Nitrogen oxide separation device that can realize automatic online cleaning

A separation device and nitrogen oxide technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of low automation, inability to achieve precise and stable control, and high labor intensity. Achieve high cleaning efficiency, ensure safe and reliable operation, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

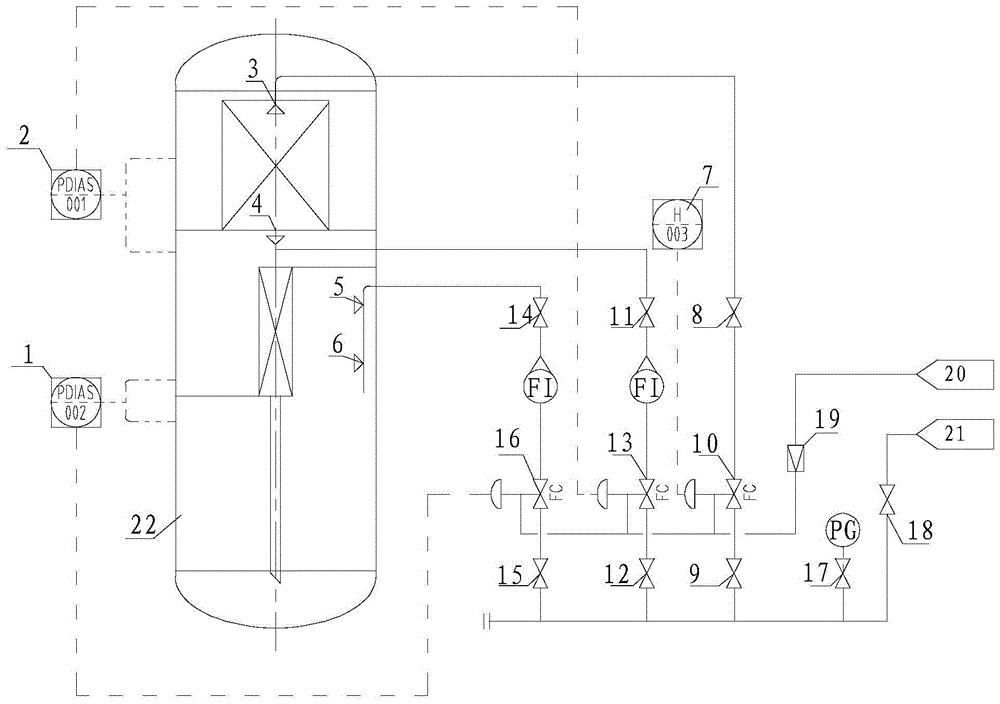

[0014] see figure 1 The nitrogen oxide separation device capable of automatic online cleaning described in the present invention includes a separation device body 22 and a spray cleaning mechanism connected thereto. The separation device body 22 is provided with upper and lower separation element chambers. The spray cleaning mechanism consists of the top spray port 3 of the upper separation element, the bottom spray port 4 of the upper separation element, the spray ports 5 and 6 of the lower separation element, the pressure difference control unit 2 of the upper separation element, and the pressure difference control unit 1 of the lower separation element , Spray control unit 7 at the top of the upper separation element, instrument air conveyor 20, spray liquid conveyor 21, pressure reducing valve 19, first electromagnetic switch valve (air source pressure: 0.6MPa, power supply pressure: 24V DC) 13, The second electromagnetic switch valve (air source pressure: 0.6MPa, power su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com