Stator core coil space half mortise and tenon rotary drying tooling

A stator core and coil technology, which is applied in the field of semi-mortise and mortise rotary tooling in the stator core coil space, can solve the problems of tooling installation and disassembly, long installation time, and easy loss of insulating paint, etc., to improve the comprehensive quality of products, The effect of improving efficiency and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing:

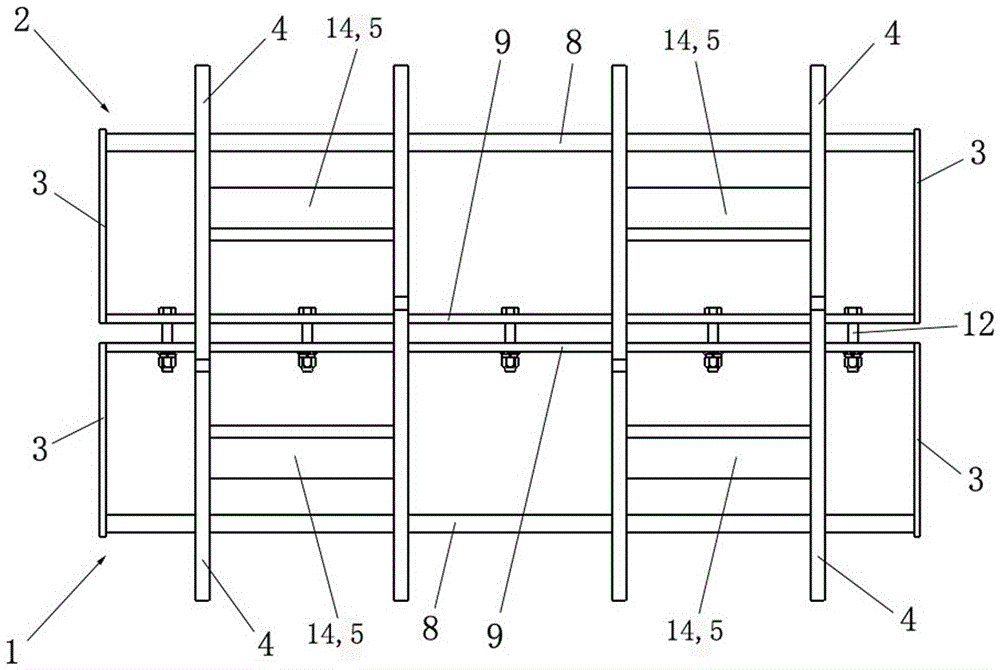

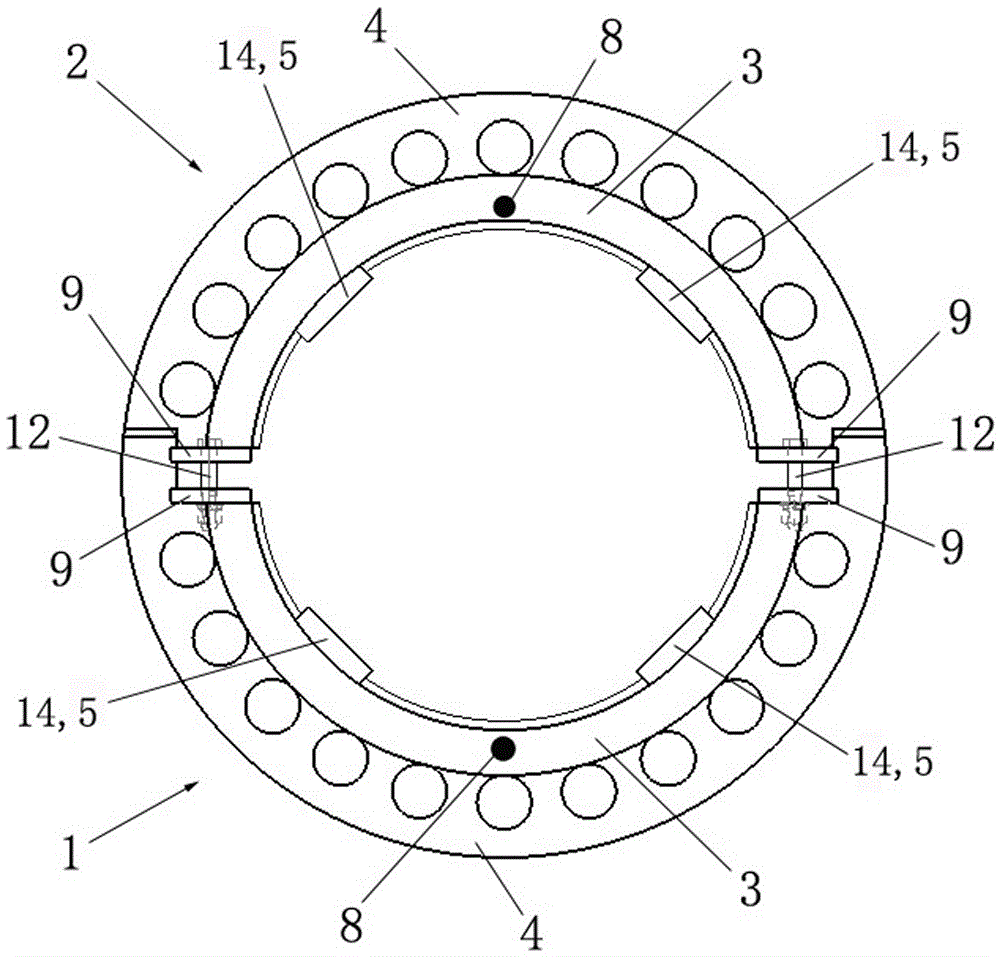

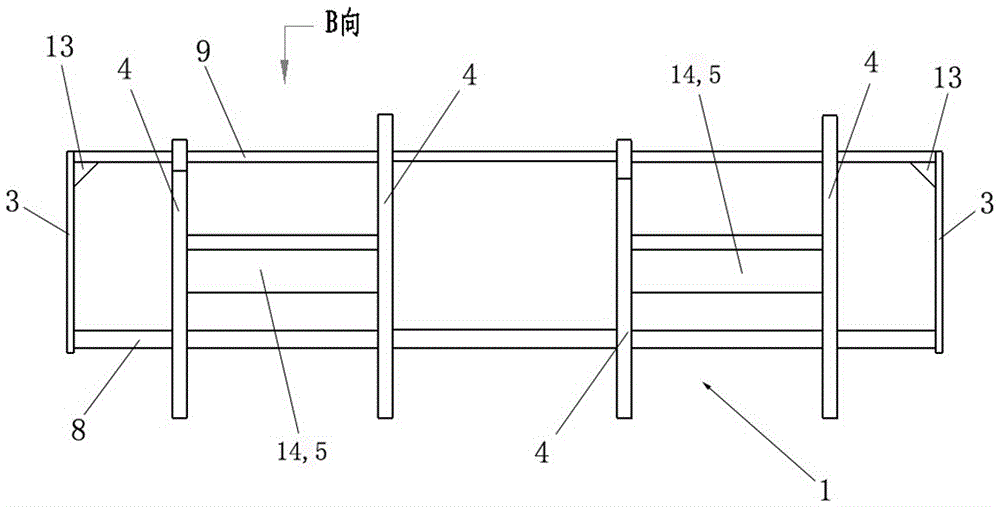

[0040] like Figure 1 to Figure 9 As shown, a stator core coil space half-mortise and tenon rotary drying tooling, including a lower tooling 1 and an upper tooling 2;

[0041]The lower tooling 1 includes two protective rings 3, and four rotating disks 4 are evenly distributed between the two protective rings 3. Both the protective rings 3 and the rotating disks 4 are designed as arc-shaped plates and arranged in parallel and coaxially. The radius of the inner arc of the protective ring 3 is equal to that of the rotating disk 4, and the radius of the outer arc of the protective ring 3 is smaller than the radius of the outer arc of the rotating disk 4; two positioning plates 14 are evenly distributed between the first and second rotating disks 4 , each positioning plate 14 is covered and fixed with a mounting plate 5, two positioning plates 14 are evenly distributed between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com