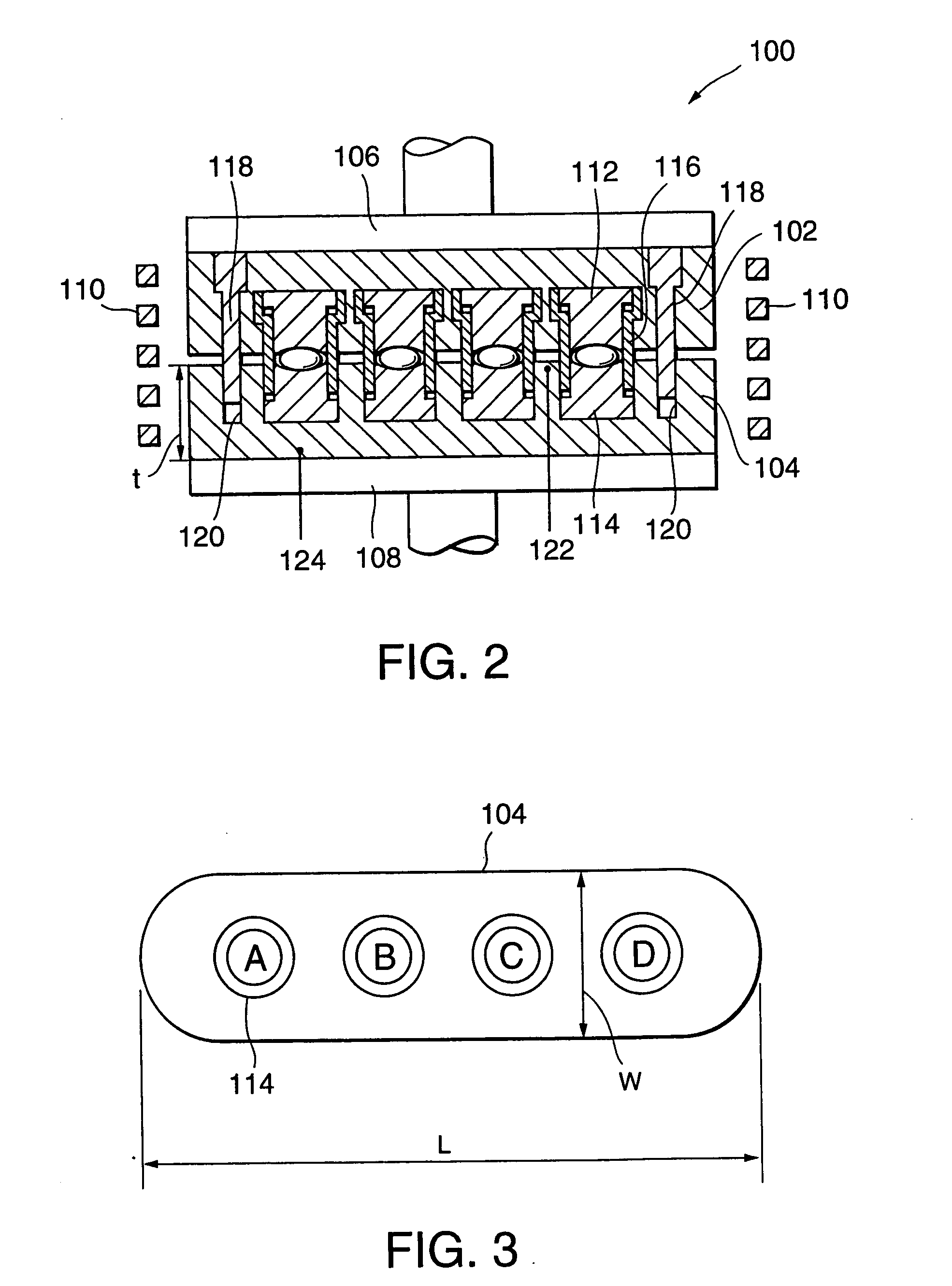

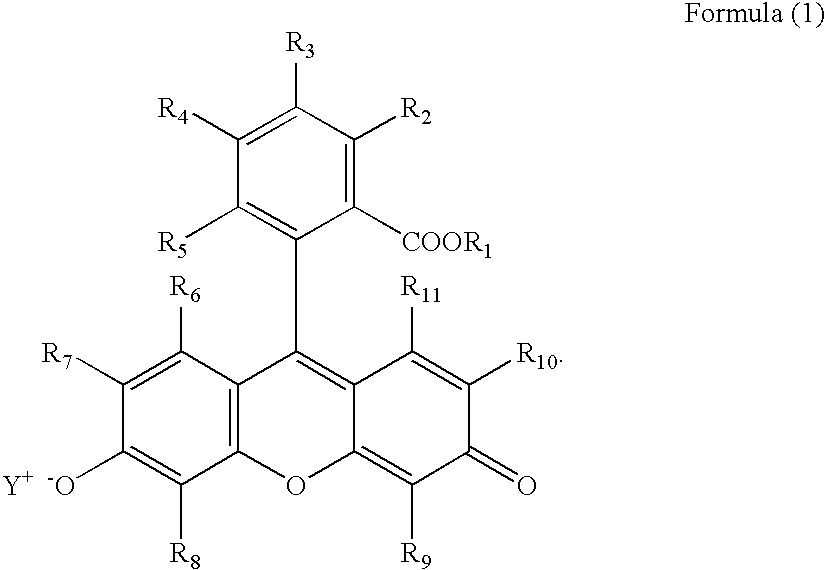

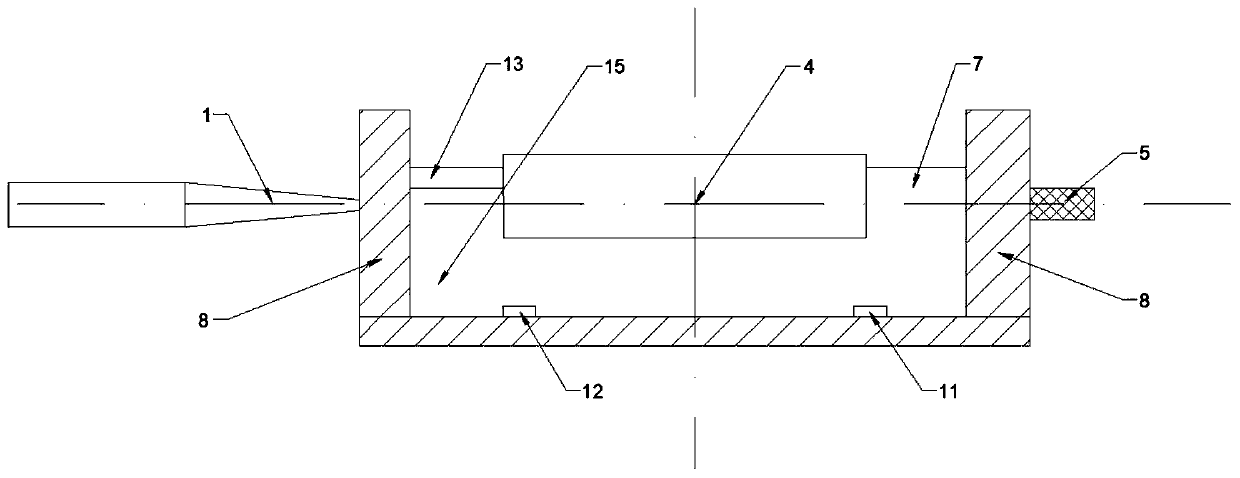

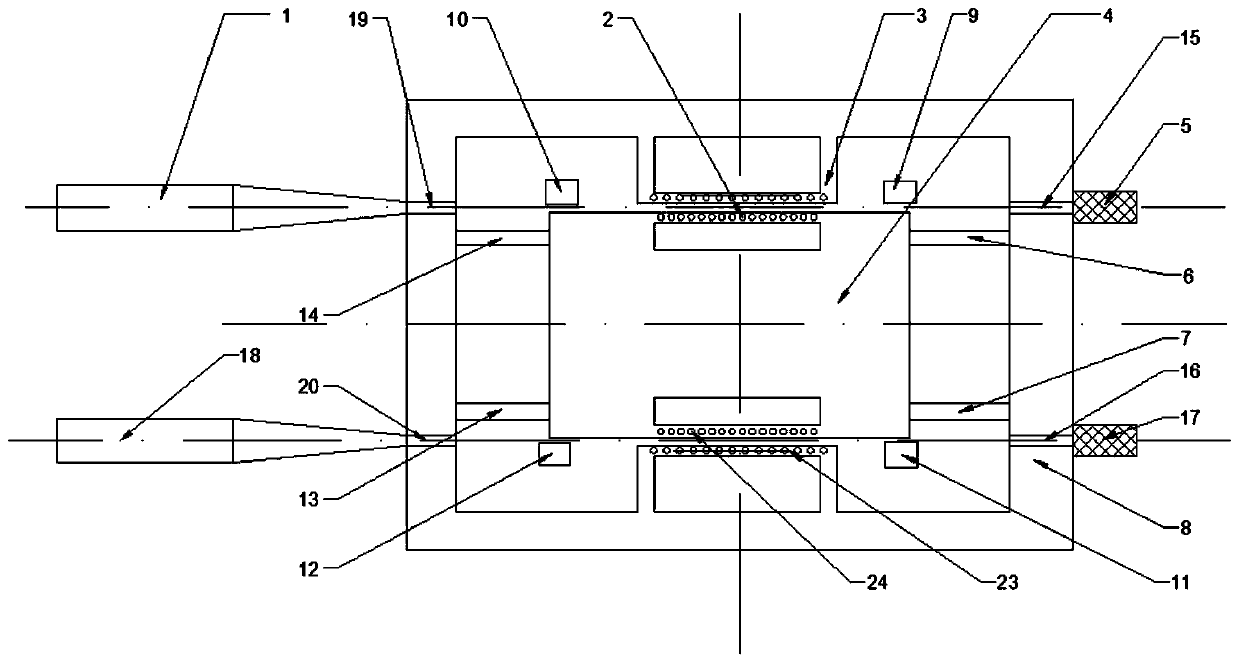

Press molding apparatus and press molding method

InactiveUS20050218538A1Improve optical precisionWarpage suppressionConfectioneryOptical articlesDrive shaftEngineering

A press molding apparatus includes upper and lower mother molds 102 and 104. Each of the mother molds 102 and 104 has four molding surfaces arranged in a single line and satisfies the relationship given by L×α×ΔT / t<0.0008, where L represents the length, t, the thickness, α, the thermal expansion coefficient, and ΔT, the temperature difference between both ends in the thickness direction during induction heating. The press molding apparatus may include a pressing mold set including upper mother molds 102a and 102b attached to a common fixed shaft 118 through upper supporting shafts 110a and 110b and lower mother molds 104a and 104b driven by a common drive shaft 120 through lower supporting shafts 112a and 112b. The upper mother molds 102a and 102b and the lower mother molds 104a and 104b are collectively heated by induction heating coils 122 and 124, respectively.

Owner:HOYA CORP

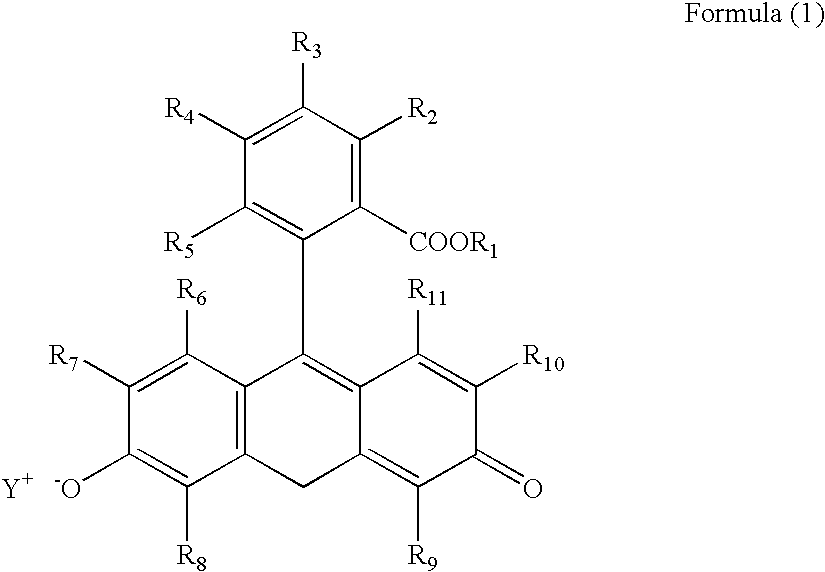

Planographic printing plate material and planographic printing plate preparing process

InactiveUS7138219B2Improve optical precisionHigh imagingPhotosensitive materialsPhoto-taking processesChemical compoundPlanographic printing

Disclosed is a planographic printing plate material comprising a hydrophilic support and provided thereon, a light sensitive layer and an overcoat layer in that order, wherein the light sensitive layer contains (a) an alkali soluble polymer, (b) a polymerizable compound having an ethylenically unsaturated bond, (c) a polymerization initiator, and (d) an anionic dye represented by the following formula (1),

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

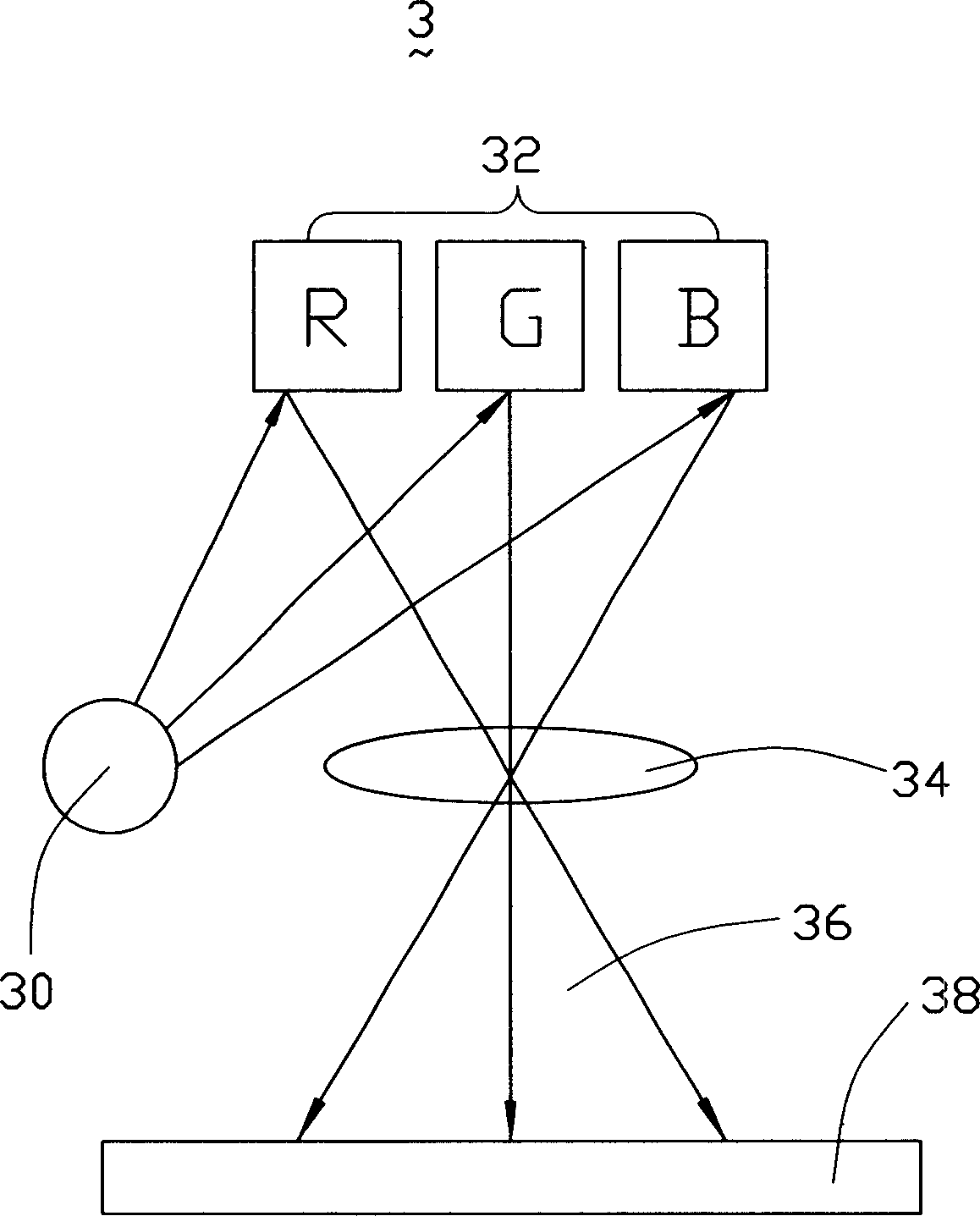

Projection type colour display device

InactiveCN1512214ASimple structureImprove optical precisionProjectorsPicture reproducers using projection devicesCMOSProjection screen

The projection type color display device includes one light source, one digital lens combination, one projecting lens, one projecting space and one projecting screen. The digital lens combination includes successively arranged silicon substrate, CMOS, metal layer, twisting pivot layer and reflecting mirror layer. White light from the light source is reflected in the digital lens combination to form red light, green light and blue light combined randomly and transmitted to the projecting lens before passing through the projecting space and reaching the projecting screen.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

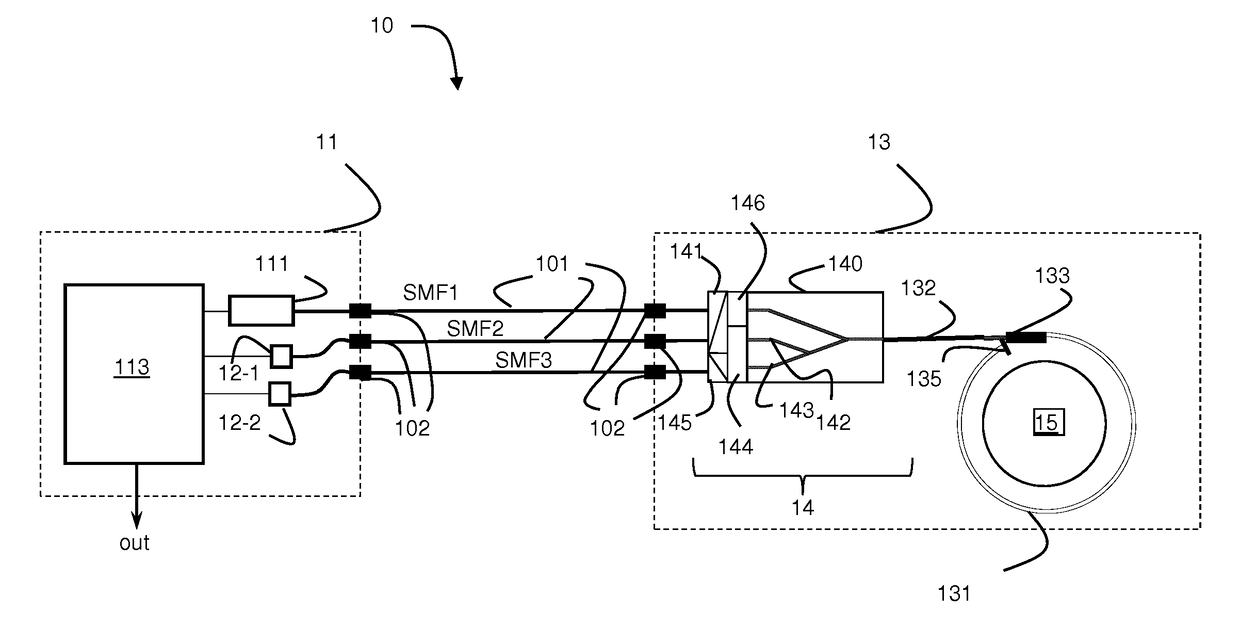

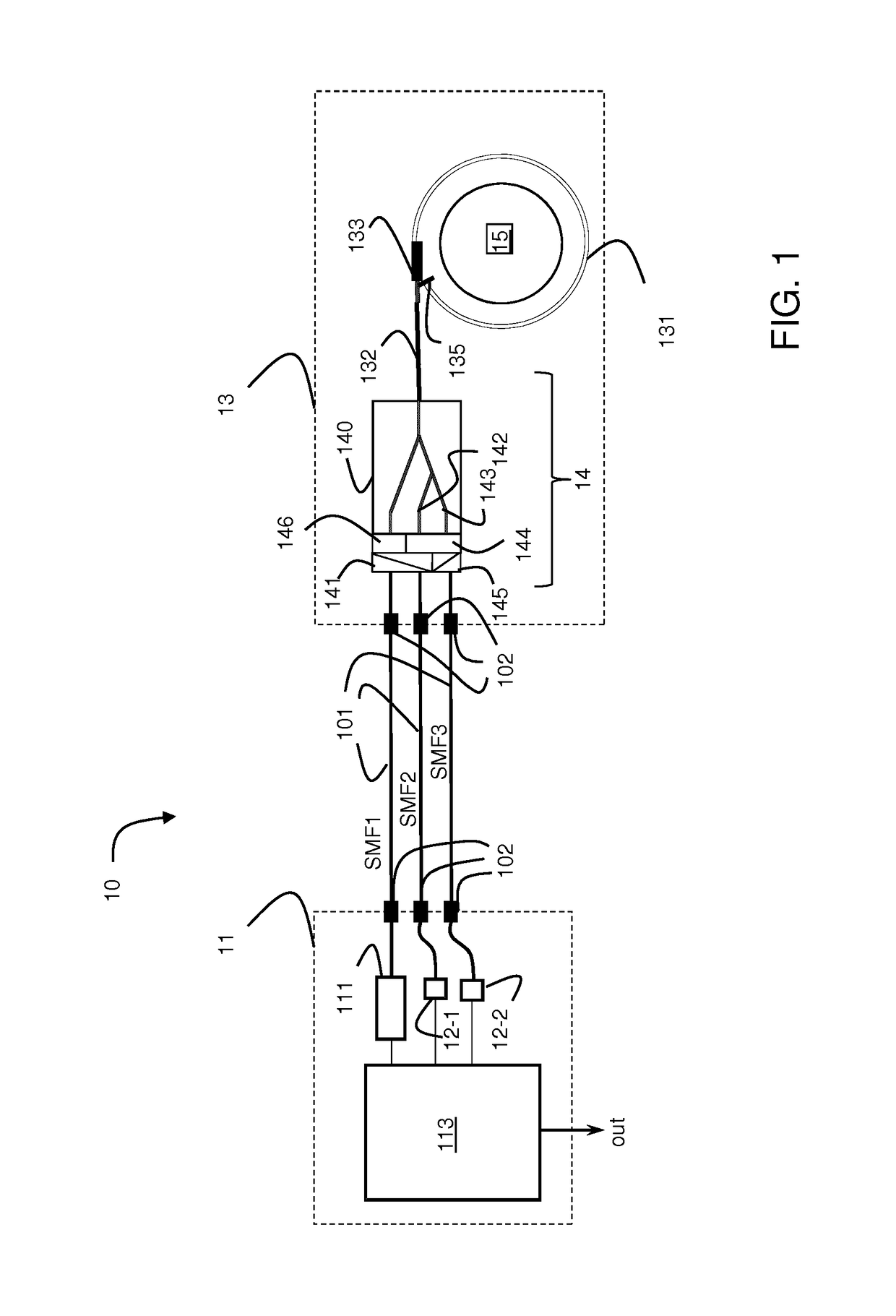

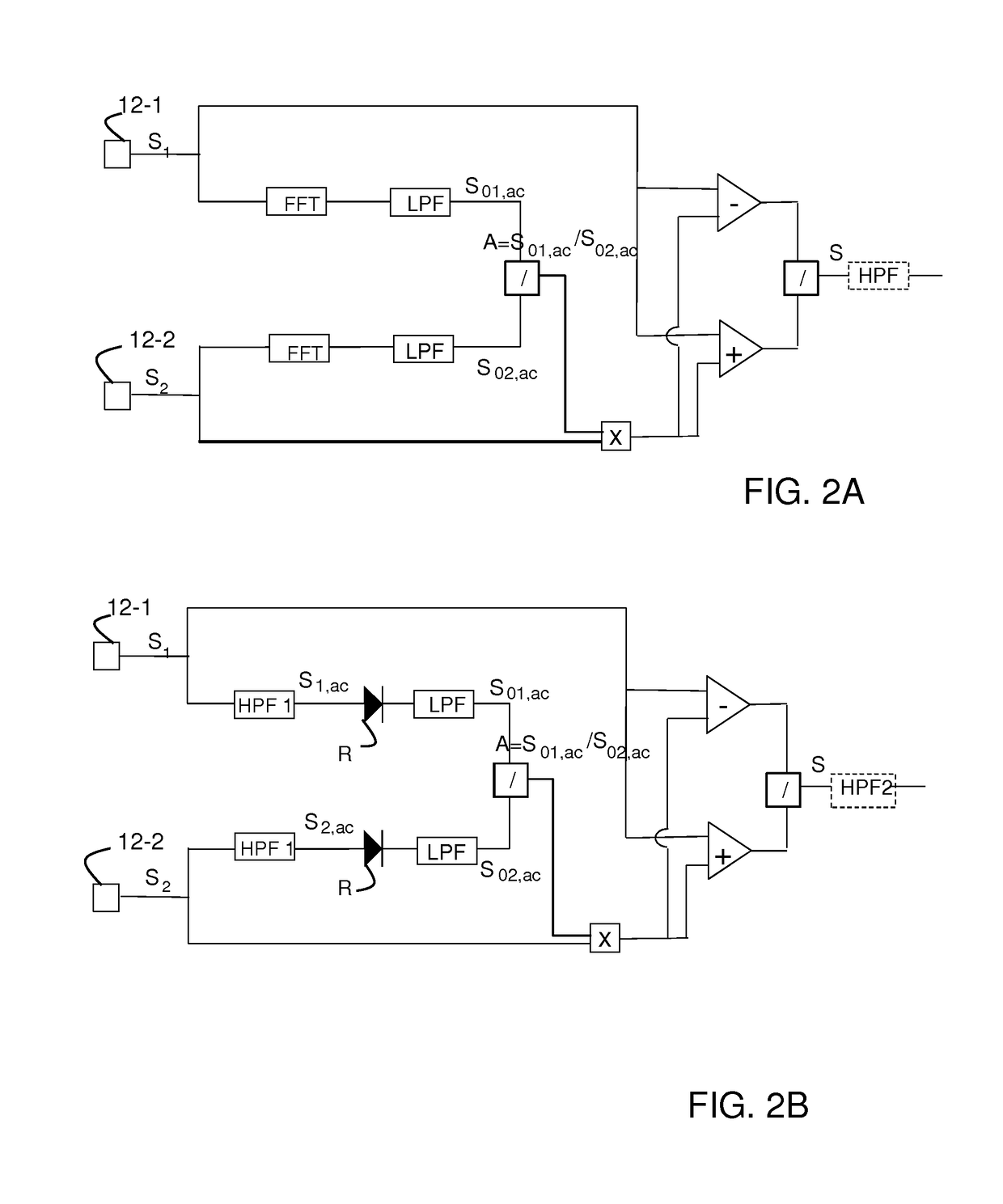

Optical sensor

ActiveUS9983236B2Improve optical precisionReduce impactMagnetic measurementsVoltage/current isolationElectricityPhase shifted

A method of increasing accuracy of optical sensors based on generating two sets of light waves having different velocities in the presence of a non-vanishing measurand field within a sensing element of the sensor is described. A defined static bias phase shift is introduced between the two sets of light waves. The sensor converts a total optical phase shift including static bias optical phase shifts and measurand-induced optical phase shifts into anti-phase optical power changes in at least two detector channels. The method includes steps of normalizing the optical power changes after their conversion into electrical detector signals in the two detector channels to reduce effects of uneven intensity or power of the light source and different loss or gain in the detector channels. Further methods, sensors and apparatus for temperature stabilizing such optical sensors and novel sensors are also presented.

Owner:HITACHI ENERGY LTD

Vacuum cup with heat preservation and disinfection functions

InactiveCN109619941ATo achieve the purpose of disinfectionNo side effectsLavatory sanitoryDisinfectionUltraviolet lightsSilica gel

The invention relates to the technical field of heat preservation and disinfection cups, in particular to a vacuum cup with heat preservation and disinfection functions. The vacuum cup comprises a stainless steel cup body and a cover body, wherein a cup body decoration ring sleeves the outer wall of the mouth of the stainless steel cup body, a silicone anti-slip mat is correspondingly arranged atthe bottom of the stainless steel cup body, the inner wall of the mouth of the stainless steel cup body sleeves a cup filter net, the inner wall of the cup filter net sleeves a lamp installation shell, quartz glass is correspondingly fixedly arranged at the end of the lamp installation shell, a reflection cup is fixedly arranged on the quartz glass and located in the lamp installation shell, an electronic aluminum base is correspondingly fixedly arranged on the reflection cup and located in the lamp installation shell, and a radiator is correspondingly fixedly arranged on the electronic aluminum base and located in the lamp installation shell. Various bacteria, viruses, parasites, algae and other pathogens in the vacuum cup are directly killed by ultraviolet light irradiation, so that thepurpose of disinfection is achieved.

Owner:龙春亮

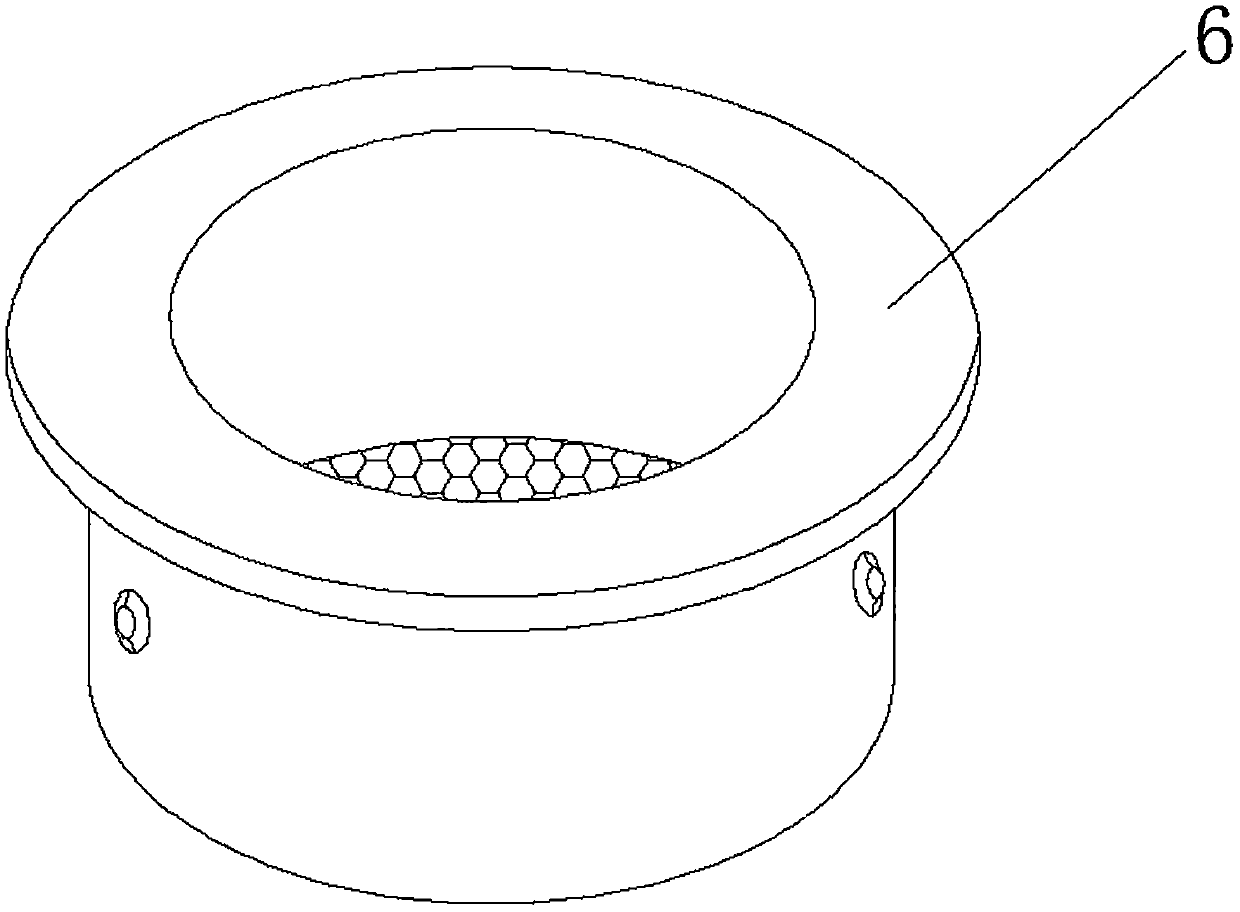

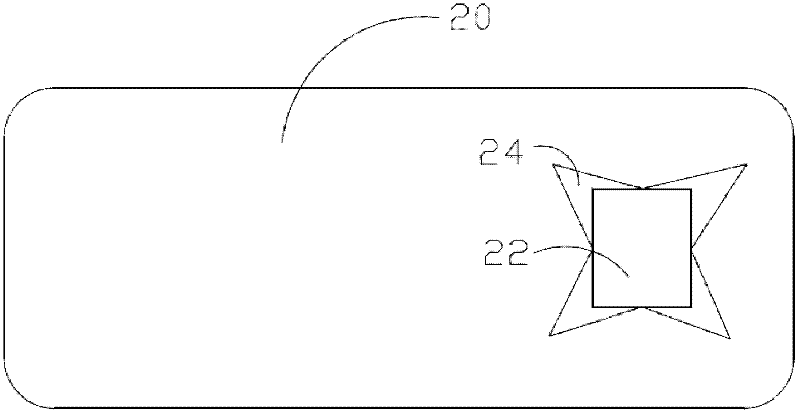

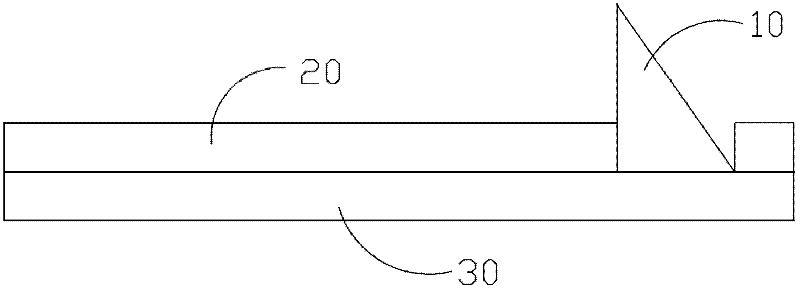

Optical unit and tool for adhering optical elements

The invention relates to an optical unit and a tool for adhering optical elements. The optical unit comprises a prism, a diaphragm and the tool, wherein the tool is arranged between the prism and the diaphragm and comprises a tool main body and at least one window part; and the window part penetrates through the tool main body and comprises four opening parts which are symmetrically arranged at the edge of the window part. By the invention, the position of the optical unit is relatively stabilized, and the using performance of the optical unit is improved.

Owner:BEIJING GK LASER TECH

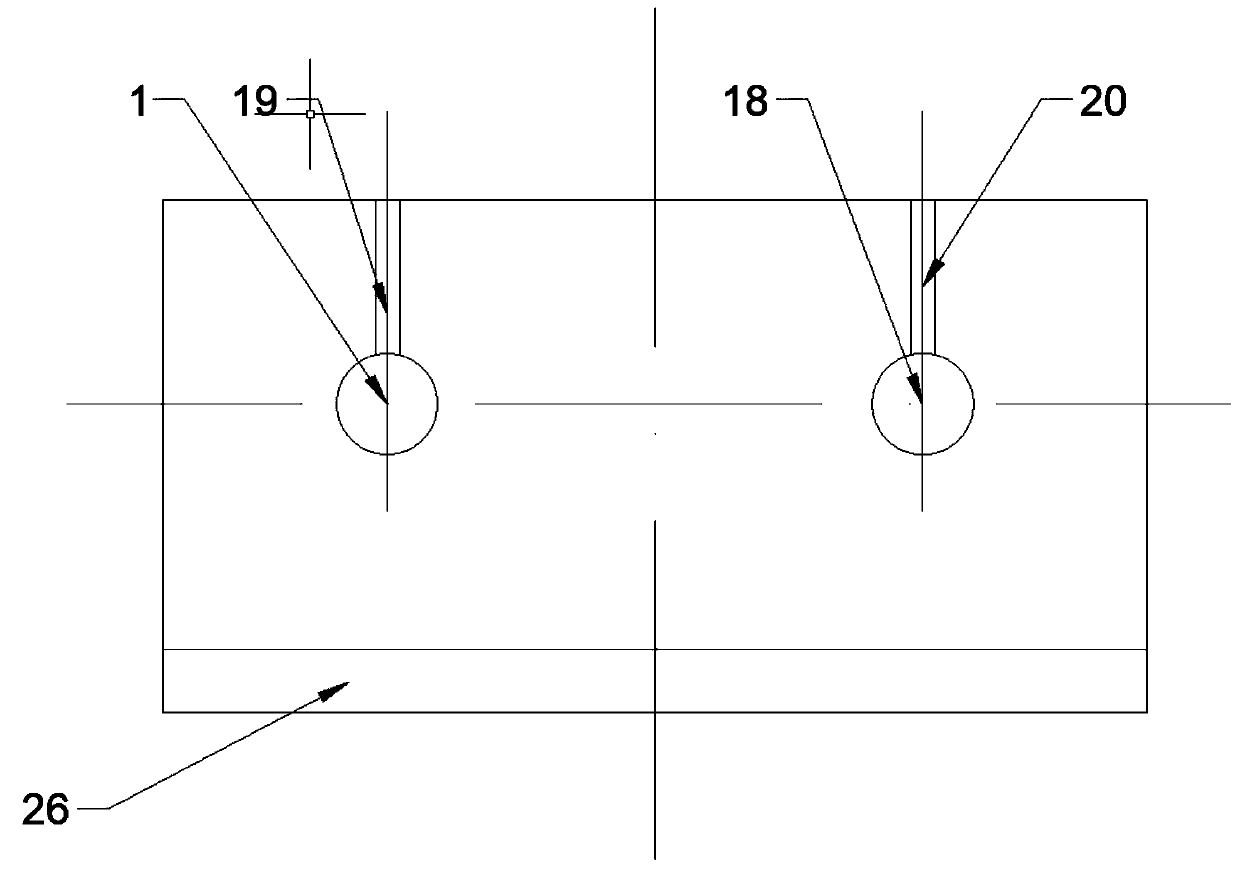

A high-precision optical accelerometer based on zipper-type photonic crystal micro-nano cavity

ActiveCN109946480BIncrease detection limit capabilityHigh sensitivityTelevision system detailsImpedence networksAccelerometerEngineering

The invention discloses a high-precision photodynamic accelerometer based on a zipper type photonic crystal micro-nano cavity. The accelerometer comprises a laser input and reception structure arranged in the left and right sides of the accelerometer structure, a silicon micro mechanical structure arranged in the middle portion of the accelerometer, and a glass substrate structure positioned in the bottom of the silicon micro mechanical structure and provided with electrodes. A laser incident structure is arranged in an input groove in the left side of a main silicon microstructure, a reception structure is arranged in an output groove in the right side of the main silicon microstructure. An optical signal serves as a measurement signal of the micro accelerometer, the sensitivity is high,the uncertainty is low, the detection limit of the micro accelerometer is improved, and the detection sensitivity is improved greatly. The zipper type photonic crystal micro-nano cavity is used, the performance is more stable and the optical precision is higher compared with a common planar parallel resonance micro-nano cavity at present, and higher acceleration sensitivity is achieved.

Owner:SOUTHEAST UNIV

Free-form optical reflector for LED (light-emitting diode) motorcycle low beam

The invention discloses a free-form optical reflector for an LED (light-emitting diode) motorcycle low beam, wherein an internal surface of the reflector is a free-form surface to form an optical reflecting surface; the bottom surface of the reflector is provided with an opening for installation of an LED; one end rightly facing the bottom surface is a light exit port of the reflector; the majority of light emitted by the LED light source is reflected by the internal surface of the reflector and then is emergent to an illuminating plane, and the other light is directly emergent to the illuminating plane. The reflector is divided into an upper part and a lower part; the free-form surface at the upper part of the internal surface of the reflector is mainly used for reflecting the light above a horizontal plane to the illuminating plane below the horizontal plane; the free-form surface at the lower part of the internal surface of the reflector is mainly used for gathering diffused light below the horizontal plane to the illuminating plane below the horizontal plane. The free-form optical reflector for the LED motorcycle low beam has the characteristics of simple structure, convenience in installation and high utilization rate of light energy; light direction can be effectively controlled and the glare effect can be inhibited; and the free-form optical reflector for the LED motorcycle low beam meets the light distribution requirements in GB5948-1998.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com