Radical self-priming fluid lubricating method for gears

A gear and lubricating oil technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the problems of insufficient oil supply for gear lubrication, complex gear structure of centrifugal lubrication method, and low oil supply efficiency, etc. Achieve the effect of thickening oil film, improving bearing capacity and high oil supply efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

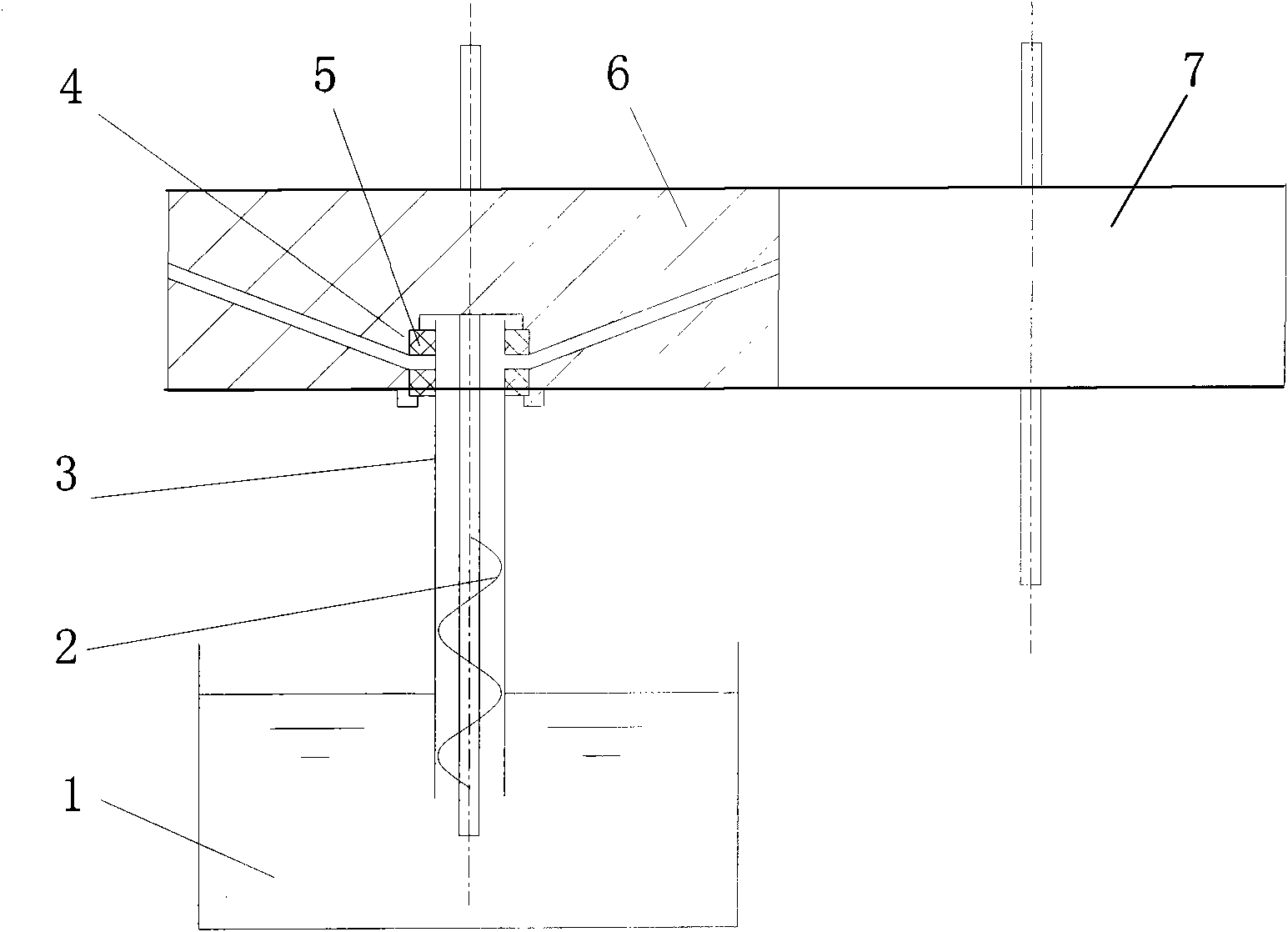

[0009] Below in conjunction with accompanying drawing, the patent of the present invention is further described.

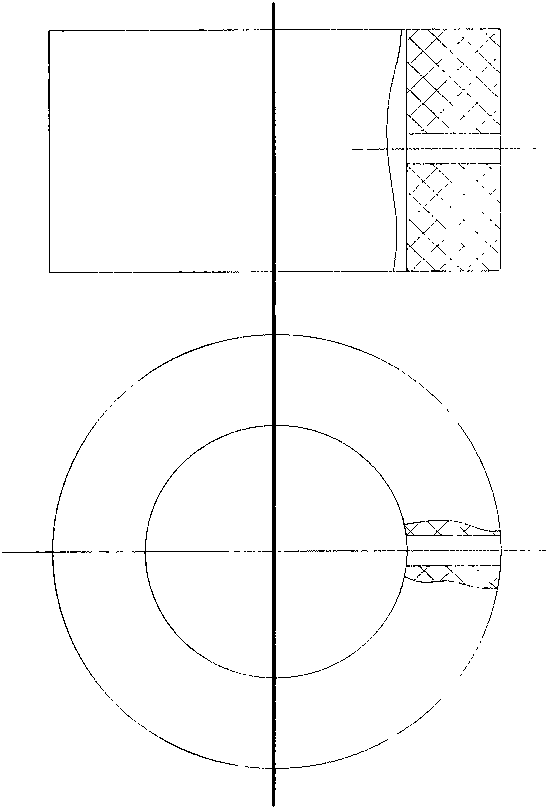

[0010] in the attached figure 1 Among them, the pump body 3 of the oil suction pump and the radial oil hole gear 6 are dynamically sealed by the sealing ring 5, and the screw 2 rotates with the gear shaft, so that the oil suction pump sucks the lubricating oil from the oil pool 1. The radial oil hole gear 6 is a gear that has an oil hole leading to each root of the gear along the radial direction. The sealing ring 5 is opened with the same number of radial holes as the radial oil hole gear 6, the two remain relatively stationary, and the radial holes of the two are kept aligned; or the sealing ring 5 is opened with a radial The oil hole remains relatively stationary with the pump body 3 of the oil suction pump, and the radial oil hole on the sealing ring 5 is aligned with the concentrated oil guide hole. On the pump body 3 of the oil suction pump, there is a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com