Casing cementing full-bore infinite stage staged fracturing well completion device and fracturing well completion method thereof

A staged fracturing, full-bore technology, applied in wellbore/well valve devices, wellbore/well components, earthwork drilling, etc. In order to meet the needs of selective water control production or secondary fracturing construction, the process is simple, and the fracturing efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

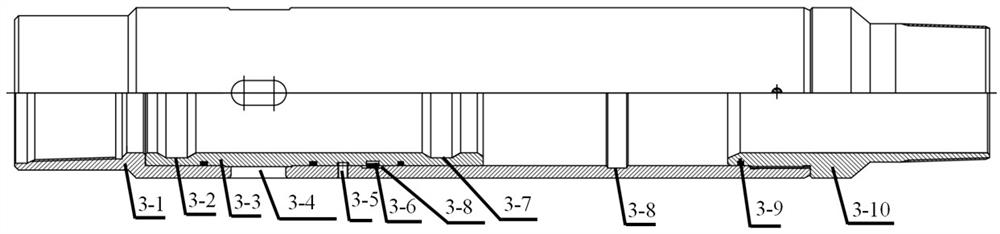

[0066] refer to figure 1 , Figure 1a' , Figure 1b' , figure 2' , Figure 2a , image 3' , Figure 4 and Figure 4a As shown, the casing cementing full-diameter infinite stage fracturing completion device includes casing string 1, multiple hydraulic casing centralizers 2, and multiple fracturing completion sliding sleeves 3 (according to the The number of stages is determined), differential pressure fracturing completion sliding sleeve 14, long-wing cementing plug 5, bumper seat valve 6 and bottom circulation valve 7. A plurality of hydraulic casing centralizers 2 are multiple and connected to the casing string 1, and a plurality of fracturing completion sliding sleeves 3 are connected to the casing string 1 to form a casing cementing full-diameter infinite stage Staged fracturing completion device, and both ends of each stage of fracturing completion sliding sleeve are equipped with hydraulic casing centralizer 2, differential pressure fracturing completion sliding s...

Embodiment 2

[0089] refer to figure 1 , Figure 1a , Figure 1b , figure 2 , Figure 2a , Figure 2b , image 3 , Figure 4 and Figure 4a As shown, as a preferred embodiment, it is basically the same as Embodiment 1, the difference is that there is a fracturing completion sliding sleeve 3 on each stage of the fracturing completion device, and the opening on the fracturing completion sliding sleeve 3 The groove 3-7 includes a guide opening 3-13, a slider groove 3-11 and a guide groove 3-12. Wherein, guide opening 3-13 is tapered and is connected with slide block groove 3-11, and slide block groove 3-11 cooperates with opening slide block 13-6, and guide groove 3-12 and guide key 13-8 match. Also be provided with connecting piece 13-7 between tool lower joint 13-9 and central pipe 13-4, form for opening slide between connecting piece 13-7 and tool upper joint 13-2 and central pipe 13-4. Block 13-6 carries out the limit groove of radial limit. A pressure cap 13-10 is sleeved betw...

Embodiment 3

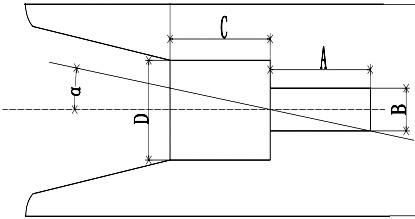

[0102] It is basically the same as Embodiment 1, the difference is that there are multiple opening grooves 3-7, which are distributed in a 360° spiral at the lower part of the inner sliding sleeve 3-3, and the opening groove 3-7 is connected with the inner sliding sleeve 3-3. The 3-axis can have an inclination angle α, and the inclination angle α is 0-60°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com