Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Improve full utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

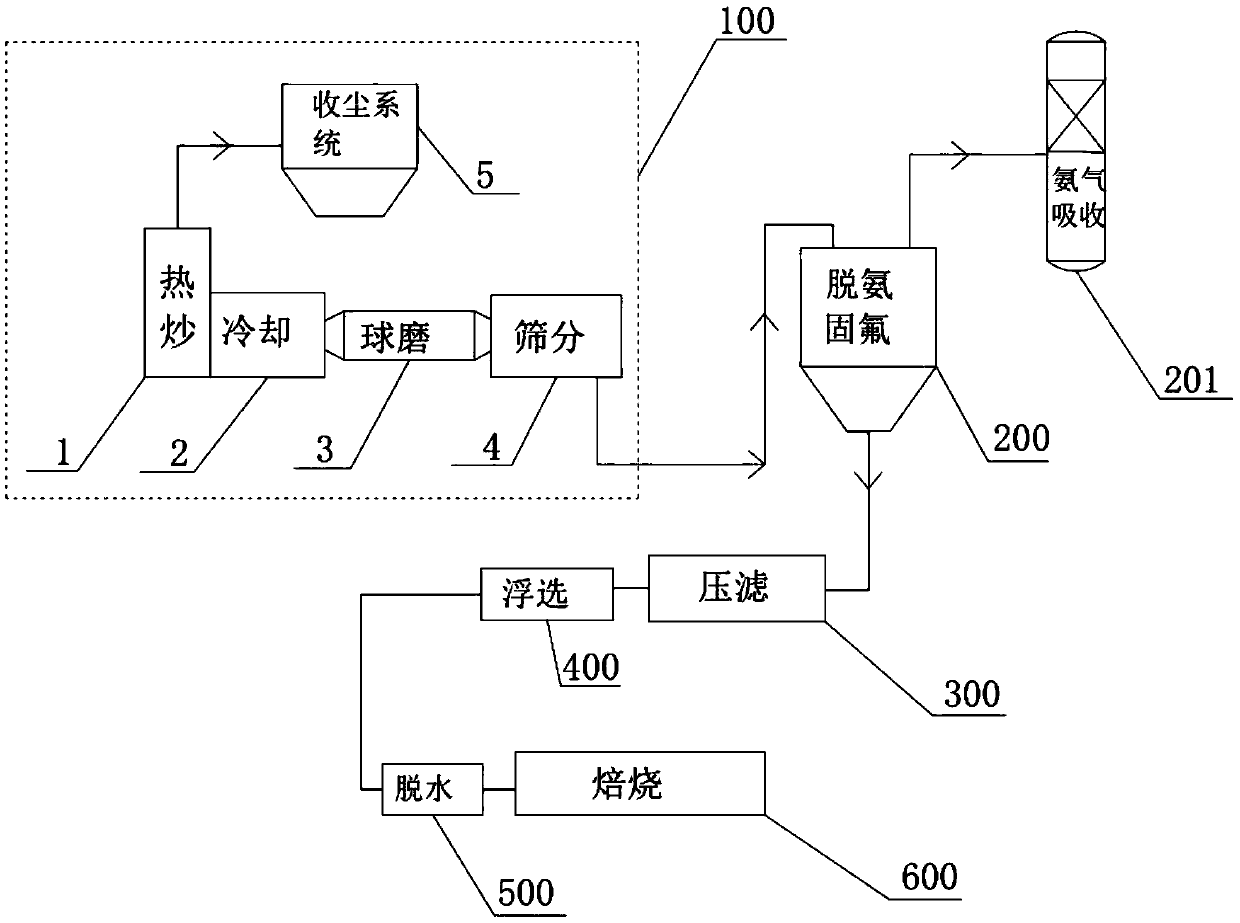

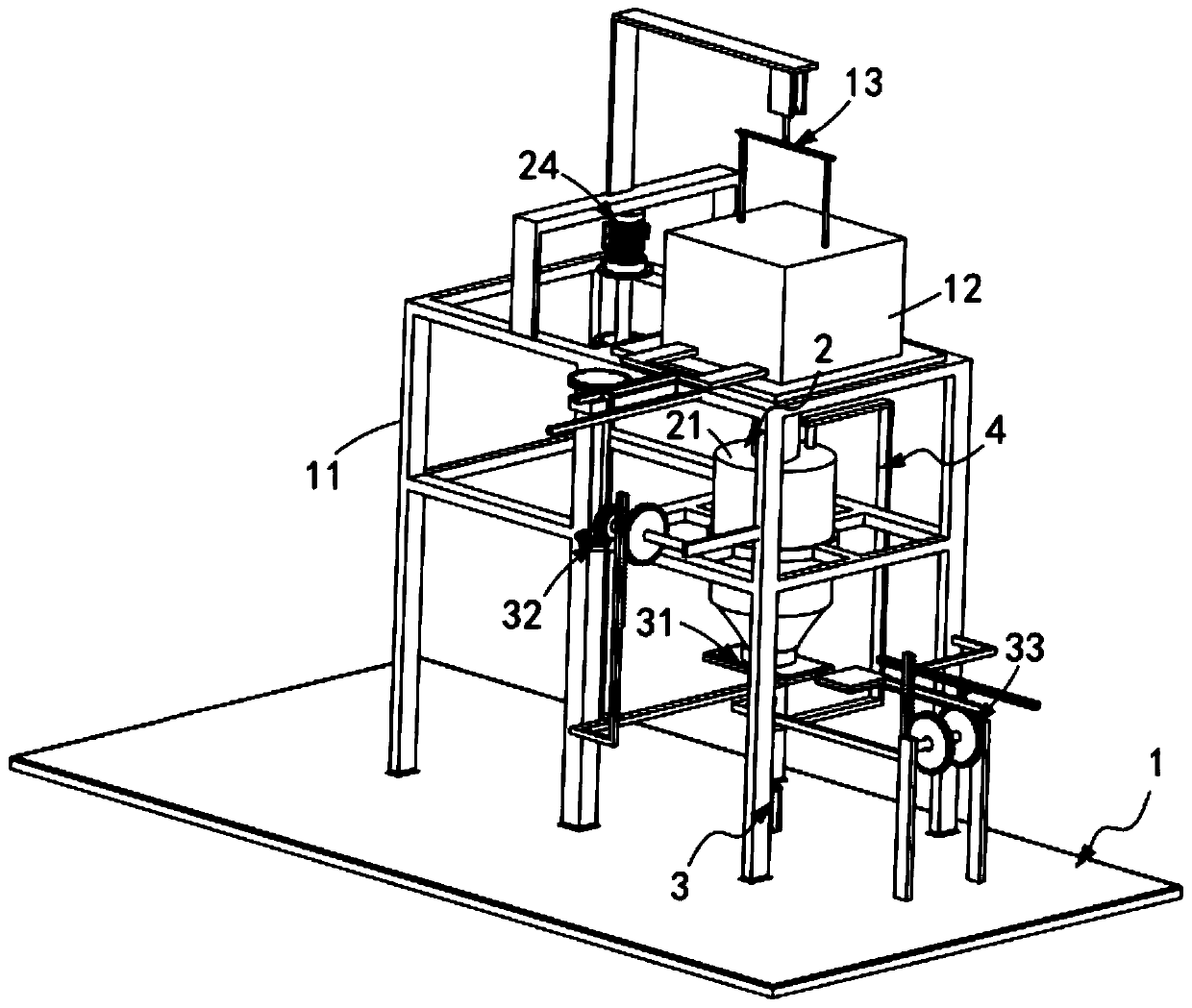

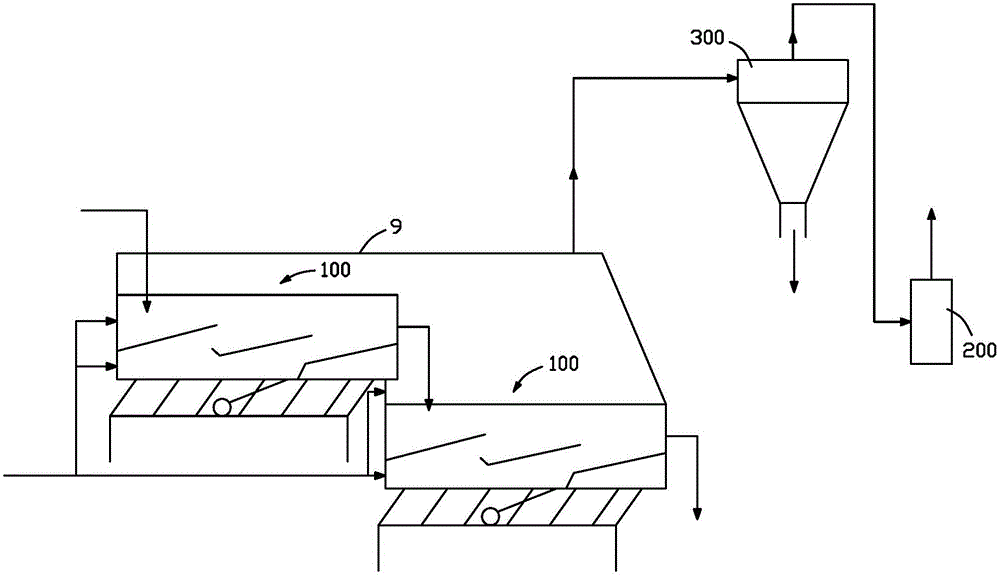

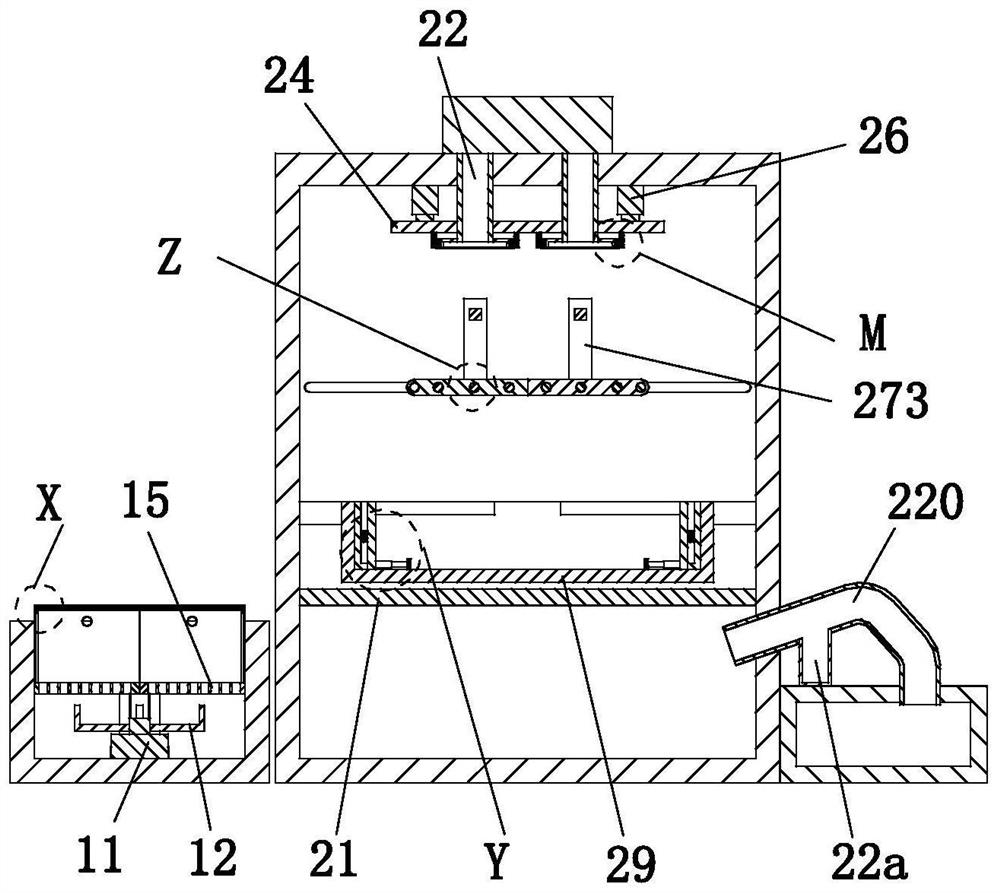

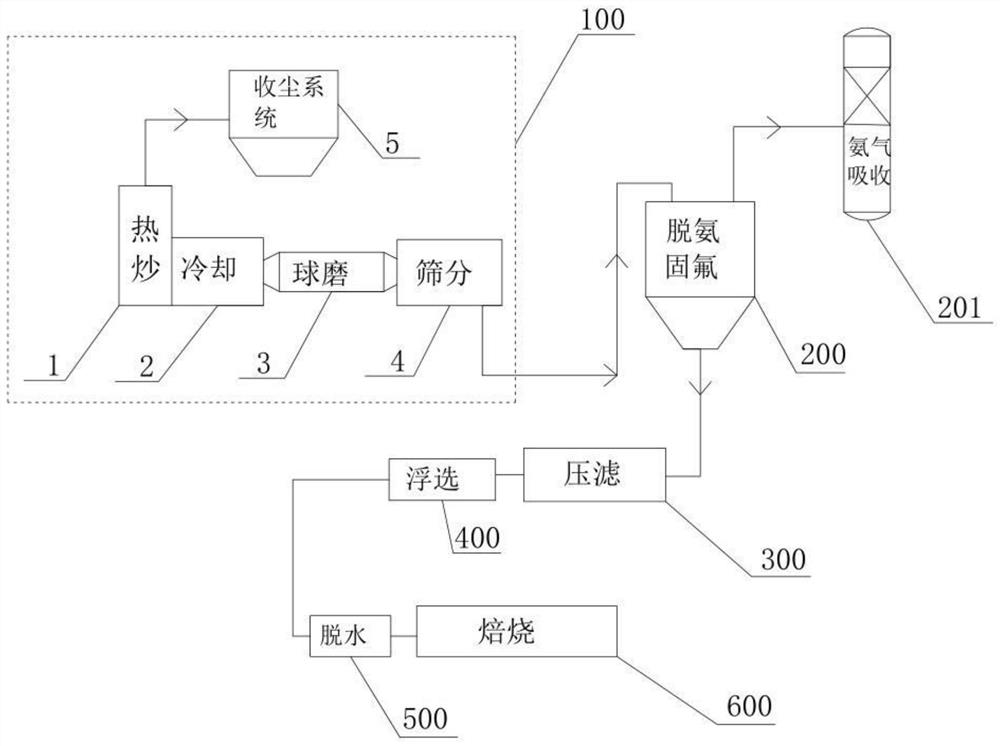

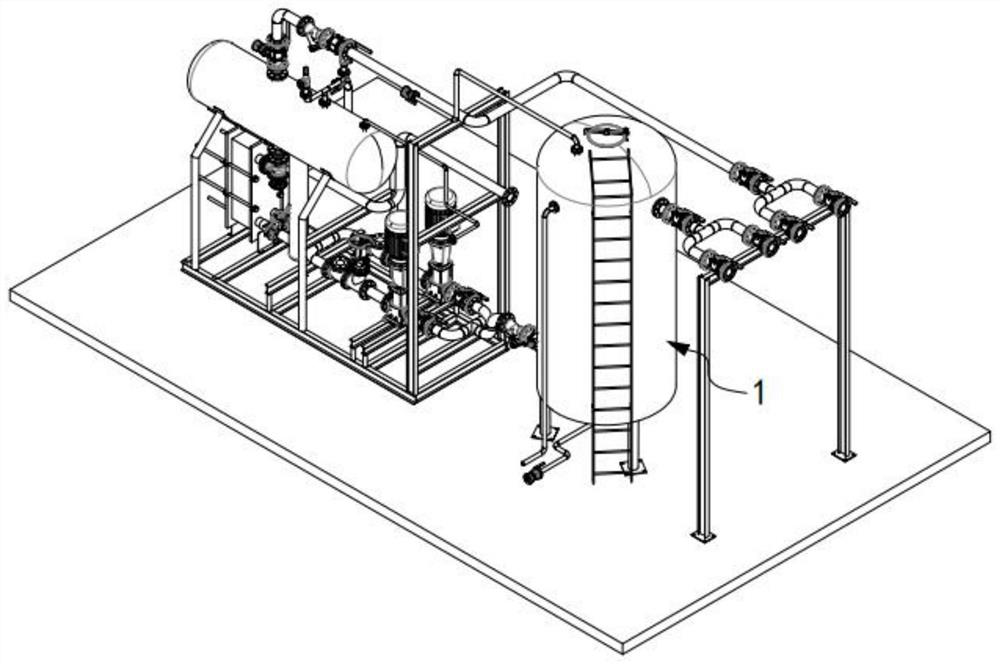

Aluminum ash harmless recycling comprehensive treatment system and method

ActiveCN109647853ASimple systemGood application prospectSolid waste disposalAluminiumAluminium oxide

The invention discloses an aluminum ash harmless recycling comprehensive treatment system and method. The method comprises the following steps that firstly, metal extraction is carried out on aluminumash through a metal extraction system to obtain large blocks of aluminum, aluminum particles and secondary aluminum ash; then deamination and fluorine-fixing are carried out on the secondary aluminumash through a deamination and fluorine-fixing system, then flotation and dewatering treatment are carried out through a flotation system and a dewatering system respectively, and after dehydration treatment, roasting treatment is carried out through a roasting system; and ammonia / ammonium salt, an electrolyte, industrial salt and aluminum oxide are correspondingly obtained. According to the aluminum ash harmless recycling comprehensive treatment system and method, all the components in the recycled aluminum ash can be fully recycled, complete harmless treatment can be carried out, moreover, no harmful substance is generated in the treatment process, the secondary pollution of the environment is avoided, and the application range of the recycled aluminum ash is greatly expanded; and the advantages of being easy to operate, low in cost, high in full utilization rate and good in application prospect are achieved.

Owner:郑州鸿跃环保科技有限公司

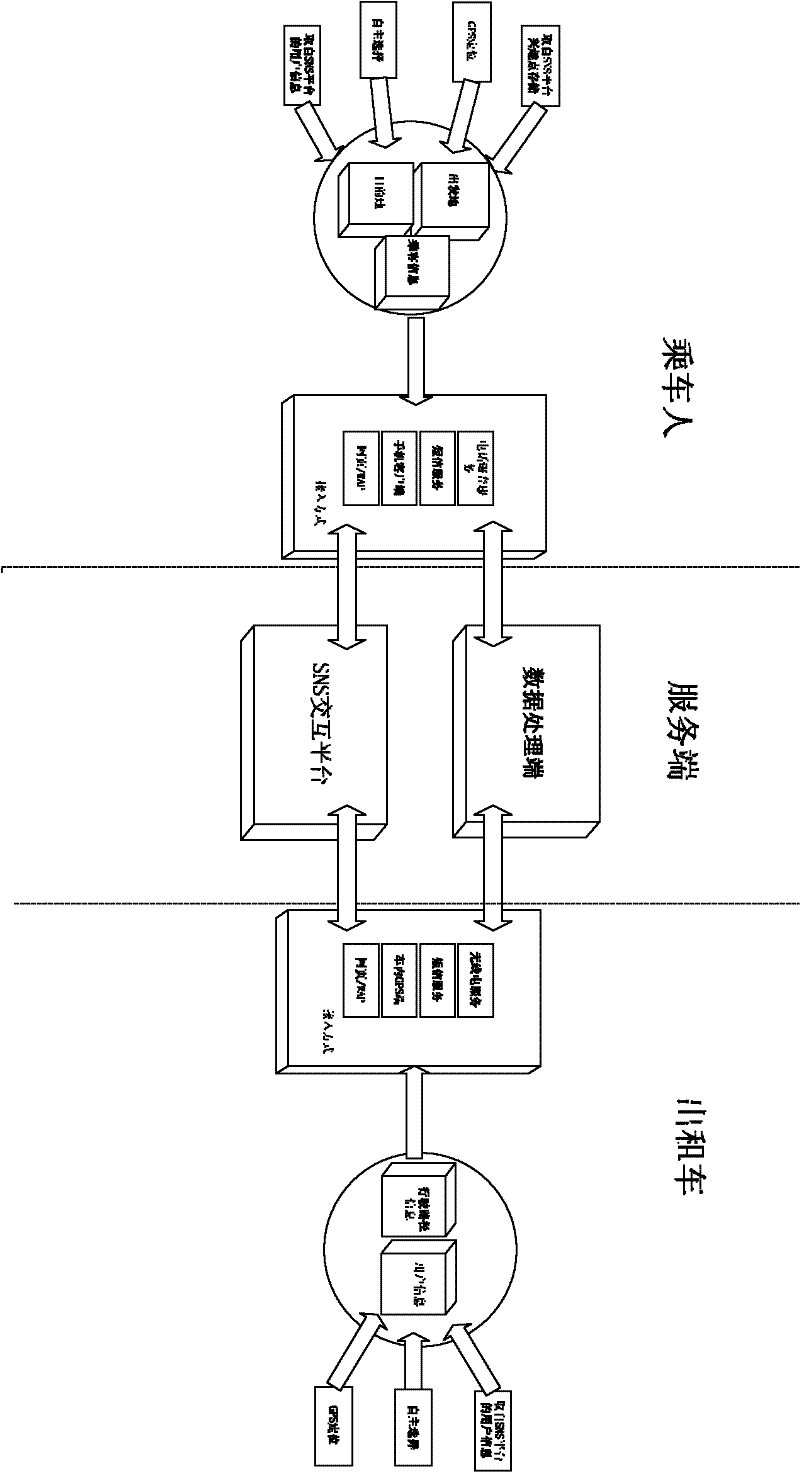

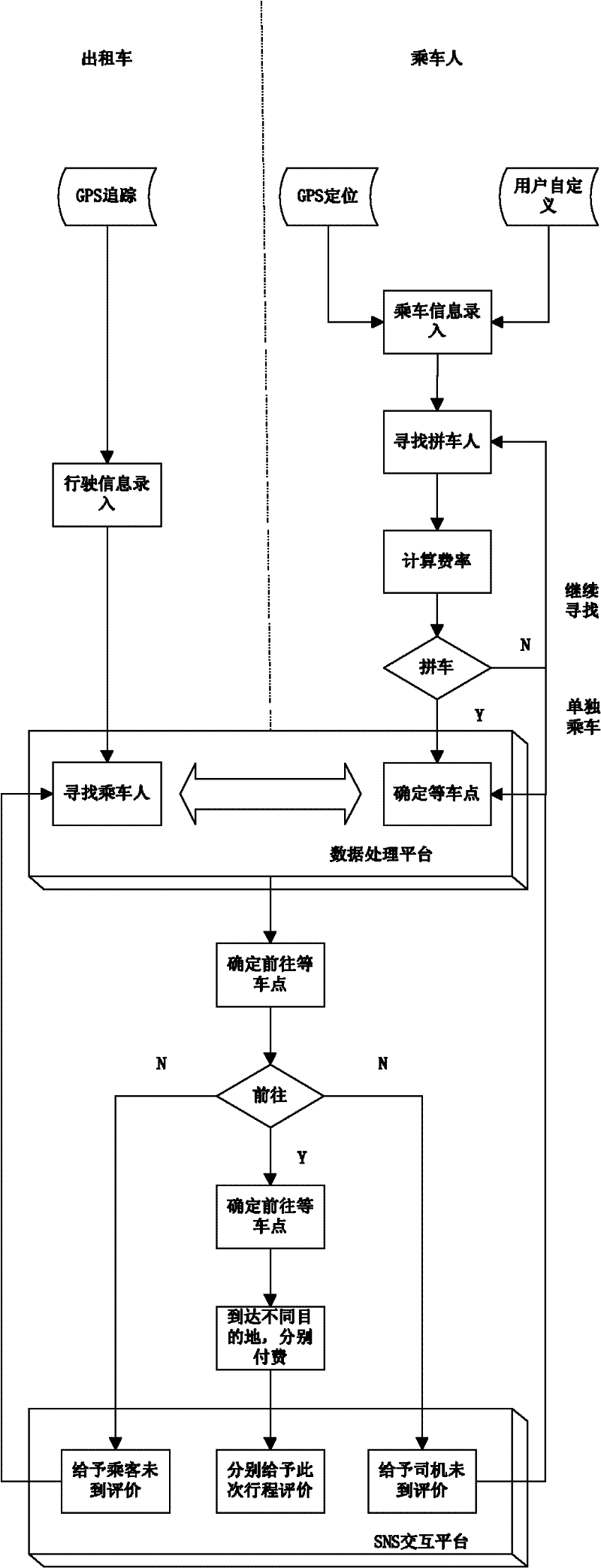

Taxi sharing system and method based on LBS and SNS

InactiveCN102202053AImprove traffic congestionImprove booking efficiencyEnergy efficient ICTTransmissionLocation-based serviceSocial network service

The invention discloses a taxi sharing system and a method based on LBS (Location Based Service) and SNS (Social Network Service). The system comprises a service processing terminal, a client which is interconnected with the service processing terminal, wherein the service processing terminal comprises an LBS information optimization processing module, an SNS interconnection interaction and rights protection platform, an information receiving module and an information sending module, the information receiving module is respectively connected with the input terminal of the LBS information optimization processing module and the input terminal of the SNS interconnection interaction and rights protection platform, the information sending module is respectively connected with the output terminal of the LBS information optimization processing module and the output terminal of the SNS interconnection interaction and rights protection platform, and the client is respectively connected with the information receiving module and the information sending module. According to the taxi sharing system, taxi resource waste in the city is effectively solved, taxi idle seats are used to greatest extent and the purpose of energy saving and environmental protection is realized.

Owner:XI AN JIAOTONG UNIV

Organic water-soluble fertilizer containing alginic acid and production method thereof

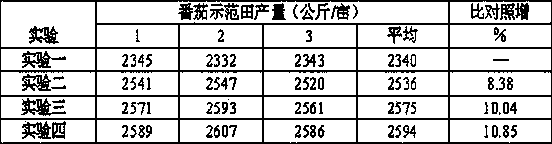

The invention discloses an organic water-soluble fertilizer containing alginic acid and a production method thereof. Each component in the fertilizer is in the following content: 60 g / L>= alginic acid>=20 g / L, 200 g / L>=NK2O>=100 g / L, 150 g / L>=organic>=75 g / L, 15 g / L>=B>=5 g / L, 1-5 g / L of mannitol and 1-5 g / L of betaine. The production method is as below: carrying out soaking cleaning, ultrasonic wall breaking and cutting on seaweeds; adding papain for reaction; separating and purifying seaweeds in an electric flocculation mode; and metering and packaging to obtain the finished product of the organic water-soluble fertilizer containing alginic acid. The production method provided by the invention has the advantages of simple manufacture, easy operation and high practicability. The produced alginic water-soluble fertilizer containing alginic acid has remarkable effect, especially realizes high flowering rate and fruit rate, good color, bright fruit color, good taste, drought resistance, early maturing early listing and strong immunity of fruits and vegetables, and is a pure natural green fertilizer uniting nutrition, yield increase and disease resistance in one.

Owner:潍坊德孚尔生物科技有限公司

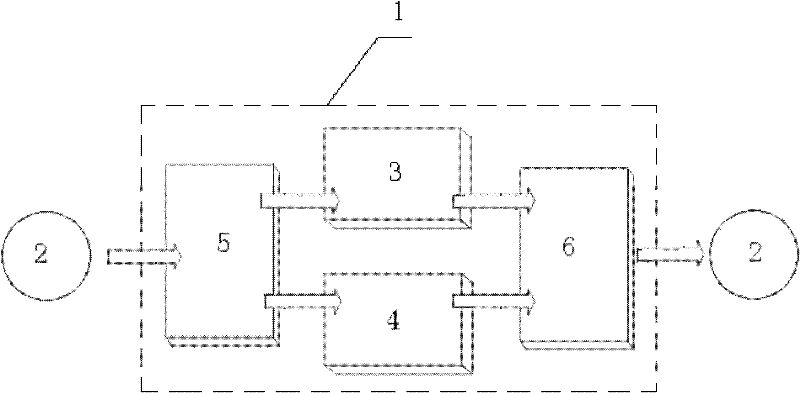

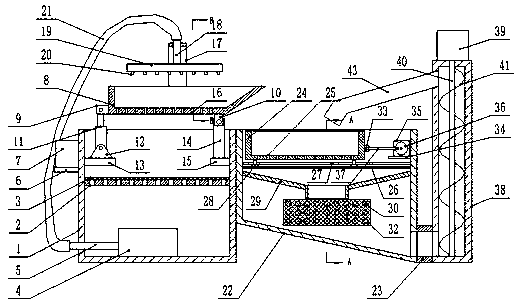

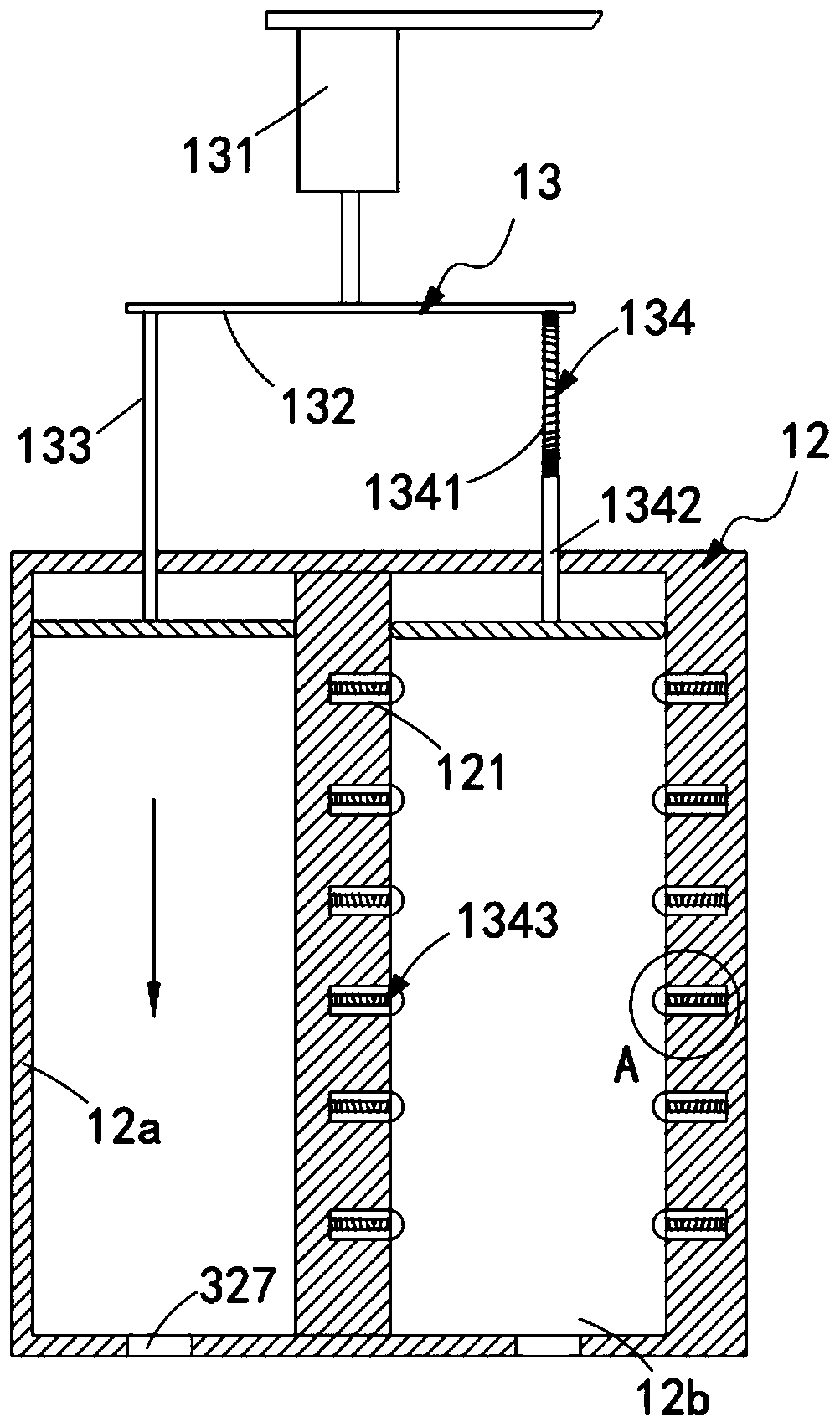

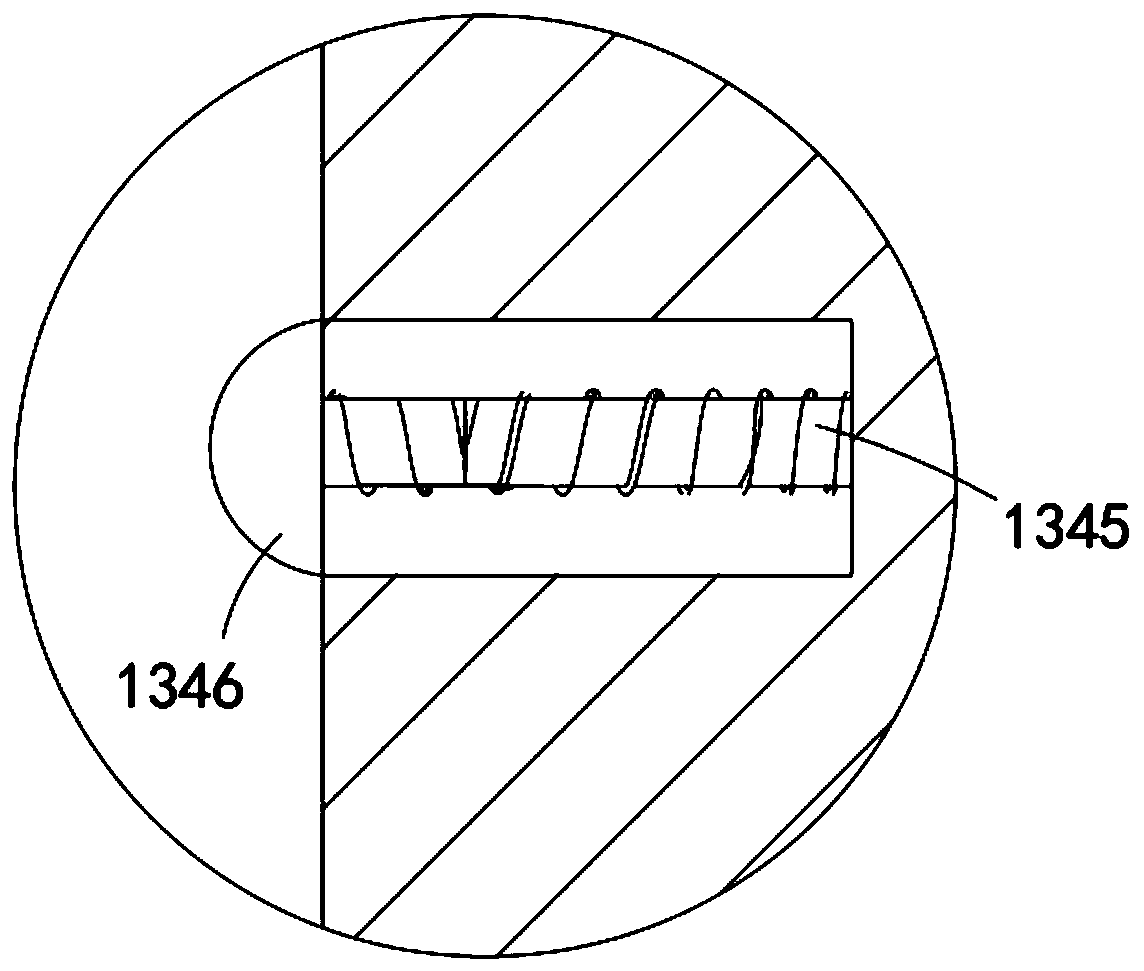

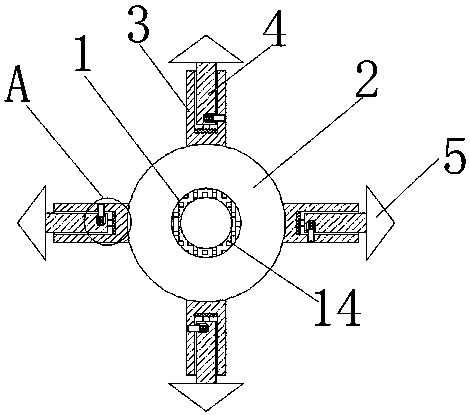

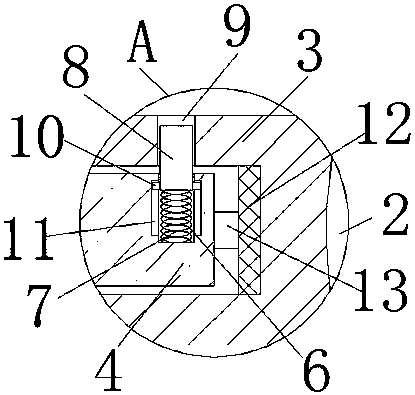

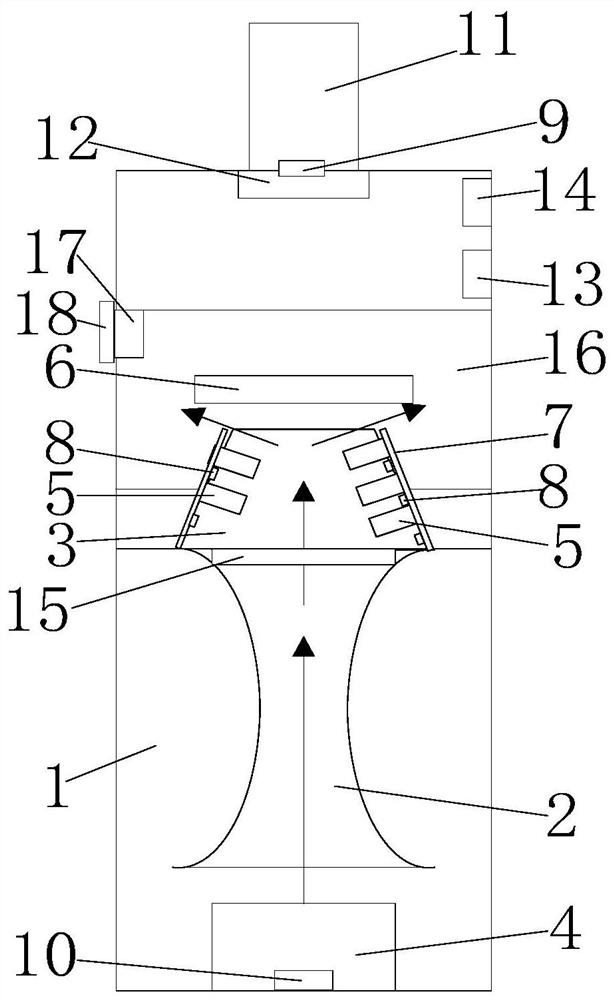

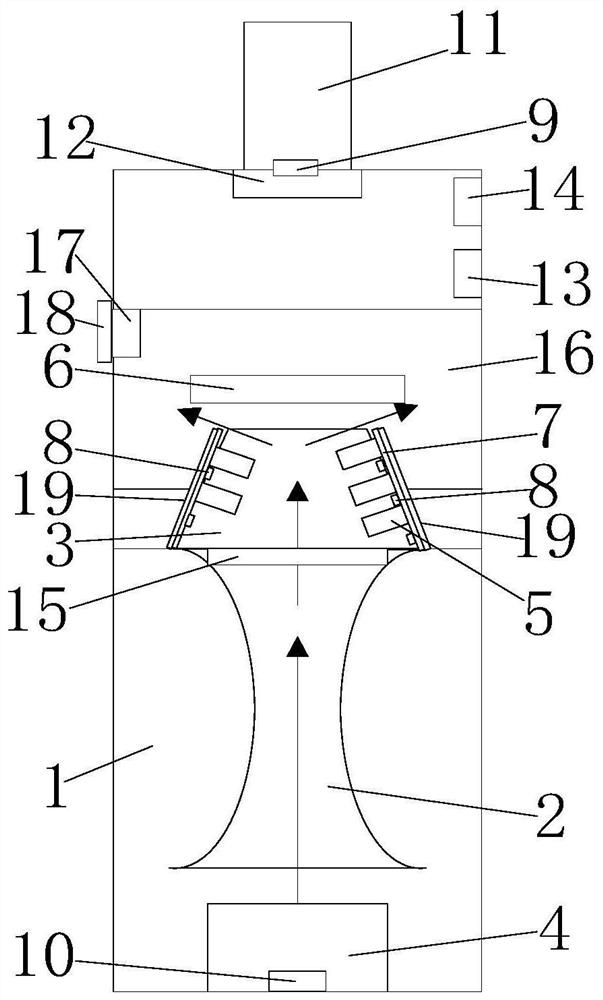

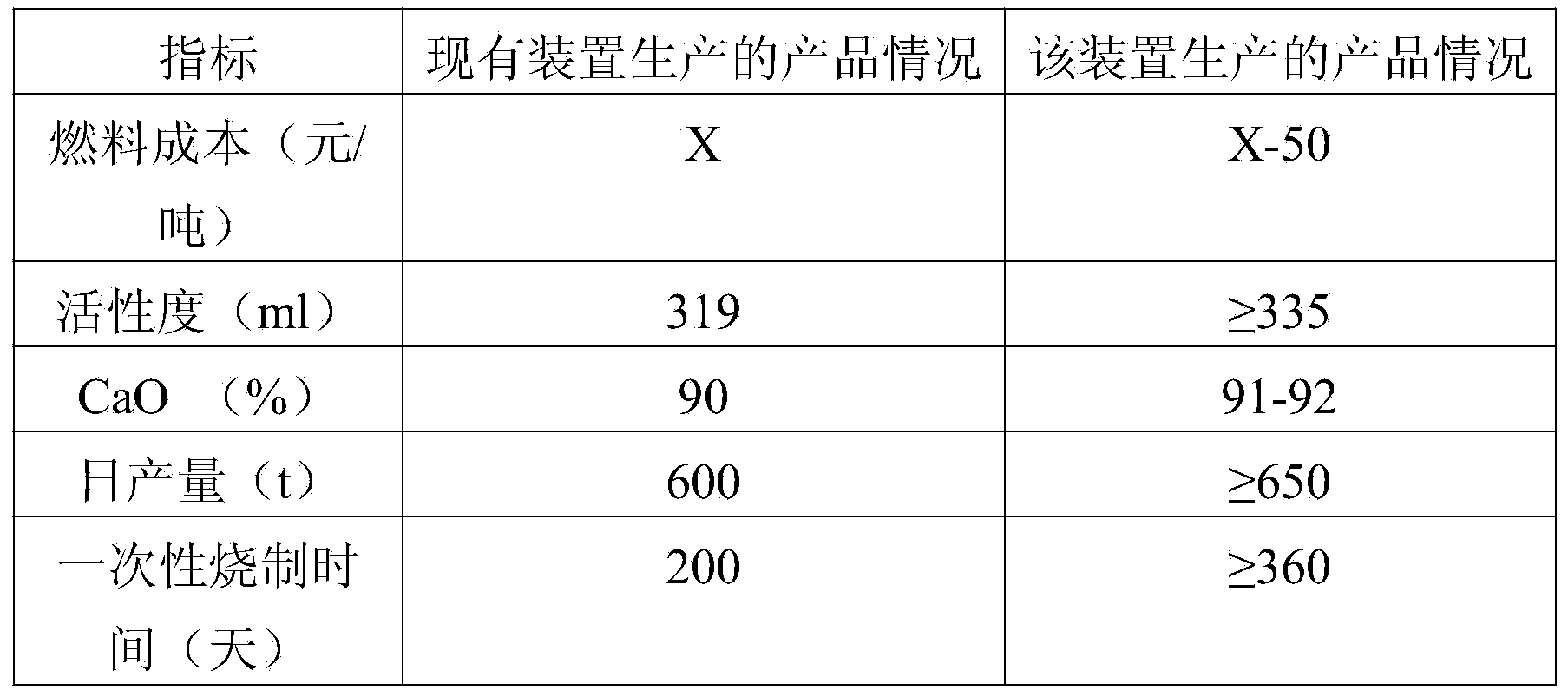

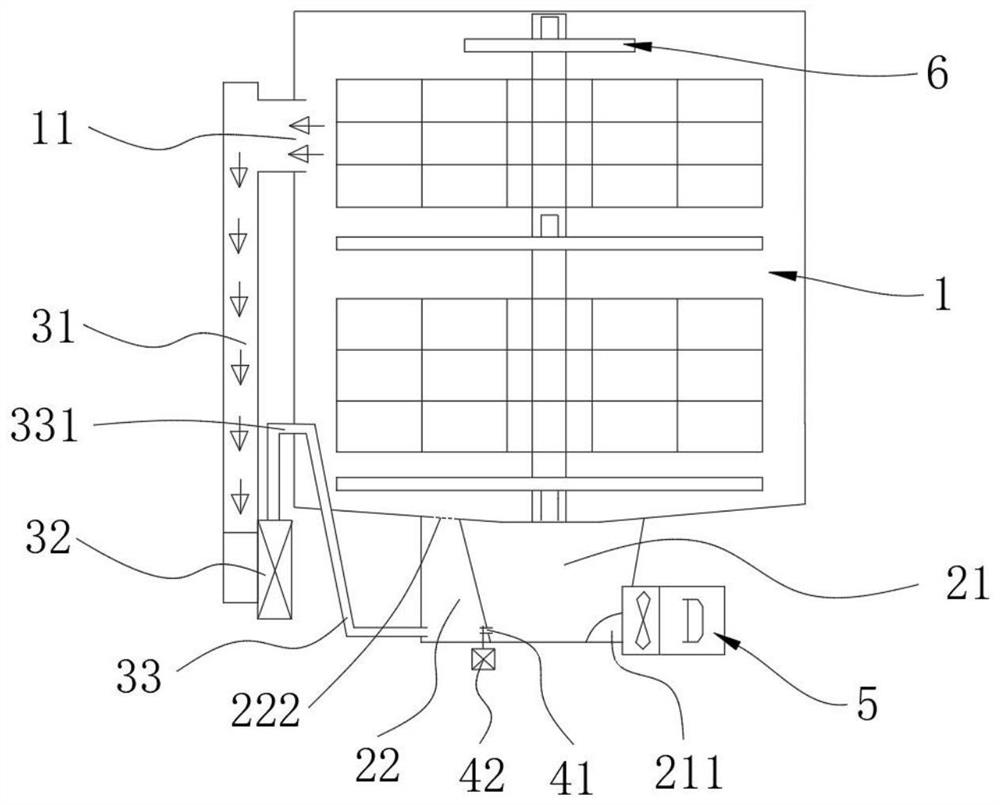

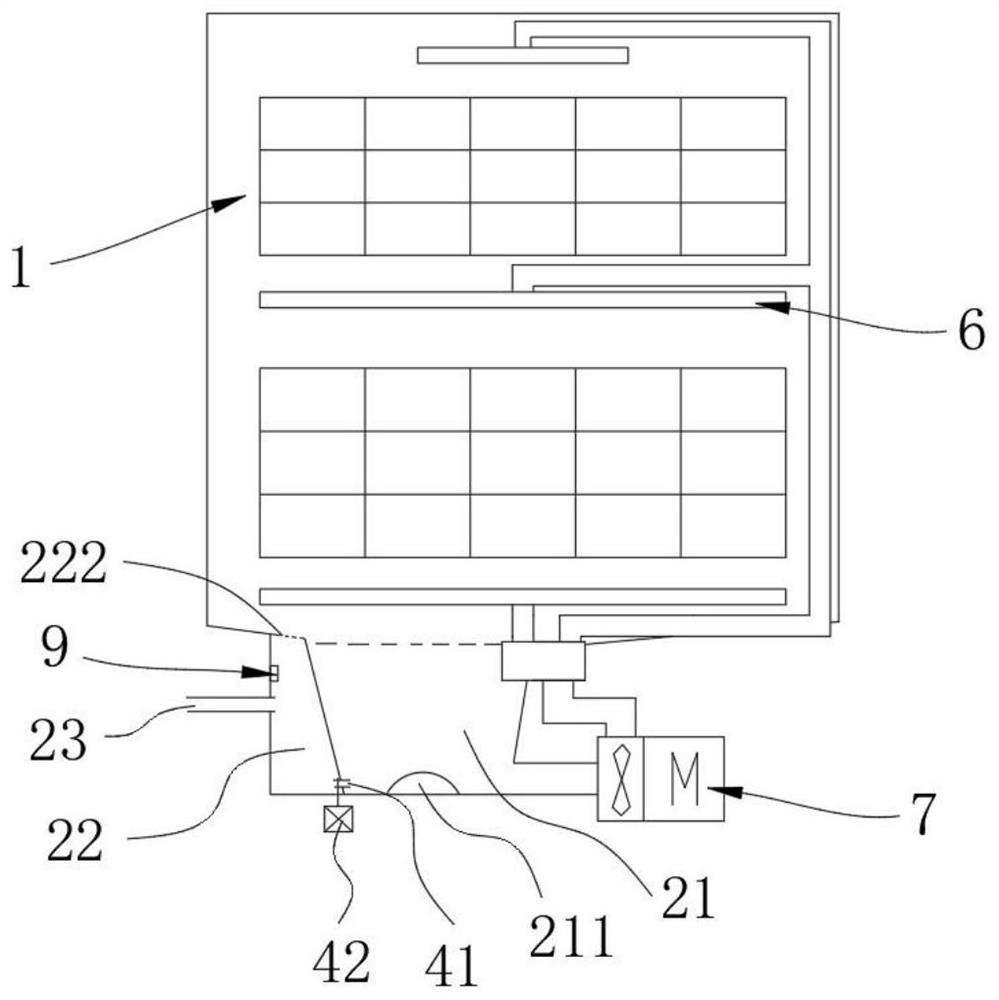

Multifunctional biomass hot water boiler

InactiveCN106196583AImprove combustion efficiencyImprove full utilizationWater heatersLump/pulverulent fuel preparationCombustion chamberEngineering

The invention discloses a multifunctional biomass hot water boiler. The multifunctional biomass hot water boiler comprises a boiler body. A support is arranged at the bottom end of the boiler body. A boiler ash chamber is arranged at the upper end of the support. A combustion chamber is arranged on the left side of the top end of the boiler ash chamber. A hot water chamber is arranged in the middle of the top end of the combustion chamber. The upper end of the left side of the combustion chamber is connected with a purification chamber through a smoke exhaust pipe. An air inlet chamber is arranged on the right side of the top end of the boiler ash chamber. A crushing chamber is arranged at the top end of the air inlet chamber. According to the multifunctional biomass hot water boiler, a crushing wheel is arranged in the crushing chamber and can completely crush fuel, and the combustion efficiency and the combustion sufficiency are improved; boiler ash can be filtered, the full utilization rate of boiler slag is increased, and the boiler slag which is not combusted fully is prevented from being wasted; waste gas generated by combustion can be effectively purified, and the situation that the waste gas is exhausted directly and consequently pollutes the environment is avoided; and the multifunctional biomass hot water boiler has the advantages of being efficient, capable of saving energy and environmentally friendly, biomass fuel is adopted for combustion, the using cost is low, and the practicability is high.

Owner:HARBIN XINGYU RIVETING

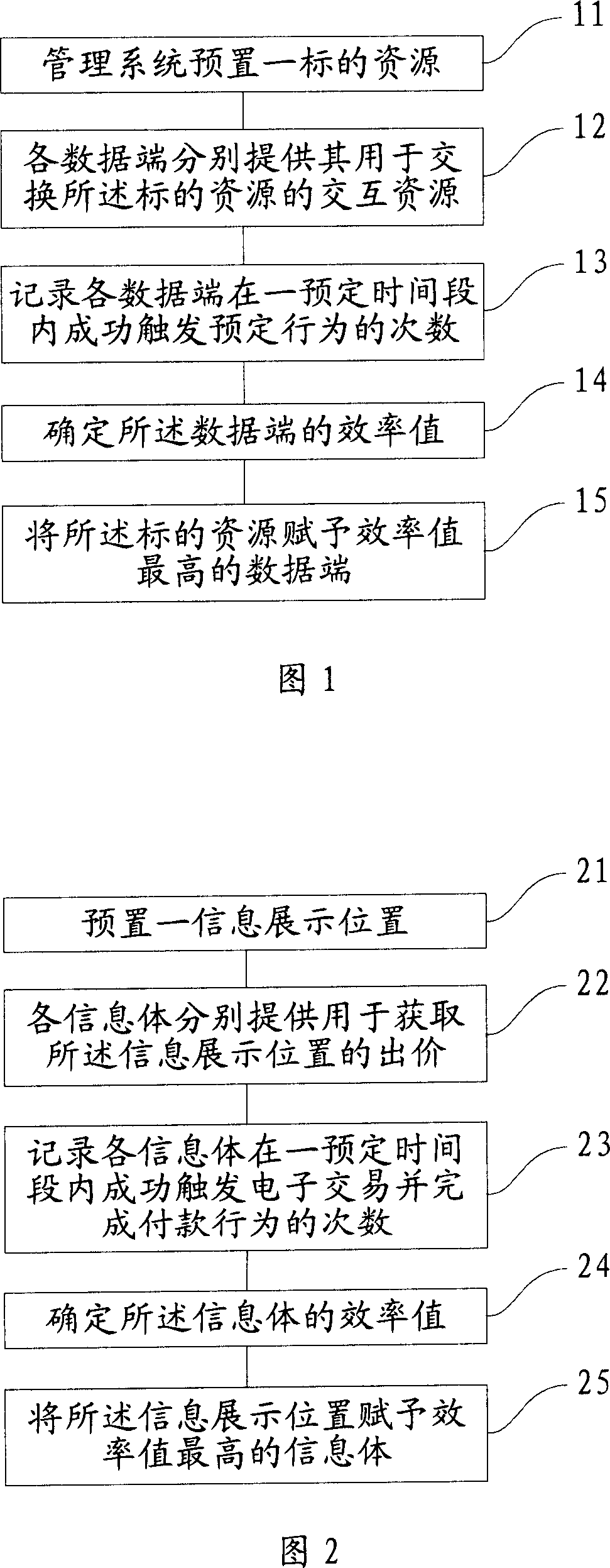

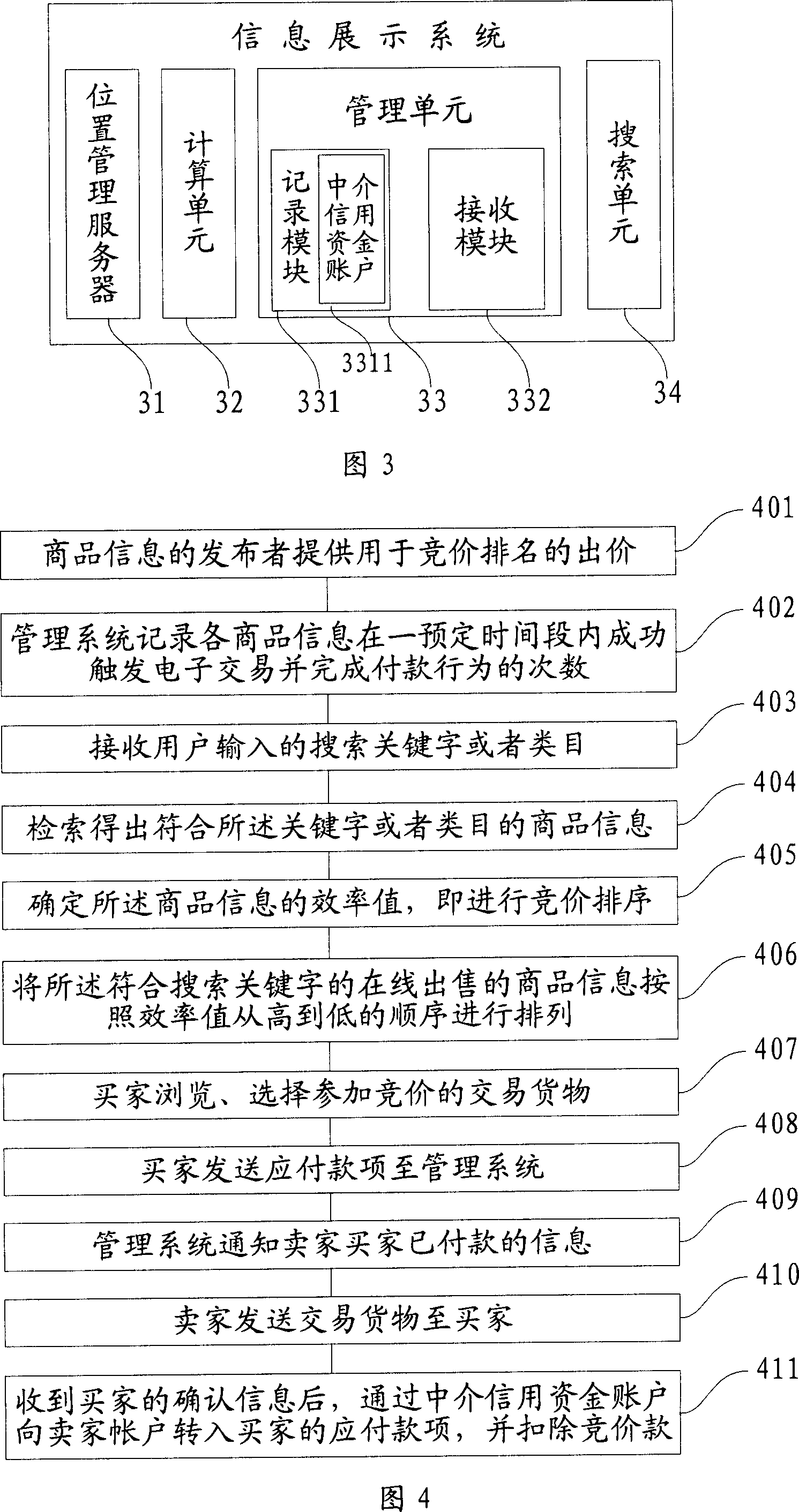

Resource competition alternating method and information showing method and system

The invention discloses approach of resource interactive competition, at least two data to target resources-interactive competition, which covers the subject of third-party resources to trigger the terminal is scheduled acts, including: a preset target resources; respectively, the data - provide resources for the subject mentioned in the exchange of interactive resources, interactive resources can be referred to quantify; management system records the data in a scheduled period of time-triggered scheduled successful conduct of the number of interactive resources, and under the above mentioned success trigger number, referred to determine the efficiency of data-value, value and efficiency described above, as well as interactive resources are referred to the number of successful trigger a positive correlation; resources will be the subject referred to the maximum efficiency of the data terminal. This invention will be used in the field of information display can be achieved access to the information released to the benefits of information display, collected management system corresponding costs can give up to the best-selling merchandise promotional opportunities to meet the request and the service side interests.

Owner:ALIBABA GRP HLDG LTD

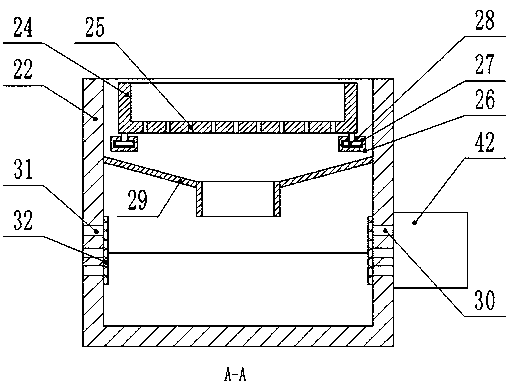

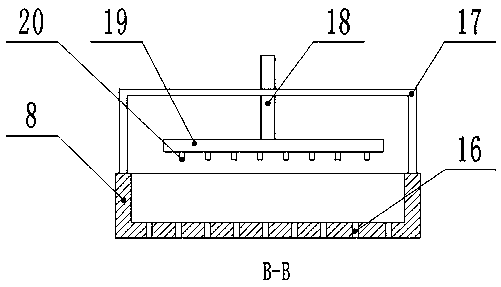

Cleaning and drying device for small metal part

InactiveCN109894421AImprove full utilizationTo achieve the purpose of cleaning and drying small hardwarePolishing machinesDrying solid materials without heatEngineeringAir blower

The invention discloses a cleaning and drying device for a small metal part. The cleaning and drying device comprises a cleaning box; an orifice plate is horizontally and fixedly arranged at the center in the cleaning box; the top surface of the orifice plate is fixedly attached with a filter screen; a submerged pump is arranged at the lower end of the orifice plate; a water outlet pipe is fixedlyconnected with the water oultet of the the submerged pump; the other end of the water outlet pipe penetrates through the side wall of the cleaning boxand protrudes out of the cleaning box; a fixing plate is fixed at one side of the cleaning box; a hydraulic station is fixedly arranged on the fixing plate, and the upper end of the cleaning box is provided with a washing tank. The device can achieve the purpose of cleaning and drying the small metal part effectively through the arrangement of the cleaning box and the drying box, and the labor is replaced effectively; the cost is low, the efficiency is high; the washing water and the sawdust in the cleaning box and the drying box can be recycled for a long time through the arrangement of the filter screen and a hot-air blower; the sufficient use rate of the washing water is improved effectively and the economical expense is saved.

Owner:WUHAN UNIV OF TECH

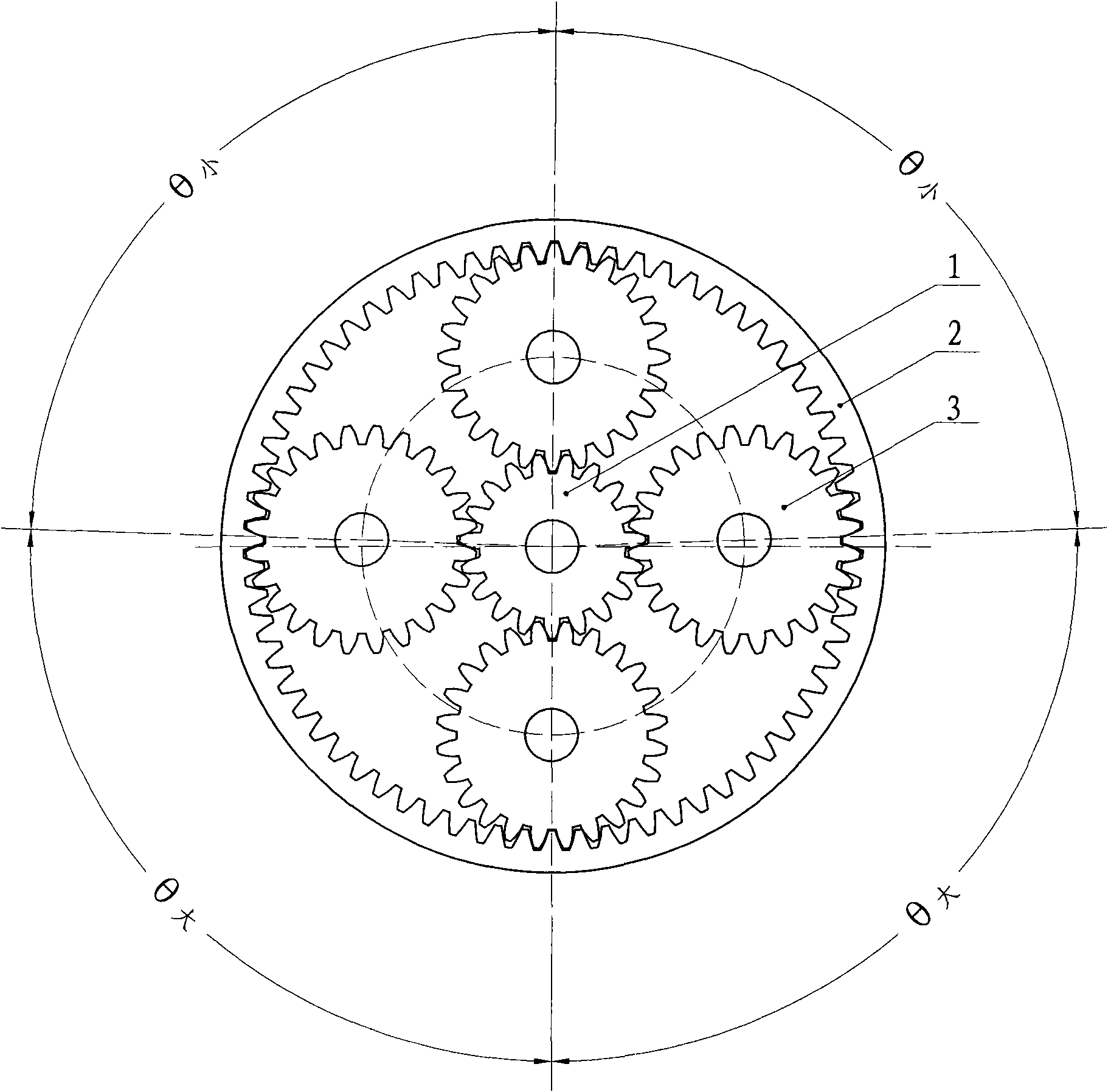

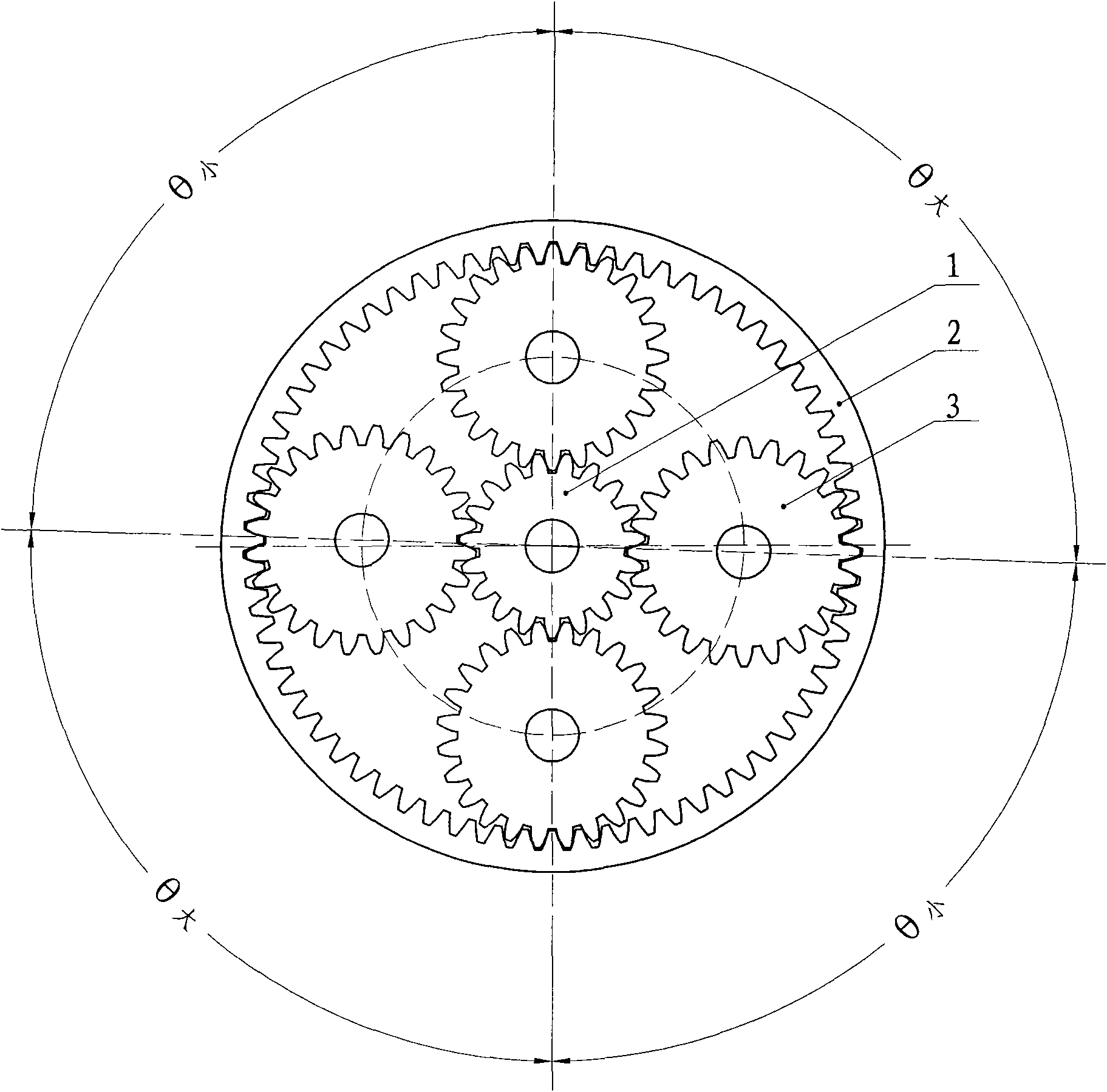

Assembling method for planetary gear transmission

ActiveCN101890637ASolve unsolvable technical problemsDevelop and improve mechanical design theoryAssembly machinesGear driveGear wheel

The invention discloses an assembling method for planetary gear transmission, and relates to the technical field of gear transmission, in particular to planetary gear transmission. In the assembling method for the planetary gear transmission, when the sum of the tooth number of a sun gear and an internal gear divides the number of planetary gears to obtain a quotient which is not an integer, in the planetary gear transmission, the planetary gears are distributed at the preset positions by adopting a circumference non-equant assembling method, so that correct meshed operation of the planetary gears is guaranteed. The circumference non-equant assembling method comprises four steps, wherein big and small included angles on the circumference can be in sequential distribution or staggered distribution. Compared with the prior art, the assembling method for the planetary gear transmission solves the technical problems which 'machine design handbook' and common reference books cannot solve, develops and improves a machine design theory, reduces the volume and weight during the gear transmission, greatly improves the full utilization rate of materials and avoids the waste of material resources; and in addition, the assembling method has a simple and clear computational formula without changing the parameters and structure of the gears per se.

Owner:NINGGUO JULONG IND

Production method for calcium hydrogen phosphate

InactiveCN104016326AQuality improvementLow impurity contentPhosphorus compoundsPhosphoric acidCalcium EDTA

The invention relates to the technical field of chemical engineering, and particularly relates to a production method for calcium hydrogen phosphate. A calcium hydrogen phosphate product is prepared by reacting calcium oxide with a certain amount of water to form a calcium hydroxide solution; then reacting the calcium hydroxide solution with urea phosphate under stirring; controlling a pH value at 5.5-6.5; reacting for 5-20 min under stirring continuously and terminating the reaction. By adopting urea phosphate as a direct resource of phosphorus in the calcium hydrogen phosphate product, processes of removing impurities such as metal ions and fluorine in a process for producing feed level calcium hydrogen phosphate by using wet-process phosphoric acid are omitted; phosphorus utilization rate in the whole process is high; removal of a lot of wastes is prevented; and production cost of calcium hydrogen phosphate is reduced. In the obtained calcium hydrogen phosphate product, phosphorus content is 16.8-17.3%; calcium content is 20.35-22.2%; and fluorine content is 0.012-0.023%. The obtained calcium hydrogen phosphate product can fully meet the standard of feed level calcium hydrogen phosphate.

Owner:GUIZHOU KAILIN GRP MINERAL FERTILIZER CO LTD

Natural and safe growth-type feed additive

InactiveCN102028102APromote growthImprove farming efficiencyAnimal feeding stuffAccessory food factorsAnimal scienceAquatic animal

The invention relates to a natural and safe growth-type feed additive which contains L-arginine-alpha-oxoglutarate, wherein the L-arginine and alpha-oxoglutarate are salified in the mole ratio of 1:2-5:1 and the weight ratio of the L-arginine-alpha-oxoglutarate added to the feed and the daily ration for animals to the feed and the daily ration for animals is 1:50-200. The weight ratio of the additive to the feed is 1:50-100 for livestock animals, 1:100-200 for poultry animals and 1:50-100 for aquatic animals.

Owner:JIANGNAN UNIV

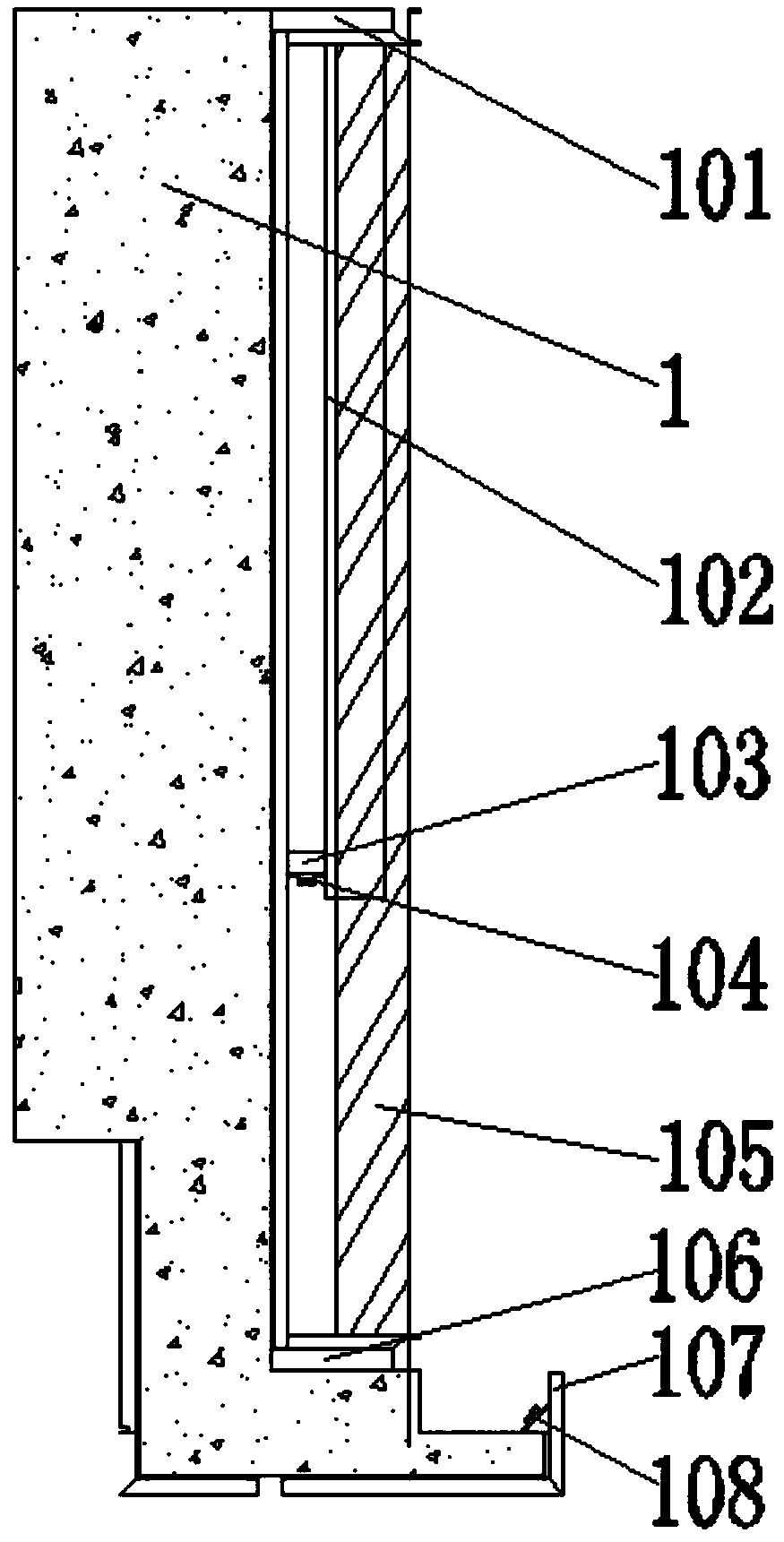

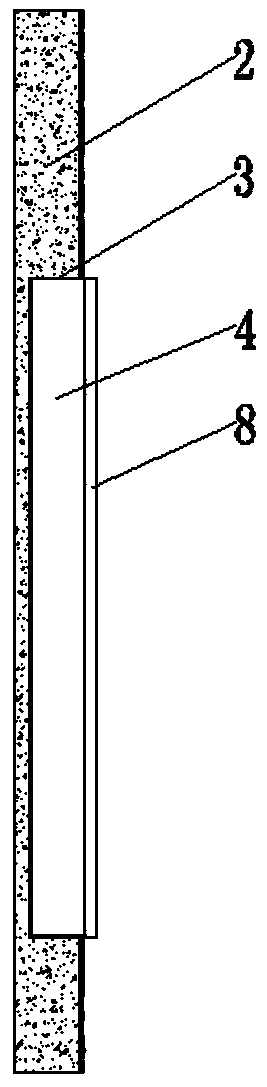

Pass sleeve

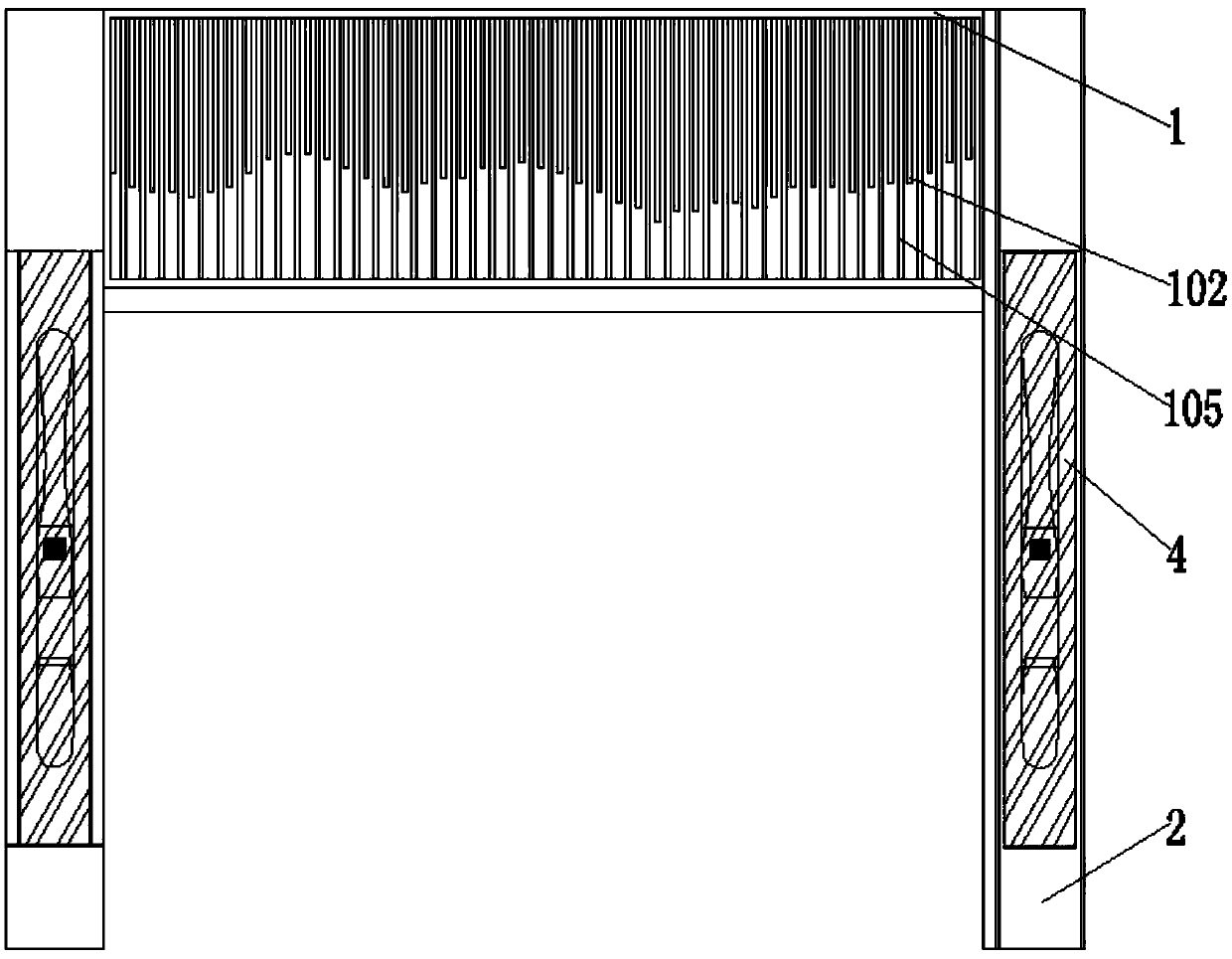

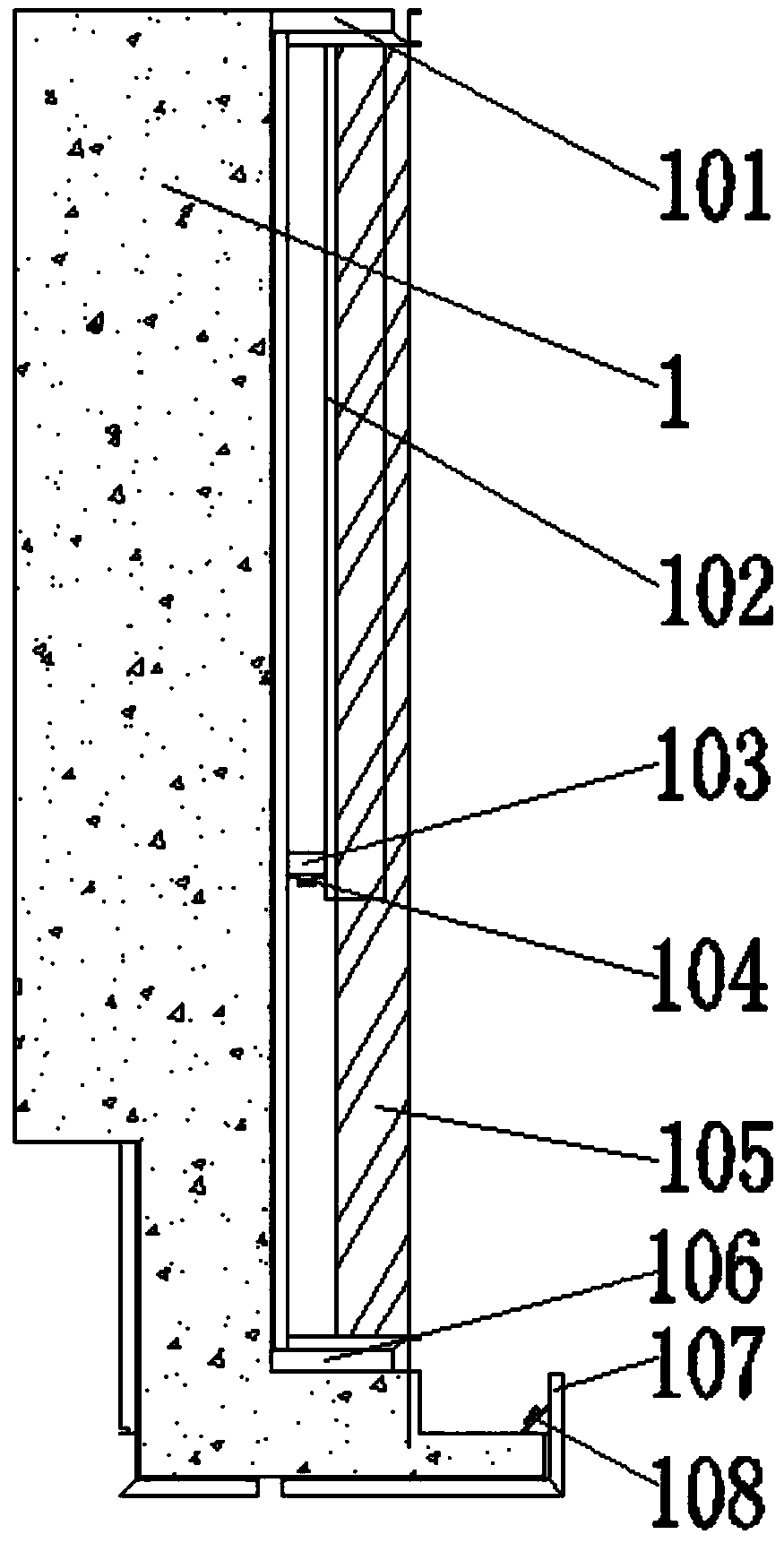

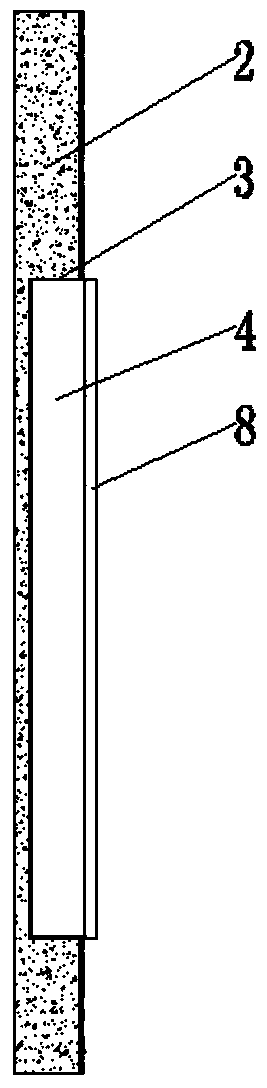

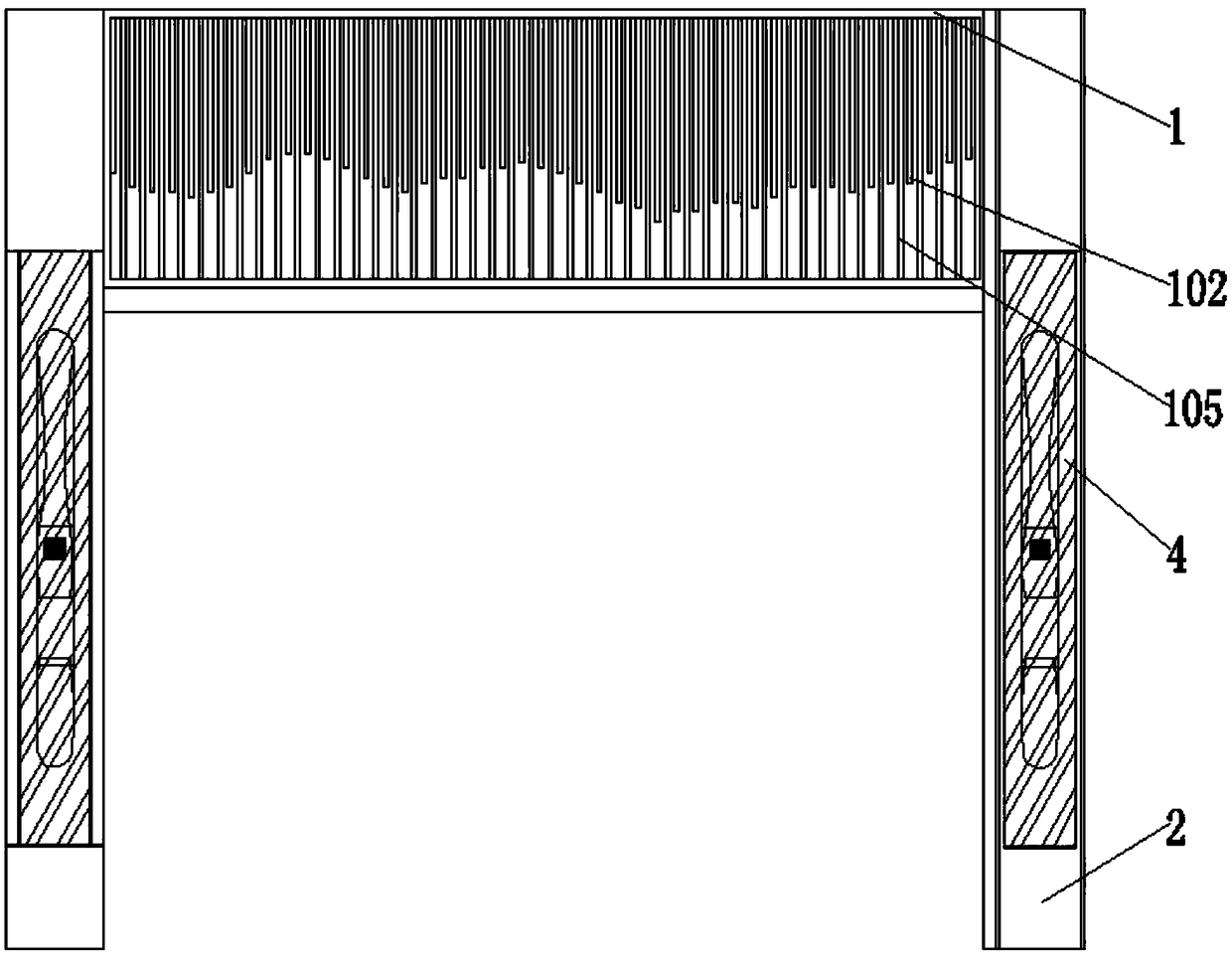

ActiveCN109083347AWon't stabQuick assemblyCovering/liningsLighting heating/cooling arrangementsWave shapeLight guide

The invention relates to the technical field of architectural decoration, in particular to a pass sleeve. The sleeve comprises an upper pass and a side pass, the lower portion of the upper pass is a second-order ladder structure, the upper pass is provided with barrier strips of different lengths, the lower ends of the plurality of barrier strips are arranged in a wave shape, and the bottom of a fixed block is provided with a first human body induction lamp belt; the side pass is provided with an installation slot, an arc-shaped positioning slot and a lamp housing, and an arc-shaped positioning block is arranged on the lamp housing; the lamp housing comprises a rectangular bottom shell, an arc mounting part, a rectangular cavity body, a radiator, a reflector and a lamp tray with an LED light belt; a light-emitting slot, a groove and a light-guiding column are arranged on the lamp tray; the lamp housing is provided with a lampshade which comprises a diffuser plate and a hemispherical lens, and the other side of a lampshade body is of an inclined plane structure; the lamp housing is provided with an elastic reverse button, and the lampshade is provided with an elastic button. The sleeve has the advantages of good lighting effect, no eye offending, convenient installation and disassembly, faster heat conduction speed, better heat dissipation effect and longer service life.

Owner:浙江卡福曼木业有限公司

Uniform mixing equipment for epoxy powder coating processing

InactiveCN111569721AImprove the mixing effectEvenly mixedTransportation and packagingRotary stirring mixersEpoxyMixed materials

The invention relates to uniform mixing equipment for epoxy powder coating processing, comprising: a raw material conveying mechanism comprising a frame, a storage bin and a pushing assembly, the storage bin comprising an A material storage space and a B material storage space; the uniform material mixing mechanism that comprises a reaction kettle, a material scattering assembly, a thinning assembly and a driving assembly; the mixed material output mechanism that comprises a lifting assembly mounted on the rack, a control assembly linked with the lifting assembly and used for controlling discharging work of the storage bin, and a material blocking assembly connected with the lifting assembly and used for controlling opening and closing of the output end of the reaction kettle; the scrapingmechanism that is arranged on the inner wall of the reaction kettle in a sliding manner in the vertical direction and is connected with the lifting assembly; according to the invention, the technicalproblems that a mixed finished product is easily adhered to the inner wall of the reaction kettle and is extremely difficult to clean during output work, and meanwhile, the utilization rate of raw materials is low are solved.

Owner:浙江众鑫新材料科技有限公司

Wave-shaped luminous pass sleeve

The invention relates to the technical field of architectural decoration, in particular to a wave-shaped luminous pass sleeve comprising an upper pass and side passes. The lower part of the upper passhas a two-stage step structure. The upper pass is provided with shielding strips with different lengths. The lower ends of multiple shielding strips are arranged in a wave shape. First human body induction lamp strips are arranged at the bottom of fixing blocks. Each side pass is provided with an installation groove, an arc-shaped locating groove and a lamp shell, and the lamp shell is provided with an arc-shaped locating block. The lamp shell comprises a rectangular bottom shell, an arc-shaped installing part, a rectangular cavity, a heat dissipating member, a reflective cover and a lamp panel with an LED lamp strip. A light-emitting groove, a groove and a light guide post are arranged on that lamp panel. A lamp cover is arranged on that lamp shell. The lamp housing is provided with elastic reverse buckles. The lamp cover is provided with elastic buckles. The wave-shaped luminous pass sleeve has the characteristics of good lighting effect without dazzling, convenient installation anddisassembling, high heat conduction speed, good heat dissipation effect and long service life.

Owner:浙江卡福曼木业有限公司

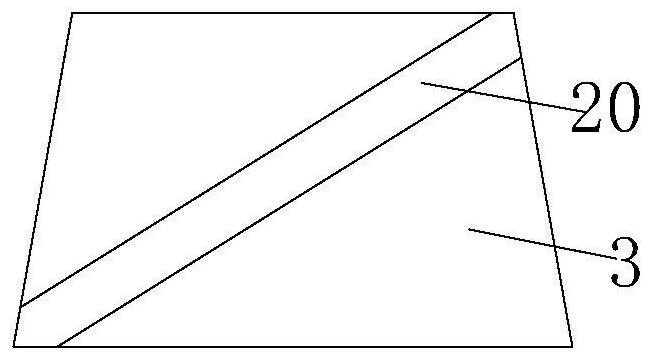

Wood splicing slot slotting tool

InactiveCN109176767AImprove full utilizationEasy to replaceWood mortising machinesWood slotting machinesEngineeringKnife handles

Owner:柳州市千山木业有限公司

Alginic acid containing water-soluble fertilizer for oranges

InactiveCN106748310AEnhanced Nutrient ManufacturingImprove delivery capacityFertilising methodsOrganic fertilisersFruit treeAdditive ingredient

The invention relates to an alginic acid containing water-soluble fertilizer for oranges. The water-soluble fertilizer comprises the following ingredients by content: alginic acid with the concentration of not smaller than 20g / L and not greater than 80g / L, N+K2O with the concentration of not smaller than 100g / L and not greater than 200g / L, B+Zn with the concentration of not smaller than 15g / L and not greater than 30g / L, and sodium nitrophenolate with the concentration of not smaller than 4g / L and not greater than 12g / L. The water-soluble fertilizer can be used for supplementing all nutrients required for the reproductive growth of the oranges in time; after the water-soluble fertilizer is applied, the water-soluble fertilizer can be used for strengthening trees, enhancing photosynthesis and strengthening the full utilization of the nutrients, nutrition manufacturing and delivery capacity; the water-soluble fertilizer is conductive to the reproductive differentiation of fruit trees, the balanced growth of leaves, flowers and fruits is promoted, the ratio of female and male flowers is changed, the falling of fruits is reduced, and thus, the water-soluble fertilizer has the effects of strengthening the flowers and protecting the fruits.

Owner:GUANGXI NANNING YITU BIOLOGICAL SCI & TECH CO LTD

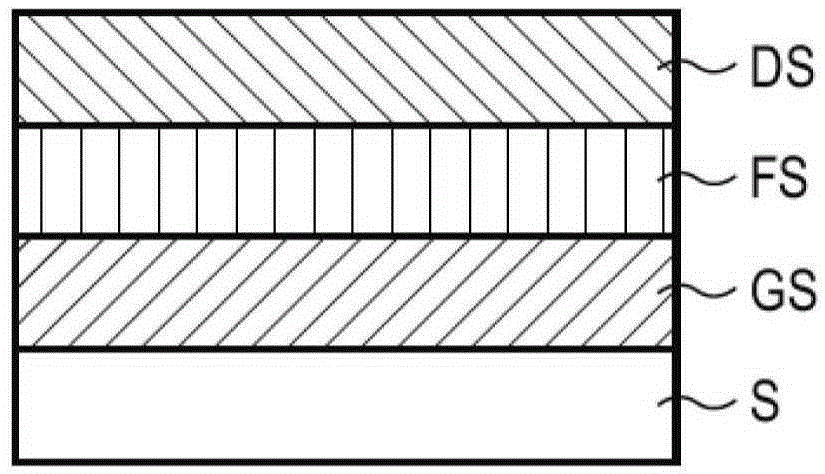

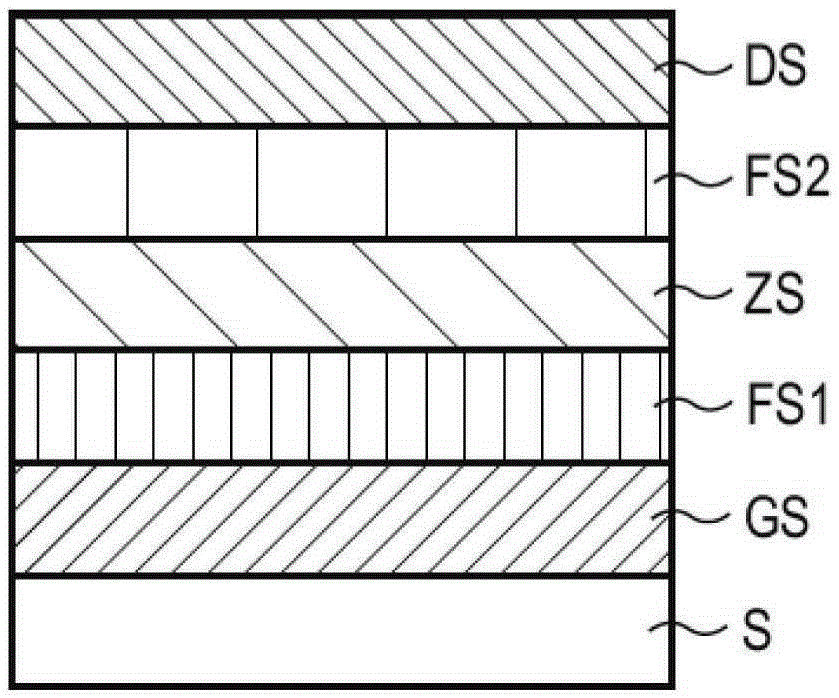

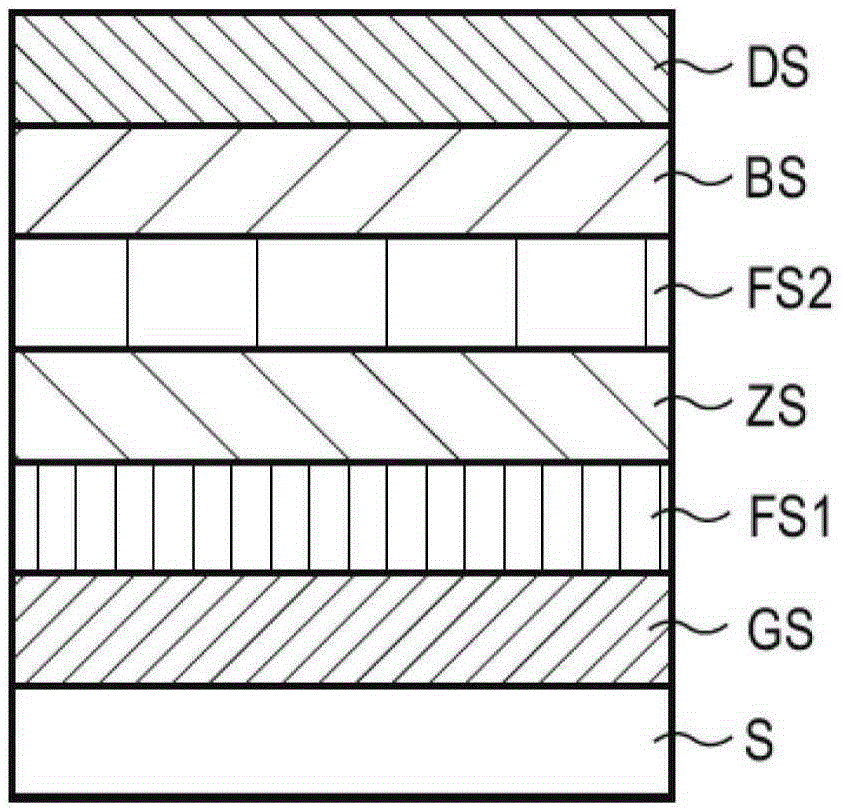

Sunlight control coating system with layer-side neutral reflection color and glass unit

The invention relates to a sunlight control coating system on an insulated transparent substrate and a glass unit. In order to enable such coating system to be provided as possible as much with neutral coating-side reflection color values and transmittance color values, the coating system includes at least the following coatings upwards viewed from the substrate: a silicon-containing dielectric base layer GS, a first functional layer FS 1, a dielectric intermediate layer ZS 1, a second functional layer FS 2, a silicon-containing dielectric top layer DS, wherein the intermediate layer ZS and / or the intermediate layer ZS are configured to be provided with low refractive indexes.

Owner:VON ARDENNE ANLAGENTECHNIK GMBH

Light-emitting pass fast to assemble and disassemble

ActiveCN108843184AQuick assemblyEasy to disassembleMechanical apparatusWindow/door framesSlide plateEngineering

The invention relates to the technical field of architectural decoration, and particularly discloses a light-emitting pass fast to assemble and disassemble. The light-emitting pass comprises an upperpass and side passes; installing grooves are formed in the side passes, arc positioning grooves are formed in the installing grooves, and transverse sliding grooves are formed in the side passes; lampshells are arranged in the installing grooves, arc positioning blocks are arranged at the two ends of the lamp shells, and the arc positioning blocks are fixed in the arc positioning grooves throughmatching of sliding plates and the transverse sliding grooves; the lamp shells comprise rectangular bottom shells and arc installing parts, reflecting covers are arranged on the arc installing parts,and lamp discs with LED lamp strips are arranged on the reflecting covers; light-emitting grooves are formed in the lamp discs, grooves are formed in the inner walls of the light-emitting grooves, andlight guide columns are arranged in the light-emitting grooves; lamp covers are arranged on the lamp shells, cylindrical fixing grooves are formed in the lamp shells, elastic inverse buckles are arranged in the cylindrical fixing grooves, cylindrical plugs are arranged on the lamp covers, and elastic buckles are arranged in the cylindrical plugs. The light-emitting pass has the advantages of being good in light effect and convenient to assemble and disassemble.

Owner:浙江卡福曼木业有限公司

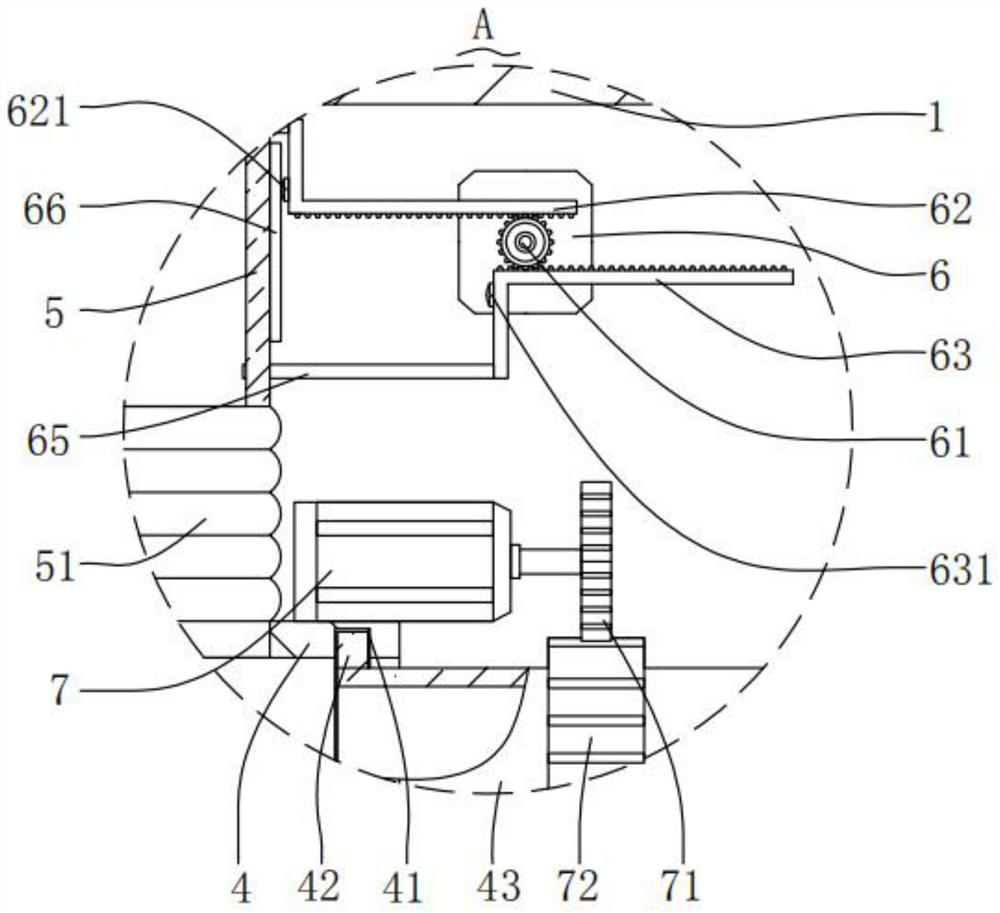

Vibration tank fall type bagasse smoke drying device

InactiveCN106440744AFully dryReduce moisture contentDrying gas arrangementsDrying solid materialsWater contentSmoke

The invention provides a vibration tank fall type bagasse smoke drying device, and belongs to the technical field of bagasse drying equipment. The vibration tank fall type bagasse smoke drying device comprises a drying module; the drying module includes a vibration plate, a motor, a rocking arm and a vibration tank; the motor is mounted on the vibration plate, and an output shaft thereof is vertically connected with the rocking arm; the vibration tank is positioned above the vibration plate, and is connected with the motor through the rocking arm; at least two grades of bearing plates are arranged in the vibration tank; the bearing plates are arranged in the swing direction of the vibration tank, and are inclined; one lower sides are inlet ends, and one higher sides are outlet ends; the outlet ends of the previous stages of bearing plates are positioned above the inlet ends of the later stages of bearing plates; the vibration tank is sealed, and is provided with a feed port, a discharge port, an intake port and an exhaust port for communicating the internal with the external of the vibration tank; the feed port is formed above the inlet end of the uppermost stage of bearing plate; and the discharge port is formed in the outlet end of the final stage of bearing plate. The vibration tank fall type bagasse smoke drying device can dry bagasse, reduces the water content of the bagasse, and improves the heat value of the bagasse as a fuel.

Owner:GUANGXI CHONGZUO XIANGGUI SUGAR

Electronic commerce piling bin fully utilizing storing space

Owner:南京陆陆伙伴网络科技有限公司

Externally applied Chinese medicinal effervescence tablet for fumigating and washing to treat external piles and anal fissure and method for preparing same

InactiveCN1994385AReduce financial burdenSufficient sources of medicineInorganic boron active ingredientsAnthropod material medical ingredientsSodium bicarbonateTherapeutic effect

The invention relates to a Chinese medicinal effervescent tablet for treating outer hemorrhoid and anal fissure, and process for preparing same, wherein the tablet is prepared from the following constituents (by weight portions): root of Dahurain angelica 10-20 parts, allume 40-50 parts, garden burnet root 10-20 parts, borax 20-30 parts, abalone shell 20-30 parts, frank incense 10-20 parts, borneol 30-40 parts, schisandra fruit 30-40 parts. The auxiliary materials include medical starch, citric acid, sodium hydrogen carbonate, sodium dodecylsulfate, and magnesium stearate.

Owner:孙玉伙

Electronic cigarette type aerosol inhalation therapeutic apparatus

InactiveCN111840717AImprove suction efficiencyReduce labor intensityMedical atomisersInhalatorsMedicineAerosolize

The invention provides an electronic cigarette type aerosol inhalation therapeutic apparatus. The apparatus comprises a rod body, a venturi tube used for accelerating airflow, a nozzle used for atomizing liquid medicine and an air compressor used for compressing the airflow. The air compressor, the venturi tube and the nozzle are arranged in the rod body, and the air compressor, the venturi tube and the nozzle are connected in sequence. Through the combination of the venturi tube and the nozzle, pressurized high-speed airflow is fully mixed with liquid medicine and collides with the nozzle togenerate mist, so that the liquid medicine is fully atomized. The user inhalation efficiency is improved, and the user labor intensity is reduced.

Owner:BEIJING SHIJITAN HOSPITAL CAPITAL MEDICAL UNIVERSTY

Culture medium for stropharia rugosoannulata with high fruiting rate and cultivation method for stropharia rugosoannulata

InactiveCN107787763AImprove full utilizationImprove reuseCalcareous fertilisersBioloigcal waste fertilisersFermentationCulture mediums

The invention belongs to the technical field of cultivation of edible mushrooms and provides a culture medium for stropharia rugosoannulata with the high fruiting rate and a cultivation method for stropharia rugosoannulata with the intention of resolving defects of a conventional production method for stropharia rugosoannulata. The culture medium is prepared by mixture of sunflower seed husks, sunflower stems, sawdust, quicklime, vitamin B1, folic acid, nicotinic acid, glucose and calcium carbonate according to a certain proportion. The cultivation method comprises the following steps: producing and cultivating stock seeds, producing and cultivating cultivated species, sowing, performing growth management on hyphae and harvesting stropharia rugosoannulata. Reutilization rate of sunflower seed husks and sunflower stems is increased. The sunflower seed husks and the sunflower stems are subjected to fermentation such that macromolecular substances are degraded. Therefore, macromolecular substances are conveniently absorbed by stropharia rugosoannulata hyphae. Due to high material taking speed the hyphae grow robustly. Cultivation material is reasonably proportioned with balanced nutrition, good in breathability of fungus material and high in water-retaining property. Therefore, high value-added utilization of waste resources is achieved. The stropharia rugosoannulata cultivated with the culture medium is rich in nutrition, large in fruiting bodies and high in yield and has biological efficiency of 120-130%.

Owner:张永强

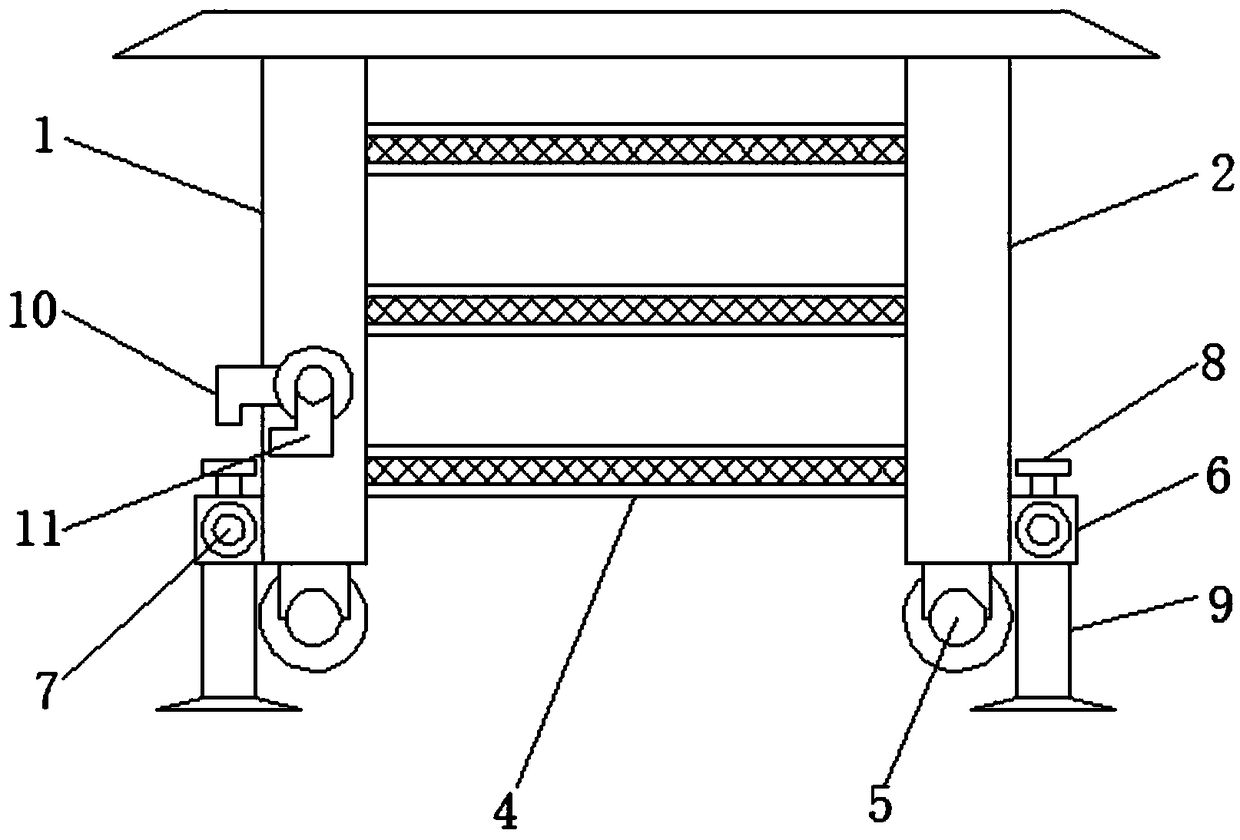

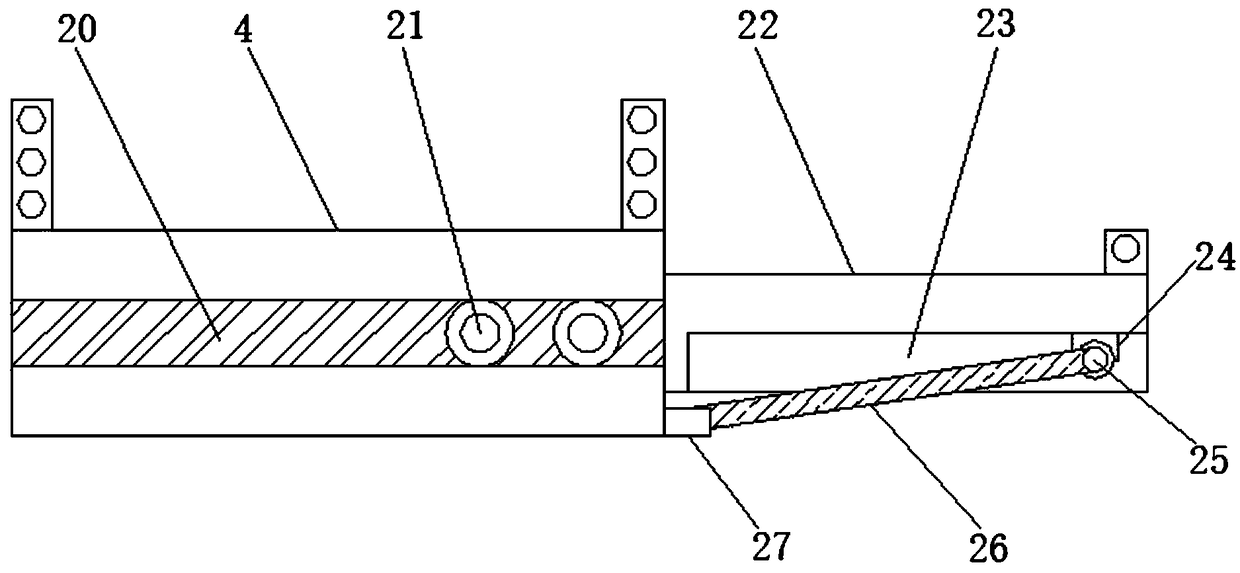

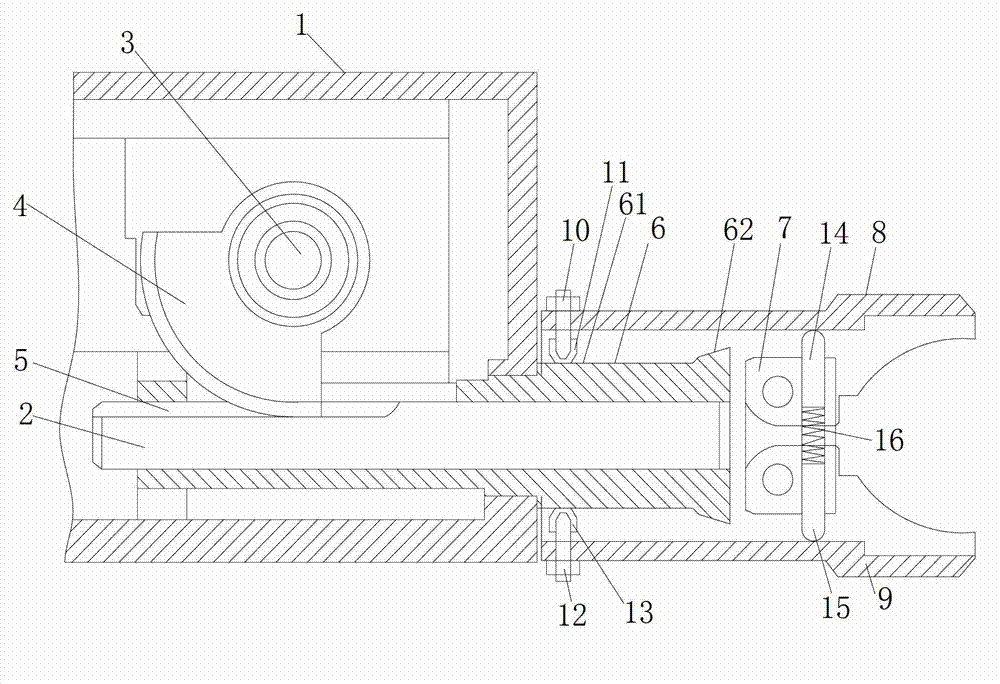

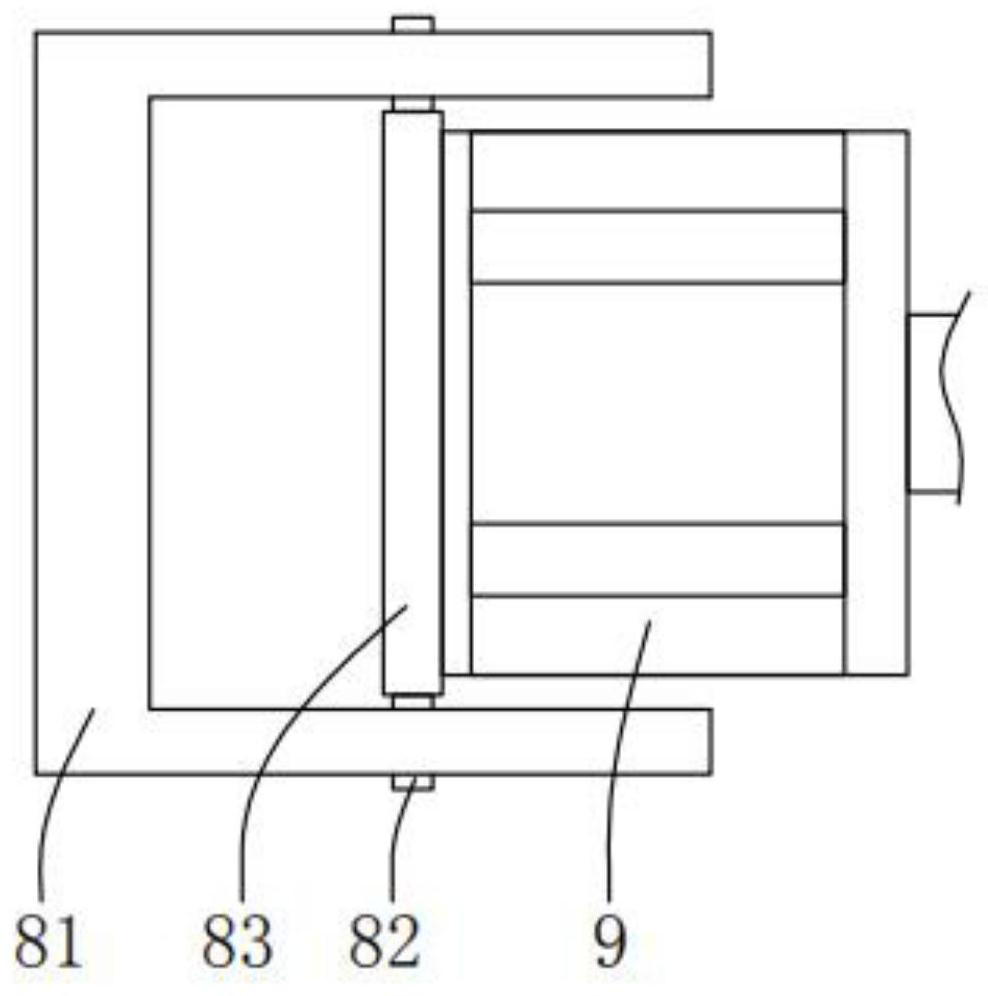

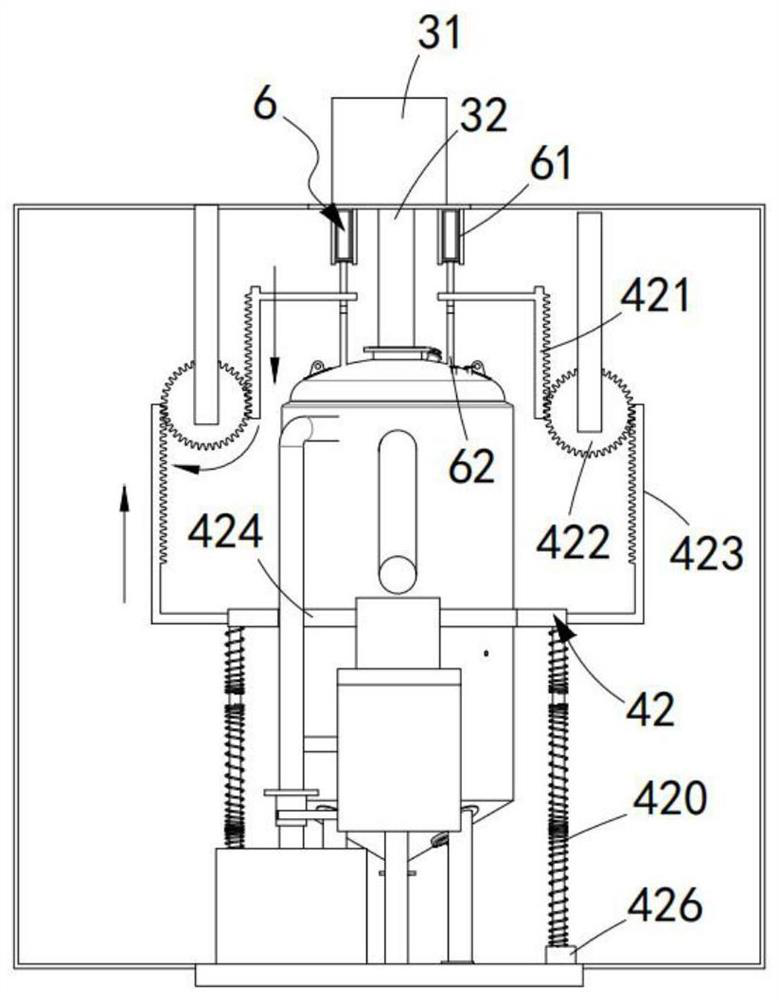

Mechanical automatic feeding and discharging device

InactiveCN102896550AGrasp the loading and unloading timeImprove full utilizationMetal working apparatusDrive shaftEngineering

The invention relates to a mechanical automatic feeding and discharging device which comprises a base, a transmission shaft and a driving mechanism, wherein one end of the transmission shaft stretches into the base; the other end of the transmission shaft stretches to the outside of the base; the driving mechanism is used for driving the transmission shaft to move; a guide sleeve for guiding the transmission shaft is arranged on the base; the outer diameter of the guide sleeve is less than the outer diameter of the other end of the guide sleeve; one end of the transmission shaft which is exposed outside the base penetrates through the guide sleeve; a finger fixing sleeve is arranged at the end part of the transmission shaft which stretches outside the guide sleeve; an upper finger is movably connected with the upper part of the finger fixing sleeve; a lower finger is connected with the lower part of the finger fixing sleeve; the left ends of the upper finger and the lower finger extend to the guide sleeve; an expanding device is arranged at the left ends of the upper finger and the lower finger; and a recovery device is arranged on the finger fixing sleeve and is used for recovering the upper finger and the lower finger. With the adoption of the device, a workpiece can be clamped and released automatically, the feeding and discharging time can be mastered accurately, the sufficient utilization rate and the working efficiency of equipment are improved, and meanwhile a great deal of labor is not wasted.

Owner:CHANGZHOU LIWEI KNIFE

Coal chemical gasification furnace

ActiveCN112063420ATo vibrateReduce cloggingGasification processes detailsSolid fuel combustionThermodynamicsCombustion

The invention relates to a coal chemical gasification furnace which comprises a furnace body, a feeding port plate, a limiting plate, a drawing rod, a front door and a processing mechanism, the furnace body is installed on the existing working ground, a feeding through groove is formed in the middle of the upper end of the furnace body, and the feeding port plate is installed between the left inner side wall and the right inner side wall of the feeding through groove through pin shafts; a limiting plate is installed at the rear end of the upper end face of the feeding port plate, the lower endof the limiting plate is connected with the upper end face of the furnace body in a sliding fit mode, and drawing rods are installed on the front end face of the furnace body in a sliding fit mode inan up-down symmetrical manner and are arranged in a bilateral symmetry mode, and the front end face of the drawing rods is connected with the rear end face of the front door, the rear end of the front door is connected with the front end of the furnace body in a sliding fit mode, the processing mechanism is arranged in the furnace body, and the arranged processing mechanism can achieve multi-cavity separate stacking combustion of fuel so that the probability of insufficient combustion of the fuel due to excessive stacking is reduced, and then the utilization rate of the fuel is increased.

Owner:SUZHOU HAILU HEAVY IND

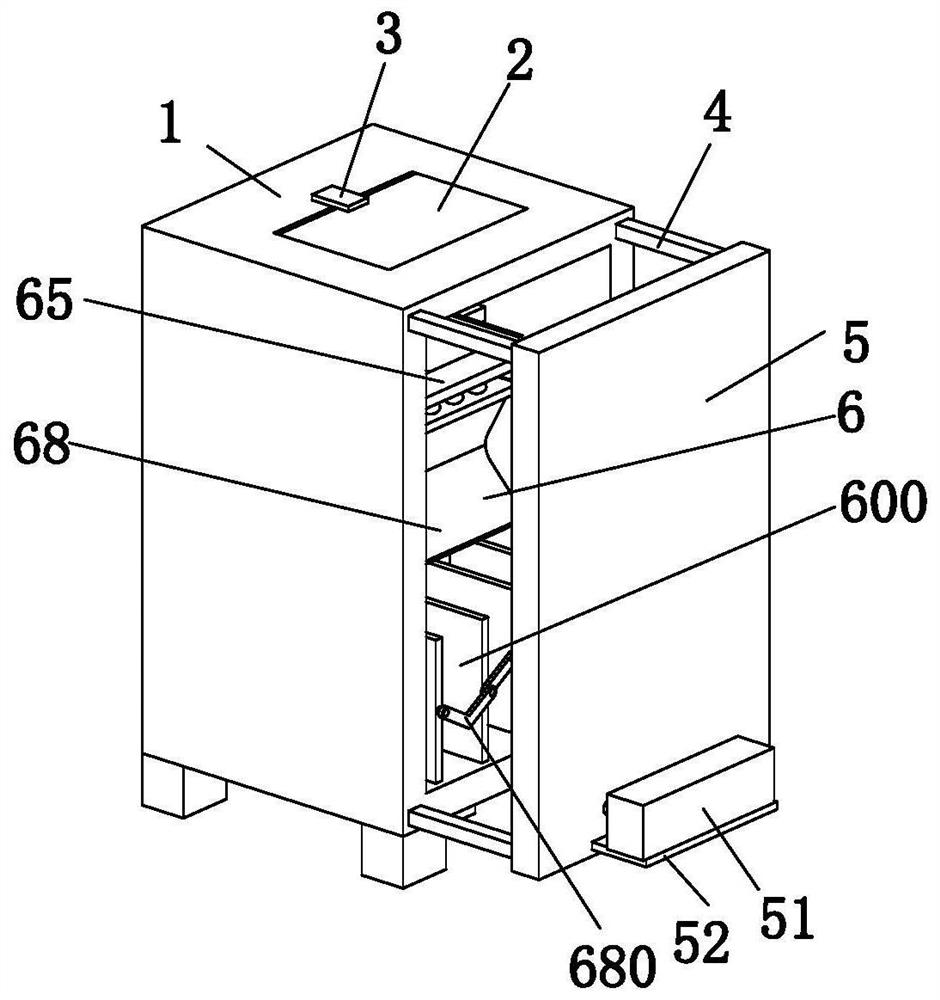

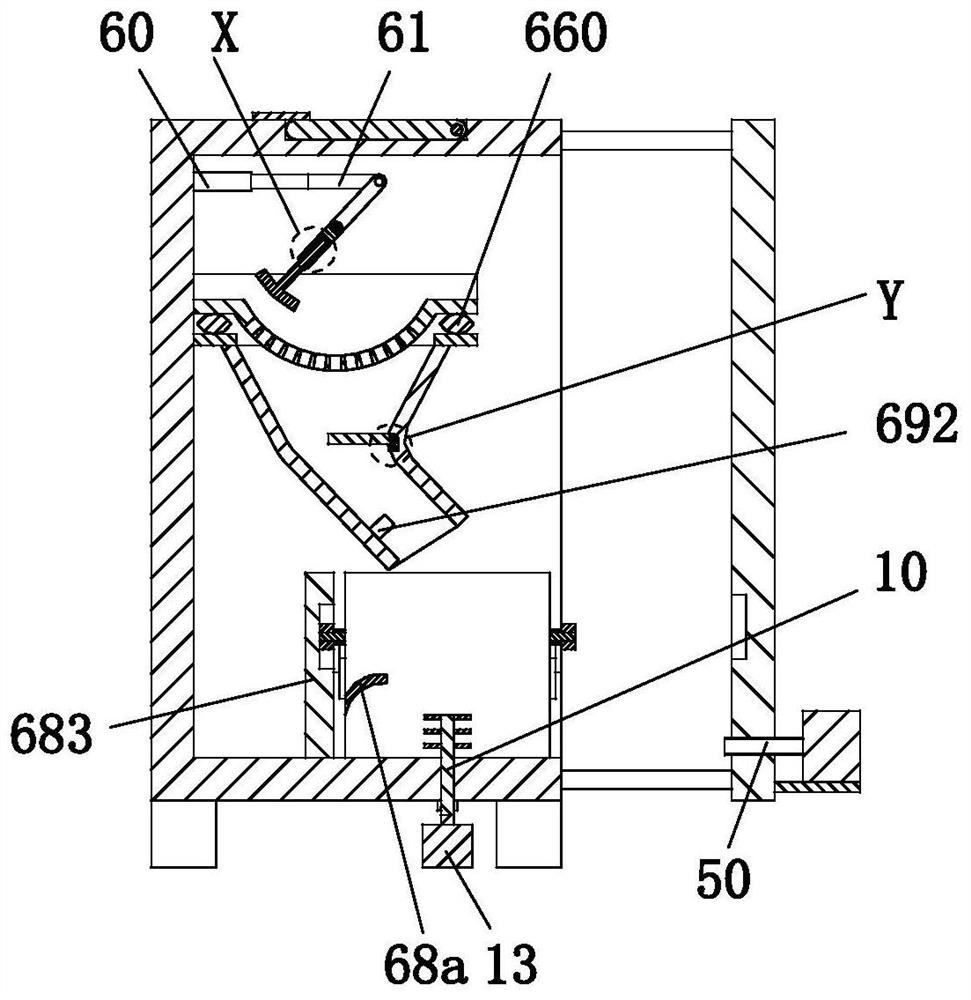

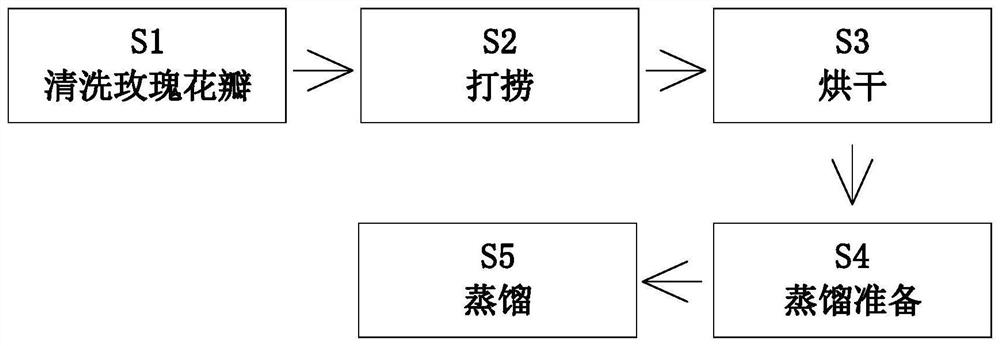

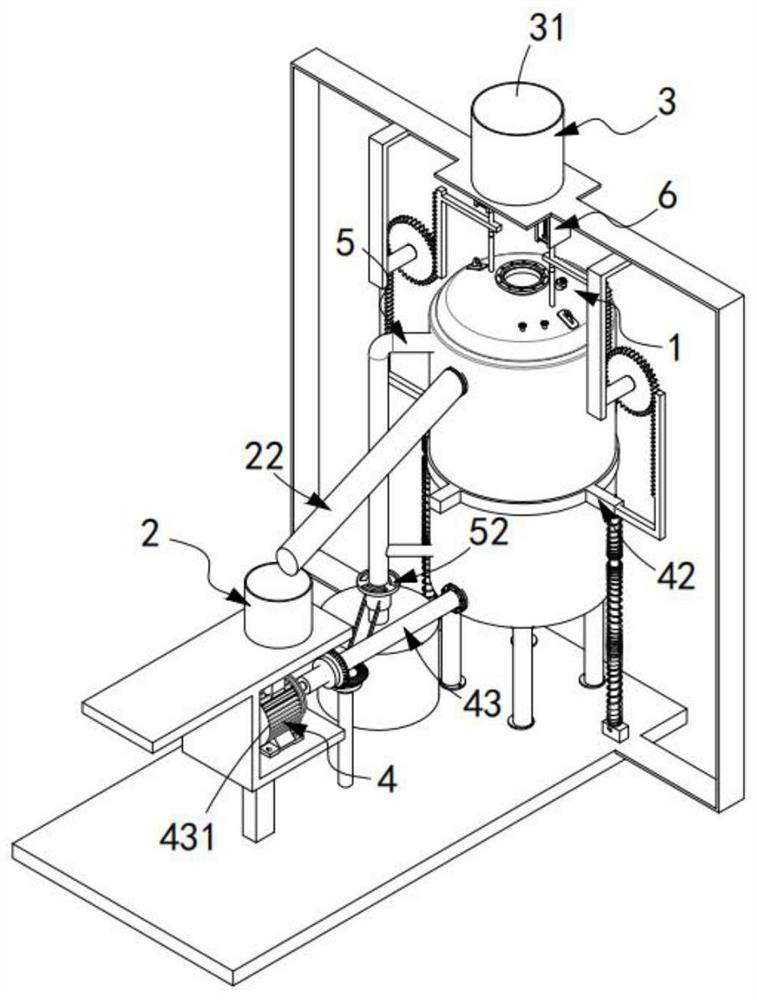

Preparation method of plant essential oil for acne-removing and whitening skin care products

ActiveCN112500931ASpeed up dryingAvoid over dryingEssential-oils/perfumesEssence oilEnvironmental geology

The invention relates to a preparation method of plant essential oil for acne-removing and whitening skin care products. A preparation device of plant essential oil foracne-removing and whitening skincare products is used. The preparation device of plant essential oil for acne-removing and whitening skin care products comprises a cleaning mechanism and a preparation mechanism, the lower end of the cleaning mechanism is installed on the existing working ground, the preparation mechanism is arranged on the right side of the cleaning mechanism, and the lower end of the preparation mechanism is connected with the existing working ground. Rose essential oil needed in the acne-removing and whitening skin care product essence is prepared by adopting the design concept of a cleaning and drying distillation integrated structure; the arranged cleaning mechanism can stir and clean the rose petals through intermittent steering vortexes, the rose petals and stirring rods are arranged in a separated mode, the phenomenon of large-area fragmentation of the rose petals can be avoided, then the full utilization degree of the rose petals is increased, and the rose petals can be conveniently and rapidly fished; and the preparation mechanism can realize closed drying and distillation of the rose petals.

Owner:上海丽舒丹医药科技有限公司

A comprehensive treatment system and treatment method for harmless and resourceful aluminum ash

ActiveCN109647853BEliminate Hazardous Waste CharacteristicsEasy to controlSolid waste disposalHazardous substanceProcess engineering

Owner:郑州鸿跃环保科技有限公司

Fluffing device with anti-splashing function for regenerated fiber production

ActiveCN112442763AWith anti-splash functionEasy to put inFibre cleaning/opening machinesFiberMechanical engineering

The invention provides a fluffing device with an anti-splashing function for regenerated fiber production. The fluffing device with the anti-splashing function for regenerated fiber production comprises a box body and a telescopic air cylinder, wherein a mounting groove is formed in the bottom of the inner wall of the box body; and the telescopic air cylinder is arranged in the mounting groove. The fluffing device with the anti-splashing function for regenerated fiber production has the advantages that raw materials above a second baffle can be conveniently fed between a fixing ring and fluffing covers on the two sides, and fluffing treatment of the raw materials is facilitated; meanwhile, the phenomena of splashing and flying out of the materials during feeding in the fiber fluffing process are effectively avoided, and full utilization rate of limiting resources is improved; and the fluffing covers rotate and swing while conveniently swing the regenerated fibers on the inner side leftwards, rightwards, upwards and downwards, so that sufficient contact between the regenerated fibers on the inner side and the output end of the fluffy machine body in the middle is guaranteed, and meanwhile, the fluffy quality and uniformity degree of the regenerated fibers are improved.

Owner:颍上鑫鸿纺织科技有限公司

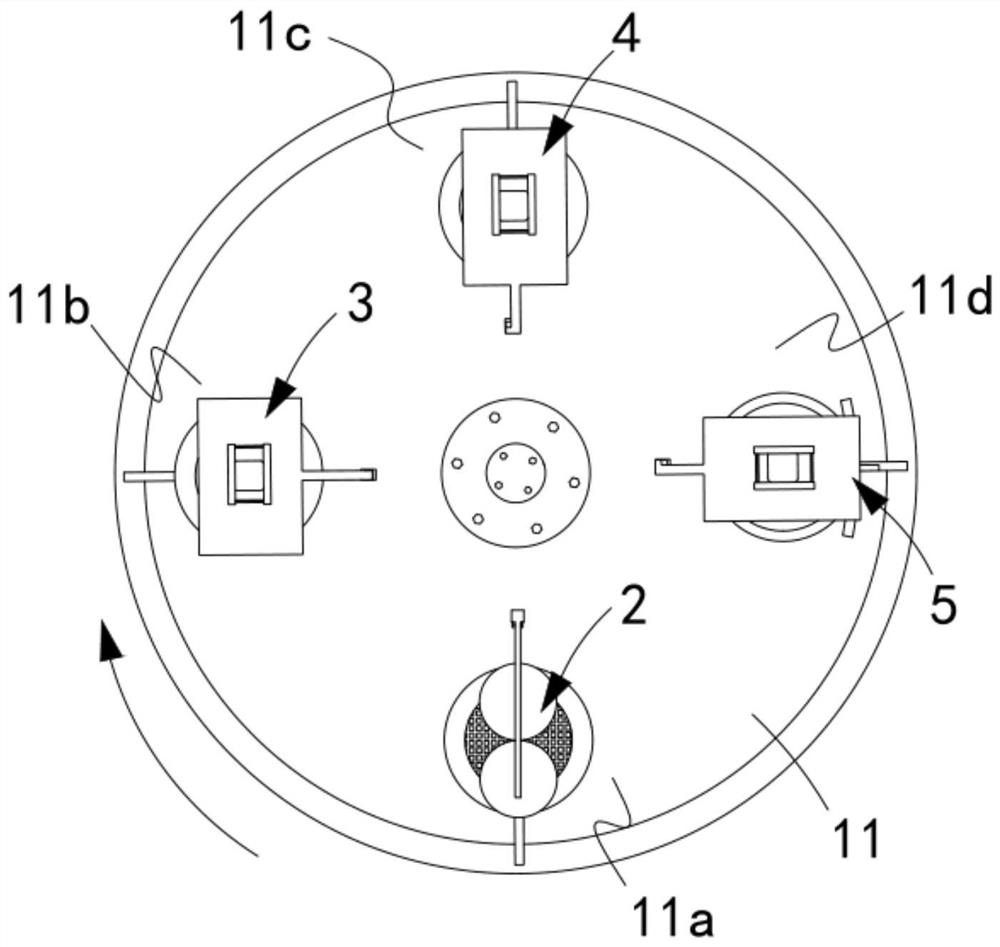

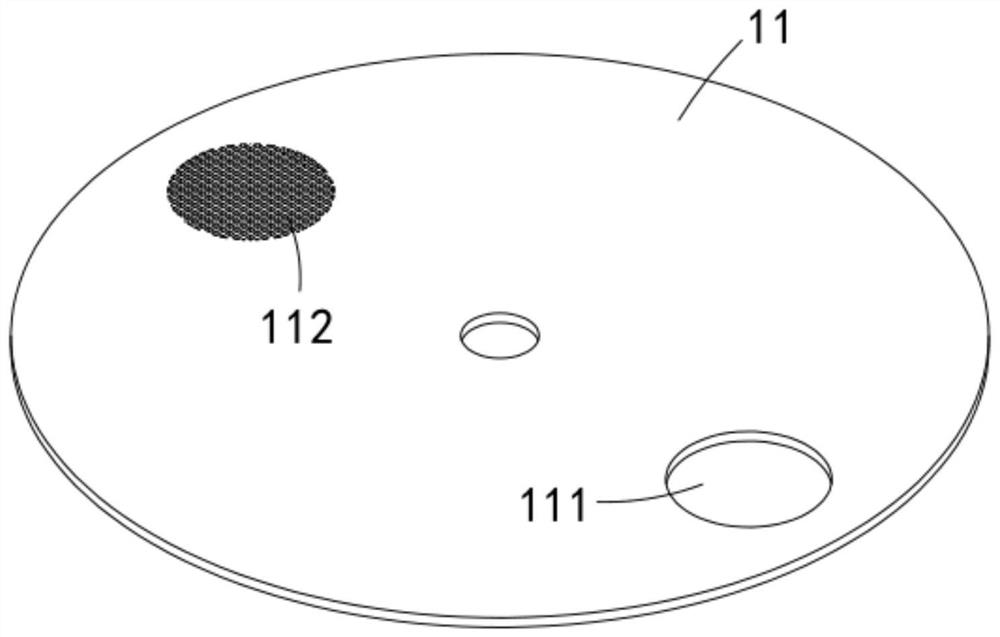

Graphite-organic compound combined artware production system

ActiveCN112157943AImprove full utilizationImprove surface propertiesShaping pressManufactured materialEngineering

The invention relates to a graphite-organic compound combined artware production system. The system comprises a driving mechanism, a feeding mechanism, a stirring mechanism, a static pressure mechanism, a coating mechanism and bearing mechanism, wherein the driving mechanism comprises a rotating disc and a driving part, the rotating disc is sequentially provided with a feeding station, a mixing station, a primary static pressure station and a coating station in the circumferential direction; the feeding mechanism is mounted on the rotating disc and located over the feeding station; the stirring mechanism is mounted on the rotating disc and is positioned over the mixing station; the static pressure mechanism is installed on the rotating disc and located over the primary static pressure station; the coating mechanism is installed on the rotating disc and located over the coating station; and the bearing mechanism comprises a fixing frame and a bearing assembly. The technical problem thatafter standing, small-particle-size compound particles precipitate to the bottommost layer, consequently, the raw material mixing and proportioning accuracy is affected, and meanwhile, redundant rawmaterials are wasted is solved.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

A processing device for preparing p-toluenesulfonyl chloride

ActiveCN112191216BReduce the temperatureImprove work efficiencyTransportation and packagingMixer accessoriesPhysical chemistryGasoline

The invention relates to a processing device for preparing p-toluenesulfonyl chloride, which includes a reaction kettle, a cleaning mechanism, a uniform dripping mechanism, a stirring mechanism and a gasoline transmission mechanism; the uniform dripping mechanism includes a water container, a first connecting pipe, and a control assembly And the pressure regulating assembly, the pressure regulating assembly is driven by the driving mechanism to move up and down in the vertical direction; the stirring mechanism includes the stirring assembly, the first transmission assembly and the driving assembly; the cleaning mechanism includes the cleaning assembly and the collecting assembly; the gasoline transmission mechanism includes the oil container and The second transmission component; the present invention solves the technical problem that in the process of hydrolysis reaction, water needs to be dropped from 70°C to 50°C in the reaction kettle to complete all the dripping work, but there are impurities in the reaction kettle and the reaction temperature is difficult to control.

Owner:湖州卓瑞化工科技有限公司

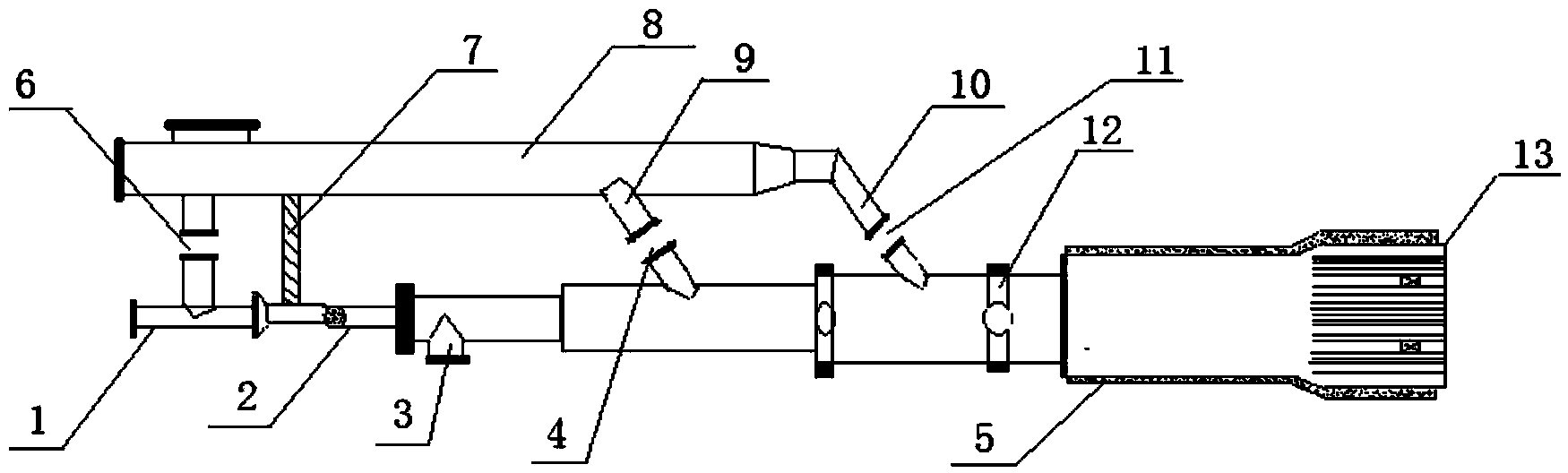

Converter gas and pulverized coal mixed combustion device

InactiveCN103672906AIncrease delivery speedBurn fasterBurnersRotary drum furnacesCombustionSurface layer

The invention relates to the mixed gas combustion technology, in particular to a converter gas and pulverized coal mixed combustion device. The converter gas and pulverized coal mixed combustion device comprises a main air flue, a spraying nozzle and a passageway structure. A protective layer is arranged on the outer surface layer of the spraying nozzle, the main air flue is stabilized through supporting columns, and the passageway structure is connected with the spraying nozzle through a connecting piece. The passageway structure is composed of a central air flue, a pulverized coal passageway, a converter gas inlet, a rotational-flow air flue and an axial-flow air flue. One end of the axial-flow air flue is connected with the tail end of the main air flue, and the other end of the axial-flow air flue is connected with the position, close to the spraying nozzle, of the passageway structure. The pulverized coal passageway is arranged between the central air flue and the converter gas inlet. The central air flue is arranged at the tail end, opposite to the spraying nozzle, of the passageway structure and connected with the main air flue. The rotational-flow air flue is arranged on the portion, behind the converter gas inlet, of the passageway structure and connected with the main air flue. The combustion speed of a rotary kiln is broken through, the heat value is improved, the temperature of the head of the rotary kiln is raised, the temperature of the tail of the rotary kiln is lowered, and the pulverized coal conveying speed and the pulverized coal combustion speed are increased, and cost is reduced.

Owner:GUIZHOU ANKAIDA IND

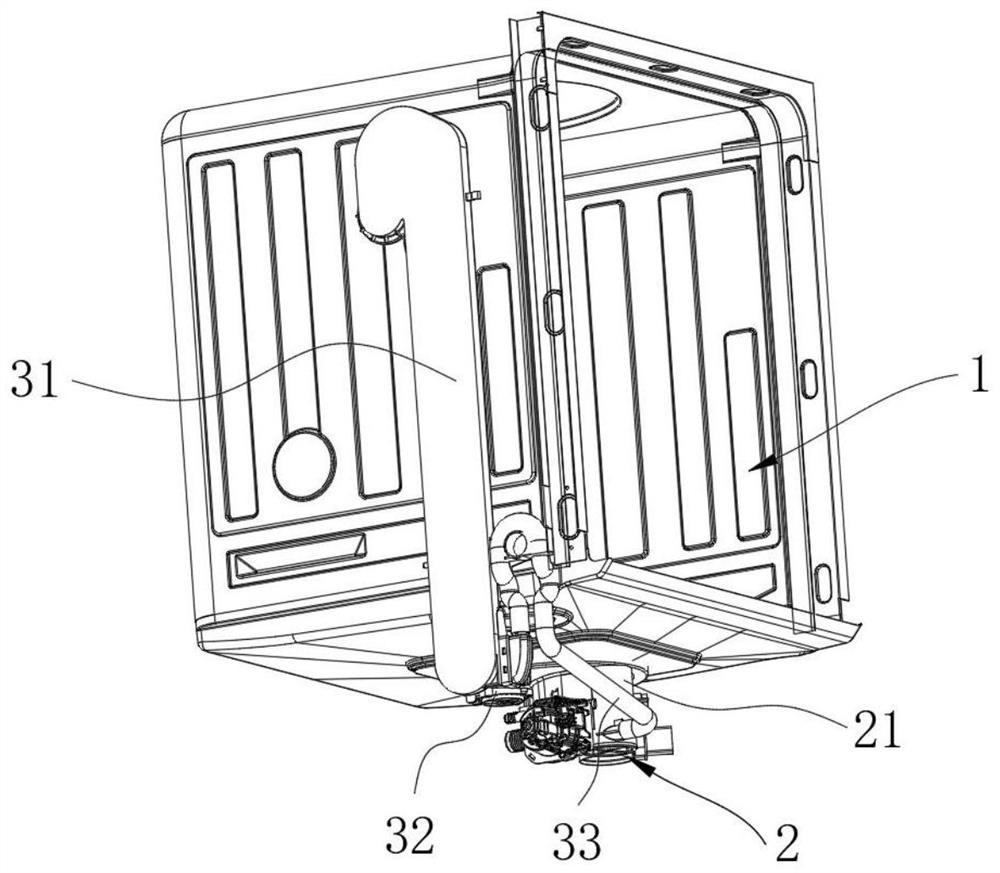

Internal circulation drying system for dish washing machine

PendingCN114081417AAvoid secondary pollutionRealize the drying functionTableware washing/rinsing machine detailsThermodynamicsWater vapor

The invention discloses an internal circulation drying system for a dish washing machine. The system comprises: an inner container, wherein a wind outlet is formed in the side wall of the inner container; a water cup provided with a water collecting cavity and a water chamber, wherein the water collecting cavity is communicated with the inner container, the water chamber is provided with a gas inlet hole and a gas permeable hole which are respectively communicated with the water chamber, and the gas permeable hole is communicated with the inner container and / or the water collecting cavity; and a wind channel assembly comprising a condensation wind channel and a gas conveying device, wherein the two opposite ends of the condensation wind channel communicate with the gas outlet and the gas inlet hole correspondingly, and the gas conveying device is arranged on the condensation wind channel or arranged between the condensation wind channel and the gas inlet hole. According to the invention, wet and hot gas is internally circulated, and a water chamber is additionally arranged in the circulating drying system for ventilation to condense water vapor of the wet and hot gas, so that the drying function is achieved while the problem that condensed water appears when the gas is exhausted out of the inner container is solved.

Owner:VATTI CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com