Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Improve on-site management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

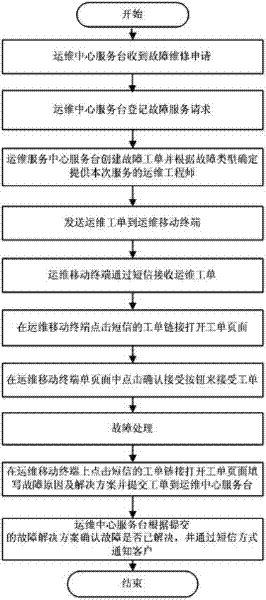

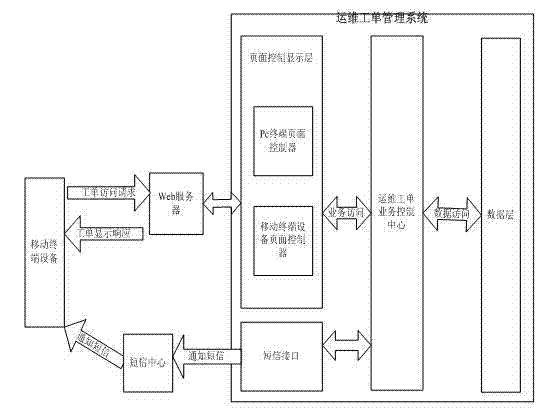

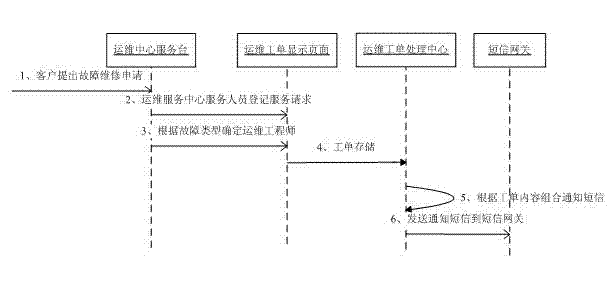

Method and device for processing operation/maintenance work orders based on mobile terminal

InactiveCN102202085AShorten execution cycleReduce time to complete feedbackTransmissionWireless communicationComputer scienceFault handling

The invention discloses a method and device for processing operation / maintenance work orders based on a mobile terminal. The method mainly comprises the following steps: 1) an operation / maintenance center information desk receives fault maintenance application; 2) the operation / maintenance center information desk registers the fault request; 3) the operation / maintenance center information desk creates a work order and determines the operation / maintenance personnel for processing the fault; 4) the operation / maintenance center information desk sends a short message to notify an operation / maintenance mobile terminal; 5) the operation / maintenance mobile terminal receives the notification short message; 6) the work order link of the short message is clicked on the operation / maintenance mobile terminal to open the work order page; 7) a receiving button is clicked on the operation / maintenance mobile terminal to receive the work order; 8) the fault is processed; 9) the work order link in the short message is clicked on the operation / maintenance mobile terminal to open the work order page, a fault solution is filled in, and the work order is submitted; and 10) the operation / maintenance center information desk determines whether the fault is solved according to the submitted fault solution, and notifies the client through a short message. By adopting the method, the operation / maintenance personnel can improve the execution and feedback speed of the work order so as to reduce the execution time of the work order.

Owner:勤智数码科技股份有限公司

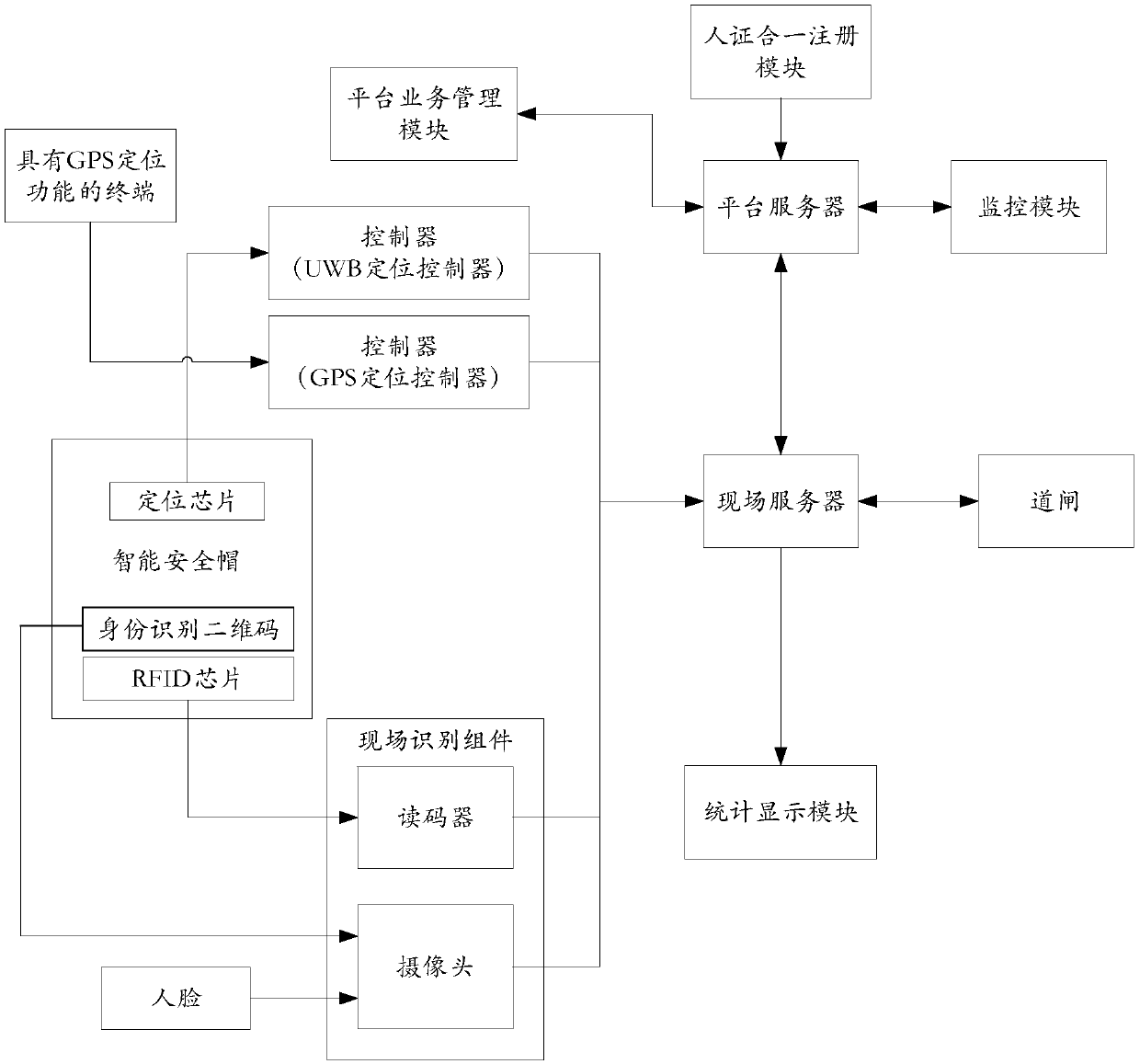

Smart barrier gate on-site monitoring system and method

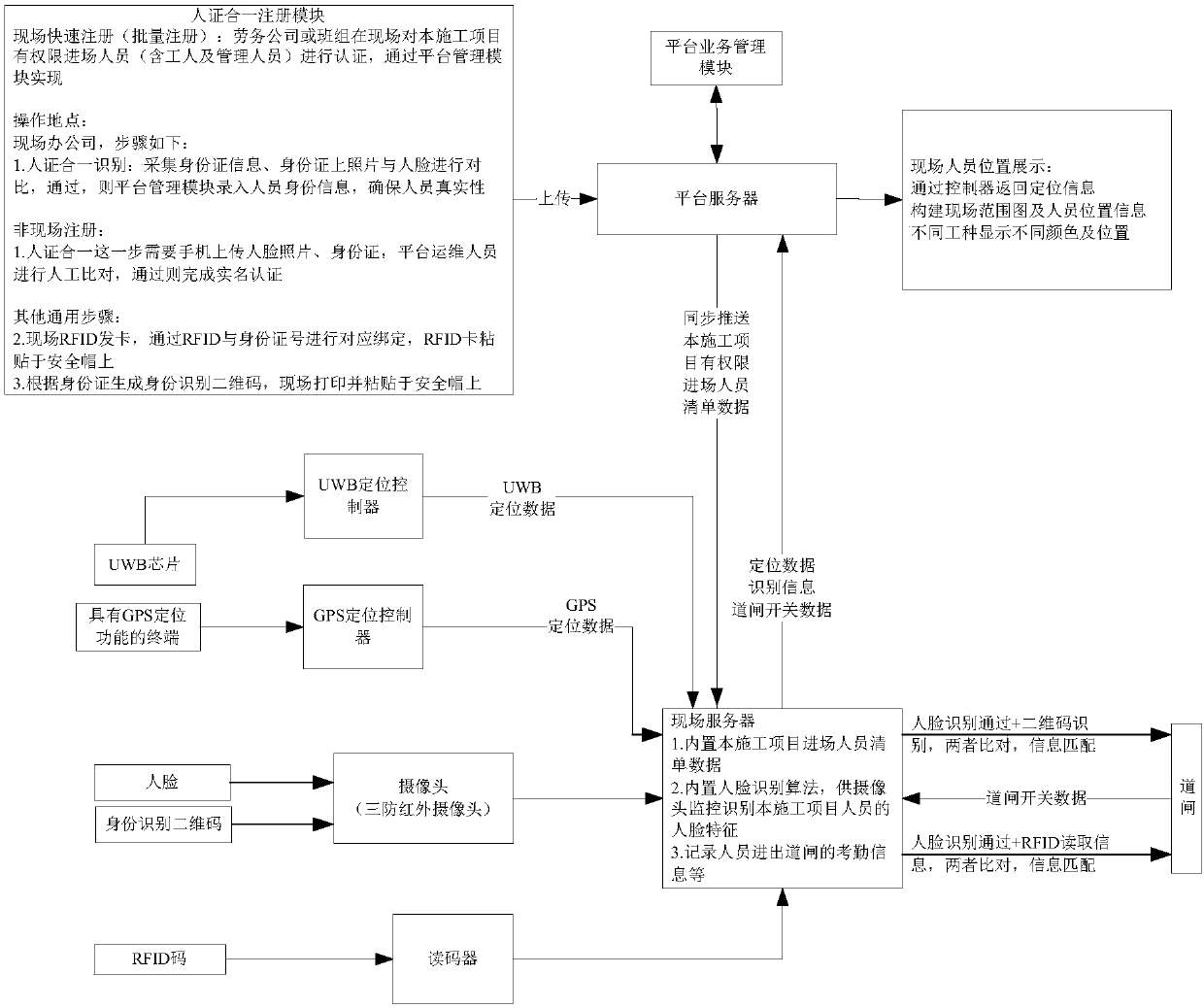

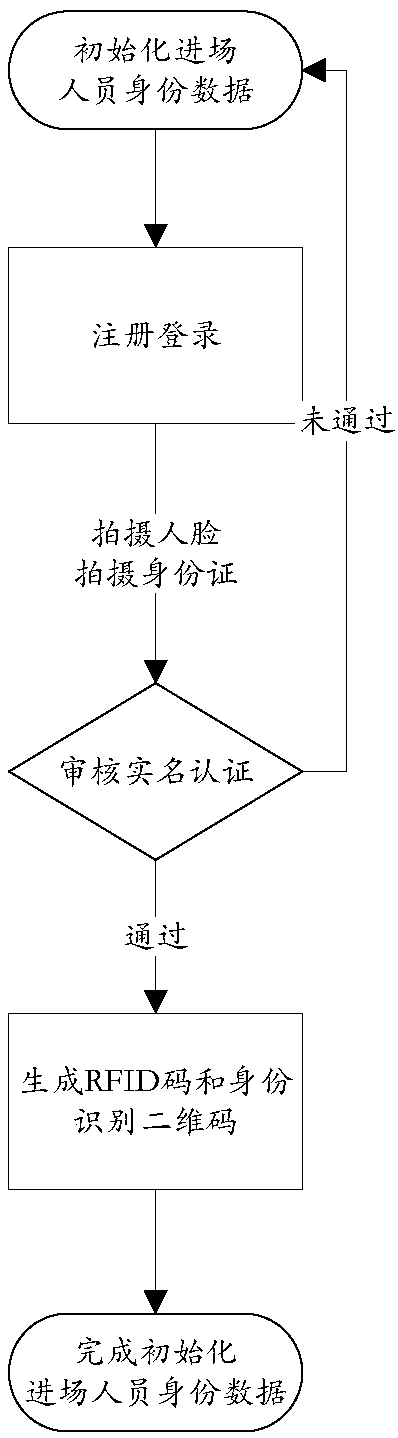

PendingCN107944838AReal attendance dataImprove on-site managementOffice automationSite managementProject organization

The invention relates to a smart barrier gate on-site monitoring system and method. The system includes a man-certificate integrated registration module, a platform business management module, a platform server, an on-site server, an on-site identification assembly and a controller; the platform business management module is used to create and manage project organization information data, identifylist data of personnel who have permission to enter the construction site; the platform server is used to synchronize the list data to the on-site server; the on-site identification assembly is usedto obtain on-site identity information of personnel entering the construction site; the on-site server is used to analyze the on-site identity information with the list data as the standard, and control the switching on and off of the barrier gate; the controller is used to locate the personnel; and the platform business management module is used for monitoring the barrier gate site according to the identification information, positioning data and switching data of the barrier gate. Personnel enter the site with their real names and real identities, ensuring that the labor worker attendance data is true and reliable, and improving the site management level and safety production level.

Owner:四川省大益科技有限公司

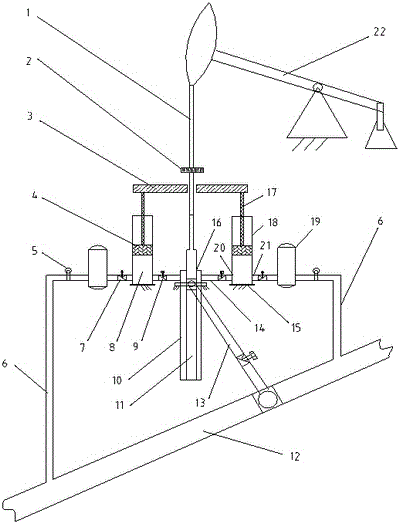

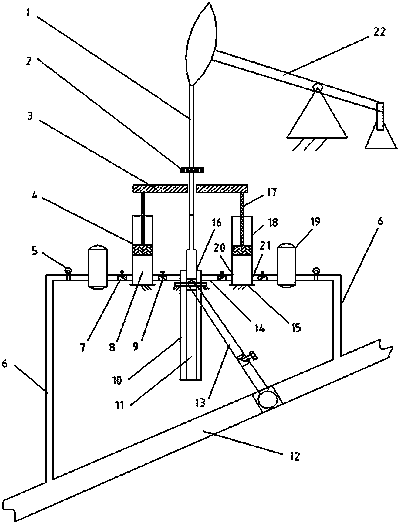

Oil well casing gas collecting device

ActiveCN102747989AAchieve compressionDynamic balance disruptionFluid removalPipeline systemsEconomic benefitsOil transportation

The invention provides an oil well casing gas collecting device. An oil pumping pipe, an oil pumping rod and a casing are arranged in an oil well, the oil pumping rod is connected onto an oil pumping unit, and the oil pumping unit pumps crude oil from the oil pumping pipe and transports the crude oil to an oil transportation pipe. The device comprises a casing connecting pipe, a one-way valve A, a boosting pump, a one-way valve B and an oil pipe connecting pipe. The boosting pump includes a connecting rod, the upper end of the connecting is fixedly connected with a pressure arm, the upper portion of the oil pumping rod is fixedly connected with a pressure button, and the pressure button is located above the pressure arm. When the boosting pump is installed, the connecting rod is parallel to the oil pumping rod, and the pressure arm is intersected with the connecting rod but is not connected with the connecting rod. When the oil pumping rod is lifted up under the driving of the oil pumping unit, casing gas drives a piston, the connecting rod and the pressure arm to move upward under the action of self pressure. When the oil pumping rod moves downward under the action of self gravity, the pressure button presses the pressure arm to drive the connecting rod and the piston to move downward, and compressed casing gas in a compression cylinder enters the oil transportation pipe. By means of the oil well casing gas collecting device, a series of problems including difficulty in traditional oil well casing gas recovering, energy waste, environment pollution, safety hazard and the like are solved. Therefore, the oil well casing gas collecting device has obvious economic benefit and environmental-protection benefit.

Owner:SHANGHAI YIJING ENERGY TECH

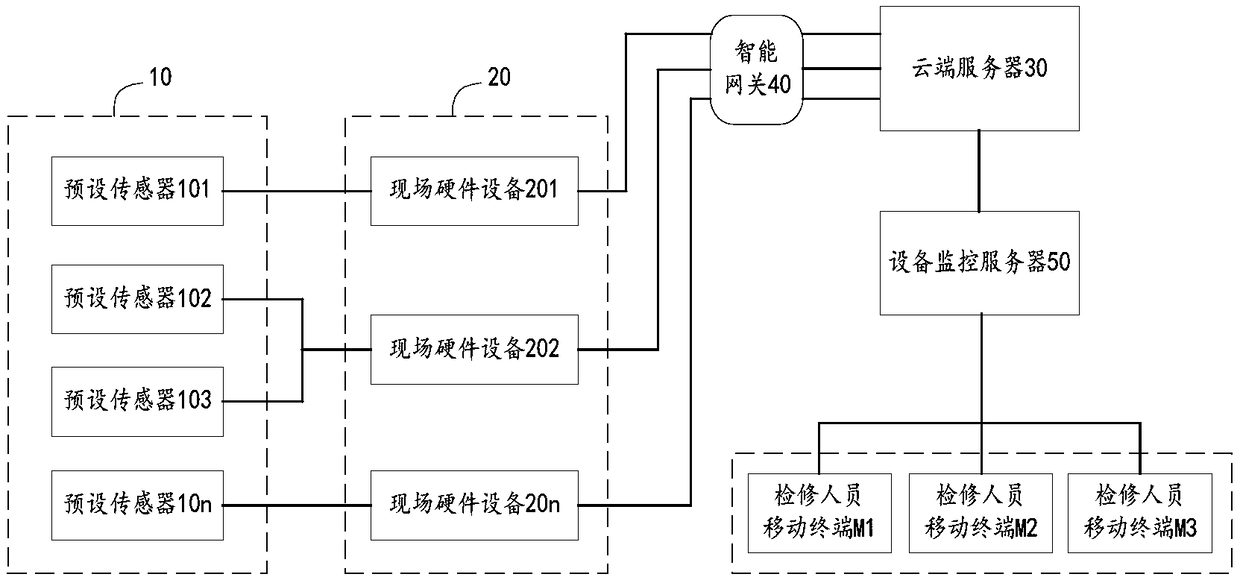

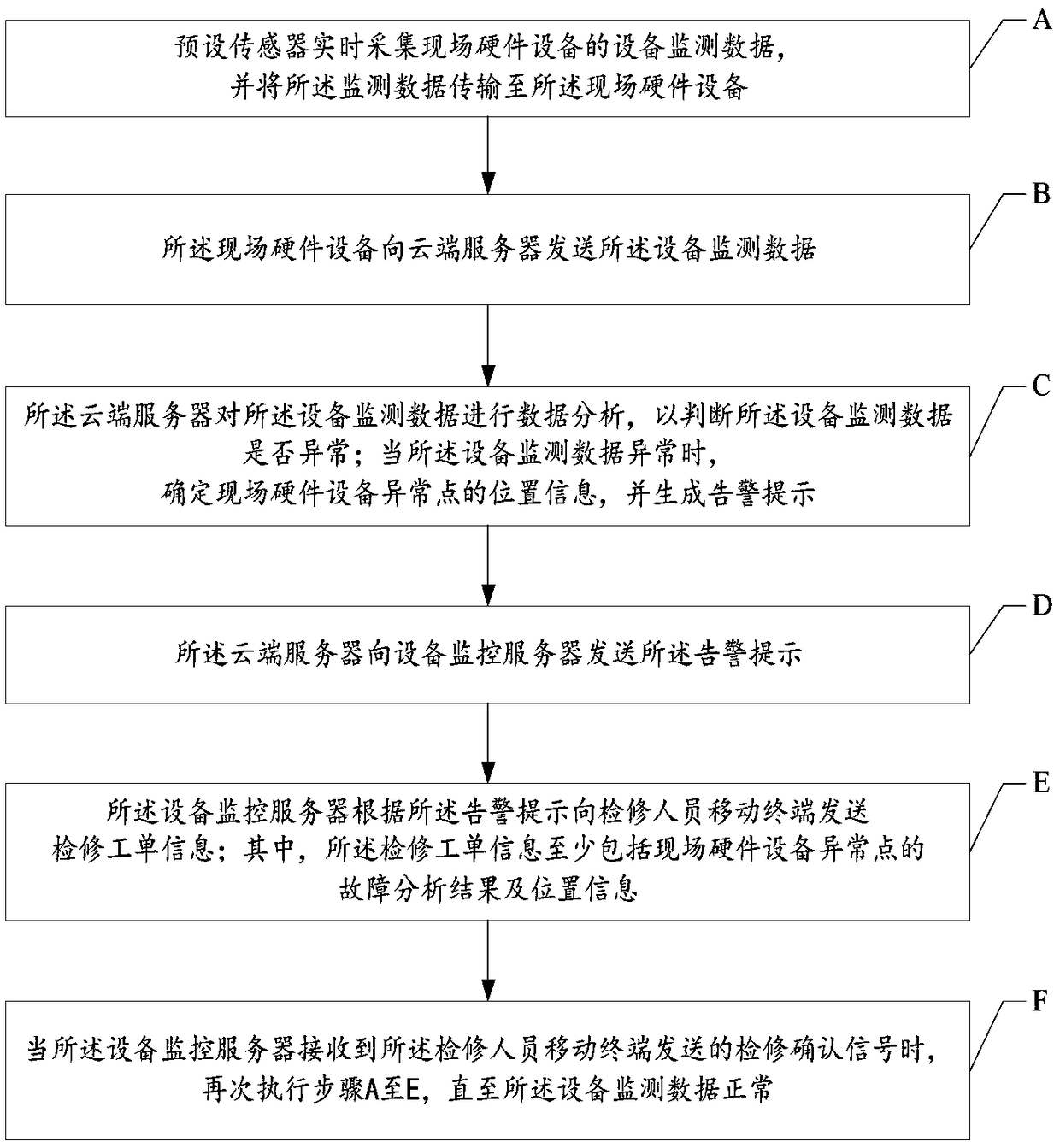

Field hardware equipment management and control system and method

InactiveCN109460835AEasy to deployLow costParticular environment based servicesResourcesControl systemEquipment monitoring

The invention provides a field hardware equipment management and control system, comprising a preset sensor, which is used for collecting equipment monitoring data of the field hardware equipment in real time. The cloud server is used for data analysis of equipment monitoring data to judge whether the equipment monitoring data is abnormal or not; When the monitoring data of the equipment is abnormal, the position information of the abnormal point of the field hardware equipment is determined, the alarm prompt is generated, and the alarm prompt is sent to the equipment monitoring server. The device monitoring server is used for sending the maintenance work order information to the maintenance personnel mobile terminal according to the alarm prompt. When the equipment monitoring server receives the overhaul confirmation signal, each part re-executes the corresponding function until the equipment monitoring data is normal. The invention also provides a field hardware device management andcontrol method. The invention solves the technical problems that it is difficult to judge the position of the abnormal equipment in time and the intelligence degree is low in the monitoring and processing scheme of the abnormal operation of the existing hardware equipment.

Owner:广州市雅天网络科技有限公司

Oil well casing gas collecting device

ActiveCN102747989BAchieve compressionDynamic balance disruptionFluid removalPipeline systemsEconomic benefitsOil transportation

The invention provides an oil well casing gas collecting device. An oil pumping pipe, an oil pumping rod and a casing are arranged in an oil well, the oil pumping rod is connected onto an oil pumping unit, and the oil pumping unit pumps crude oil from the oil pumping pipe and transports the crude oil to an oil transportation pipe. The device comprises a casing connecting pipe, a one-way valve A, a boosting pump, a one-way valve B and an oil pipe connecting pipe. The boosting pump includes a connecting rod, the upper end of the connecting is fixedly connected with a pressure arm, the upper portion of the oil pumping rod is fixedly connected with a pressure button, and the pressure button is located above the pressure arm. When the boosting pump is installed, the connecting rod is parallel to the oil pumping rod, and the pressure arm is intersected with the connecting rod but is not connected with the connecting rod. When the oil pumping rod is lifted up under the driving of the oil pumping unit, casing gas drives a piston, the connecting rod and the pressure arm to move upward under the action of self pressure. When the oil pumping rod moves downward under the action of self gravity, the pressure button presses the pressure arm to drive the connecting rod and the piston to move downward, and compressed casing gas in a compression cylinder enters the oil transportation pipe. By means of the oil well casing gas collecting device, a series of problems including difficulty in traditional oil well casing gas recovering, energy waste, environment pollution, safety hazard and the like are solved. Therefore, the oil well casing gas collecting device has obvious economic benefit and environmental-protection benefit.

Owner:SHANGHAI YIJING ENERGY TECH

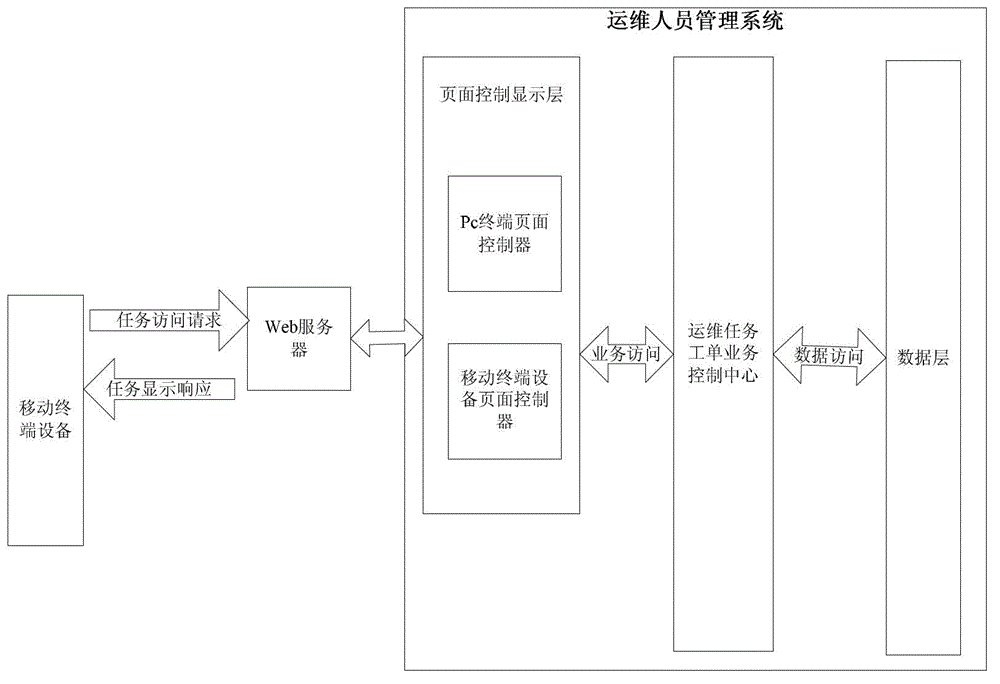

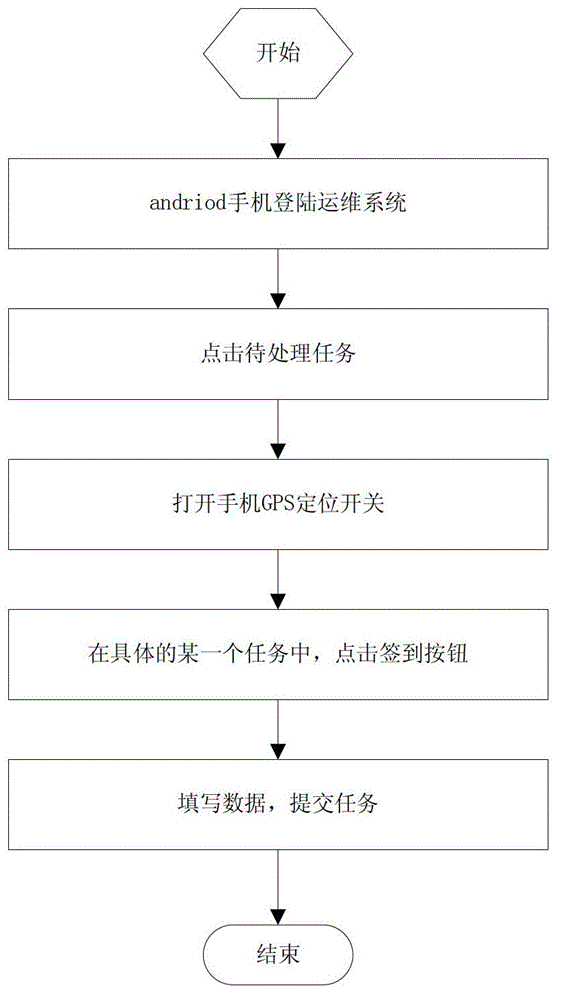

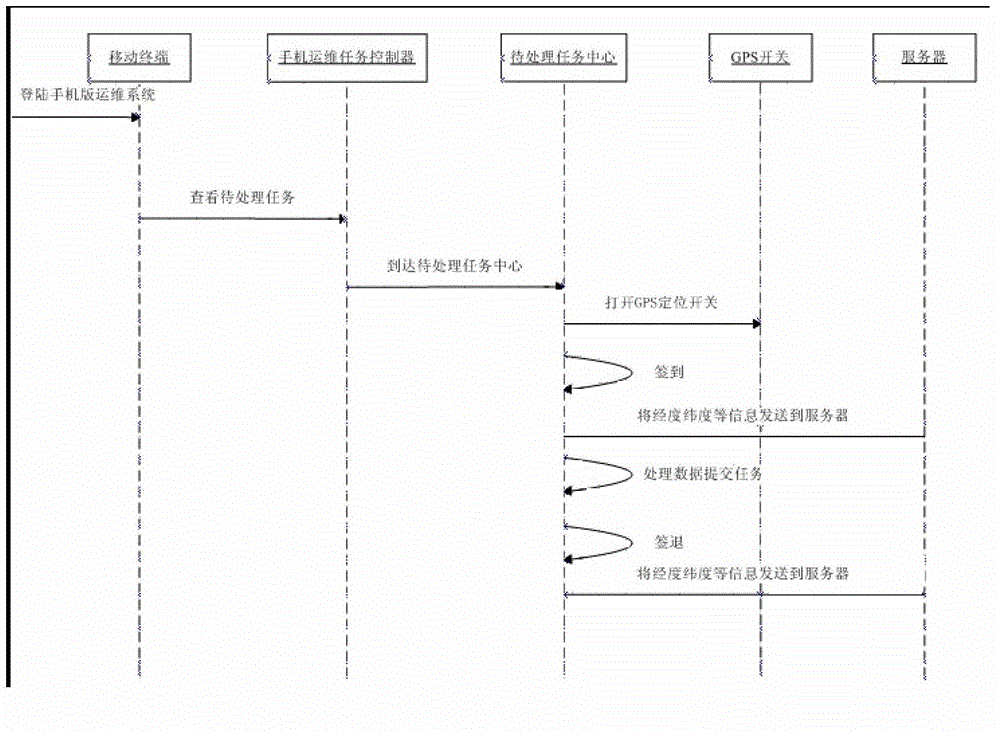

Operation personnel management method and system based on mobile phone GPS positioning

InactiveCN103942744AShorten execution cycleReduce time to complete feedbackData processing applicationsComputer scienceWireless data transmission

The invention discloses an operation personnel management method and system based on mobile phone GPS positioning. The operation personnel management system comprises an operation management center, a wireless data transmission system and a field terminal. Data is transmitted between the field terminal and the operation management center through the wireless data transmission system; the field terminal is an intelligent mobile phone; the intelligent mobile phone is provided with a GPS positioning function; after operation personnel register the system, the operation management center transmits task data to the field terminal; when the operation personnel click a sign-in button, the field terminal intelligent mobile phone automatically obtain such information as longitudes, latitudes, time and the like for transmitting to an operation management center server; in a task, the field terminal intelligent mobile phone transmits data back to the operation management center in real time; and during sign-off, the information as the longitudes, the latitudes, the time and the like is automatically obtained and transmitted to the operation management center. The method and system provided by the invention can assist field operation work with organization and management so as to improve the execution speed of a task work order, improve the transmission accuracy of operation data, and facilitate the management of the field operation personnel.

Owner:勤智数码科技股份有限公司

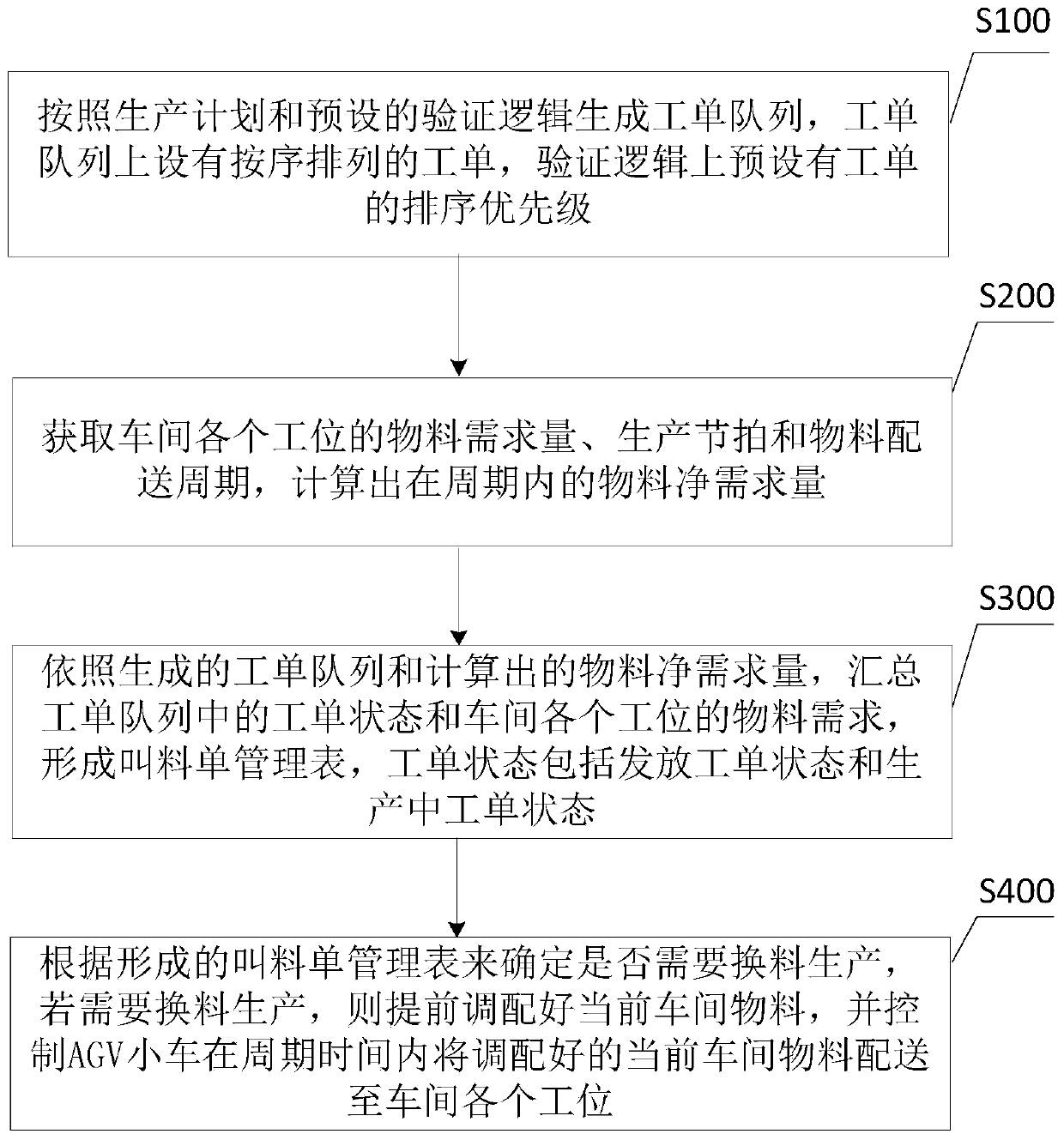

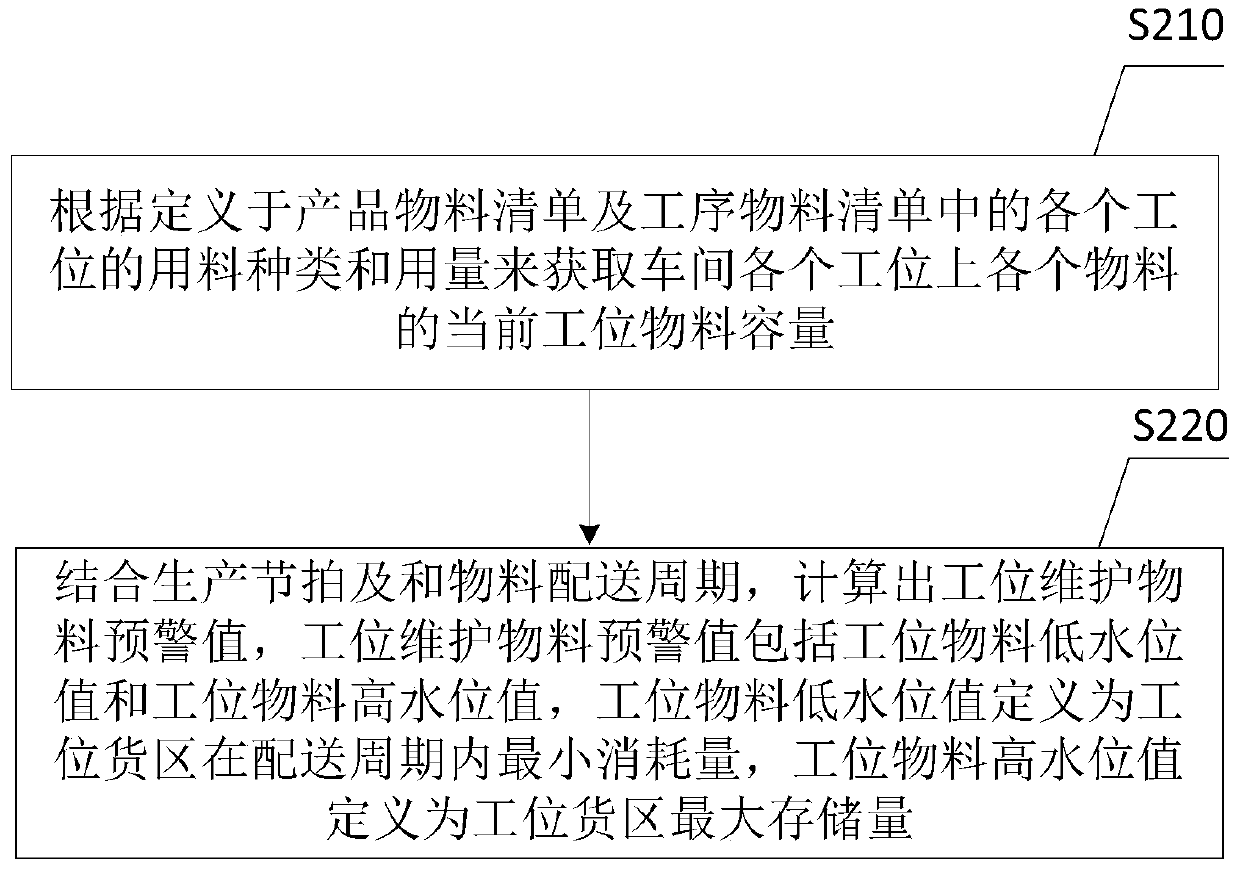

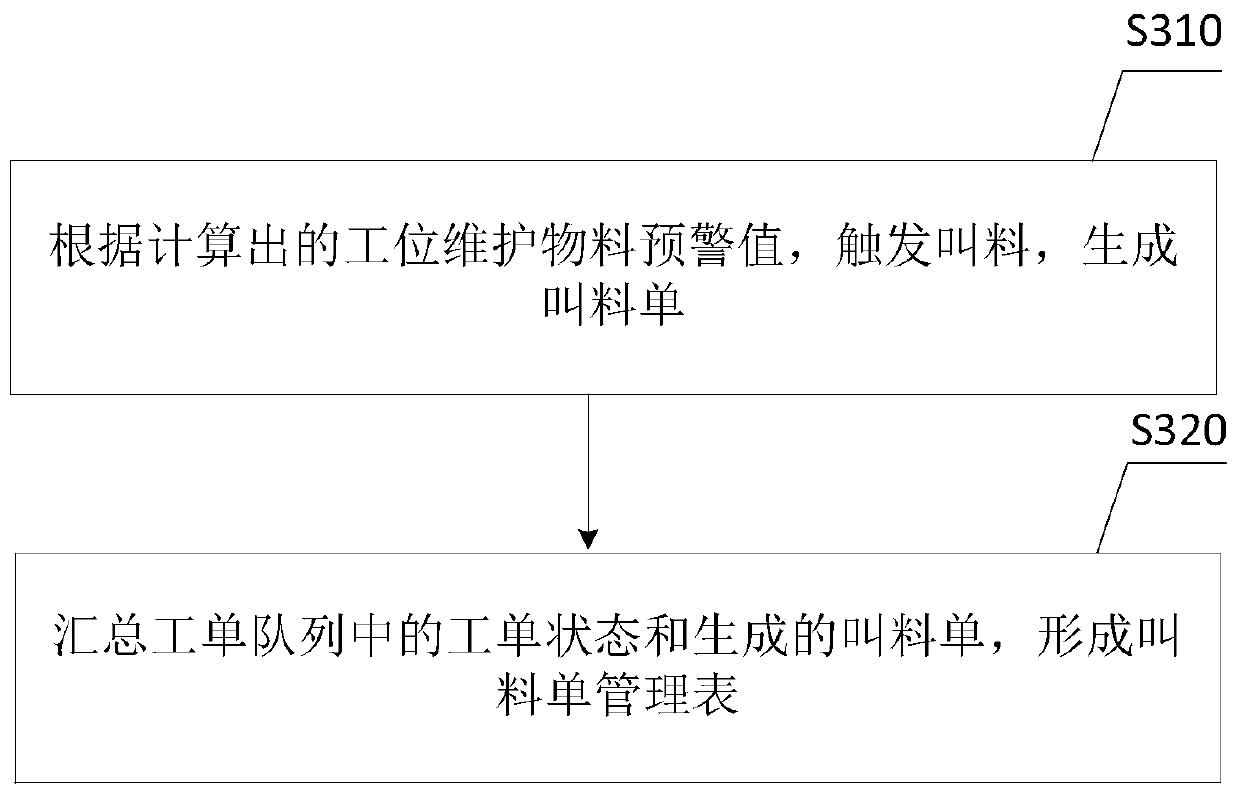

Vehicle scheduling method and system based on Internet of Things

InactiveCN111311154AReduce accumulationImprove punctualityResourcesLogisticsProduction lineThe Internet

The invention provides a vehicle scheduling method and system based on the Internet of Things. The method comprises the steps: generating a work order queue according to a production plan and preset verification logic; obtaining the current station material capacity, the production takt and the material distribution period of each station of the workshop, and calculating the material net demand inthe period; according to the generated work order queue and the calculated material net demand, summarizing the work order state in the work order queue and the material demand of each station of theworkshop to form a material calling list management table; according to the formed material calling list management table, whether material changing production is needed or not is determined, if material changing production is needed, the current workshop materials are allocated in advance, and the AGV is controlled to distribute the allocated current workshop materials to all stations of the workshop within the period time. According to the vehicle scheduling method and system based on the Internet of Things, material accumulation of online stations is reduced, and production line field management is improved; and the punctuality and the accuracy of material distribution are improved.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

Assembly process for IGBT (insulated gate bipolar transistor)

ActiveCN102386109AImprove proficiencyConducive to the implementation of standard operationSemiconductor/solid-state device manufacturingWork in processEngineering

The invention discloses an assembly process for an IGBT (insulated gate bipolar transistor). During the assembly process, a plurality of working position points are set, a working position device region is arranged in each corresponding working position point, and several inspectors are assigned. The assembly process for the IGBT comprises the following steps of: (1) setting a working position 1 where insulating silicone grease is coated; (2) setting a working position 2 where the IGBT and a radiator are pre-fastened; (3) setting a working position 3 where the radiator is fastened; (4) setting a working position 4 where heating resistors are assembled in the preset positions; (5) setting a working position 5 where a driving circuit board is fixed; (6) setting a working position 6 where the modular internal wiring of the component formed in the step (5) is completed; and after the above steps are completed in order, delivering the semi-finished products to a storage region. The process improves quality control and increases work efficiency.

Owner:CHAJNA MAJNING DRAJVS EHND AUTOMEHJSHN KO

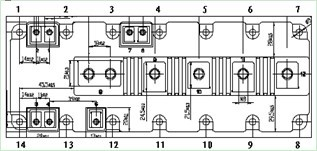

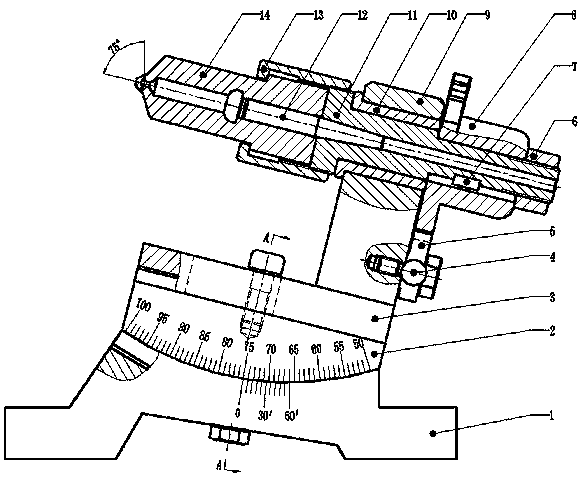

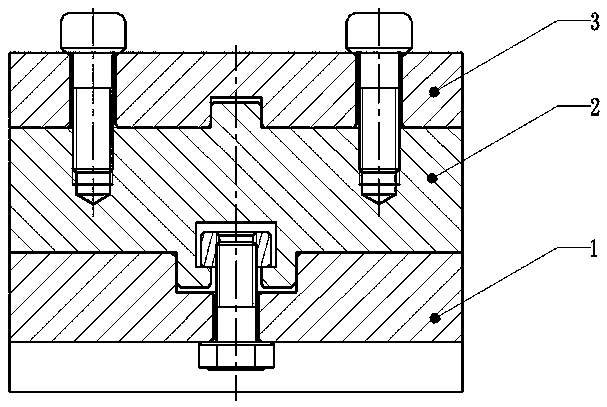

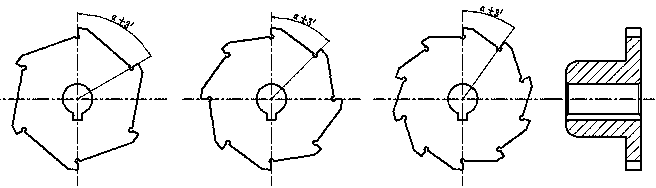

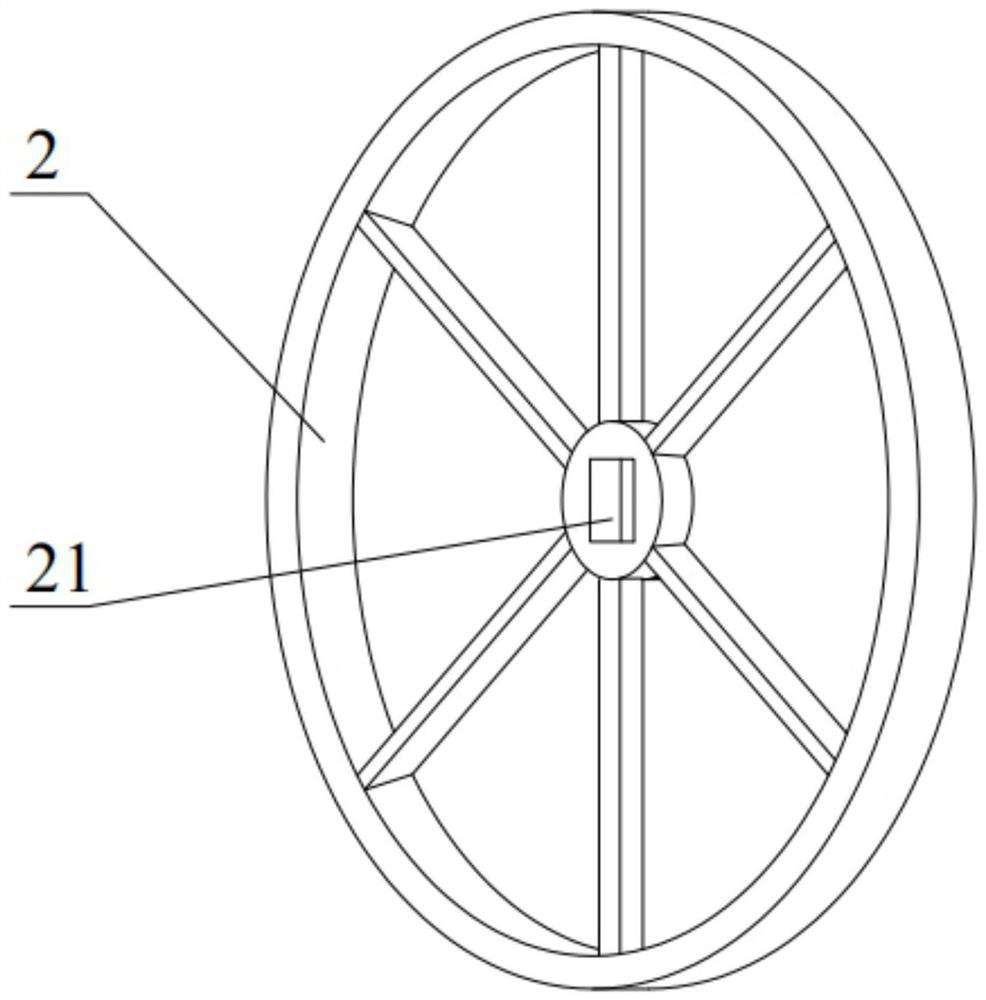

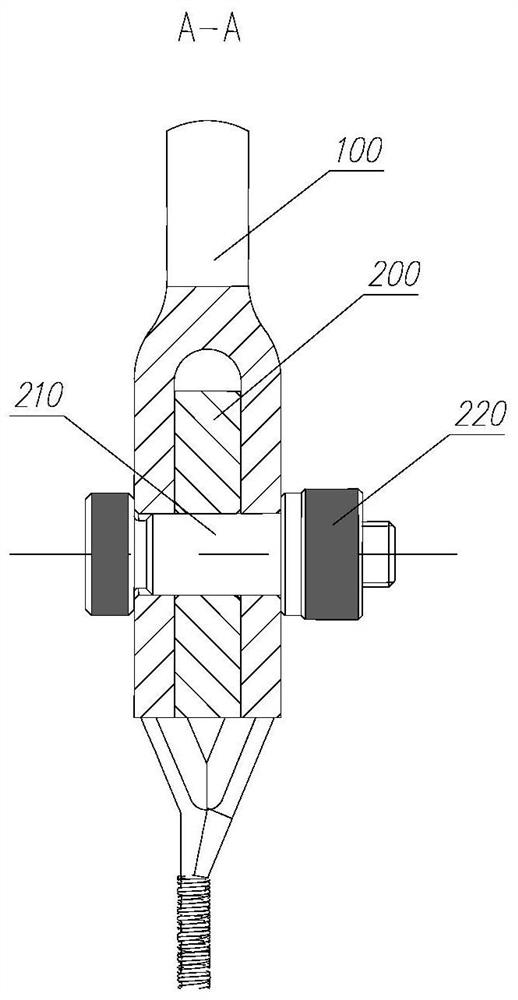

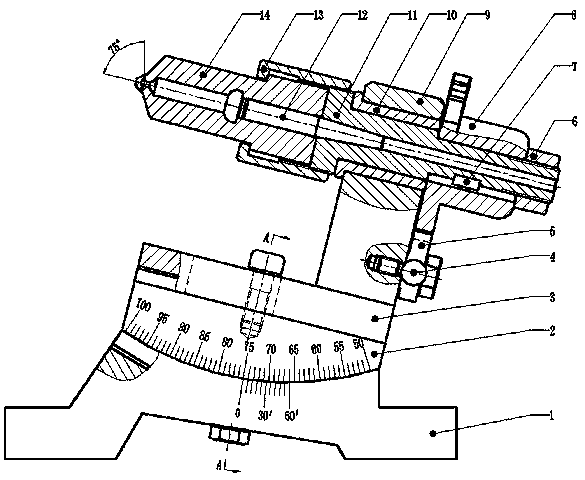

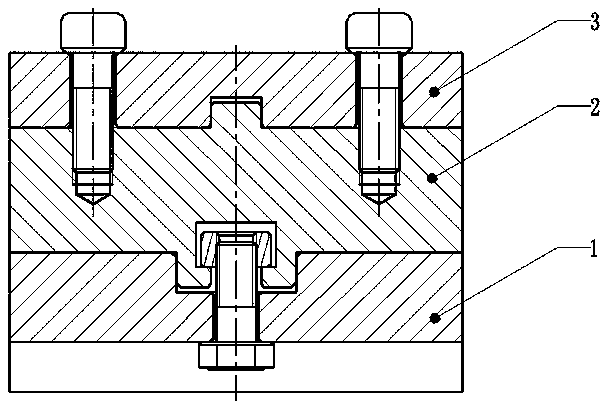

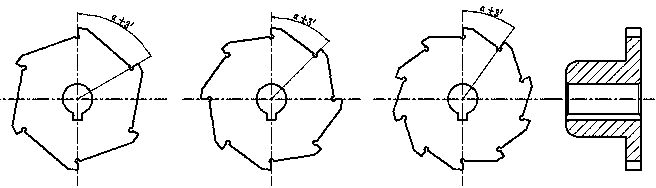

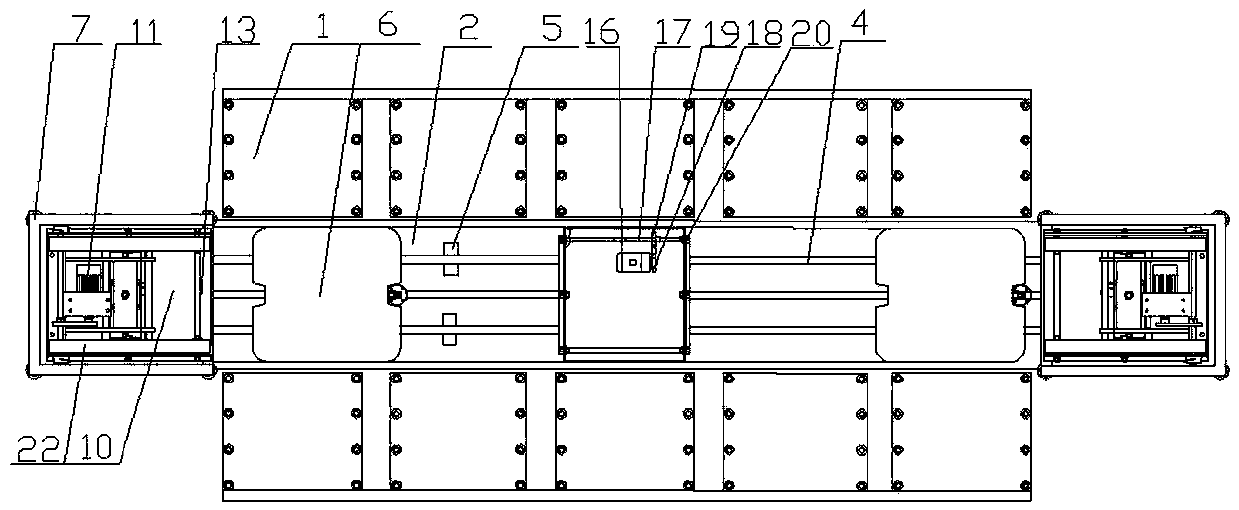

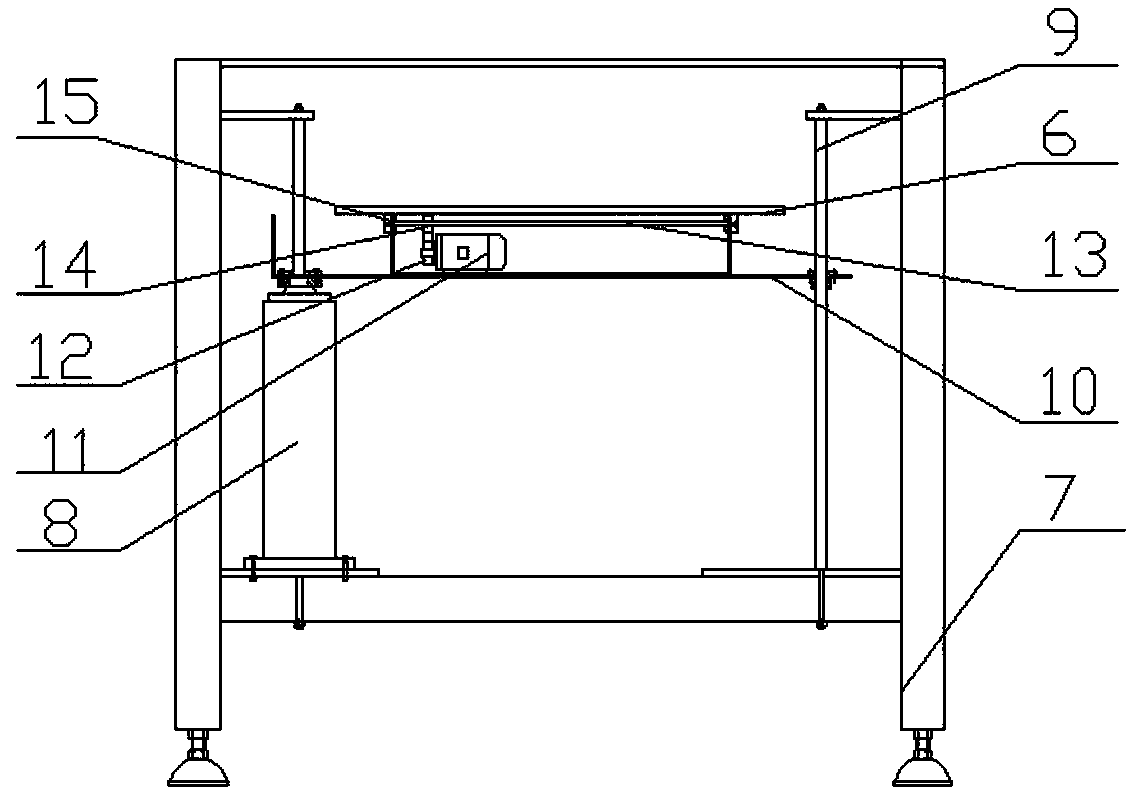

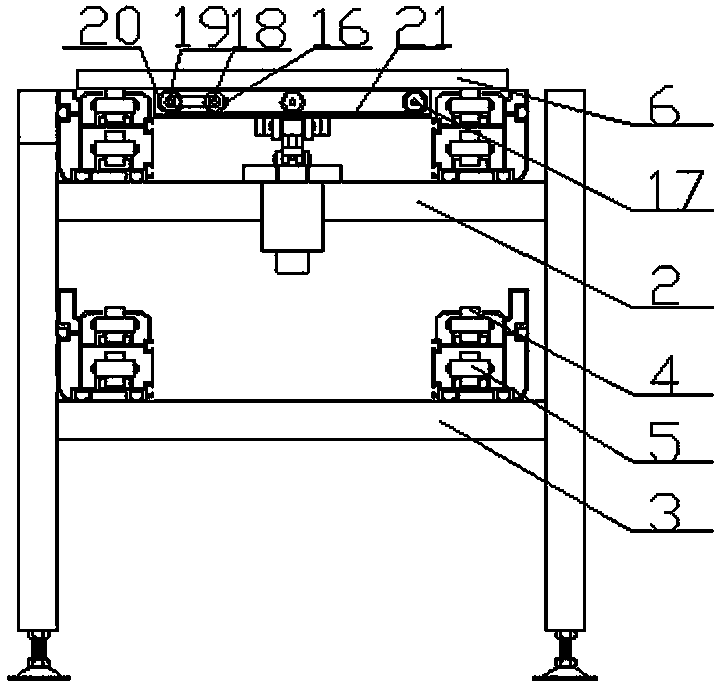

Flexible rapid-type-changing combination-type oil spraying nozzle spraying hole precise drilling clamp

ActiveCN109986381AGuaranteed accuracyGuaranteed wear resistancePrecision positioning equipmentPositioning apparatusAssistive device/technologySpray nozzle

The invention relates to the technical field of drilling machining auxiliary equipment, in particular to a flexible rapid-type-changing combination-type oil spraying nozzle spraying hole precise drilling clamp. The flexible rapid-type-changing combination-type oil spraying nozzle spraying hole precise drilling clamp comprises a base; an angle scale is connected to the base through a sliding block;a slide chute is formed in a sliding base, and the sliding base is locked with the angle scale through bolts; the sliding base is fixedly connected to a supporting post; a pawl is arranged on the supporting post through a fixing shaft; a balance weight is arranged on the pawl; a pawl clamping groove is combined with an index ratchet wheel clamping groove; the index ratchet wheel is fixedly connected to the periphery of a rotary spindle through a feather key; an index ratchet wheel is axially locked with the rotary spindle through a locking nut; a changeable positioning core shaft is connectedinto the rotary spindle; and a workpiece is locked on the changeable positioning core shaft through a holding-down nut. By adopting the flexible rapid-type-changing combination-type oil spraying nozzle spraying hole precise drilling clamp, the prominent problems of current oil spraying nozzle production enterprises that clamps are various; management is difficult; and manufacturing cost is high are solved. Product manufacturing cost can be greatly lowered; an on-site management level is enhanced; and meanwhile, the flexible rapid-type-changing combination-type oil spraying nozzle spraying hole precise drilling clamp can be promoted for use in the same industry.

Owner:菏泽广信船配油嘴油泵有限公司

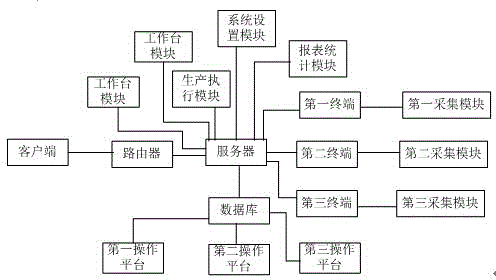

Small and special stepping motor production information management system

InactiveCN104318369AImprove pass rateIncrease productivityTechnology managementResourcesDatabase serverSystem configuration

The invention discloses a small and special stepping motor production information management system which comprises a workbench module, a plan management module, a production execution module, a report form statistics module, a system configuration module and a server. The workbench module, the plan management module, the production execution module, the report form statistics module and the system configuration module are connected with the server. The small and special stepping motor production information management system conducts automatic collection from equipment, needs no manual recording, completely eradicated human errors as all data are stored in the database server, and improves management efficiency.

Owner:哈特盈致(中山)智能科技有限公司

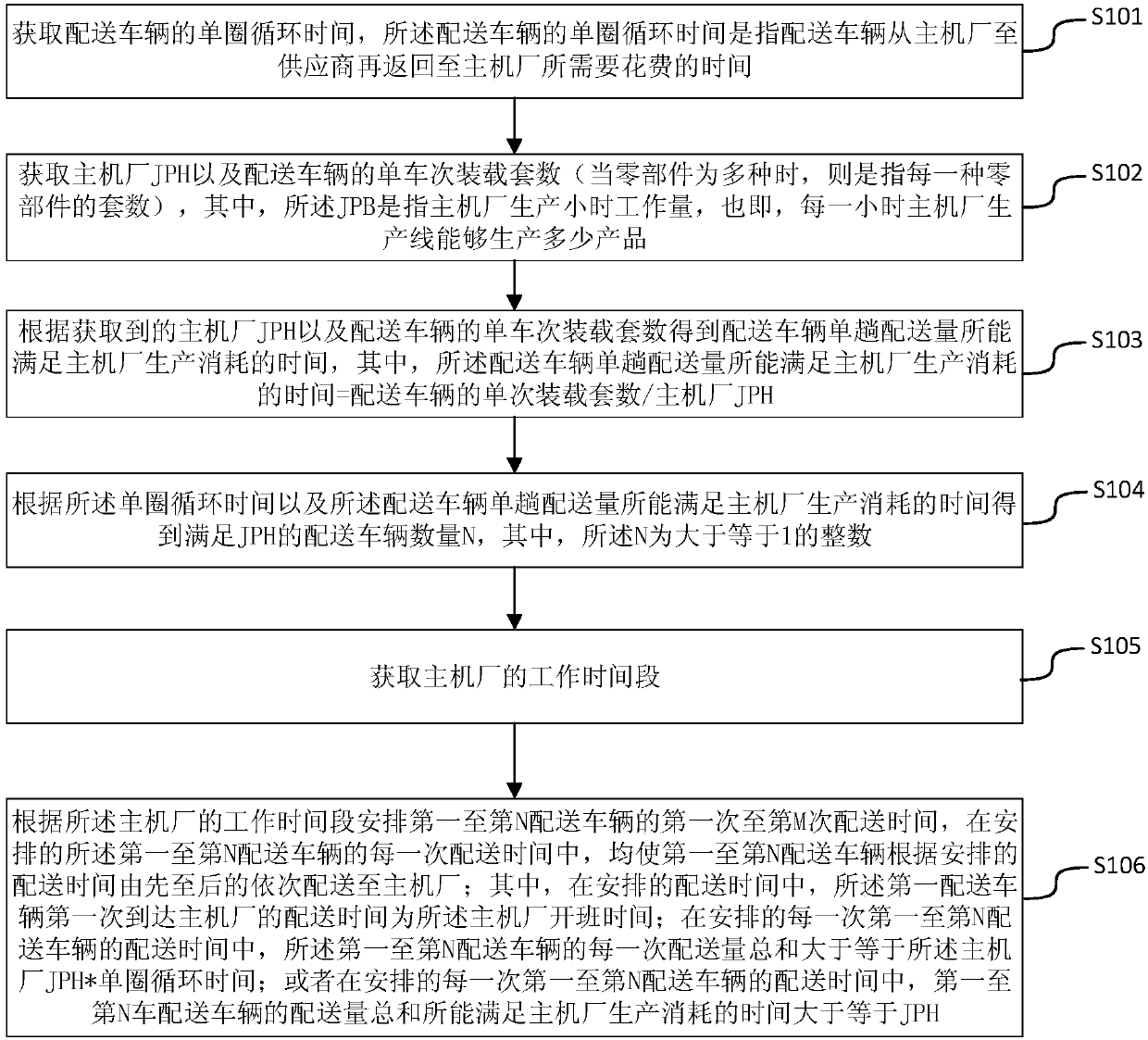

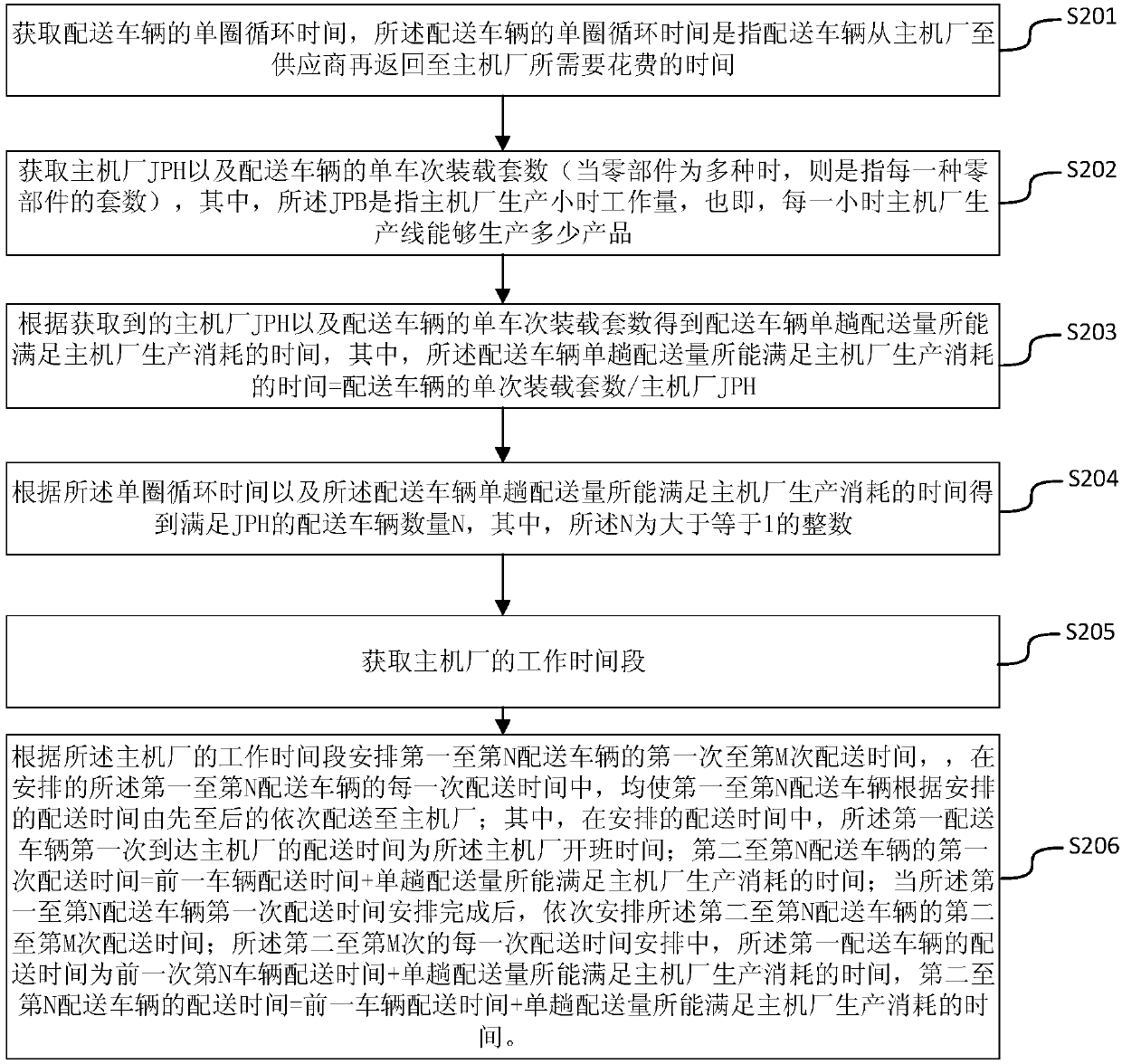

Logistics transport vehicle distribution time quick arrangement method

InactiveCN107679662AReduce cost wasteReduce investmentForecastingResourcesWork periodLogistics management

The invention discloses a logistics transport vehicle distribution time quick arrangement method. The method includes the following steps that: the single-lap cycling time of distribution vehicles isacquired, wherein the single-lap cycling time of the distribution vehicles is time for the distribution vehicles to move from a host manufacturer to a supplier and then go back to the host manufacturer; the JPH of the host manufacturer and the number of the sets of parts loaded by the distribution vehicles each time are acquired; time consumed for the single-round distribution quantity of the distribution vehicles to satisfy the production of the host manufacturer is obtained according to the obtained JPH of the host manufacturer and the number of the sets of the parts loaded by the distribution vehicles each time; and the number of distribution vehicles which satisfy the JPH is obtained according to the single-lap cycling time and the time consumed for the single-round distribution quantity of the distribution vehicles to satisfy the production of the host manufacturer; the working period of the host manufacturer is obtained; and the first time to M-th time distribution time of the first distribution vehicle and M-th distribution vehicle are arranged according to the working period of the host manufacturer.

Owner:CHONGQING CHANGAN MINSHENG APLL LOGISTICS

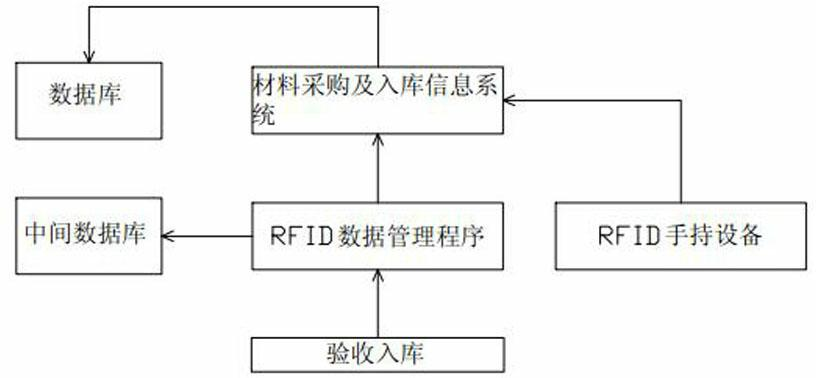

Acetic acid device special material safety management system by using radio frequency identification devices (RFID)

InactiveCN102682316AInventory SecurityAvoid loss and confusionCo-operative working arrangementsLogisticsAnti theftDynamic monitoring

Disclosed is an acetic acid device special material safety management system by using radio frequency identification devices (RFID). The system is characterized by comprising a data management system (1), readers (2) and electronic tags (3), wherein the data management system (1) is respectively connected with a plurality of readers (2), and the plurality of readers (2) are respectively connected with a plurality of electronic tags (3). Accordingly, the system collects data in the electronic tags by using readers, follows logistics information, monitors the whole status of the logistics information and achieves real-time anti-theft and in-and-out monitoring functions through in-and-out recording, dynamic monitoring and alarming and the like, then the operation process is clear, and the information is accurate, timely and complete.

Owner:SHANGHAI JINNENG SAFETY TECH

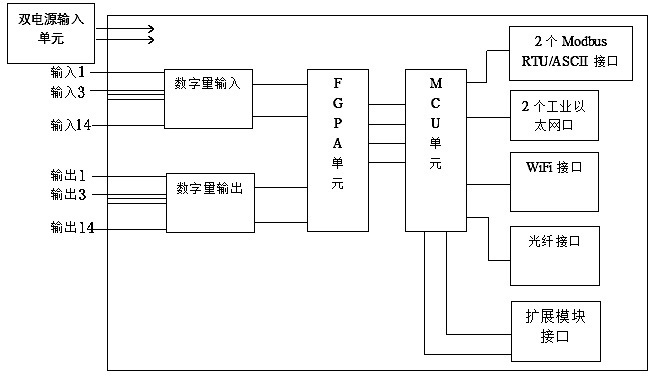

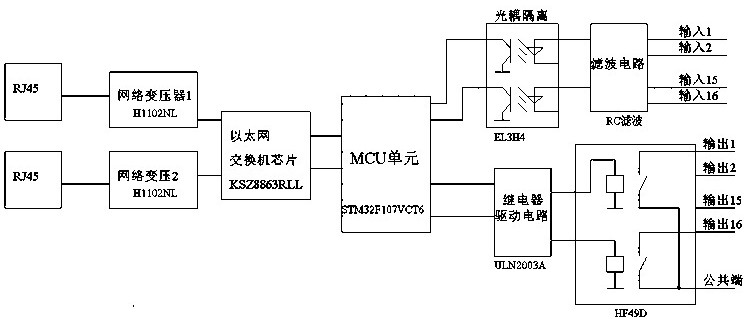

Control device and system for applying intelligent area controller to monitoring system

InactiveCN113311776AReduce usageFast transmissionProgramme controlComputer controlIndustrial EthernetCommunication interface

The invention discloses a control device for applying an intelligent area controller to a monitoring system, the device comprises an MCU unit, an FPGA unit, an input and output unit and a transmission unit, the input and output unit is connected with the MCU unit through the FPGA unit, and the MCU unit is in communication interaction with external equipment and an industrial Ethernet through being connected with the transmission unit; wherein the transmission unit comprises a plurality of communication interfaces, and the communication interfaces at least comprise two RS485 communication interfaces, two Ethernet communication interfaces, two optical fiber interfaces, two Modbus RTU / ASCII interfaces, a WiFi interface and an expansion module interface. The equipment integrates a design scheme of two industrial Ethernet ports and two optical fiber interfaces; the industrial Ethernet and optical fiber transmission improve the transmission speed, the transmission distance and the anti-interference performance; the optical fiber transmission can replace a large number of cables, the use of copper is reduced, and the effects of energy conservation and emission reduction are achieved; according to the invention, secondary development and programming debugging of equipment are not needed; the use difficulty is reduced, the use is simple, the maintenance is convenient, and the working efficiency is improved.

Owner:成都华拓为科技有限公司

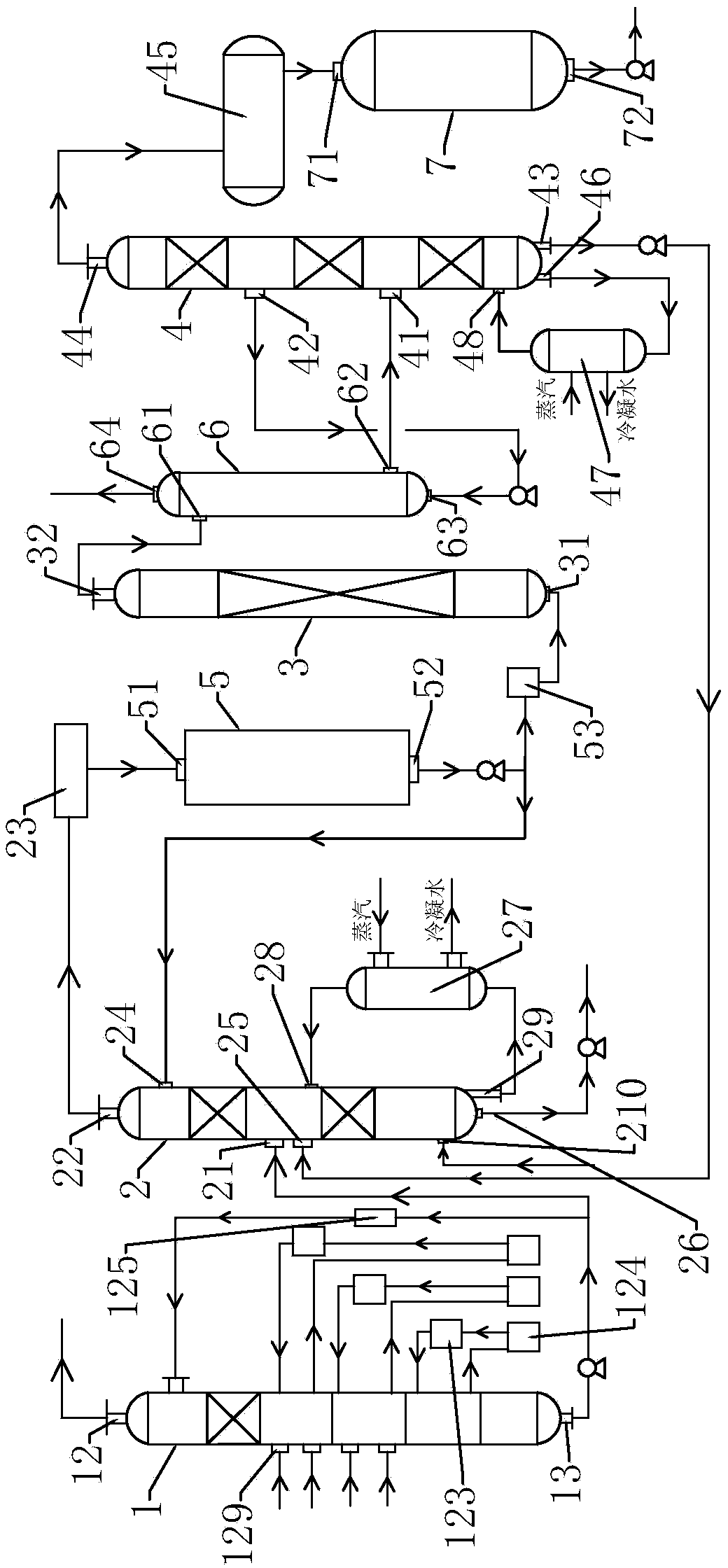

Production apparatus for nitromethane

InactiveCN103588644AImprove efficiencyReduce loadOrganic chemistryOrganic compound preparationProduction lineAutomatic control

The invention relates to the field of chemical engineering and especially discloses a production apparatus for nitromethane. The production apparatus comprises a synthesis reaction tower, a separating tower, a dehydrating tower and a rectifying tower. A synthesis reaction tower material inlet at the central part of the synthesis reaction tower is communicated with a material source through a pipeline, and a synthesis reaction tower material outlet at the bottom of the synthesis reaction tower is communicated with a separating tower first feed inlet at the central part of the separating tower via a material pump through pipelines, and a separating tower top discharge outlet at the top of the separating tower is communicated with a first intermediate tank feed inlet at the top of a first intermediate tank via a third condenser through pipelines. The production apparatus for nitromethane has the following beneficial effects: continuous production of a whole production line is realized, the level of automatic control is substantially increased, labor intensity is mitigated, production is safer, more efficient and environment-friendlier, a synthesis reaction is more complete, more uniform and more thorough, energy consumption is reduced, and product quality is improved.

Owner:LINYI YUANBO CHEM IND

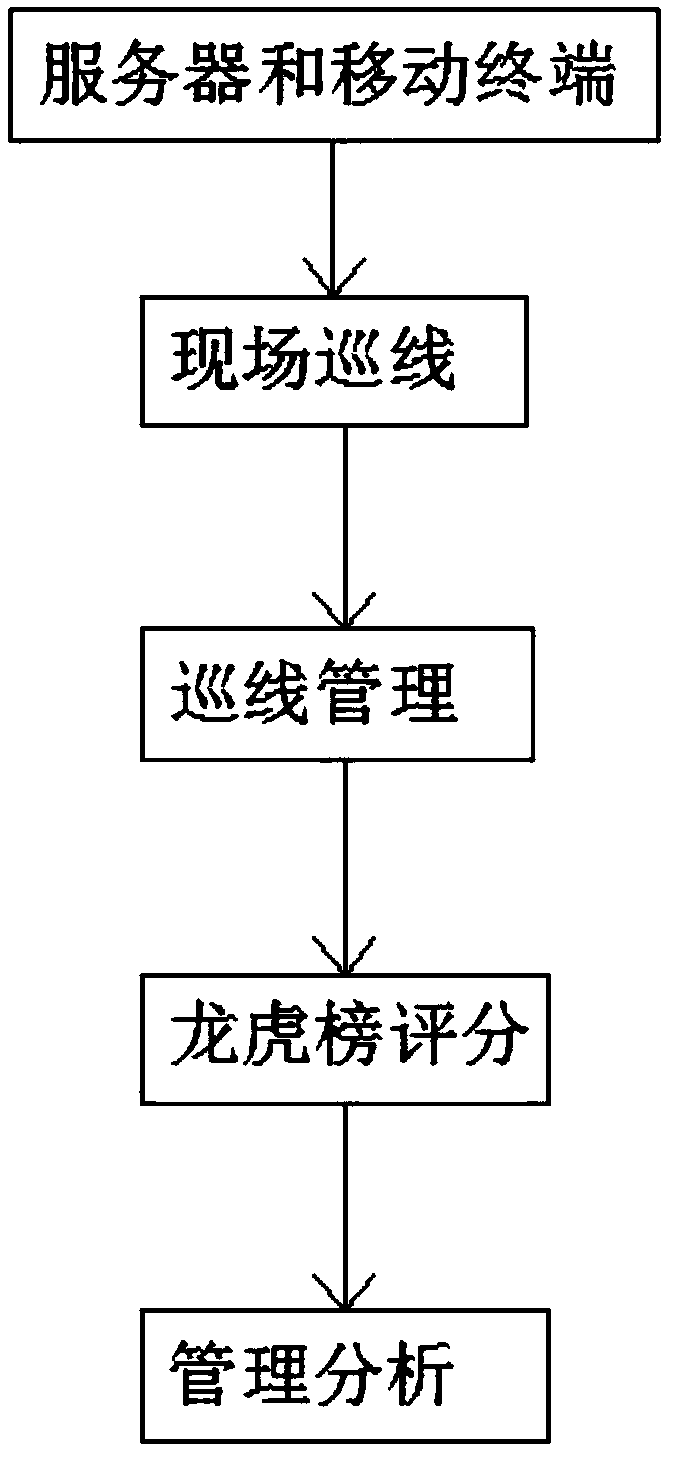

An intelligent line patrol system

PendingCN109345199AIncrease motivationEliminate wasteOffice automationManufacturing computing systemsThree levelComputer module

The invention discloses an intelligent line patrol system, comprising a server and a mobile terminal for accessing and connecting the server based on a B / S structure. The server and the mobile terminal comprise: a field line patrol module: wherein management personnel executes three-level line patrol process management, including a reminder function; the management personnel executes three-level line patrol process management. Patrol Management Module: Including patrol record module, problem module, audit module and case base module, through the patrol record module, managers can query and manage all levels of patrol problem records, through my problem module, managers can manage the patrol problem I want to improve, through my audit module, managers can manage the audit patrol problem that needs me; Through the case base module. The invention can improve the enthusiasm of the management cadres from the high level to the basic level to improve the site, solve the problems existing in the site, eliminate the waste in the management, standardize the management of the site, and improve the management level of the site through the three-level patrol line.

Owner:深圳市数本科技开发有限公司

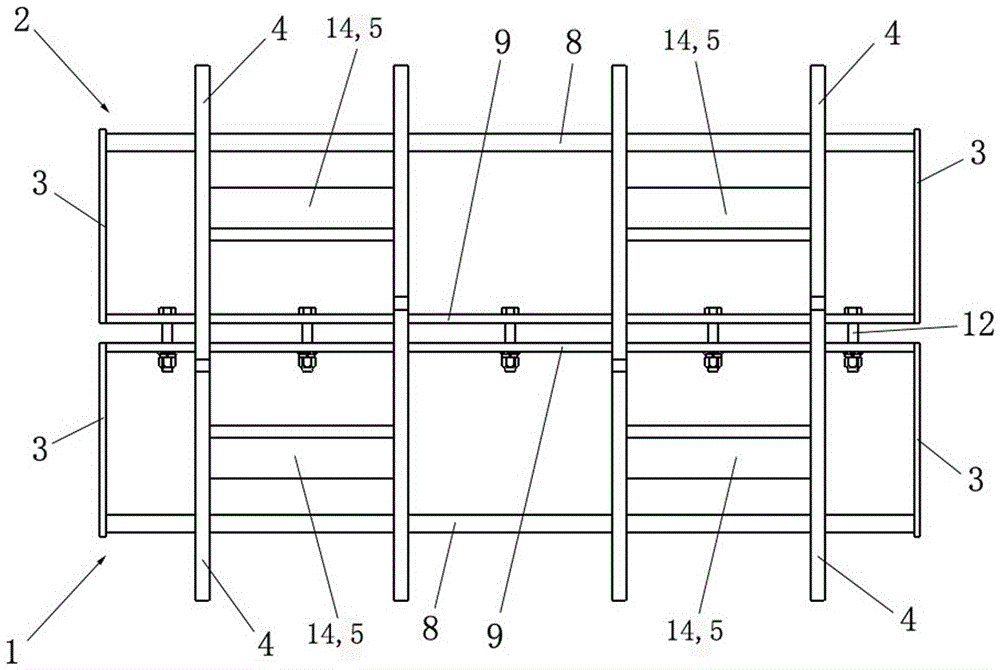

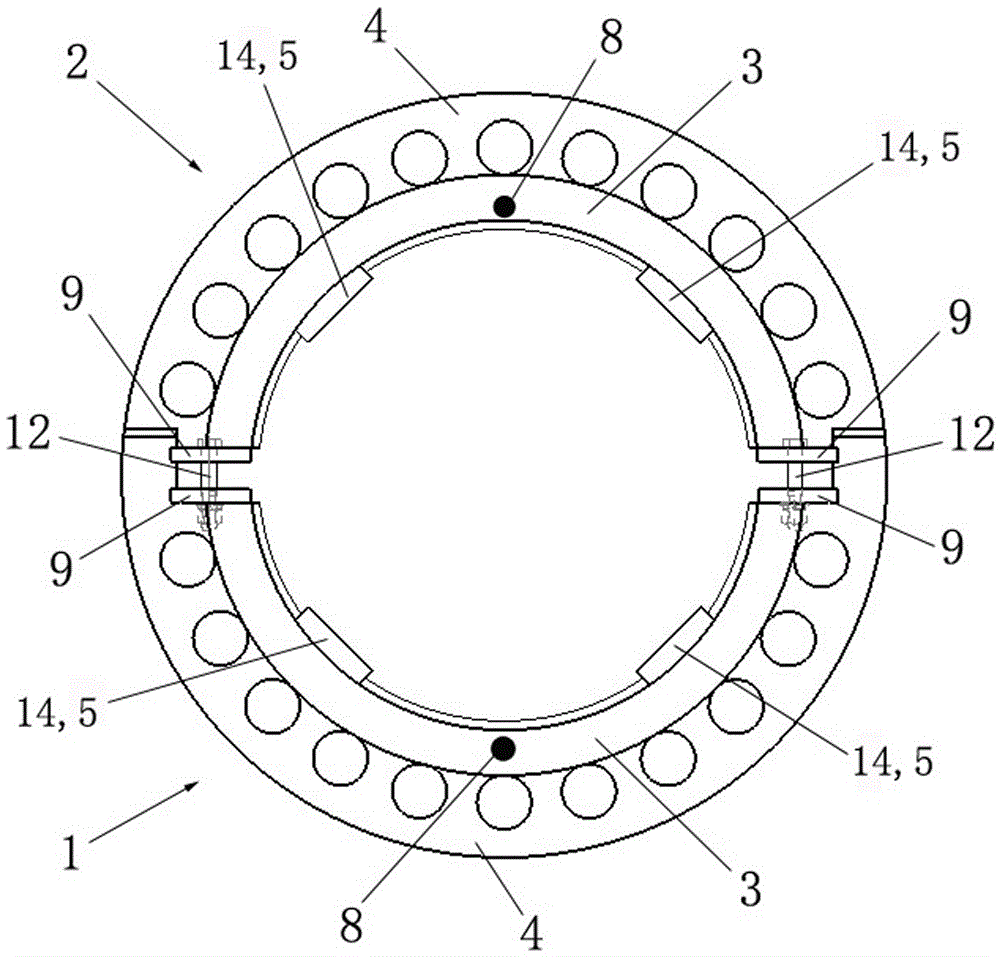

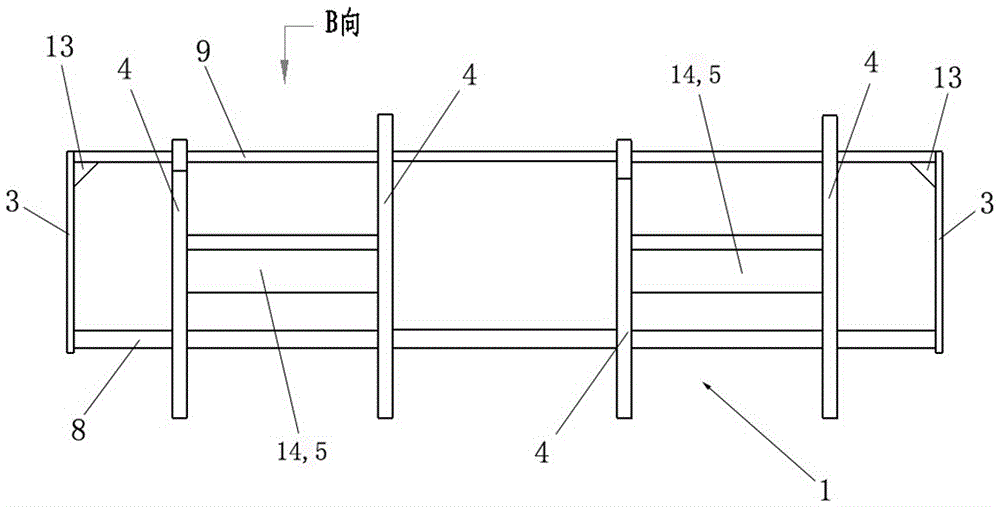

Stator core coil space half mortise and tenon rotary drying tooling

ActiveCN104135126BImprove efficiencyReduce churnManufacturing dynamo-electric machinesMortise and tenonEngineering

The invention is a semi-mortise and tenon rotary drying tool for stator core coil space, which solves the problems of difficult installation and disassembly, long installation time, easy loss of insulating paint and the like in the existing rotary drying tool. The tooling of the present invention is composed of the lower tooling and the upper tooling with the same structure butt joint fastening, and the upper and lower tooling are composed of a protective ring, a rotating disc, a positioning plate, a mounting plate, a longitudinal beam, a tightening plate, bolts and the like. Each matching part of the tooling of the present invention is a non-complete mortise and tenon structure, which is convenient for cleaning the retained insulating paint, but after the overall combination, the structural rigidity of the tooling is used to form an open mortise and tenon structure, so that the positioning of the tooling is accurate and reliable . The efficiency of the tooling of the present invention is more than 5 times higher than that of the original tooling, because it shortens the time for the product to be rotated from the paint tank to the oven, reduces the loss of insulating varnish, greatly improves the product quality, and solves the urgent need for production. The labor intensity of the operator is reduced.

Owner:CRRC YONGJI ELECTRIC CO LTD

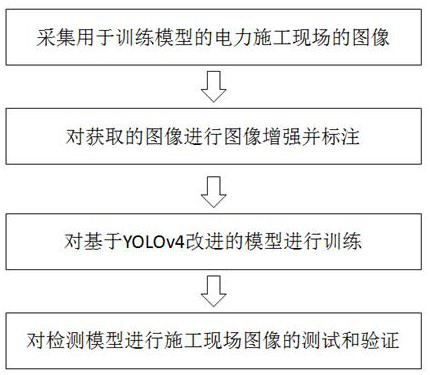

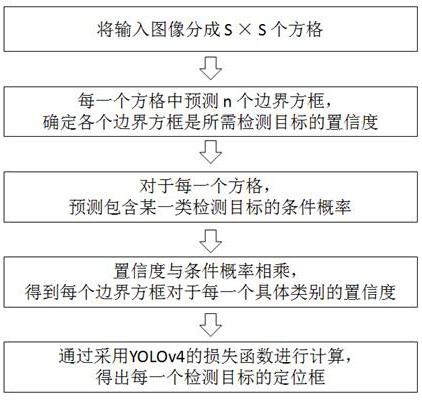

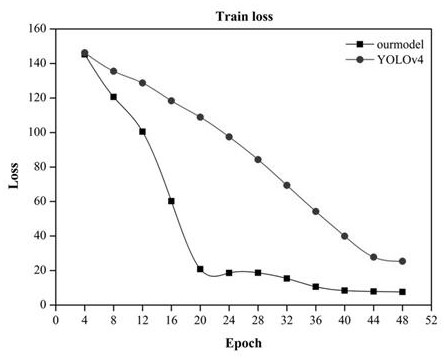

A method for detecting irregularities in electric power smart construction sites based on improved yolov4 algorithm

ActiveCN112149761BReduce the amount of parametersImprove feature extraction capabilitiesImage enhancementImage analysisAlgorithmEngineering

Owner:JIANGSU ELECTRIC POWER INFORMATION TECH

Construction Services Management Methods

ActiveCN108197779BImprove management levelEnhance the imageFinanceResourcesConstruction managementKnowledge management

The invention discloses a construction service management method, including a construction management method, an attendance checking method, a credit investigation and recruitment method, a fund lending method, an education and training method, and a professional skills certification method. The construction service management method of the present invention is mainly used to solve the problems of disadvantaged groups, high mobility, low wages, less education and training, high occupational risks, and poor sense of belonging faced by migrant workers in the construction industry, and at the same time, it can improve the construction development method. and the management level of the construction party.

Owner:四川省大益科技有限公司

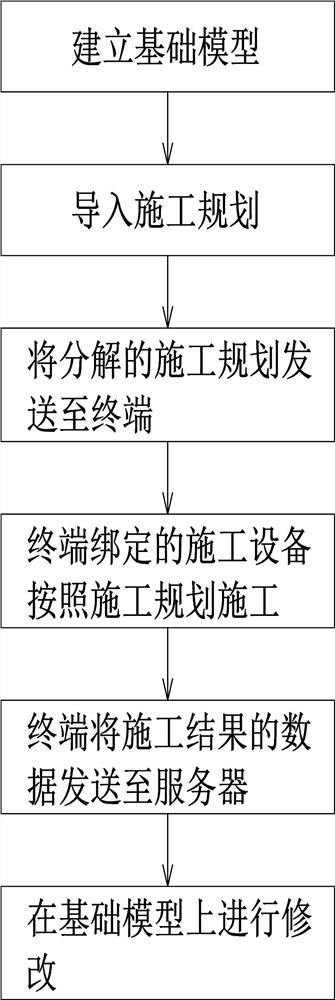

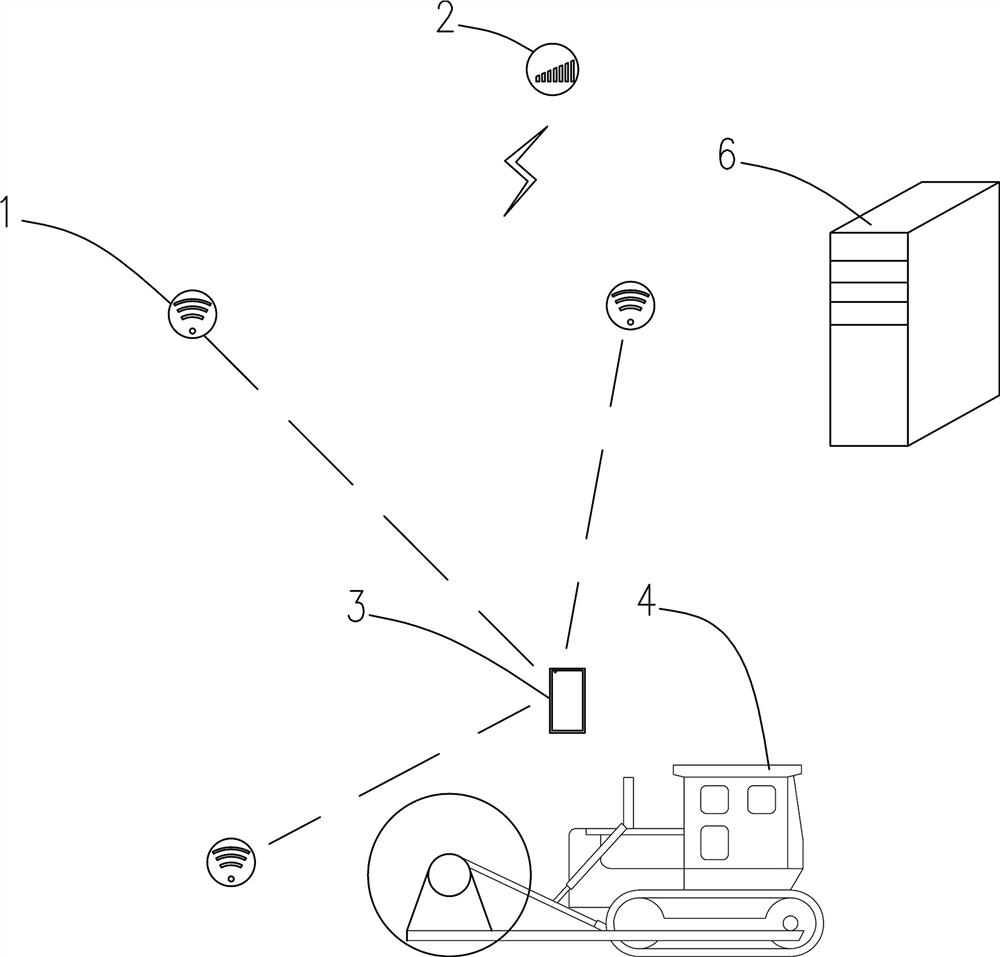

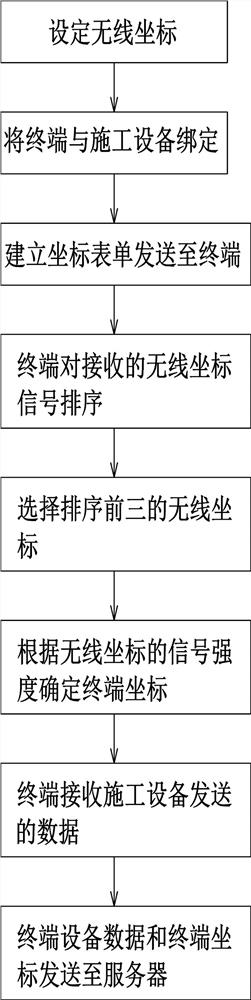

Real-time construction monitoring and management system without GPS (Global Positioning System) signal

PendingCN114189932AImprove practicalityReduce hardware costsNetwork topologiesBroadcast service distributionIntelligent managementGlobal Positioning System

The invention provides a construction real-time monitoring management system without a GPS signal. The system comprises a wireless coordinate, a terminal and construction equipment. The number of the wireless coordinates is multiple, the multiple wireless coordinates are arranged in a construction site in an array mode, WiFi chips are arranged in the wireless coordinates and used for sending wireless WiFi signals, and the distance between the wireless coordinates is smaller than the signal coverage range; the terminal is a mobile phone or a tablet computer, the terminal calculates the coordinates of the terminal according to the signal intensity of the wireless coordinates, and the terminal is connected with the server through the wireless base station; the terminal is bound with the construction equipment, the construction equipment is provided with a main control device, the main control device is electrically connected with the terminal, and the terminal sends data to the server. According to the method, coordinate positioning is realized by using a broadcast WIFI signal and a mobile phone as a terminal, the positioning precision can reach cm level, the hardware cost of coordinate positioning is greatly reduced, GPS positioning signals do not need to be collected completely, and the method is very suitable for intelligent management of construction equipment on a construction site.

Owner:国能大渡河猴子岩发电有限公司

Pattern conveying belt coiling device and using method thereof

Owner:SHANDONG PHOEBUS RUBBER

Optimization method for pulsating assembly line of small bypass ratio aeroengine

ActiveCN113059347BSimplify the process contentLow skill level requiredAircraft componentsAssembly machinesProcess engineeringAssembly line

The invention discloses a method for optimizing a pulsating assembly line of an aero-engine with a small bypass ratio, which includes optimizing the assembly process flow, determining the pulsating beat, determining the pulsating station, determining the product flow mode between the stations, configuring station resources, optimizing the process layout and Pilot run. The present invention breaks the original "big pot meal" mode in which multiple people work collectively, greatly reduces the number of workers at each station, realizes the fine management and operation of each station, eliminates the phenomenon of "slacker work", and improves the use of labor The process content of each station is simplified, the process division is more clear, the main body of quality responsibility is clear, and the requirements for the skill level of workers are reduced. As time goes by, the proficiency of workers will be greatly improved, and the consistency of assembly will be improved; The reform of engine assembly from "discrete mode" to "production line mode" has improved the on-site management level, assembly efficiency and assembly quality.

Owner:PLA NO 5719 FACTORY

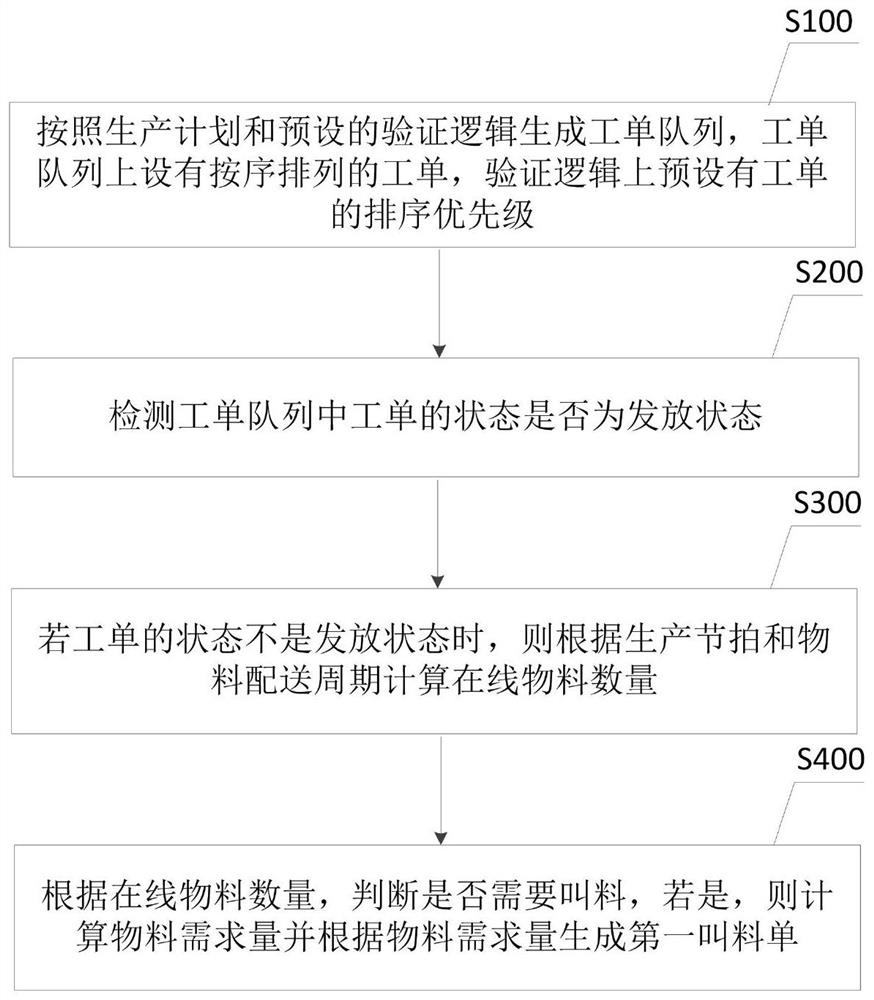

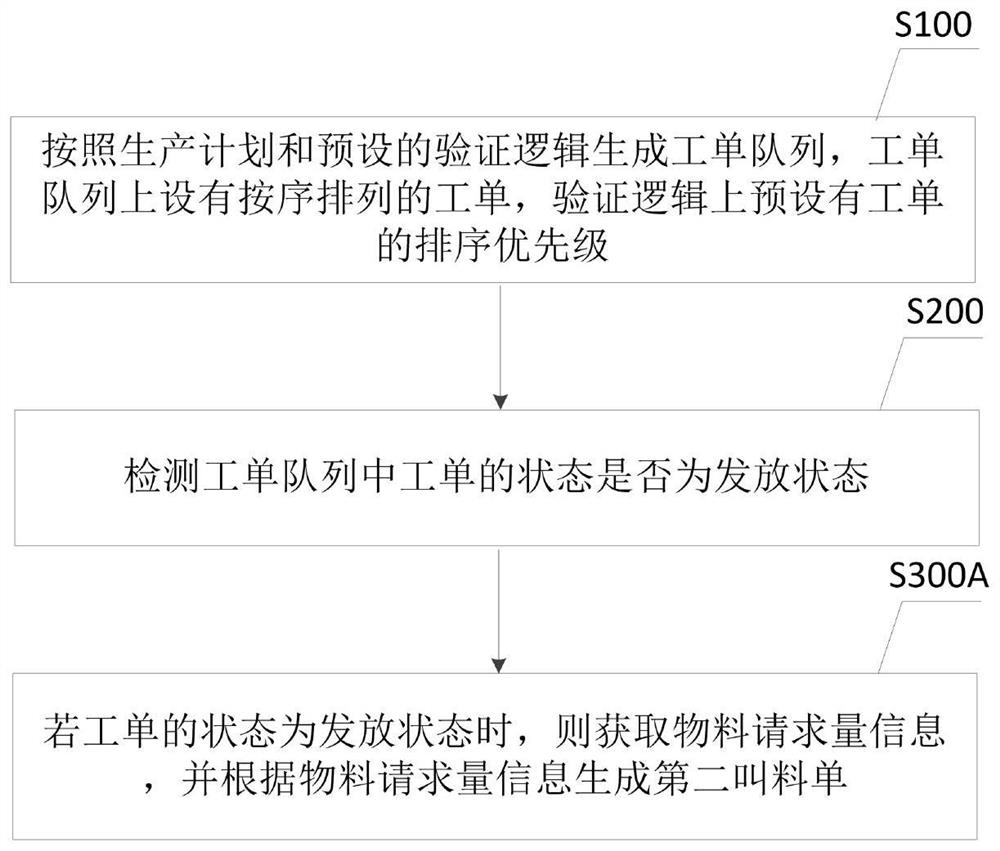

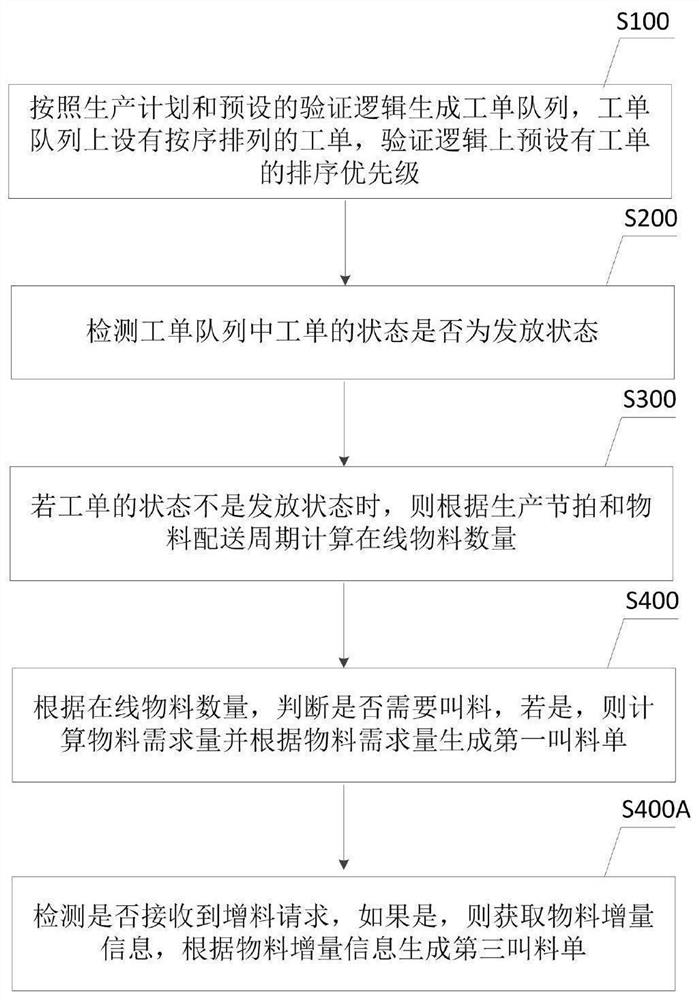

Material distribution control method and device in pull workshop

ActiveCN110390473BReduce accumulationImprove on-site managementResourcesLogisticsProduction lineBill of materials

The invention provides a pull-type workshop material distribution control method and device, the method includes the steps of: generating a work order queue according to the production plan and the preset verification logic, the work order queue is provided with work orders arranged in order, and the verification logic is The sorting priority of the work order is preset; check whether the status of the work order in the work order queue is the release status; if the status of the work order is not the release status, calculate the quantity of online materials according to the production tact and material delivery cycle; according to the online material Quantity, to determine whether to call for materials, if so, calculate the material demand and generate the first bill of material based on the material demand. The material distribution method and device in the workshop provided by the present invention can reduce the accumulation of materials at the online stations, improve the on-site management of the production line, reduce production stoppages caused by untimely material distribution, and reduce or even cancel the warehouse area near the line.

Owner:GUANGZHOU SIE CONSULTING CO LTD

A flexible, fast-changing, combined injector nozzle hole precision drilling fixture

ActiveCN109986381BGuaranteed accuracyGuaranteed wear resistancePrecision positioning equipmentPositioning apparatusRatchetInjector nozzle

The invention relates to the technical field of drilling processing auxiliary equipment, in particular to a flexible, fast-changing, combined precision drilling jig for injection nozzle holes, including a base, the angle plate and the base are connected by a slider, and the sliding base has a The chute is locked with the angle plate through bolts. The sliding base is fixedly connected to the supporting column, a pawl is installed on the supporting column through a fixed shaft, the counterweight is installed on the pawl, the pawl slot is combined with the indexing ratchet slot, and the indexing ratchet is connected to the indexing ratchet through the sliding key. The rotating main shaft is fixed circumferentially, and the indexing ratchet is axially locked with the rotating main shaft through a lock nut. The rotating main shaft is connected with a replaceable positioning mandrel, and the workpiece is locked on the replaceable positioning mandrel through a compression nut. The invention can solve the outstanding problems of many fixtures, difficult management and high manufacturing cost in the current fuel injector manufacturing enterprises, can greatly reduce the product manufacturing cost, improve the on-site management level, and can also be popularized and applied in the same industry.

Owner:菏泽广信船配油嘴油泵有限公司

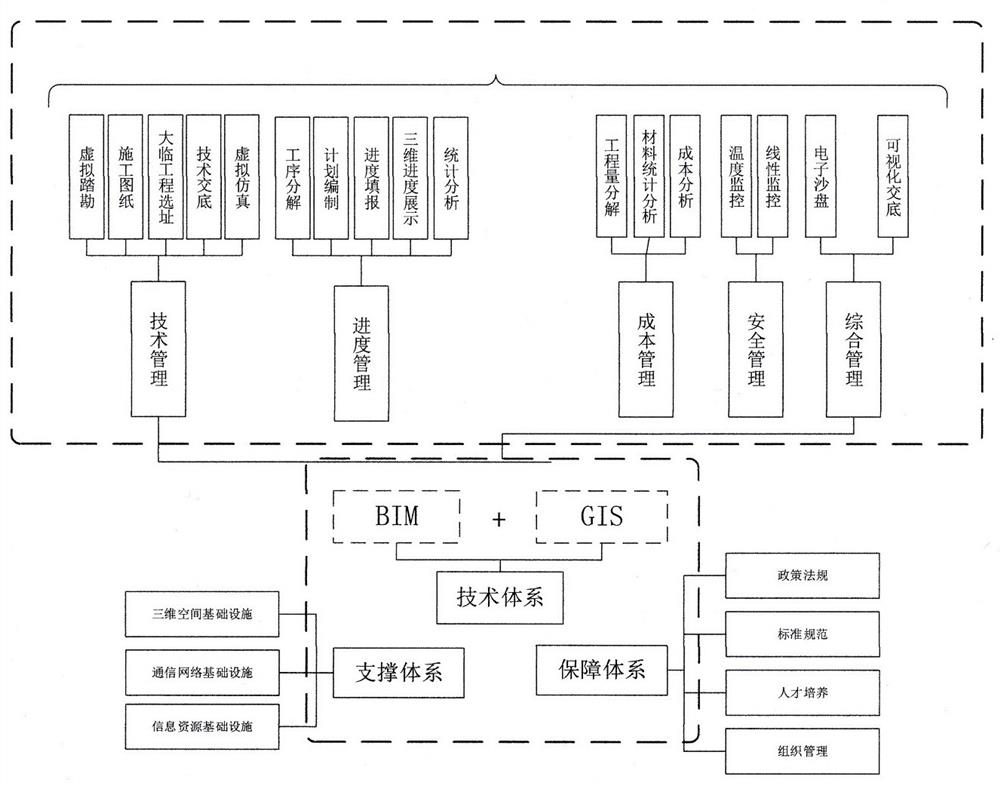

A construction control method for large-span continuous beam swivels based on BIM technology

ActiveCN111021265BRealize all-round monitoringImprove on-site managementGeometric CADBridge erection/assemblyInformation repositoryInformatization

A BIM technology-based construction management and control method for railway long-span continuous beam rotation belongs to the field of information management of railway long-span continuous beam rotation. It is mainly invented to solve the difficult problem of fine management of bridge swivel site construction at present. Comprehensive management includes on-site viewing of the electronic sand table and disclosure of 3D visualization technology for comprehensive management. Technical management includes on-site live viewing of the electronic sand table, 3D visualization technology disclosure, and collision inspection. Progress management compares and analyzes the actual progress and planned progress according to the prepared construction progress plan, and automatically calculates the delayed construction period. Cost management uses the model that has been built to directly count and generate project quantities. Safety management monitors the swivel beam support, establishes the association between the BIM model and the equipment, and forms an information database for safety and quality management. The advantage is to assist managers in effective decision-making and fine management, ensuring that management elements such as construction plans, schedules, and quality are manageable and controllable.

Owner:CHINA RAILWAY 19TH BUREAU GRP 1ST ENG +1

Process production system used for stator coil insulation

ActiveCN102820747BReduce usageOptimize the connection relationship between processesApplying solid insulationStator coilTransverse plane

Owner:CRRC YONGJI ELECTRIC CO LTD

Assembly process for IGBT (insulated gate bipolar transistor)

ActiveCN102386109BImprove proficiencyConducive to the implementation of standard operationSemiconductor/solid-state device manufacturingQuality controlWork in process

The invention discloses an assembly process for an IGBT (insulated gate bipolar transistor). During the assembly process, a plurality of working position points are set, a working position device region is arranged in each corresponding working position point, and several inspectors are assigned. The assembly process for the IGBT comprises the following steps of: (1) setting a working position 1 where insulating silicone grease is coated; (2) setting a working position 2 where the IGBT and a radiator are pre-fastened; (3) setting a working position 3 where the radiator is fastened; (4) setting a working position 4 where heating resistors are assembled in the preset positions; (5) setting a working position 5 where a driving circuit board is fixed; (6) setting a working position 6 where the modular internal wiring of the component formed in the step (5) is completed; and after the above steps are completed in order, delivering the semi-finished products to a storage region. The process improves quality control and increases work efficiency.

Owner:CHAJNA MAJNING DRAJVS EHND AUTOMEHJSHN KO

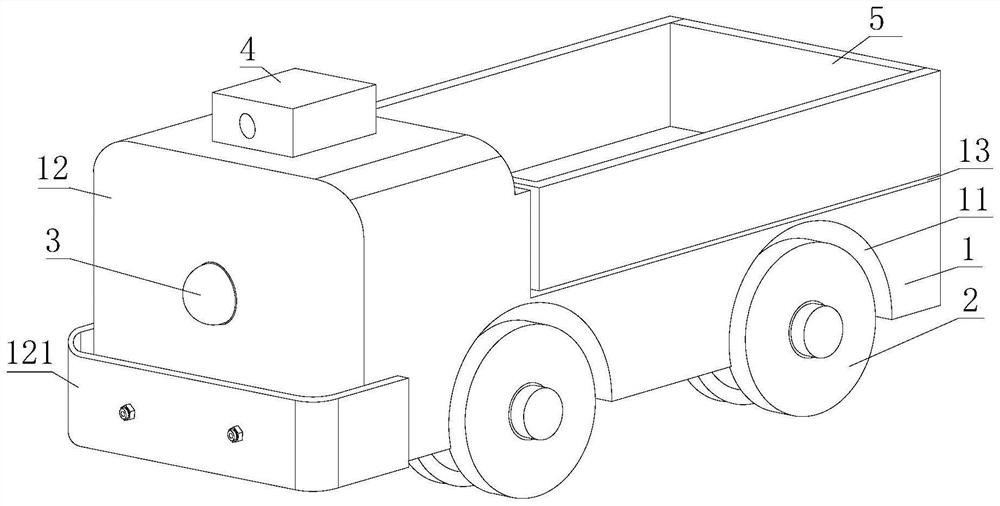

Raw material distribution device with tracking function for construction site and implementation method thereof

PendingCN112572269AImprove on-site managementFunctionalClosed circuit television systemsItem transportation vehiclesControl systemElectric machinery

The invention discloses a raw material distribution device with a tracking function for a construction site and an implementation method thereof, and belongs to the technical field of construction site raw material distribution. The raw material distribution device comprises a conveying vehicle body, a mounting half groove is formed in the lower portion of the conveying vehicle body, and a power assembly is mounted in the mounting half groove; and the power assembly comprises a moving motor, a connecting shaft rod, rolling wheels, a moving control system and a supporting plate. According to the raw material distribution device with the tracking function for the construction site and the implementation method thereof, material inspection can be managed and controlled, field management can be improved, the functions are practical, the effect is good, the working efficiency is improved, automatic tracking is achieved for conveying raw materials, the feeding efficiency is improved, and when line errors occur, the main control module enables the alarm circuit to give an alarm so that personnel are reminded to check conditions, and real-time positioning is realized; and through the modethat a charging box body inclines, the materials are effectively output, the discharging efficiency is improved, the inconvenience of manual discharging is reduced, and the production benefits are improved.

Owner:GUANGZHOU HUALI SCI & TECH VOCATIONAL COLLEGE

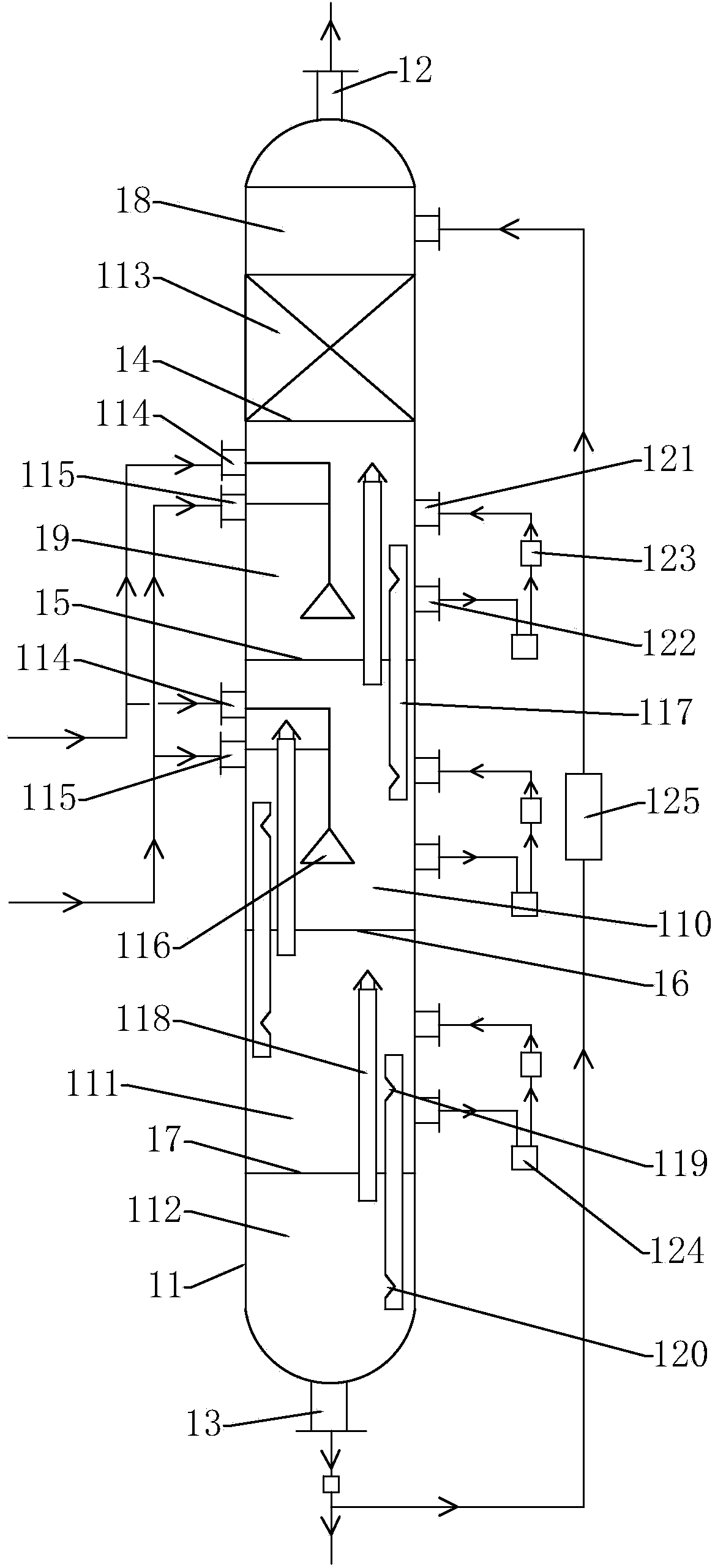

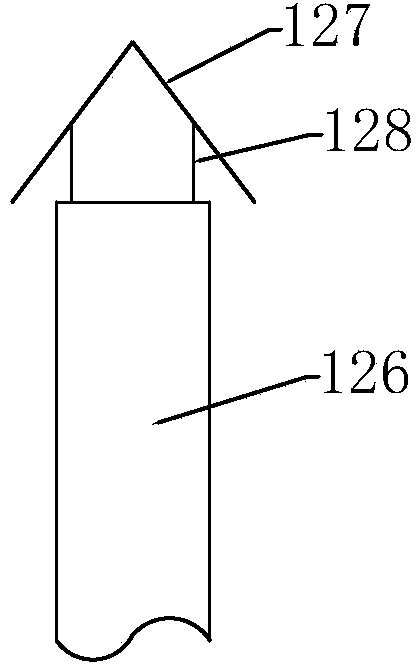

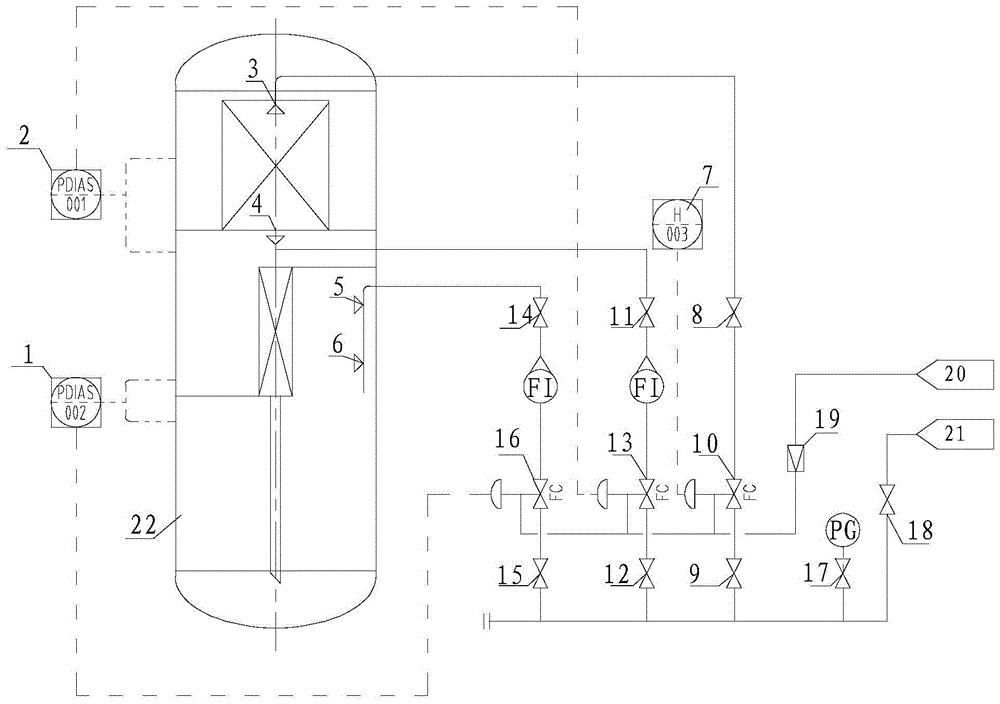

Nitrogen oxide separation device that can realize automatic online cleaning

The invention relates to a nitrogen oxide separating device capable of being automatically and online washed. The nitrogen oxide separating device comprises a separating device body and a spraying washing mechanism. The spraying washing mechanism is composed of an upper-separating-element top spraying opening, an upper-separating-element bottom spraying opening, lower-separating-element spraying openings, an upper-separating-element pressure difference control unit, a lower-separating-element pressure difference control unit, an upper-separating-element top spraying control unit, an instrument air conveyer, a spraying liquid conveyer, a plurality of electromagnetic switching valves and a plurality of stop valves. The output end of the instrument air conveyer and the output end of the spraying liquid conveyer are communicated with the air input ends and the liquid input ends of the electromagnetic switching valves respectively, and the output ends of the electromagnetic switching valves are connected to the input ends of the lower-separating-element spraying openings and the input end of the upper-separating-element top spraying opening. By means of the nitrogen oxide separating device, automatic online spraying washing of the nitrogen oxide separating device is achieved, the spraying washing mechanism can be accurately started in time, washing efficiency is high, safe and reliable running of the nitrogen oxide separating device can be effectively guaranteed, and the site management level of an enterprise is improved.

Owner:XIAN TONGDA TECH CO LTD

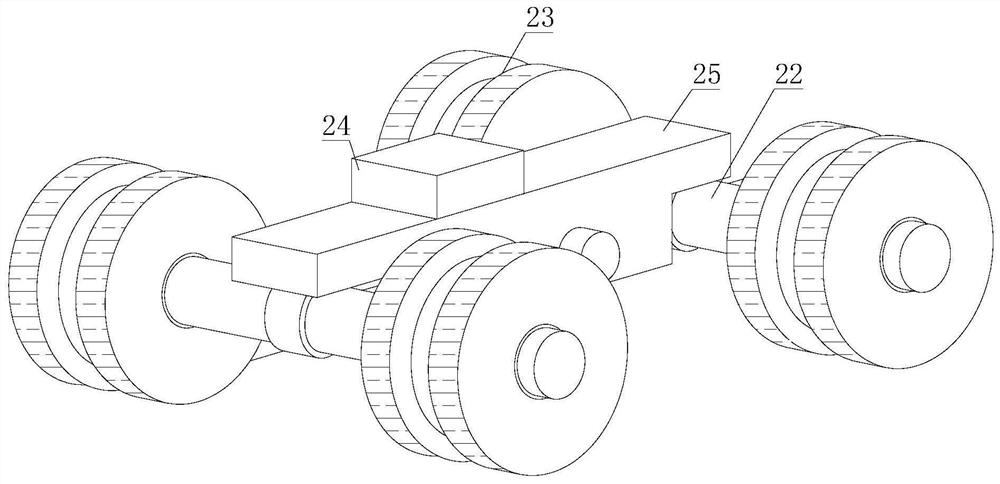

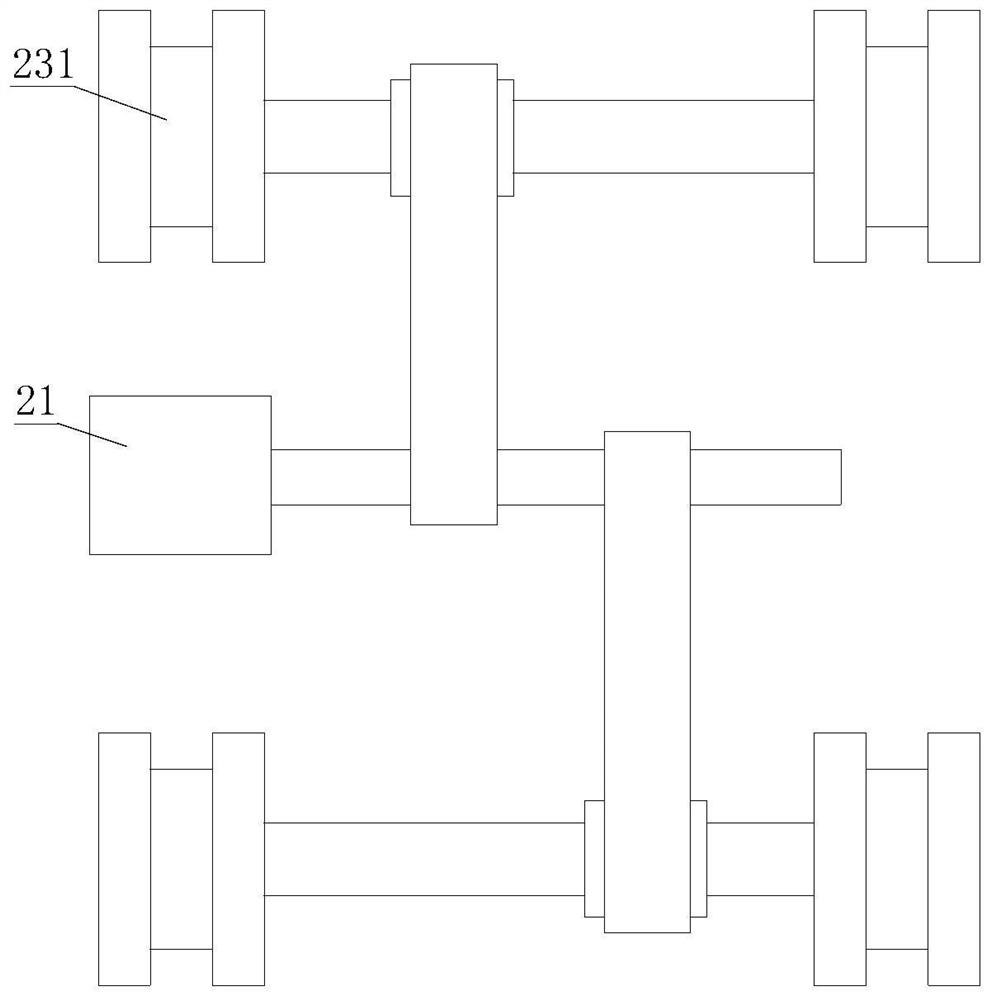

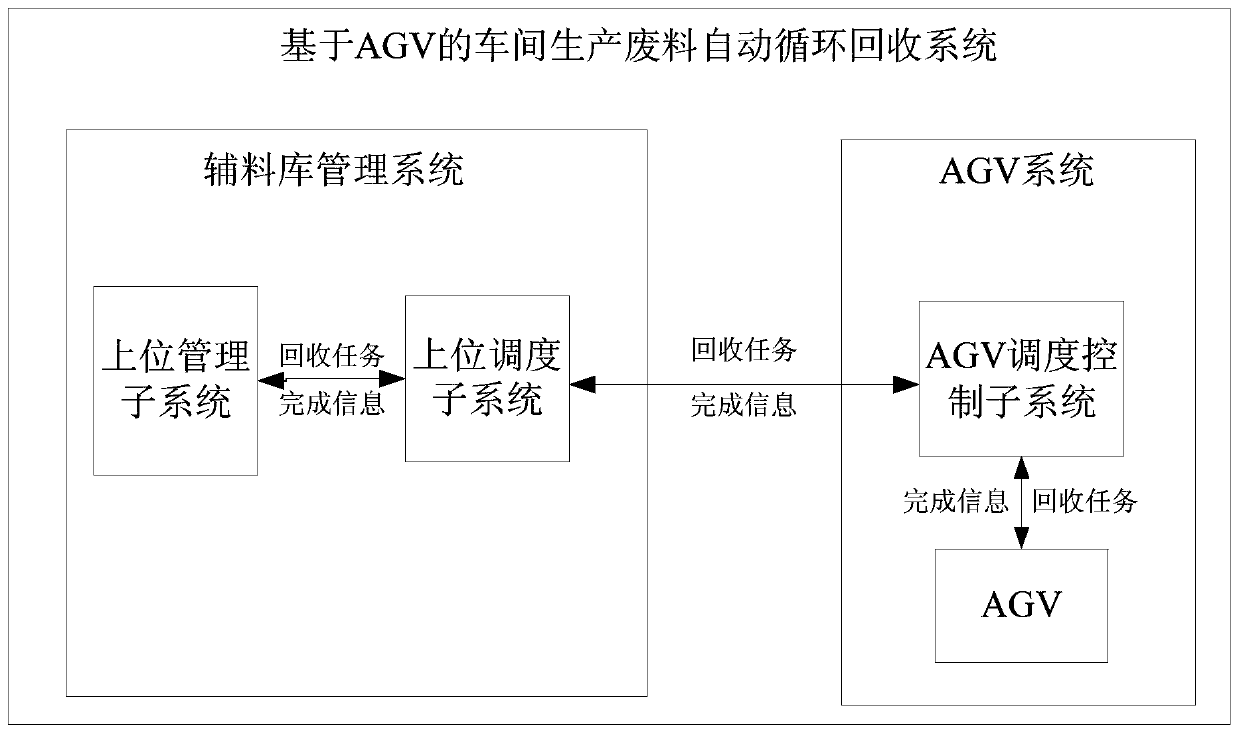

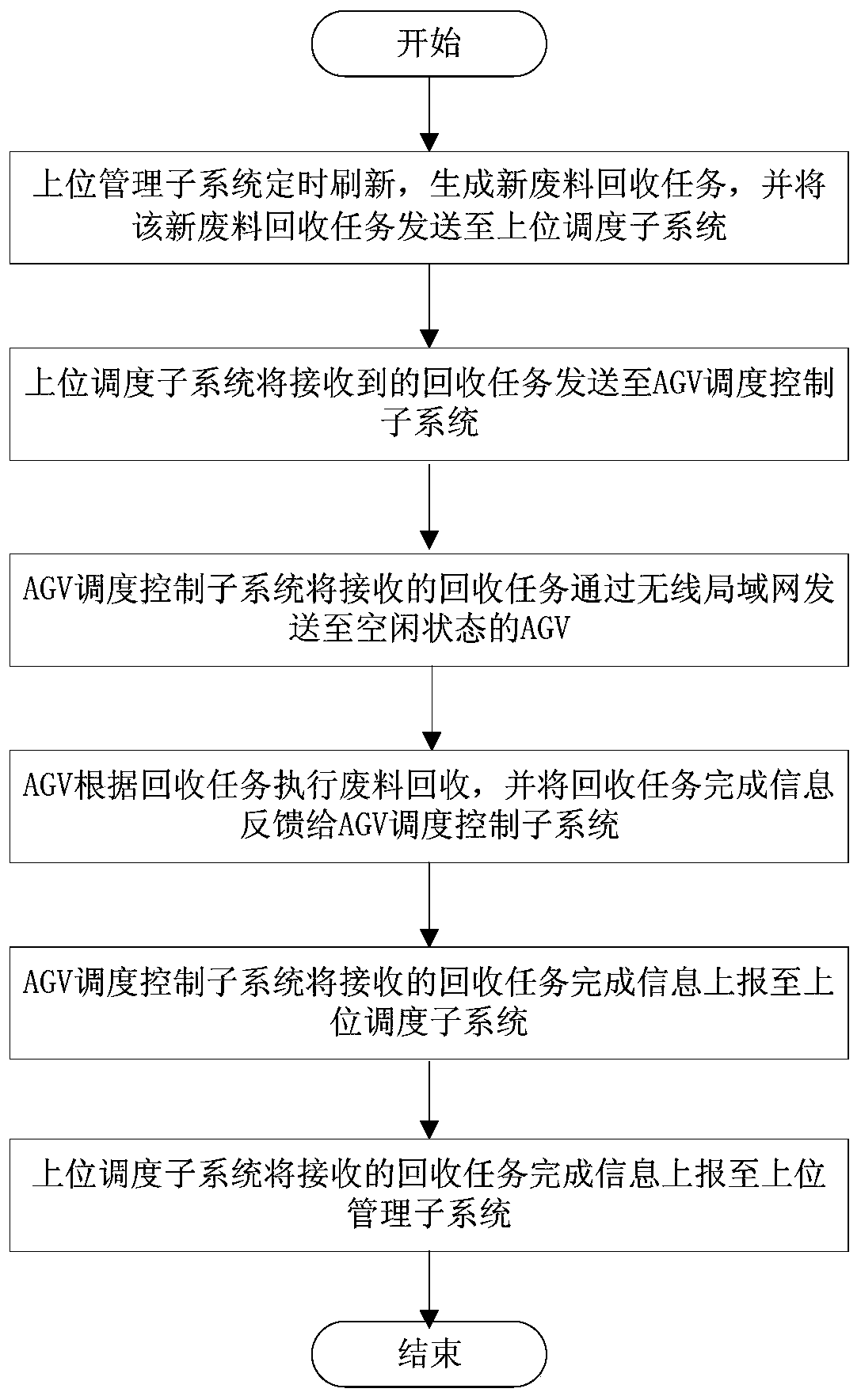

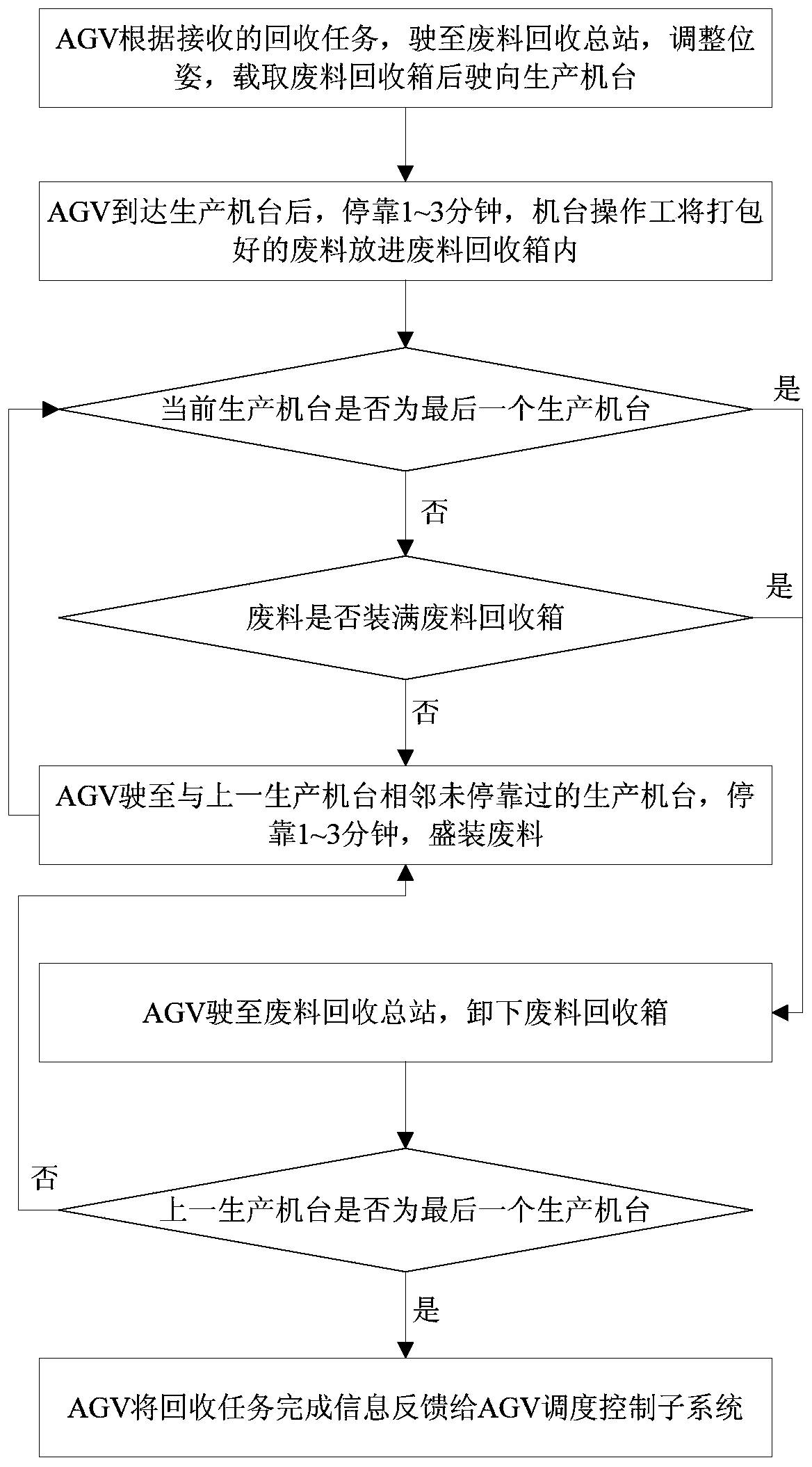

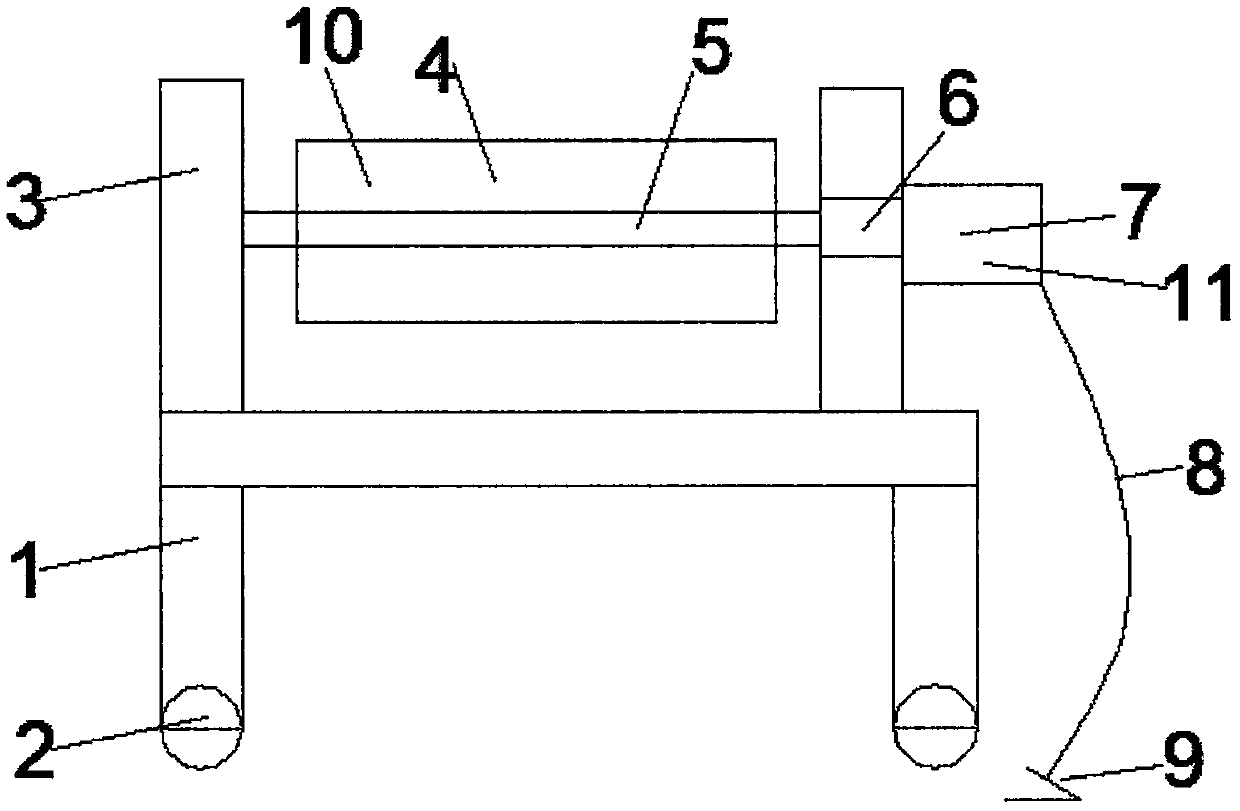

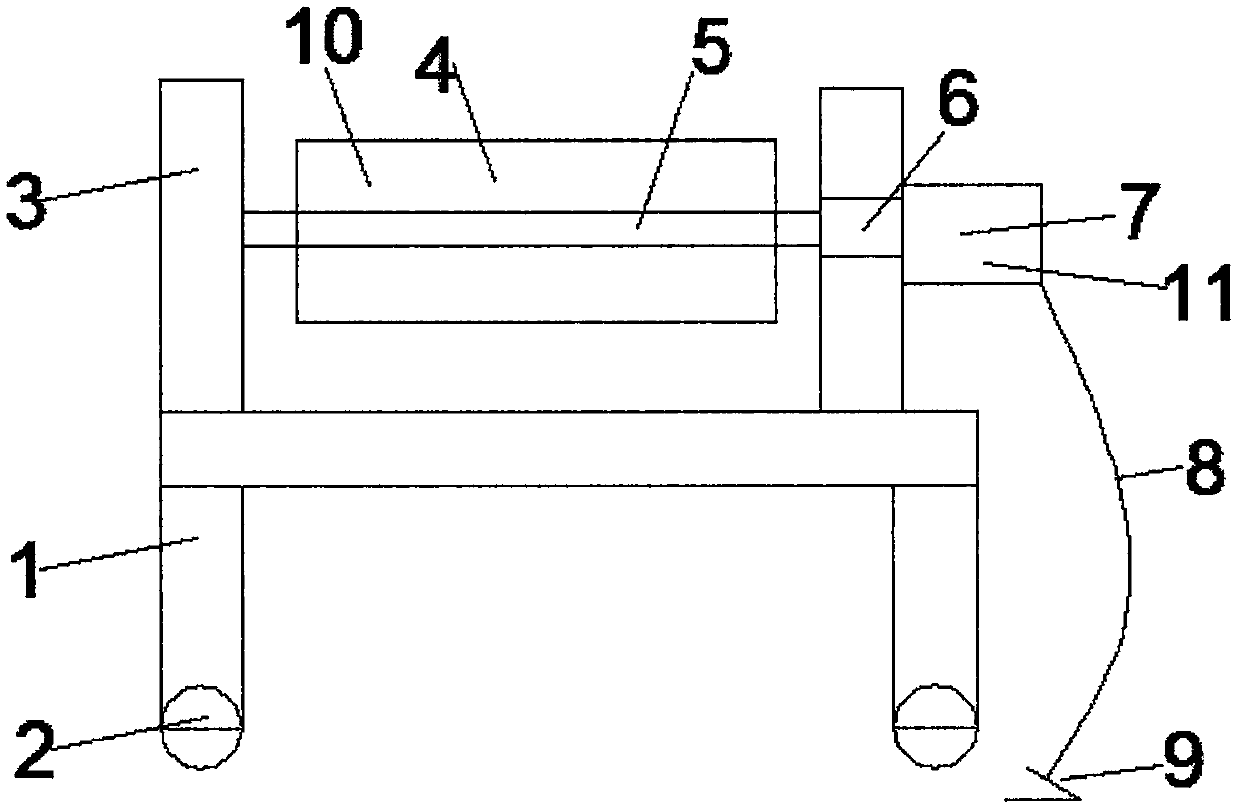

An AGV-based automatic recycling system and method for production waste in workshops

ActiveCN107491048BImprove recycling efficiencyHigh degree of automationElectric/hybrid propulsionTotal factory controlWaste collectionProcess engineering

The invention discloses an AGV-based workshop production waste automatic recycle collecting system. The system comprises an accessory library management system, and an AGV system which communicates with the accessory library management system through a wireless network. The accessory library management system comprises an upper management sub system and an upper scheduling sub system in mutual wireless communication. The AGV system comprises an AGV and an AGV scheduling control sub system which communicates with the AGV. The upper management sub system controls the AGV to carry out production waste collection at a fixed time and a fixed site through the upper scheduling sub system and the AGV scheduling control sub system. The invention also discloses a method for carrying out collection by using the above system. According to the method, the time and path of AGV waste collection can be changed according to production reality, and a need of intelligent and flexible production is satisfied.

Owner:CHINA TOBACCO ZHEJIANG IND

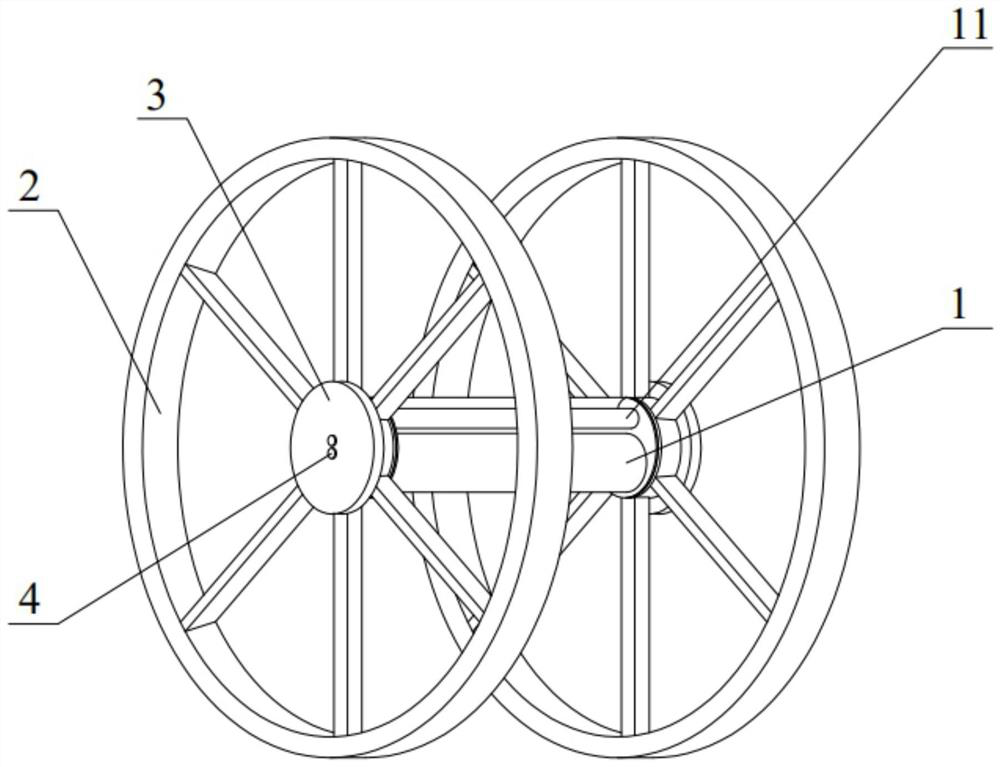

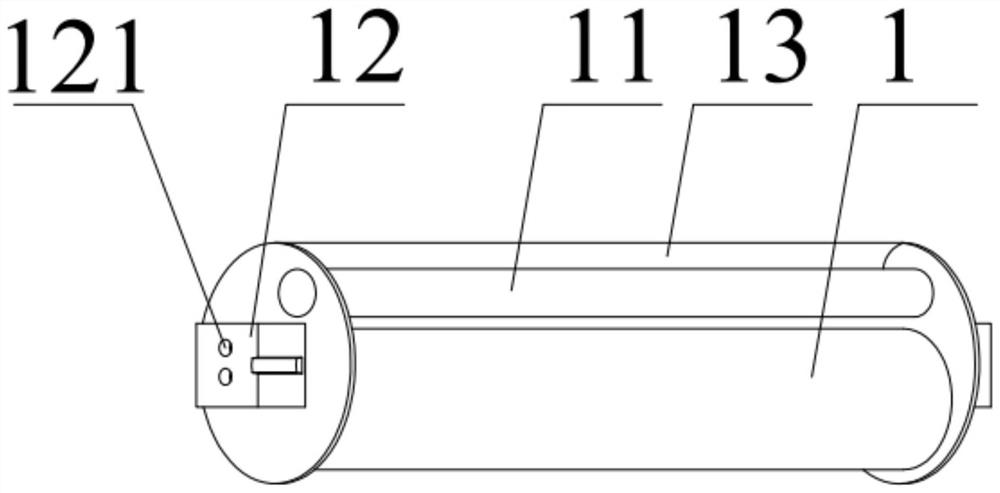

High-efficiency winding device

The invention discloses a high-efficiency winding device. The high-efficiency winding device comprises a base, a winding mechanism and a control device. The winding mechanism comprises a support, a rotary plate and a rotary shaft. The support is arranged on the top of the base. The rotary shaft is installed in the middle of the support. The rotary plate is installed on the rotary shaft. The control device comprises a transmission shaft, a motor, a wire and a pedal. The rotary shaft is connected with the transmission shaft. The transmission shaft is connected with the motor. The motor is connected with the wire and the pedal. The motor is controlled by the pedal to rotate. Universal wheels are installed on the lower part of the base. With the high-efficiency winding device, the production labor intensity of workers can be reduced in the production process, the use cost is reduced, it is beneficial for workers to use the high-efficiency winding device to carry out work conveniently and quickly, the working efficiency can be improved conveniently, the product quality is improved, and on-site management is improved.

Owner:天津明源机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com