Optical element molding method based on graphene-like electrothermal film

An optical element, graphene technology, applied in optical elements, glass molding, glass re-molding and other directions, can solve the problems of high energy consumption, long thermal cycle time, low production efficiency, etc., to prevent adhesion, high optical precision , the effect of fast heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

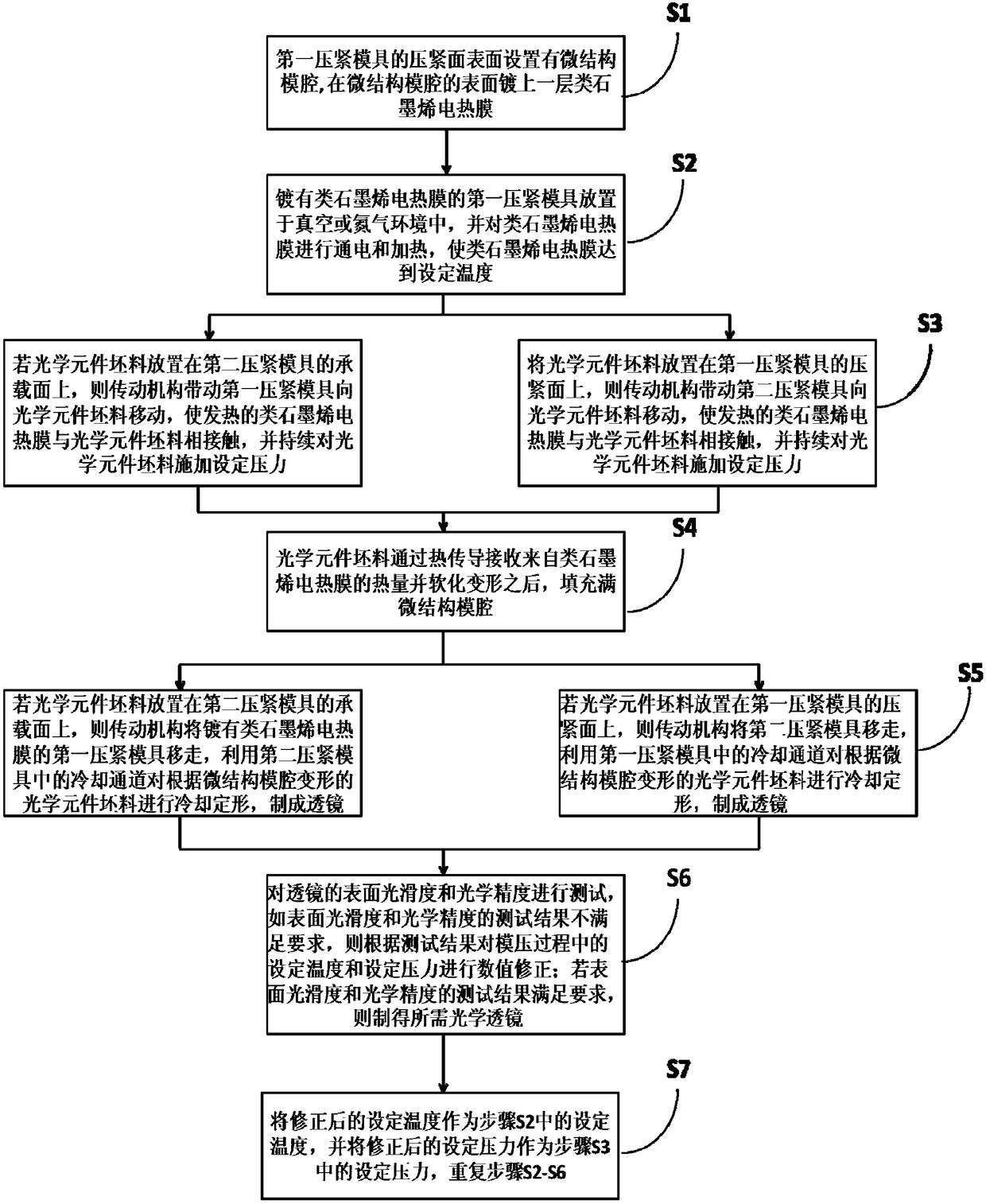

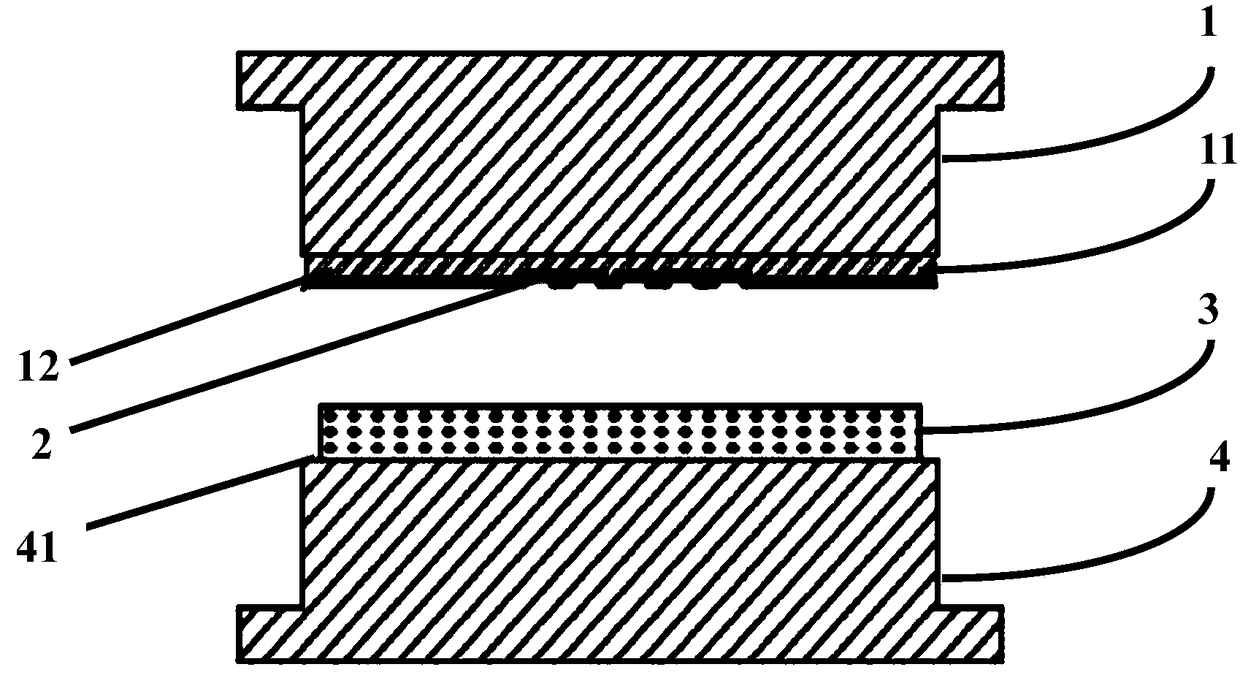

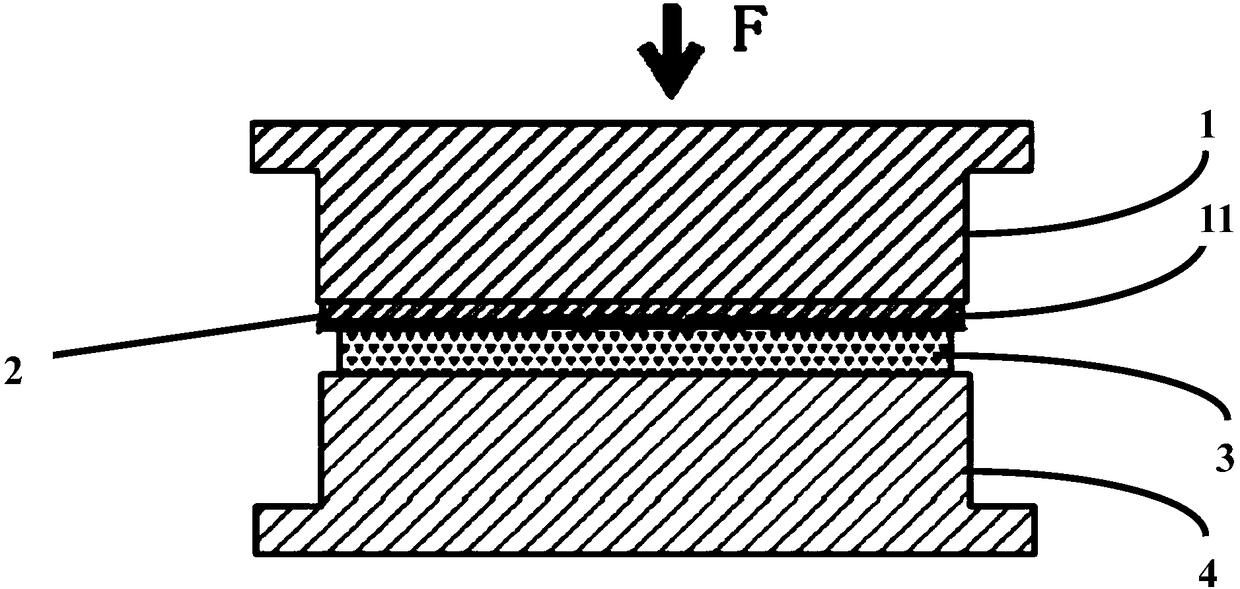

[0031] figure 1 It is a schematic flow chart of a preferred embodiment of the molding method for optical elements based on graphene-like electrothermal film of the present invention. combine figure 2 As shown, this kind of optical element molding method based on graphene-like electrothermal film includes the following steps: S1, the surface of the pressing surface 11 of the first pressing mold 1 is provided with a microstructure mold cavity 12, and in the microstructure mold cavity The surface of 12 is coated with a layer of graphene-like electrothermal film 2.

[0032] S2. The first compression mold 1 coated with the graphene-like electric heating film 2 is placed in a vacuum or nitrogen environment, and the graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com