A comprehensive treatment system and treatment method for harmless and resourceful aluminum ash

A comprehensive treatment and recycling technology, which is applied in the harmless and resourceful comprehensive treatment system of aluminum ash and its treatment field, can solve the problems of secondary pollution of the environment, inability to obtain aluminum ash components, incomplete treatment, etc., and achieve simple system , beneficial to the long cycle, avoiding the effect of adding use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

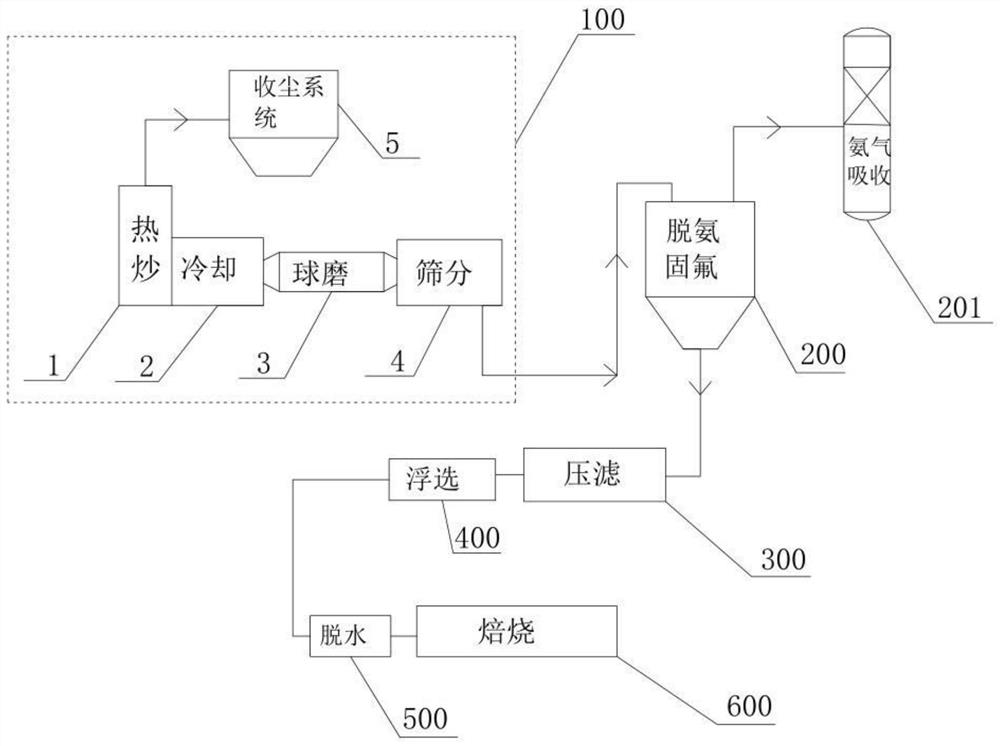

[0042] A comprehensive treatment system for harmless and resourceful aluminum ash, such as figure 1 As shown, the system includes a frying system 1, a cooling system 2, a ball milling system 3, a screening system 4, a deammonization and fluorine fixing system 200, a filter press system 300, a flotation system 400, a dehydration system 500 and a roasting system 600, each Transport between systems through material conveying system or conveyor belt;

[0043] The system also includes a dust collection system 5, the dust collection system 5 communicates with the hot frying system 1; the system also includes an ammonia gas absorption system 201, and the ammonia gas absorption system 201 is connected to the deammonization and fluorine fixing system 200 through a gas delivery pipeline. connected.

[0044] Using this system: the collected aluminum ash is first fried in the hot frying system (the flue gas generated during the hot frying process enters the dust collection system through...

Embodiment 2

[0047] One of the comprehensive treatment methods for harmless recycling of aluminum ash, the method comprises the following steps:

[0048] (1) Metal extraction

[0049] Using a conventional frying ash separation system, the collected aluminum ash is heated, cooled, ball milled, and sieved to obtain bulk aluminum, aluminum particles and secondary aluminum ash (the recovery rate of metal aluminum is ≥90%);

[0050] The average particle size of the secondary aluminum ash is 200-300 meshes; the main components of the secondary aluminum ash are mainly 35% of alumina, 17% of chloride salt, 30% of aluminum nitride, 3% of electrolyte, 15% of metal aluminum, Heavy metals and heavy metal oxides 0%.

[0051] (2) Deamination

[0052] Stirring and leaching the secondary aluminum ash obtained in step (1) in hot water at 50°C for 8 hours, after the reaction is completed, collecting the generated ammonia gas, and recovering the remaining slurry after the ammonia gas is generated;

[0053...

Embodiment 3

[0063] A second method for harmless and resourceful comprehensive treatment of aluminum ash, the method includes the following steps:

[0064] (1) Metal extraction

[0065] Using a conventional frying ash separation system, the collected aluminum ash is heated, cooled, ball milled, and sieved to obtain bulk aluminum, aluminum particles and secondary aluminum ash (the recovery rate of metal aluminum is ≥90%);

[0066] The average particle size of the secondary aluminum ash is 200-300 mesh; the main components of the secondary aluminum ash are mainly 60% of alumina, 15% of chloride salt, 14% of aluminum nitride, 5% of electrolyte, 5% of metal aluminum, Heavy metals and heavy metal oxides 1%.

[0067] (2) Deamination

[0068] Stirring and leaching the secondary aluminum ash obtained in step (1) in hot water at 80°C for 4 hours, after the reaction is completed, collecting the generated ammonia gas, and recovering the remaining slurry after the ammonia gas is generated;

[0069]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com