Field hardware equipment management and control system and method

A technology of hardware equipment and management and control system, applied in the field of Internet of Things, can solve the problems of difficulty in timely judgment of monitoring and processing solutions, low degree of intelligence, etc., and achieve the effect of timely and effective maintenance confirmation, convenient deployment, and low transformation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

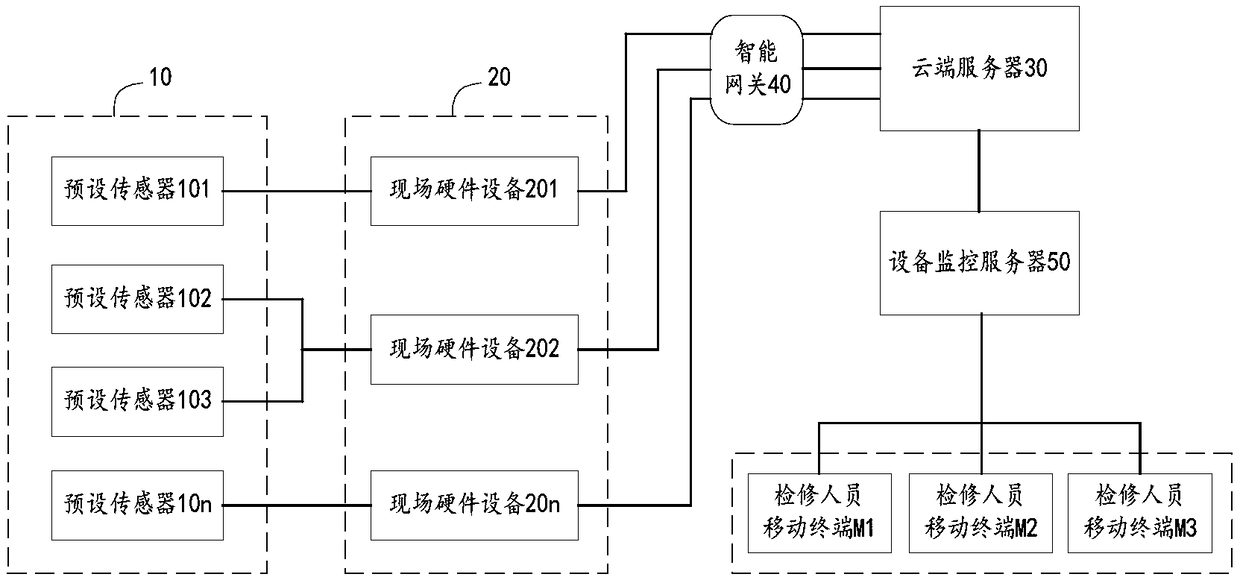

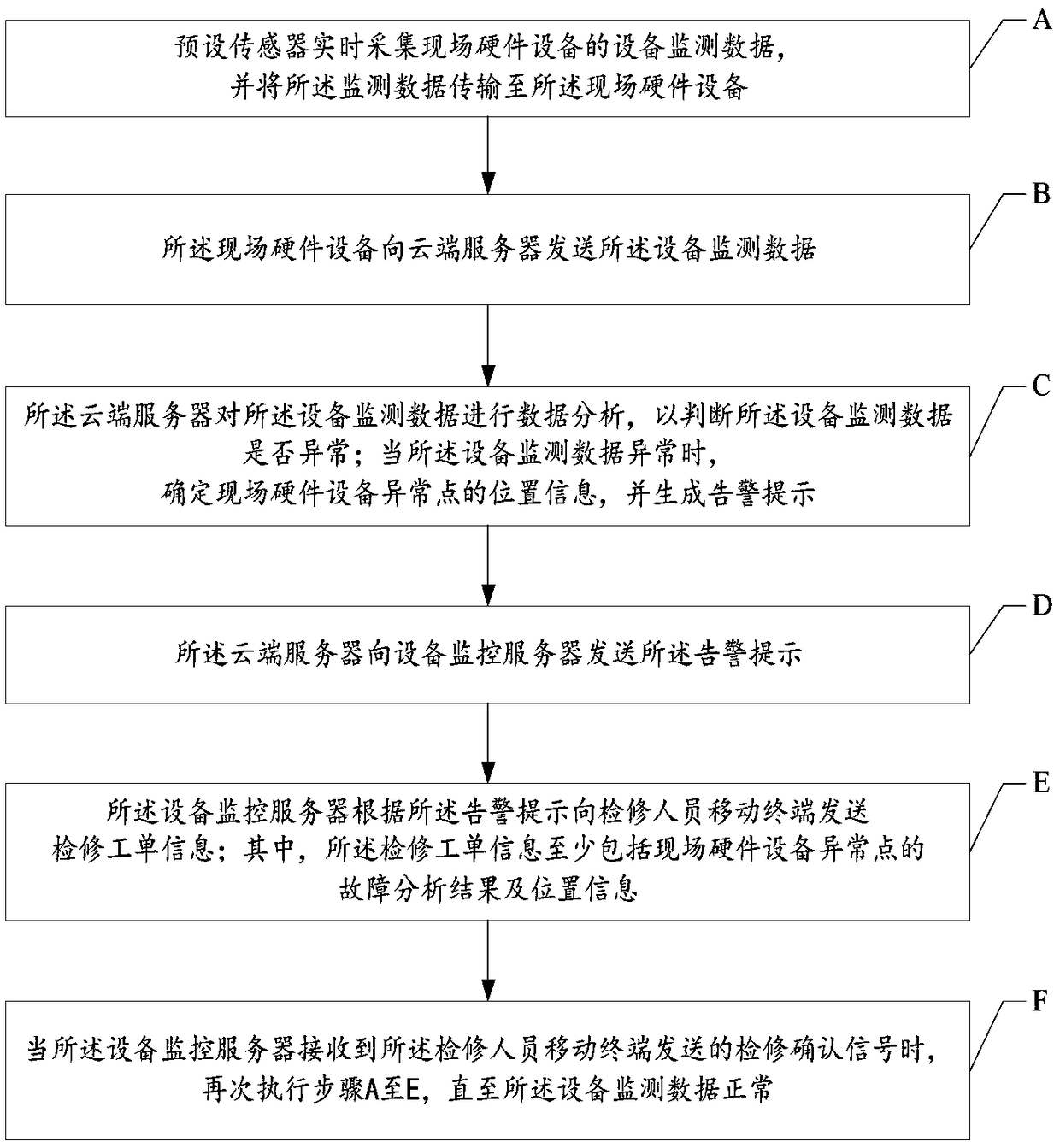

[0039] The present invention provides an on-site hardware device management and control system, such as figure 1 As shown, the system includes the following parts: a preset sensor 10, on-site hardware equipment 20, a cloud server 30, an equipment monitoring server 50, and a maintenance personnel mobile terminal; wherein, the preset sensor 10 is connected to the on-site hardware equipment 20;

[0040] The preset sensor is used to collect equipment monitoring data of the on-site hardware equipment in real time, and transmit the monitoring data to the on-site hardware equipment;

[0041] In each embodiment of the present invention, the on-site hardware device 20 specifically refers to various hardware devices (such as figure 1 201, 202 to 20n shown), such as hardware equipment (such as transformers, servers, water pumps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com