Composite in-out oil valve common rail oil pump

An oil inlet and outlet valve, compound technology, used in fuel injection pumps, engine components, machines/engines, etc., can solve the problems of large axial size, difficult to ensure manufacturing precision, high risk, etc., and achieve overall size reduction , Improve the efficiency of oil supply and avoid the risk of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

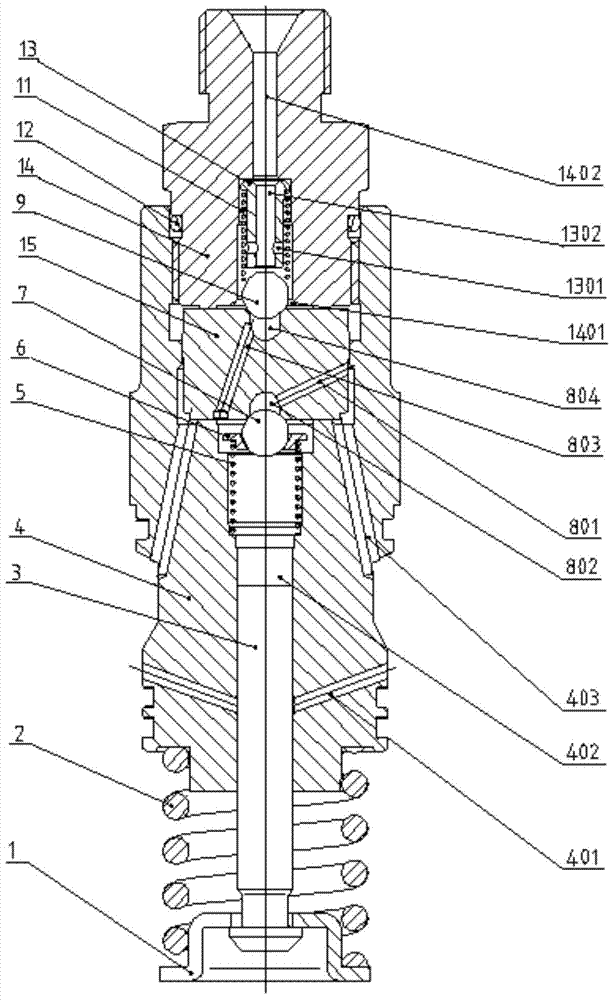

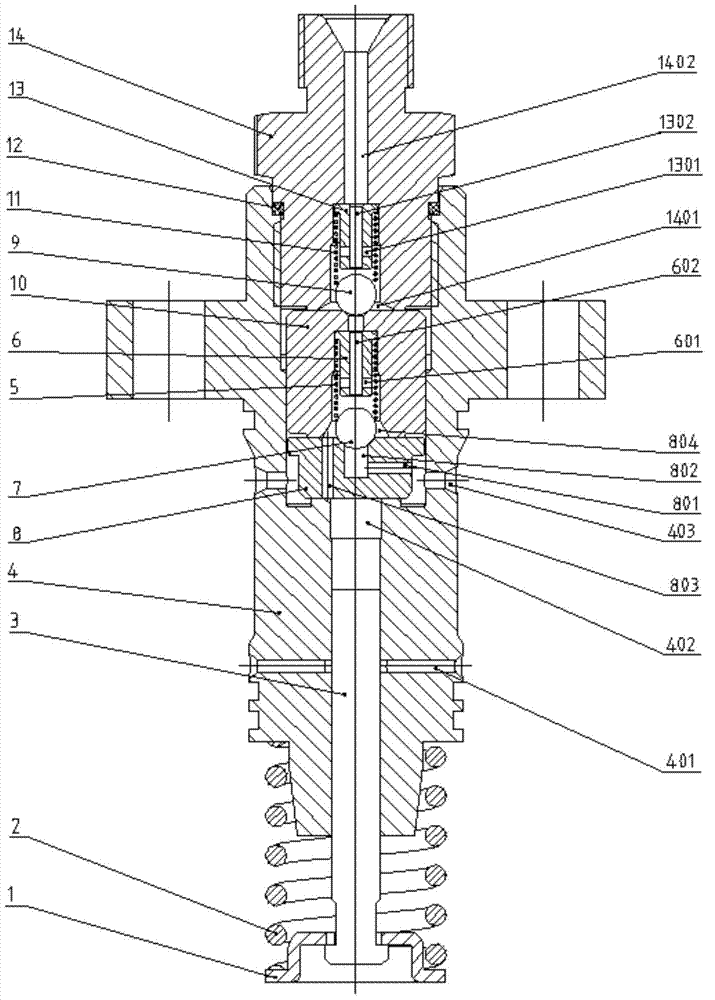

[0011] refer to figure 1 . The composite oil inlet and outlet valve common rail oil pump for diesel engine common rail system includes, the inlet and outlet valve body 15 coaxially installed in the inner cavity of the fuel injection pump body 4, and the oil inlet and outlet valve body 15 located on the spring seat 1 of the oil pump connected to the lower end surface of the fuel injection pump body 4 The oil pump spring 2 and the plunger 3 passing through the central axis hole of the fuel injection pump body 4. The center of the upper and lower shaft ends is shaped with the oil inlet and outlet valve body 15 of the oil inlet steel ball seat hole 802 and the oil outlet steel ball seat hole 804 contacting the sealing steel ball, and the coaxial hole is assembled on the lower end surface of the oil outlet joint 14 . The oil inlet and outlet valve body 15 is located between the oil inlet valve spring seat 6 and the oil outlet valve spring. Under the action of the plunger 3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com