Sunlight control coating system with layer-side neutral reflection color and glass unit

A coating system and solar technology, applied in the field of glass parts, can solve the problems of unsightly and unsatisfactory vision, and achieve the effect of improving full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

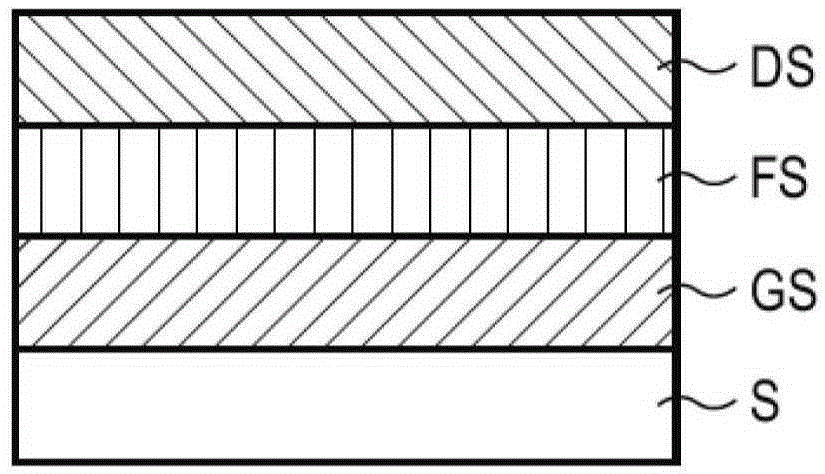

[0058] Solar control coating systems according to the prior art ( figure 1 ) looking upwards from the substrate S (6 mm thick glass) comprising the following coatings: Si 3 N 4 Composition of the underlying GS, layer thickness in the range of 9 to 17nm is composed of chromium carbide CrN x The composed functional layer FS and the top layer DS also composed of Si3N4 have a layer thickness in the range of 18 to 54 nm. This coating system achieves as Figure 4 The stated color values and resistance values of greater than 1000 Ω therefore classify the coating system according to the prior art as non-conductive.

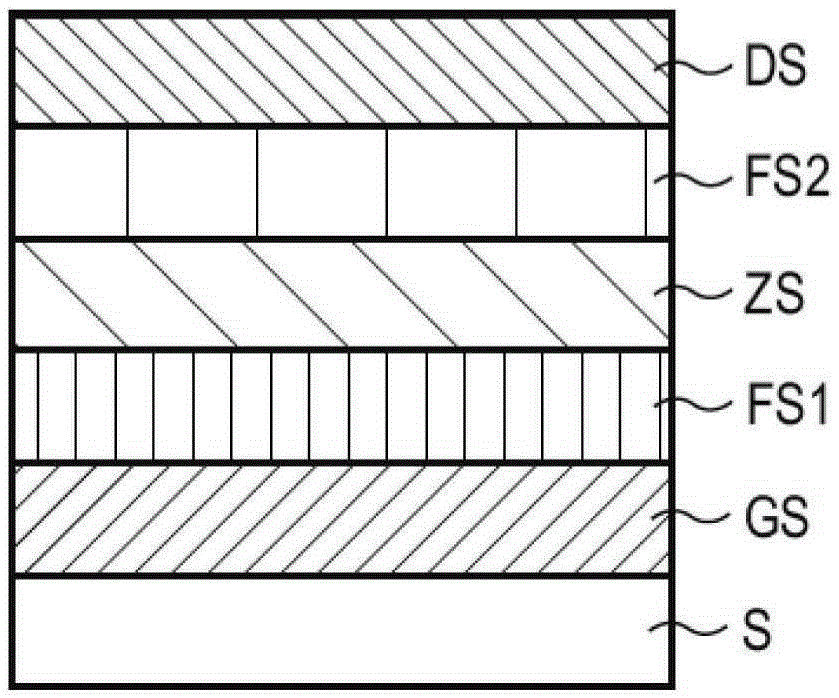

[0059] According to the first embodiment of the coating system of the present invention ( figure 2 ), on a glass substrate S with a thickness of 6 mm, the Si 3 N 4 Composition of the underlying GS. Immediately above it is a nickel-chromium nitride (NiCrN x ) or chromium carbide (CrN x ) composed of the first functional layer FS1. Arranged directly above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com