High-pressure gear pump bearing with sealing structure

A gear pump with sealing technology, which is applied in the direction of rotating bearings, bearings, bearing components, etc., can solve the problems of large leakage and affect the oil supply efficiency of the gear pump, and achieve the effect of avoiding gap leakage and improving oil supply efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

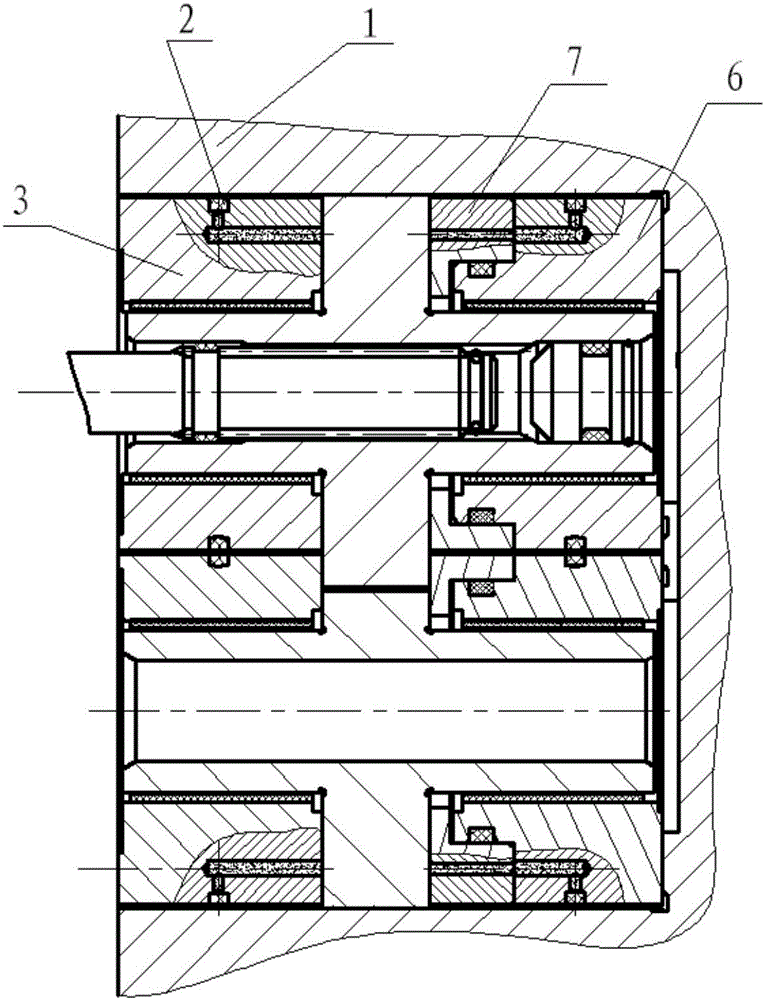

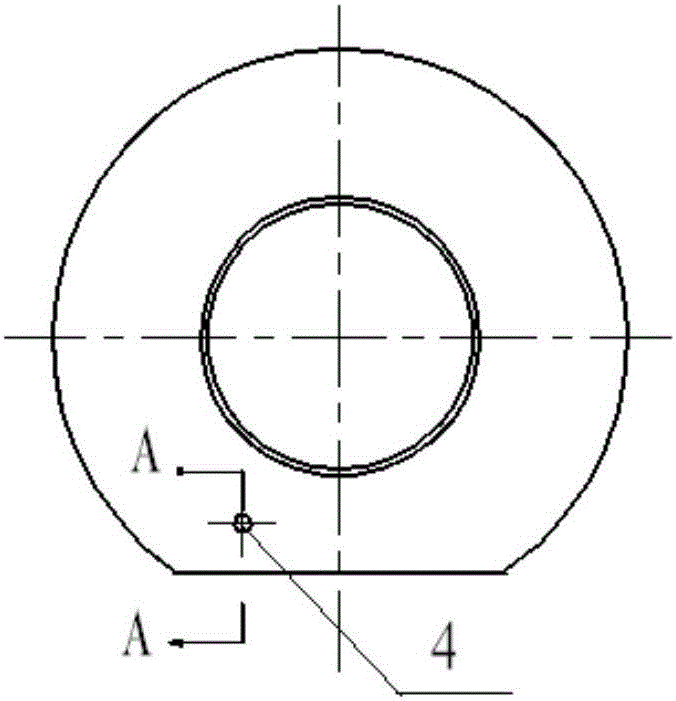

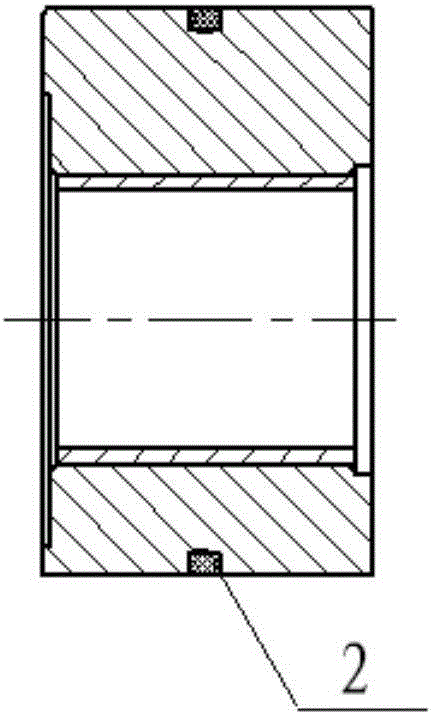

[0016] The present invention will be described in further detail below. Referring to the accompanying drawings, a high-pressure gear pump with a sealed structure is composed of a high-pressure gear pump bearing 3, a thrust bearing 6, a floating bearing 7, a housing 1 and gears. An annular sealing ring groove is designed on the high pressure gear pump bearing 3 and the thrust bearing 6, and the rectangular sealing ring 2 is installed in the sealing ring groove. In the gear pump cavity of the casing 1, a high pressure gear pump bearing 3 is installed at one end of the high pressure gear, and a floating bearing 7 and a thrust bearing 6 are installed at the other end. On the high-pressure gear pump bearing 3, the floating bearing 7, and the thrust bearing 6, an oil through hole is designed, and the oil through hole guides the high-pressure fuel oil at the outlet of the gear pump on the bearing end face to the bottom of the rectangular sealing ring 2 installation groove on the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com