Internal circulation drying system for dish washing machine

A technology of drying system and dishwasher, which is applied in the washing machine/rinsing machine of tableware, parts and applications of washing machine/rinsing and rinsing machine of tableware, etc. It can solve the problems of unfavorable energy saving, secondary pollution of tableware, and affecting drying efficiency, etc. , to achieve the effect of improving full utilization, preventing secondary pollution, and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

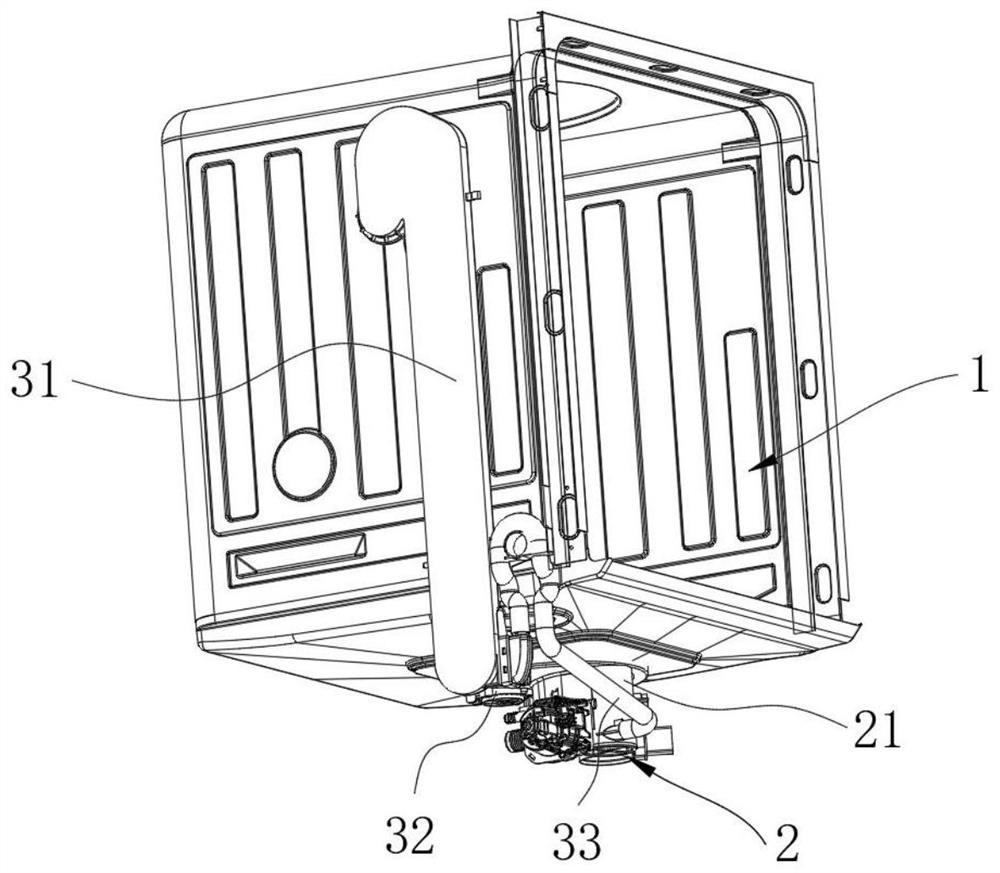

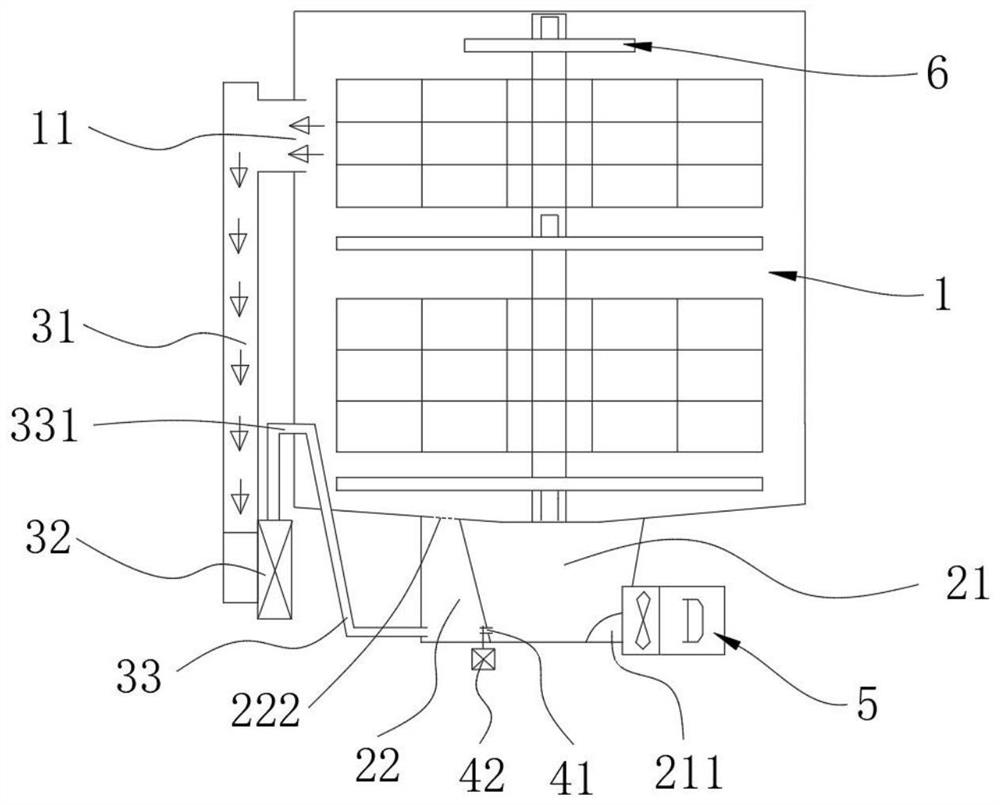

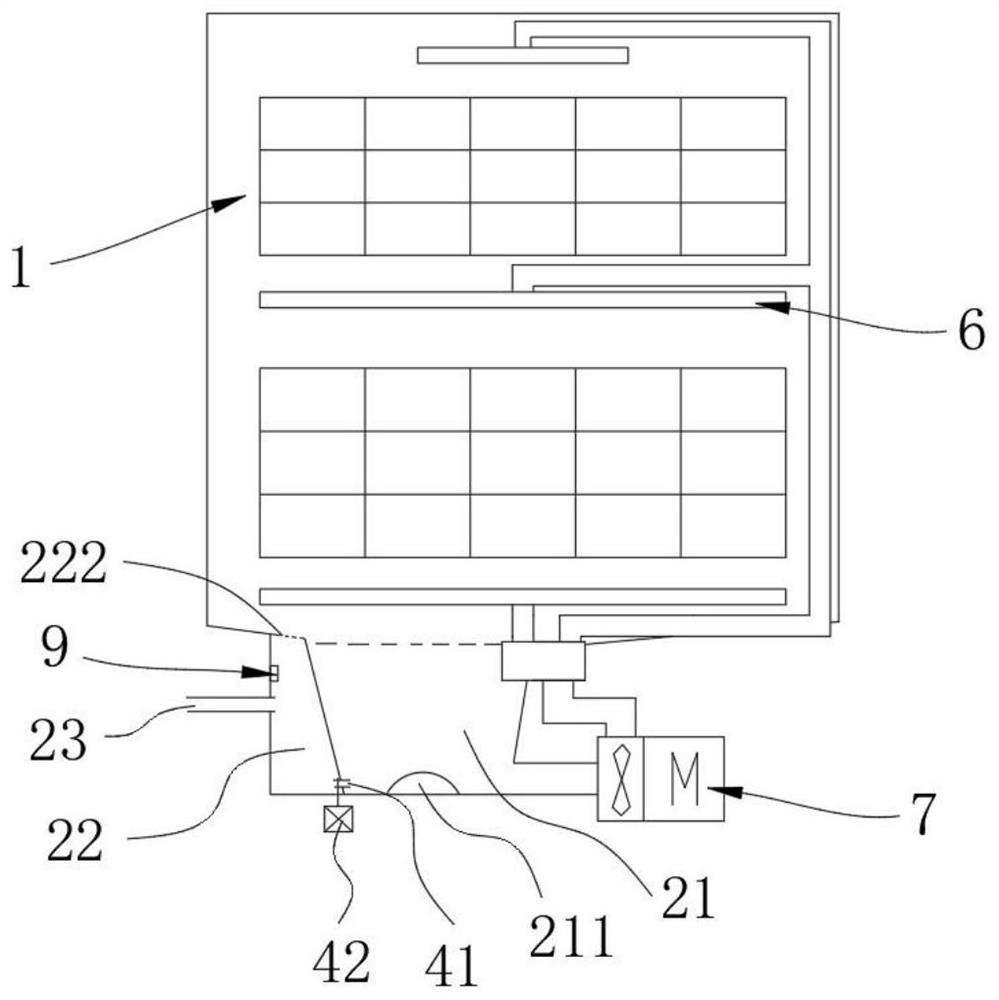

[0035] refer to figure 1 , this embodiment provides an internal circulation drying system for a dishwasher, including an inner container 1, a water cup 2, an air duct assembly (not shown in the figure) and a controller (not shown in the figure). The side wall of the inner liner 1 is provided with an air outlet 11 through which hot and humid gas passes. The water cup 2 is arranged at the bottom of the inner container 1 and is provided with a water collection chamber 21 and a water chamber 22 , and the water collection chamber 21 is connected to the inner container 1 . The water chamber 22 has an air intake hole 221 and a vent hole 222 respectively communicating with it, the vent hole 222 is used for air and / or water to pass through, and the vent hole 222 communicates with the inner tank 1 and / or the water collection chamber 21, that is, the water chamber 22 The vent hole 222 of the water chamber 22 can directly only communicate with the inner bag 1, or the vent hole 222 of the...

Embodiment 2

[0059] refer to Image 6 , The difference between this embodiment and Embodiment 1 is that a water vapor isolation structure 8 is provided in the water chamber 22 , and the water vapor isolation structure 8 is located above or below the vent hole 222 . Thus, through the water vapor isolation structure 8, the water content of the gas flowing from the vent hole 222 to the inner container 1 can be reduced, and the drying effect can be further improved.

[0060] Specifically, the water vapor isolation structure includes a water vapor isolation net 81, and the water vapor isolation net 81 can be arranged in the water chamber 22 and between the air inlet 221 and the air vent 222, or attached to the bottom of the air vent 222, or arranged on the air vent 222. Between the hole 222 and the liner 1 .

[0061] When the water vapor isolation net 81 is arranged in the water chamber 22, the water vapor isolation net 81 is arranged in the water chamber 22, and it divides the water chamber 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com