Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Improve fracturing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid clean fracturing fluid and preparation method thereof

InactiveCN101812290AImprove fracturing efficiencyImprove fracturing effectDrilling compositionInorganic saltsAcid fracturing

The invention relates to acid clean fracturing fluid and a preparation method thereof. The acid clean fracturing fluid consists of the following components in percentage by mass: 2 to 6 percent of surfactant, 1 to 4 percent of inorganic salt, 0.05 to 0.15 percent of counter-ion salt, 0.1 to 0.3 percent of cosolvent, 2 to 10 percent of acid and the balance of water. The method comprises the following steps of: dissolving the surfactant in the acid to prepare uniform liquid; adding the liquid into aqueous solution containing the inorganic salt, the counter-ion salt and the cosolvent; and stirring the mixture for 1 to 2 minutes to obtain the fluid having good viscoelasticity. The acid clean fracturing fluid is used for the fracturing of oil-gas fields at the temperature of between 60 and 120 DEG C, has the advantages of low viscosity, high elasticity, low friction resistance, high sand carrying, high effective control joints, increment on joint length and the like, can realize sand acid fracturing and finish all processes of acid fracturing and acidification, and has no residues after gel breaking and no damage to stratums.

Owner:SHAANXI UNIV OF SCI & TECH

Method for realizing temporary plugging redirecting multiple crack fracturing inside horizontal well section

ActiveCN105672970ADegradable volume fractionTemporarily blocked fastFluid removalDrilling compositionFiberViscosity

The invention relates to a method for realizing temporary plugging redirecting multiple crack fracturing inside a horizontal well section. The method comprises the following steps: firstly preparing a temporary plugging redirecting working liquid which includes a degradable temporary plugging agent, degradable fibers, and a low-viscosity transport liquid; conducting sectional fracturing, and conducting pump casting in an order of a preset liquid-a sand carrying fluid-the temporary redirecting working liquid; and after the completion of the entire fracturing, waiting for the temporary redirecting working liquid to degrade, and discharging the temporary redirecting working liquid. According to the method, plugging efficiency is increased through the adoption of the multiple dimension degradable temporary plugging agent, leakage loss among inter-crack liquid is reduced, and plugging success rate is increased. After construction, the degradable temporary plugging agent, and the degradable fibers are completely degraded under well bottom temperature, leave no residue and produce no pollution to artificial cracks. The method of the invention is conducive to rapid plugging of cracks, increases success rate of temporary plugging redirecting fracturing, reduces construction cost, and increase oil and gas reservoir recovery efficiency.

Owner:PETROCHINA CO LTD

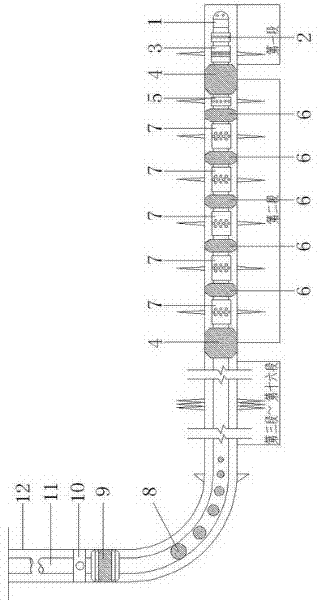

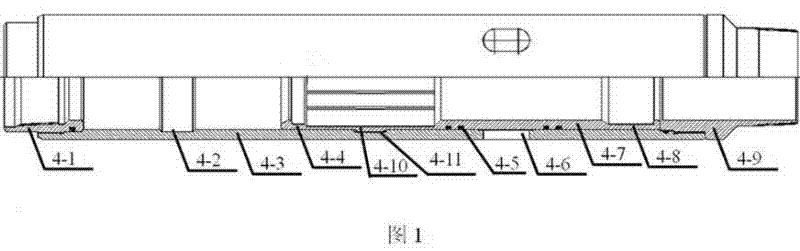

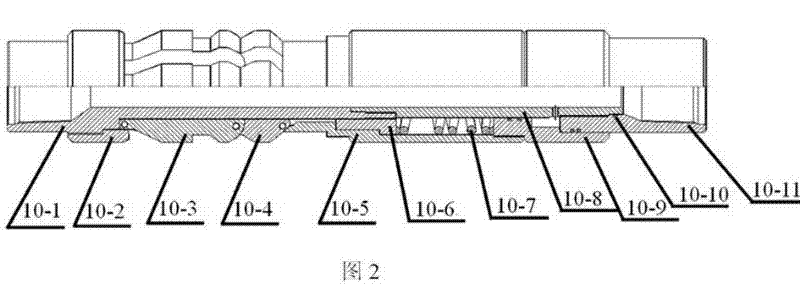

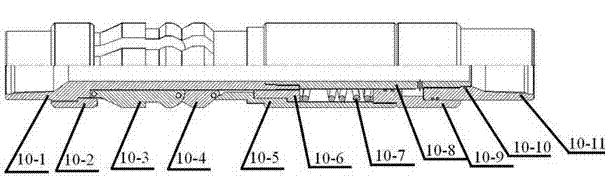

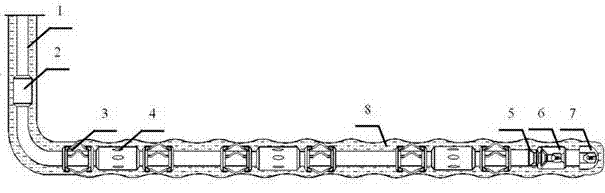

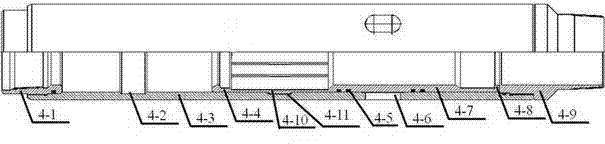

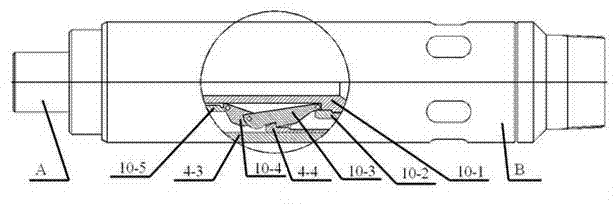

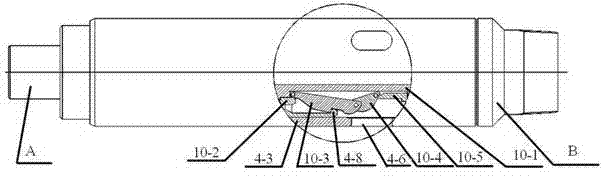

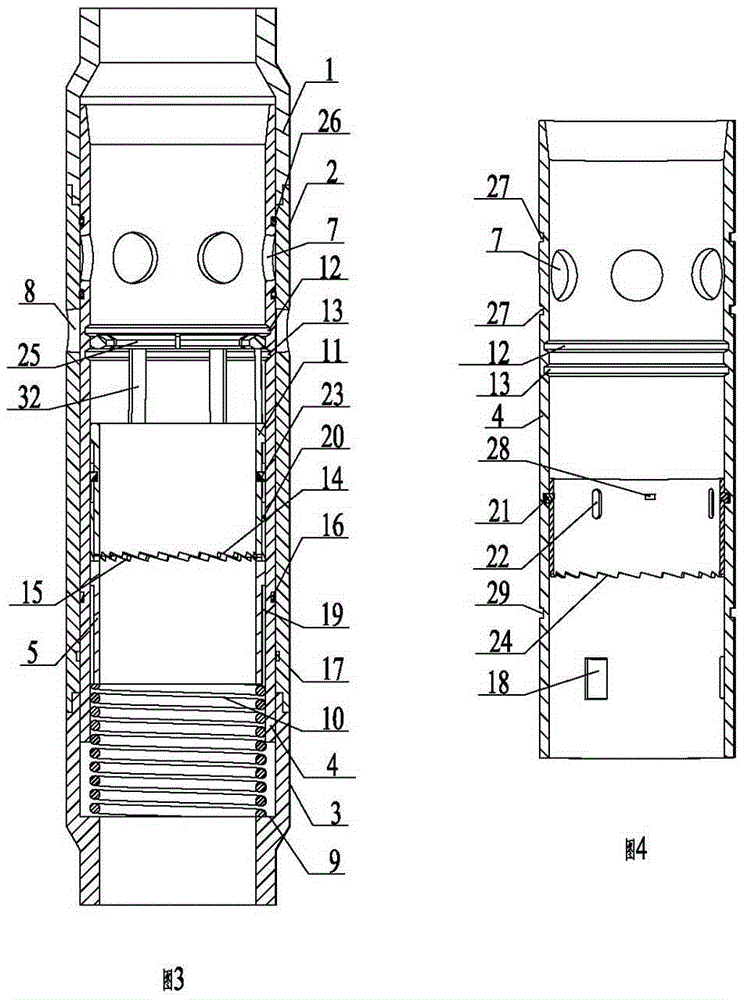

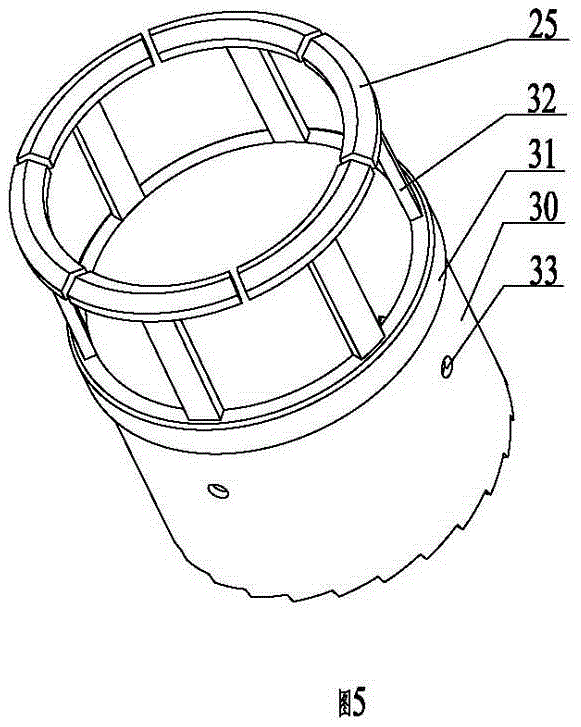

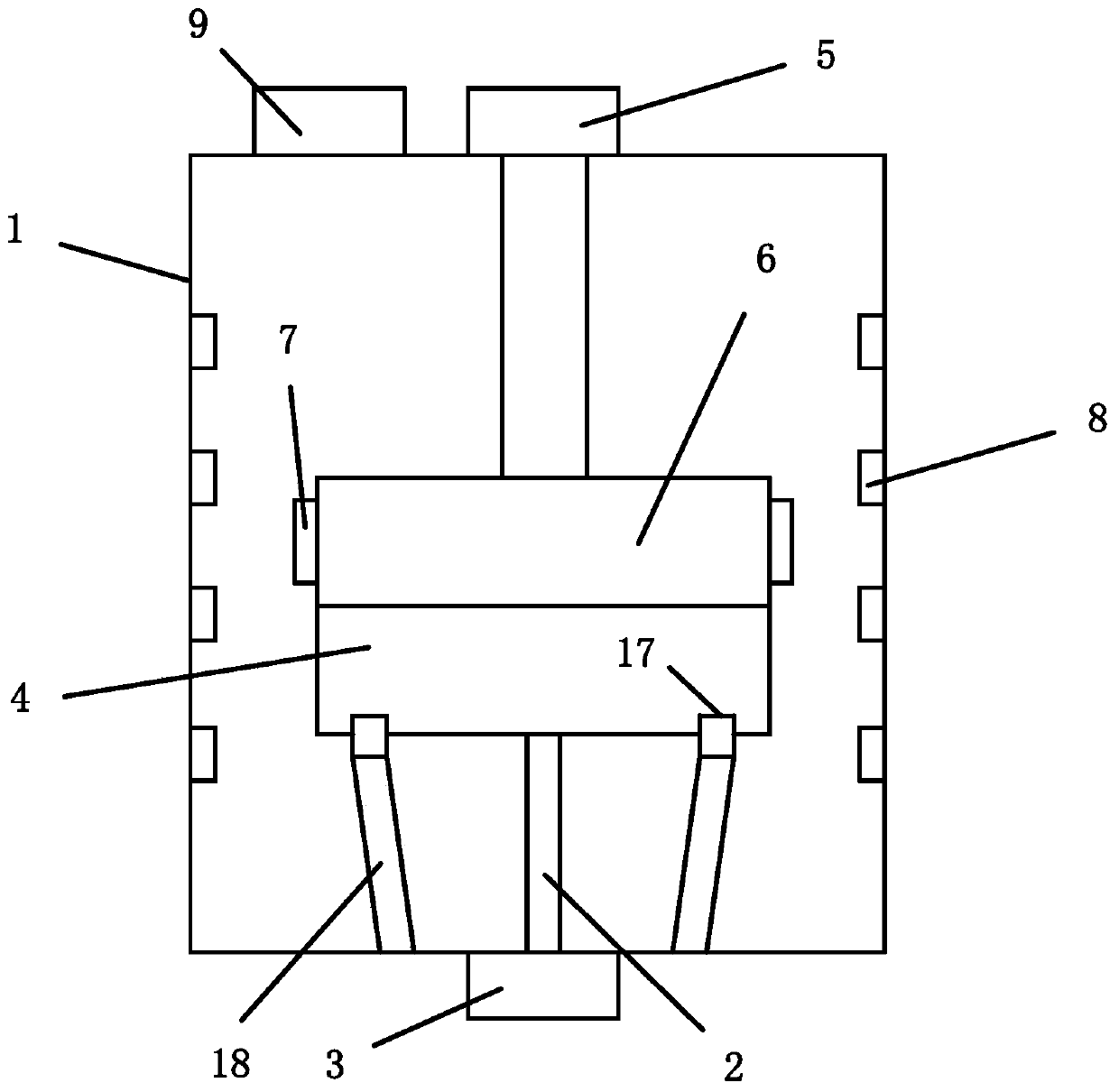

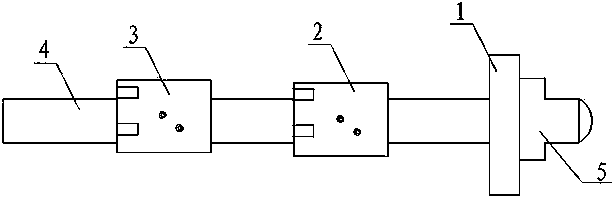

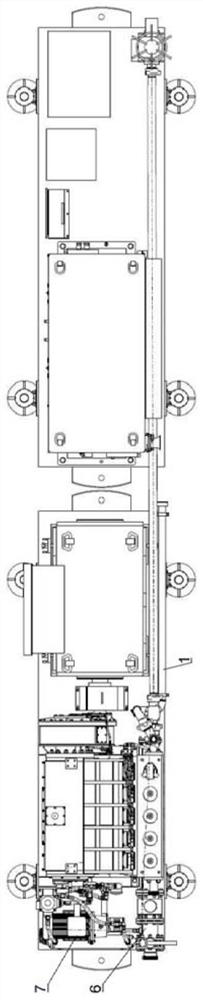

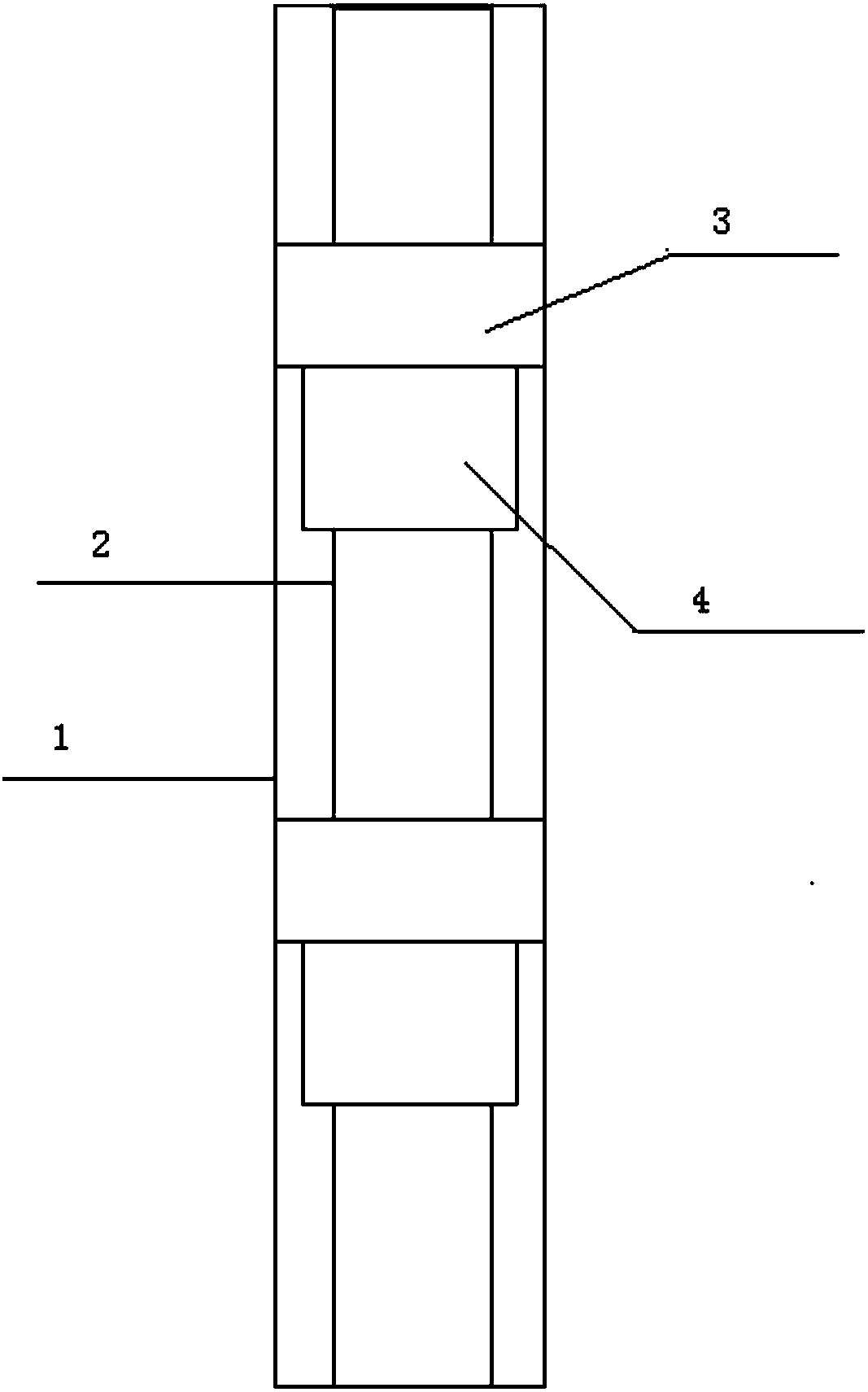

High-efficiency fracturing combined device for multi-stage horizontal well

The invention relates to a special underground tool for conventional oil gas, shale gas and coal bed gas, in particular to a high-efficiency fracturing combined device for a multi-stage horizontal well. The high-efficiency fracturing combined device comprises an open hole packer, a high-efficiency fracturing sliding bush, a small open hole packer, a ball fracturing sliding bush and the like; the first section is provided with a conventional fracturing device; and the second section is provided with the high-efficiency fracturing combined device which has the same structure as high-efficiency fracturing combined devices from the third section to the sixteenth section. An upper joint of the high-efficiency fracturing sliding bush is in threaded connection with a front connecting sliding bush; the lower end of the front connecting sliding bush is connected with the upper end of a middle connecting sliding bush; the lower end of the middle connecting sliding bush is connected with a back connecting sliding bush; the lower end of the back connecting sliding bush is screwed with a lower joint through threads; an upper step of a front baffle is matched with a lower step of the front connecting sliding bush; the lower end of the front baffle is contacted with the lower end of a back baffle; and the lower end of the back baffle is contacted with the upper end of a C-shaped ball seat. The high-efficiency fracturing combined device has high sealing property and high fracturing well completion efficiency, can realize multi-stage fracturing, and improves the technical level and economic benefit of a fracturing technology.

Owner:SOUTHWEST PETROLEUM UNIV

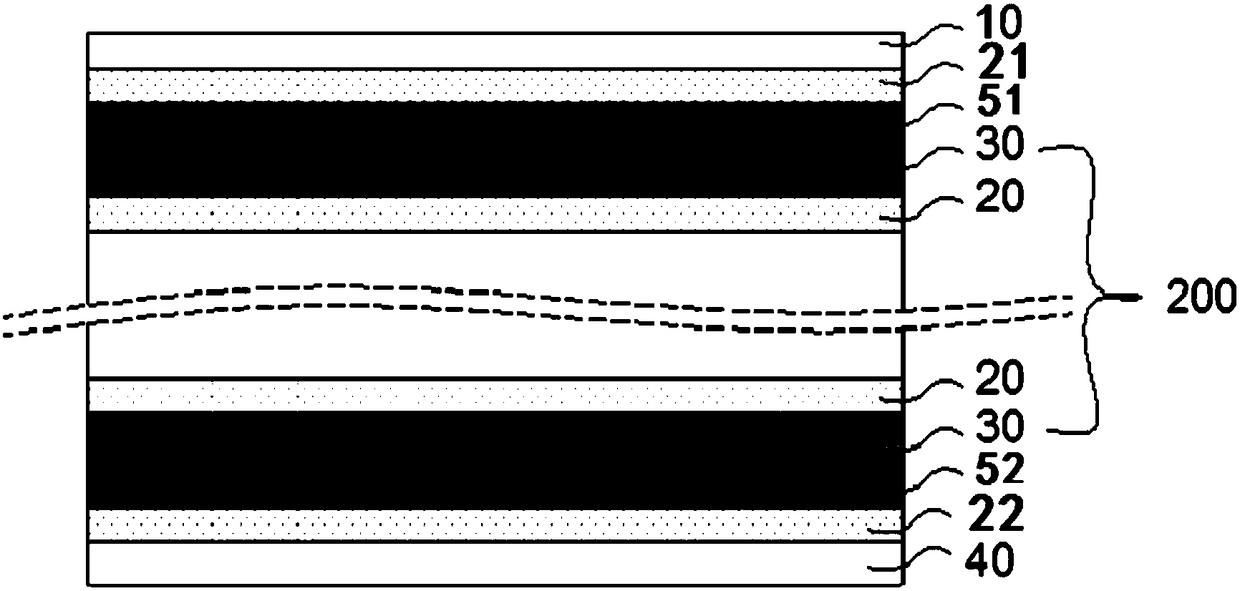

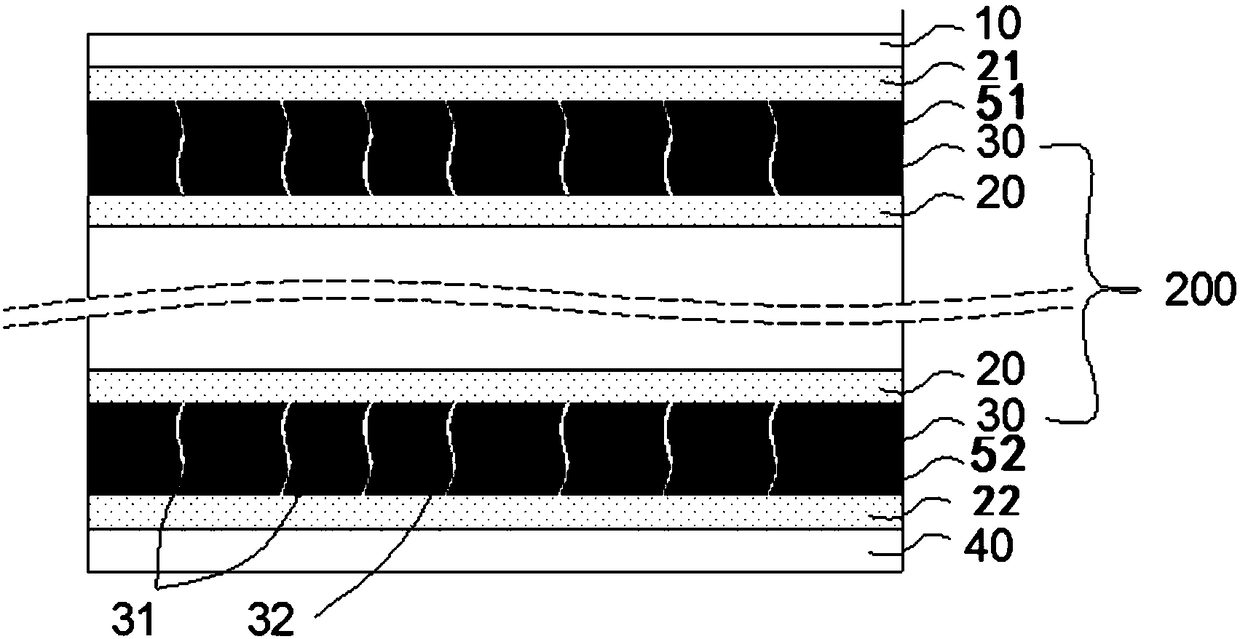

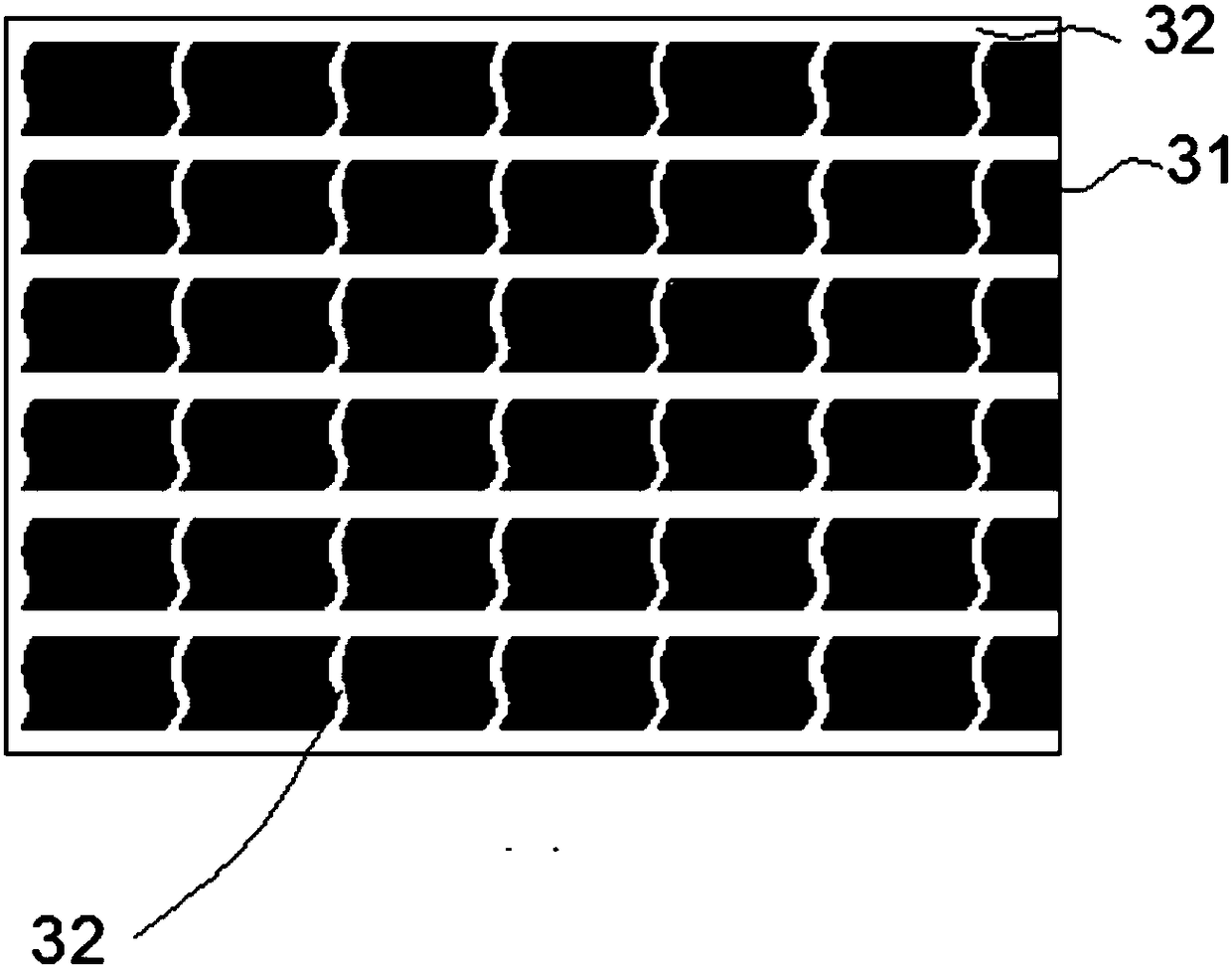

Magnetic isolation material and preparation method and application thereof

ActiveCN108430204AImprove shielding effectImprove thermal conductivityMagnetic/electric field screeningCircuit arrangementsTectorial membraneMagnetic isolation

The invention relates to the field of magnetic isolation material, and discloses a magnetic isolation material and a preparation method and application thereof. The magnetic isolation material comprises a magnetic layer and protective films and an off-type films arranged on different sides of the magnetic layer, wherein the magnetic layer comprises at least one magnetic material sheet layer. The magnetic material sheet layer comprises a plurality of magnetic material chips and the gap between the magnetic material chips are at least partially filled with air; a first glue layer is arranged between the protective film and the magnetic layer and a second glue layer is arranged between the off-type film and the magnetic layer. The preparation method overcomes the problems of complex preparation process of the magnetic isolation material in the prior art, and the prepared magnetic isolation material is with better performance.

Owner:苏州格优微磁磁材有限公司

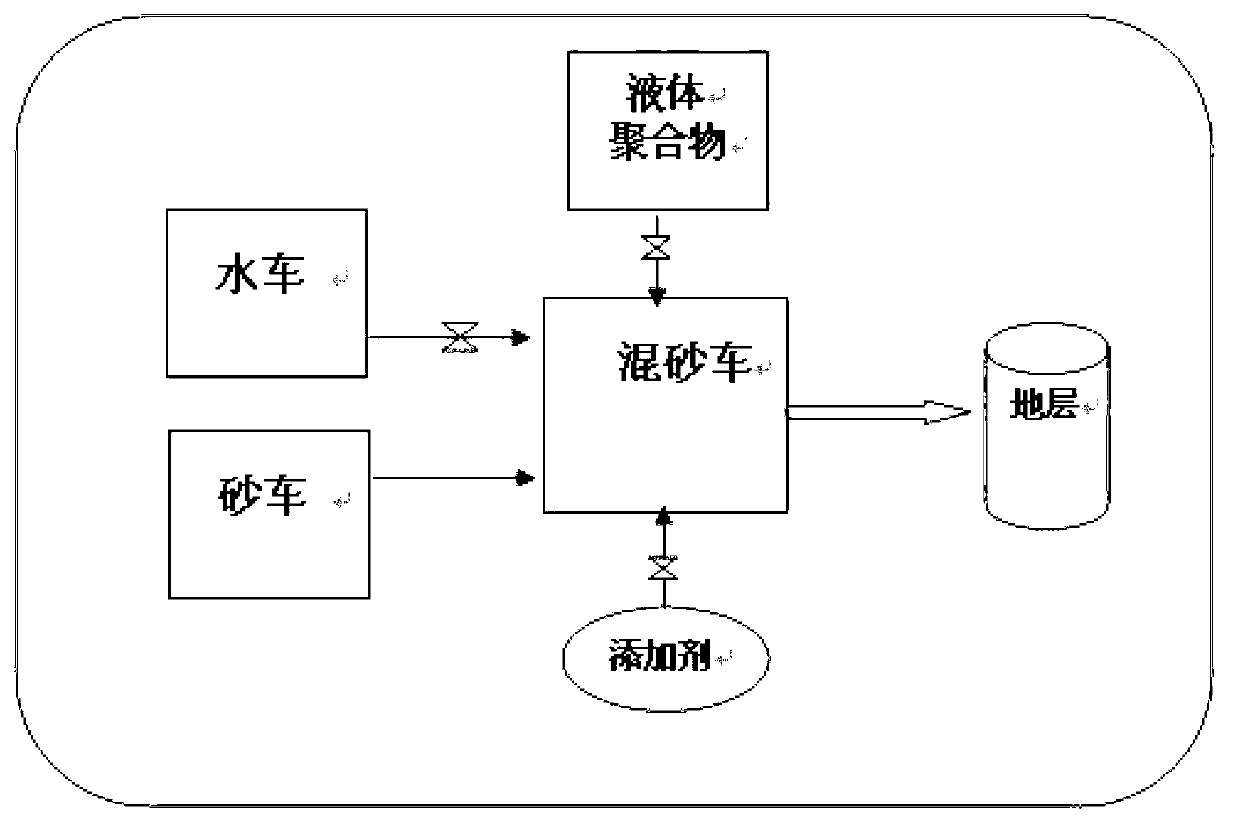

Fracturing process for online continuous preparation based on liquid polymer

InactiveCN102996107AQuality improvementReduce operating costsFluid removalDrilling compositionProcess engineeringMaterials science

The invention discloses a fracturing process for online continuous preparation based on a liquid polymer. The method comprises the steps of directly and proportionately pumping the high-content liquid polymer into a fracturing blender truck through a proportioning pump in an in-situ online adding manner; and adding water and propping agent into the liquid polymer, and mixing the water, the propping agent and a thickening polymer together proportionately under agitation of the fracturing blender truck, wherein the ratio of sand can be up to 15%-100% and even 250%. According to the method, the preparation does not need to be implemented in a liquid preparation station or a preparation pool, and the continuous preparation and construction can be achieved. The method closely combines preparation and construction, and truly fulfills the purposes of convenience in operation, reduction of construction costs, economization, environment protection, oil reservoir protection, yield increase, and efficiency enhancement.

Owner:SUNCOO PETROLEUM TECH

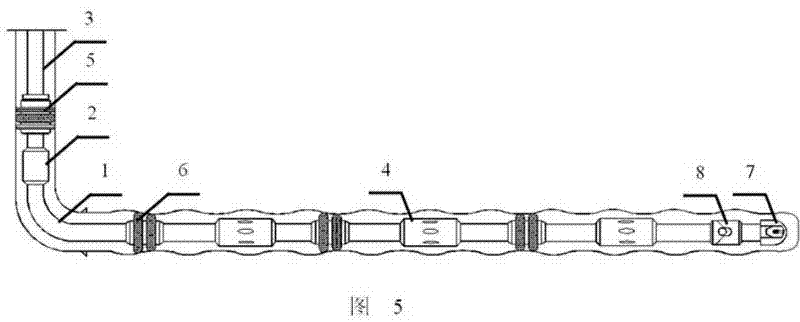

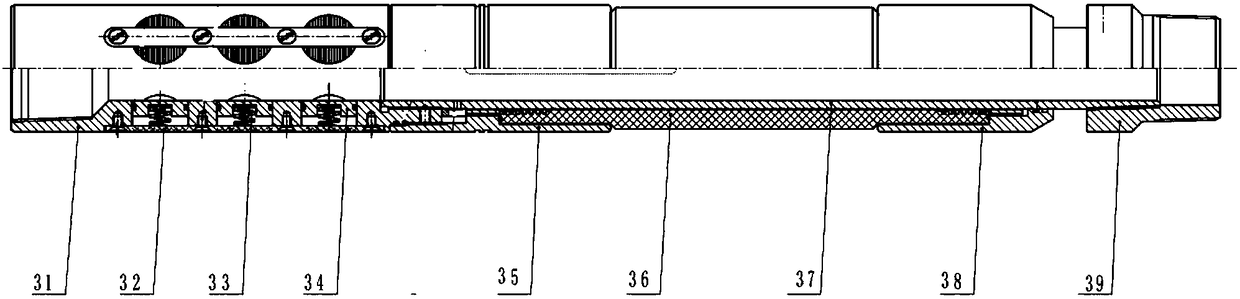

Open hole staged fracturing well completion pipe string provided with controllable valve and hydraulic control switching pipe string

ActiveCN102330546AIncrease the lengthLarge displacementFluid removalWell/borehole valve arrangementsHorizontal wellsCoiled tubing

The invention discloses an open hole staged fracturing well completion pipe string provided with a controllable valve and a hydraulic control switching pipe string, which are suitable for well completion processes of horizontal wells and straight wells. The hydraulic control switching pipe string is tripped to open and close the open hole staged fracturing well completion pipe string provided with the controllable valve, so that multilayer-section fracturing well completion construction is realized, and development requirements of low-permeability oil reservoirs and unconventional oil and gas resources are met. The pipe string is sequentially connected with a drill stem running tool, a top suspension packer, a hydraulic control switching retention cylinder, a switchable control valve, an open hole fracturing packer connected with the control valve, a shaft isolating valve and a bottom circulating valve from top to bottom by using a bushing. The hydraulic control switching pipe string comprises a hydraulic control switching tool and a continuous oil pipe; and a set of hydraulic control switching tool is connected to the bottom of the continuous oil pipe. The switchable control valve has the internal drift diameter of the same size; sand fracturing well completion can be performed on a stratum by using the bushing; and thus, requirements of large-displacement and large-scale fracturing reconstruction are met, the crack length, the crack number and the flow guide capacity are increased, and the production capacity and the recovery ratio are effectively increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Controlled-valve placed well-cementing staged-fracturing well-completion string and hydraulically-controlled switch string

ActiveCN102410009AIncrease the lengthLarge displacementFluid removalWell/borehole valve arrangementsHorizontal wellsWell cementing

The invention discloses a controlled-valve placed well-cementing staged-fracturing well-completion string and a hydraulically-controlled switch string, which are suitable to be applied to a well-completion process for horizontal wells and vertical wells, and through tripping in the hydraulically-controlled switch string to start and close the controlled-valve placed well-cementing staged-fracturing well-completion string, multi-layer-and-section fracturing well-completion construction is realized, thereby meeting the needs of development on low-permeability oil reservoirs and unconventional oil / gas resources. The controlled-valve placed well-cementing staged-fracturing well-completion string, from top to bottom, is sequentially connected with a hydraulically-controlled switch tool detention cylinder, a switchable control valve and hydraulic casing centralizers connected with the two ends of the switchable control valve, a pressed settling valve and a bottom circulating valve by using a casing; and at least a set of switchable control valve and hydraulic casing centralizers connected with the two ends of the switchable control valve are equipped in the string. The hydraulically-controlled switch string comprises hydraulically-controlled switch tools and a continuous oil pipe, and a set of hydraulically-controlled switch tool is connected to the bottom of the continuous oil pipe. The switchable control valves are same in inner drift diameter (same in size), and can carry out well completion on stratums through the sand fracturing of the casing, thereby satisfying the needs of large-displacement and large-scale fracturing reformation.

Owner:CHINA PETROLEUM & CHEM CORP +1

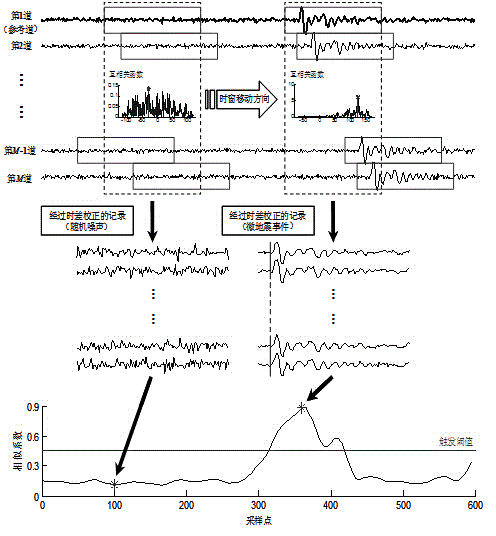

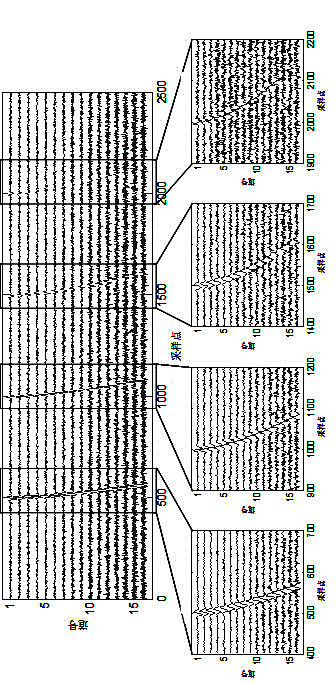

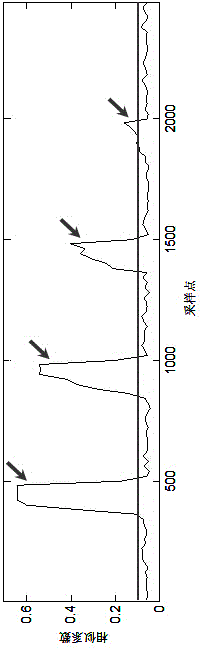

Automatic underground micro earthquake event identification method based on multichannel scanning superposition

InactiveCN106154324AImprove fracturing efficiencyIncrease success rateSeismic signal processingSeismology for water-loggingBackground noiseTime difference

The present invention provides a method for automatic recognition of downhole microseismic events based on multi-channel scanning and superposition, which includes: filtering original microseismic monitoring data collected in the field to remove noise interference ; select the sliding time window to divide the microseismic record into continuous multi-segment records; select one with high signal-to-noise ratio from the segmented records as the reference trace, and calculate the cross-correlation function between the reference trace and other traces to obtain trace time difference information; Use the time difference information to adjust the time window position of each channel to correct the time difference of the record; calculate the multi-channel similarity coefficient, and use the multi-channel similarity coefficient to detect microseismic events. The automatic identification method of downhole microseismic events based on multi-channel scanning superposition can effectively and automatically extract weak microseismic events from background noise, improve identification efficiency and greatly reduce the labor intensity of processing personnel.

Owner:中石化石油工程地球物理有限公司胜利分公司

Staged fracturing well completion method using hydraulic-controlled switch to open/close controllable valves

ActiveCN102373900AIncrease the lengthUnlimited number of fracturing stagesFluid removalWell/borehole valve arrangementsHorizontal wellsCoiled tubing

The invention relates to a staged fracturing well completion method using a hydraulic-controlled switch to open / close controllable valves, is used for staged fracturing well completion of sleeves in petroleum horizontal wells or vertical wells, and can meet the development demands of low-permeability reservoir and unconventional oil gas resources. The method comprises: arranging openable / closable control valves the number of which is corresponding to the layer stages required to be staged-fractured in a well in a fracturing well completion tubular pile, and installing the control valves in the well; connecting a set of hydraulic-controlled switch tool to the bottom by using a connecting oil pipe to obtain an operation tubular pile, and installing in the fracturing well completion tubular pile; and carrying out hydraulic control on the operation tubular pile, and opening / closing the selected openable / closable control valves in the fracturing well completion tubular pile by using the hydraulic-controlled switch so as to finish staged fracturing well completion construction of the sleeves in the well stage. The staged fracturing well completion method has the advantages that: controllable valves with maximum latus rectum can be used according to the specific condition of the well completion tubular pile; a set of hydraulic-controlled switch can realize opening / closing of multiple controllable valves; the fracturing stage number is not limited; sleeve sand fracturing well completion can be adopted in stratum; and the demands of large output and large-scale fracturing transformation can be met.

Owner:CHINA PETROLEUM & CHEM CORP +1

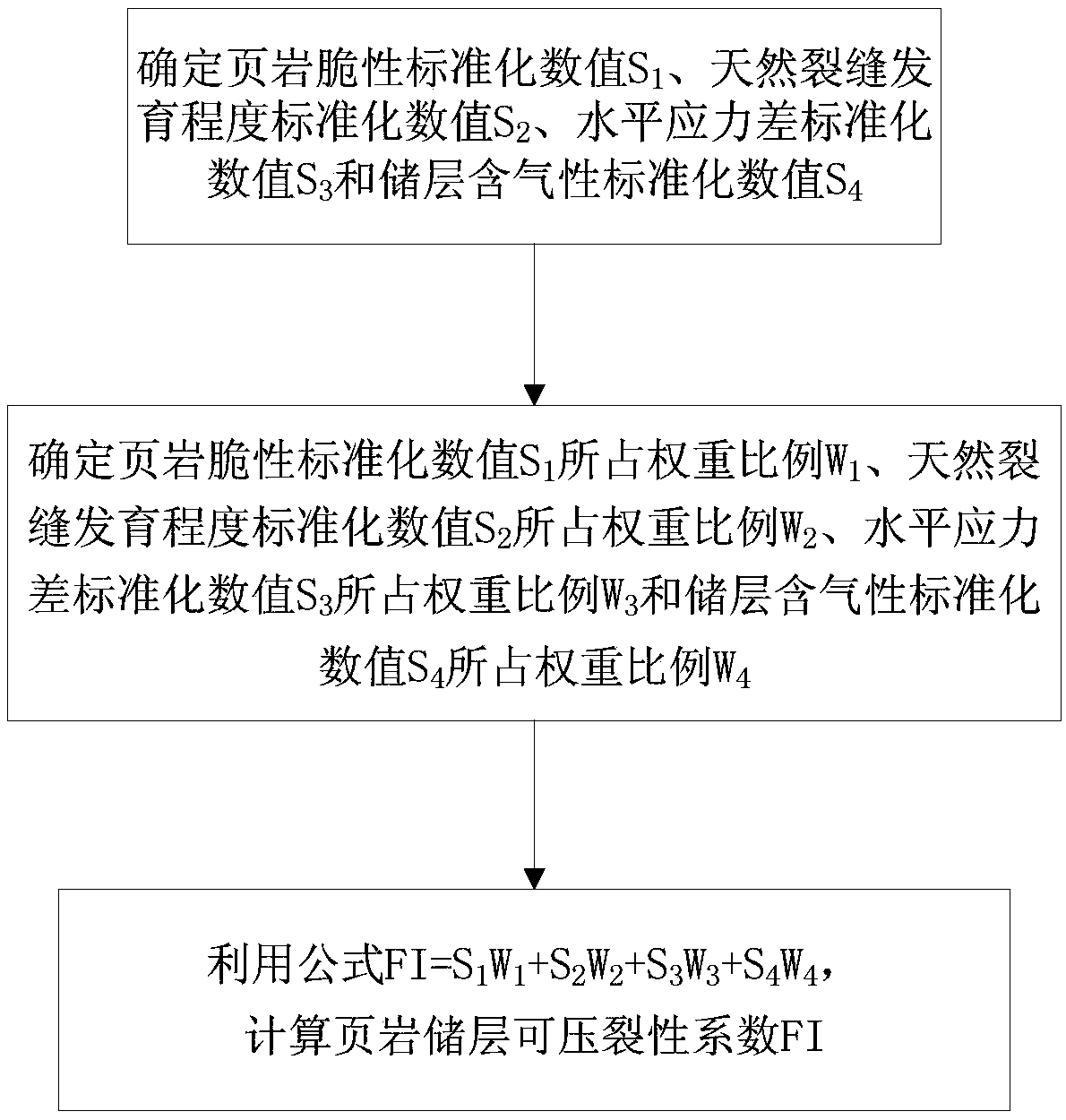

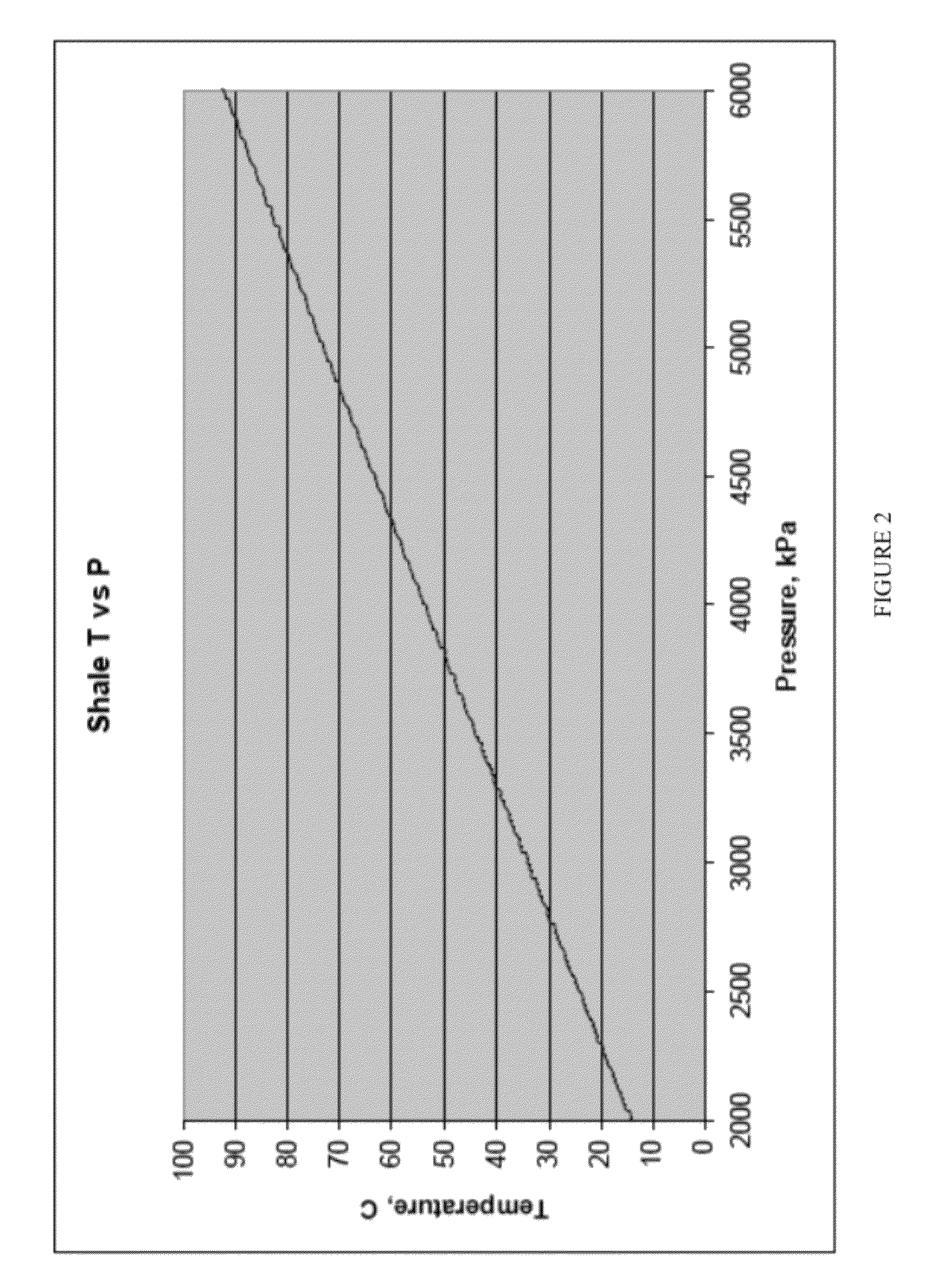

Method for determining compressibility coefficient of shale reservoir

InactiveCN109209329AStable gas production capacityAccurate fracturing coefficientData processing applicationsFluid removalHorizontal stressSoil science

The invention discloses a method for determining the compressibility coefficient of a shale reservoir. The method comprises the following steps: determining a shale brittleness standardization value S1, a natural crack development degree standardization value S2, a horizontal stress difference standardization value S3 and a reservoir gas containing standardization value S4; and determining the weight ratio W1 of the shale brittleness standardization value S1, and the weight ratio W2 of the natural crack development degree standardization value S2, the weight ratio W3 of the horizontal stress difference standardization value S3 and the weight ratio W4 of the reservoir gas containing standardization value S4 by adopting an analytic hierarchy process; and calculating the compressibility coefficient Fi of the shale reservoir by means of the formula FI=S1W1+S2W2+S3W3+S4W4. By adopting the method, the obtained compressibility coefficient of the shale reservoir is more accurate and reasonable, and the technical support is provided for field shale gas well perforation fracture parameter arrangement optimization.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

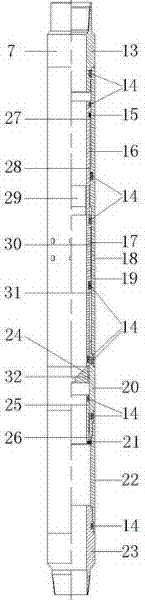

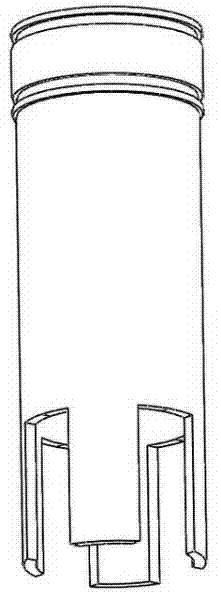

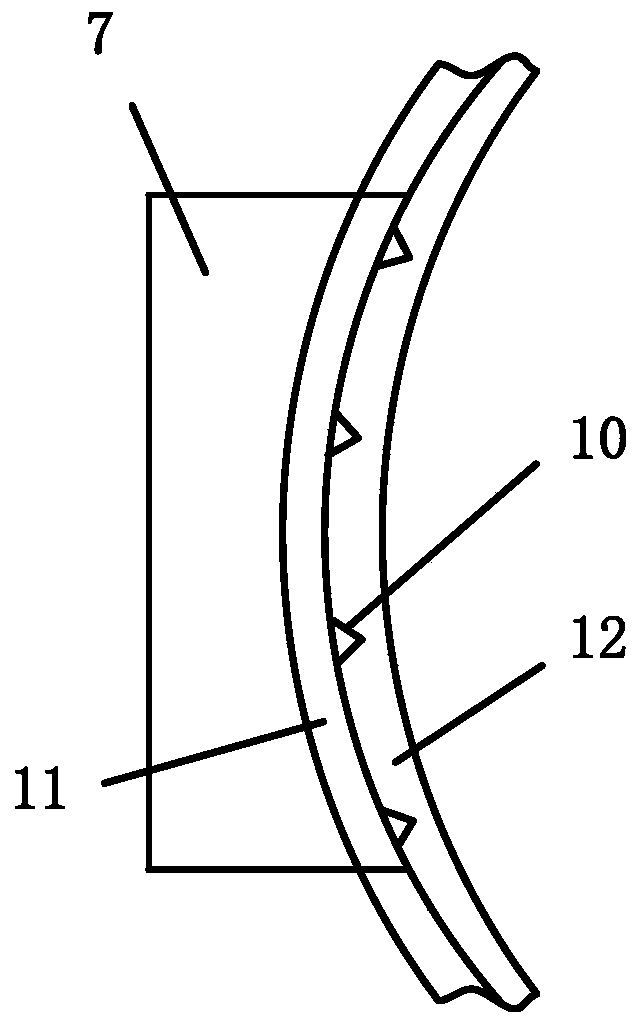

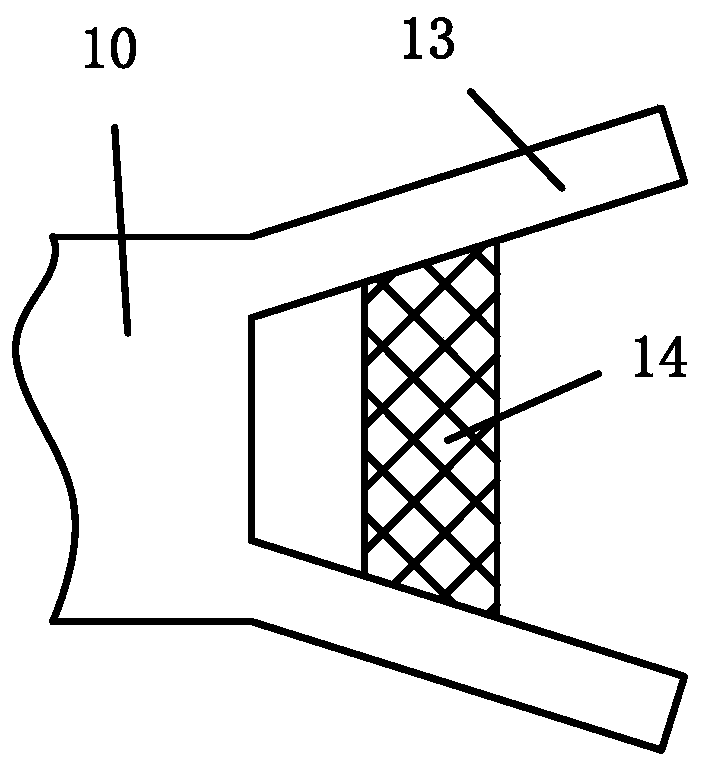

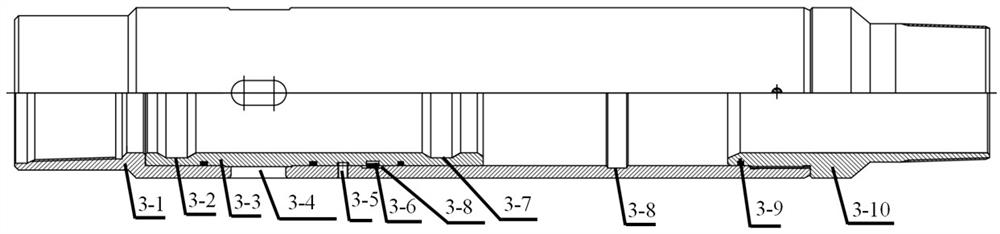

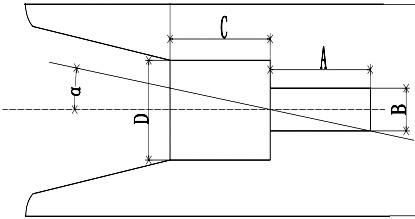

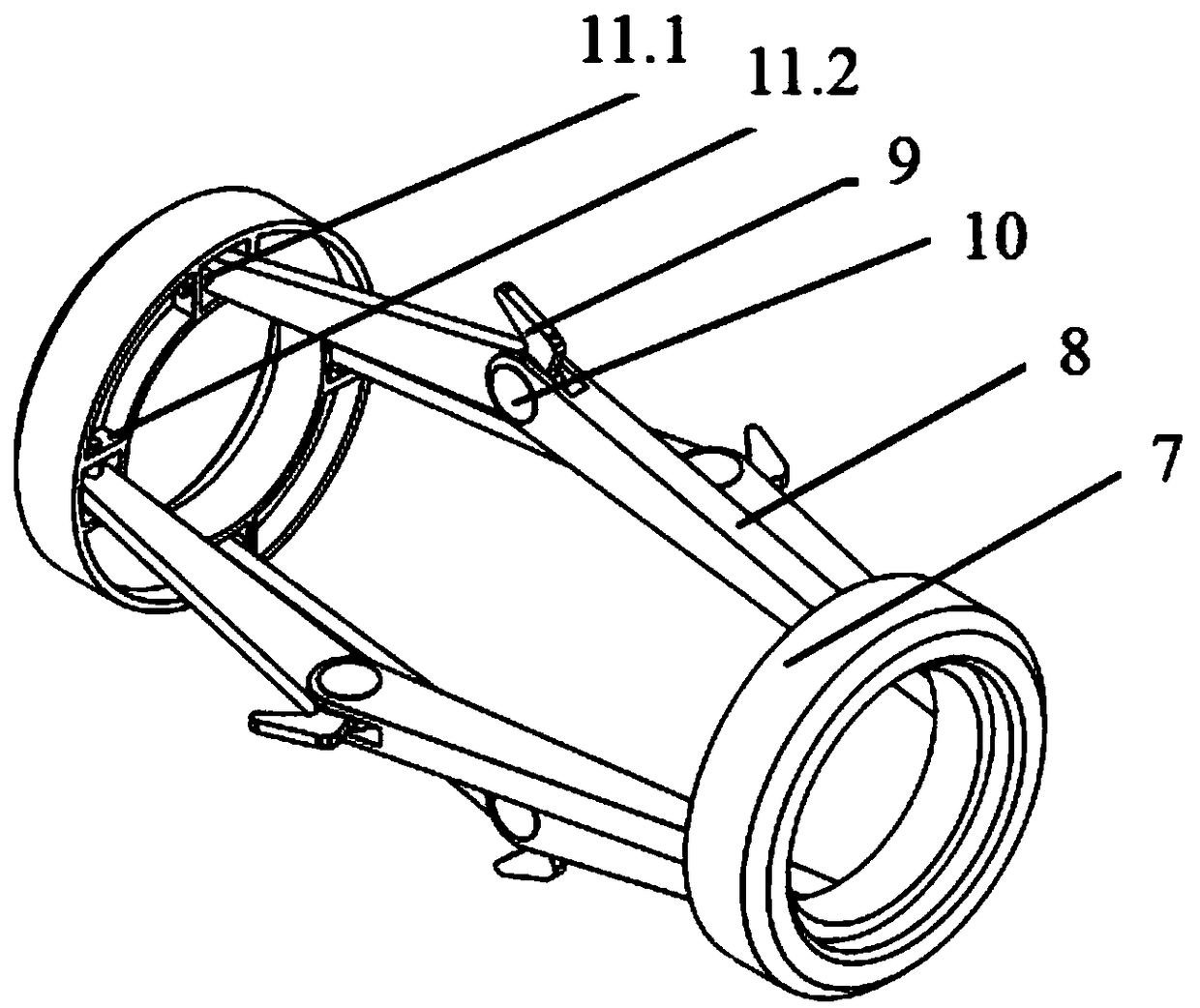

Rotary control stepless ball fracturing sliding sleeve

ActiveCN106194110AEliminates grinding and milling operationsCompact and reasonable structureConstructionsFluid removalEngineeringMechanical engineering

The invention relates to the technical field of ball fracturing sliding sleeves, in particular to a rotary control stepless ball fracturing sliding sleeve. The rotary control stepless ball fracturing sliding sleeve comprises an upper connector, a sliding sleeve body, a lower connector, an inner sliding sleeve and a rotary control sliding sleeve. The outer side of the lower portion of the upper connector and the inner side of the upper portion of the sliding sleeve body are fixedly installed together. The inner side of the lower portion of the sliding sleeve body and the outer side of the upper portion of the lower connector are fixedly installed together. The lower portion of the inner sliding sleeve and the sliding sleeve body are fixedly installed together through shear pins. Two or more internal fracturing holes are distributed in the upper portion of the inner sliding sleeve along the circumference. The rotary control stepless ball fracturing sliding sleeve is reasonable and compact in structure and convenient to use, stepless ball fracturing is achieved, technical support is provided for opening all fracturing reservoirs through fracturing balls in the same size, the number of fracturing layers is not restrained by the diameters of fracturing balls, pressure loss at ball seats with different diameters in the existing fracturing operation process is reduced, ball seat grinding and milling procedures are omitted, fracturing efficiency is improved, fracturing cost is reduced, and the rotary control stepless ball fracturing sliding sleeve can be applied to underground fracturing production increase operation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

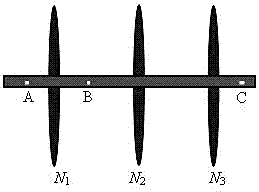

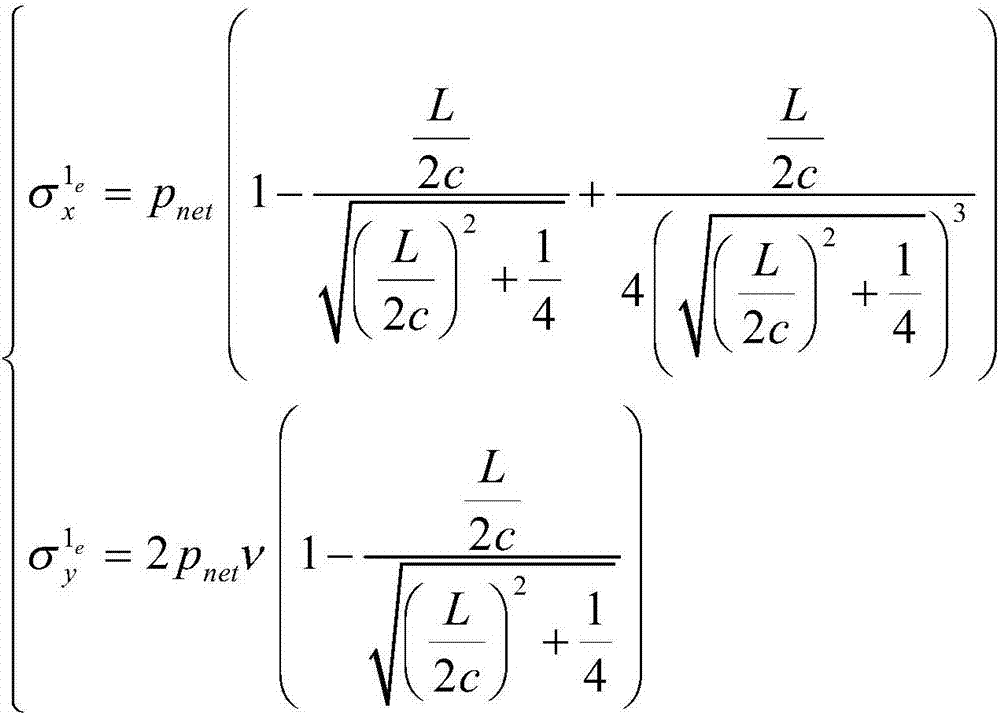

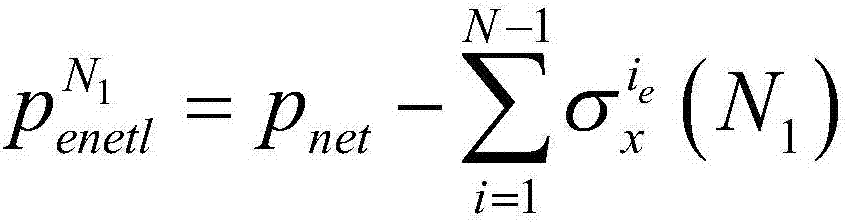

Optimized design method for positions of horizontal well segmented multi-cluster fracturing perforation clusters

ActiveCN106930743AThe calculation result is accurateReduce the risk of sand pluggingFluid removalSpecial data processing applicationsEnvironmental geologyEleventh

The invention relates to an optimized design method for the positions of horizontal well segmented multi-cluster fracturing perforation clusters. The optimized design method comprises the steps that first, the positions of the perforation clusters of a first fracturing segment are determined according to borehole characteristics and development requirements; second, induced stress generated at a crack of the last perforation cluster of the first fracturing segment is calculated; third to sixth, the position of the first perforation cluster of an N fracturing segment is initially selected; seventh to tenth, the position of the next perforation cluster is initially selected, till the transverse transformation ranges of a perforation cluster crack and a previous perforation cluster crack are connected end to end; eleventh, the seventh step to the tenth step are repeated, till the requirement of the N fracturing segment number design is met; twelfth, the effective net pressure and induced stress of a crack at the last perforation cluster of the N fracturing segment relative to a stratum close to an (N+1) fracturing segment are calculated; and thirteenth, N is equal to N+1, the third step to the twelfth step are repeated, till the requirement of the transformation length of the horizontal segment of a well is met. The optimized design method better conforms to the actual working condition of segmented multi-cluster fracturing.

Owner:来安县永阳知识产权运营有限公司

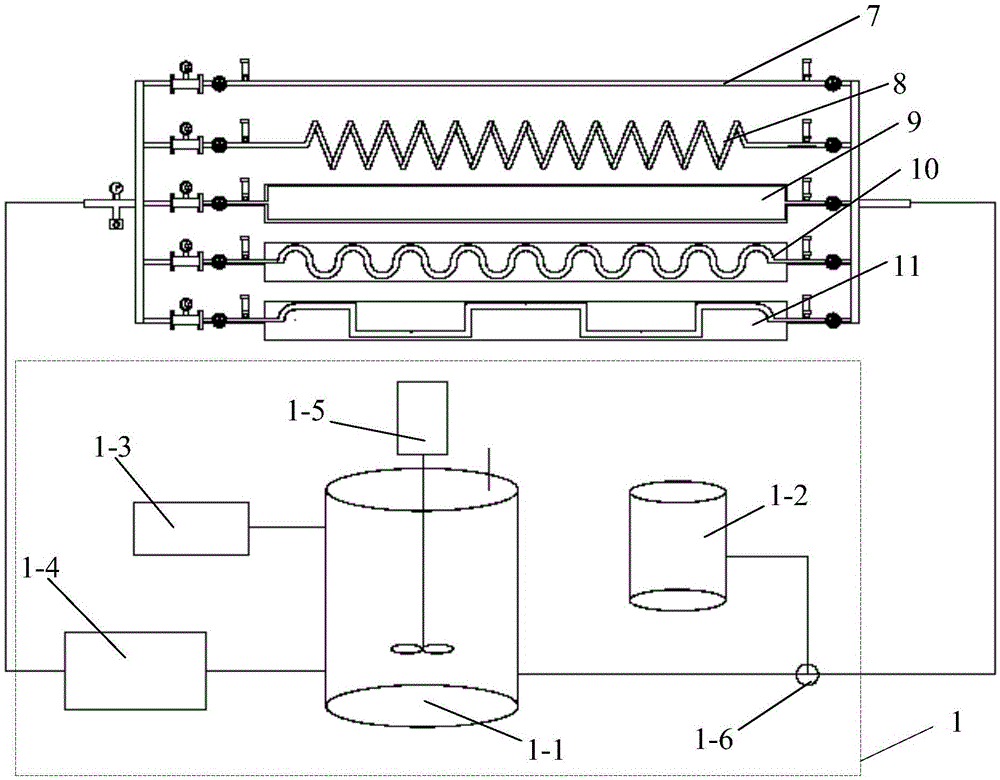

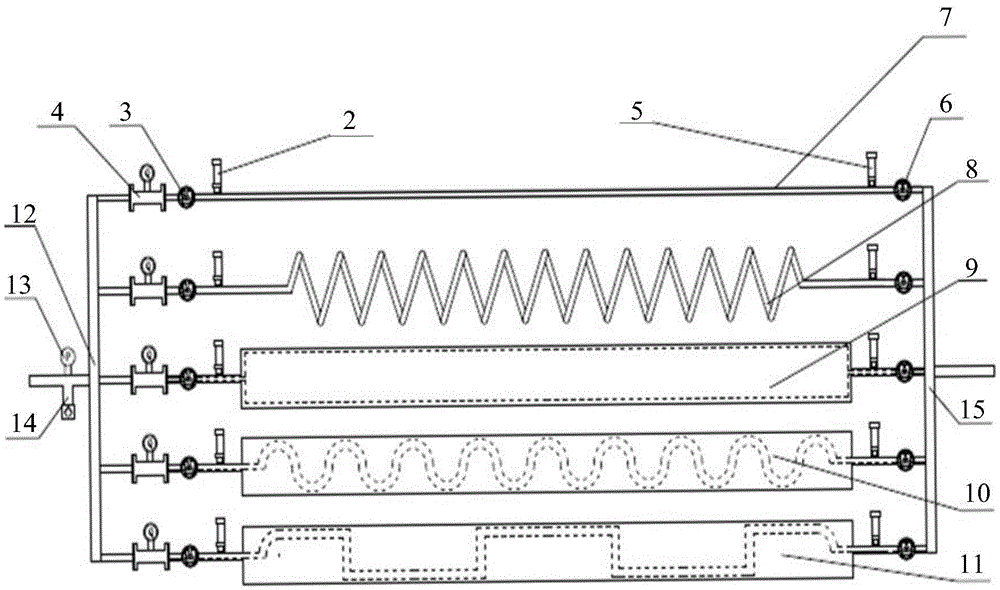

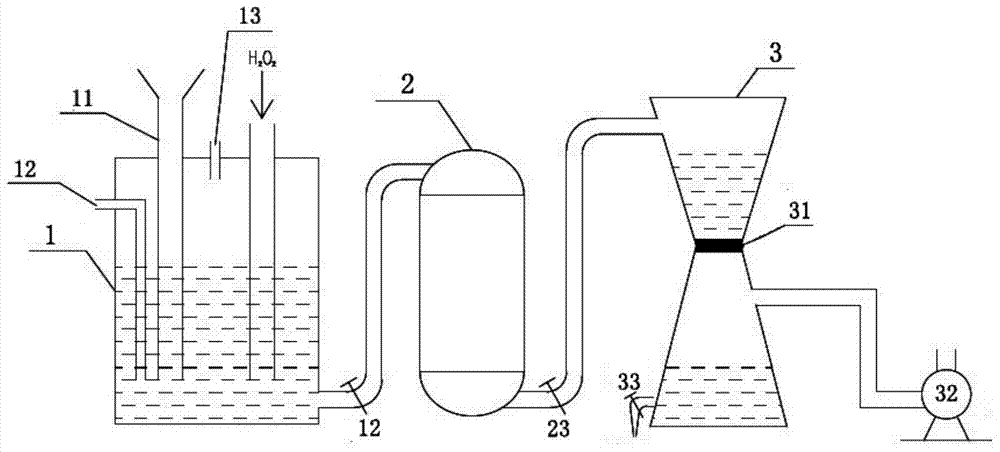

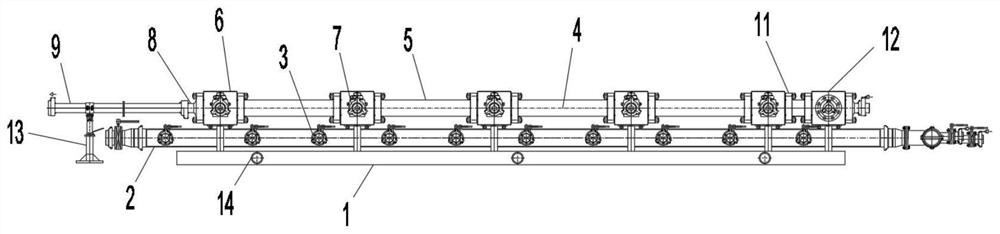

Fracturing fluid friction resistance testing device and method

InactiveCN105628557AImprove fracturing efficiencyNo limitationsFlow propertiesUnderground spaceEngineering

The invention discloses a fracturing fluid friction resistance testing device and method.The device comprises a material supply device and M friction resistance testing channels.The fluid outlet of the material supply device is connected with the first port of each friction resistance testing channel through an input pipeline.The second port of each friction resistance testing channel is connected into the material supply device through an output pipeline.The first port of each friction resistance testing channel is provided with a front pressure transmitter, a front adjustable flow valve and a flow meter.The second port of each friction resistance testing channel is provided with a rear pressure transmitter and a rear adjustable flow valve.The M friction resistance testing channels include at least one horizontal circular channel, at least one spiral circular channel, at least one horizontal fracture channel, at least one S-shaped fracture channel and at least one square wave type fracture channel which are connected in parallel.Therefore, the technical problem that in the prior art, the underground space internal fracturing fluid friction resistance theory is lack of reliable indoor data is solved, and fracturing efficiency can be easily improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

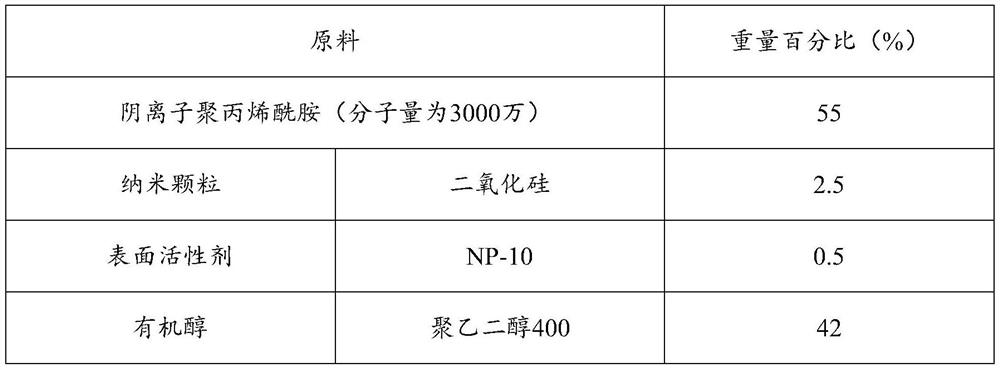

Alcohol-soluble slickwater system for fracturing as well as preparation method and application of alcohol-soluble slickwater system

ActiveCN112375557AImprove thixotropyImprove suspension abilityGeneral water supply conservationDrilling compositionAcid fracturingAlcohol

The invention discloses an alcohol-soluble slickwater system for fracturing as well as a preparation method and application of the alcohol-soluble slickwater system, and relates to the technical fieldof acid fracturing agents. The slickwater system is composed of the following components in percentage by weight: 20.0-60.0% of a polyacrylamide polymer, 0.5-4.0% of nano particles, 0.1-3% of a surfactant, and the balance of organic alcohol.

Owner:四川川庆井下科技有限公司

High strength ultralight ceramsite propping agent, and preparation method and applications thereof

ActiveCN110804432AImprove thermal efficiencyWell formedFluid removalDrilling compositionManganeseMullite

The invention discloses a high strength ultralight ceramsite propping agent, which is composed of bauxite, sodium silicate, silica micro powder, nano silica, and manganese ore powder according to a mass ratio of 55-70: 5-10: 10-20: 0-10: 5-10. The apparent density is 1.00-1.75 g / cm3, the bearing strength is greater than 80 MPa, and the phase component comprises a corundum phase, a mullite phase, and a glass phase. The shortages of the prior art can be overcome. The construction technical demands of water fracturing or water-free fracturing of middle-deep layer shale gas (oil) can be effectively satisfied. The operation cost of fracturing is effectively reduced.

Owner:NORTH CHINA INST OF AEROSPACE ENG +1

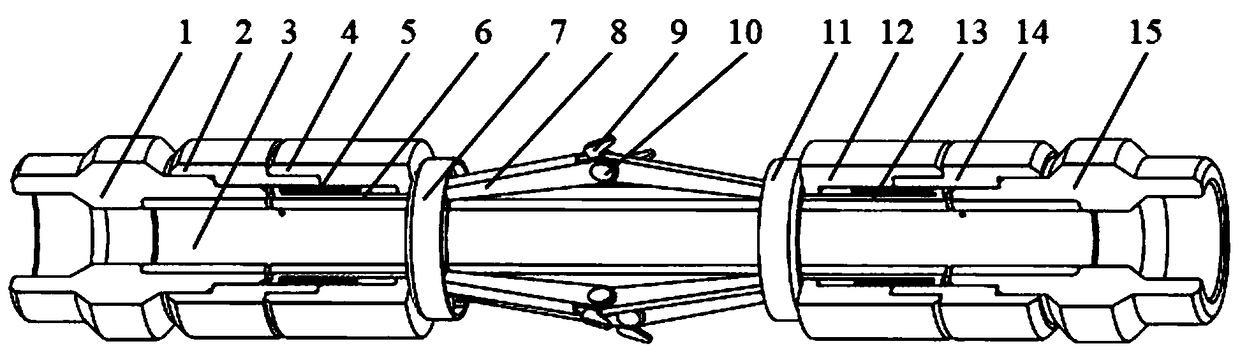

Dual-cluster hydraulic jet tubular column and dual-cluster hydraulic jet annulus fracturing method

ActiveCN103470241AImprove pressure resistanceGood repeatabilityFluid removalSingle stageSpray nozzle

The invention provides a dual-cluster hydraulic jet tubular column and a dual-cluster hydraulic jet annulus fracturing method. As a CTY-211 packer is provided with a check valve device, the pressure in an oil pipe is increased by increasing the discharge capacity, so as to enable fluid in a sliding sleeve spray gun and a single-stage spray gun to form high-speed jet flow for perforation. After the perforation is finished, the tubular column is lifted by 1.5 meters and then put down until a pressure gauge indicates the pressure change of 8-10 tons, namely the packer is set, then the sliding sleeve spray gun is in a blockage state after a well mouth is closed and the tubular column is lifted, and sand fluid is simultaneously injected into an oil sleeve annulus and the oil pipe for carrying out fracturing. The sand fluid in the oil pipe carries out fracturing only through the lower single-stage spray gun and can prevent sand plugging and reduce friction resistance, so that the service life of a spray nozzle is greatly improved. The oil sleeve annulus can carry out large-capacity fracturing, so the fracturing efficiency is improved, multilayer fracturing during once drill-down is realized, and the occurrence of hazards is reduced. After the fracturing is finished, the oil pipe and the oil sleeve annulus can be cleaned in a manner that fluid is injected into the oil pipe and flows out from the oil sleeve annulus.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

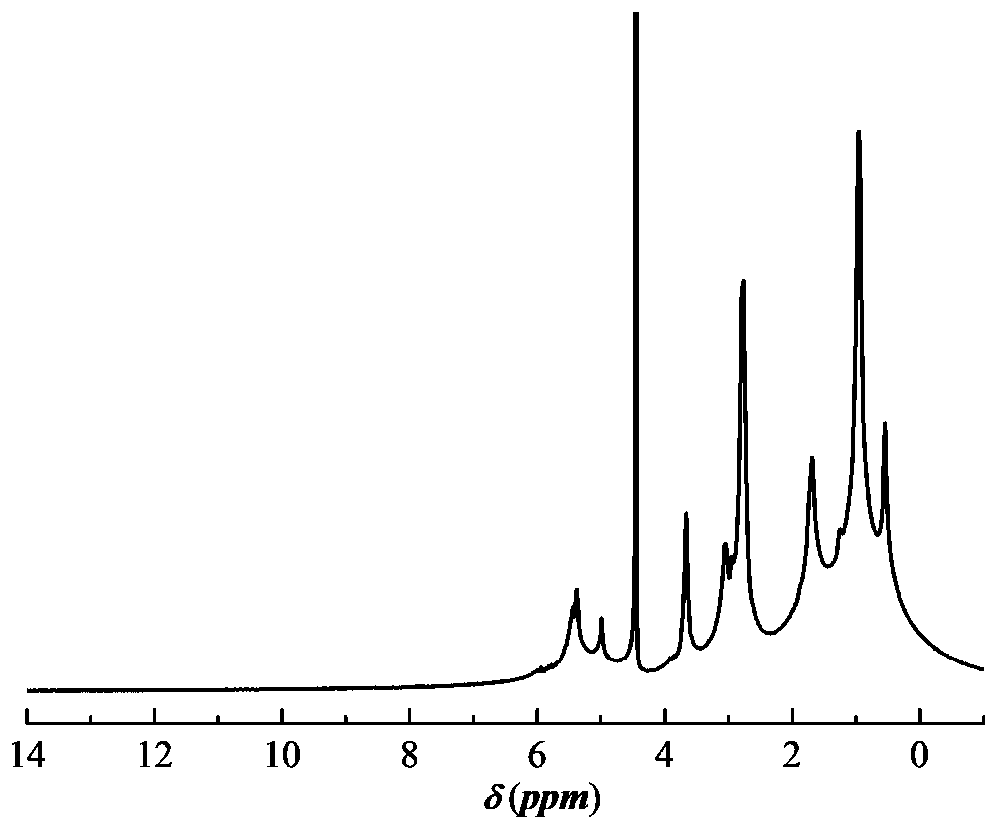

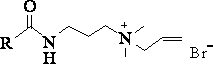

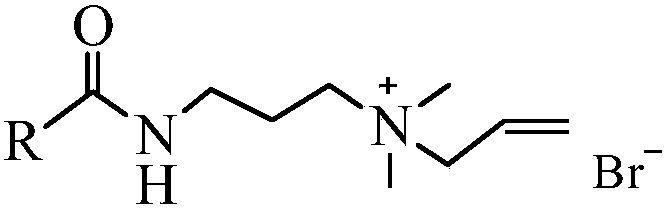

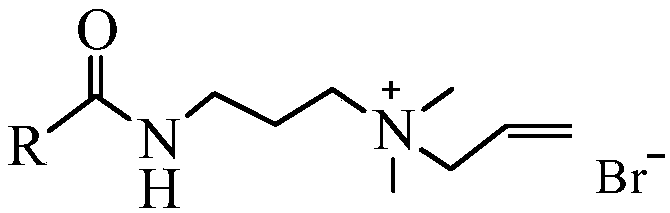

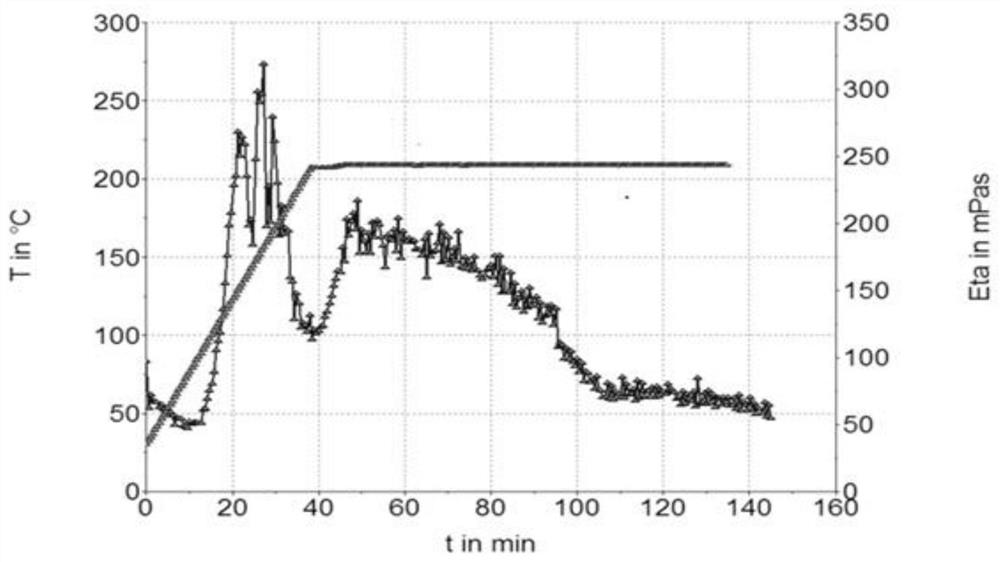

High-salt-resistant viscoelastic surfactant cleaning fracturing fluid and preparation method thereof

ActiveCN109705835AResistant to high saltHigh viscosityOrganic compound preparationCarboxylic acid amides preparationCarbon numberInorganic salts

The invention discloses a high-salt-resistant viscoelastic surfactant cleaning fracturing fluid and a preparation method thereof. The fracturing fluid contains a cationic surface active agent, and thestructural formula of the cationic surface active agent is shown as the following formula. In the formula, R<1>' is selected from saturated alkyls with a carbon number n meeting a relationship of 16<=n<=24, unsaturated alkyls with a carbon number n meeting a relationship of 16<=n<=24, and a compound as shown in the following formula, wherein R<1> is selected from saturated alkyls with a carbon number n meeting a relationship of 16<=n<=24, and unsaturated alkyls with a carbon number n meeting a relationship of 16<=n<=24; and R<2> is selected from saturated alkyls with a carbon number C meetinga relationship of 3<=C<=7, unsaturated alkyls with a carbon number C meeting a relationship of 3<=C<=7, and short-chain alkylbenzene (C<=5). The cationic surfactant has good resistance to inorganic salts, and the principle is that the R<2> substituent groups block mutual proximity between polar head groups of the cationic surface active agent under a high-mineralization-degree condition, and thenprecipitation of the cationic surface active agent is avoided, so that the micelle continues keeping a dense three-dimensional network structure, and tackifying performance is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Ultra-light ceramsite proppant for clear water fracturing or water-free fracturing, and preparation method thereof

InactiveCN107151554ARealize comprehensive utilizationReduce manufacturing costFluid removalDrilling compositionVolumetric Mass DensityMaterials science

The invention discloses an ultra-light ceramsite proppant for clear water fracturing or water-free fracturing, and a preparation method thereof, and belongs to the technical field of shale gas fracturing. According to the present invention, the preparation method of present invention is different from the existing proppant preparation method; the technical route comprises material preparation, granulation, high temperature molding, and late-stage high temperature sintering; the product visual density is 1.0-1.7 g / cm<3>, and the bearing strength is more than 52 MPa; the main phase components comprise a corundum phase, a mullite phase and a glass phase; the product is suitable for clear water fracturing or water-free fracturing of shale gas, can effectively reduce the fracturing operating cost, can completely use the oil-gas production capacity, and can substantially improve the whole fracturing effect; and the used main raw material is the low-grade bauxite, such that the production cost can be effectively reduced, and the comprehensive utilization of low-grade bauxite can be achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for improving high pressure water rotary jet velocity

InactiveCN107762455ASolve for uniformitySolve the problem of easy sand jamming during fracturingFluid removalUltrasonic cavitationHigh pressure water

The invention discloses a method based on increasing the speed of the high-pressure water rotary jet. The treatment liquid is pressed by a cement truck, passes through a one-way valve and a filter, and then enters a rotary generator to generate multiple radial high-pressure water jets. Two organ pipe nozzles, in which two inclined power nozzles eject lateral jets to generate rotational torque, which drives the nozzle to rotate, and two radial nozzles generate radial high-frequency self-vibrating cavitation jets, which directly impact the pipe wall and formation, and the tool is in the downhole It moves up and down while rotating, and the rotation speed is controlled by the rotation controller. There are four hydraulic pulses per revolution, and at the same time, three physical effects of low-frequency rotating hydraulic waves, high-frequency oscillating shock waves, and cavitation noise ultrasonic waves are generated. Complete treatment of the perforated well section. The process can improve the fracturing effect, make the fracturing uniform, and at the same time, the phenomenon of sand jamming will not occur, and the fracturing efficiency will be improved.

Owner:郭莉

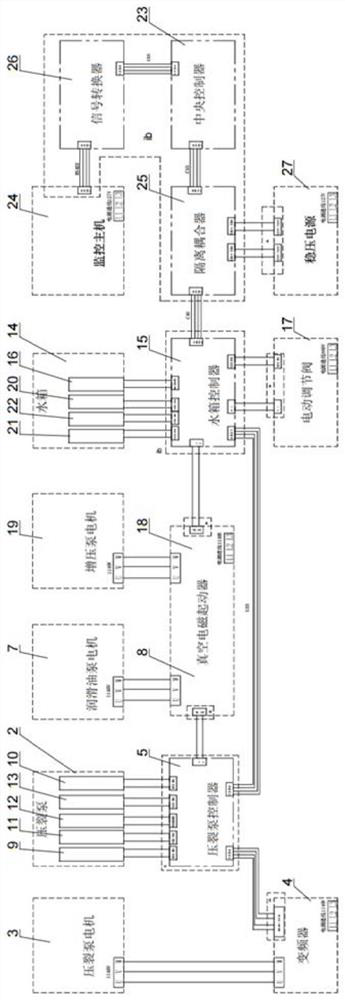

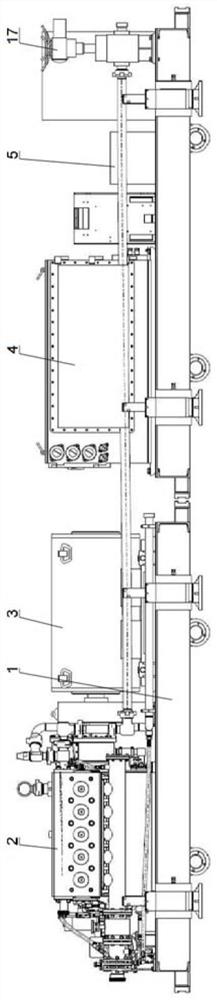

Fracturing pump set control system and control method

PendingCN114198292AQuick and continuous adjustmentHigh degree of automationPositive displacement pump componentsUnderground miningFrequency changerThermodynamics

The invention provides a fracturing pump set control system and method, and the system comprises a central control unit which is used for receiving a target pressure value of a fracturing pump; the fracturing pump sensor group is used for detecting the actual pressure value of the fracturing pump; the fracturing pump controller is electrically connected with the central control unit and the fracturing pump sensor set and used for comparing the target pressure value with the actual pressure value and judging whether the actual pressure value suddenly drops or not; the frequency converter is electrically connected with the fracturing pump controller; compared with the prior art, the coal seam fracturing system has the advantages that the rotating speed of the fracturing pump motor can be rapidly and continuously adjusted, the automation degree is high, the coal seam fracturing efficiency is effectively improved, and the safety of coal seam fracturing operation is higher.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD +1

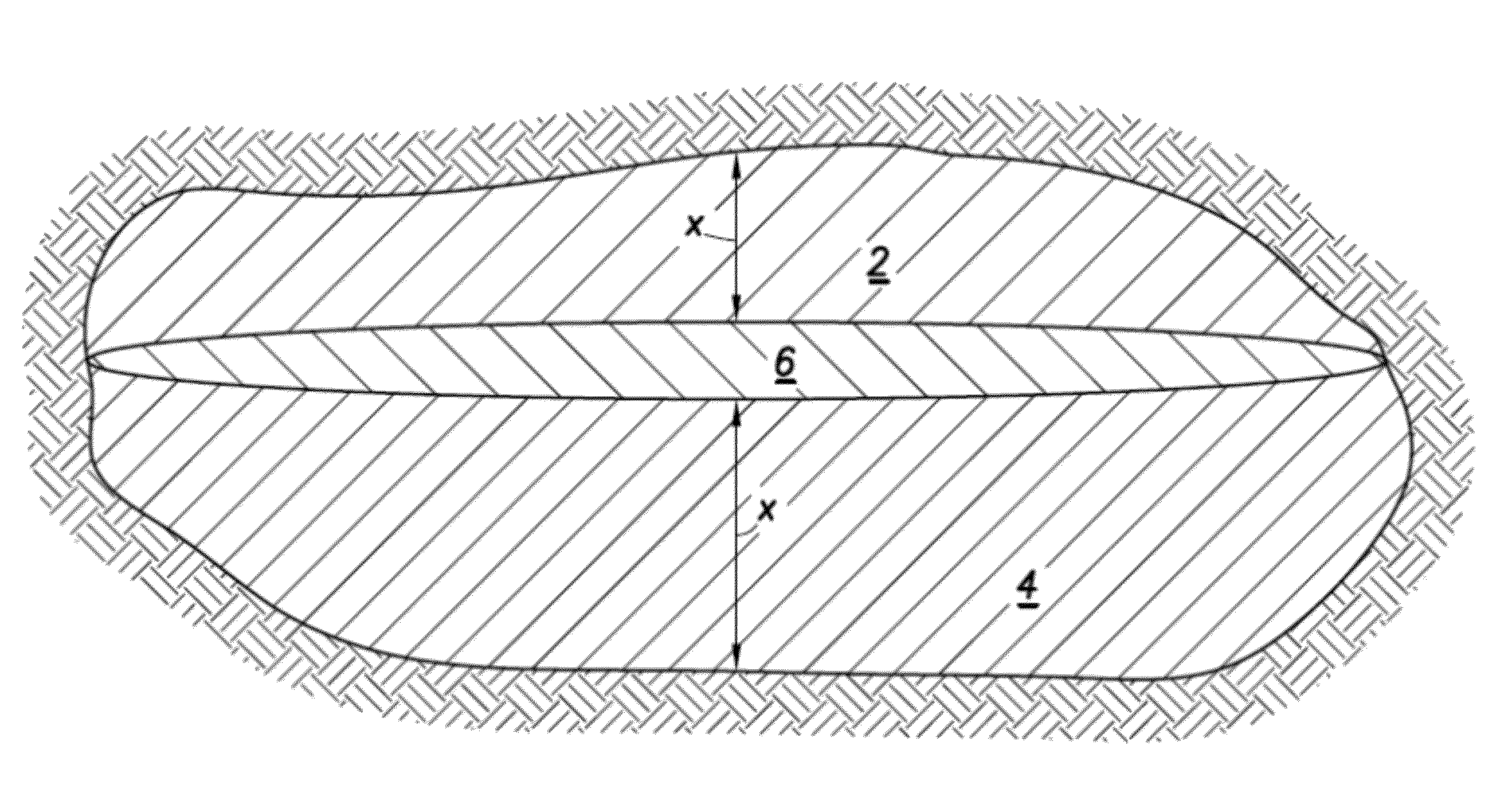

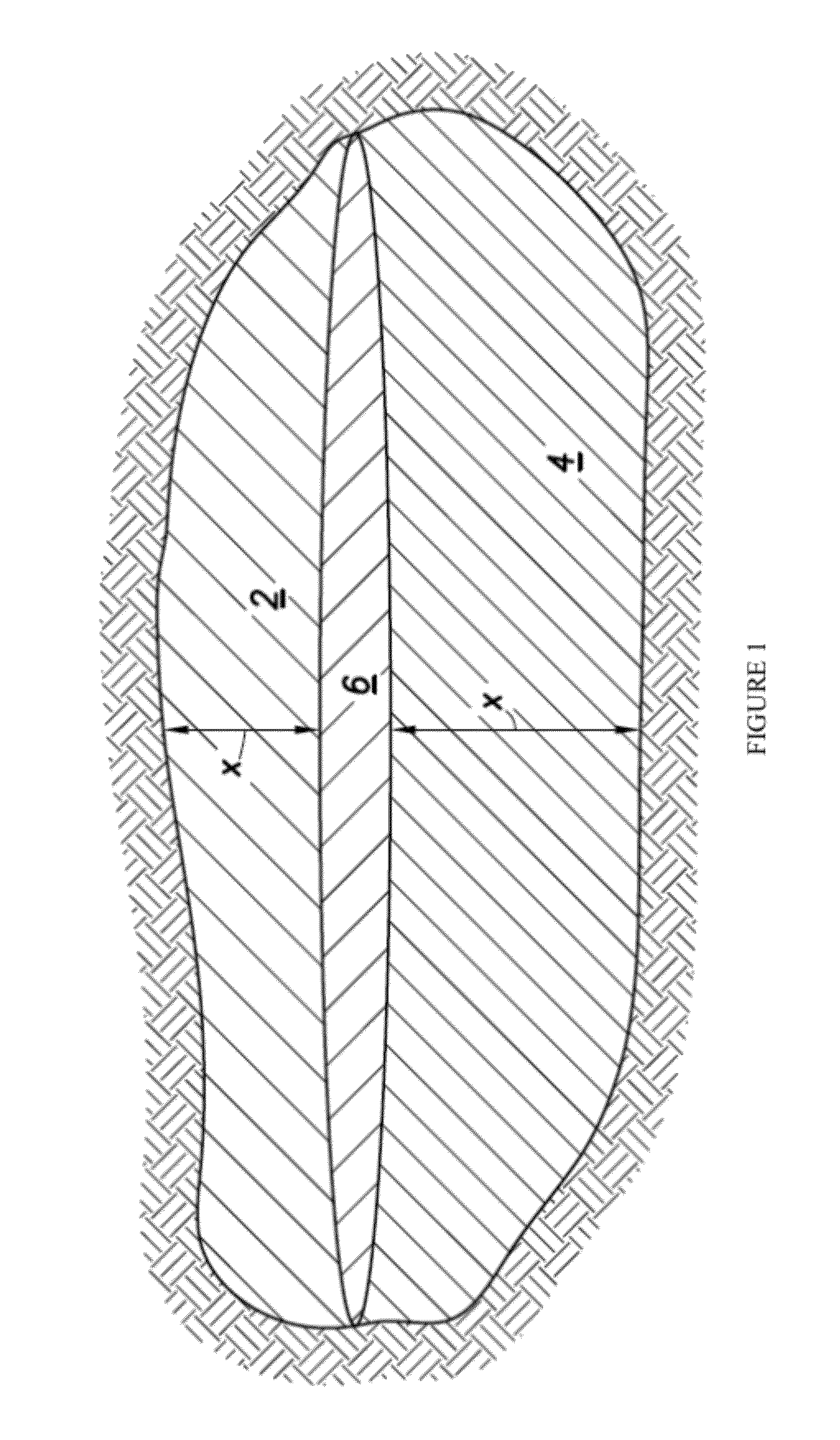

RF fracturing to improve SAGD performance

ActiveUS8534350B2Improve fracturing efficiencyIncreased cost-effectivenessInsulationFluid removalFuel oilEngineering

A method of producing heavy oil from a heavy oil formation with steam assisted gravity drainage. The method begins by drilling a borehole into a heavy oil formation comprising a steam barrier between a first pay zone and a second pay zone, wherein the steam barrier prevents a steam chamber to be formed between the first pay zone and the second pay zone. The steam barrier is then heated with a radio frequency. The steam barrier is then fractured to permit a steam chamber to be formed within the first pay zone and the second pay zone. Heavy oil is then produced from the heavy oil formation with steam assisted gravity drainage.

Owner:HARRIS CORP +1

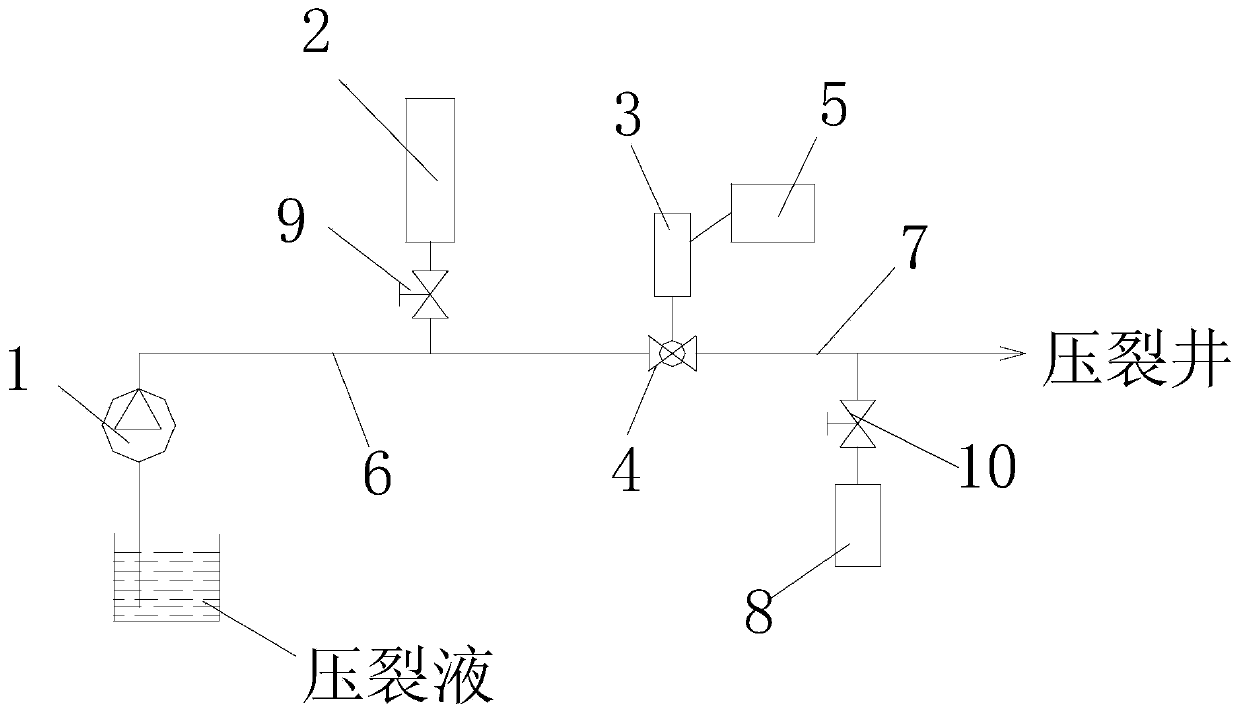

Pulser for fracturing

The invention relates to a pulser for fracturing. The pulser includes a constant-speed constant-pressure pump, an energy accumulator, a servo motor, an automatic valve and a PLC control center, wherein the constant-speed constant-pressure pump communicates with a water inlet of the automatic valve through a liquid inlet pipe, a water outlet of the automatic valve communicates with a fracturing well through a liquid outlet pipe, the automatic valve is connected with the servo motor, the servo motor drives the automatic valve to open and close and is connected with the PLC control center, the PLC control center controls the rotate speed of the servo motor, the energy accumulator is arranged at the front end of the water inlet of the automatic valve, and the energy accumulator communicates with the liquid inlet pipe through a first valve. According to the pulser for fracturing, the PLC control center controls the rotate speed of the servo motor, thus opening frequency of a ball valve is controlled, fracturing liquid enters the fracturing well and forms certain pulse, thus pulse fracturing of rock is achieved, usage amount of the fracturing liquid is largely lowered, and the fracturingefficiency is high.

Owner:南通美软自动化科技有限公司

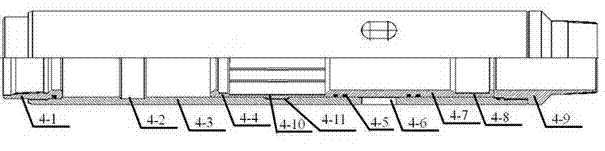

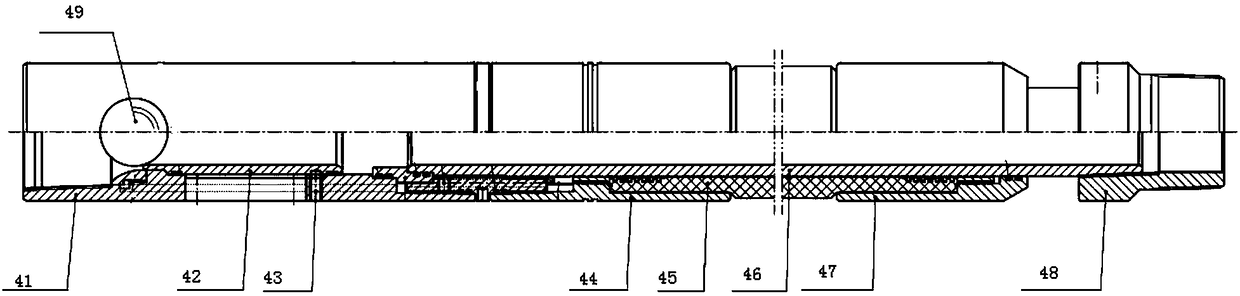

Casing cementing full-bore infinite stage staged fracturing well completion device and fracturing well completion method thereof

PendingCN114482958ARealize any fixed-point openingStaged fracturing stages are not limitedFluid removalWell/borehole valve arrangementsHorizontal wellsWell cementing

The invention discloses a casing well cementation full-bore infinite stage staged fracturing well completion device and a fracturing well completion method thereof. The fracturing well completion device and the fracturing well completion method are suitable for fracturing well completion processes of horizontal wells and vertical wells. The device comprises a casing string, a plurality of hydraulic casing centralizers, a plurality of fracturing well completion sliding sleeves, a plurality of differential pressure type fracturing well completion sliding sleeves, a long-wing well cementation rubber plug, a bump pressure seating valve and a bottom circulating valve, and the hydraulic casing centralizers and the fracturing well completion sliding sleeves are connected to the casing string in a matched mode to form the casing well cementation full-bore infinite stage staged fracturing well completion device. The fracturing well completion sliding sleeve is of a full-bore design, and the opening tool and the fracturing well completion sliding sleeve are matched one by one to complete the sliding sleeve opening action. The staged fracturing stage number is not limited; the one-key one-opening of the fracturing well completion sliding sleeve at any fixed point can be realized, the one-key multi-opening of the one-stage multi-cluster fracturing well completion sliding sleeve can also be realized, the full bore of a well completion pipe string is realized after fracturing, the continuous, rapid, large-scale, multi-stage and multi-cluster fracturing construction requirements are met, and the fracturing efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Staged fracturing slide sleeve opening-closing device

InactiveCN109488275ASimple structureEasy to operateFluid removalWell/borehole valve arrangementsEngineeringHigh pressure

The invention relates to a staged fracturing device in the field of petroleum machinery, in particular to a staged fracturing slide sleeve opening-closing device, comprising an upper connector, an upper connection sleeve, a center tube, an upper fixing sleeve, a spring, an upper inner slide sleeve, an upper slide support, a connection rod, a slide sleeve opening-closing claw, a pin, a lower slidesupport, a lower fixing sleeve, a lower inner slide sleeve, a lower connection sleeve and a lower connector. The upper end of the upper connector is connected with a tubing; the lower end of the upperconnector is in threaded connection with the upper end of the upper connection sleeve; the lower end of the upper connection sleeve is in threaded connection with the upper end of the upper fixing sleeve; the right end of the upper fixing sleeve is provided with the upper slide support. In principle, elastic potential energy of the spring is stored and released under the action of a high-pressurefluid so that the slide sleeve opening-closing claw is extended and contracted, thereby opening or closing a fracturing slide sleeve. The staged fracturing slide sleeve opening-closing device has theadvantages that the staged fracturing slide sleeve opening-closing device is simple in structure and convenient to operate, can run stably and reliably, can meet the field requirements of various conditions for open-hole staged fracturing of a multi-stage slide sleeve of a horizontal well, and can provide full fracturing development for reservoirs.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for evaluating fracturing effects by analyzing tracers in multi-section fracturing flow-back fluid

ActiveCN104500047AIntuitive and accurate fracturingReduce mistakesConstructionsFluid removalFracturing fluidSample processing

The invention provides a method for evaluating fracturing effects by analyzing tracers in a multi-section fracturing flow-back fluid. The method comprises the steps of sampling in an oil producing well and treating the sample, detecting the concentration of each tracer in the treated flow-back fracturing fluid, and evaluating the fracturing effect of each layer according to the concentrations of the tracers. The fracturing conditions judged by use of the method are visual and accurate, quantitative and low in error, and have an important guiding effect on the fracturing of the sections of the same layer; the design scheme is optimized for the conditions of different stratums; as a result, the fracturing efficiency is improved and the cost is reduced.

Owner:PETROCHINA CO LTD

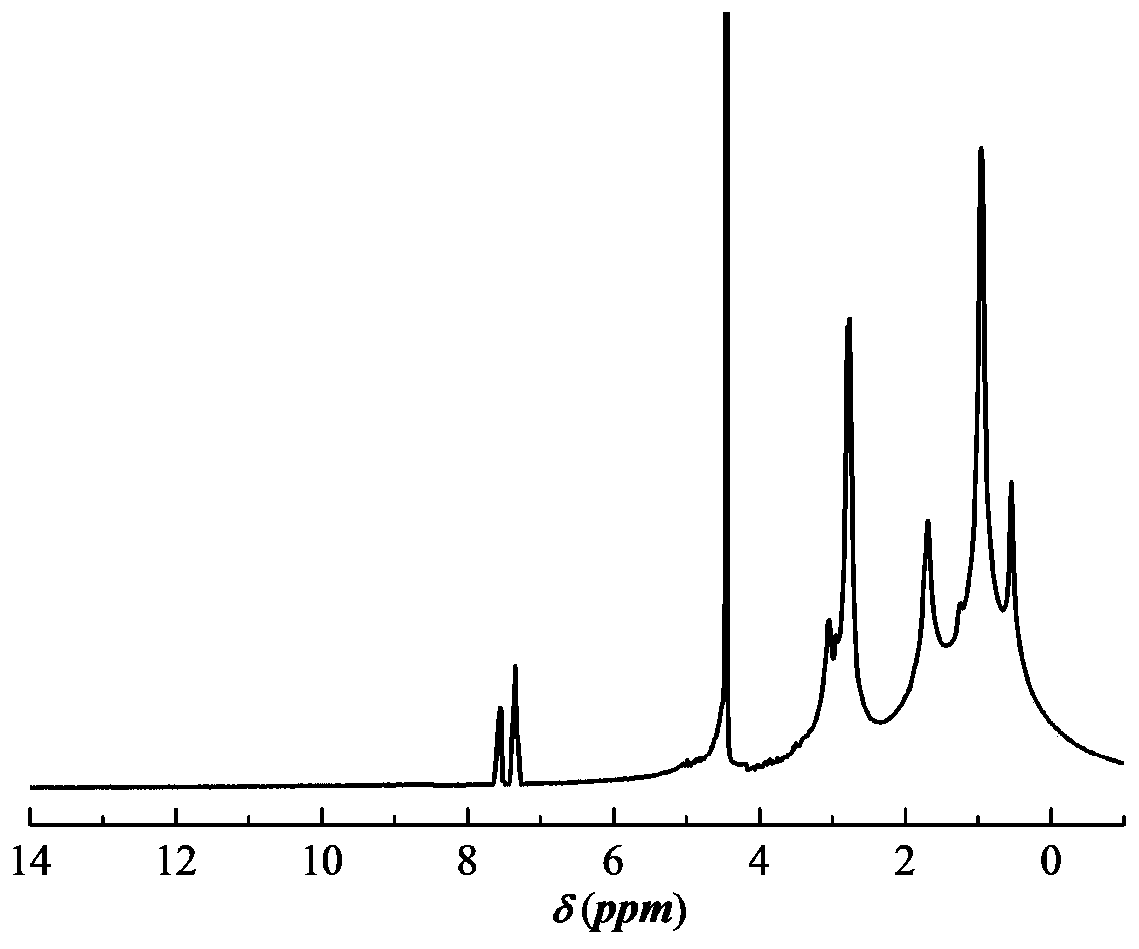

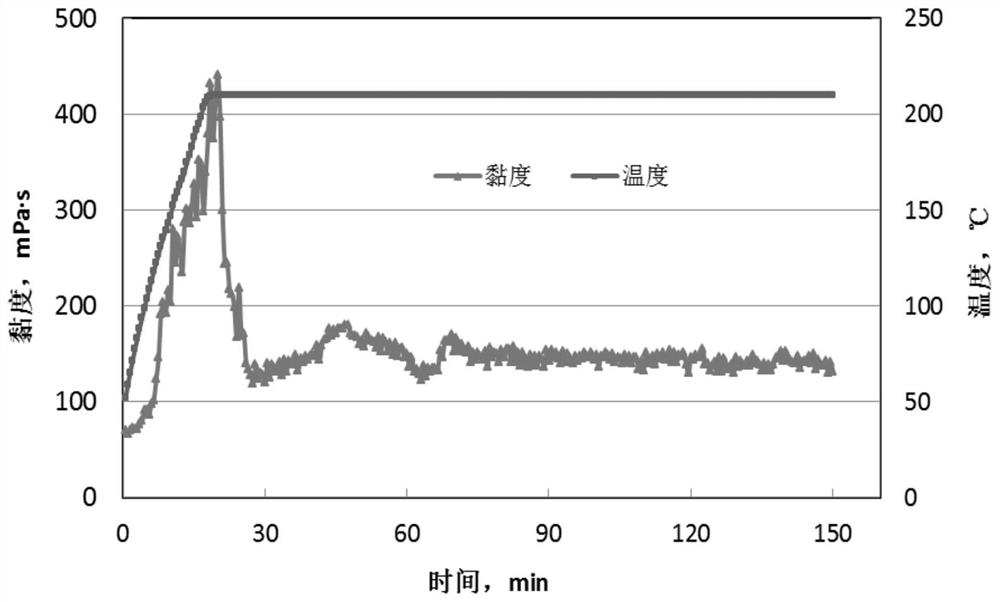

A controllable viscoelastic supramolecular clean fracturing fluid system and its preparation method

ActiveCN107841303BImprove stabilityImprove universalityFluid removalDrilling compositionInorganic saltsOrganic acid

The invention provides an adjustable viscoelastic supramolecular clean fracturing fluid system and a preparation method thereof. The clean fracturing fluid system is composed of the following components in mass percentage: 1.0-6.0% cationic surfactant; 0.2-6.0% organic acid 1.0%; Inorganic salt 0.1-2.0%; Amphiphilic polymer 0.1%-1.0%; Water 98.6-90.0%. When preparing, first prepare super long-chain fatty amide cationic surfactant, dissolve inorganic salt in water, and then Then add amphiphilic polymer, organic acid and cationic surfactant in sequence, and after fully stirring, a supramolecular cleaning fracturing fluid can be obtained; this supramolecular cleaning fracturing fluid has the property of adjustable viscosity, through Join to achieve different performance requirements. At the same time, it can effectively fracture the formation, with simple configuration, small dosing amount, strong sand-carrying property, and good temperature resistance, which avoids the problems of large dosing amount and poor temperature resistance in the existing conventional clean fracturing fluid system, and improves the pressure. Improve fracturing efficiency, reduce fracturing costs, and expand applicable formation conditions.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Biological enzyme fracturing technology for oil fields and oil wells

InactiveCN102383774ASolve the three common problemsAvoid cold damageFluid removalCross-linkOil field

The invention discloses a biological enzyme fracturing technology for oil fields and oil wells. The technology comprises the following steps of: connecting a ground pipeline, testing the pressure of a high-pressure pipeline, backwashing a well, starting a pump for fracturing till a fracturing pressure is displayed, and starting injection after the pressure is stable, wherein the injection has the sequence of: injecting an ahead fluid, injecting a base fluid, adding a cross-linking agent and a propping agent at the same time of injecting the base fluid, injecting a gel breaker, closing the mounting wellhead to build the pressure, controlling blow-out of a pressure oil pipe, and pulling out a shaft pipe column after the pressure of the wellhead is dispersed. The technology solves the problems of cold damage, water damage and residue damage, and has the advantages of good environmentally-friendly effect, wide application range, high compatibility, thorough gel breakage, simplicity in operation and high cost performance.

Owner:XI'AN PETROLEUM UNIVERSITY

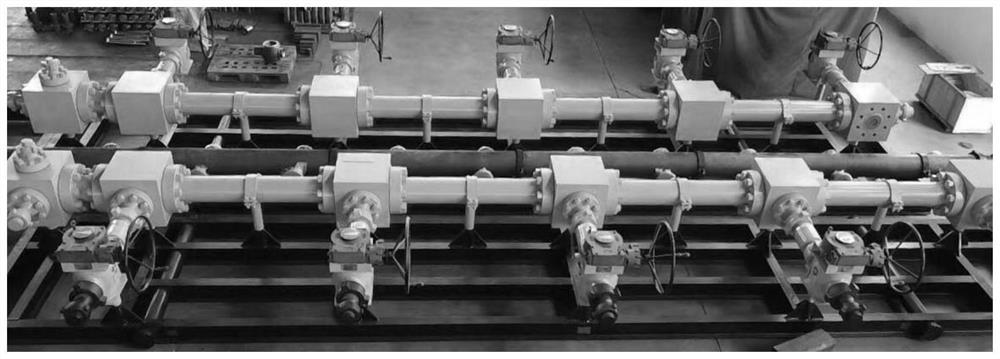

175MPa high-pressure large-drift-diameter fracturing manifold

ActiveCN114687720AEasy to install and disassembleEasy to moveGeothermal energy generationFluid removalButterfly valveMechanics

The 175MPa high-pressure large-drift-diameter fracturing manifold comprises a prying frame assembly and a collecting pipe combination, the collecting pipe combination is arranged at the top end of the prying frame assembly, a plurality of double-clip type acid-resistant butterfly valves are arranged on the outer walls of the two sides of the collecting pipe combination at intervals, branch pipe assemblies are arranged on the two sides of the collecting pipe combination respectively, and the branch pipe assemblies are connected with the prying frame assembly. The two branch pipe assemblies are communicated through a first flange short-circuit connector. The invention aims to provide the 175MPa high-pressure large-drift-diameter fracturing manifold which is high in pressure bearing capacity and safe to use.

Owner:YANCHENG XUDONG MASCH CO LTD

Protective sleeve volume fracturing pipe string

PendingCN108505983ASelf-proclaimedGuaranteed tightnessFluid removalSealing/packingSteel ballUltimate tensile strength

The invention discloses a protective sleeve volume fracturing pipe string, belongs to the technical field of petroleum exploitation equipment, and particularly relates to a fracturing pipe string. Theprotective sleeve volume fracturing pipe string comprises a sleeve, an oil tube, an anchor packer and a self-sealing sandblaster. The protective sleeve volume fracturing pipe string has the followingbeneficial effects that the anchor packer adopts a firmer sealing method, the self-sealing sandblaster has a good self-sealing property, an upper connector of the sandblaster and an anti-recoil shearpin of the sandblaster sliding sleeve can ensure the smooth passing of a steel ball, the loss of fracturing throttling is reduced, the fracturing efficiency is improved, a rubber cylinder and a sandblaster rubber cylinder can ensure the sealing performance of the anchor packer and the self-sealing sandblaster and enable a nozzle of the sandblaster to be away from the sleeve, the impact on the sleeve is reduced, the size of the equipment is reduced through the integrated connection of self-sealing sandblaster and the anchor packer, and the construction intensity is greatly reduced.

Owner:磐石市长城机械厂

Preparation method of metal chelate and high-temperature polymer fracturing fluid

ActiveCN113121581AHigh temperature resistantShear resistantGroup 4/14 organic compounds without C-metal linkagesTitanium organic compoundsOrganic acidPolyol

The invention provides a preparation method of a metal chelate and a high-temperature polymer fracturing fluid, and the method comprises the following steps: carrying out chelation reaction on a high-valence metal substance and a ligand substance in water to obtain the metal chelate, wherein metal in the high-valence metal substance is zirconium and / or titanium, the ligand substance comprises a weak coordination substance and a strong coordination substance, the weak coordination substance is polyhydric alcohol and / or polyhydric alcohol amine, and the strong coordination substance is organic acid and / or organic acid salt. The high-temperature polymer fracturing fluid provided by the invention mainly comprises a polymer thickening agent, the metal chelate cross-linking agent, a cleanup additive, a clay stabilizer and a demulsifying agent, and can still realize the effect of delaying cross-linking under a high-temperature condition. The fracturing fluid has the advantages of high temperature resistance, shearing resistance, temperature control crosslinking, low friction resistance, low filtration loss and the like, is suitable for fracturing transformation of ultra-high-temperature deep well reservoirs, and solves the problems of high viscosity and high friction resistance of a tubular column temperature control fracturing fluid in ultra-deep and ultra-high-temperature well fracturing large-displacement construction.

Owner:中石化石油工程技术服务有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com