Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Improve oil supply efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

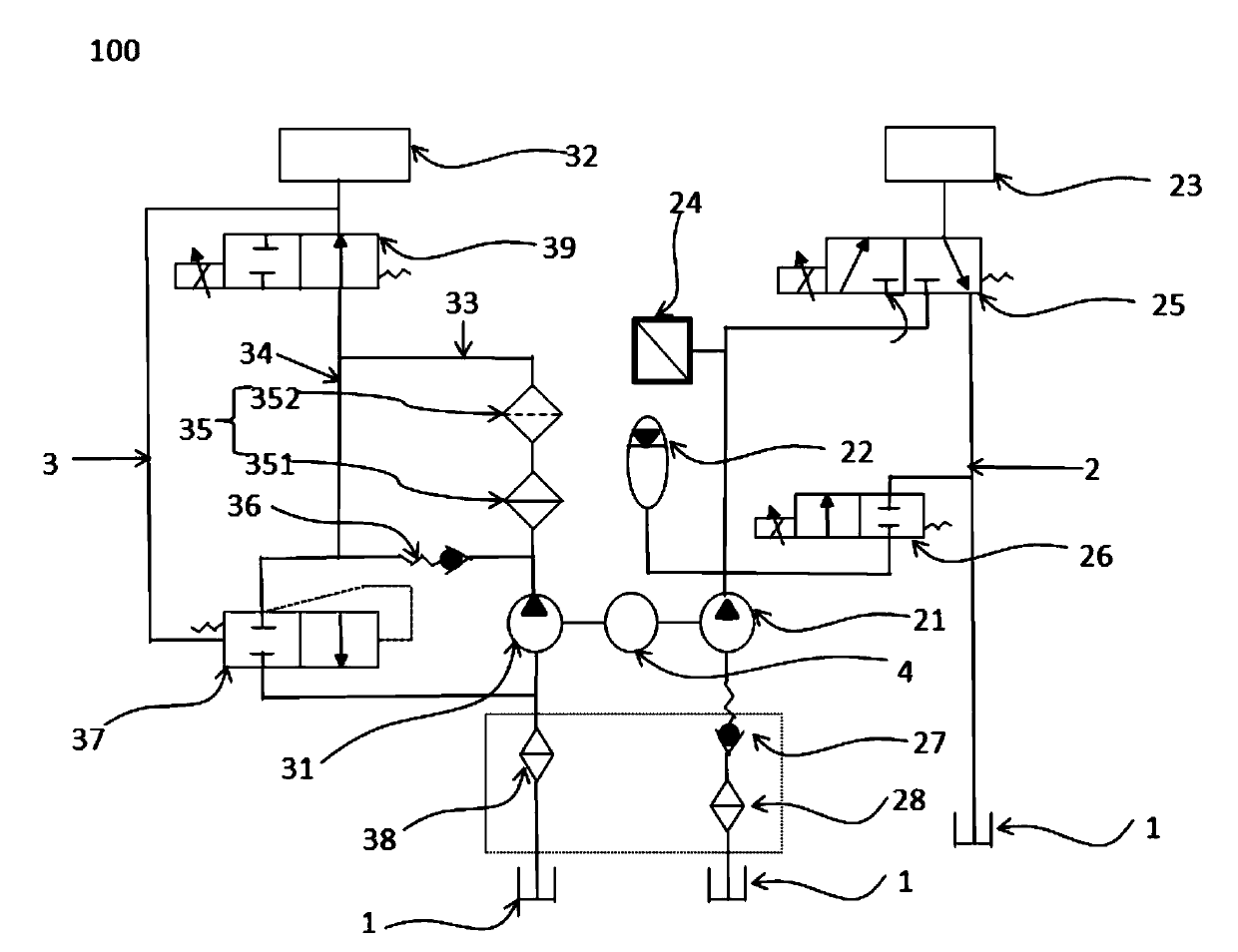

Gearbox oil supply and lubrication system

ActiveCN111561485AHighly integratedImprove oil supply efficiencyServomotorsGear lubrication/coolingActuatorOil intake

The invention discloses a gearbox oil supply and lubrication system. The gearbox oil supply and lubrication system comprises an oil pool, a high-pressure loop and a lubricating loop, wherein the high-pressure loop comprises a first electronic oil pump, an energy accumulator and a first actuator, an oil inlet of the first electronic oil pump communicates with an oil pool pipeline, an oil outlet ofthe first electronic oil pump communicates with an opening of the energy accumulator and an oil inlet pipeline of the first actuator, and an opening of the energy accumulator communicates with the oilinlet pipeline of the first actuator; the lubricating loop comprises a second electronic oil pump and a second actuator, an oil inlet of the second electronic oil pump communicates with the oil poolpipeline, a main pipeline and a bypass pipeline are arranged between an oil outlet of the second electronic oil pump and an oil inlet of the second actuator, a cooling device is arranged on the main pipeline, and a first one-way valve is arranged on the bypass pipeline; and the first electronic oil pump and the second electronic oil pump share one driving piece. According to the system, by means of the high-pressure loop and the lubricating loop, the integration level is improved, and the accuracy of oil supply is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

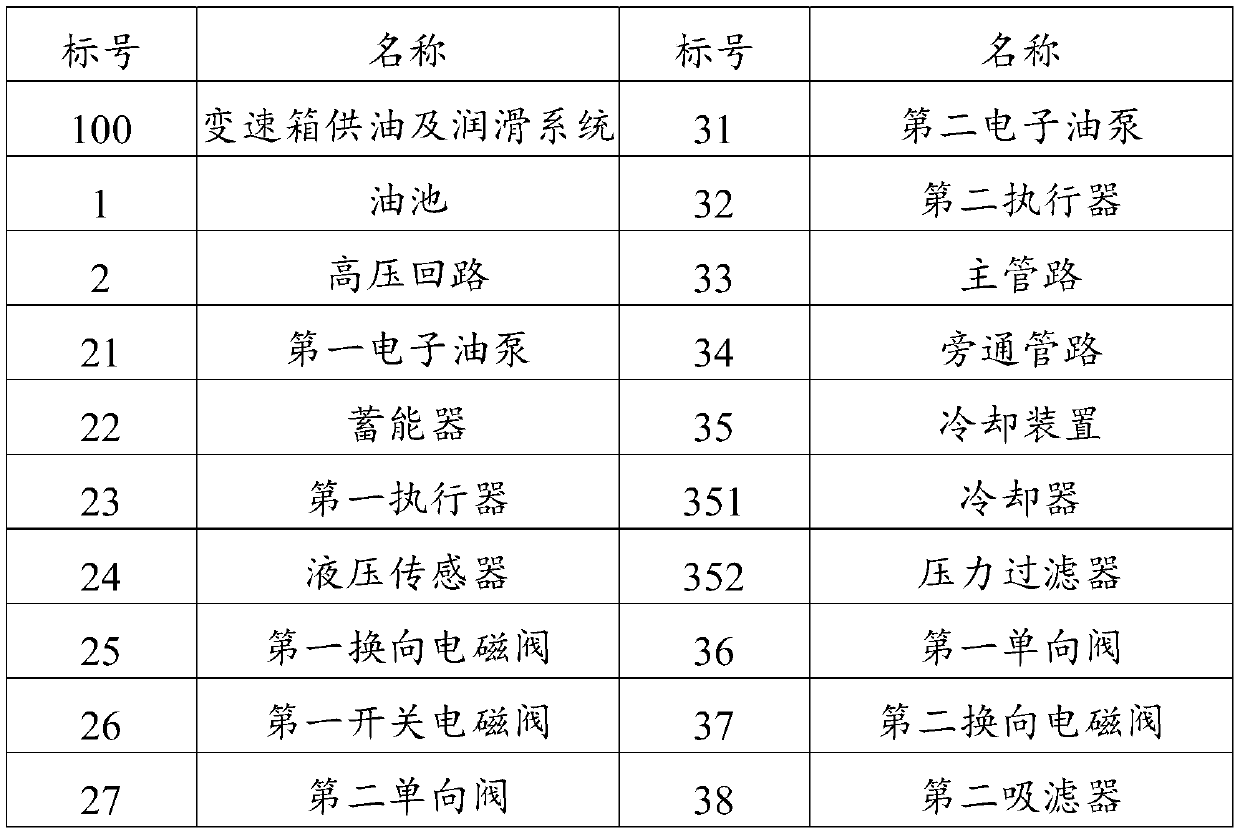

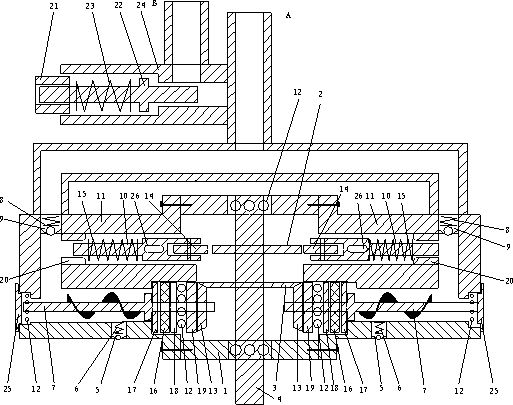

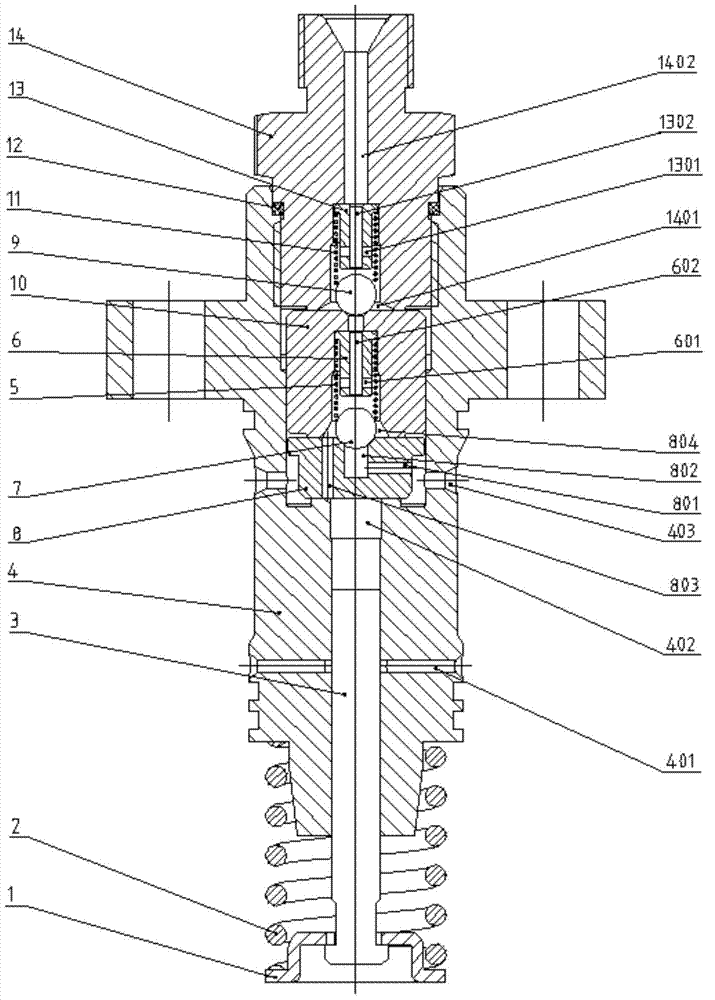

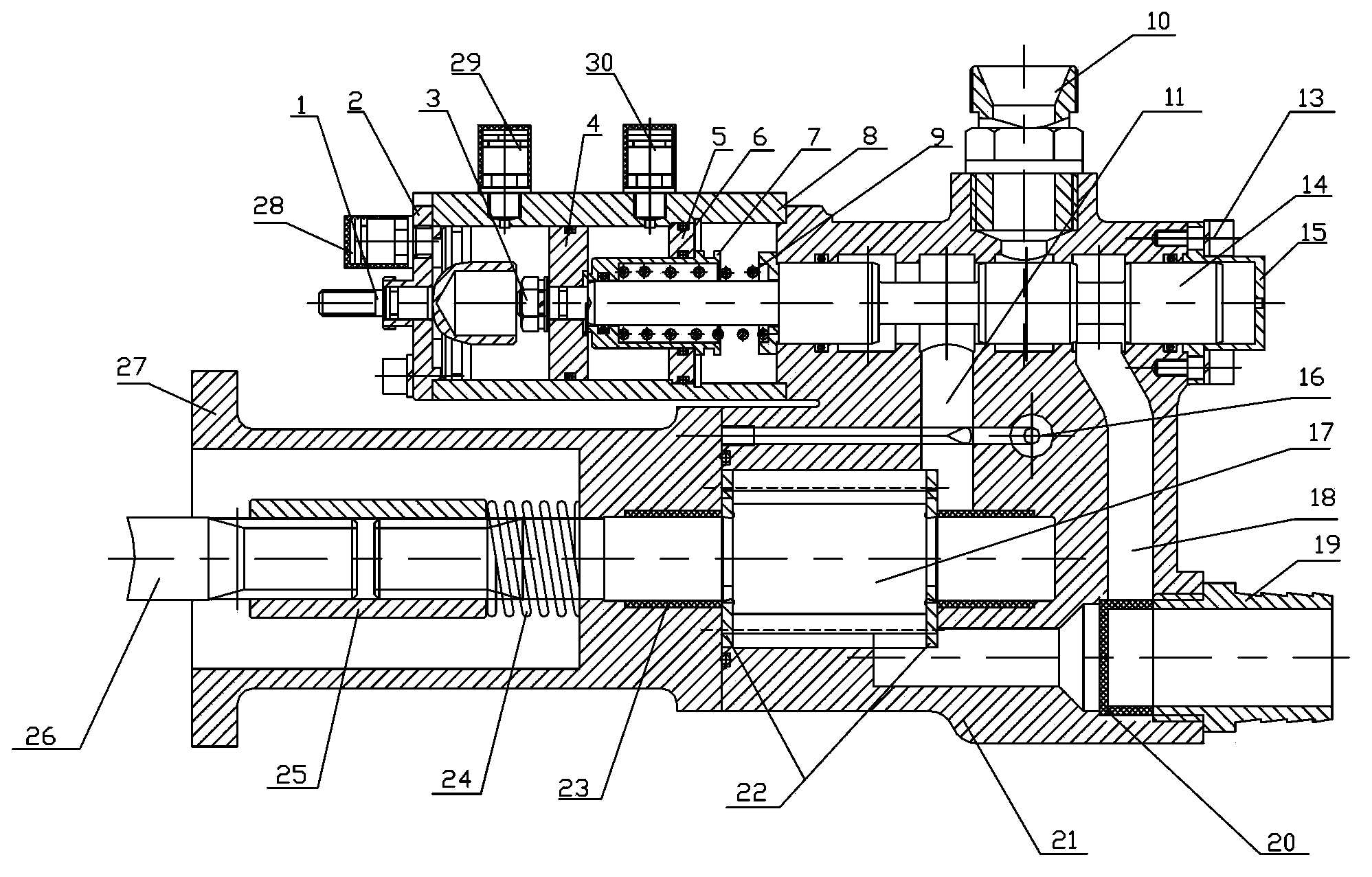

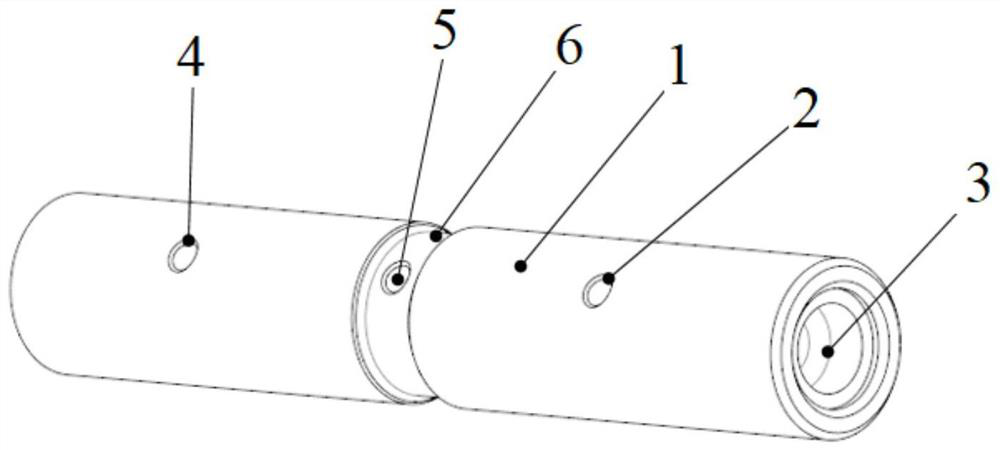

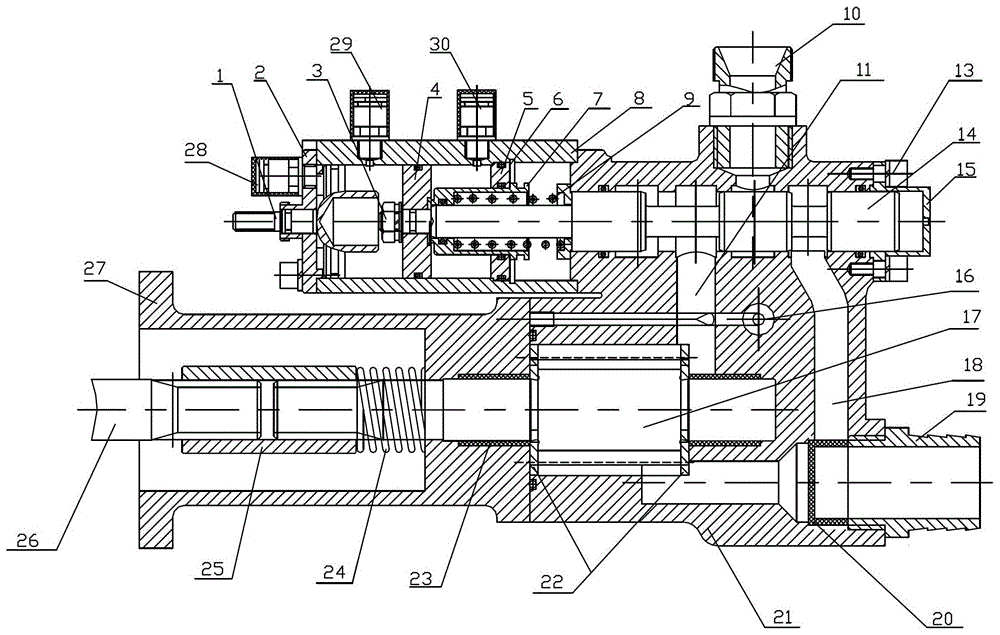

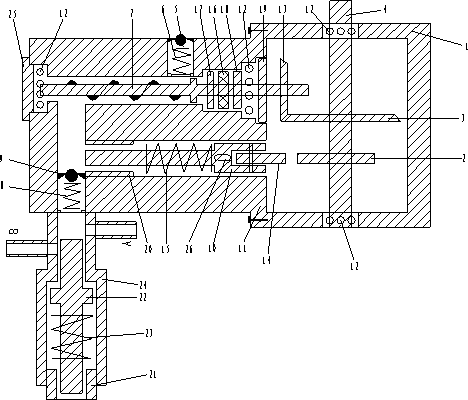

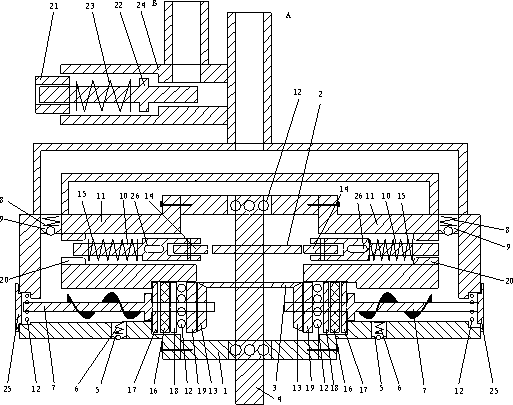

Spiral rod oil distribution energy storage plunger pump

InactiveCN102434424ASolve the problem of not being able to synchronizeEnsure safetyPumpsPositive-displacement liquid enginesHydraulic pumpCam

A spiral rod oil distribution energy storage plunger pump belongs to hydraulic pumps. A spindle box body of the plunger pump is connected with a plunger pump box body, and a driving bevel gear and a cam are installed on a spindle in the spindle box body. A plunger is installed in a plunger pump cavity of the plunger box body, a sliding wheel is arranged at the top of the plunger, a spring is installed in the middle of the plunger, and a cylinder sleeve is connected onto a plunger cavity body at the lower portion of the plunger. A driven bevel gear, a flange, screw rod bearings, an upper gasket, an oil seal and a lower gasket are sequentially connected onto a spiral rod, the spiral rod bearings are connected to the bottom of the screw rod and to the position between the upper gasket and the flange, and a spiral rod cavity screw is connected to the bottom of the spiral rod cavity. An input one-way valve spring is arranged on an input one-way valve, an output one-way valve is installed at the lower half portion of the plunger box body, a sliding plug and a sliding plug spring are installed in an energy storage safety valve, a pressure regulating hollow screw is installed at the top of the energy storage safety valve, and a normal work liquid outlet and a hyperpressure liquid outlet are arranged on the energy storage safety valve. The spiral rod oil distribution energy storage plunger pump has the advantages that a fly wheel is installed on a shaft head of a power machine, acting can be achieved by means of inertia kinetic energy of the fly wheel, and energy is saved.

Owner:胡传胜

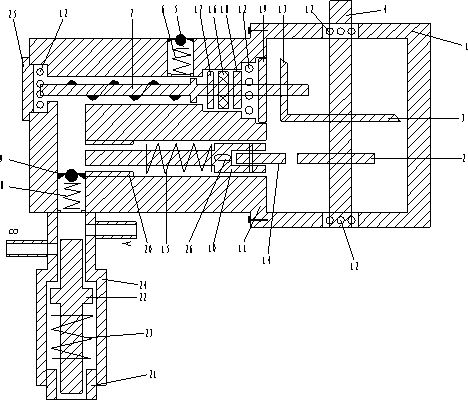

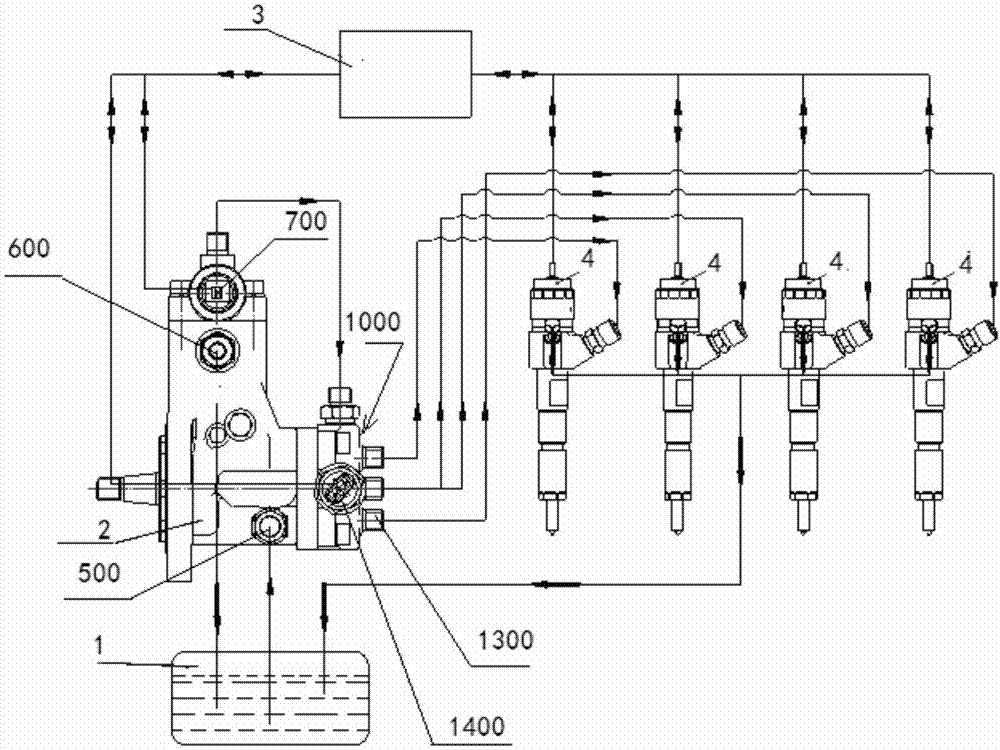

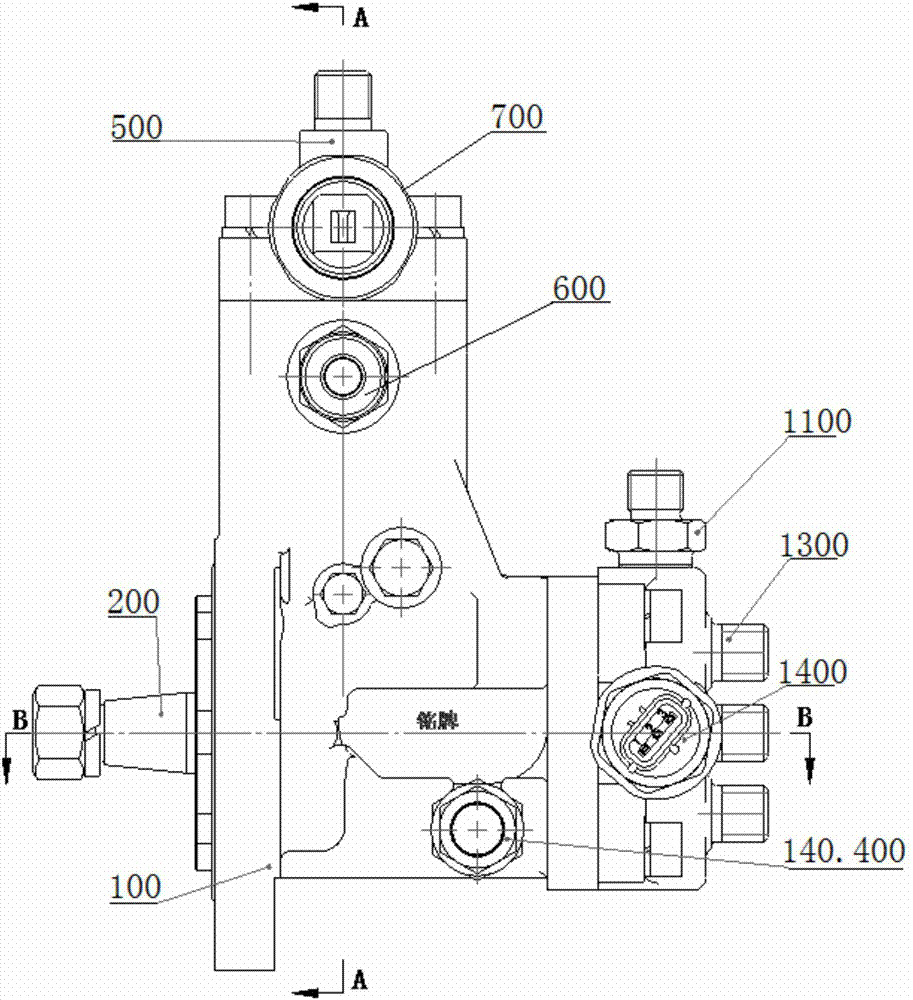

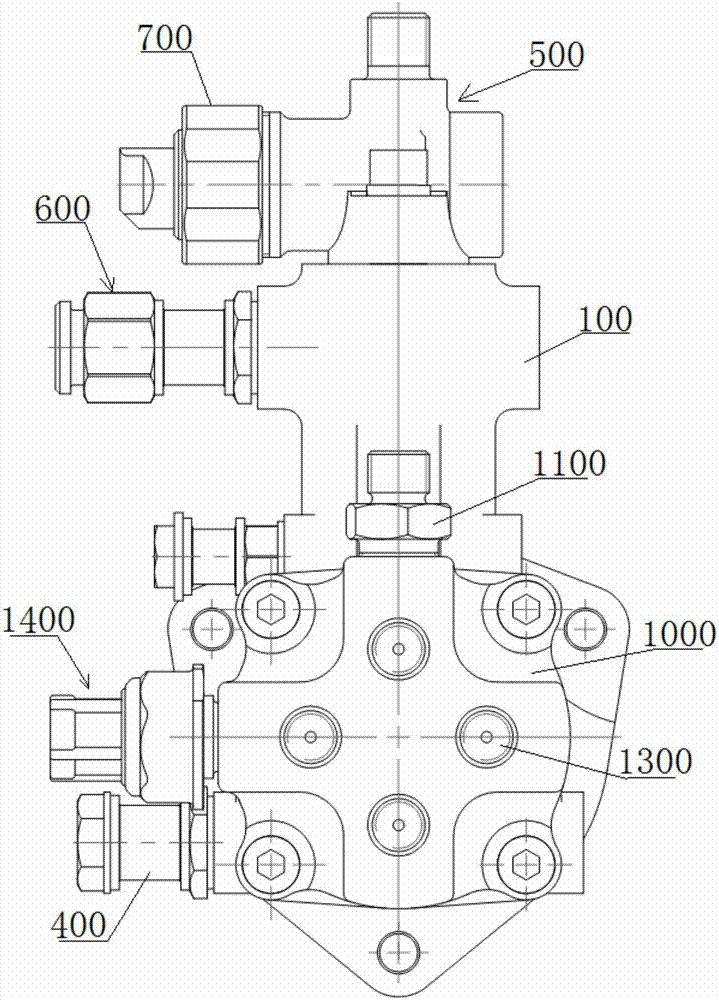

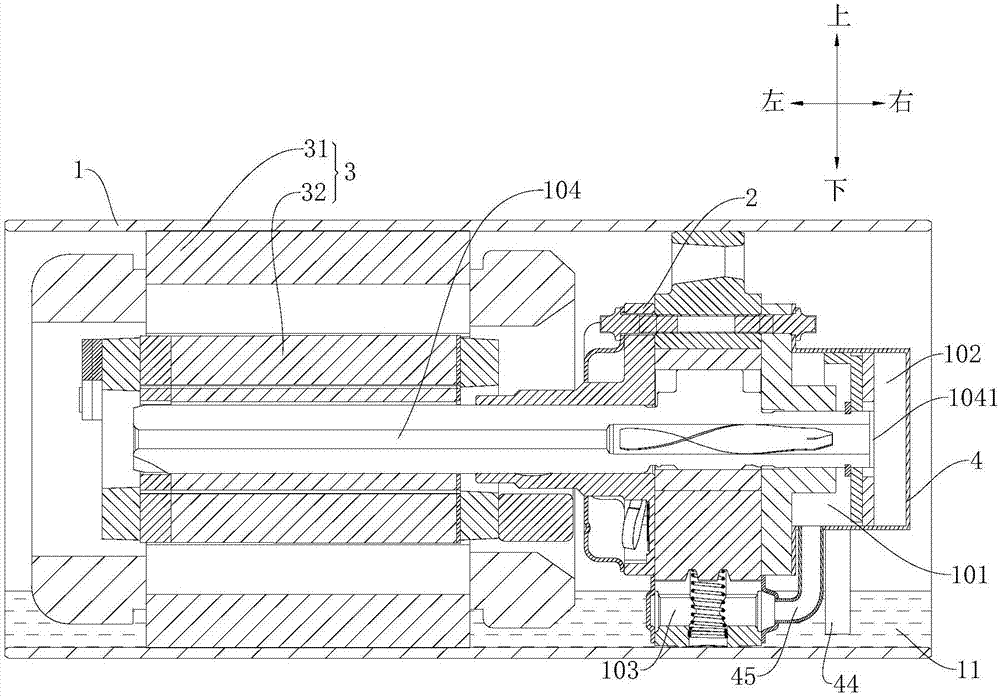

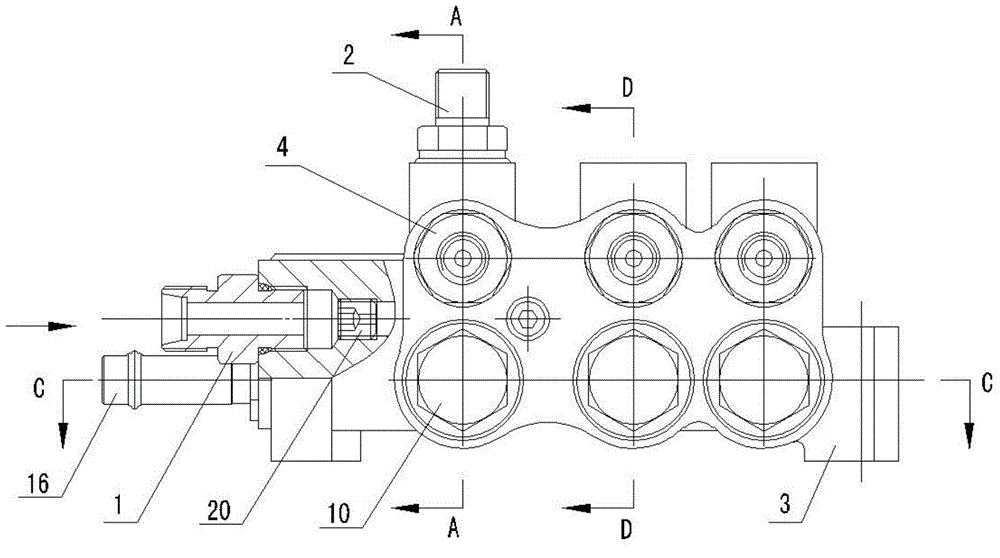

CF common rail system

PendingCN107975445ASave installation spaceAchieve integrationElectrical controlMachines/enginesCommon railFuel tank

The invention discloses a CF common rail system. The CF common rail system comprises an oil tank, a pump and rail integrated type common rail oil supplying pump, an ECU and at least one oil injector.An oil inlet of an oil delivering pump in the pump and rail integrated type common rail oil supplying pump communicates with the oil tank through an oil pipe. An outlet of a pressure stabilizing valvepart in the pump and rail integrated type common rail oil supplying pump communicates with the oil tank through an oil pipe. At least one oil outlet joint on a pressure accumulator in the pump and rail integrated type common rail oil supplying pump is connected with an oil inlet pipe joint on the at least one oil injector through a high-pressure oil distributing pipe. A pressure transducer in thepump and rail integrated type common rail oil supplying pump is in signal connection with the ECU. The ECU is further in control connection with an electromagnet in an electromagnetic valve part in the pump and rail integrated type common rail oil supplying pump and electromagnets in the oil injectors. The ECU controls the energized state of the electromagnet in the electromagnetic valve part inthe pump and rail integrated type common rail oil supplying pump so as to control the working state of the pump and rail integrated type common rail oil supplying pump. The oil injectors control the oil injecting time, pre-injecting and / or post-injecting through the ECU, so that needs of an engine are met accurately.

Owner:NANYUE FUEL INJECTION SYST CO LTD

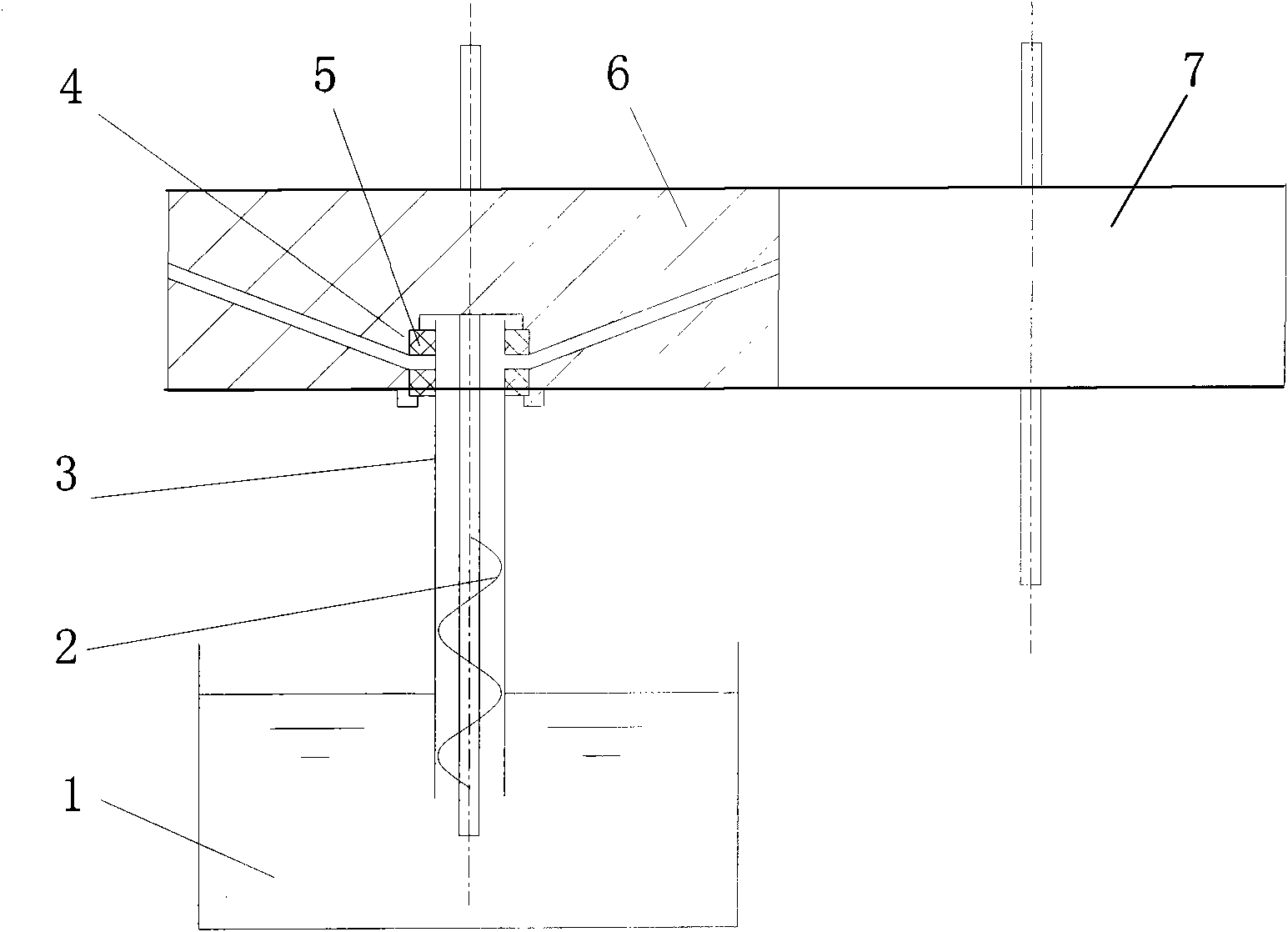

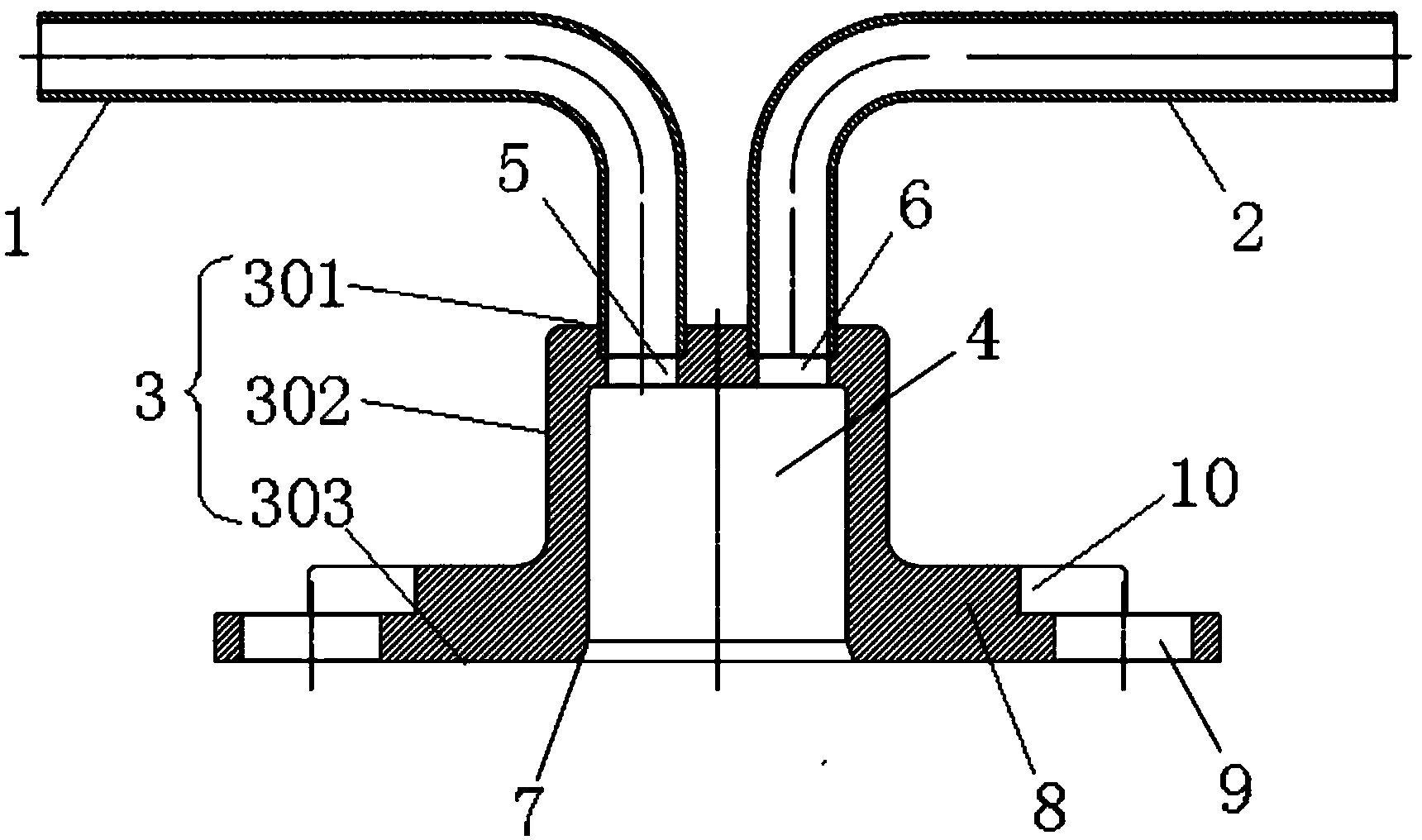

Radical self-priming fluid lubricating method for gears

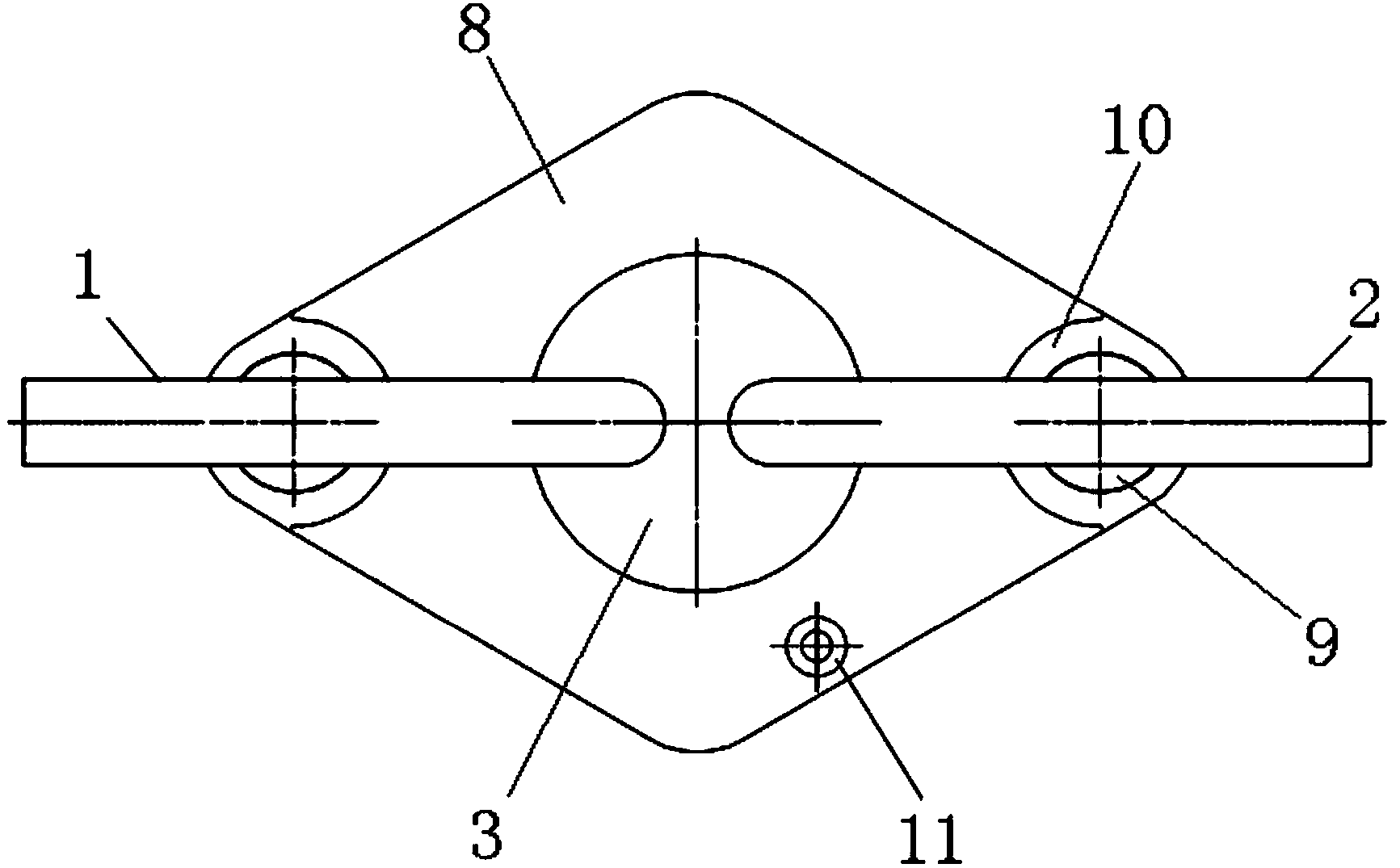

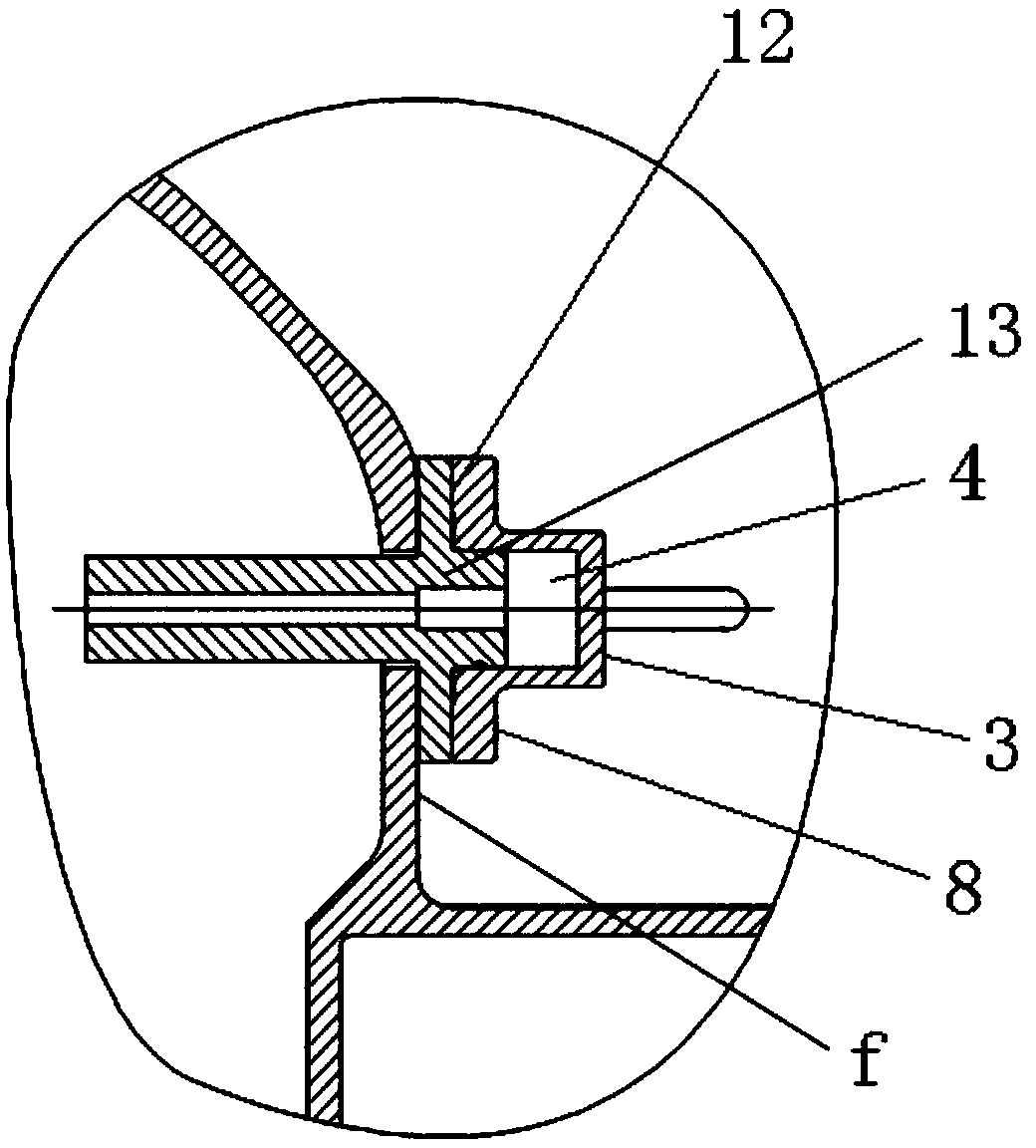

InactiveCN101586657AImprove carrying capacityImprove oil supply efficiencyGear lubrication/coolingGear driveGear wheel

The invention discloses a lubricating method for gears, comprising a oil-absorbing pump, a radial oil hole gear, a sealing ring and a concentrated oil guiding hole. The oil-absorbing pump is a screw pump or a spiral pump. The screw of the oil-absorbing pump and the gear has a same rotating shaft component. The sealing ring is arranged with radial holes with same quantity of the holes on the radial oil hole gear in a relevant static state; the radial hole are aimed; one radial oil hole on the sealing ring is relevantly static with the pump body of the oil-absorbing pump; the radial oil hole on the sealing ring is aimed at the concentrated oil guiding hole. The radial oil hole gear is the gear passing to every component along the radial direction. The concentrated oil guiding hole is arranged on the pump body of the oil-absorbing pump facing the gear meshing area. The oil-absorbing pump delivers the lubricating oil to the concentrated oil guiding hole and enters the sealing ring oil hole and the radial oil hole and enters the gear root part of the meshing position and the surface area of two gear profiles of the gears to achieve the gear lubrication. The invention can solve oil lacking phenomenon of gear pair without any additional power; the oil offering rat is high with an advantage of enhancing loading capacity.

Owner:章易程

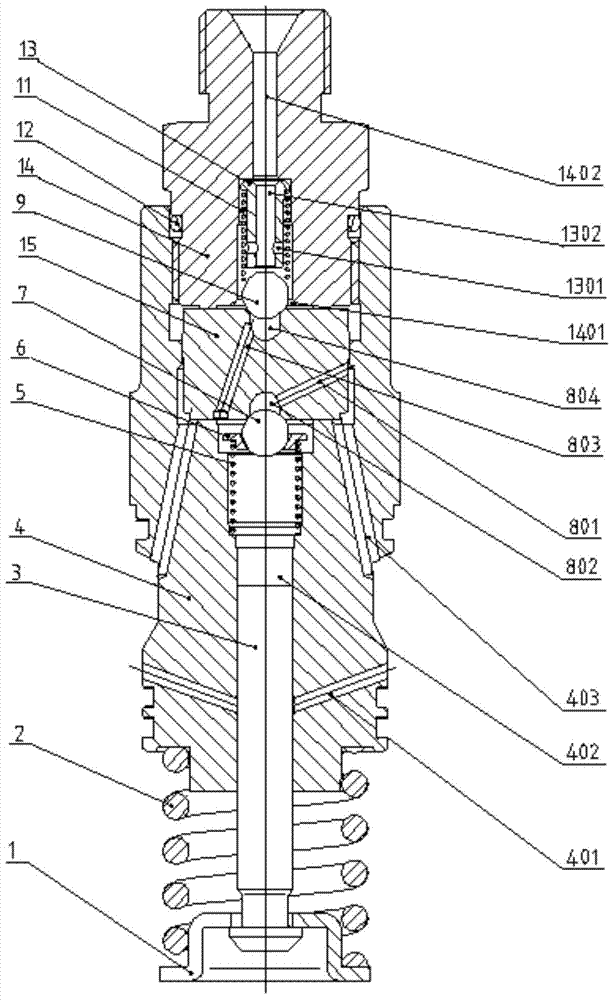

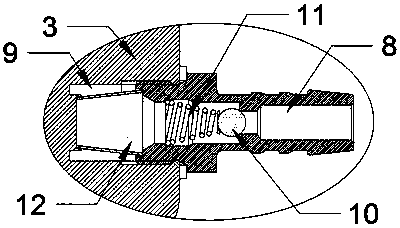

Composite in-out oil valve common rail oil pump

InactiveCN103573507ASmall sizeAvoid risk of leakageMachines/enginesFuel injecting pumpsInlet channelCommon rail

The invention discloses a composite in-out oil valve common rail oil pump. The oil pump comprises an in-out oil valve body (15), an oil outlet channel (803), an oil inlet channel (801) and an oil inlet valve steel ball (7); the in-out oil valve body is assembled in an inner cavity of an oil injection pump body (4); an oil inlet steel ball seat hole (802) and an oil outlet steel ball seat hole (804) contacting and sealing steel balls are formed in the centers of the upper and lower shaft ends of the in-out oil valve body; the oil outlet channel is coaxially assembled at the lower end surface of an oil outlet joint (14), provides pressure oil for a high-pressure cavity under the action of a plunger (3), obliquely extends from the end surface of the bottom of the in-out oil valve body to the oil outlet steel ball seat hole positioned in the center of the upper end to form a high-pressure oil channel communicated with the upper part of the plunger and the lower part of an oil outlet valve steel ball (9); the oil inlet channel is communicated with a low-pressure channel, is downwards obliquely communicated with the oil inlet steel ball seat hole in the center of the lower end from the waist part of a cylinder of the in-out oil valve body; the oil inlet valve steel ball (7) opens and closes the oil inlet channel under the action of an in-out oil valve spring (5). One in-out oil valve body is adopted to replace two parts of an oil inlet valve body and an oil outlet valve body, the high-pressure volume is reduced by a half, and the whole dimension is greatly reduced.

Owner:成都威特电喷有限责任公司

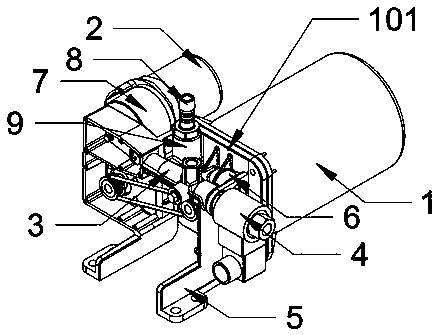

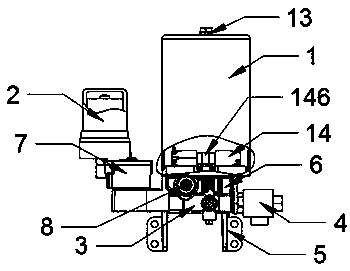

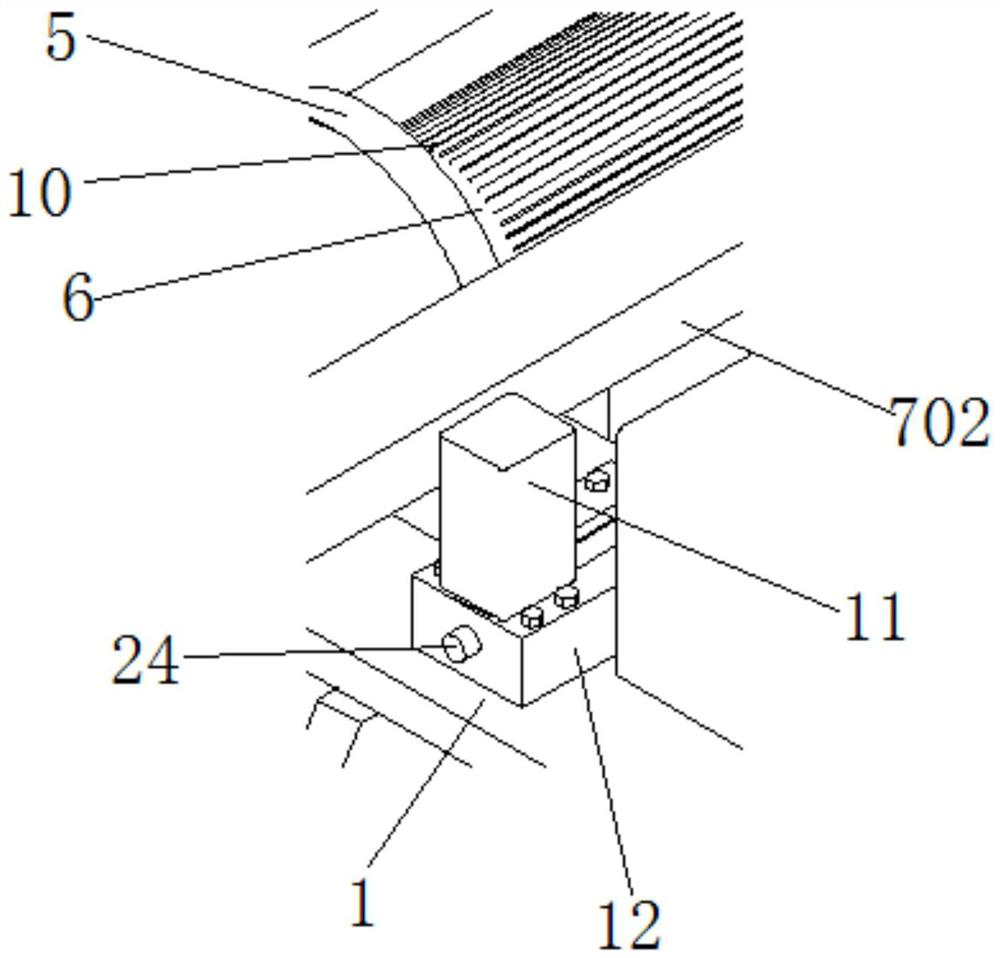

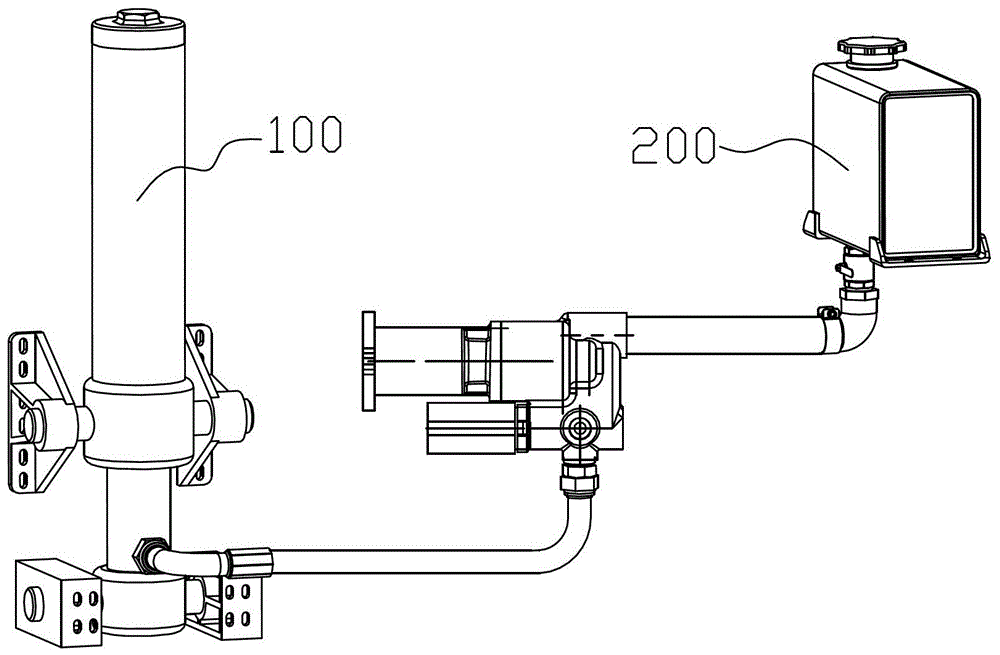

Electric grease lubrication pump

PendingCN110260141AAvoid air suctionReasonable structural installationLubricating pumpsLubrication containersOil and greaseLubrication

The invention discloses an electric grease lubrication pump. The electric grease lubrication pump comprises an oil storage barrel, a motor, a pump body, a threaded cartridge valve, an unloading valve, reduction gearboxes, an oil inlet pipe, an oil inlet cavity, a filtering cylinder, an oil pressing device and a transmission belt device, wherein a pump body is fixedly arranged at the bottom of the oil storage barrel, the motor is arranged on one side of the oil storage barrel, and two reduction gearboxes are symmetrically installed at the bottom of the motor, and the oil pressing device is arranged at the position, located at an oil outlet, of the inner bottom end of the oil storage barrel, and the reduction gearboxes at one side of the bottom of the motor is in transmission connection with the pump body. The whole structure of the grease lubrication pump is reasonable in structure, the filtering device is directly installed inside the oil inlet cavity through the filtering cylinder, so that the filtering structure is simplified, and the installation space is saved, meanwhile, outer shells of the oil storage barrel and the pump body are integrally formed and fixed, the traditional separation and matching type installation are changed, and the sealing degree is improved, so that long-time use is avoided; and oil impregnate and oil leakage faults are avoided from the connection positions of the oil storage barrel and the pump body.

Owner:ZHUJI HUABEI LUBRICATION MACHINERY

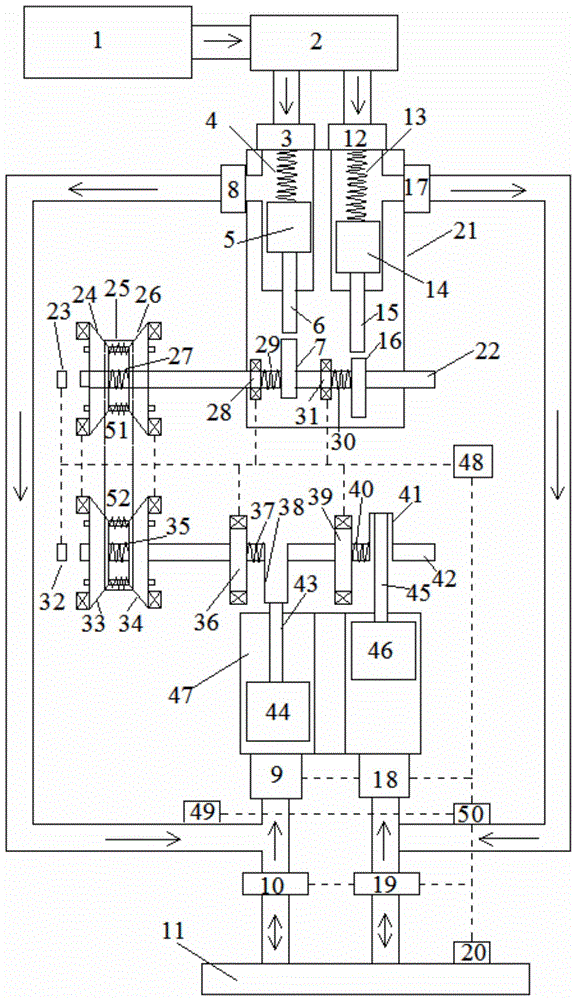

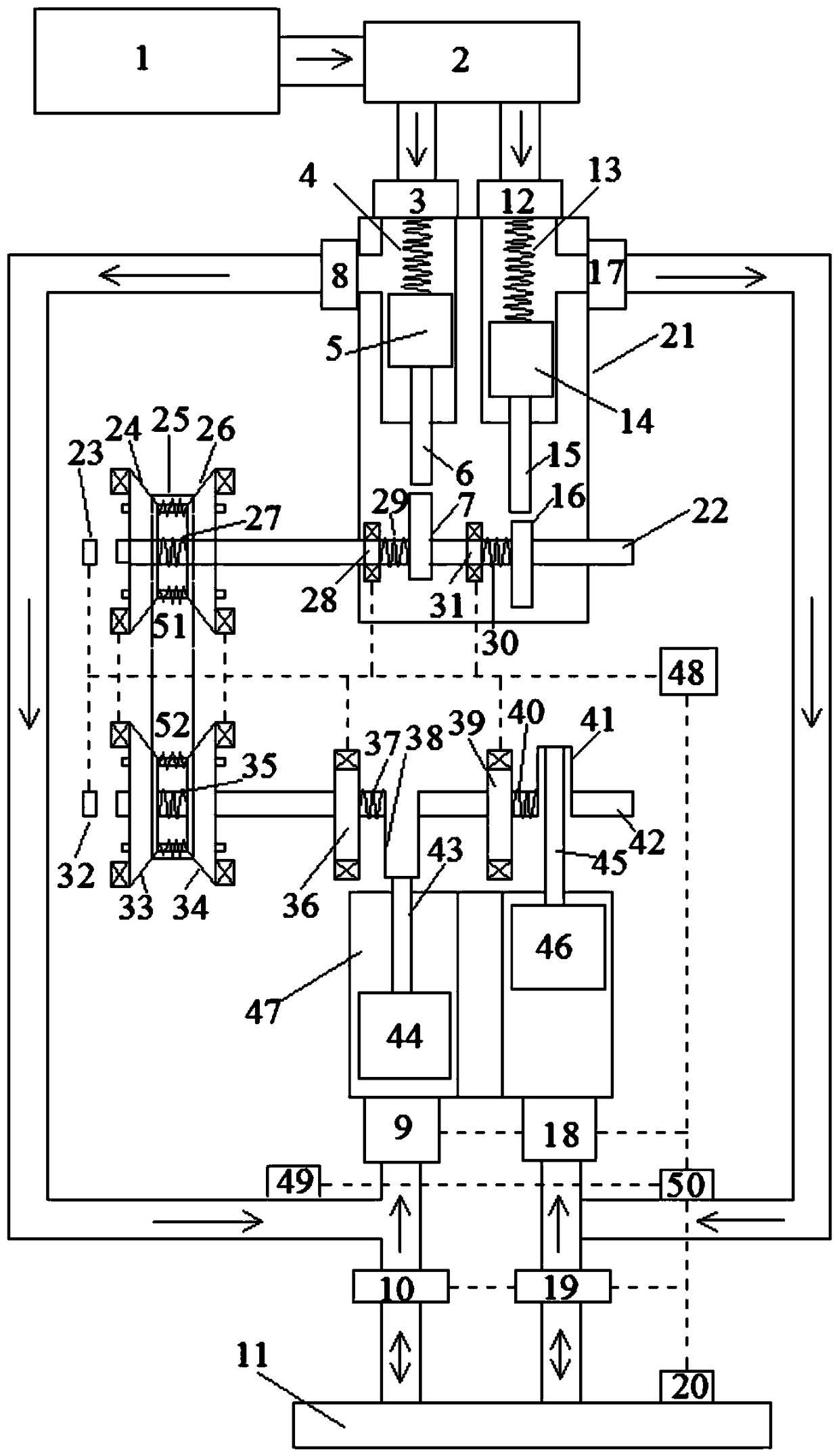

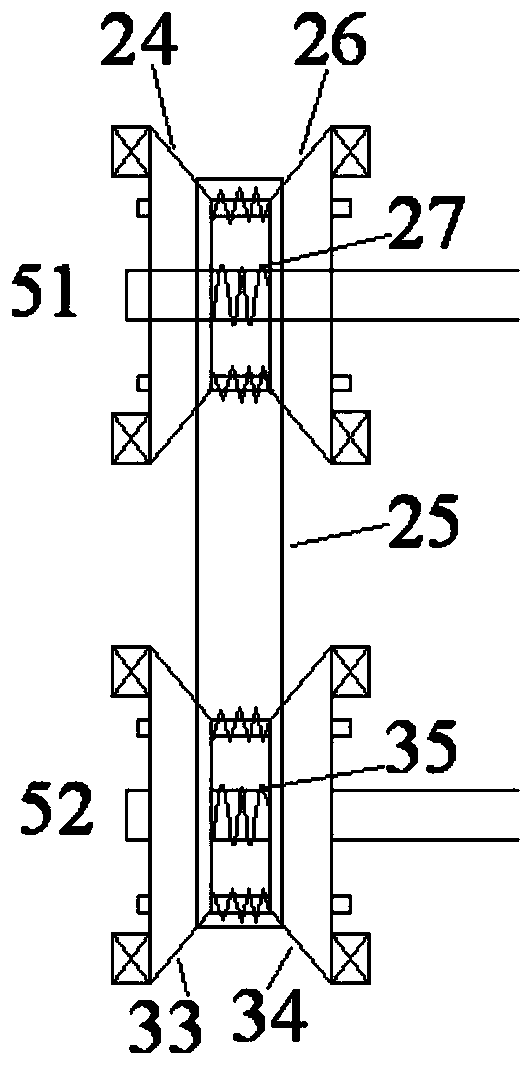

Energy-saving diesel engine having multistage variable oil-supply transmission ratio and multiple running modes

ActiveCN106762507AImprove efficiencyImprove stabilityPositive displacement pump componentsPiston pumpsLow speedHigh pressure

The invention discloses an energy-saving diesel engine having a multistage variable oil-supply transmission ratio and multiple running modes. The energy-saving diesel engine comprises a high-pressure oil pump, a diesel engine body and an oil tank, the high-pressure oil pump is of a double-oil-cylinder structure, the diesel engine body is of a double-piston-cylinder structure, two piston cylinders are respectively communicated with two oil cylinders correspondingly through electric-control oil injectors, plungers of the two oil cylinders correspondingly contact with two cams on a cam shaft respectively through pushing rods, pistons of the two piston cylinders are correspondingly connected with two connecting rod drivers on a crankshaft respectively through connecting rods, an oil supply speed-variable transmission mechanism is arranged between the cam shaft and the crankshaft, and the two electric-control oil injectors are communicated with a pressure-storage energy storing tank respectively through electric-control one-way valves. The multistage variable oil-supply transmission ratio can be automatically adjusted according to rotating speed of the diesel engine, low-speed oil-supply efficiency and stability can be improved, and high-speed oil-supply energy waste can be reduced; the multiple running modes can be started according to road conditions, so that fuel consumption of the diesel engine can be reduced, and emission pollution can be lowered.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

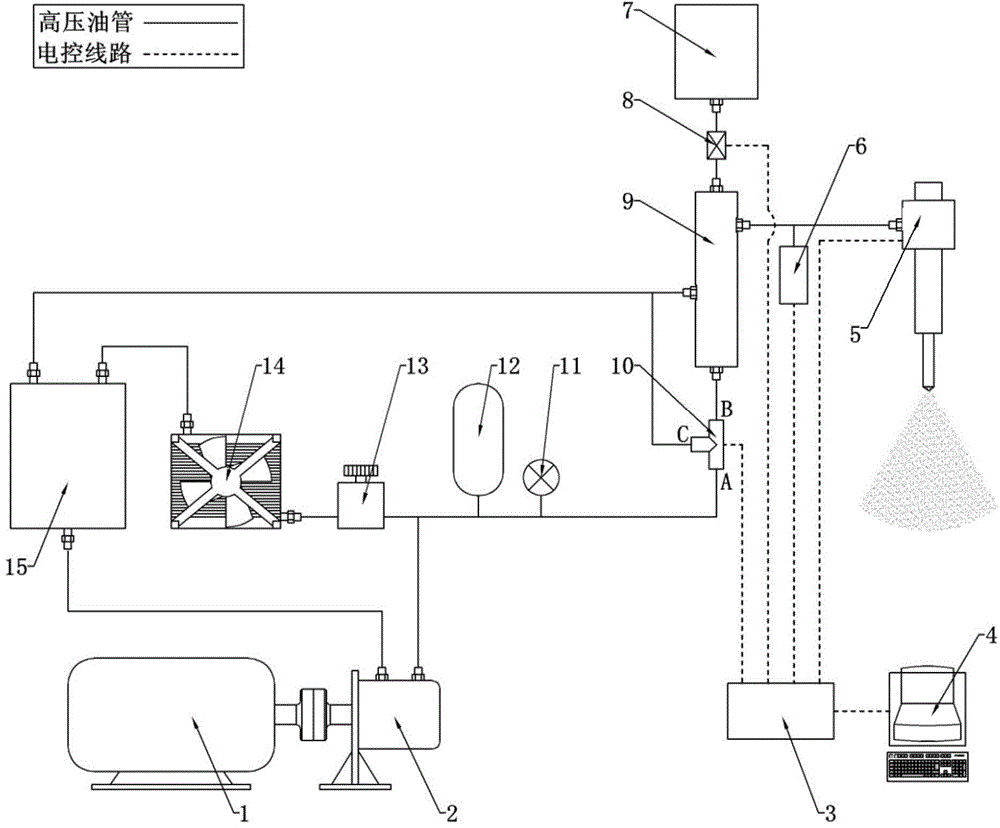

Hydraulic amplifying type ultrahigh-pressure fuel supply device

InactiveCN104879258AReduce wasteImprove oil supply efficiencyEngine testingFuel injection apparatusPistonContinuous operation

The invention provides a hydraulic amplifying type ultrahigh-pressure fuel supply device. The hydraulic amplifying type ultrahigh-pressure fuel supply device comprises a hydraulic oil tank, a fuel oil tank, an electric control valve, a pressure amplifying cavity and an electric control three-way valve. A T-shaped piston is arranged in the pressure amplifying cavity, a return spring is arranged in the pressure amplifying cavity, and the pressure amplifying cavity is provided with a hydraulic oil inlet and outlet, a high-pressure oil outlet, a fuel oil inlet and an oil discharge outlet. the fuel oil inlet is communicated with the fuel oil tank via the electric control valve, the hydraulic oil inlet and outlet is communicated with the oil supply pipeline of the hydraulic oil tank via the electric control three-way valve, and the oil discharge outlet is communicated with an oil return pipeline of the hydraulic oil tank, and the high-pressure oil outlet is communicated with an oil injector. The hydraulic amplifying type ultrahigh-pressure fuel supply device has the advantages that by changing pressure in a low-pressure cavity, fuel oil pressure in the high-pressure cavity is adjustable continuously, and pressure value is not over 300 MPa. In addition, the hydraulic amplifying type ultrahigh-pressure fuel supply device can supply fuel oil according to needs without continuous operation when used for atomizing characteristic test with low injection intervals, waste of high-pressure fuel oil is reduced and oil supply efficiency is improved.

Owner:CHINA NORTH ENGINE INST TIANJIN

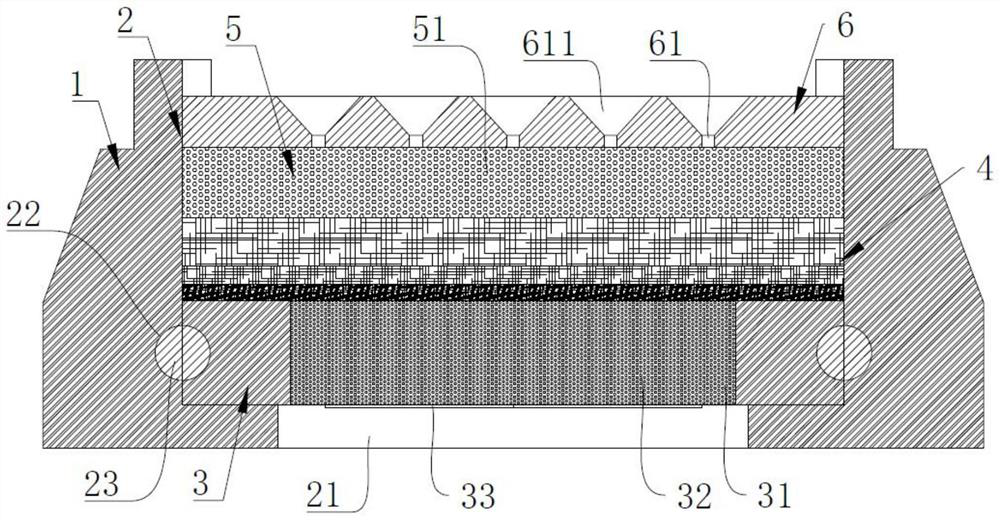

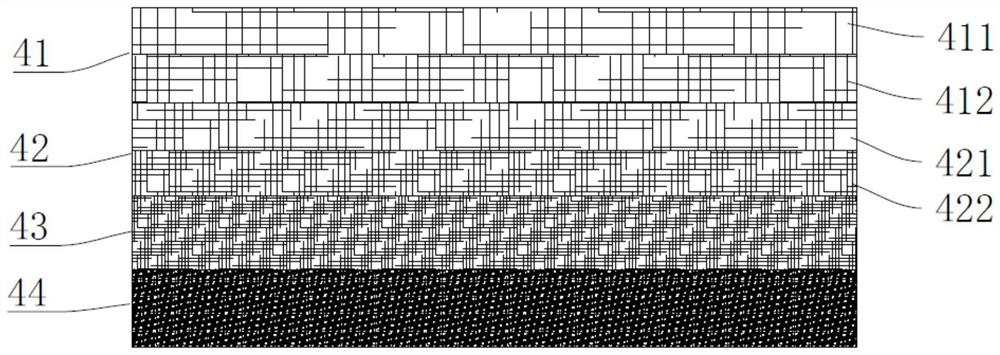

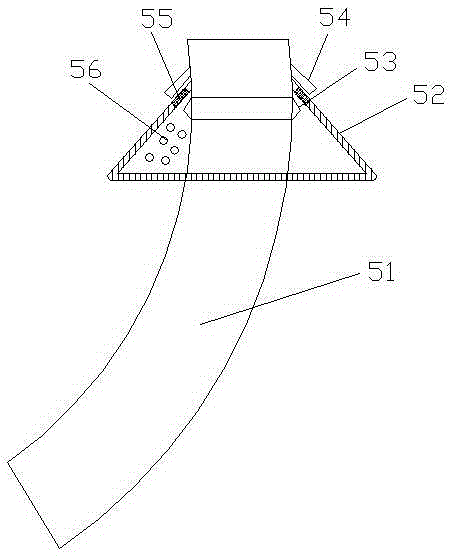

Porous silicon heating structure with oil storage packaging structure and electronic cigarette comprising porous silicon heating structure

The invention relates to the technical field of electronic cigarettes, in particular to a porous silicon heating structure with an oil storage packaging structure and an electronic cigarette comprising the porous silicon heating structure, and the porous silicon heating structure comprises a fixed seat, an atomization cavity formed in the fixed seat, and a heating sheet body, oil storage cotton, an oil conveying sheet and an oil guide sheet which are sequentially arranged in the atomization cavity from bottom to top, and the heating sheet body is provided with a permeation area; micropores are uniformly distributed in the permeation area, the micropores are connected with the oil storage cotton, oil conveying holes are uniformly distributed in the oil conveying sheet, the oil conveying holes are communicated with the oil storage cotton, a heating circuit is arranged on the heating sheet body, oil guide holes are formed in the oil guide sheet, and the oil guide holes are communicated with the oil conveying holes; the heating circuit is arranged in the permeation area and deviates from one surface of the oil storage cotton; through the cooperation of the oil conveying sheet and the oil storage cotton, the electronic cigarette can be used for storing tobacco tar, sufficient tobacco tar can be conveniently provided when the electronic cigarette is used every time, the heating and atomizing effects on the tobacco tar are good, and the taste is improved.

Owner:SHENZHEN KELAI PENG TECH CO LTD

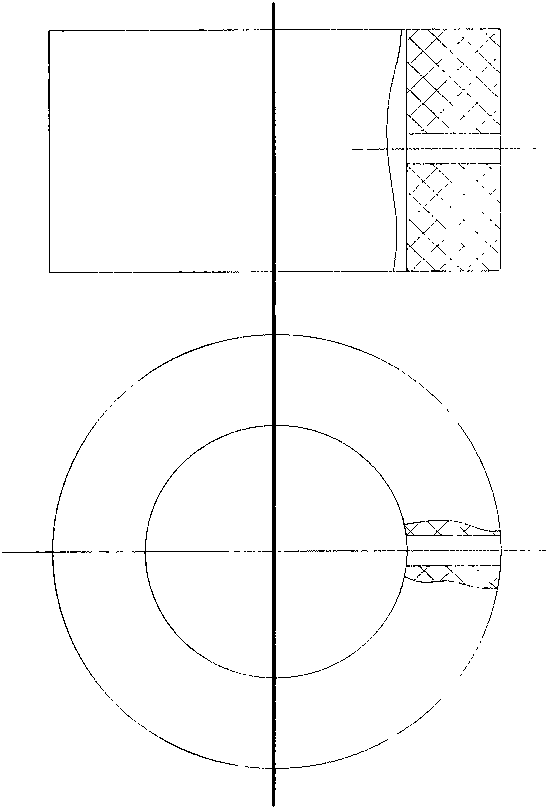

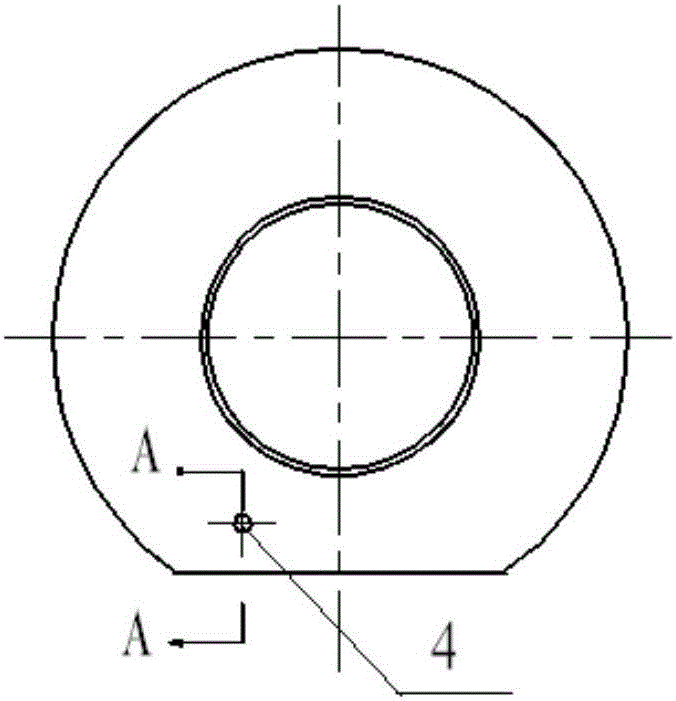

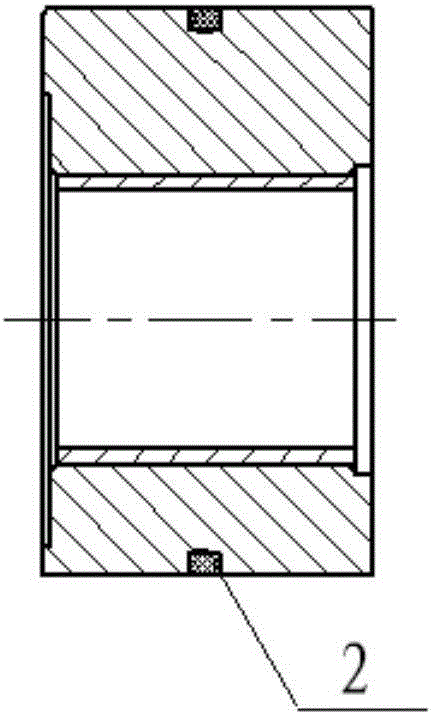

High-pressure gear pump bearing with sealing structure

InactiveCN106438680AImprove oil supply efficiencyPrevent gap leakageShaftsBearing componentsGear pumpHigh pressure

The invention relates to a high-pressure gear pump bearing with a sealing structure; and the high-pressure gear pump bearing is used for reducing the fuel leakage after pumping when a high-pressure gear pump works, so that the oil supply efficiency of the gear pump is improved. Because of existence of the part machining dimensional tolerance and geometric tolerance, in order to guarantee normal installation of the bearing in a shell cavity, a certain gap is guaranteed between the outer diameter of the bearing and the inner diameter of the shell cavity, so that the fuel leakage is inevitable. The high-pressure gear pump bearing with the sealing structure is provided with a peripheral sealing groove in the outer surface; and an oil passing hole is formed in the end surface bonded with a gear, and is communicated with the sealing groove. High-pressure radial pressure is applied to a rectangular sealing ring in the sealing groove through high-pressure oil to realize peripheral seal. The rectangular-section sealing ring is added on the bearing to guarantee sealing between the bearing and a shell to prevent leakage of the high-pressure fuel in an outlet of the gear pump from the gap between the bearing and the shell.

Owner:BEIJING HANGKE ENGINE CONTROL SYST SCI & TECH

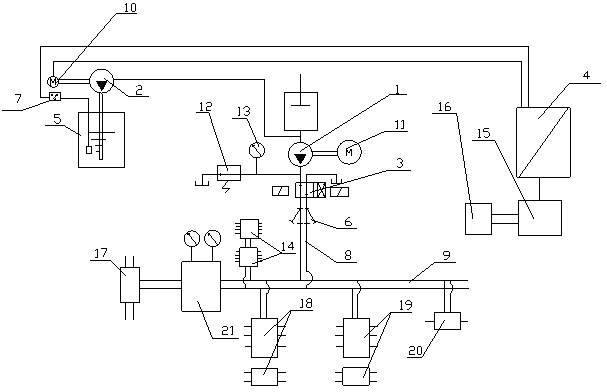

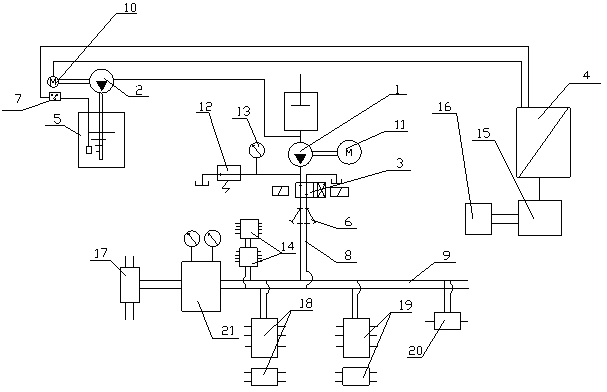

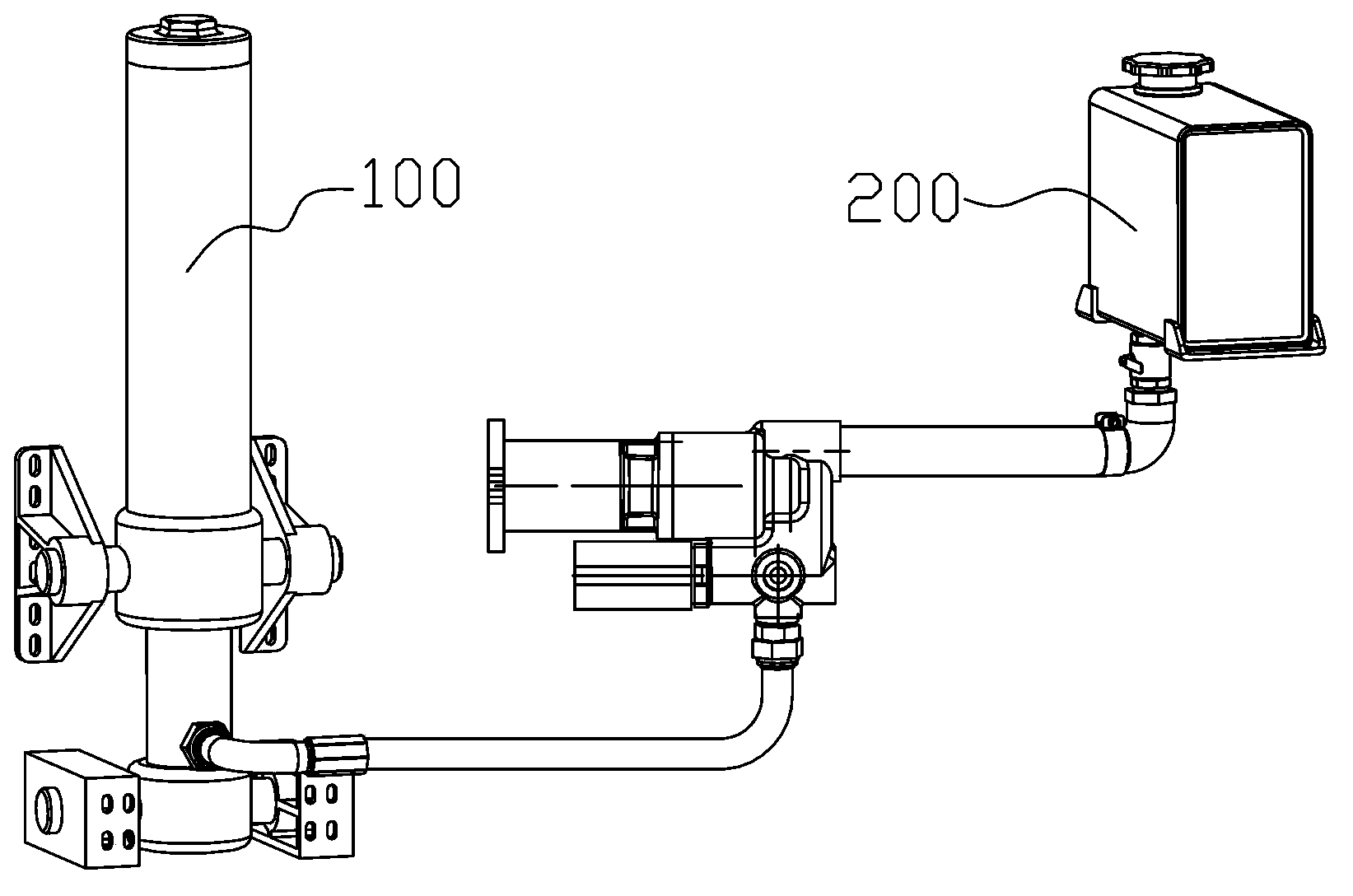

Two-wire centralized lubrication system

InactiveCN102052554AWidely distributedRealize centralized oil supplyEngine lubricationDifferential pressureFuel tank

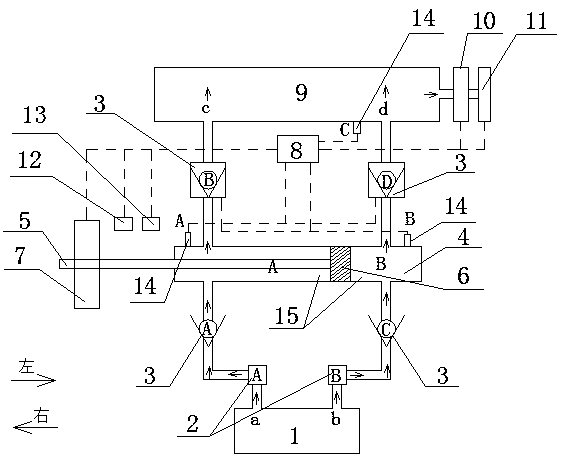

The invention relates to a two-wire centralized lubrication system which comprises an electric lubricant pump, a lubricant pump motor, a fuel tank and a control cabinet, wherein a liquid level sensor is arranged in the fuel tank, and a refueling pump is embedded in the fuel tank; the refueling pump is connected with the electric lubricant pump, and the electric lubricant pump is provided with a safety valve and a solenoid directional valve; a pipeline for connecting the safety valve and the solenoid directional valve is provided with a pressure gage, the solenoid directional valve is connected with a longitudinal main oil supply pipe, and the longitudinal main oil supply pipe is provided with a grease filter and connected with a horizontal main oil supply pipe; one side of the horizontal main oil supply pipe is connected with a two-wire distributor A and a two-wire distributor C, the horizontal main oil supply pipe is connected with a differential pressure switch by the two-wire distributor A, and the differential pressure switch is connected with a two-wire distributor B; and the other side of the horizontal main oil supply pipe is connected with a two-wire distributor D and a two-wire distributor E, the control cabinet is connected with a remote monitoring computer, and the remote monitoring computer is connected with an alarm. The two-wire centralized lubrication system has the advantages that because lubricating points are distributed widely, a plurality of lubricating points can be lubricated; and meanwhile, the two-wire centralized lubrication system can be monitored remotely.

Owner:樊建良

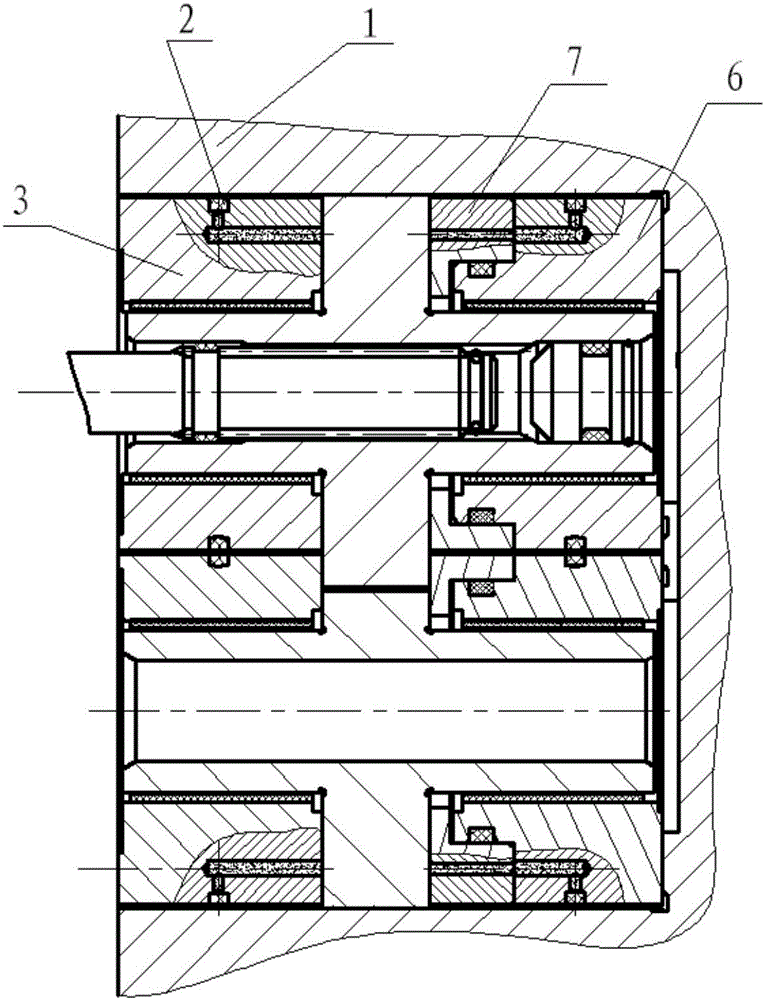

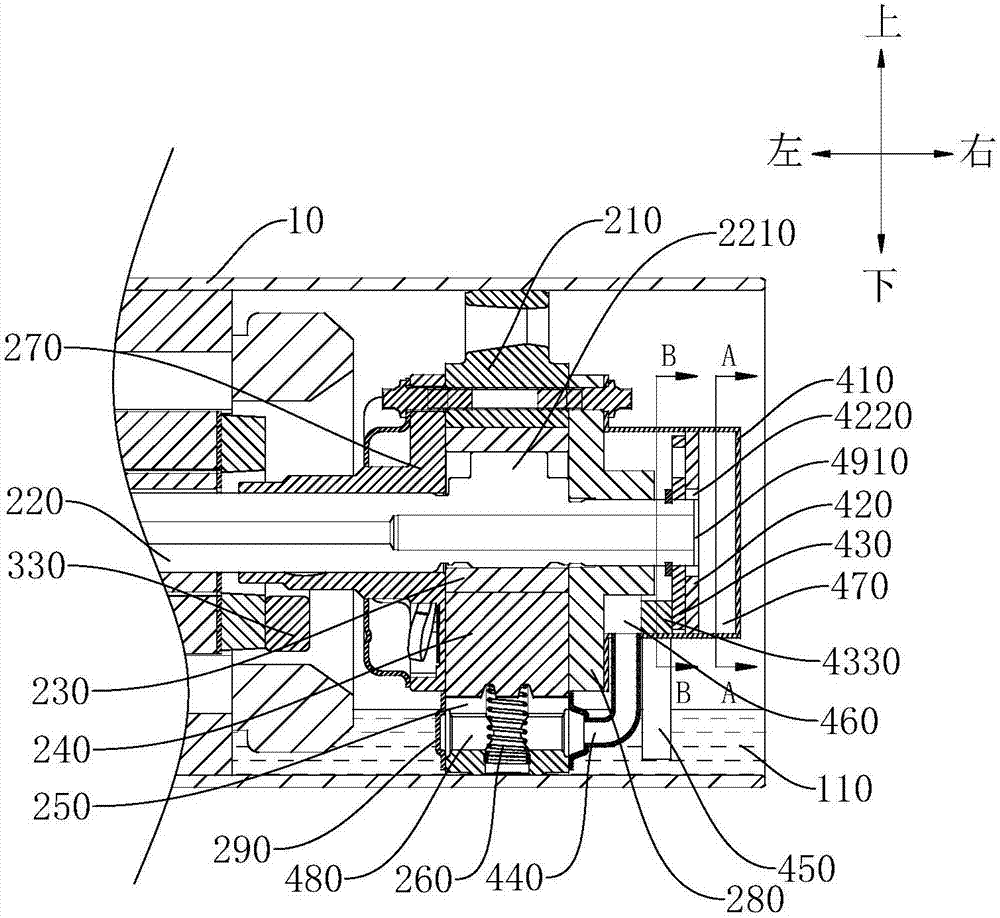

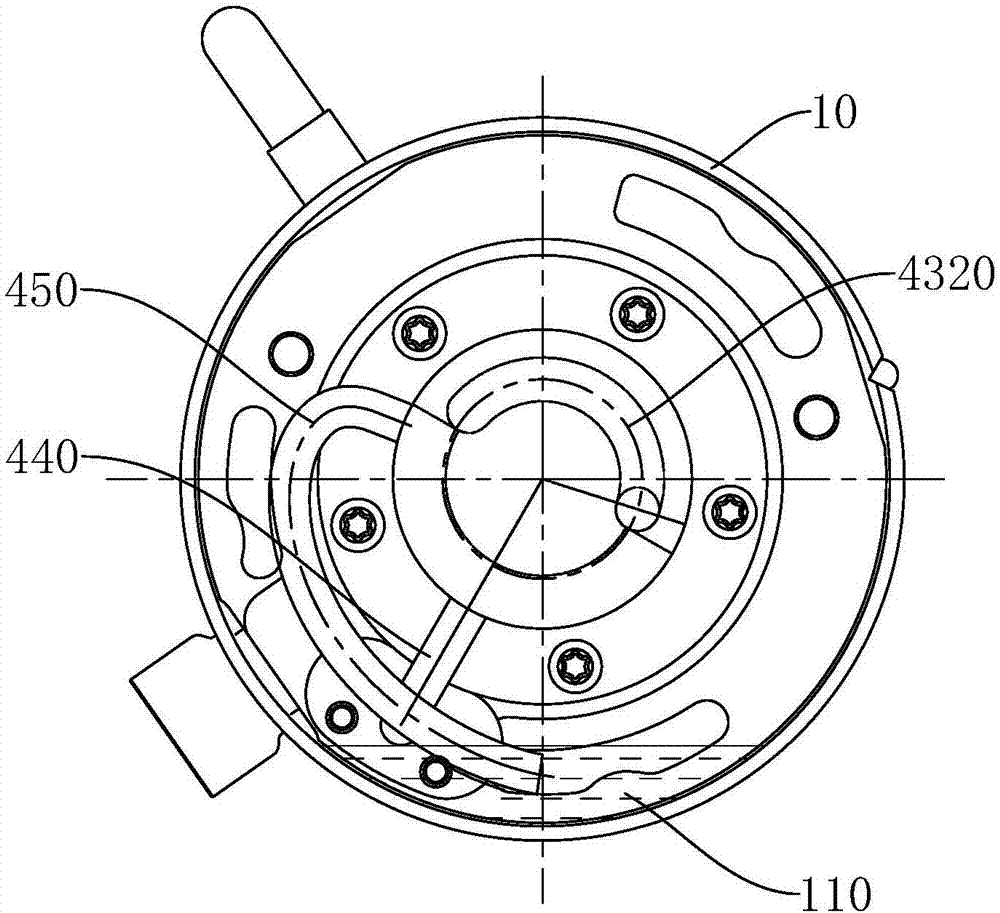

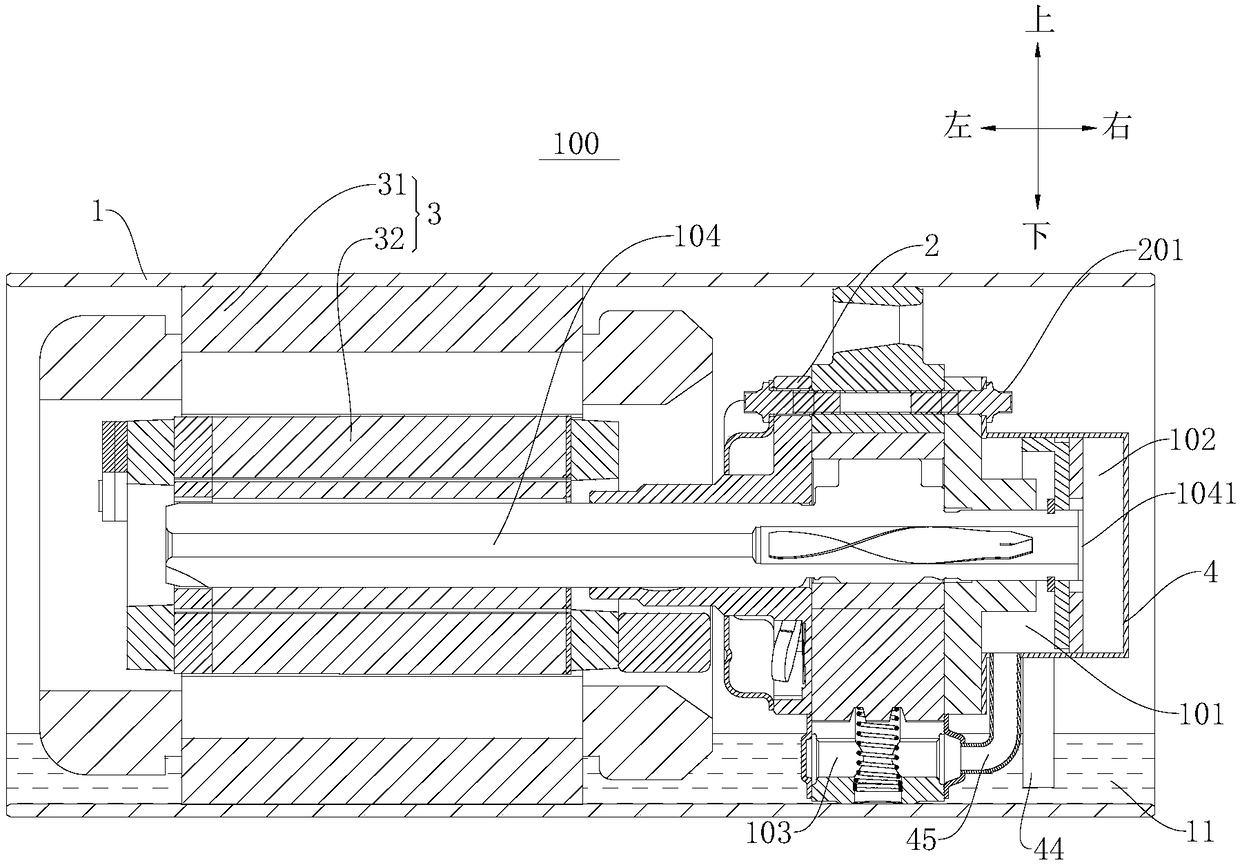

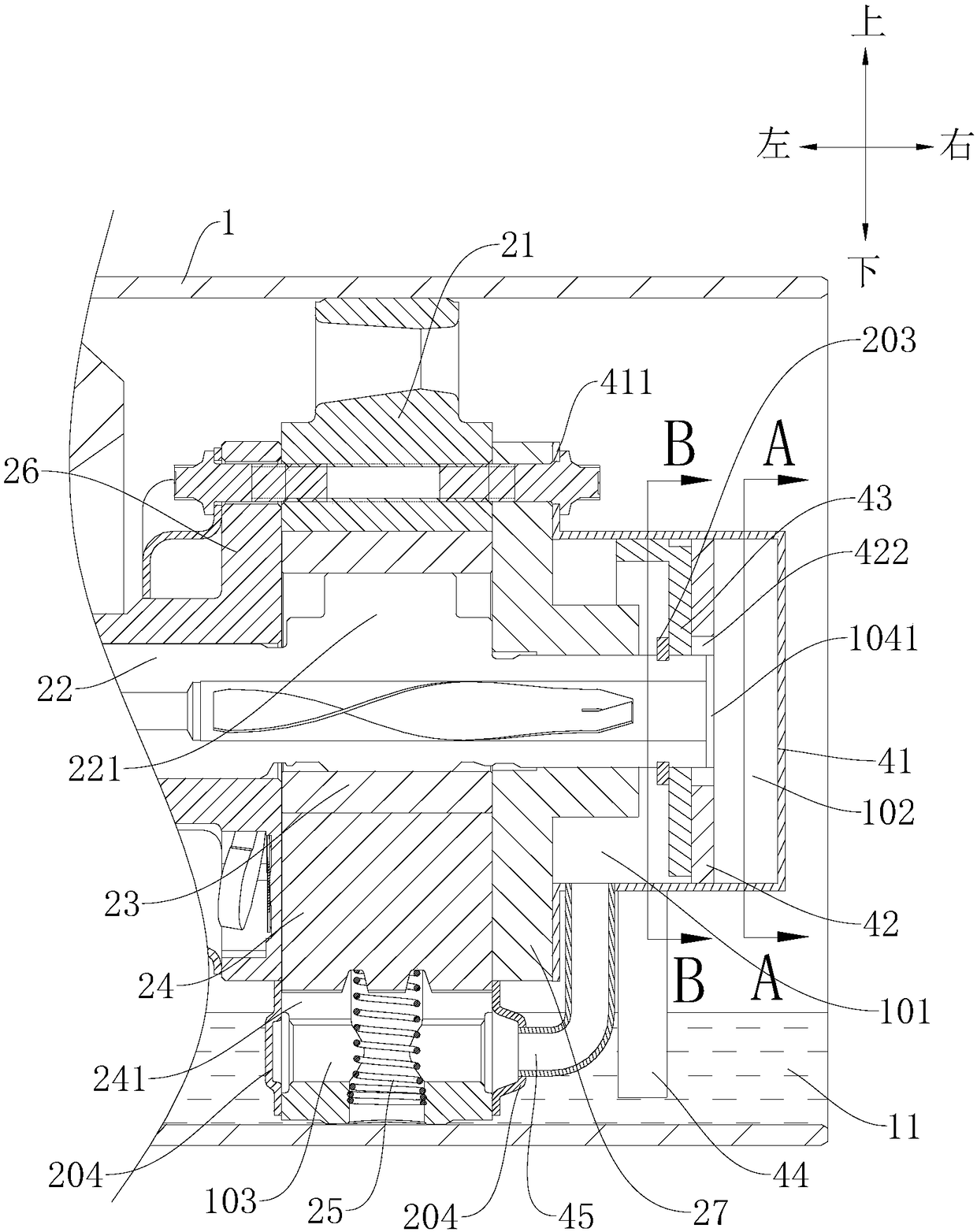

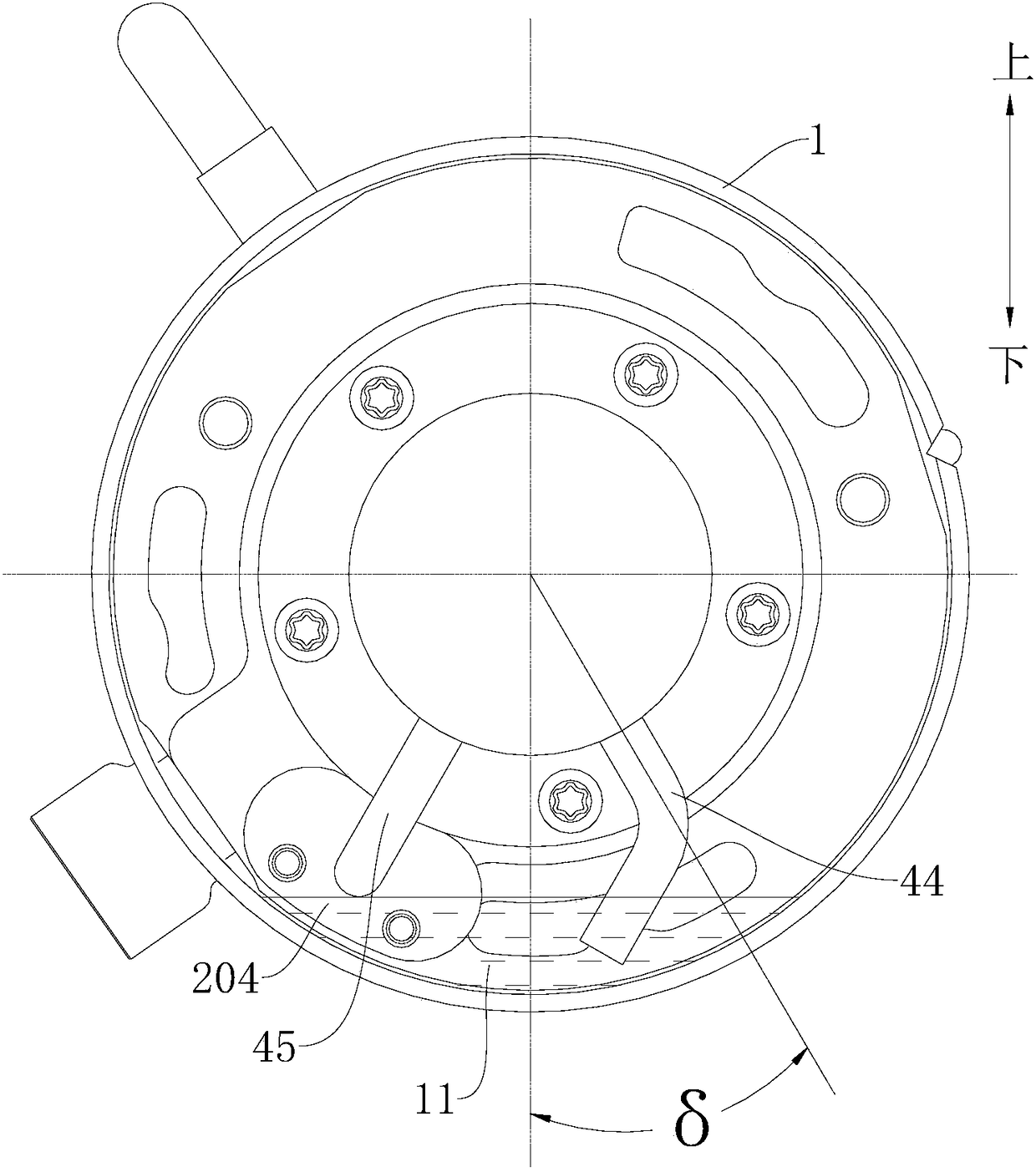

Compressor

ActiveCN106907323ALower the altitudeAvoid rotor churning problemsRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsPistonCrankshaft

The invention discloses a compressor. The compressor comprises a shell, a compression mechanism with an illumination oil passage, a motor assembly and an oil feeding mechanism. An oil pool is arranged in the shell. The compression mechanism is arranged in the shell and comprises at least one air cylinder, a crankshaft, a piston and a sliding piece, wherein the piston is arranged on an eccentric portion of the crankshaft in a sleeving mode and located in an air cylinder cavity of the air cylinder, and the sliding piece is arranged in a sliding piece groove of the air cylinder in a reciprocating mode. The motor assembly is arranged in the shell and connected with the crankshaft. The oil feeding mechanism is arranged in the shell and defines a first oil feeding cavity and a second oil feeding cavity, the second oil feeding cavity communicates with the lubricating oil passage, and the oil feeding mechanism is configured to enable the first oil feeding cavity and the second oil feeding cavity to communicate with the oil pool in a switching mode. According to the compressor, the oil sucking process of sucking oil from the oil pool and the oil supply process of supplying oil to the lubricating oil passage do not interfere with each other, the oil sucking and oil supply power is sufficient, and the lubricating effect is good.

Owner:GUANGDONG MEIZHI PRECISION MFG

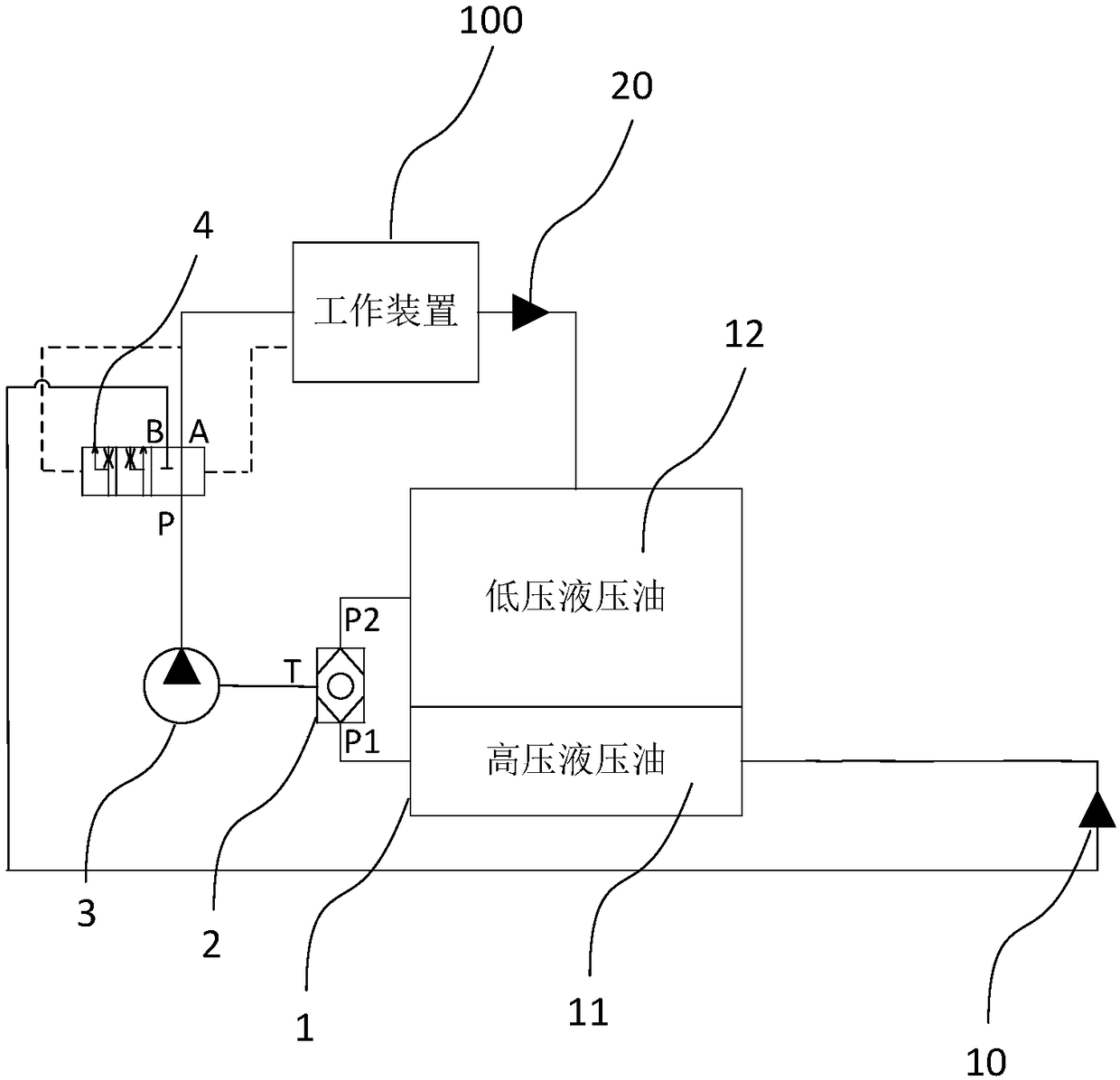

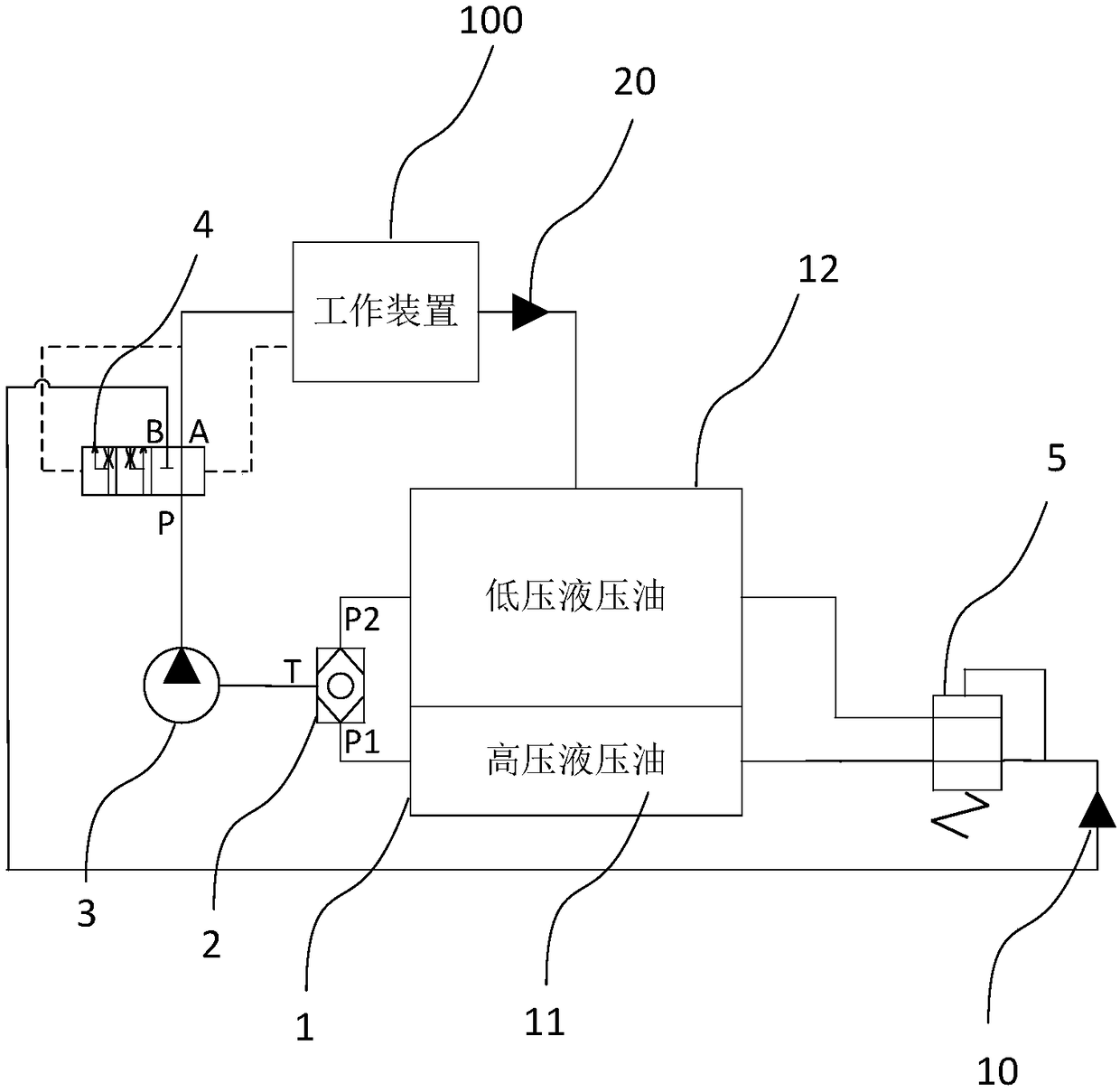

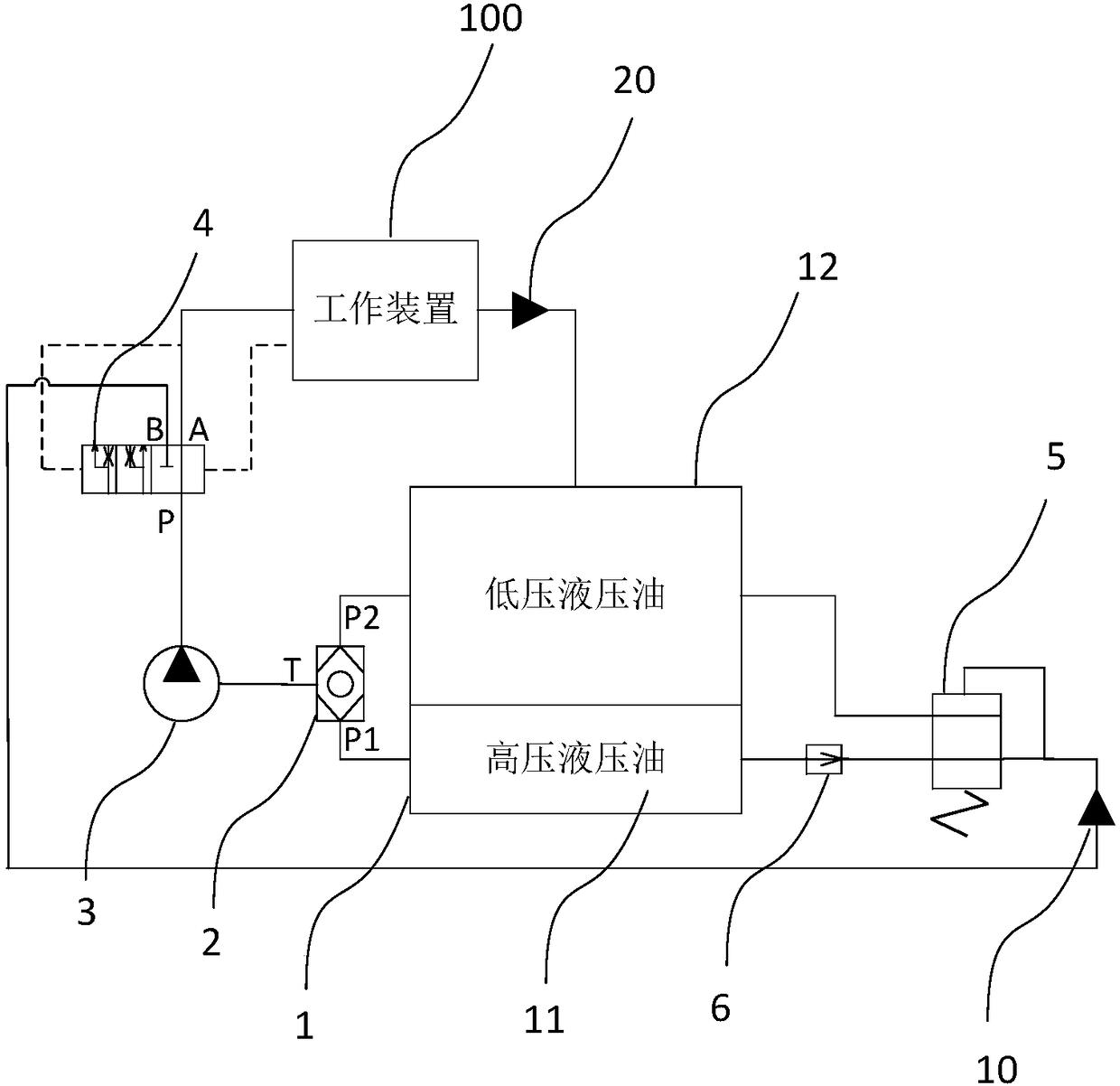

Oil supply device for engineering vehicle

ActiveCN109139614AReduced energy required for pressurizationShort time spentServomotor componentsServometer circuitsOil supplyEngineering

The invention belongs to the technical field of engineering vehicles and relates to an oil supply device for an engineering vehicle. The oil supply device comprises an oil tank, a shuttle valve, an oil pump, a priority valve and a working device, wherein the oil tank is used for storing high-pressure hydraulic oil and low-pressure hydraulic oil; the shuttle valve is used for conveying the high-pressure hydraulic oil or the low-pressure hydraulic oil to the oil pump according to the oil condition in the oil tank; the oil pump is used for conveying the high-pressure hydraulic oil or high-pressure hydraulic oil which is formed after the low-pressure hydraulic oil is pressurized to the priority valve; the priority valve is used for conveying the high-pressure hydraulic oil to the working device, and conveying the redundant high-pressure hydraulic oil to the oil tank according to the pressure of an oil path; and the working device is used for conveying low-pressure hydraulic oil which is formed after the working of the high-pressure hydraulic oil to the oil tank. Through the oil supply device, the redundant high-pressure hydraulic oil can be conveyed to and stored in the oil tank; whenthe working device requires hydraulic oil again, the high-pressure hydraulic oil stored in the oil tank can be conveyed, and then energy required for the pressurization of the oil pump can be reduced;and furthermore, the time required for supplying the high-pressure hydraulic oil to the working device can be shortened, and then the efficiency of oil supply to the engineering vehicle can be improved.

Owner:BYD CO LTD

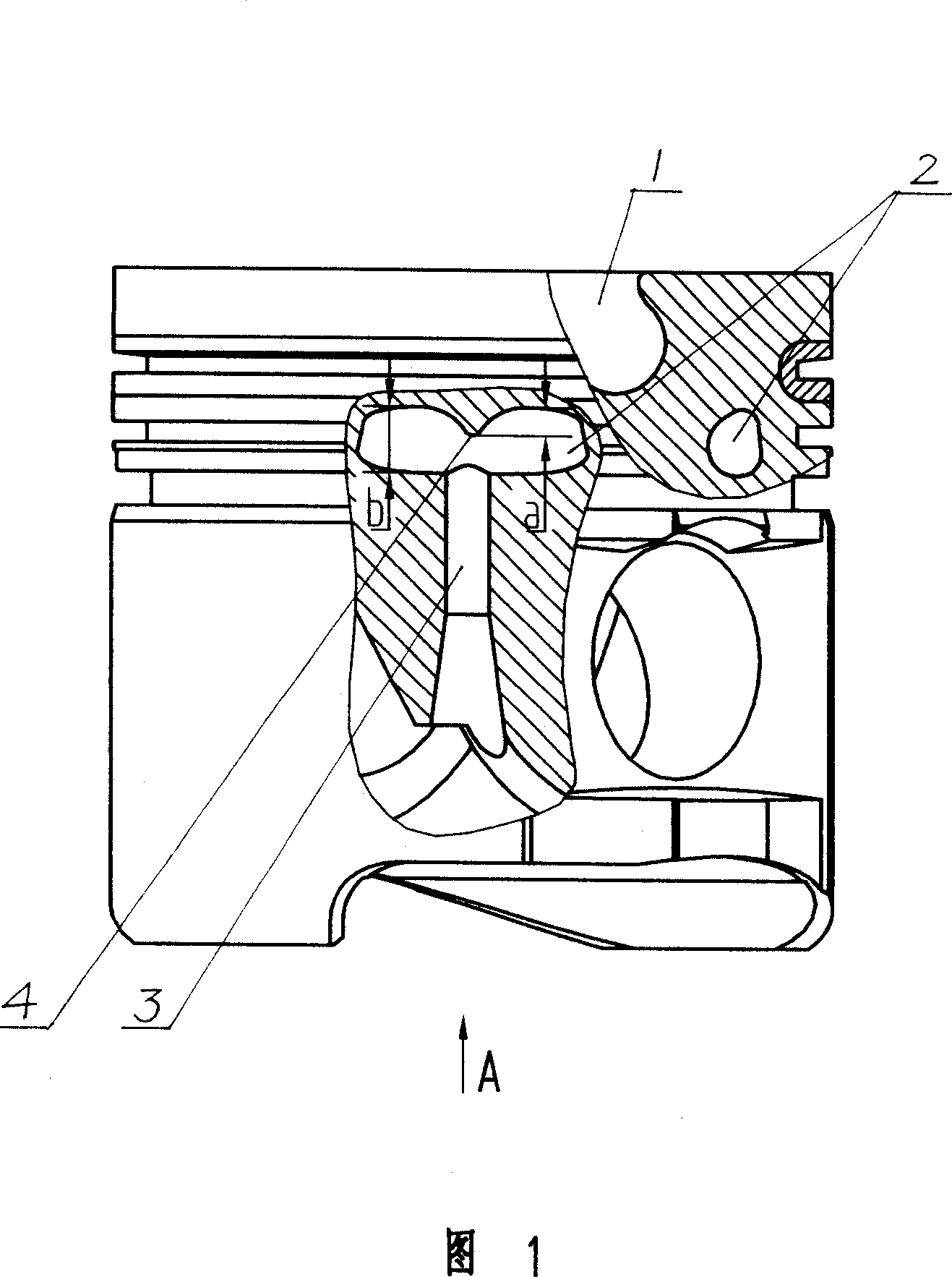

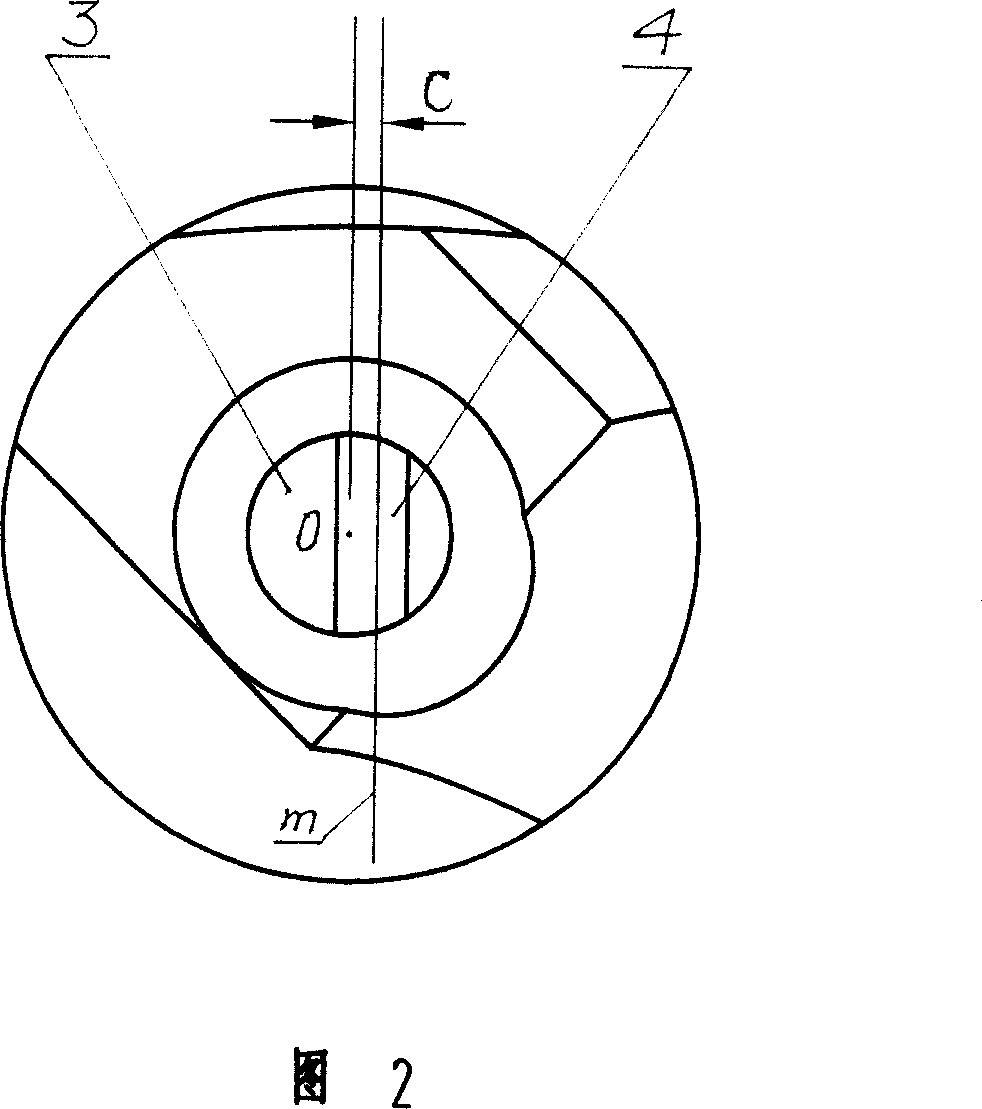

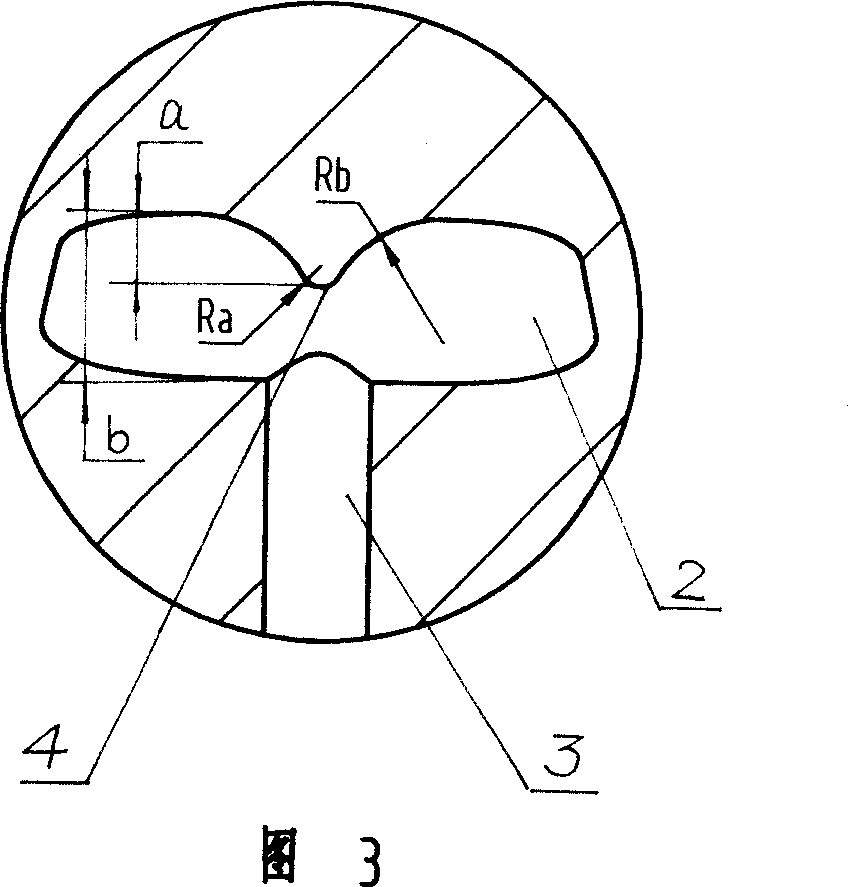

High efficiency chilled high intensification piston of diesel engine

InactiveCN101063427AEasy to manufactureReduce hindranceMachines/enginesPistonsCombustion chamberProjection line

A highly effective cooling highly-reinforced diesel engine piston is provided with an annular oil cavity on lower portion of a burning chamber in the piston, wherein the position of the oil cavity relative to an oil inlet is provided with a distribution boss along the radial direction of the piston, and a projection line in the ridge center of the distribution boss relative to the top plate of the piston is positioned in the projection area in the top plate of the piston. The projection line has a bias value of 0-3mm as deviating to the oil inlet center, and the height of the boss is 1 / 8-3 / 4 of the height of the oil cavity, and two sides of the boss cross-section is a sloping line or an arcuate path, or a parabolic curve. The invention is used in the diesel engine with average effective pressure higher than 1. 3MPa and can enhance the oil-supplying efficiency of fluid oil efficiently, and also can control the oil flow distribution in two side oil cavities efficiently as the center of the burning chamber no reclosing with the center of the piston, thereby cooling the piston evenly and enhancing the cooling effect.

Owner:YANGDONG CO LTD

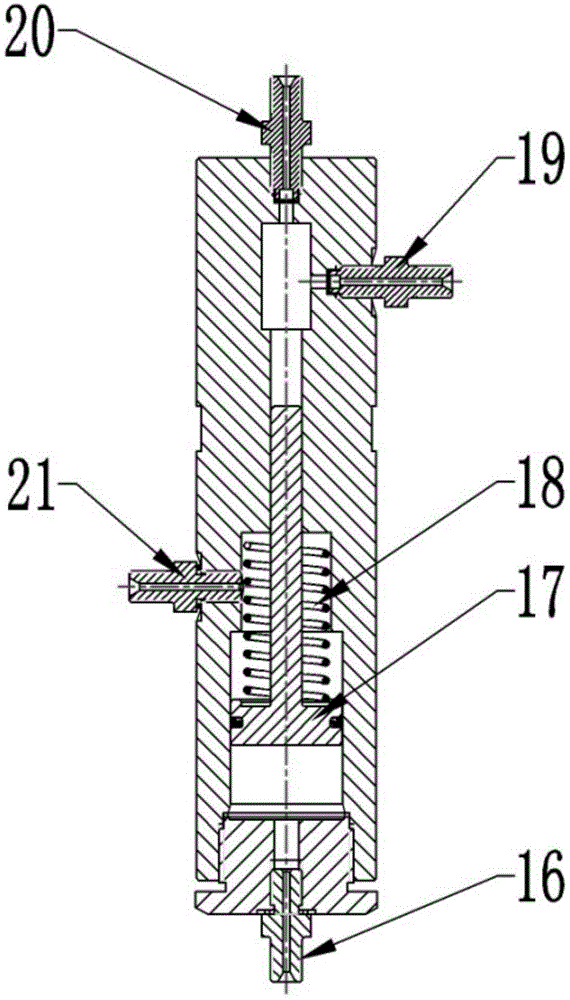

In-cylinder direct-spray high-pressure pump

PendingCN110185565AImprove reliabilityReduced stiffness requirementsMachines/enginesFuel injecting pumpsSolenoid valveEngineering

The invention relates to an in-cylinder direct-spray high-pressure pump. The in-cylinder direct-spray high-pressure pump comprises a pump body, wherein an oil inlet and an oil outlet are formed in thepump body; a stable-pressure cavity, a low-pressure cavity, a high-pressure cavity, a first connecting oil path and a second connecting oil path are arranged in the pump body; the oil inlet communicates with the first connecting oil path through the stable-pressure cavity; the first connecting oil path communicates with the second connecting oil path through the low-pressure cavity and the high-pressure cavity in sequence; the second connecting oil path communicates with the oil outlet; a solenoid valve is arranged in the low-pressure cavity; a plunger piston device is arranged in the high-pressure cavity; the oil outlet is equipped with a pressure release valve; the pressure release cavity communicates with the low-pressure cavity or the high-pressure cavity; the pressure release valve comprises a sealing base with a through hole therein, a stud and a ball body arranged between the sealing base and the stud; the ball body and the sealing base can be connected in a sealing mode; the ball body is linked and matched with the stud; and a pressure release valve spring is arranged between the stud and the inner wall of the pressure release cavity. The pressure release valve structure is changed into spherical surface seal from plane seal, so that sealing effect is good, a sealing form is more stable, the closing effect is quicker, and oil supply efficiency of the high-pressure pumpis improved.

Owner:JIANGSU BATON TECH CO LTD

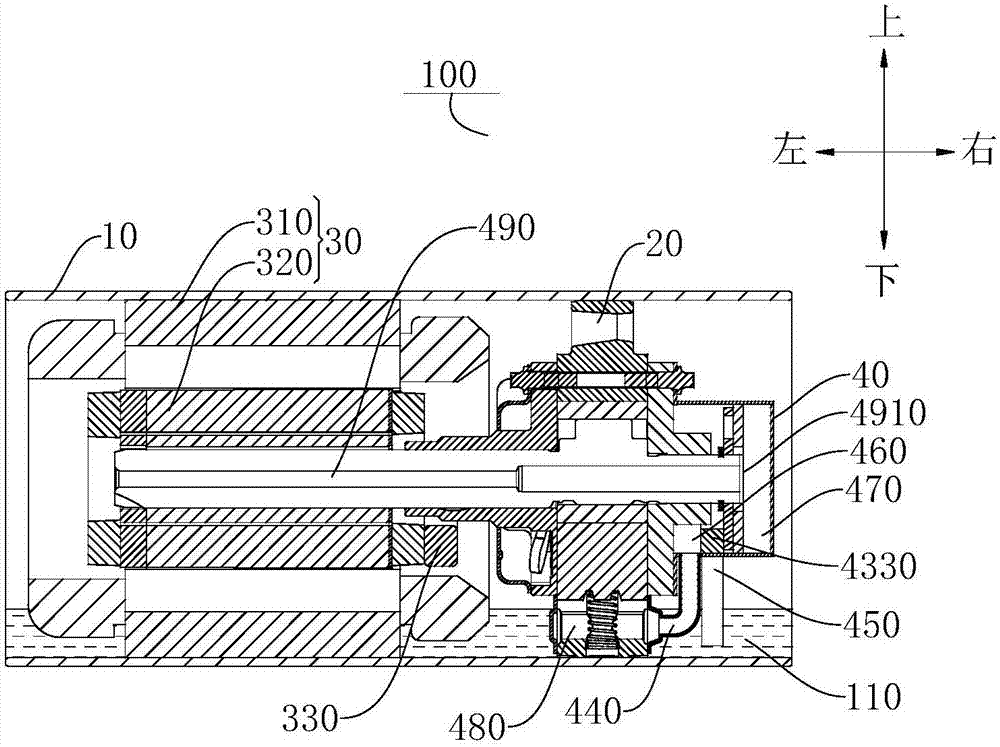

Compressor

InactiveCN107165828AImprove oil supply efficiencySimple structureRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsCrankshaftPiston

The invention discloses a compressor which comprises a shell, a compressing mechanism, a motor assembly and an oiling mechanism. The oiling mechanism comprises a case, a communicating pipe, an oil suction pipe and a switching part, wherein the switching part comprises a body and a balance plugging block. According to the compressor of the embodiment, the switching part is arranged in the oiling mechanism, and thus a first oiling cavity and a second oiling cavity can communicate with an oil pool in a switched mode, the oil sucking process of the oiling mechanism sucking oil from the oil pool and the oil supply process of the oiling mechanism supplying oil to a lubricating oil way of the compressing mechanism are mutually not interfered, and sufficient power for oil sucking and oil supplying of the oiling mechanism is guaranteed. By arranging the balance plugging block on the switching part, not only can eccentric mass of an eccentric part and eccentric mass of a piston be balanced, but also the mass of a balance block arranged near the compressing mechanism can be reduced, and therefore the height of the balance block can be reduced, the crankshaft flexibility is lowered, the clearance sound is lowered, and the structure of the compressing mechanism is optimized.

Owner:GUANGDONG MEIZHI COMPRESSOR

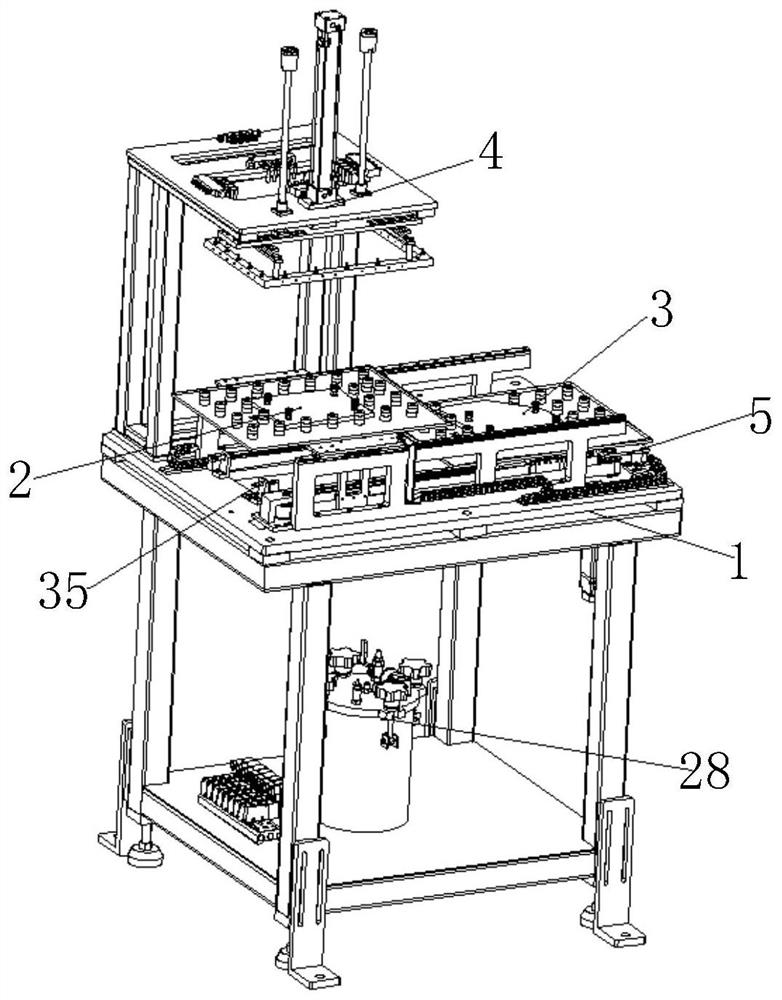

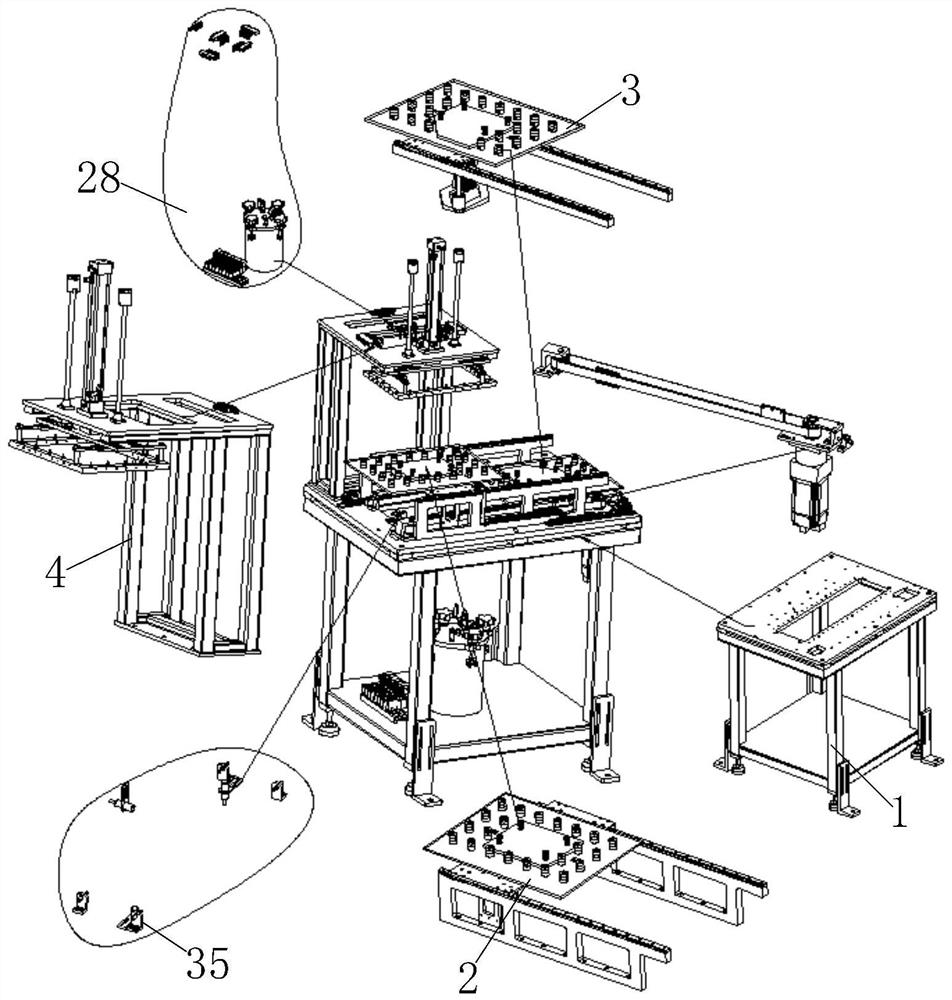

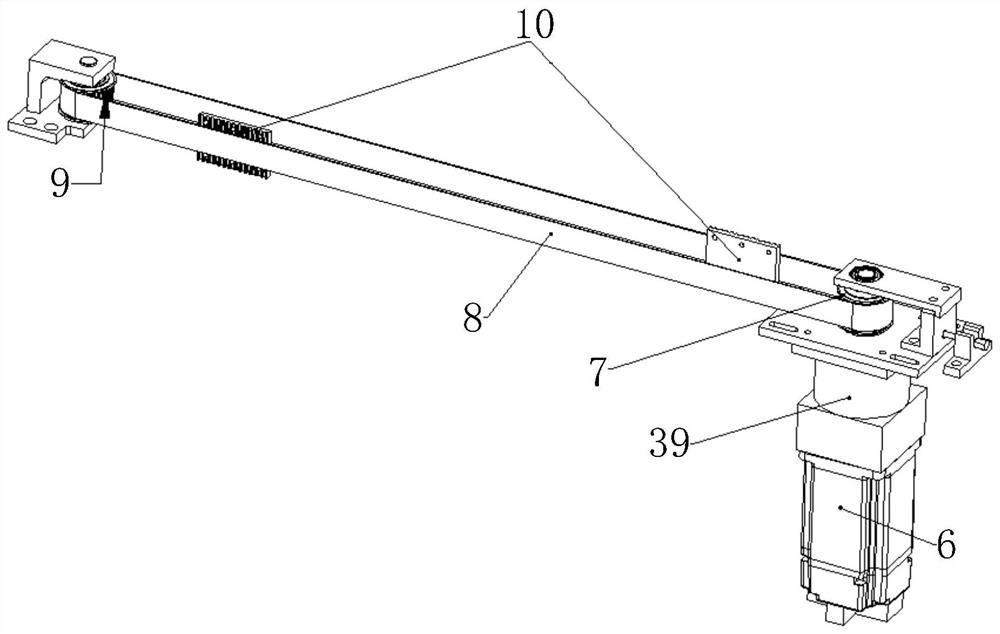

Double-station automatic oiling equipment

PendingCN111957531AImprove automationReduce labor intensityLiquid surface applicatorsConveyorsAgricultural scienceAgricultural engineering

The invention provides double-station automatic oiling equipment which comprises a support, a first transplanting mechanism, a second transplanting mechanism, an oiling mechanism and a power mechanism. The first transplanting mechanism and the second transplanting mechanism are movably arranged at the top end of the support, the oiling mechanism is arranged above the support, the first transplanting mechanism is arranged above the second transplanting mechanism, the oiling mechanism is arranged above the first transplanting mechanism and the second transplanting mechanism, the output end of the oiling mechanism corresponds to notebook metal shells on the first transplanting mechanism and the second transplanting mechanism, the bottom of the power mechanism is arranged on the right side ofthe top end of the support, the power mechanism is positioned below the first transplanting mechanism and the second transplanting mechanism, and the top of the power mechanism is respectively in transmission connection with the first transplanting mechanism and the second transplanting mechanism.

Owner:CHONQING HUASHU ROBOT CO LTD

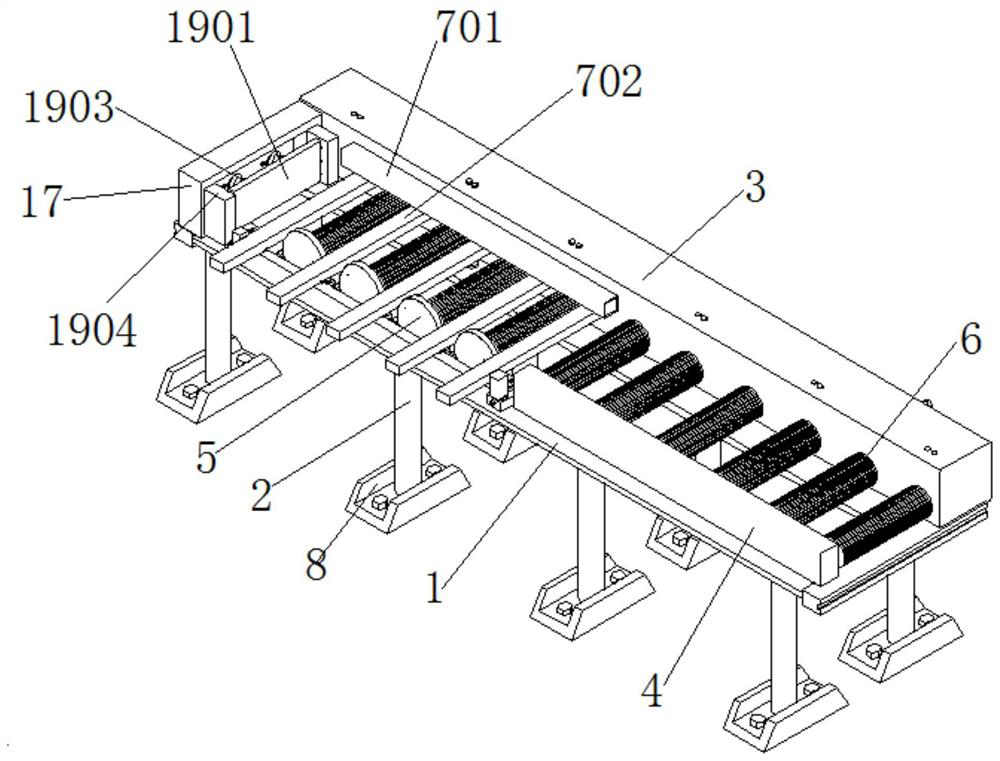

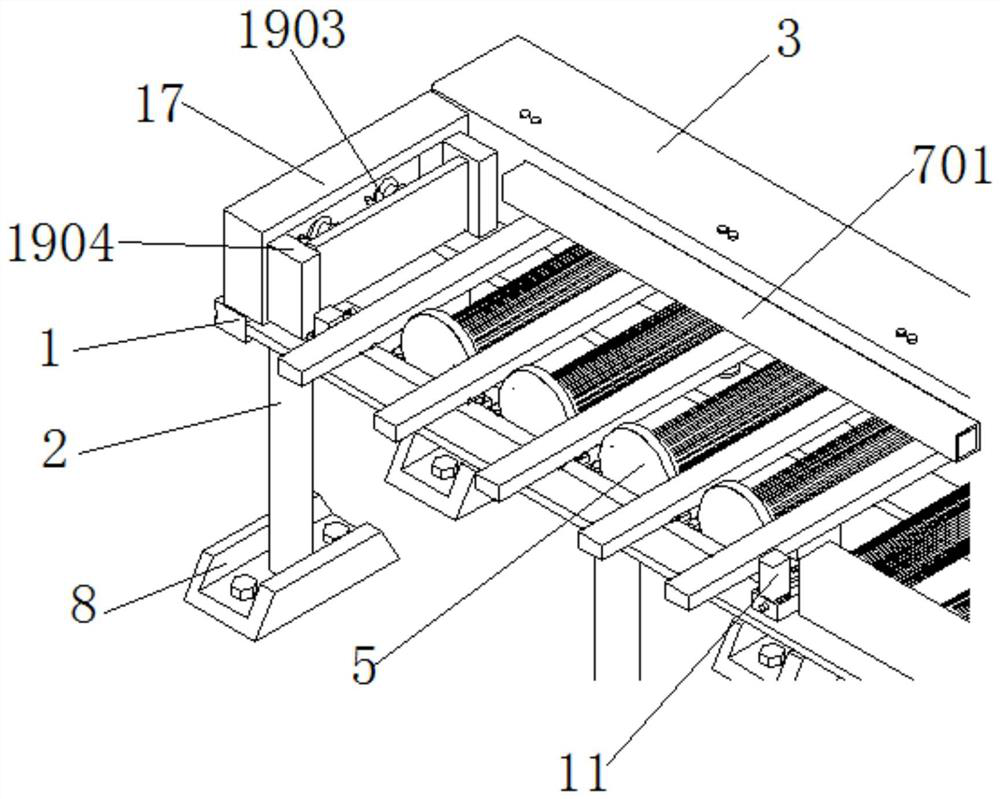

Method for promoting discharging stabilization of reinforced polypropylene (HRPP) double-wall corrugated pipe for buried drainage and pollution discharge

The invention provides a method for promoting discharging stabilization of a reinforced polypropylene (HRPP) double-wall corrugated pipe for buried drainage and pollution discharge, and belongs to thetechnical field of production of pipes. The discharging device comprises a support frame, support legs, a driving device shell, a driven device shell, discharging roller support seats, discharging rollers, a material bouncing rack and a buffer mechanism, wherein rubber protruding strips are arranged on the surfaces of the discharging rollers, so that the static friction force between the discharging rollers and a drainage pipe can be increased, and the impact between the drainage pipe and the discharging rollers can be relieved through the elasticity of the rubber protruding strips; by arranging a sliding seat, damage of the elastic material to an air cylinder is reduced, and by arranging an oil storage bin and oil supply rollers at the bottom end of the sliding seat, the sliding smoothness of a sliding block and a sliding groove can be improved; by arranging an end aligning plate and the buffering mechanism, the ends of the drainage pipe can be kept aligned, the impact force generated when the drainage pipe is aligned can be reduced, and the end of the drainage pipe and the buffering plate are prevented from being damaged in the collision process; and by arranging guide reinforcing blocks and balls, the service life of a guide movable rod can be prolonged.

Owner:FUJIAN HOSHING PLASTICS

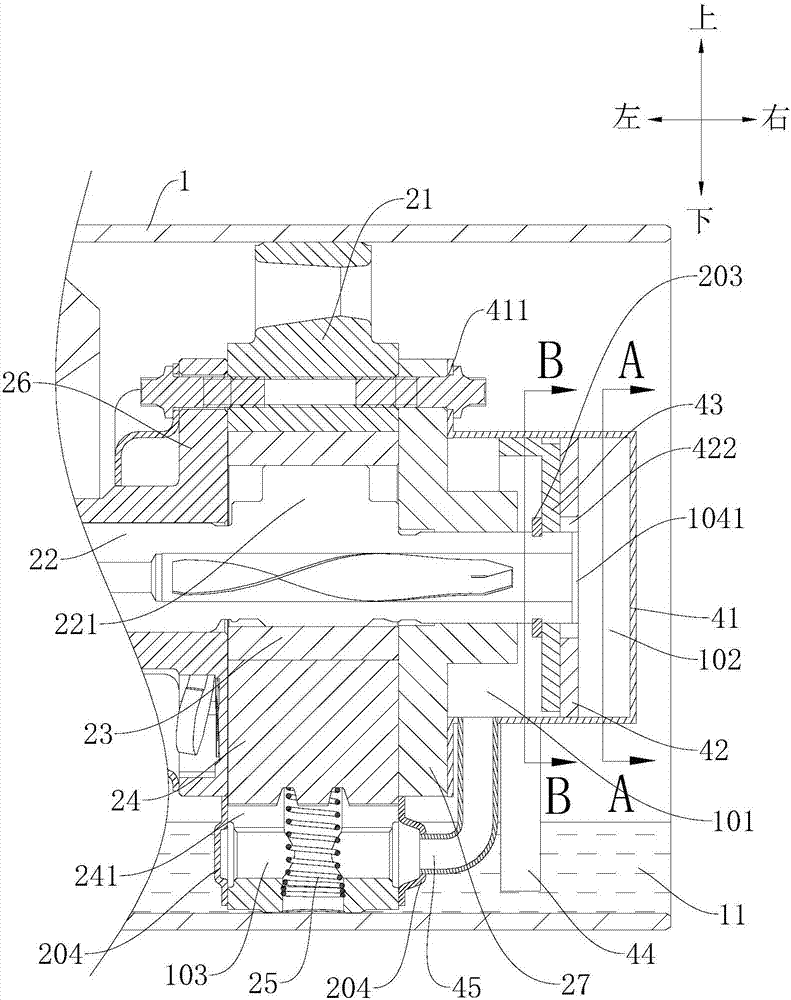

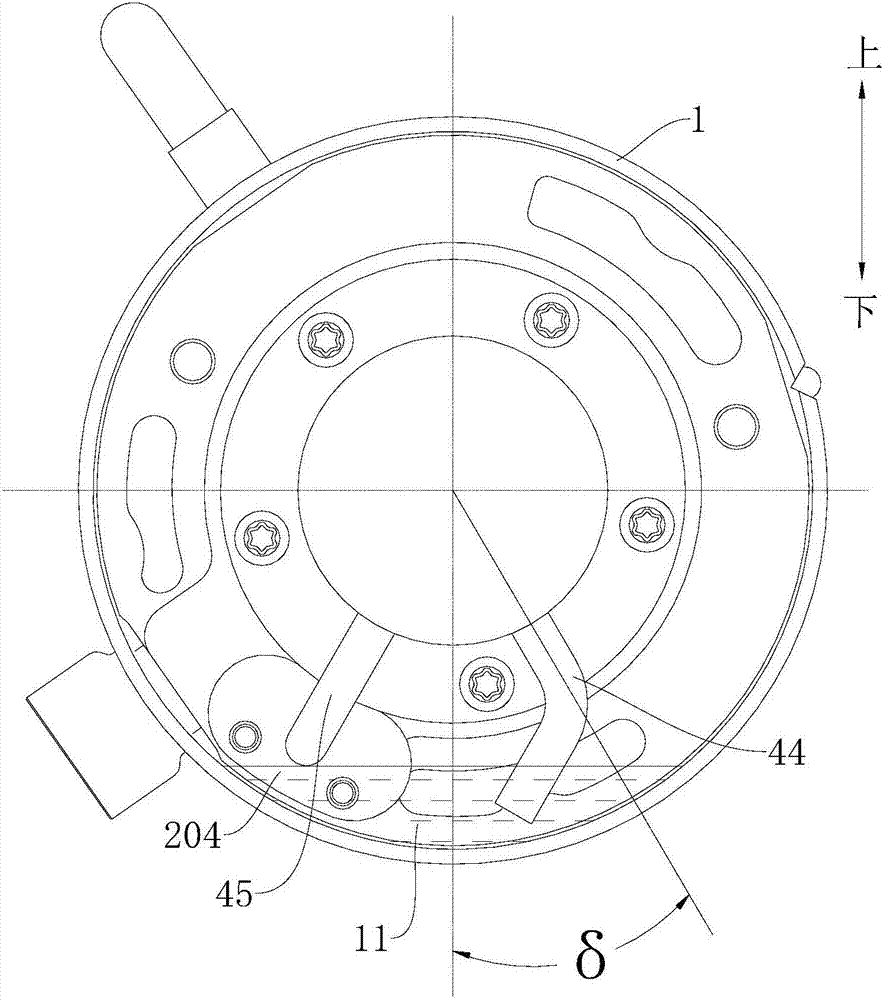

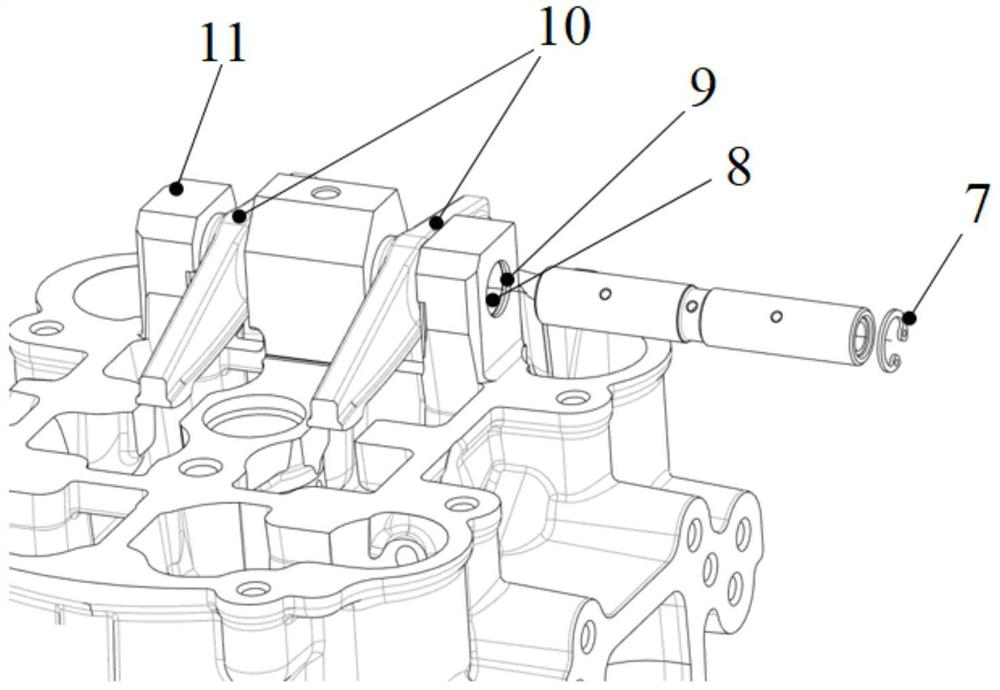

Engineering vehicle hydraulic pump valve integrated system

ActiveCN104100591AOptimize hydraulic components and control circuitsImprove oil supply efficiencyServomotor componentsIntegrated systemsSystem pressure

The invention discloses an engineering vehicle hydraulic pump valve integrated system. The engineering vehicle hydraulic pump valve integrated system comprises a pump valve rear body which is formed in an integral-cast mode and is provided with a gear pump and a reversing valve body, the reversing valve body of the pump valve rear body is connected with an air cylinder body and is provided with a central spindle which can penetrate through the interior of the reversing valve body and the interior of the air cylinder body in a sliding mode, and the reversing valve body and the central spindle are arranged in a dynamic seal mode nearby the adjacent position of the air cylinder body and the pump valve rear body; oil inlet and oil returning openings are formed in the pump valve rear body, the oil inlet and oil returning openings are communicated to the reversing valve body through an oil returning channel, the oil inlet and oil returning openings simultaneously pass through the gear pump and are communicated to the reversing valve body through an internally-arranged oil inlet channel, the two channels and oil outlets formed in the pump valve rear body are respectively communicated to different cavities in the reversing valve body, the different cavities are combined with the position of the central spindle to form an inlet and outlet oil returning way of the integrated system, and an overflow valve is arranged on the internally-arranged oil inlet channel in a communicated mode. A hydraulic element and a control circuit are optimized, the oil supply efficiency is improved, the system pressure is reduced, and the service life is prolonged.

Owner:CHONGQING HANGYU IND

Fuel manifold joint for gas turbine and gas turbine

ActiveCN104018942AReduce the chance of leaksImprove the effect of atomization sprayTurbine/propulsion fuel supply systemsGas turbine plantsGas turbinesMachining

The invention discloses a fuel manifold joint for a gas turbine and the gas turbine. The fuel manifold joint comprises an oil inlet pipe, an oil outlet pipe and a nozzle joint, wherein the oil inlet pipe is connected with an external oil way, and the oil outlet pipe is used for supplying oil for a fuel nozzle at the downstream of the oil way; the nozzle joint is used for mounting the fuel nozzle and comprises an upper wall face, a side wall face and a mounting end face used for mounting in a fitting manner; one or more blind holes connected wit the input end of the fuel nozzle in a sealing manner are formed in the mounting end face of the nozzle joint; the input end of the fuel nozzle closes an opening of the blinding hole, and a fuel buffer cavity is formed in the blind hole; an oil inlet pipe access opening leading to the fuel buffer cavity is formed in the upper wall face or the side wall face of the nozzle joint, and the oil inlet pipe is connected into the oil inlet pipe access opening in the sealing manner; an oil outlet pipe access opening leading to the fuel buffer cavity is formed in the upper wall face or the side wall face of the nozzle joint, and the oil outlet pipe is connected into the oil outlet pipe access opening in the sealing manner. The fuel manifold joint has the advantages of simple structure, convenience in dismounting and mounting and reliability in use, and the machining cost and the maintenance cost are reduced.

Owner:CHINA AVIATION POWER MACHINE INST

Engine valve rocker arm installation structure

ActiveCN111271147BReduce wearImprove oil supply efficiencyValve arrangementsLubrication of auxillariesMarine engineeringCylinder head

The invention discloses an engine valve rocker arm installation structure, comprising an engine cylinder head and a rocker shaft, the rocker shaft is rotatably arranged on the engine cylinder head, and the rocker shaft has a function for receiving The annular oil groove of the lubricating oil of the cover, the oil inlet hole communicated with the annular oil groove, the axial oil channel communicated with the oil inlet hole, and the first part communicated with the axial oil channel and used to guide the lubricating oil to the first rocker arm installation area An oil outlet hole and a second oil outlet hole communicated with the axial oil passage and used to guide lubricating oil to the second rocker arm installation area, the annular oil groove is located between the first oil outlet hole and the second oil outlet hole, the shaft The oil passage extends axially along the rocker arm shaft, and the first rocker arm installation area and the second rocker arm installation area are used to respectively install a valve rocker arm. The installation structure of the engine valve rocker arm of the present invention satisfies the condition of forming an oil film between the rocker arm shaft and the valve rocker arm, can effectively reduce wear between the rocker arm shaft and the valve rocker arm, and can significantly improve the oil supply efficiency.

Owner:安徽航瑞航空动力装备有限公司

Energy-saving diesel engine with multi-stage variable fuel supply transmission ratio and multi-operation mode

ActiveCN106762507BImprove efficiencyImprove stabilityPositive displacement pump componentsPiston pumpsLow speedFuel tank

The invention discloses an energy-saving diesel engine having a multistage variable oil-supply transmission ratio and multiple running modes. The energy-saving diesel engine comprises a high-pressure oil pump, a diesel engine body and an oil tank, the high-pressure oil pump is of a double-oil-cylinder structure, the diesel engine body is of a double-piston-cylinder structure, two piston cylinders are respectively communicated with two oil cylinders correspondingly through electric-control oil injectors, plungers of the two oil cylinders correspondingly contact with two cams on a cam shaft respectively through pushing rods, pistons of the two piston cylinders are correspondingly connected with two connecting rod drivers on a crankshaft respectively through connecting rods, an oil supply speed-variable transmission mechanism is arranged between the cam shaft and the crankshaft, and the two electric-control oil injectors are communicated with a pressure-storage energy storing tank respectively through electric-control one-way valves. The multistage variable oil-supply transmission ratio can be automatically adjusted according to rotating speed of the diesel engine, low-speed oil-supply efficiency and stability can be improved, and high-speed oil-supply energy waste can be reduced; the multiple running modes can be started according to road conditions, so that fuel consumption of the diesel engine can be reduced, and emission pollution can be lowered.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

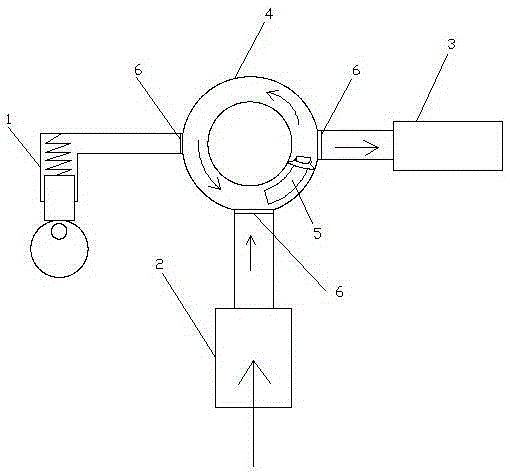

A circular circuit oil pressure valve

ActiveCN103775786BReduce formationImprove oil supply efficiencyPipe elementsOil pressurePetroleum engineering

The invention relates to an oil supply device and especially relates to an oil pressure valve for an annular loop. The oil pressure valve for the annular loop comprises an oil pump, an oil inlet one-way valve, an oil outlet one-way valve, an annular oil pipe and an umbrella-shaped oil-melting block, wherein the oil pump is communicated with the annular oil pipe; an oil inlet end of the oil inlet one-way valve is communicated with the annular oil pipe; the oil outlet one-way valve is communicated with the annular oil pipe; the umbrella-shaped oil-melting block is arranged in the annular oil pipe. The umbrella-shaped oil-melting block in the oil pressure valve for the annular loop provided by the invention can form a loop in the oil pressure valve and can move forward in the pipeline along one direction. An umbrella-shaped cover of the umbrella-shaped oil-melting block is utilized to scrape an inner wall of the annular oil pipe, so that the forming of an oily wall on the inner wall of the annular oil pipe is reduced and the oil supply efficiency is increased.

Owner:JIANGSU CREATE PRECISION TECH

Engineering vehicle hydraulic pump valve overall system

ActiveCN104100591BReduce Repeated Wall ThicknessReduce fuel consumptionServomotor componentsGear pumpInlet channel

The invention discloses an engineering vehicle hydraulic pump valve integrated system. The engineering vehicle hydraulic pump valve integrated system comprises a pump valve rear body which is formed in an integral-cast mode and is provided with a gear pump and a reversing valve body, the reversing valve body of the pump valve rear body is connected with an air cylinder body and is provided with a central spindle which can penetrate through the interior of the reversing valve body and the interior of the air cylinder body in a sliding mode, and the reversing valve body and the central spindle are arranged in a dynamic seal mode nearby the adjacent position of the air cylinder body and the pump valve rear body; oil inlet and oil returning openings are formed in the pump valve rear body, the oil inlet and oil returning openings are communicated to the reversing valve body through an oil returning channel, the oil inlet and oil returning openings simultaneously pass through the gear pump and are communicated to the reversing valve body through an internally-arranged oil inlet channel, the two channels and oil outlets formed in the pump valve rear body are respectively communicated to different cavities in the reversing valve body, the different cavities are combined with the position of the central spindle to form an inlet and outlet oil returning way of the integrated system, and an overflow valve is arranged on the internally-arranged oil inlet channel in a communicated mode. A hydraulic element and a control circuit are optimized, the oil supply efficiency is improved, the system pressure is reduced, and the service life is prolonged.

Owner:CHONGQING HANGYU IND

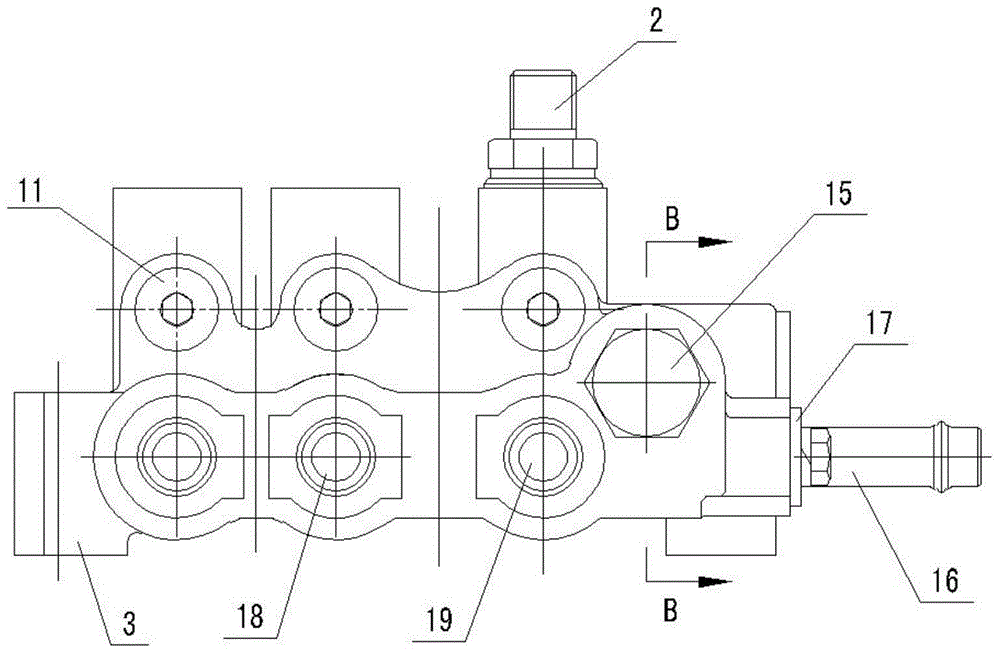

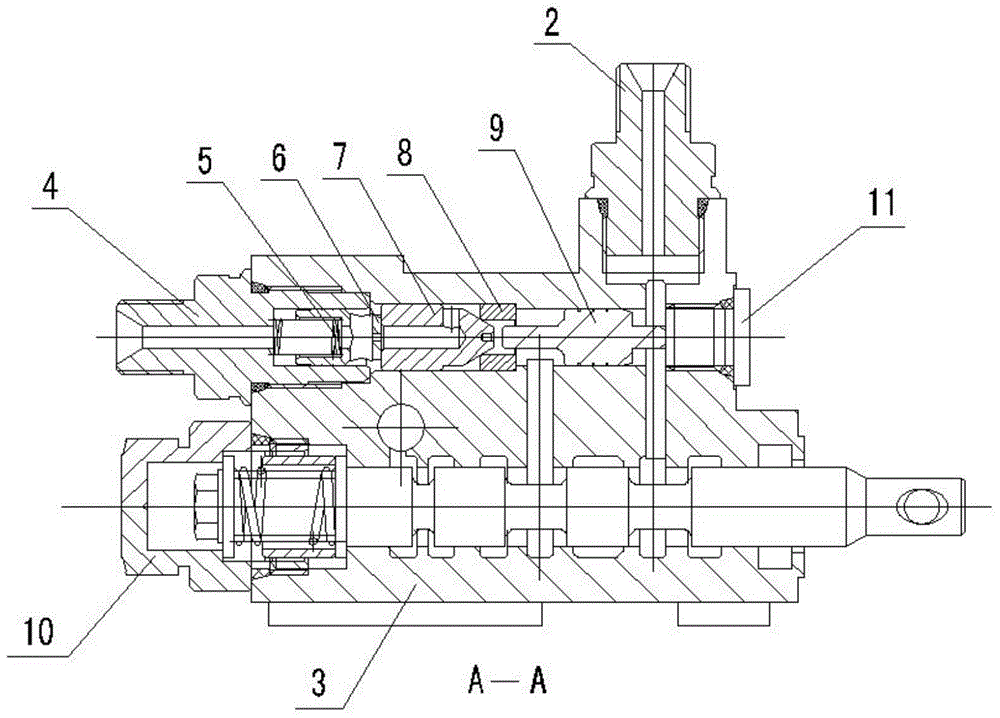

Slicing-type manual multi-way reversal valve

InactiveCN105042119AImprove oil supply efficiencyReduce energy lossMultiple way valvesFuel tankEngineering

The invention discloses a slicing-type manual multi-way reversal valve which is characterized in that various reversal valve parts are connected in parallel in a valve body; an oil inlet of a main throttle valve positioned at one end of the valve body is communicated with a main oil inlet connector of the valve body to form a main oil way; an oil outlet of the main throttle valve is connected with the corresponding reversal valve parts by mutually independent branch oil ways; a pressure oil independence oil inlet connector is introduced, and enters a hydraulic control one-way valve through the reversal valve parts; and an oil outlet of the hydraulic control one-way valve is connected with various branch operating oil cylinders and returns back to an oil tank through an oil return connector. The slicing-type manual multi-way reversal valve is compact in structure, small in size, good in sealability and reliable in function, and is particularly suitable for application in hydraulic systems of farm machineries such as a harvester.

Owner:HEFEI UNIV OF TECH

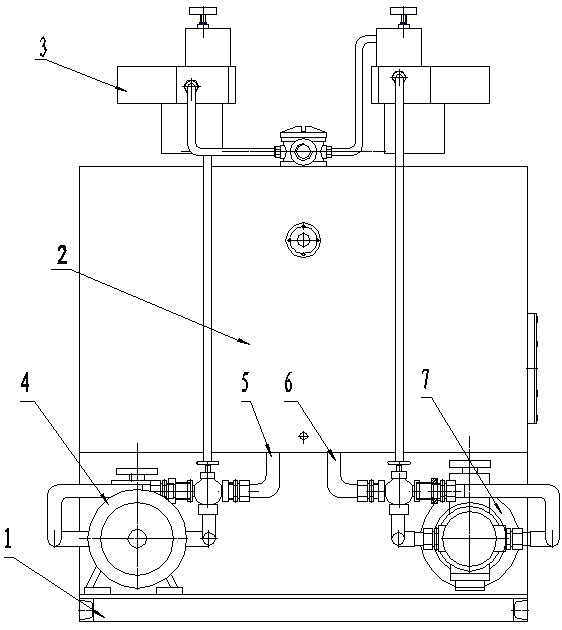

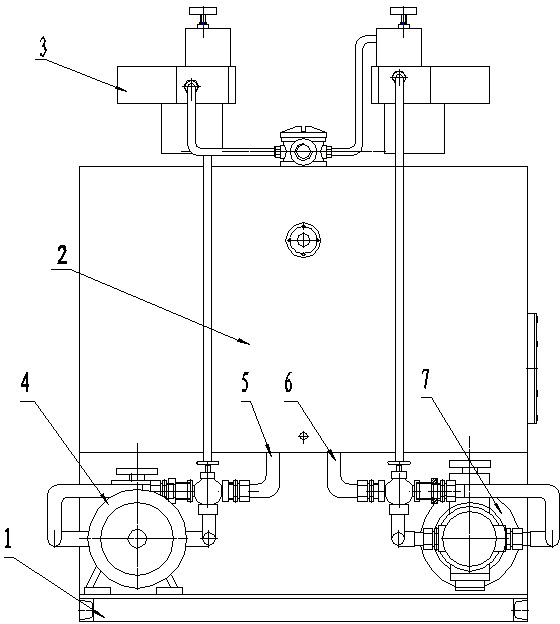

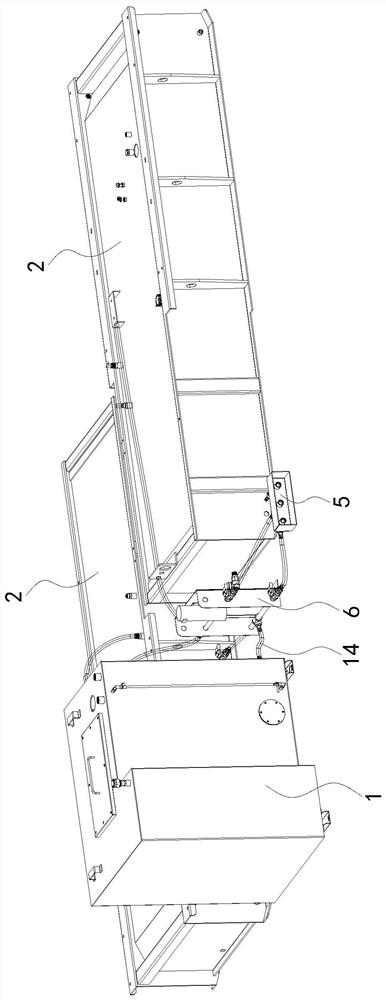

Underneath type double-pump alternating current hydraulic working station for hydraulic steering engine

InactiveCN102632989ACompact structureReduced processing performanceSteering ruddersFluid-pressure actuator componentsElectric machineEngineering

The invention relates to the field of hydraulic systems, and particularly relates to an underneath type double-pump alternating current hydraulic working station for a hydraulic steering engine. The underneath type double-pump alternating current hydraulic working station mainly comprises an engine seat, an oil tank, a special steering engine valve set, a first motor pump set, a second motor pump set, a first oil suction opening and a second oil suction opening, wherein the first motor pump set and the second motor pump set are arranged on the engine seat below the oil tank; the first motor pump set is connected with the oil tank through the first oil suction opening; the second motor pump set is connected with the oil tank through the second oil suction opening; and the special steering engine valve set is connected with the first motor pump set and the second motor pump set respectively. According to the embodiment of the invention, the alternating current hydraulic working station has a relatively compact structure, so that only one oil tank is needed, and the conventional complementation oil tank is eliminated; and therefore, the steel materials are saved by 45 percent, and the cost of a product is saved greatly.

Owner:江苏吉信远望船舶设备有限公司

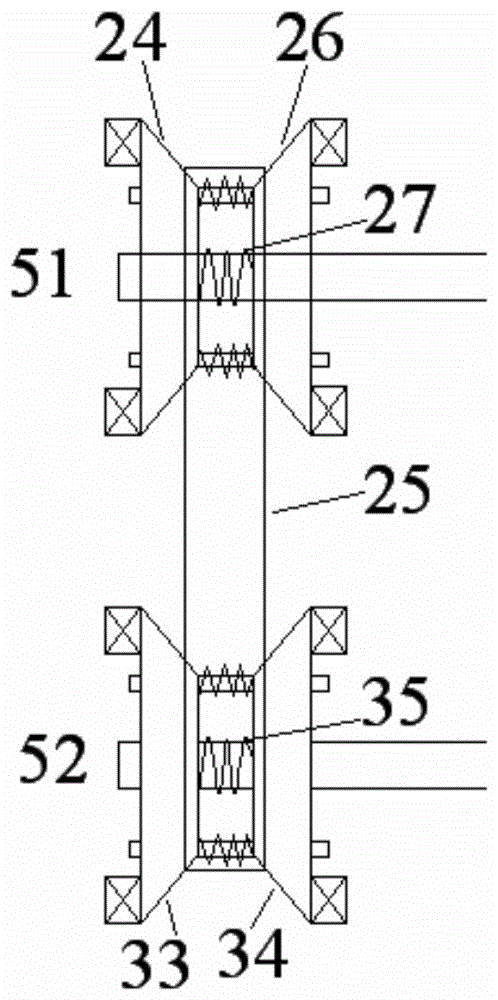

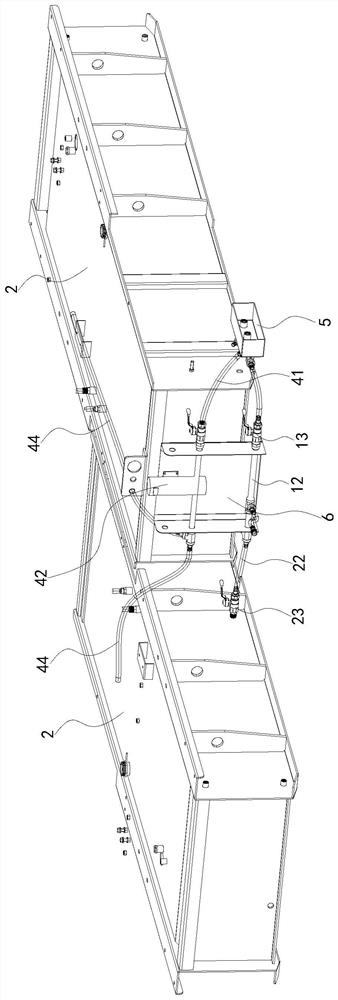

Multi-one-way-valve combined energy-saving reciprocating oil supply device capable of achieving self-adaptation in-advance mutual starting

PendingCN108843473AAvoid flow backAvoid wastingEngine controllersMachines/enginesTraffic capacityFuel tank

The invention discloses a multi-one-way-valve combined energy-saving reciprocating oil supply device capable of achieving self-adaptation in-advance mutual starting. The multi-one-way-valve combined energy-saving reciprocating oil supply device capable of achieving self-adaptation in-advance mutual starting comprises an oil supply device body and an electrical control system. The oil supply devicebody comprises an oil tank, a filter, a reciprocating oil supply pump and an electric control oil atomizer. The reciprocating oil supply pump is composed of a piston rod, a piston and an oil supply cavity. The oil supply cavity is divided into a left oil supply cavity body A and a right oil supply cavity body B through the piston. The left oil supply cavity body A is provided with an oil supply loop ac, the right oil supply cavity body B is provided with an oil supply loop bd, the lower ends of the two oil supply loops are connected with the oil tank, the upper ends of the two oil supply loops are connected with a pressure stabilizer, and the right end of the pressure stabilizer is provided with a flow limiting valve and the electric control oil atomizer, and the flow limiting valve and the electric control oil atomizer are connected with a controller through lines. The multi-one-way-valve combined energy-saving reciprocating oil supply device capable of achieving self-adaptation in-advance mutual starting is simple in structure, capable of saving energy, reliable and capable of achieving the function of self-adaptation in-advance mutual starting, the requirement of multiple workconditions of an engine for the oil supply amount is met, good economic benefits are achieved, and the application range is wide.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

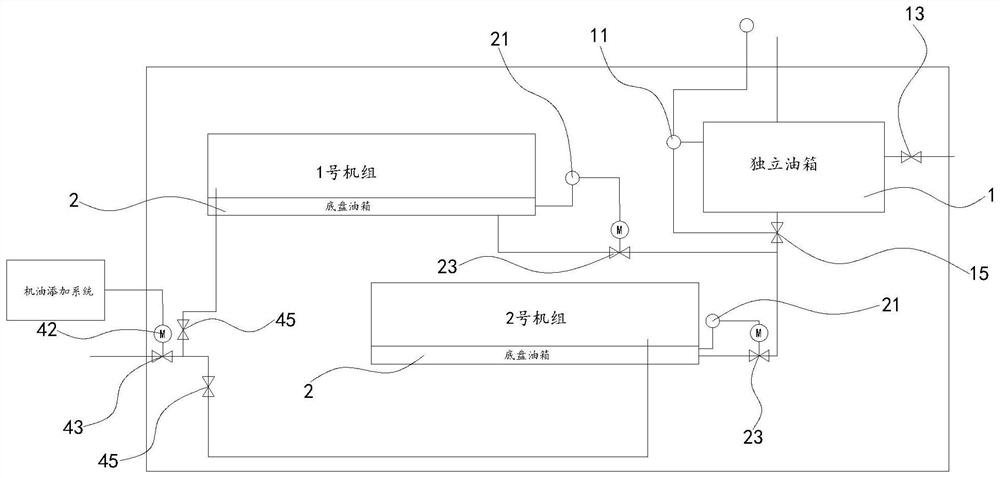

Diesel generating set fuel tank management system

ActiveCN114352449AImprove oil supply efficiencyMachines/enginesLiquid fuel feedersFuel tankProcess engineering

The invention relates to an oil tank management system of a diesel generating set. The oil tank management system comprises an independent oil tank, more than two chassis oil tanks and a control module, the independent oil tank is communicated with more than two chassis oil tanks respectively, the independent oil tank supplies oil to the more than two chassis oil tanks respectively, and a first liquid level sensor used for monitoring the oil quantity of the independent oil tank is arranged in the independent oil tank; each chassis oil tank is provided with a second liquid level sensor for monitoring the oil quantity of the chassis oil tank; each second liquid level sensor is electrically connected with the control module, and the control module controls the independent oil tank to supply oil to the chassis oil tank according to oil quantity signals transmitted by the second liquid level sensors. Different from the prior art, the use and maintenance time of other diesel generating sets can be prolonged, and the service life of the diesel generating set is prolonged.

Owner:福州德塔电源技术有限公司

compressor

ActiveCN106907323BPowerfulImprove oil supply efficiencyRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsReciprocating motionCrankshaft

The invention discloses a compressor. The compressor comprises a shell, a compression mechanism with an illumination oil passage, a motor assembly and an oil feeding mechanism. An oil pool is arranged in the shell. The compression mechanism is arranged in the shell and comprises at least one air cylinder, a crankshaft, a piston and a sliding piece, wherein the piston is arranged on an eccentric portion of the crankshaft in a sleeving mode and located in an air cylinder cavity of the air cylinder, and the sliding piece is arranged in a sliding piece groove of the air cylinder in a reciprocating mode. The motor assembly is arranged in the shell and connected with the crankshaft. The oil feeding mechanism is arranged in the shell and defines a first oil feeding cavity and a second oil feeding cavity, the second oil feeding cavity communicates with the lubricating oil passage, and the oil feeding mechanism is configured to enable the first oil feeding cavity and the second oil feeding cavity to communicate with the oil pool in a switching mode. According to the compressor, the oil sucking process of sucking oil from the oil pool and the oil supply process of supplying oil to the lubricating oil passage do not interfere with each other, the oil sucking and oil supply power is sufficient, and the lubricating effect is good.

Owner:GUANGDONG MEIZHI PRECISION MFG

Spiral rod oil distribution energy storage plunger pump

InactiveCN102434424BSolve the problem of not being able to synchronizeEnsure safetyPumpsPositive-displacement liquid enginesHydraulic pumpEngineering

A spiral rod oil distribution energy storage plunger pump belongs to hydraulic pumps. A spindle box body of the plunger pump is connected with a plunger pump box body, and a driving bevel gear and a cam are installed on a spindle in the spindle box body. A plunger is installed in a plunger pump cavity of the plunger box body, a sliding wheel is arranged at the top of the plunger, a spring is installed in the middle of the plunger, and a cylinder sleeve is connected onto a plunger cavity body at the lower portion of the plunger. A driven bevel gear, a flange, screw rod bearings, an upper gasket, an oil seal and a lower gasket are sequentially connected onto a spiral rod, the spiral rod bearings are connected to the bottom of the screw rod and to the position between the upper gasket and the flange, and a spiral rod cavity screw is connected to the bottom of the spiral rod cavity. An input one-way valve spring is arranged on an input one-way valve, an output one-way valve is installed at the lower half portion of the plunger box body, a sliding plug and a sliding plug spring are installed in an energy storage safety valve, a pressure regulating hollow screw is installed at the top of the energy storage safety valve, and a normal work liquid outlet and a hyperpressure liquid outlet are arranged on the energy storage safety valve. The spiral rod oil distribution energy storage plunger pump has the advantages that a fly wheel is installed on a shaft head of a power machine, acting can be achieved by means of inertia kinetic energy of the fly wheel, and energy is saved.

Owner:胡传胜

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com