Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Improve clamping rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steering column device

Owner:NSK LTD

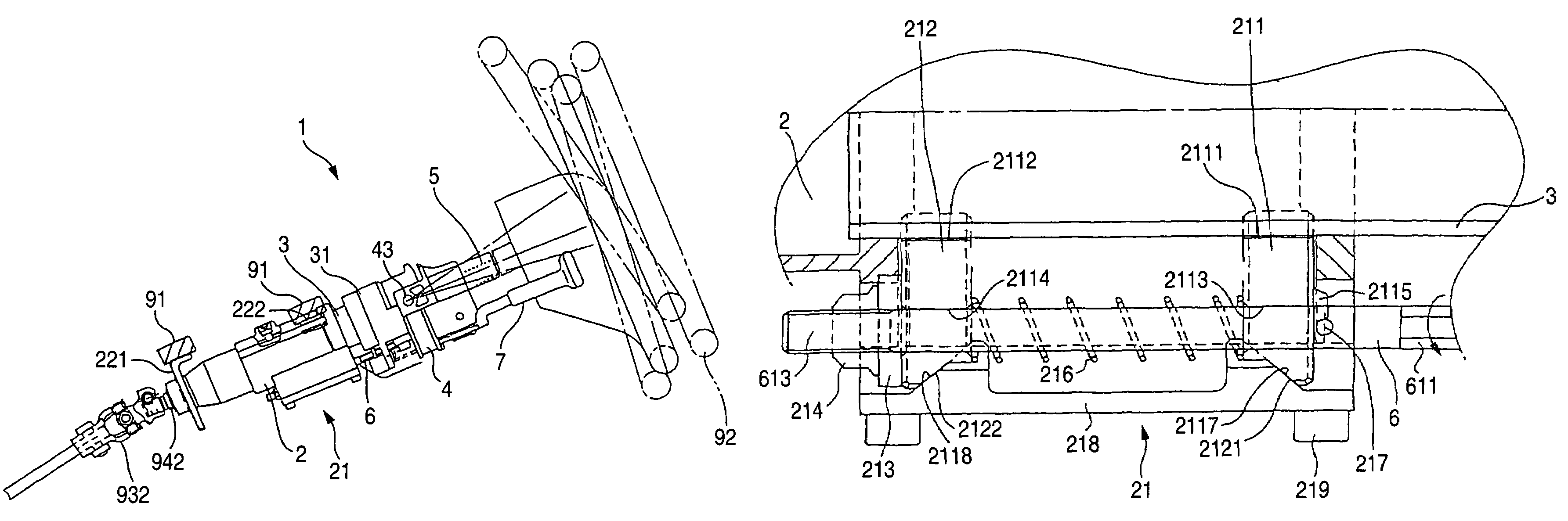

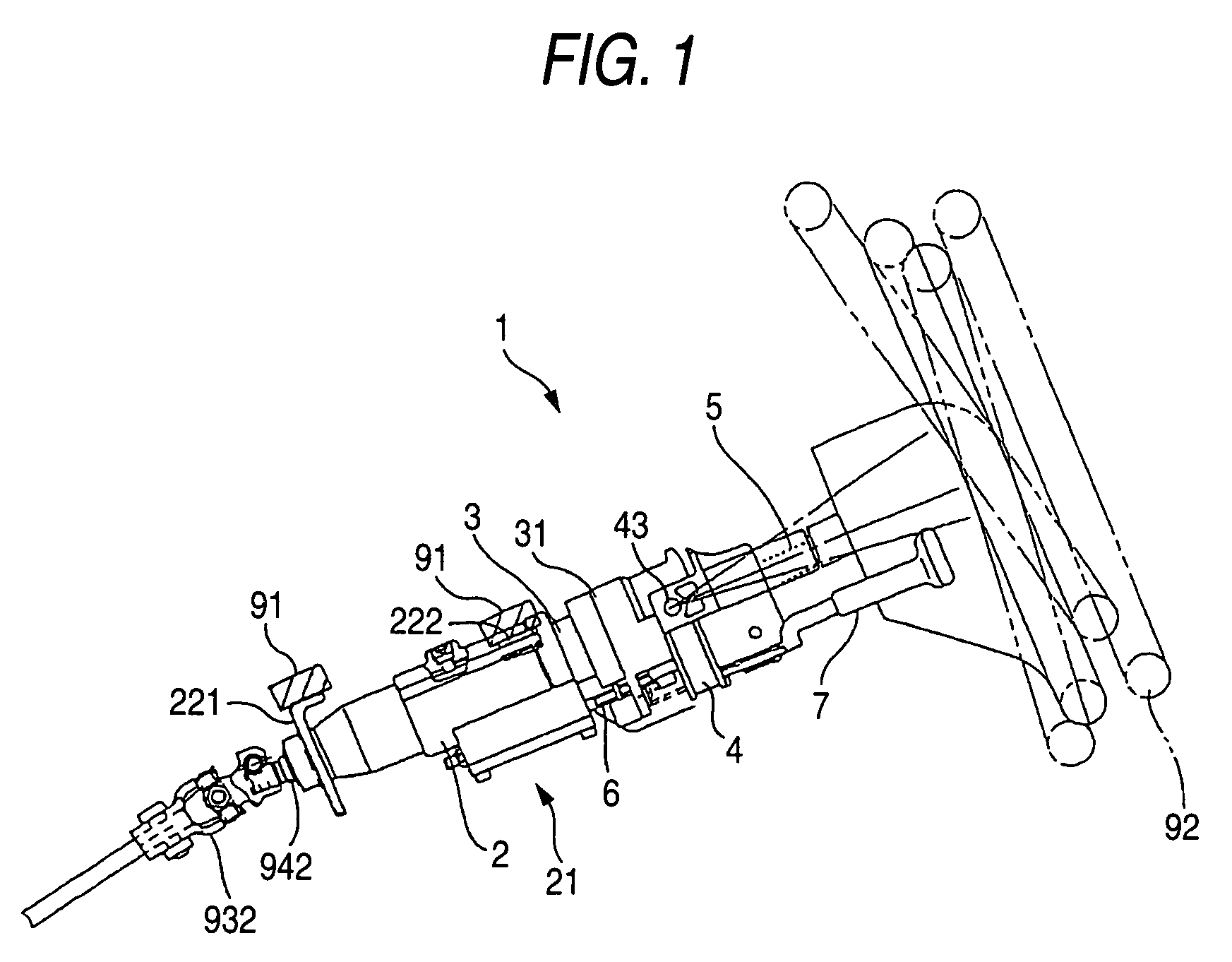

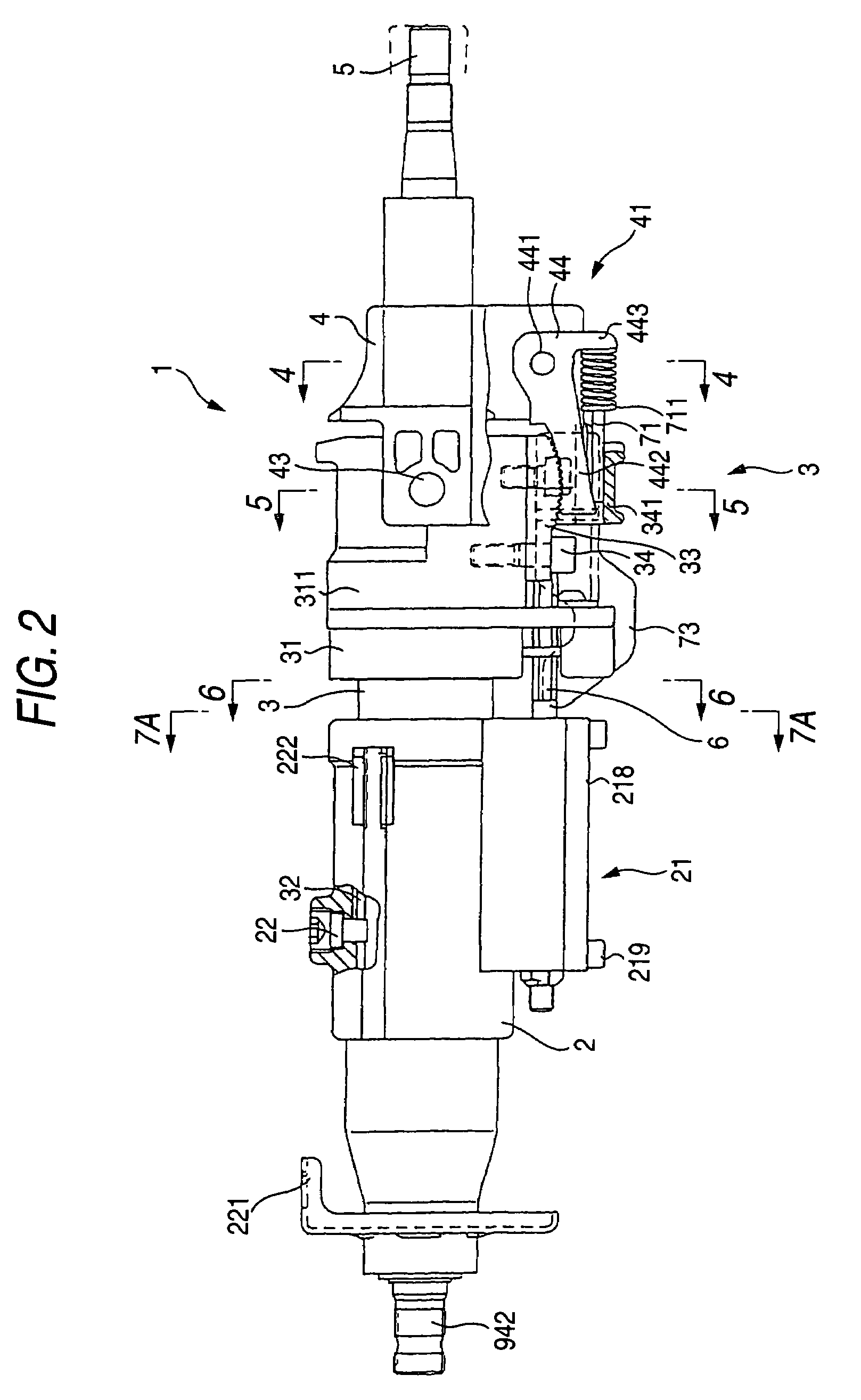

Steering column apparatus

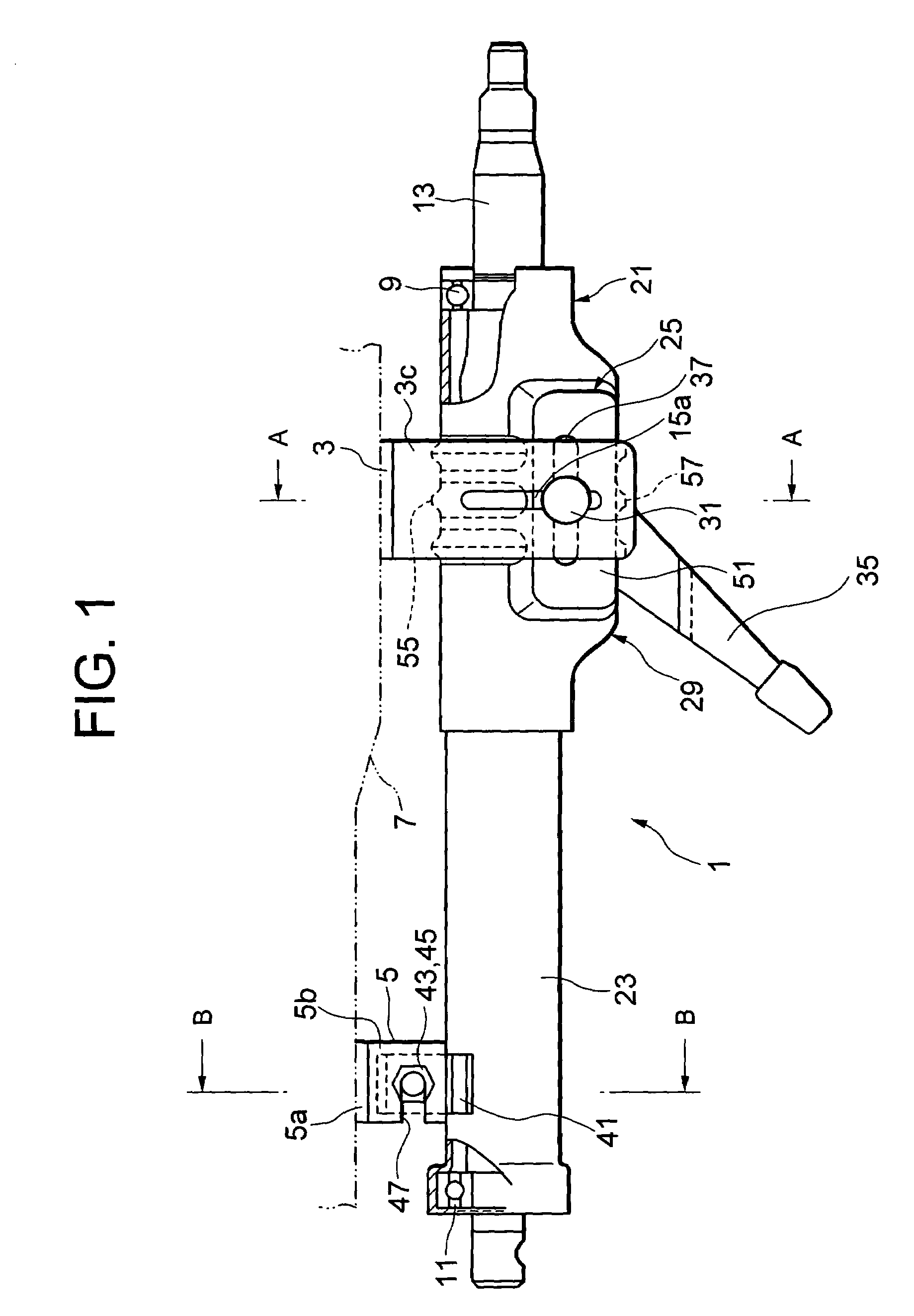

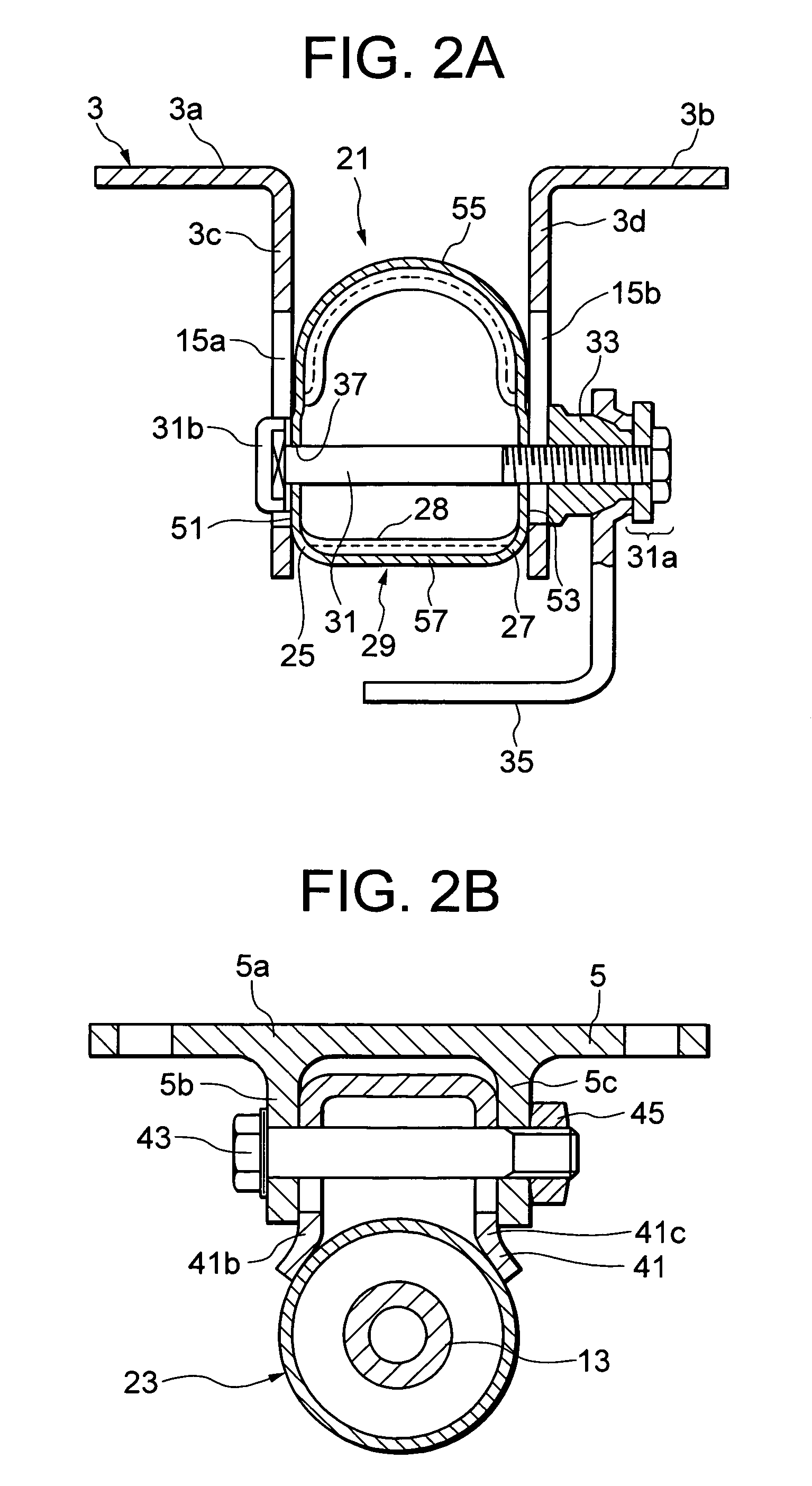

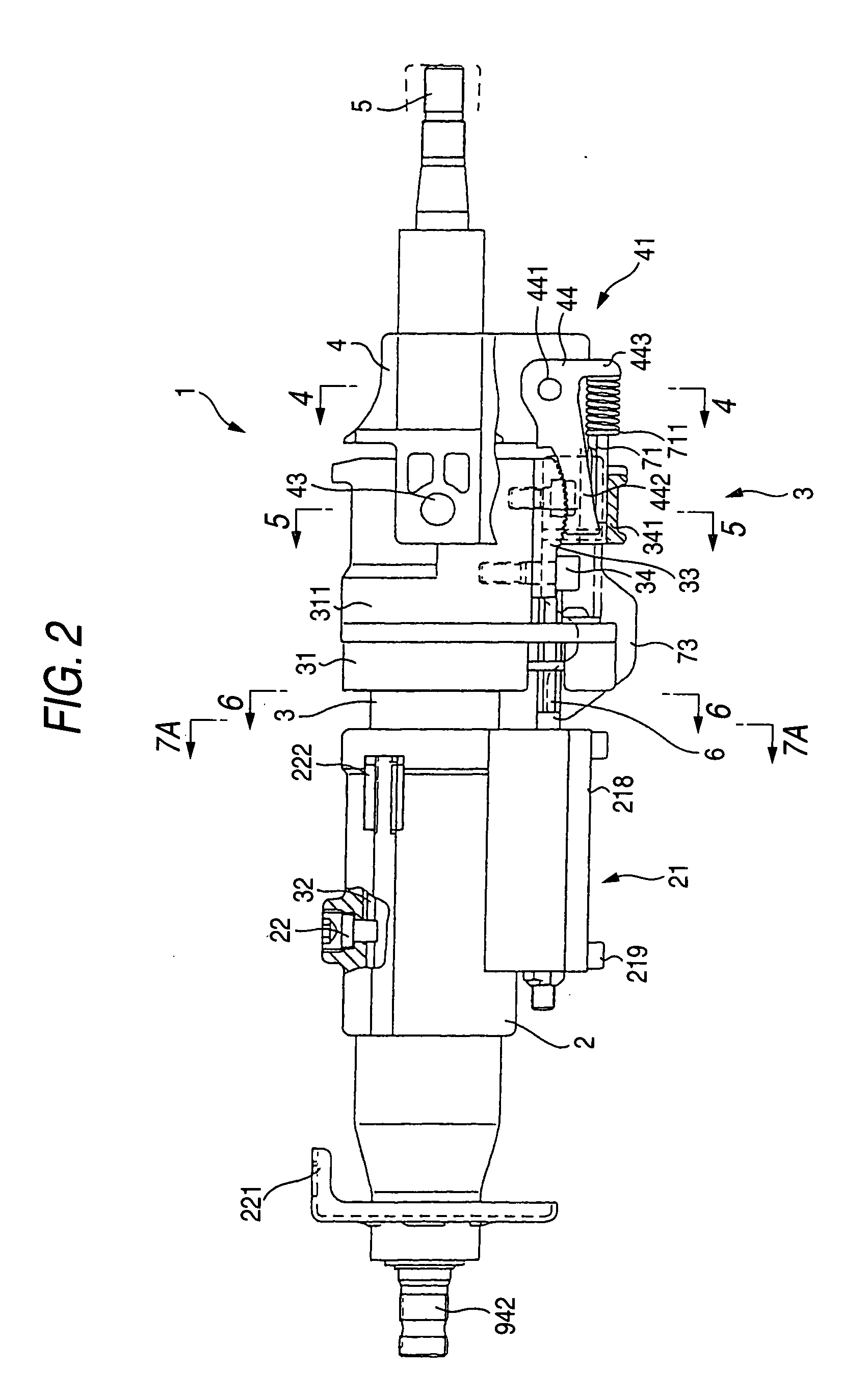

InactiveUS20050081674A1Improve clamping rigidityEasy to adjustSteering columnsSteering wheelSteering column

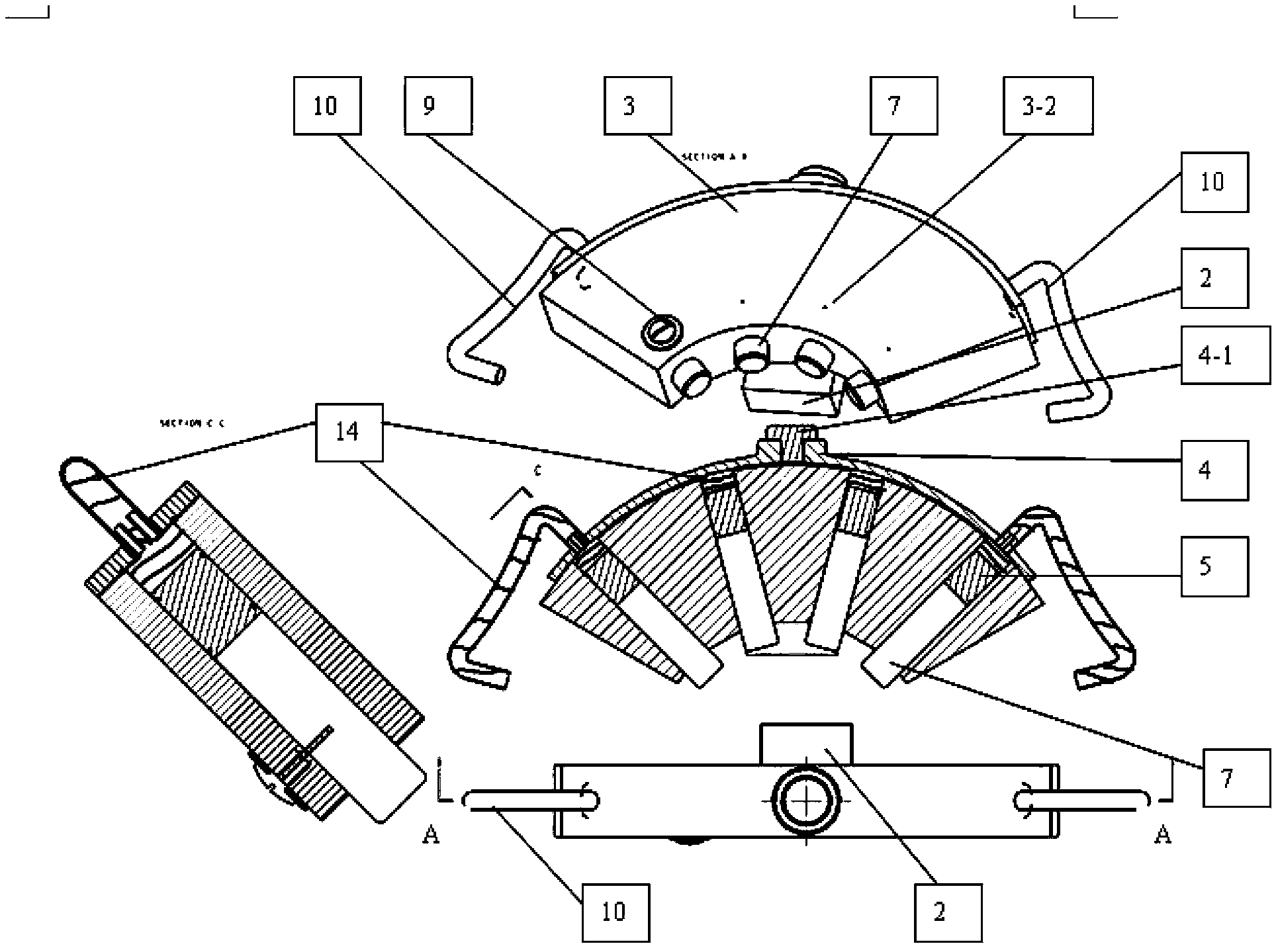

A steering column apparatus includes: a stationary column member; a movable column member whose one end is supported on the stationary column member nonrotatably about a center axis and movably along the center axis; a column head disposed on the other end of the movable column member; a wheel shaft supported rotatably on the column head; a column clamp for clamping and unclamping the movable column member with respect to the stationary column member at two or more points which are spaced along the center axis of the movable column member; and a control lever whose operation lever end is positioned in the vicinity of a steering wheel and which is capable of operating the column clamp.

Owner:NSK LTD +1

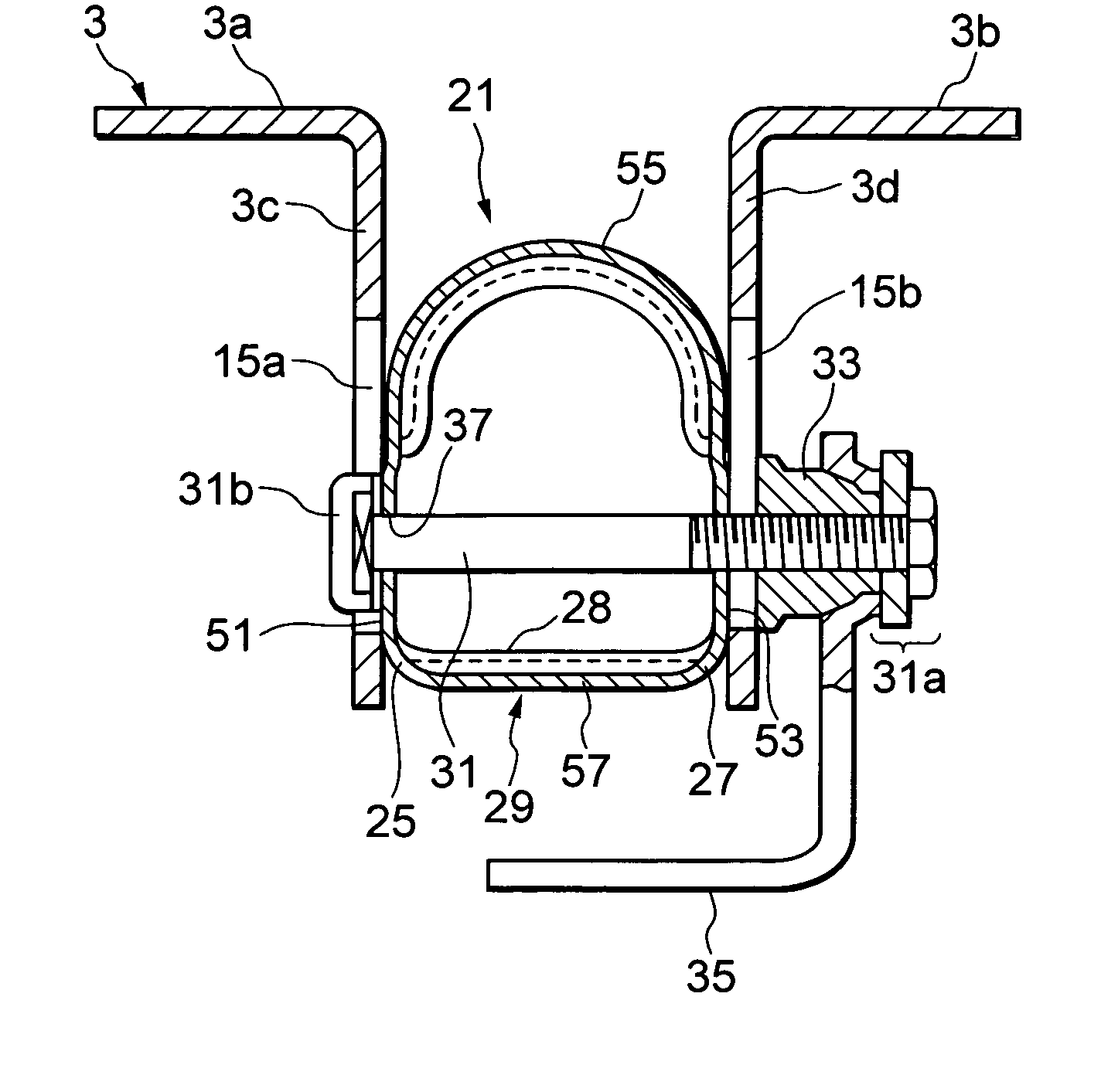

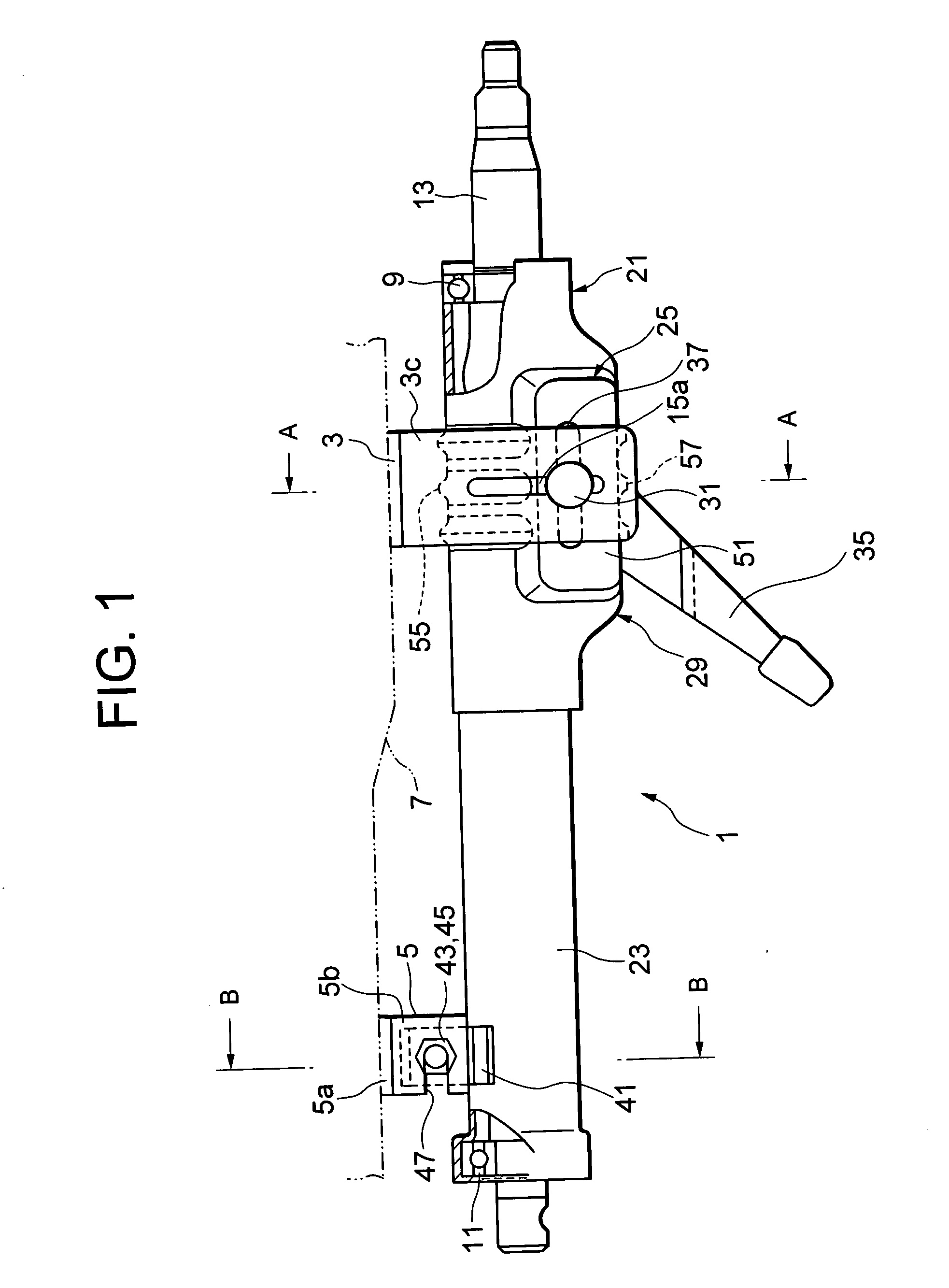

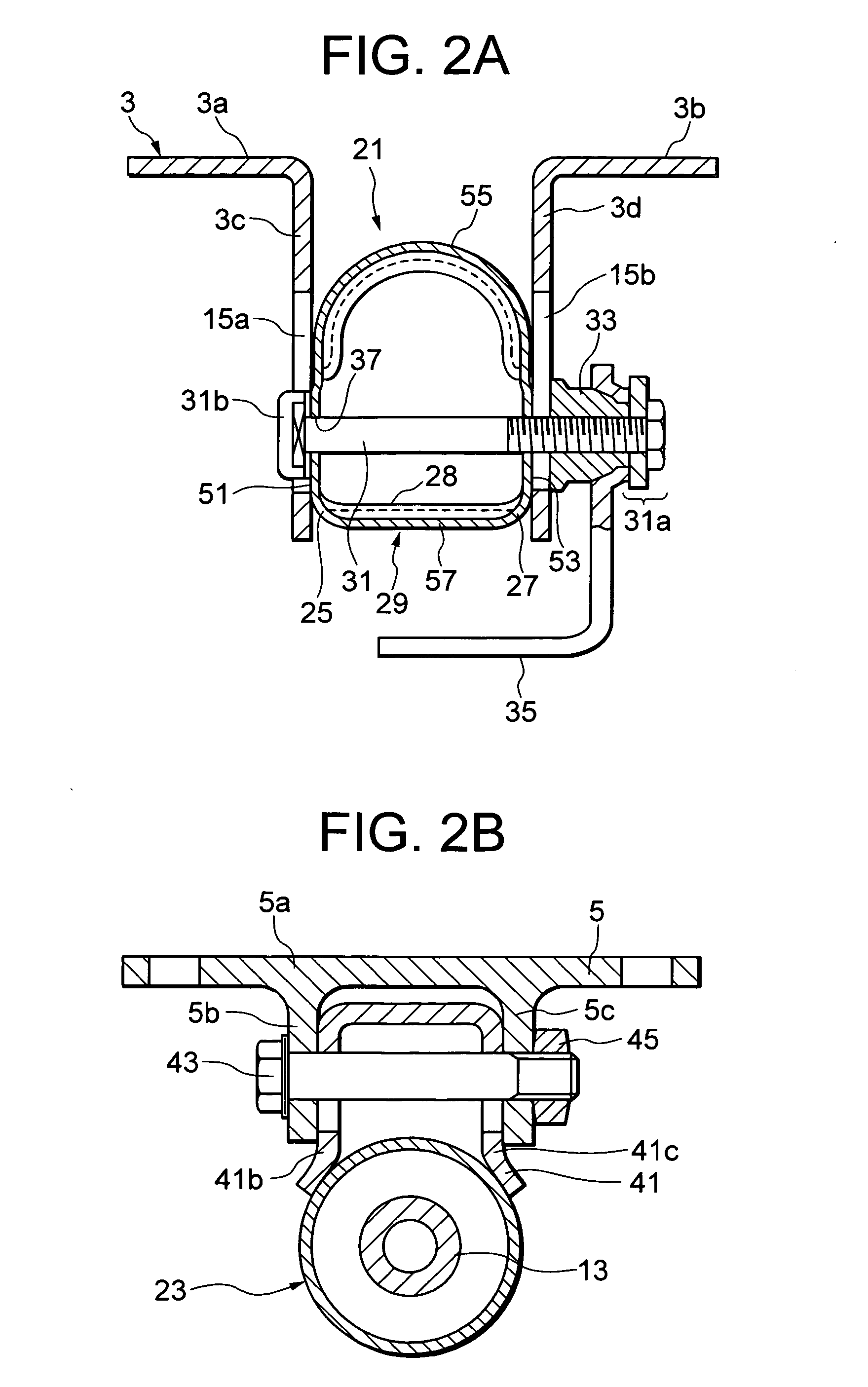

Steering column device

A steering column apparatus comprising: a steering column provided with a body-side bracket mounted to a body strength member to have a pair of side plate portions opposed each other to be extended in a vertical direction, and a substantially cylindrical distance unit for supporting a steering shaft to be rotatable therein and having a pair of pressed and expanding portions formed to be expanded by plastic working to be pressed and supported by the side plate portions of the body-side bracket; and an adjusting mechanism capable of adjusting a position of the steering column with respect to the side plate portions of the body-side bracket within a predetermined range, wherein the steering column is formed with a reinforcement portion for enhancing the clamping rigidity of the distance unit with respect to the side plate portions.

Owner:NSK LTD

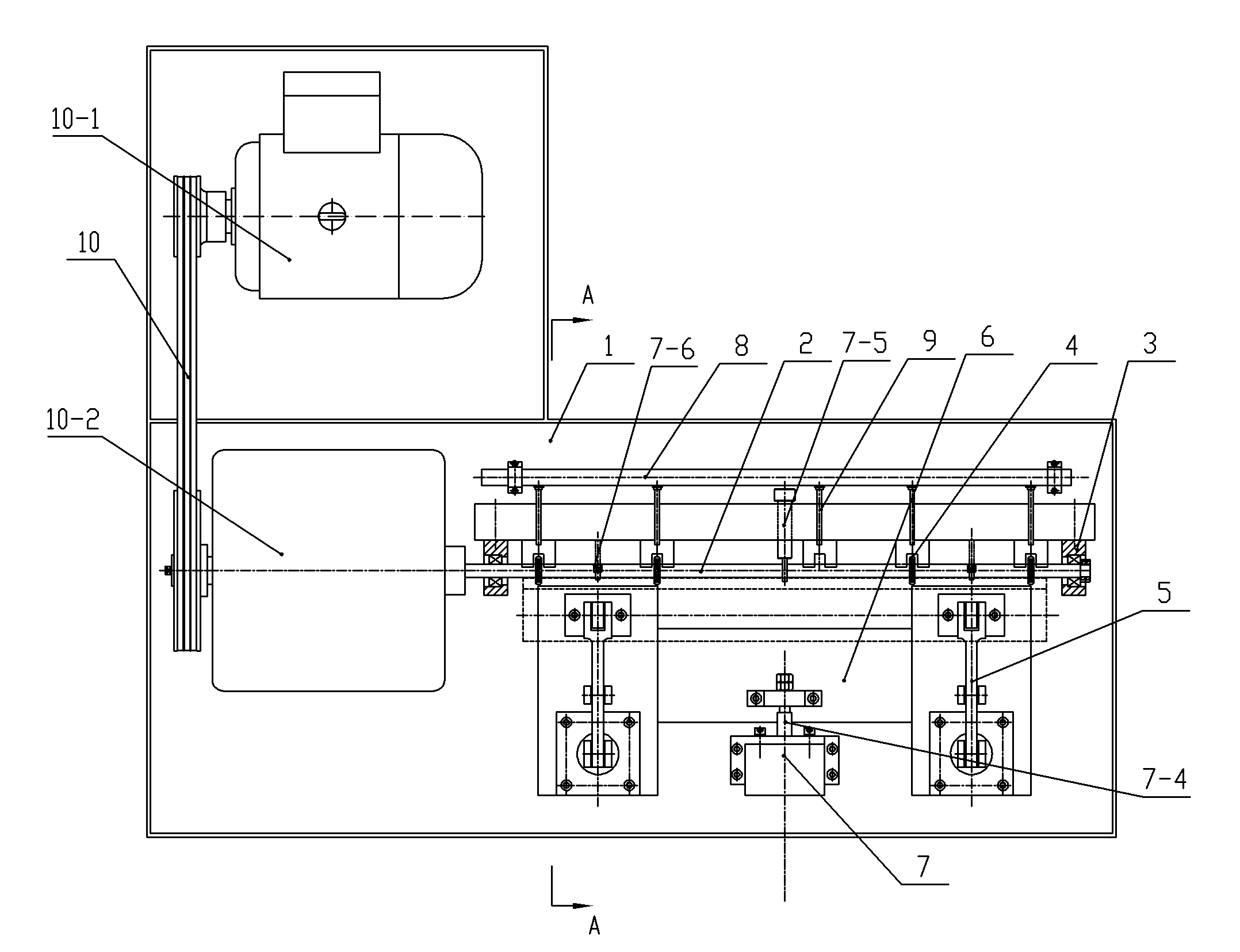

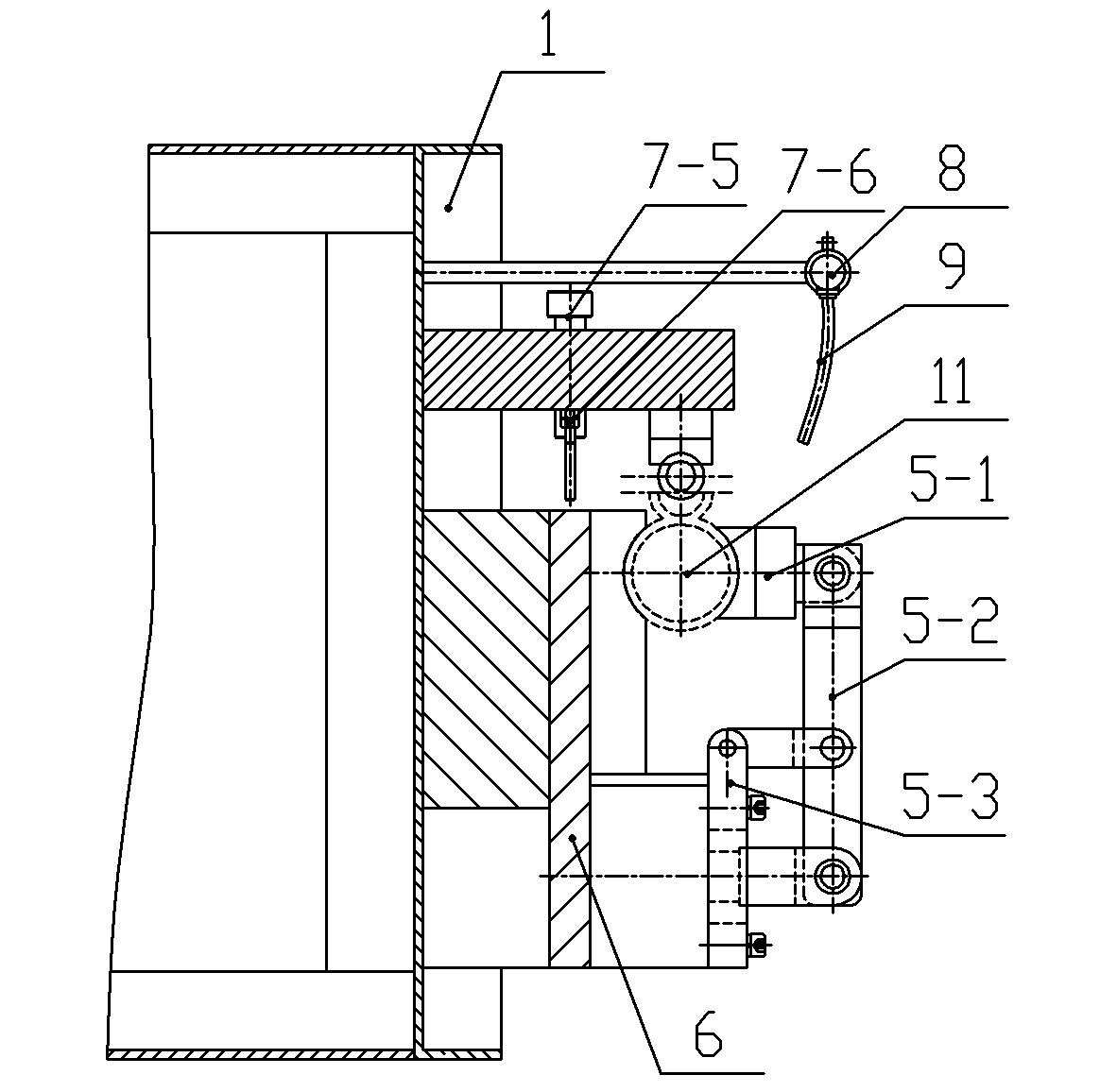

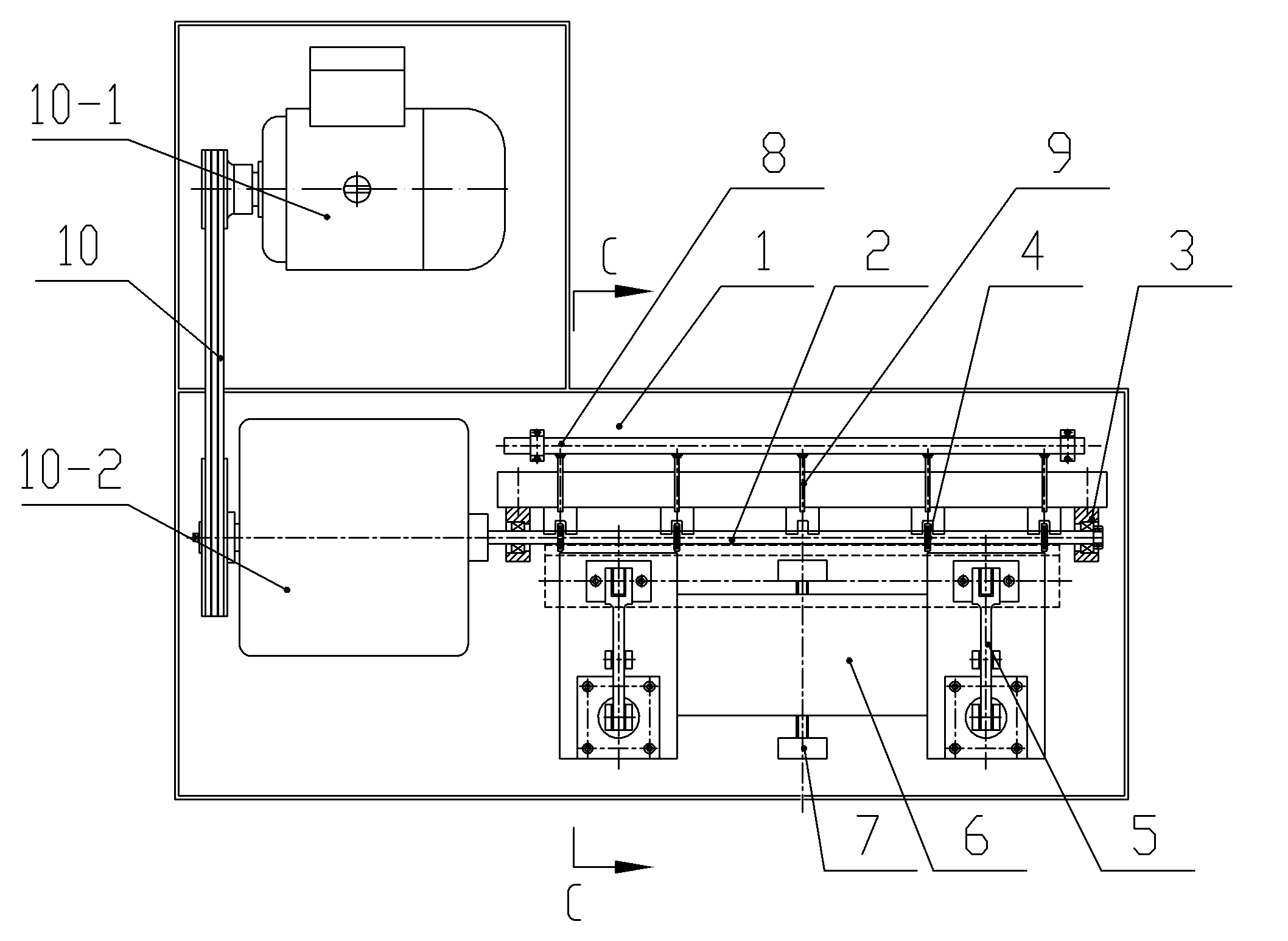

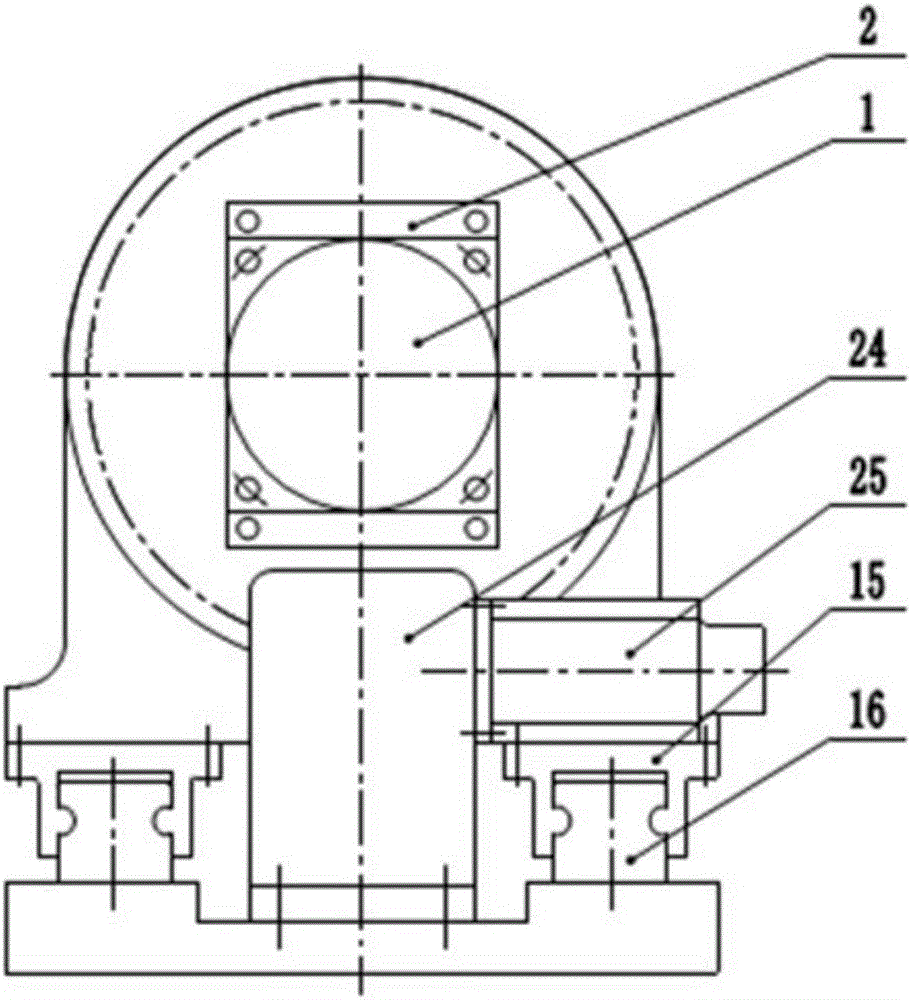

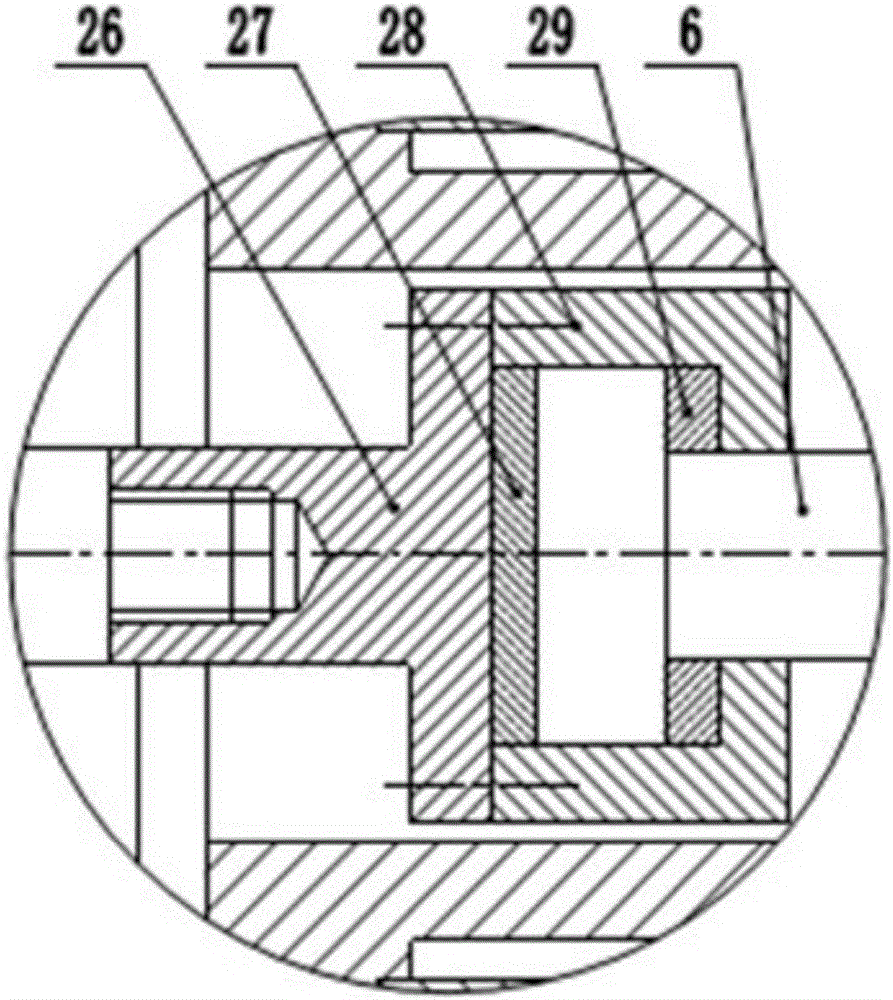

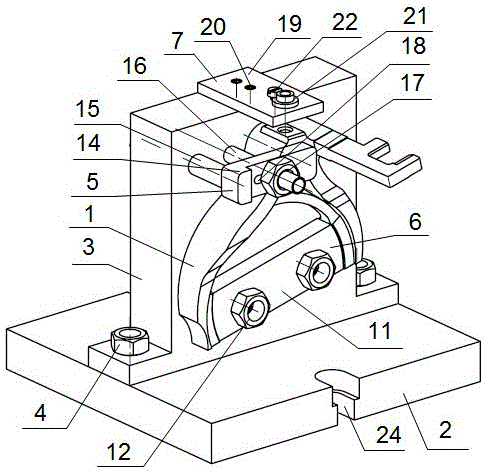

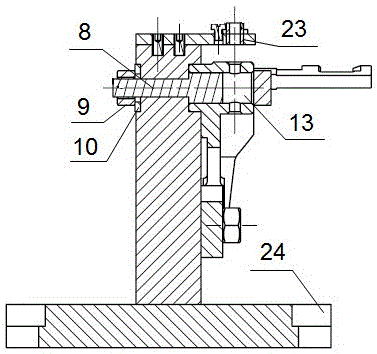

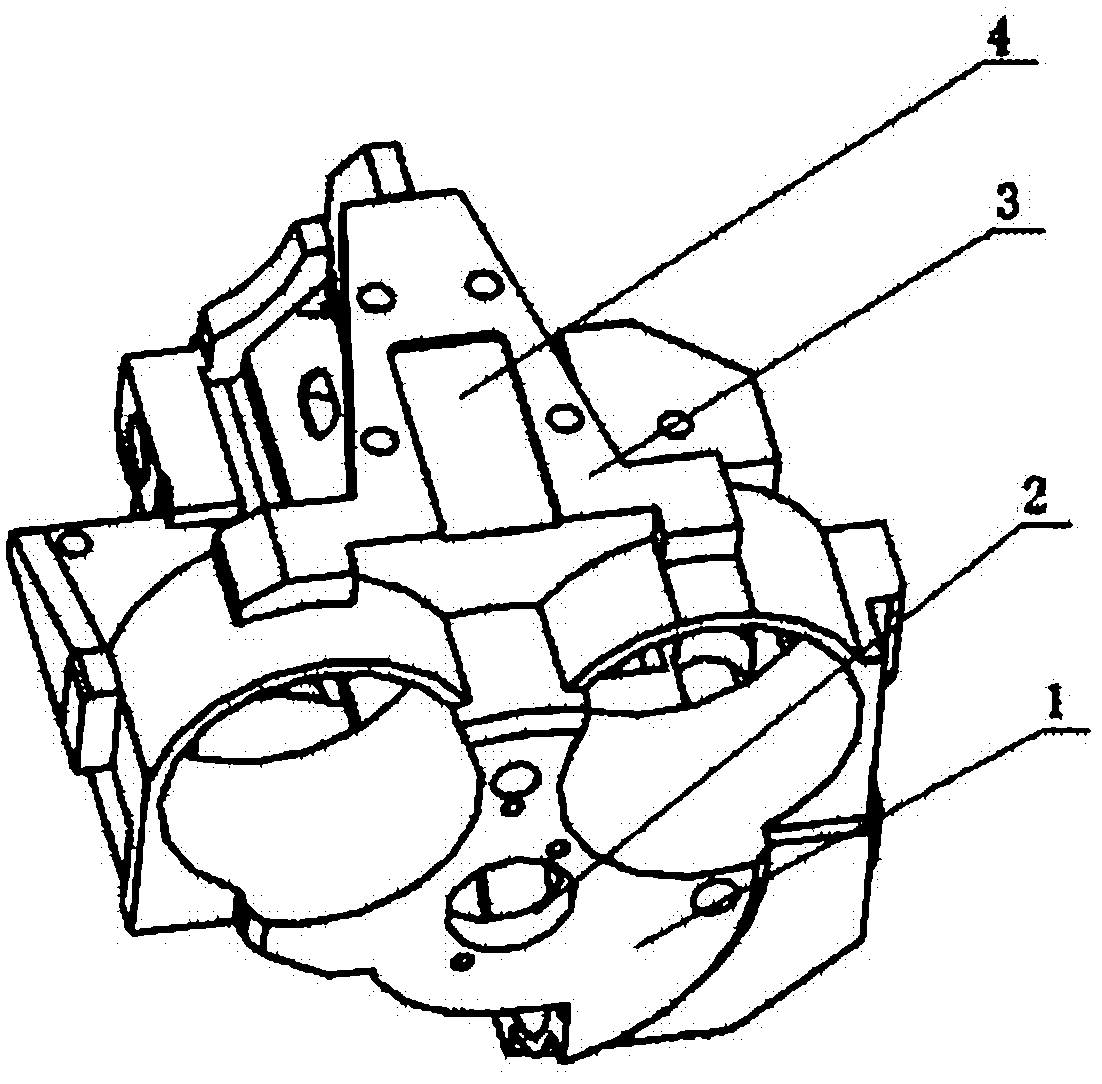

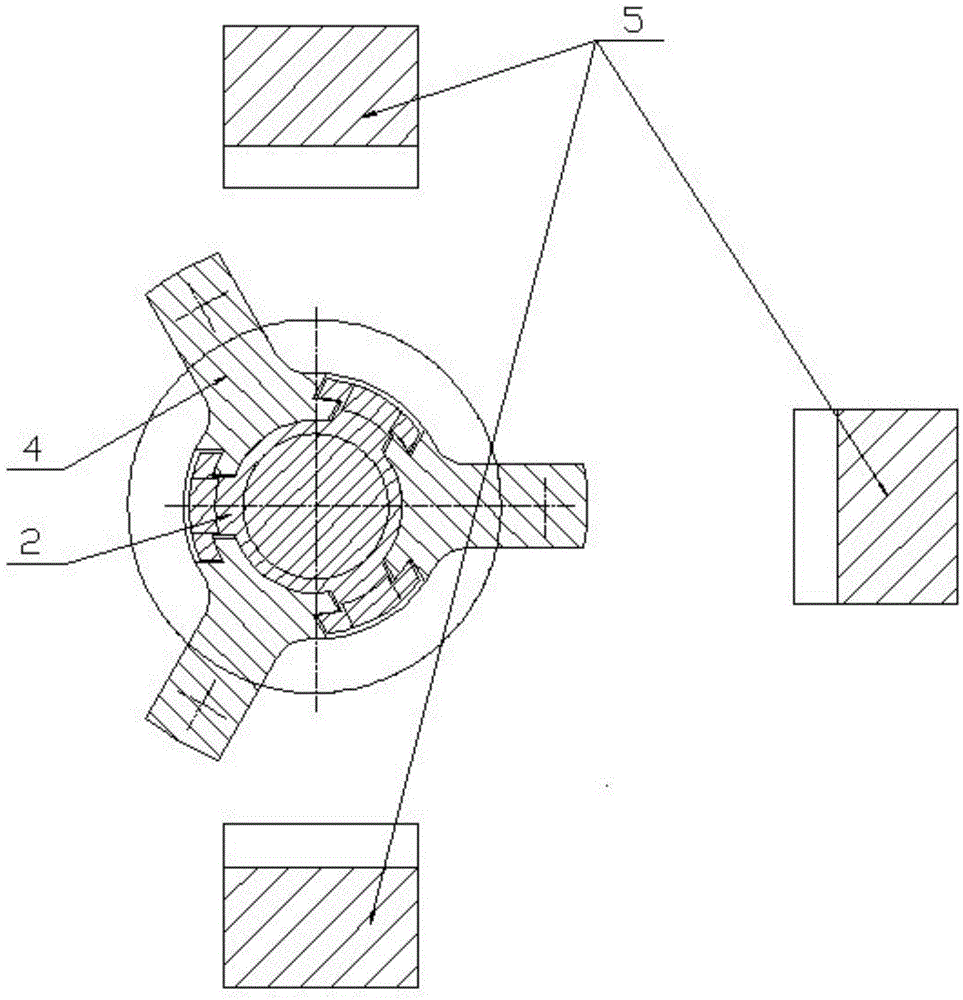

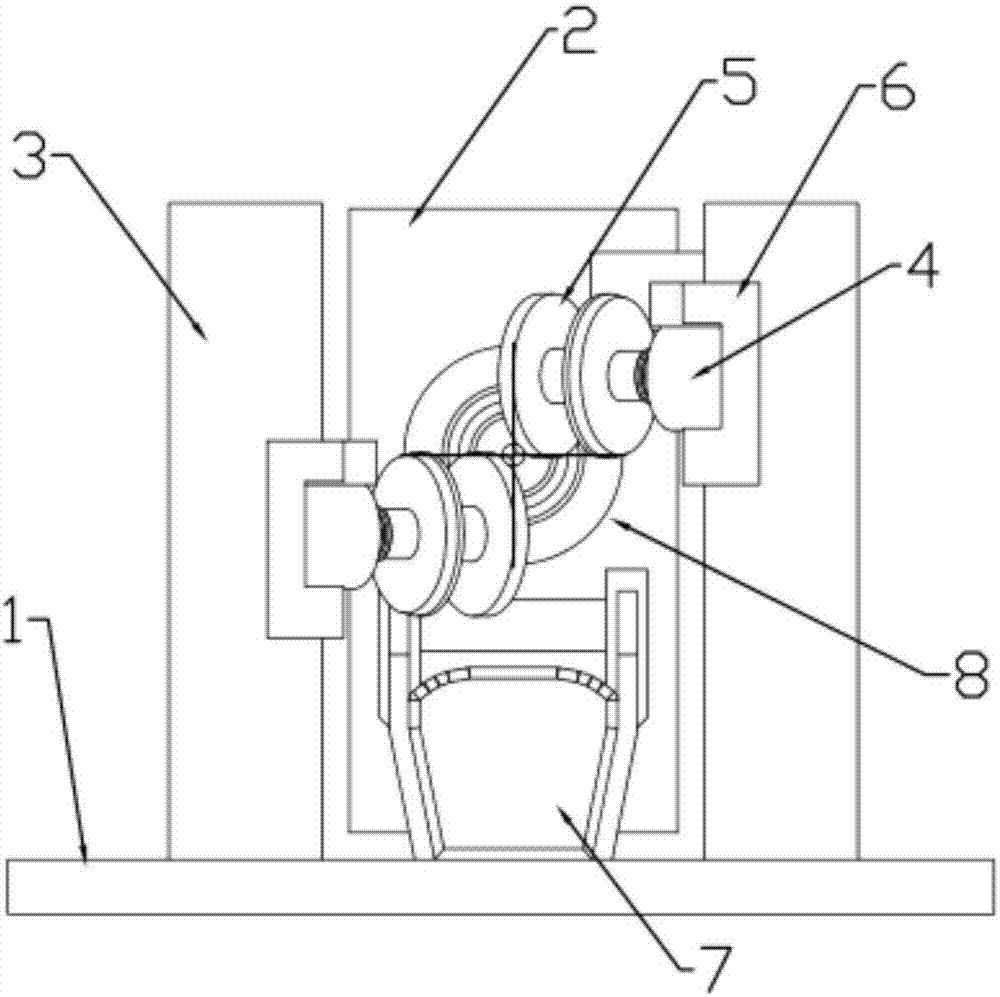

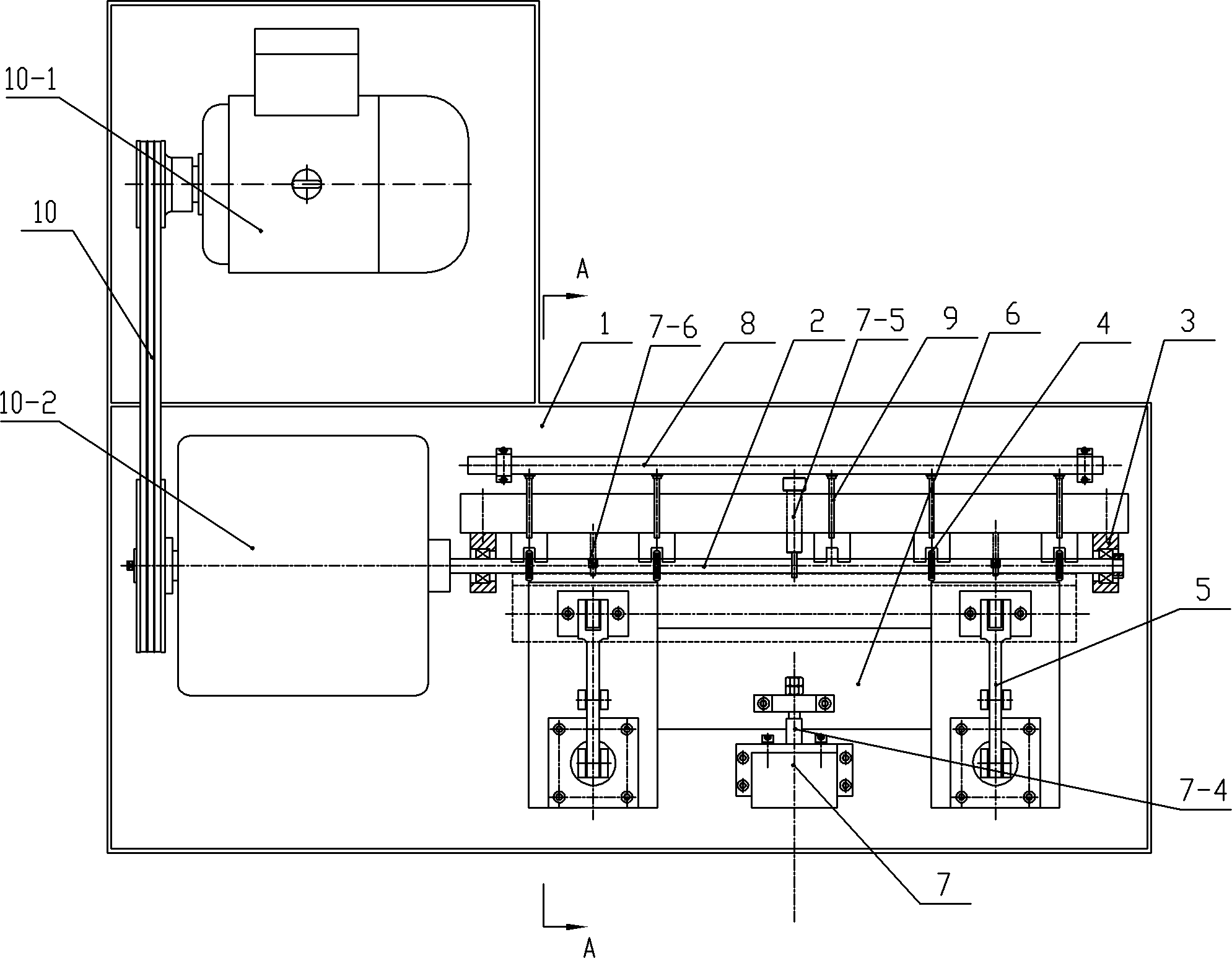

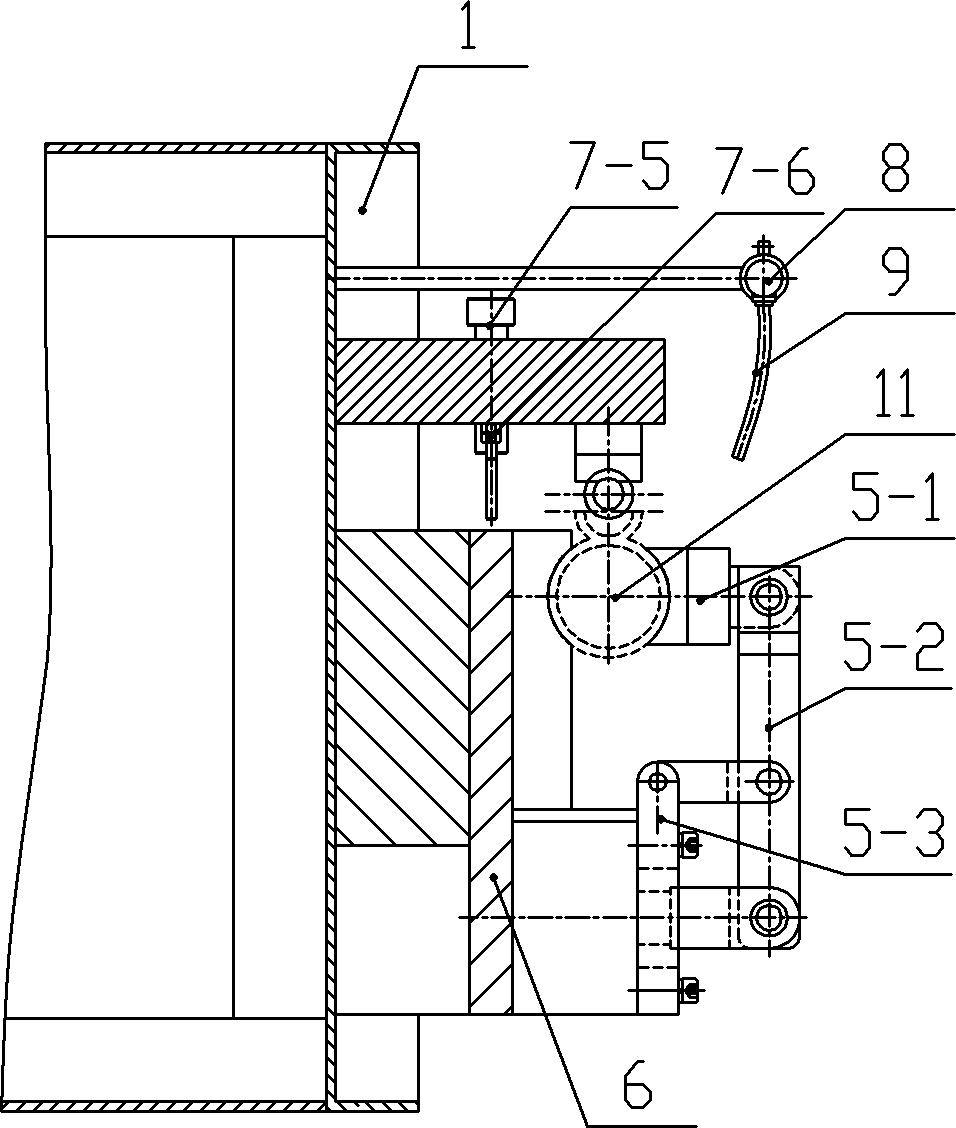

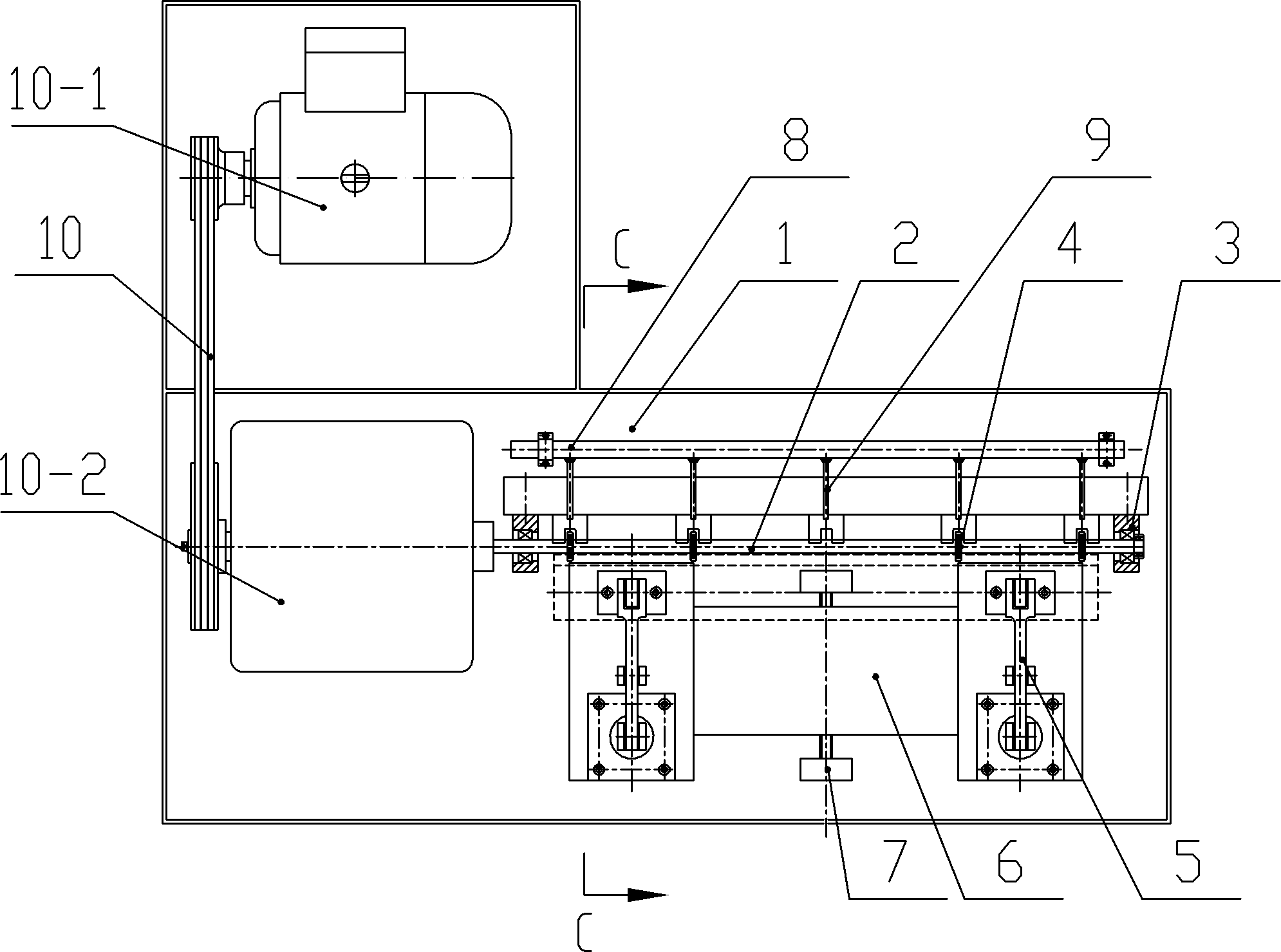

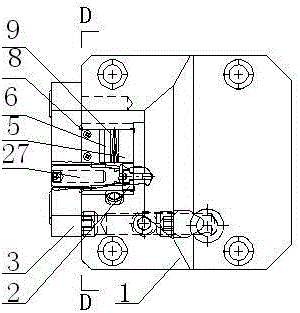

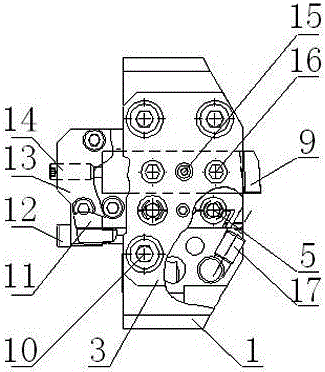

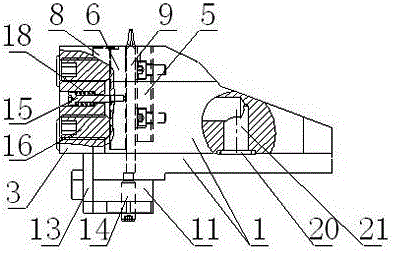

Machine special for cutting waist-shaped arc groove

ActiveCN102091816AImprove clamping efficiencyImprove clamping rigidityMilling equipment detailsEngineeringMotive power

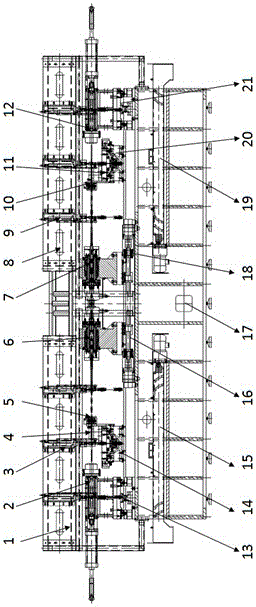

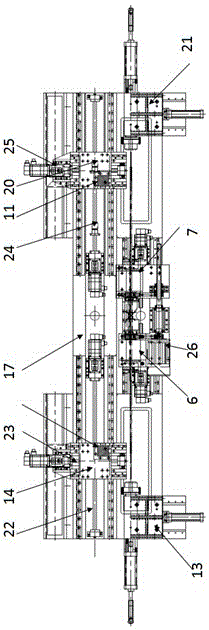

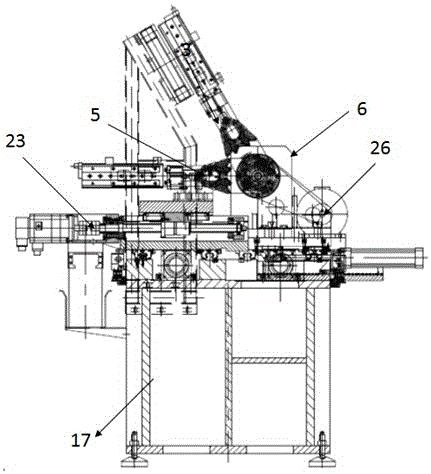

The invention relates to a machine for cutting a groove on a semi-round tube, in particular to a machine special for cutting a waist-shaped arc groove. The machine comprises a workbench, a groove cutting mechanism, a workpiece clamping mechanism, a groove cutting feed mechanism and a cooling mechanism; the groove cutting mechanism comprises a motive power mechanism, a groove cutting cutter, and acutter shaft bracket; the motive power mechanism transfers motive power to the grove cutting cutter to rotate the groove cutting cutter so as to perform groove cutting operation; the workpiece clamping mechanism comprises a workpiece clamping hand, a motive power transfer joint and a motive power device; and the motive power device transfers the motive power to the workpiece clamping hand throughthe motive power transfer joint, and the workpiece clamping hand works to tightly clasp a workpiece. The groove cutting feed mechanism comprises a carriage and a carriage diving mechanism arranged onthe workbench and used for driving the carriage to be fed or retreated; and a workpiece clamping mechanism is arranged on the carriage. The machine can radially cut arc grooves or waist-shaped arc grooves on a cambered surface of the semi-round tube conveniently, efficiently and accurately.

Owner:CHANGZHOU TENGLONG AUTO PARTS CO LTD

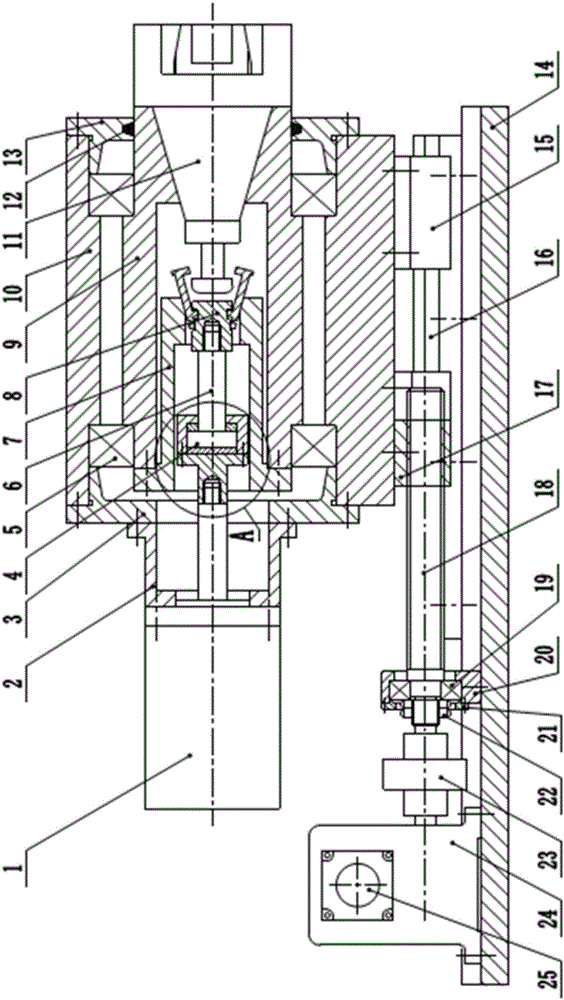

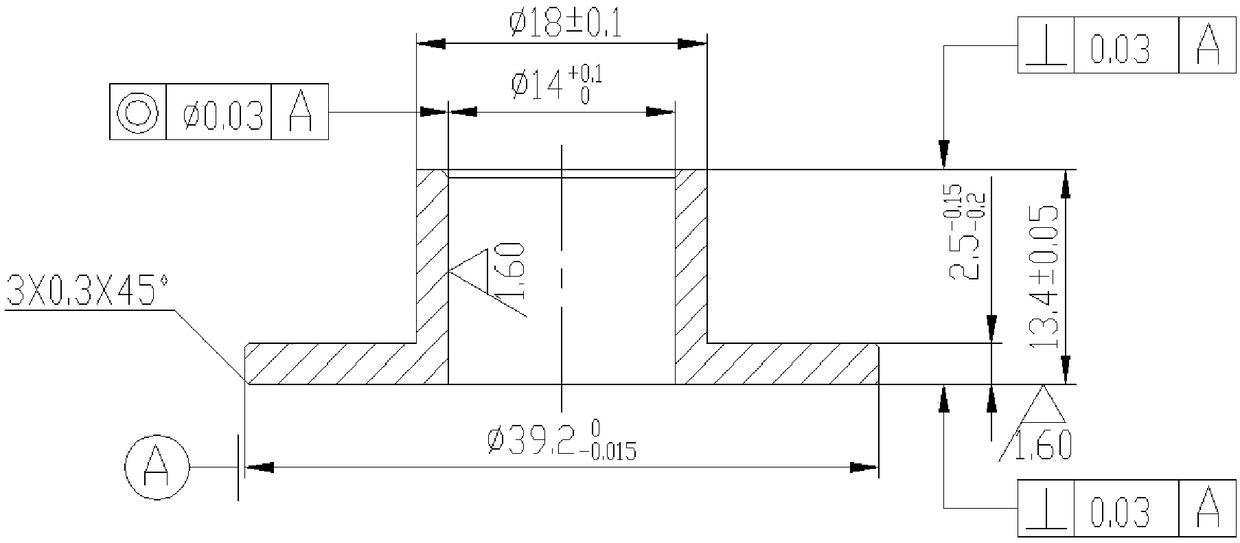

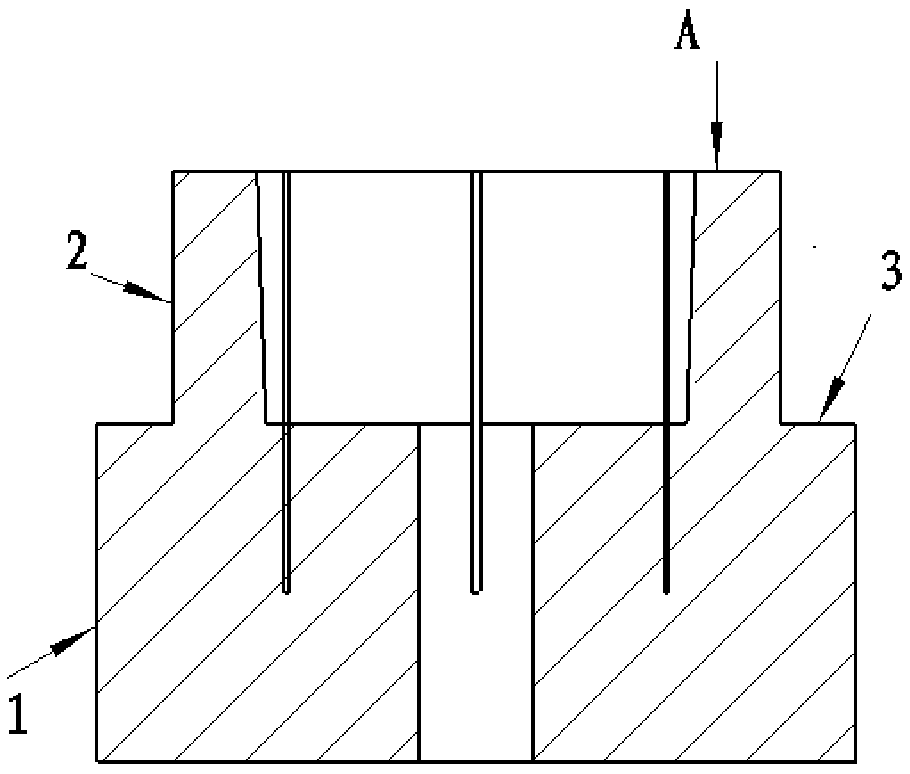

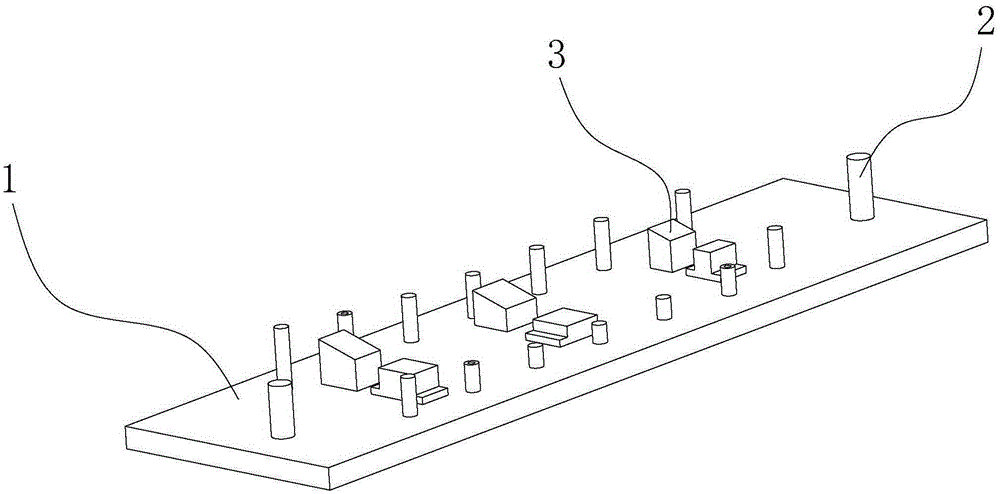

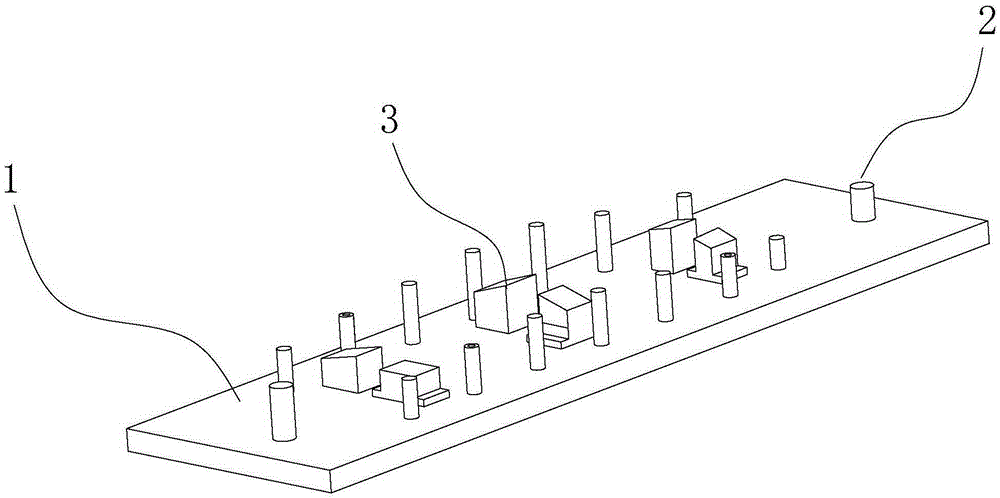

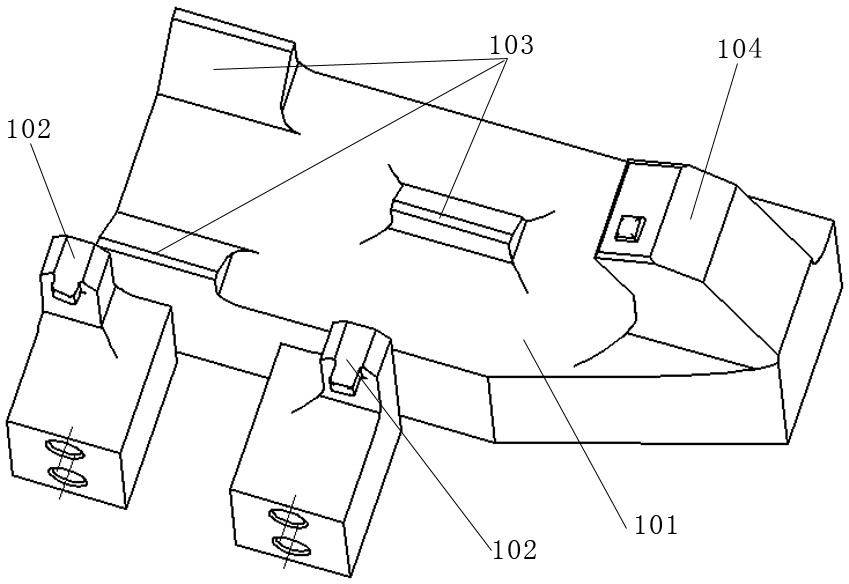

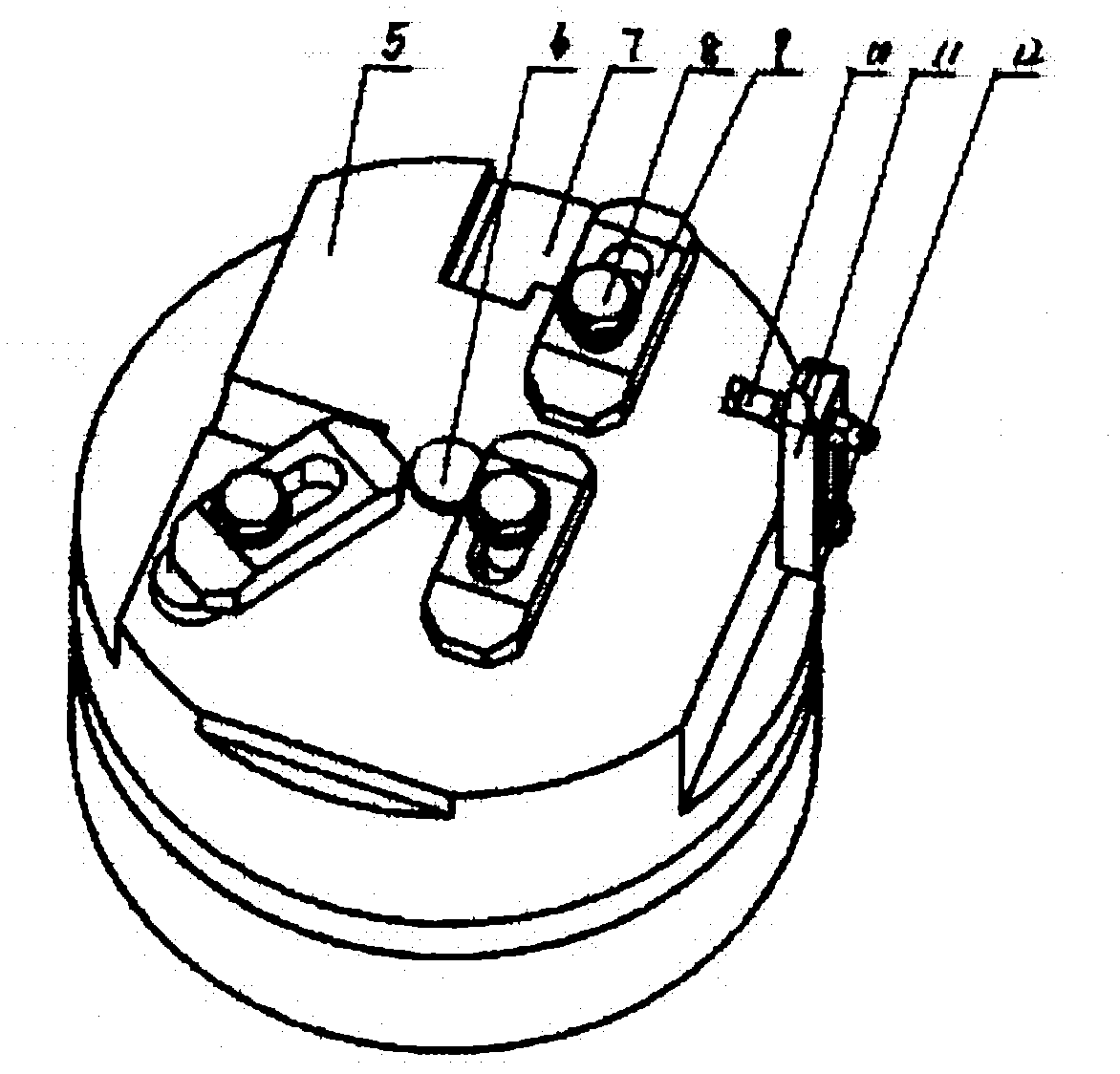

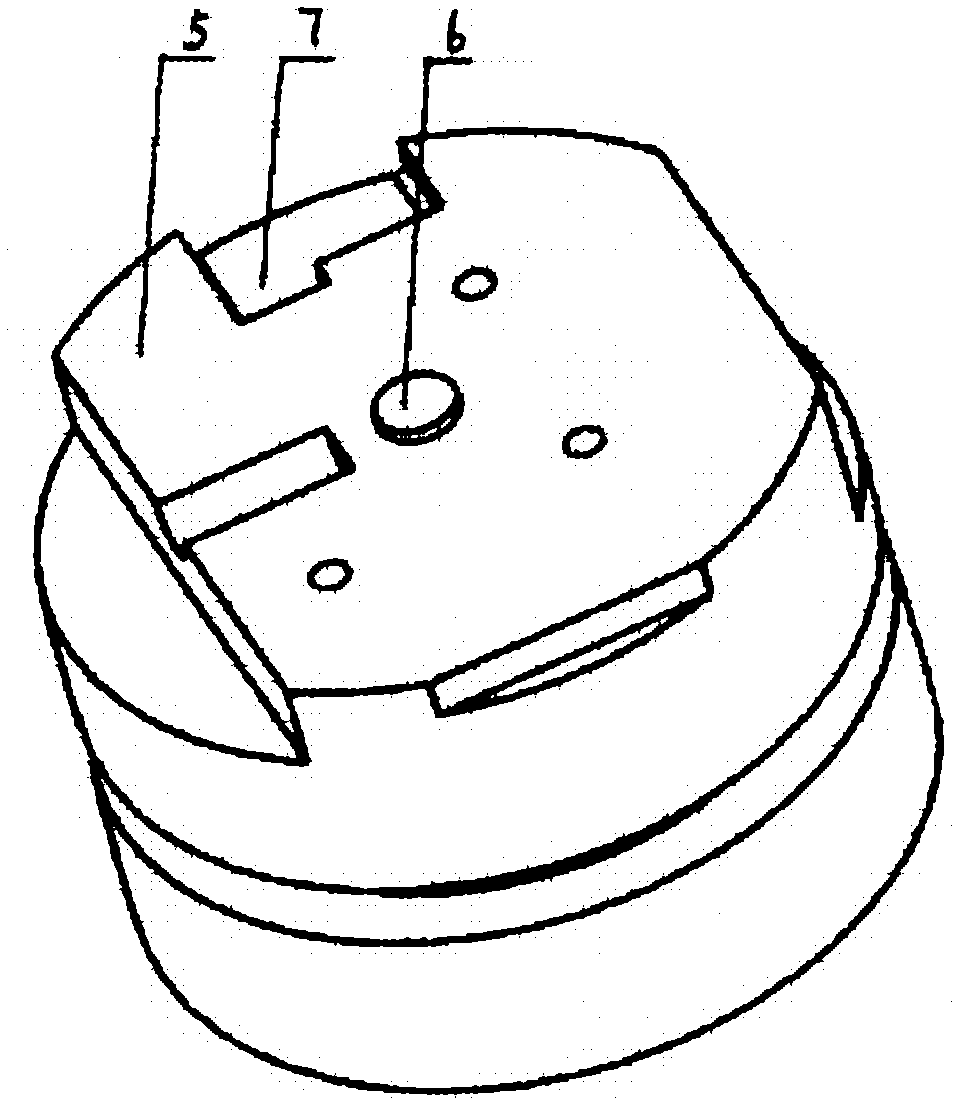

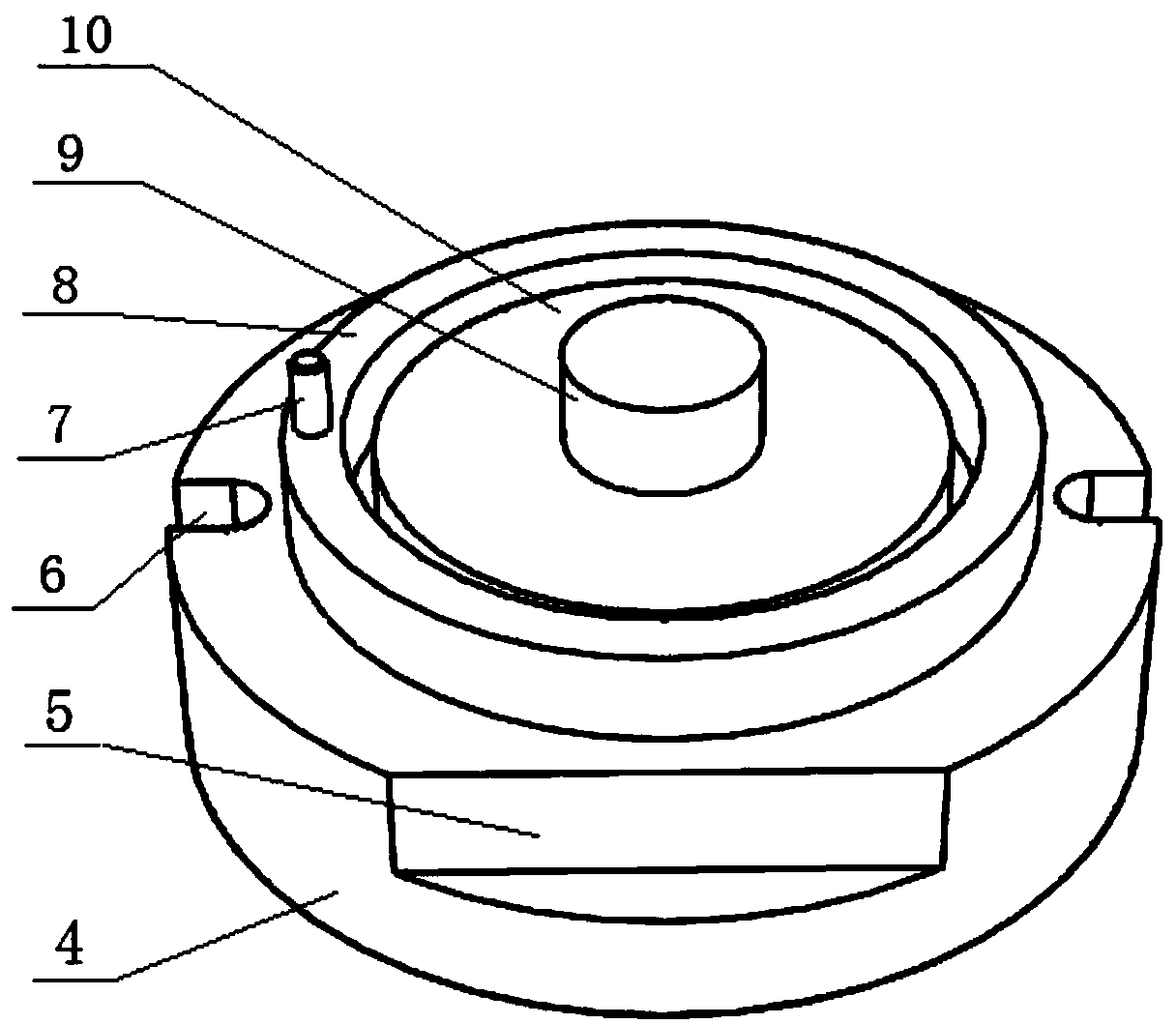

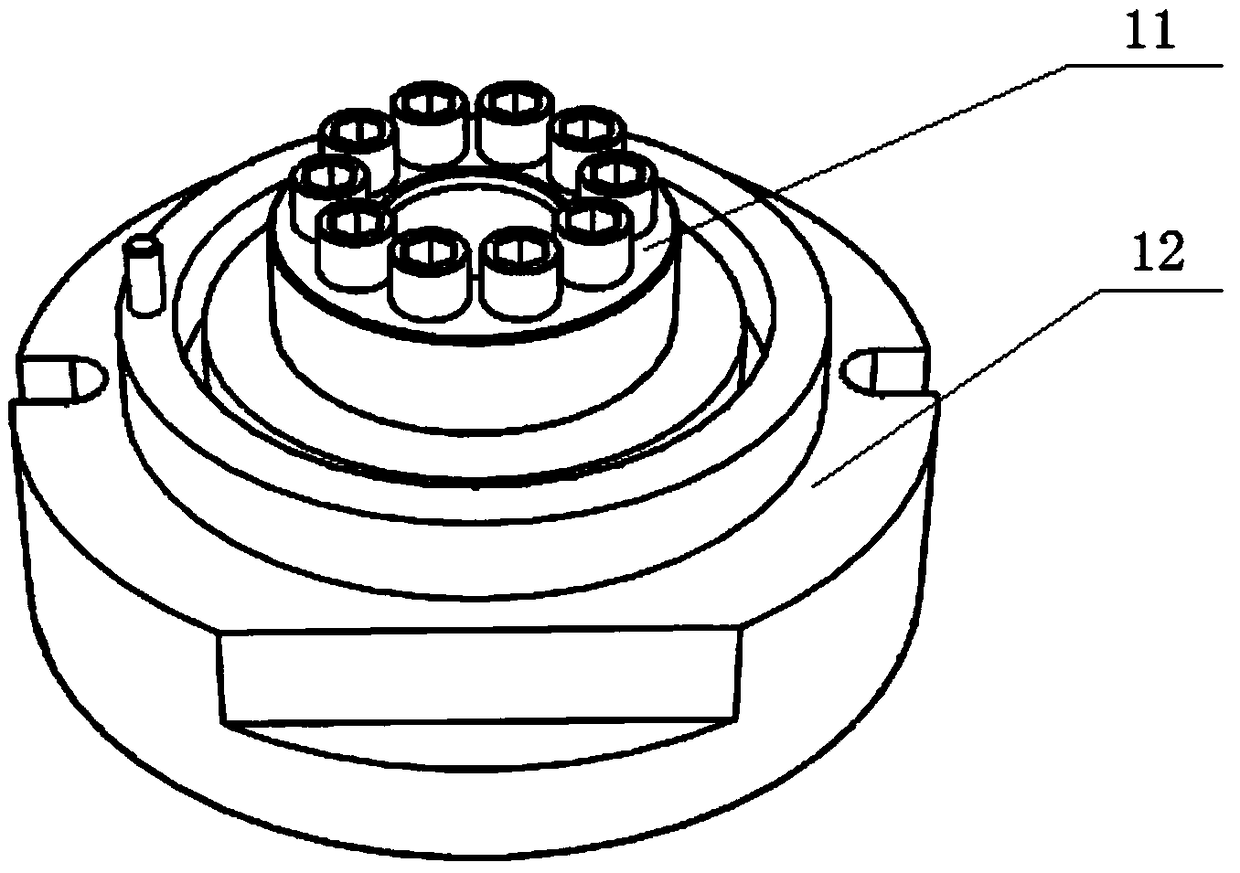

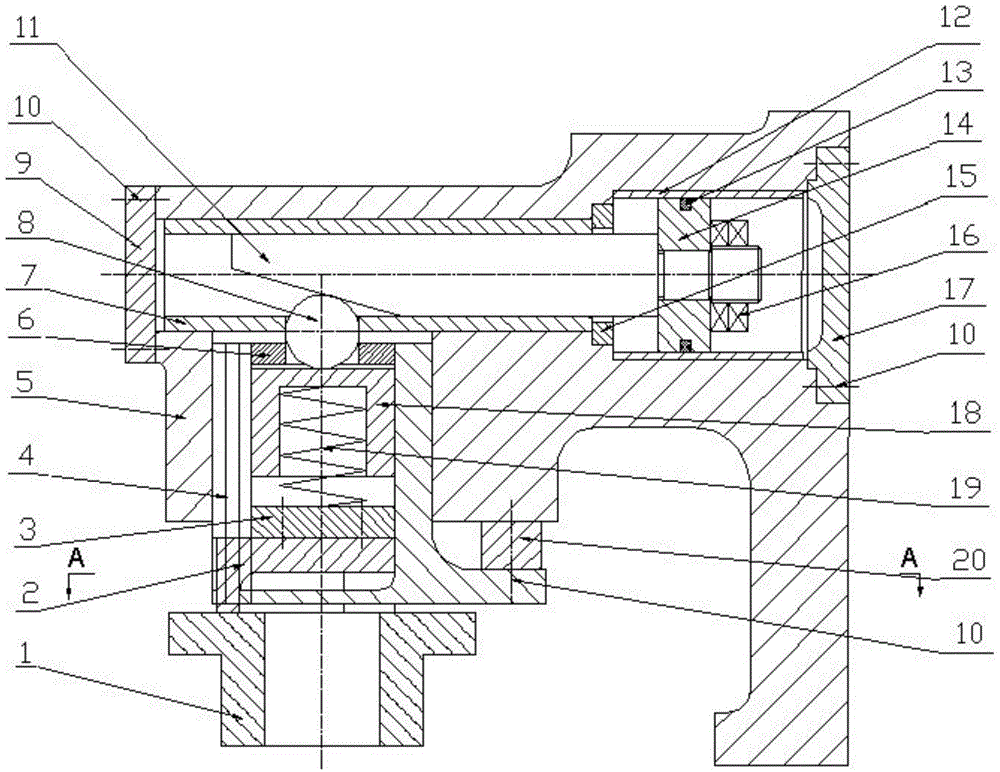

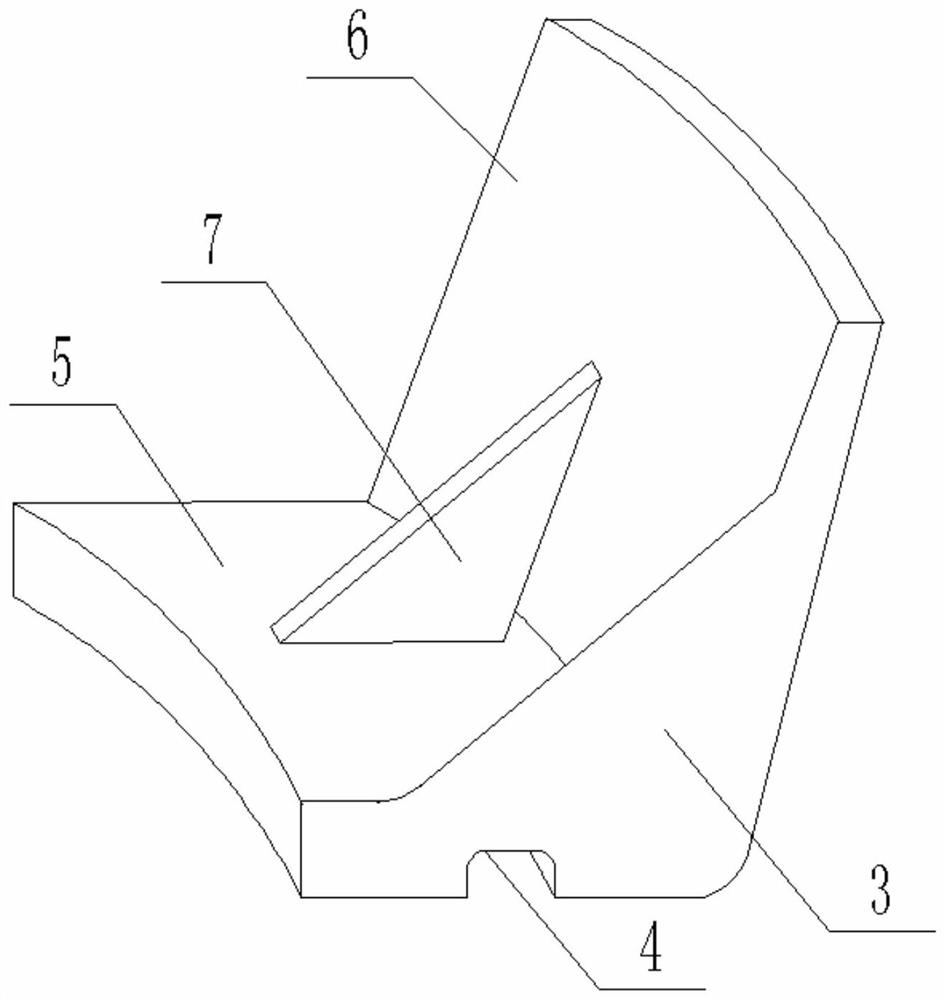

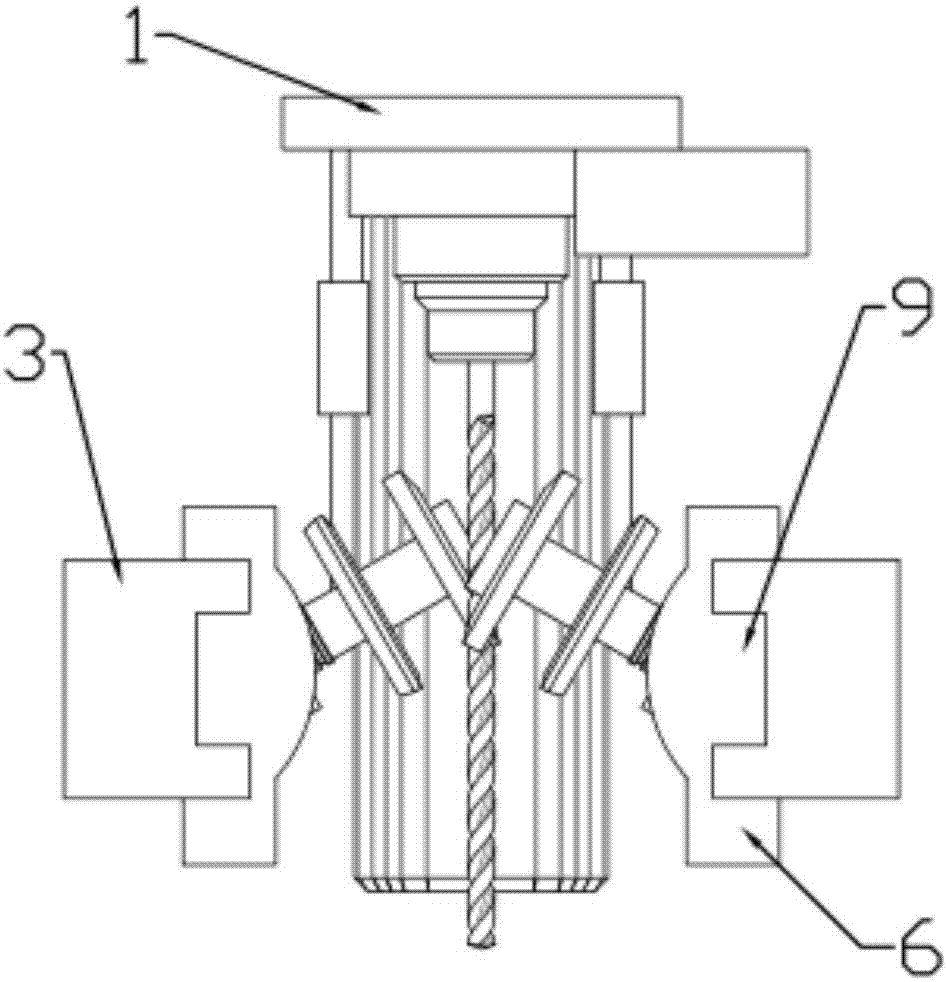

Tensioning clamp for sheet-type part subjected to rotary milling processing

ActiveCN105729182AImprove clamping rigidityImprove processing qualityPositioning apparatusMetal-working holdersEngineeringProcessing cost

The invention provides a tensioning clamp for a sheet-type part subjected to rotary milling processing. The tensioning clamp for the sheet-type part subjected to the rotary milling processing consists of a pedestal, a tensioning component and a clamping component, wherein the clamping component comprises a clamping driving device, a box body, a rotary shaft, a retainer cup, a movement crossover joint, a connecting rod, a pulling claw and a symmetrical clamping head; the tensioning component comprises a tensioning driving device, a transmission device and a guide rail sliding block device. According to the tensioning clamp for the sheet-type part subjected to the rotary milling processing, the sheet-type part is fixed by adopting a tensioning way; the clamping rigidity of the part can be effectively improved; the cutter relieving deformation in the processing process of the part is reduced; the processing vibration is restrained; the processing quality of the part is improved; the service life of a knife tool is prolonged; therefore, the processing cost is decreased; tensioning force is controlled through the tensioning driving device; the tensioning force can be guaranteed to be uniform and can be further regulated according to requirement; the symmetrical clamping head is tensioned to clamp the part through the clamping driving device; the rotary center of the part can be guaranteed to be unchangeable in a clamping process; the clamping deformation cannot be caused; further, the operation is simple; a clamping error caused by a human factor can be avoided.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Clamping and machining method for turning of thin-wall weak-rigidity part

InactiveCN109482907AGuaranteed geometric tolerance requirementsImprove quality reliabilityTurning machinesPositioning apparatusEngineeringMachining process

The invention provides a clamping and machining method for turning of a thin-wall weak-rigidity part and belongs to the technical field of the machining process. The clamping and machining method is suitable for a lathe clamping tool for the thin-wall weak-rigidity part. The lathe clamping tool for the thin-wall weak-rigidity part comprises an expansion jig and an expansion bolt. According to themethod, the clamping tool is used for clamping the part. Through the clamping tool, the defects existing in the clamping and machining method of the existing process are overcome, the efficiency of alathe machining the thin-wall part can be improved, and the unqualified rate of products can be reduced.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

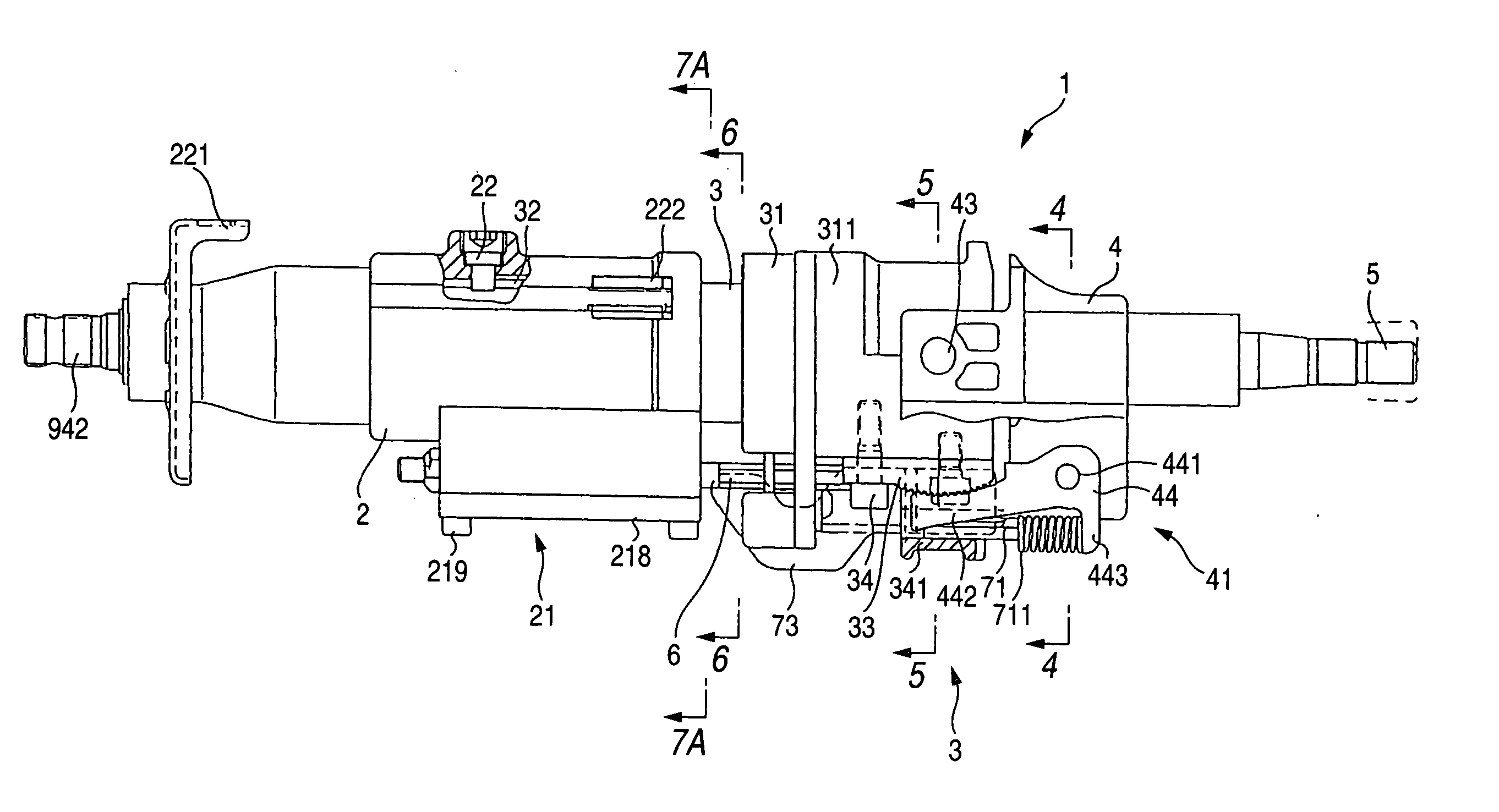

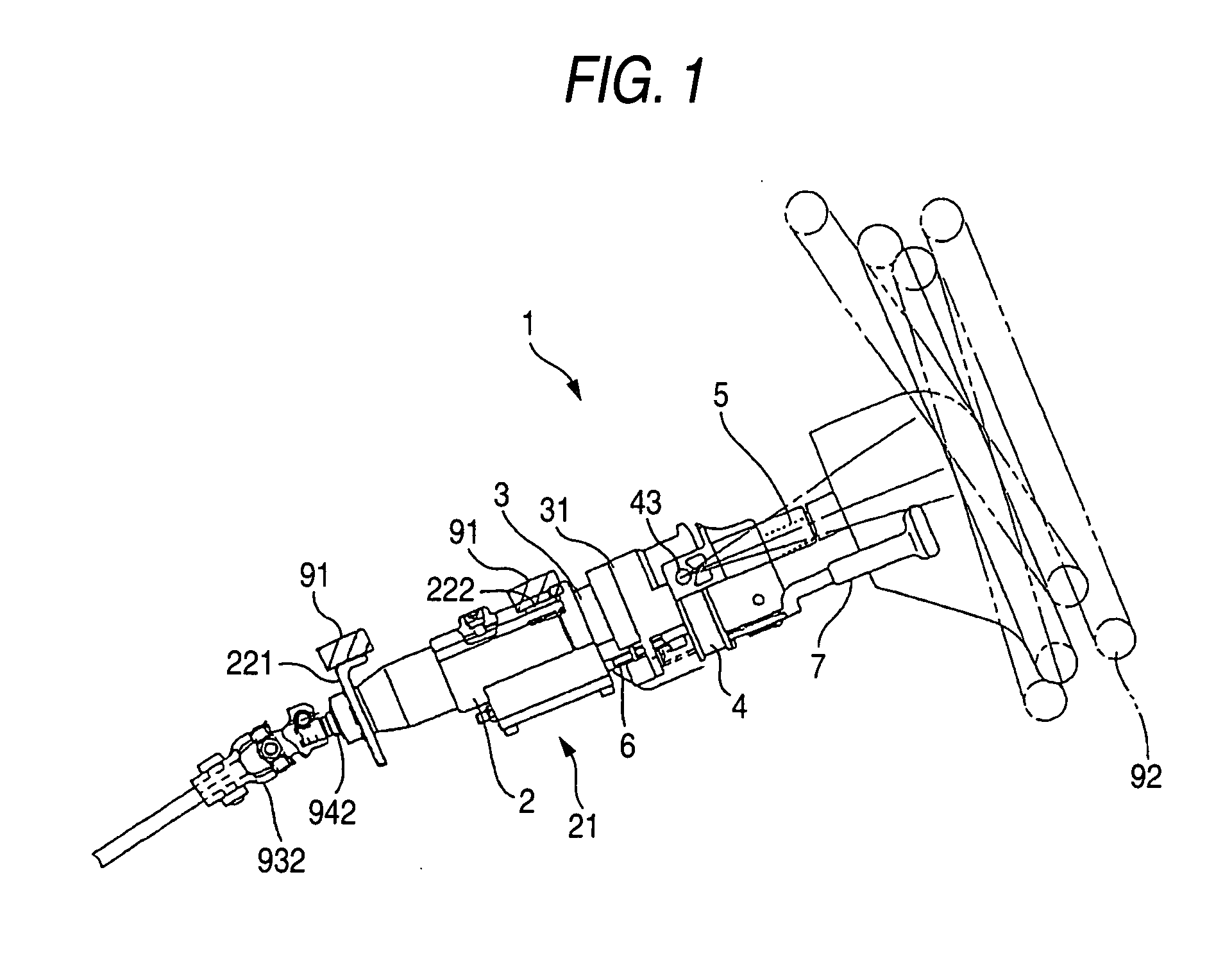

Steering column apparatus

InactiveUS7412911B2Improve clamping rigidityEasy to adjustSteering columnsSteering columnSteering wheel

A steering column apparatus includes: a stationary column member; a movable column member whose one end is supported on the stationary column member nonrotatably about a center axis and movably along the center axis; a column head disposed on the other end of the movable column member; a wheel shaft supported rotatably on the column head; a column clamp for clamping and unclamping the movable column member with respect to the stationary column member at two or more points which are spaced along the center axis of the movable column member; and a control lever whose operation lever end is positioned in the vicinity of a steering wheel and which is capable of operating the column clamp.

Owner:NSK LTD +1

Clamp for drilling of shifting fork

InactiveCN105081836AAchieve positioningAchieve orientationDrilling/boring measurement devicesPositioning apparatusEngineeringMechanical engineering

The invention provides a clamp for drilling of a shifting fork, and belongs to the technical field of machining. The clamp comprises a compressing assembly, a locating assembly and a threaded hole guide assembly. A plug of the locating assembly penetrates a bearing support, and the rear end of the plug is arranged on the bearing support through a plug nut. An anti-rotation block is arranged between the inner end faces of two feet of the shifting fork. The lower end of a compressing plate bearing column of the compressing assembly is arranged on the bearing support, the upper end of the compressing plate bearing column abuts against one side of a compressing plate, and the other side of the compressing plate is pressed on the shifting fork. The lower end of a compressing adjusting rod is arranged on the bearing support, and the upper end of the compressing adjusting rod penetrates a U-type groove of the compressing plate and is locked by a compressing locking nut. A guide bearing plate of the threaded hole guide assembly is horizontally arranged on the upper side of the bearing support through bearing plate mounting screws. A guide sleeve is arranged in a clamping groove and compressed on the guide bearing plate through a guide sleeve mounting screw. The clamp is good in clamping effect, and the accuracy of the position of a threaded hole and drilling quality are improved through the threaded hole guide assembly.

Owner:全红英

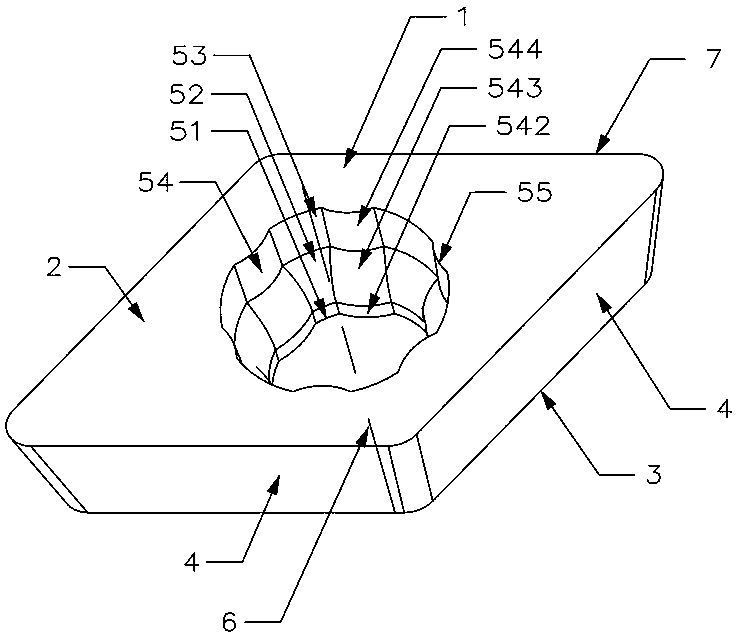

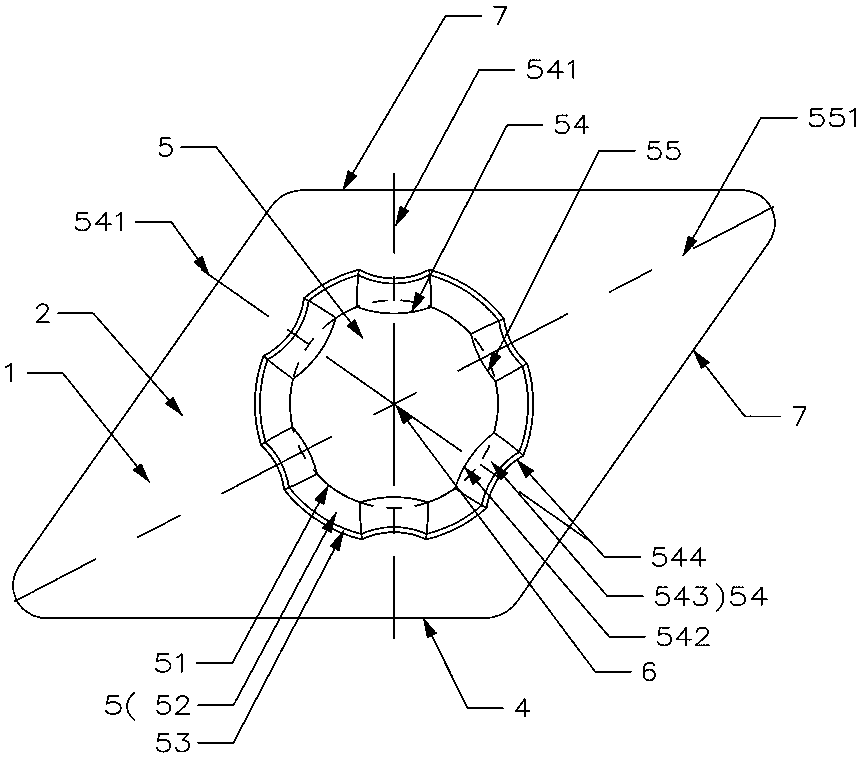

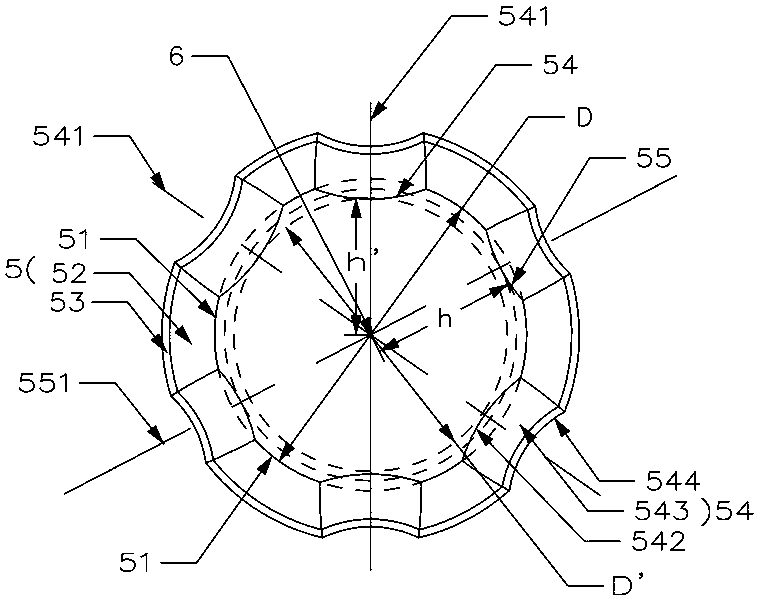

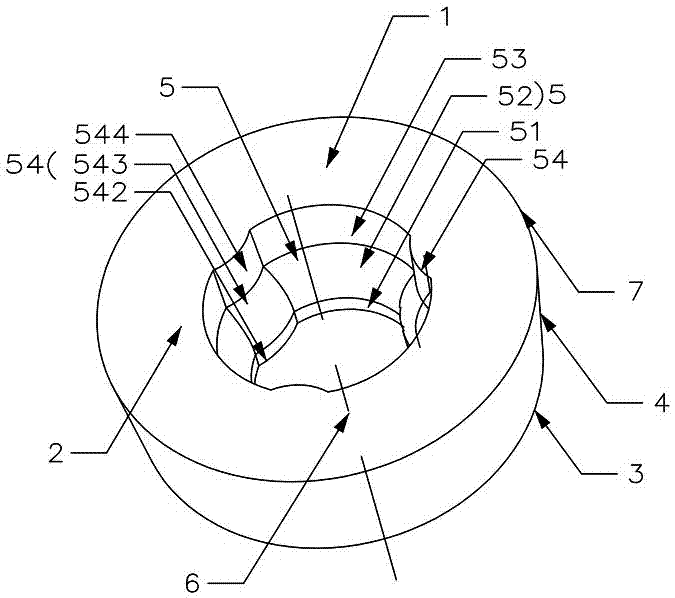

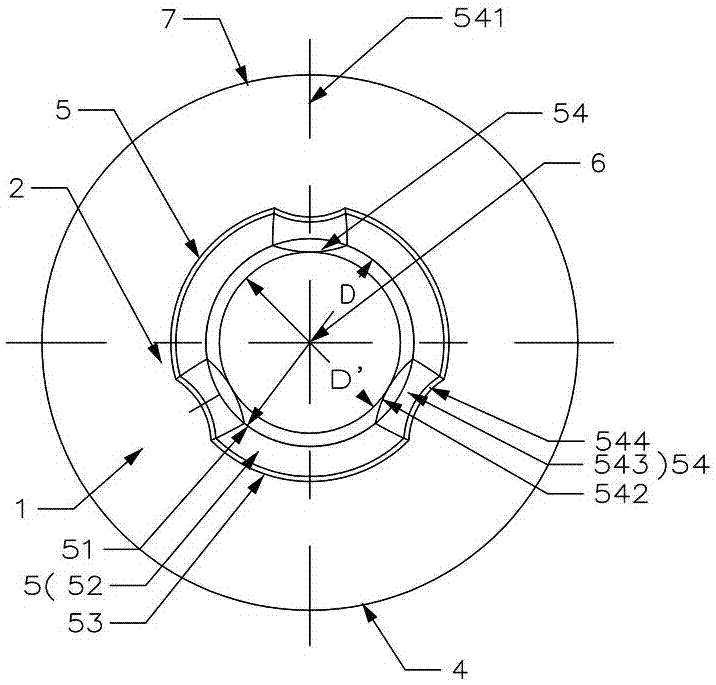

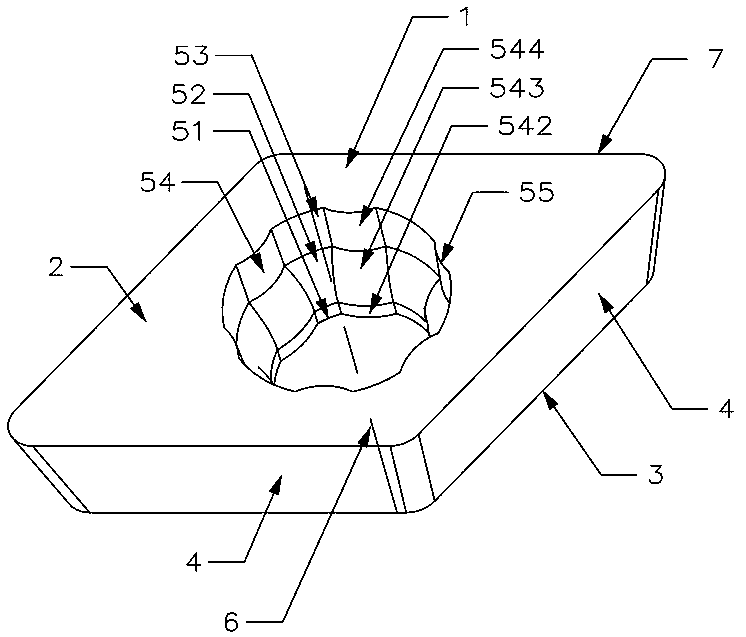

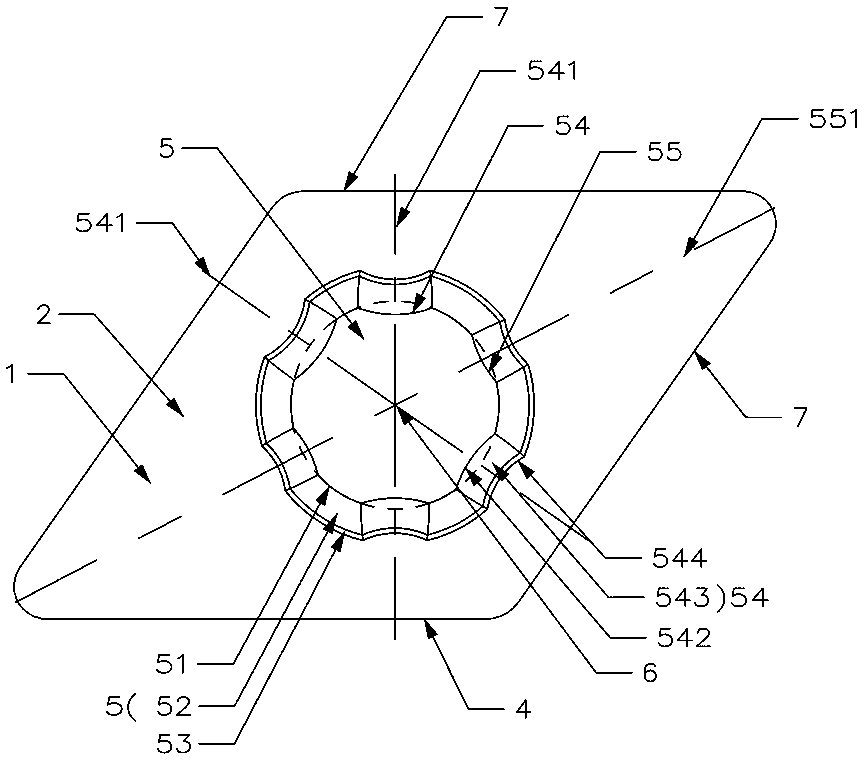

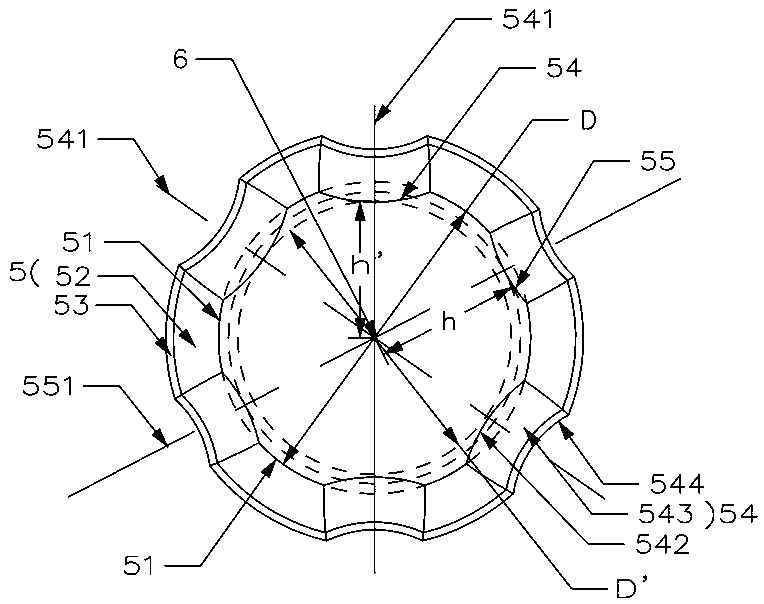

Polygonal cutting blade with bulge parts in hole and cutter

ActiveCN107775019AImprove clamping rigidityHigh strengthCutting insertsTurning toolsEngineeringFastener

The invention discloses a polygonal cutting blade with bulge parts in a hole and a cutter. The polygonal cutting blade comprises a blade body consisting of an upper surface, a lower surface and a plurality of side surfaces connected with the upper surface and the lower surface, wherein a center hole penetrating through the upper surface and the lower surface is formed in the blade body, the bladebody is in central symmetry about the central axis of the center hole, each side surface and the upper surface intersect to form a plurality of cutting edges, one bulge part is arranged in the position, corresponding to each side surface, of the inner surface of the center hole, and the bulge parts directly face the corresponding side surfaces. The cutting blade has the characteristics of positioning reliability and stability, multiple clamping and long service life. The cutter comprises the cutting blade, fastening screws and the center hole of the cutting blade produce over-positioning multidirectional clamping under multiple constraints, deformation directions and areas unfavorable for fasteners are effectively controlled, the vibration of the cutting blade can be effectively attenuated during cutting, and the service life of the cutter is prolonged.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

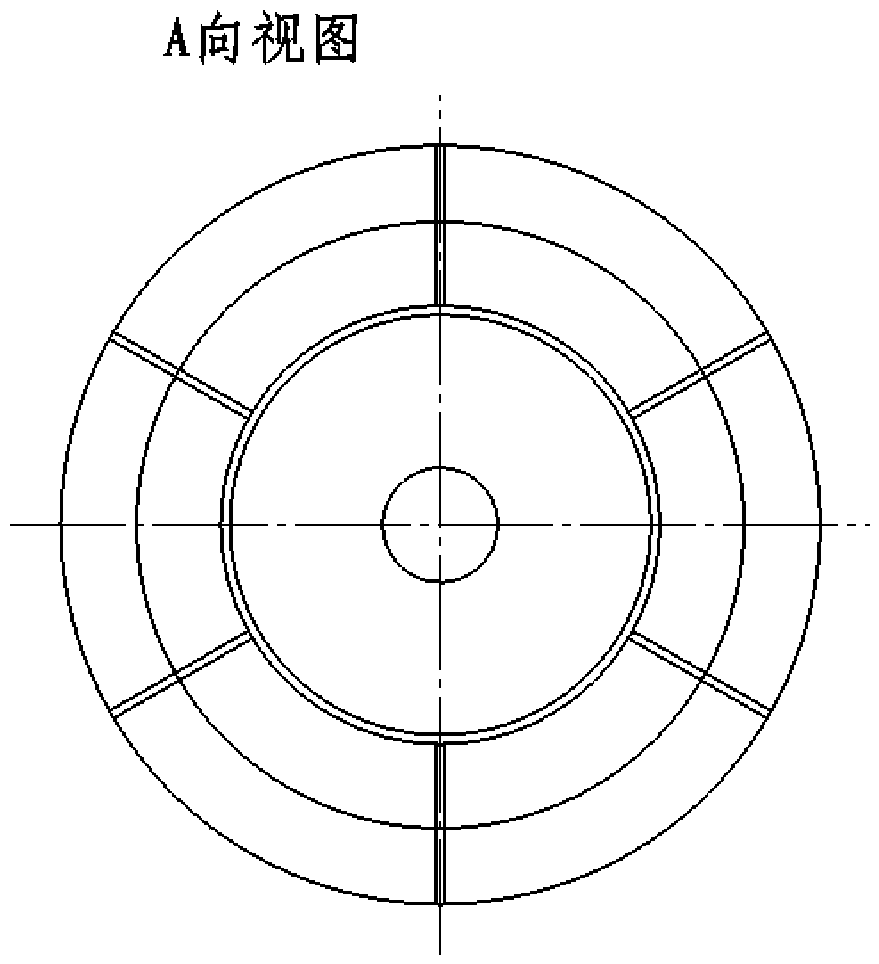

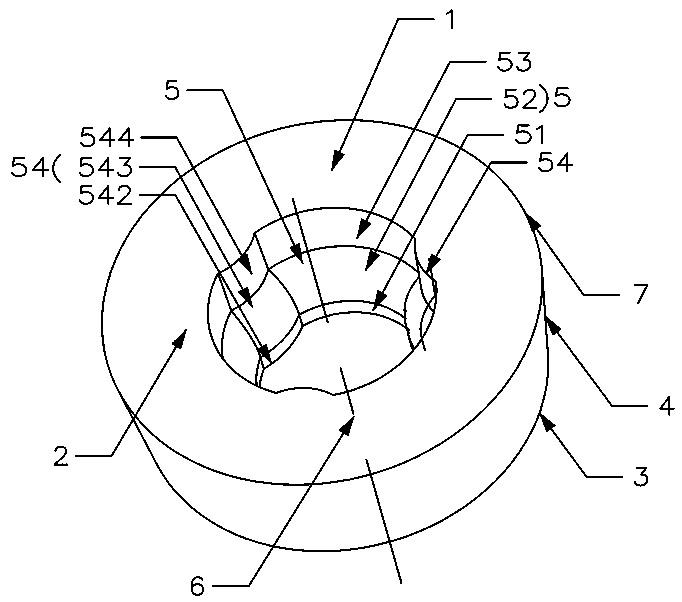

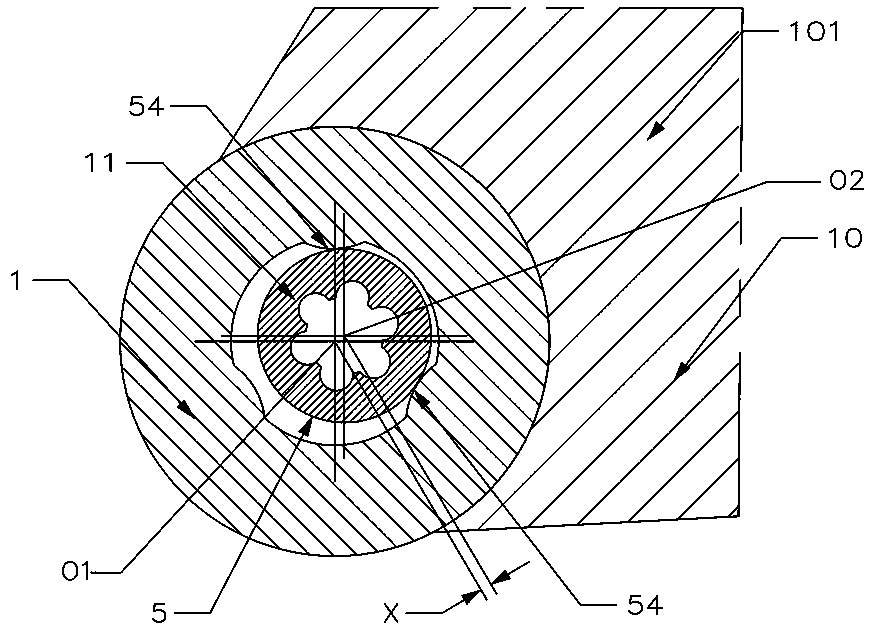

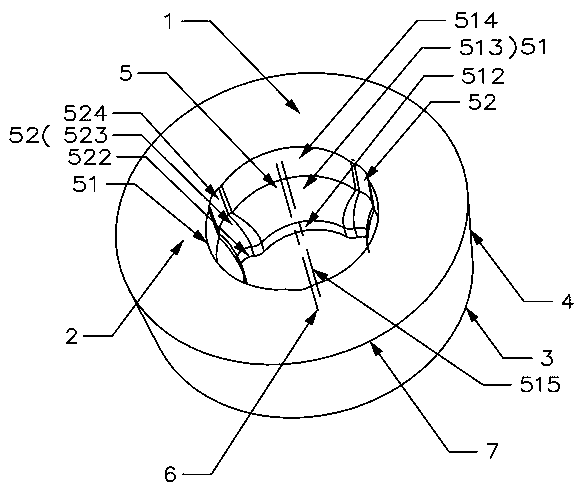

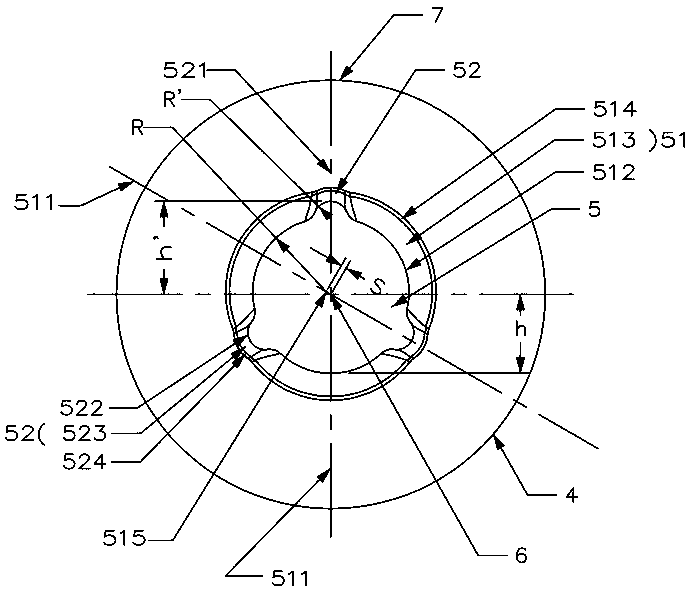

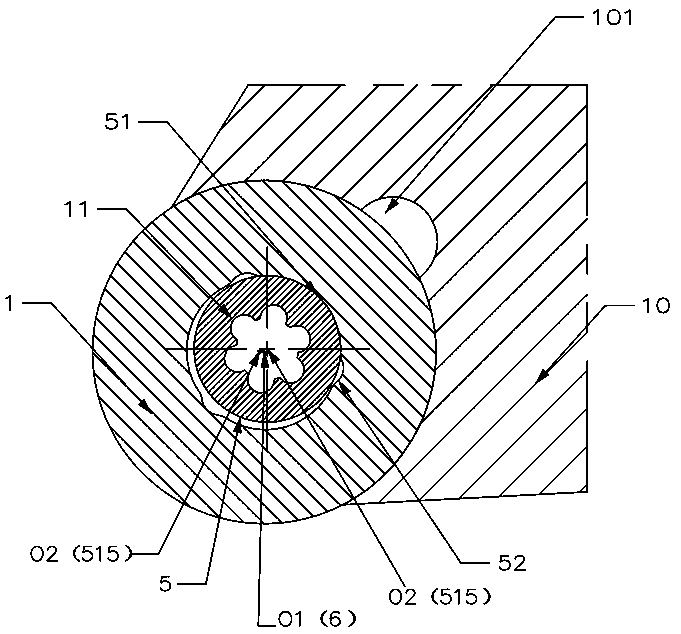

Circular blade with accurate positioning structure and cutting tool

ActiveCN107498610AEasy to installImprove clamping rigidityMetal working apparatusTurning toolsEngineeringMechanical engineering

The invention discloses a circular blade with an accurate positioning structure and a cutting tool. The circular blade comprises a blade body, wherein the blade body is composed of an upper surface, a lower surface and a side face which is used for connecting the upper surface with the lower surface; and the blade body is provided with a center hole which penetrates through the upper surface and the lower surface, the blade body is centrosymmetric relative to the central axis of the center hole, the upper surface intersects with the side face to form a cutting edge, the inner surface of the center hole is provided with at least two lug bosses, and the included angle between every two adjacent lug bosses is smaller than 180 degrees. The cutting blade has the advantages that positioning is reliable and stable, multi-ply clamping can be achieved, and the service life is long. The cutting tool is provided with the circular blade, sliding or rotating of the circular blade in the peripheral direction in the using process can be eliminated, the stability of the cutting edge in a cutting region is guaranteed, other cutting processes are prevented from participating in one cutting process, the usable frequency of the circular blade on the cutting tool is effectively stabilized, and then the service life of the cutting tool is prolonged.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Method for machining thin web titanium alloy edge strip

ActiveCN105312645AGuaranteed thickness accuracyReduce distortionMilling equipment detailsMilling cutterTitanium alloy

The invention discloses a method for machining a thin web titanium alloy edge strip, wherein the method is convenient to operate and capable of eliminating part deformations. The method for machining the thin web titanium alloy edge strip comprises the following steps in order: rough machining, semi-finish machining and finish machining; in the process of rough machining, firstly, a hard alloy end mill is adopted for rough machining of a part at a large cutting depth, a low rotating speed and a low feed speed; and secondly, a clamped indexable milling cutter is adopted as a machining cutter for equal-height cutting machining at a small cutting depth in such a manner of fast feed. The method for machining the thin web titanium alloy edge strip is capable of quickly removing black allowance and improving the machining efficiency; besides, the allowance of each portion is uniform, which is favorable for programming during semi-finish machining of the part, and further, machining cutting can be more steady.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

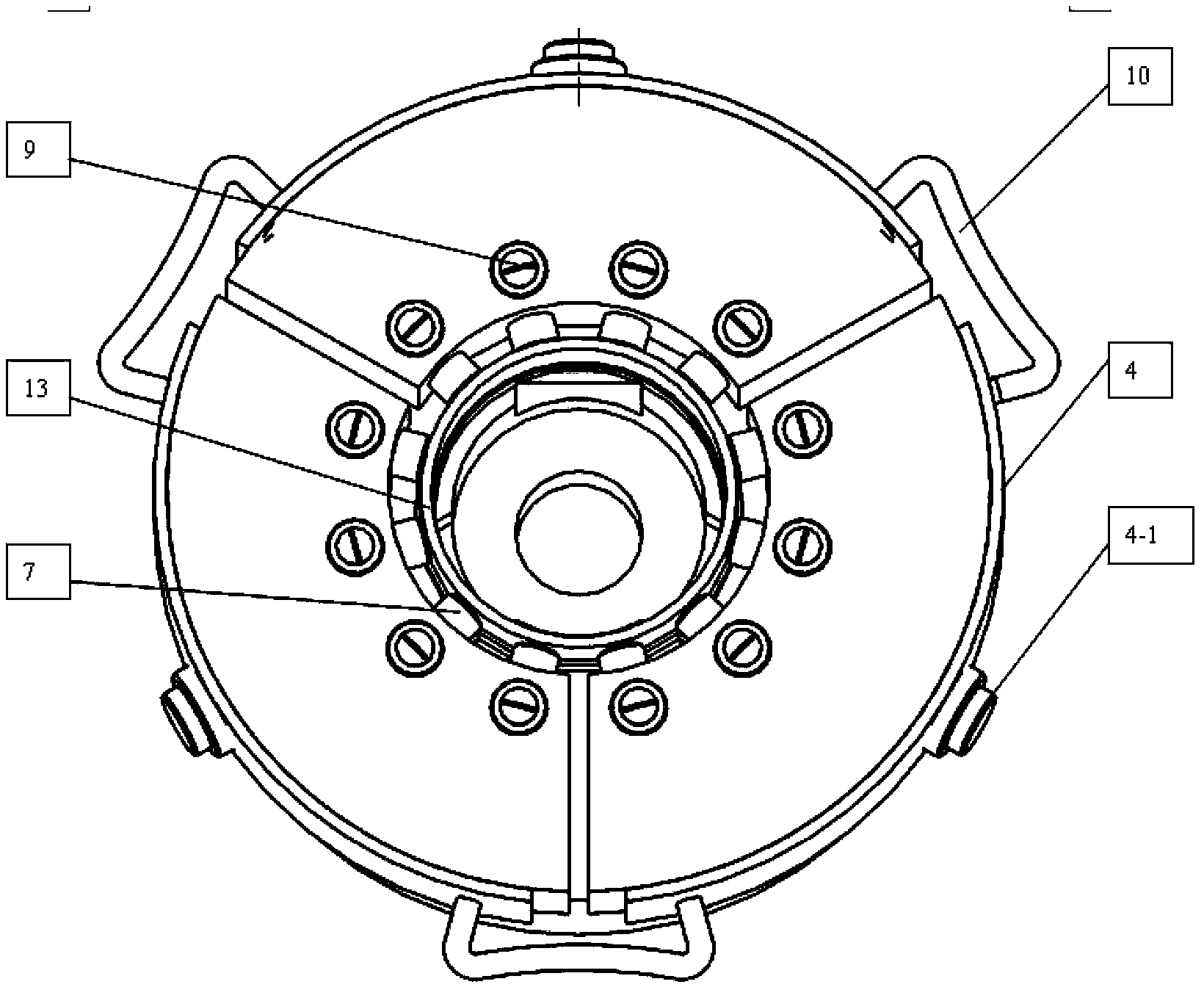

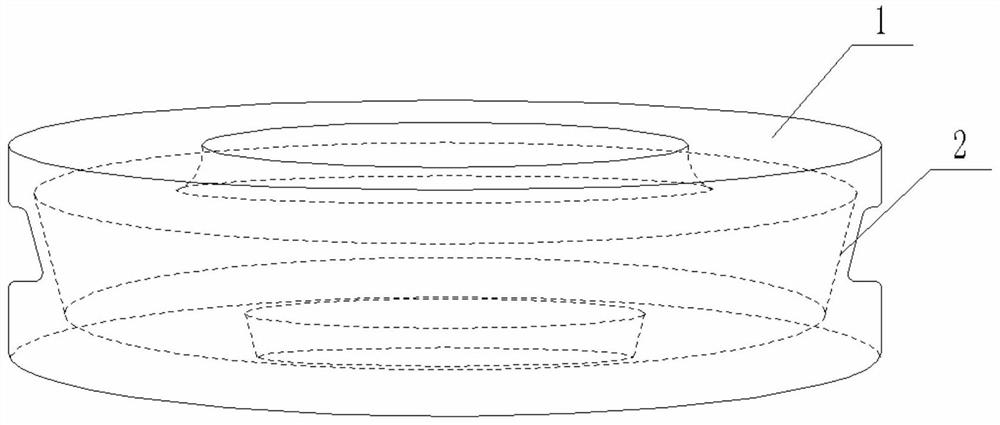

Annular part fixture

InactiveCN102728765BUniform clamping forceReduce residual stressForging/hammering/pressing machinesRadial motionEngineering

The invention relates to an annular part fixture, which comprises a three-jaw wedge power chuck seat and a plurality of base jaws arranged on the three-jaw wedge power chuck seat. The annular part fixture is characterized in that the base jaws are fixedly connected with a clamping jaw hydraulic seat, a plurality of clamping jaw base holes are evenly arranged on the clamping jaw hydraulic seat with the circle center of the three-jaw wedge power chuck seat serving as the axle center, clamping jaw pistons and clamping jaws are successively arranged in the clamping jaw base holes, and the clamping jaw pistons push the clamping jaw to perform radial motion along the circle center of the three-jaw wedge power chuck seat under the action of internal hydraulic oil of the clamping jaw base holes. The annular part fixture can clamp irregularly-shaped annular forge piece blanks evenly and has the advantages that clamping force is more balanced, residual stress is remarkably reduced, required clamping force is smaller and clamping rigidity is larger, and clamping is firm.

Owner:JIANGSU UNIV

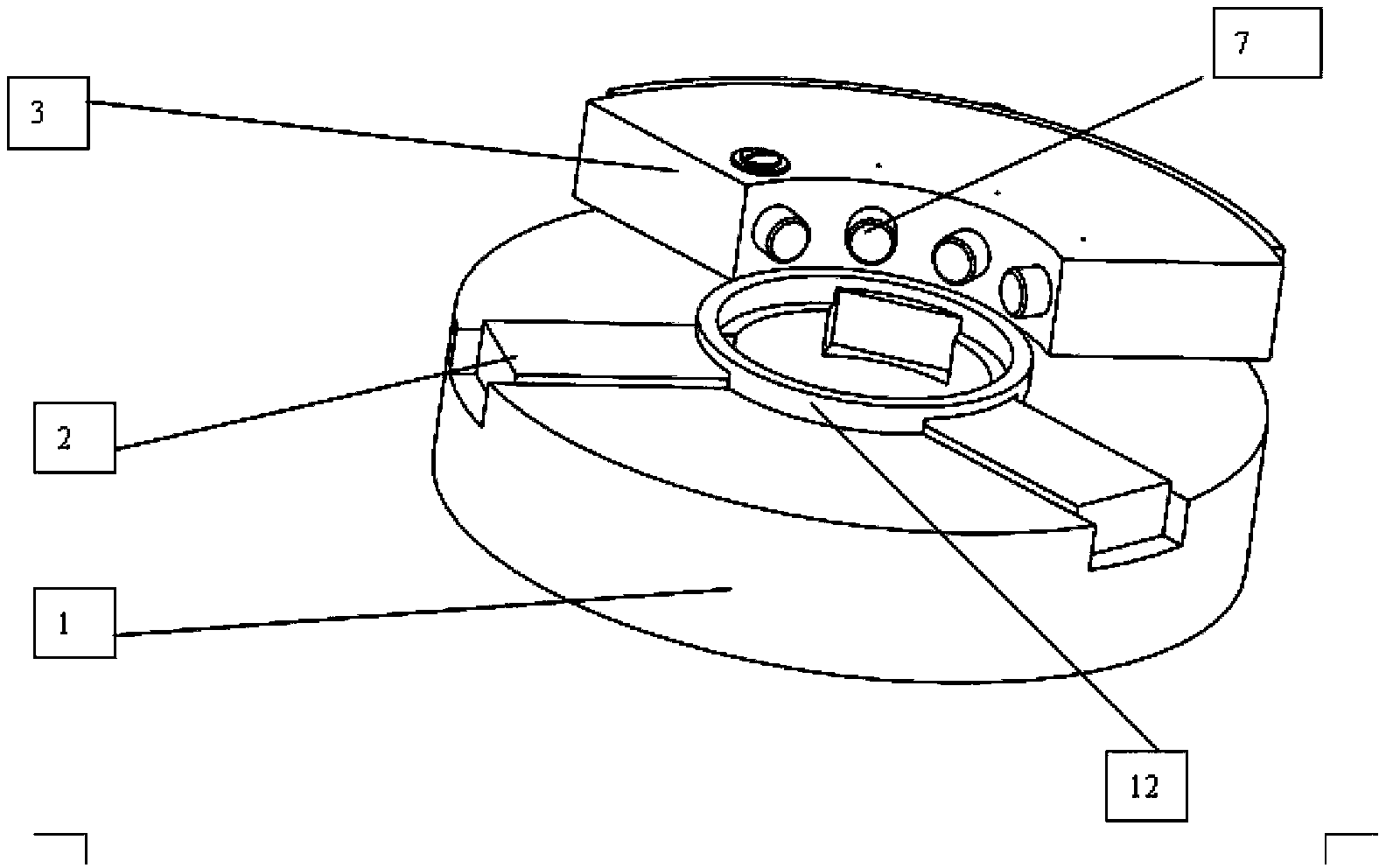

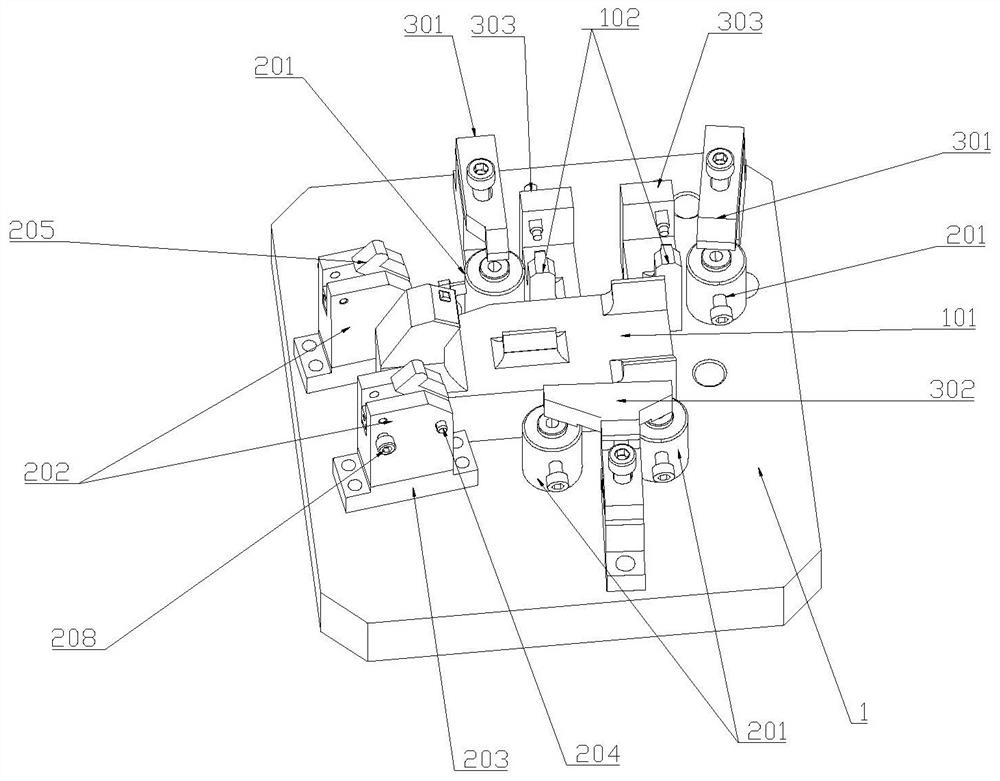

Grinding clamp suitable for turbine multi-connected guide vane part assembly

The grinding clamp suitable for the turbine multi-connection guide vane part assembly can be used for clamping the turbine multi-connection guide vane part assembly, clamping is convenient, stability is high, and the clamping rigidity of vanes can be enhanced. The device comprises a mounting bottom plate, and a positioning mechanism, a supporting mechanism and a pressing mechanism are mounted on the mounting bottom plate; the positioning mechanism comprises a blade positioning block and a blade outer ring runner surface clamp positioning block, and the top of the blade positioning block protrudes upwards to form a positioning boss I and a positioning boss II; the supporting mechanism comprises a first supporting structure and a second supporting structure, the first supporting structure corresponds to the bottoms of the inner ring and the outer ring of the part, and the second supporting structure is used for supporting the inner radial face of the part. The pressing mechanism comprises a first pressing structure, a second pressing structure and a third pressing structure. The first pressing structure is used for pressing an outer ring of a part, the second pressing structure is used for pressing an inner ring of the part, and the third pressing structure is used for being matched with a blade outer ring runner face clamp positioning block to clamp the outer ring runner face of the part.

Owner:WUXI TURBINE BLADE

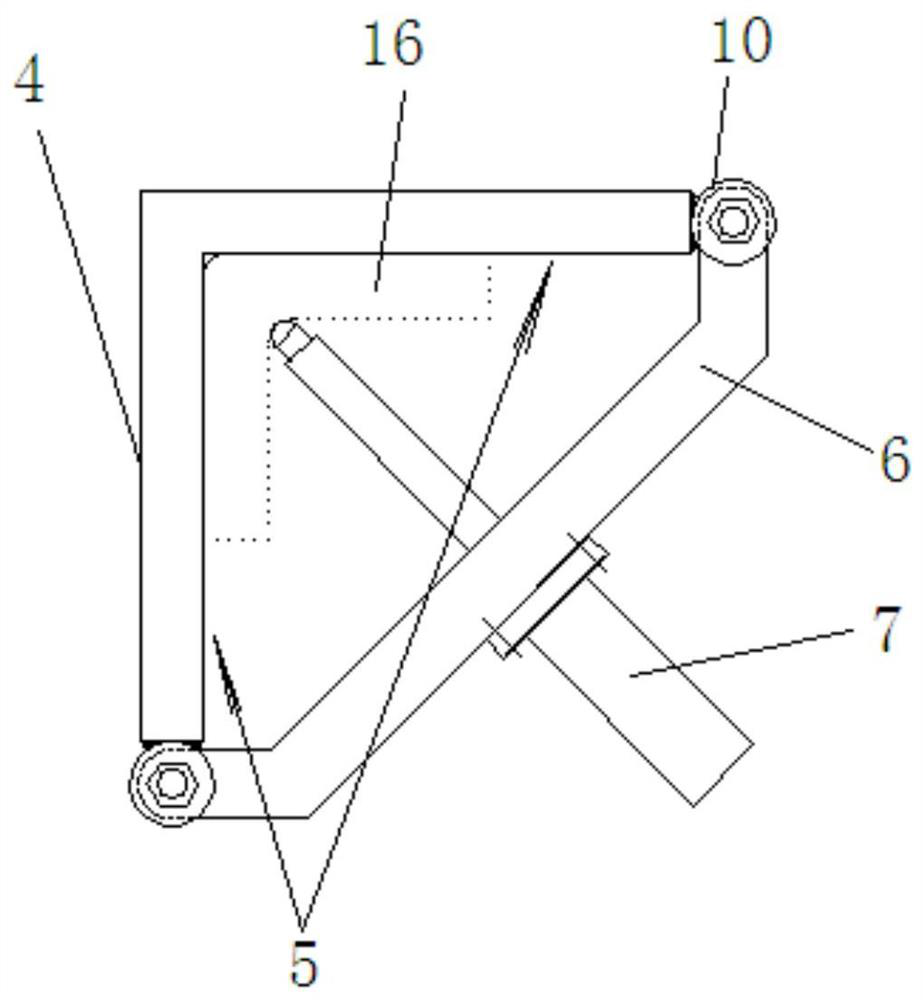

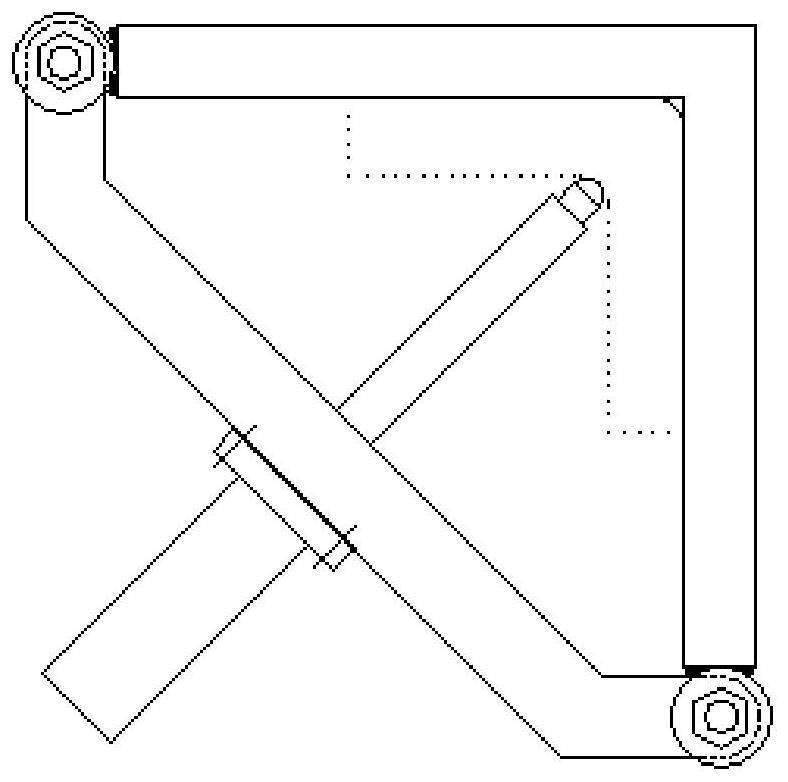

Clamping and auxiliary supporting linkage mechanism

InactiveCN106624899AImprove clamping rigidityImprove stabilityWork holdersPositioning apparatusMechanical engineeringSpherical form

Owner:SUZHOU VOCATIONAL UNIV

Numerical control processing method and special processing fixture for inertial platform body

ActiveCN102357815AReduced settling timeReduce the number of correctionsPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention relates to a numerical control processing method and a special processing fixture for an inertial platform body. The special processing fixture comprises a fixture A and a fixture B. The numerical control processing method comprises the following steps: (1) mounting and adjusting bases of the fixture A and fixture B; (2) processing a reference surface, a positioning surface and a positioning hole of the inertial platform body; (3) processing the positioning surface, a positioning slot and other parts of the inertial platform body; and (4) processing other surfaces of the inertial platform body. The invention provides a processing method and a processing tool capable of conveniently clamping and quickly adjusting. By adopting CAM (Computer Aided Manufacturing) programming, the processing method and the processing tool have the advantages of easy processing, centralized processes, low production cost, high production efficiency, high processing precision and the like. By adopting the processing method provided by the invention, the defects of the prior art, such as long processing time of a single piece, low efficiency, high manufacturing cost and the like, are overcome, and the process flow and the manufacturing time of the platform body can be greatly reduced. By twice clamping and positioning, the processing for all the surfaces of a part along six directions is finished on a double operating platform horizontal type processing center.

Owner:TIANJIN NAVIGATION INSTR RES INST

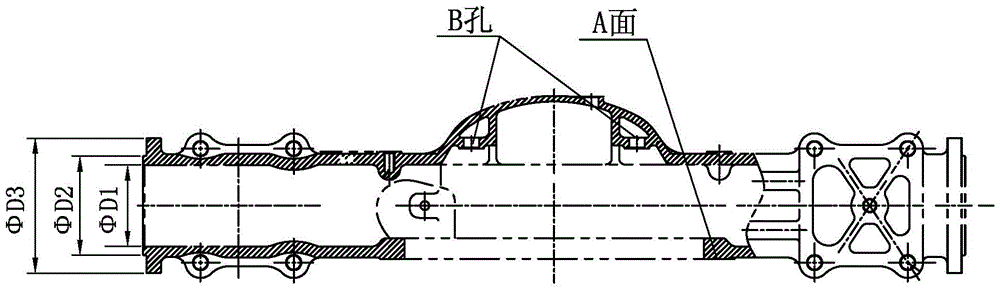

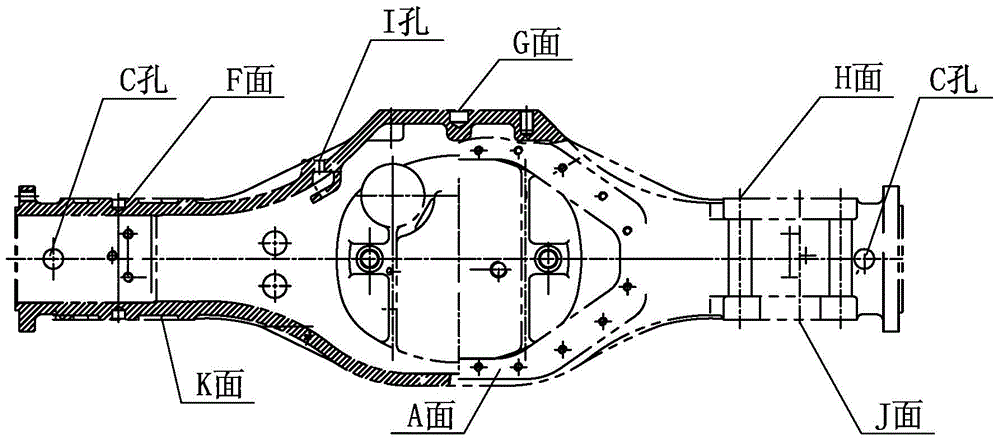

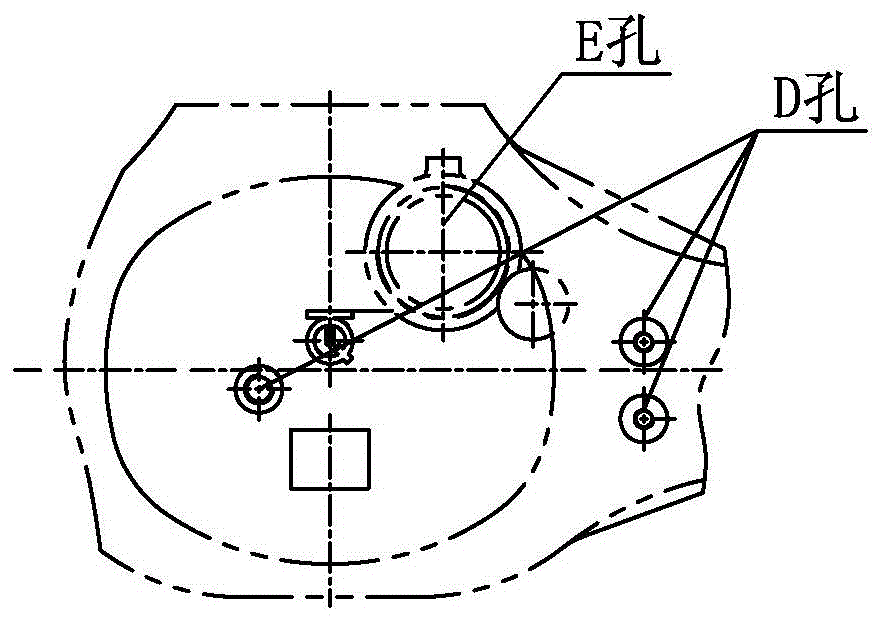

A clamping and fixing device for processing heavy truck axle housings

ActiveCN104646703BImprove processing efficiencyGuaranteed machining accuracyTailstocks/centresChucksNumerical controlTruck

The invention discloses a clamping and fixing device for machining an axle shell of a heavy truck. The clamping and fixing device comprises a pedestal, an automatic hydraulic clamping mechanism, a hydraulic three-jaw chuck, an automatic hydraulic leveling mechanism, an auxiliary hydraulic support component, an auxiliary hydraulic clamping mechanism and a top type automatic hydraulic tailstock. The hydraulic three-jaw chuck is connected with a fourth shaft of a numerically-controlled machine tool, the fourth shaft of a numerically-controlled machine tool is connected with a rotary hydraulic oil tank, the automatic hydraulic clamping mechanism is installed on the top type automatic hydraulic tailstock, the automatic hydraulic leveling mechanism is used for helping the pipa panel of the axle shell to automatically level, the hydraulic three-jaw chuck is used for clamping the flange hole in one end of the axle shell, the top type automatic hydraulic tailstock is used for clamping the flange hole in the other end of the axle shell, the auxiliary hydraulic support component is used for supporting the axle shell, and the auxiliary hydraulic clamping mechanism and the automatic hydraulic clamping mechanism are used for clamping the surface of the axle shell. According to the clamping and fixing device for machining the axle shell of the heavy truck, the automation degree is high, the axle shell of the heavy truck is firmly and reliably clamped and positioned, and the machining efficiency and the machining quality of the axle shell are improved.

Owner:NINGBO HAITIAN PRECISION MASCH CO LTD

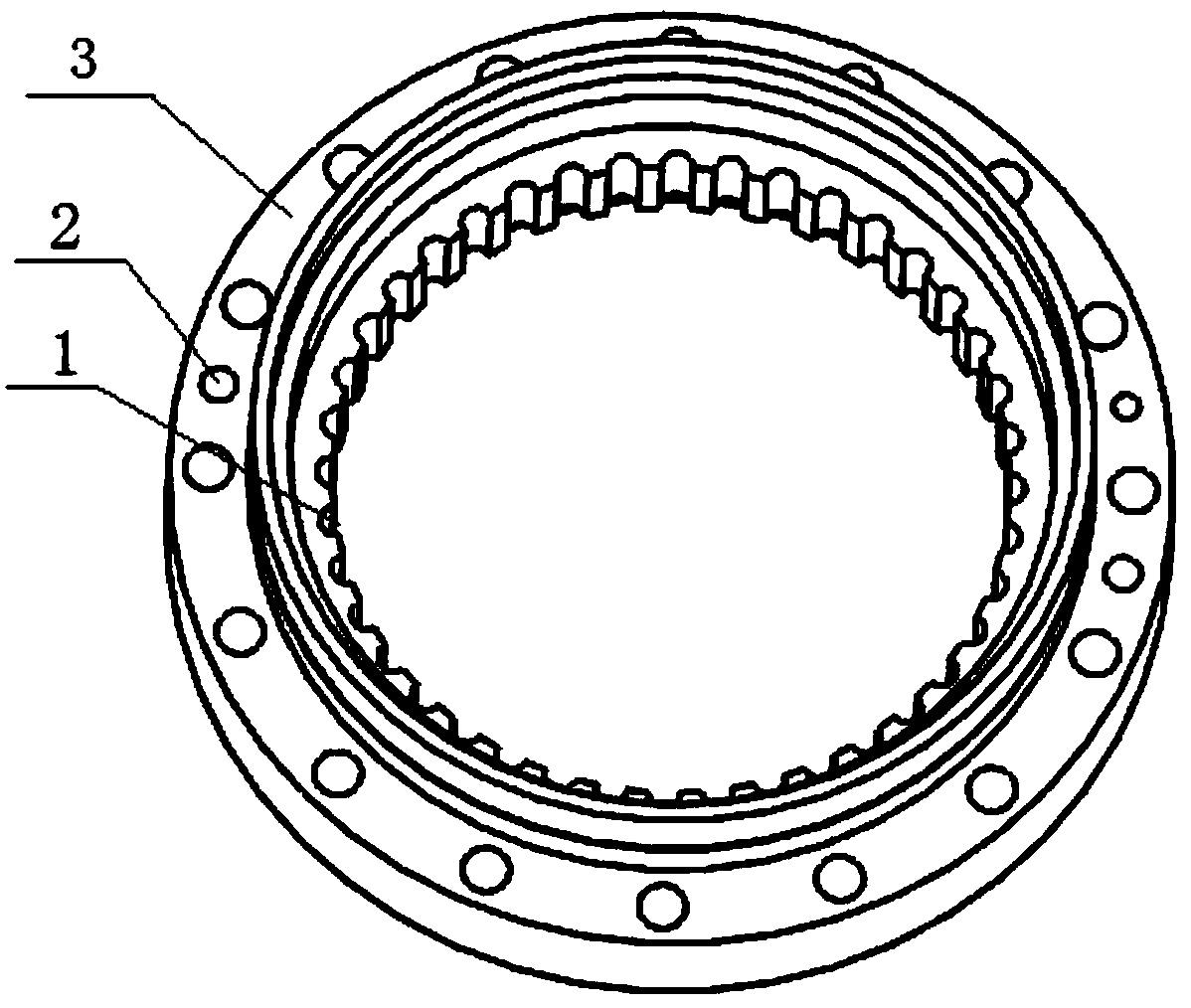

Method and device for machining internal teeth of planetary cycloidal pin gear reducer housing

InactiveCN109158708AEasy clampingReduce cumulative errorAutomatic control devicesFeeding apparatusReduction driveReducer

The invention relates to a method and device for machining internal teeth of a planetary cycloidal pin gear reducer housing. A tool is installed on a vertical machining center, a workpiece is assembled on the tool, alignment of the tool is carried out, the tool is static after the workpiece is completely machined, and the workpiece is detached for machining a new workpiece. The invention further provides the method for machining the internal teeth of the planetary cycloidal pin gear reducer housing and a flexible device. When the method and device are used for machining the internal teeth of the planetary cycloidal pin gear reducer housing, machining of all pin tooth holes can be completed through one-time clamping, machining errors and assembly errors are reduced, the manufacturing accuracy is improved, the production speed is accelerated, and products meet the high precision requirements of reducers.

Owner:天津旗领机电科技有限公司

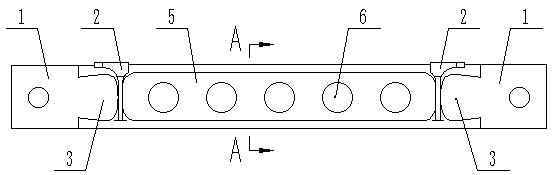

Processing method of weakly rigid I-shaped component

ActiveCN109434168AImprove clamping rigidityAchieve steady state processingMilling equipment detailsComputer scienceMachining

The invention relates to a processing method of a weakly rigid I-shaped component, and belongs to the technical field of machining, in particular to a processing method of a long and thin thin-walledhigh-strength component; and the goal of performing anti-deformation efficient processing on the weakly rigid I-shaped component is achieved by employing a combined processing measure of component rigidity-gradient steady-state processing and minimum control over cutting stress. The employed technical solution is that the processing method of the weakly rigid I-shaped component comprises the following steps of a clamping step: clamping with a double-parallel jaw vice; and a processing step: processing the weakly rigid I-shaped component in sequence of processing from two ends to the center byemploying a processing way of high-speed milling; moreover, when a groove in an I-shaped structure is processed, two technology grooves are firstly milled at a high speed; and the technology grooves are the two end parts of the groove in the I-shaped structure. The processing method disclosed by the invention is used for processing the weakly rigid I-shaped component.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY +1

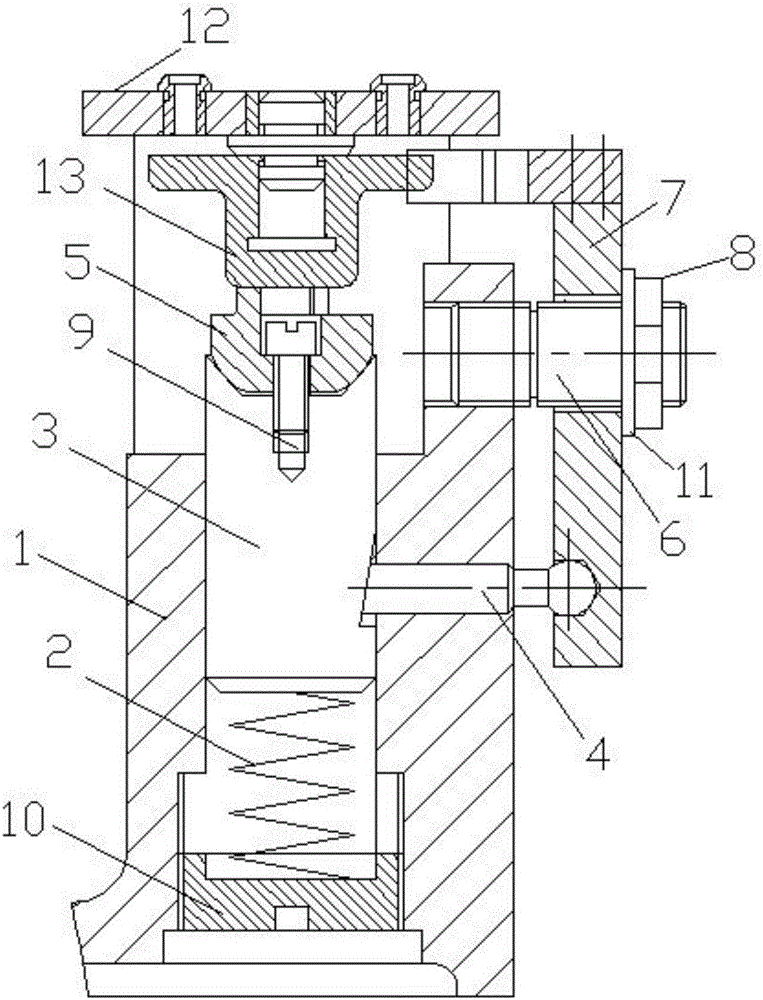

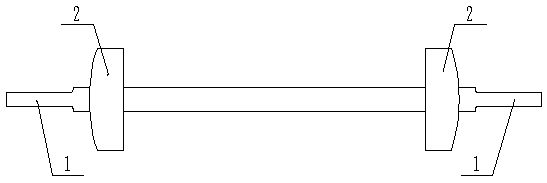

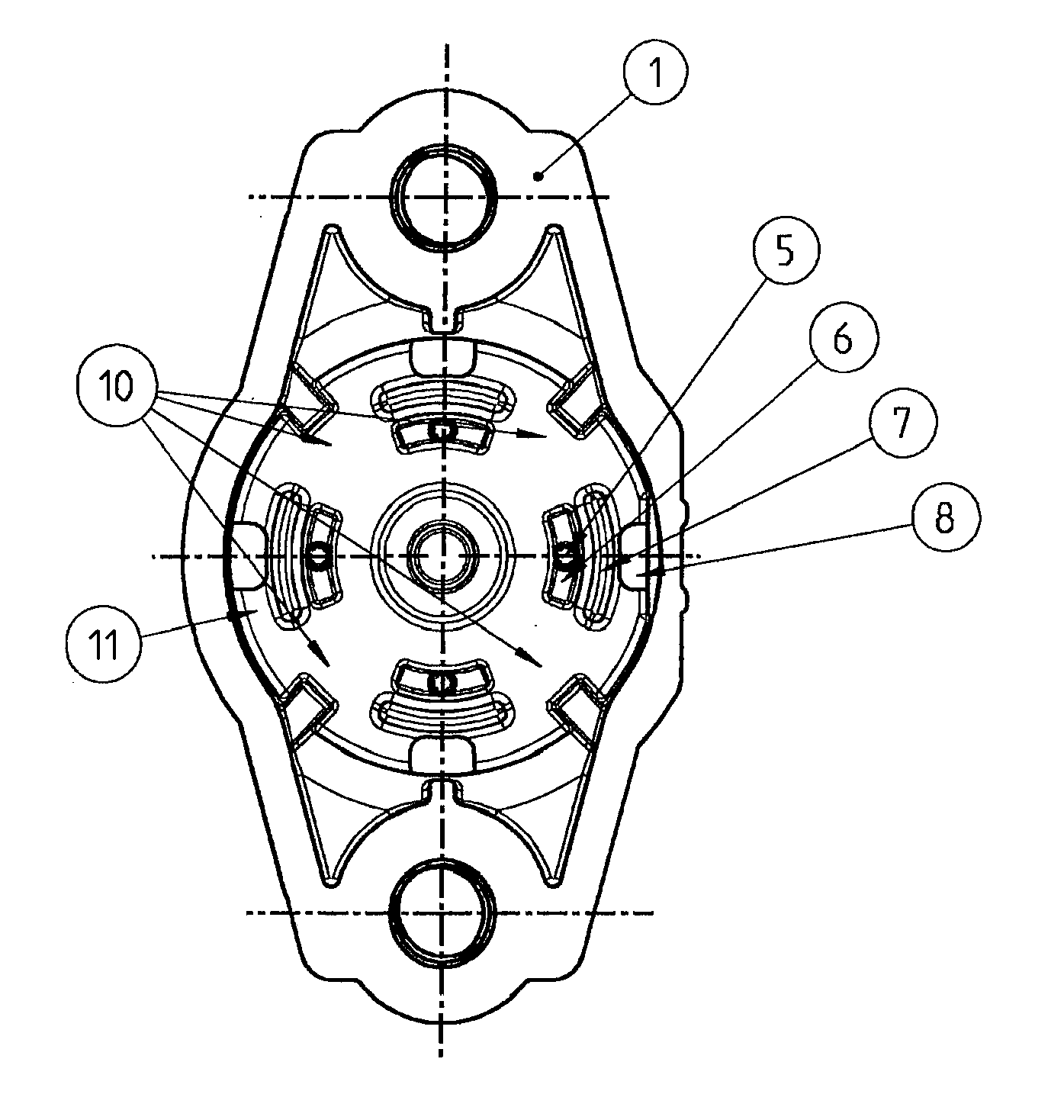

Special clamp for realizing multi-point clamping

InactiveCN104802109AImprove clamping rigidityImprove stabilityWork holdersPositioning apparatusEngineeringMechanical engineering

The invention relates to a special clamp for realizing multi-point clamping. The special clamp comprises a clamp body, wherein a piston rod which is in horizontal arrangement and can move is arranged in the clamp body, the lower side of one end of the piston rod is provided with an inclined surface, the other end of the piston rod is provided with a piston, a guide sleeve with the Y-shaped cross section is arranged in the clamp body and under a position, provided with an inclined surface, of the piston, a spring sleeve, a spring and a press block which can vertically move are sequentially arranged in the guide sleeve from top to bottom, a rolling post is arranged between the spring sleeve and the inclined surface, the two sides of the rolling post are provided with position limiting rings, the lower end of the press block is provided with three press claws in circumferential distribution, and the three press claws can extend out of the guide sleeve for tightly pressing a workpiece. The special clamp has the advantages that through hydraulic driving, three press claws arranged on the press block are simultaneously in contact with the workpiece, the installing and clamping rigidity of the workpiece are improved, and the stability and the reliability of the installation and clamping are improved.

Owner:SUZHOU VOCATIONAL UNIV

A lathe fixture suitable for processing thin-walled ring block parts

ActiveCN112475951BAvoid vibrationImprove qualificationWork clamping meansPositioning apparatusMachining deformationAero engine

The invention relates to the technical field of aero-engines, in particular to a lathe fixture suitable for processing thin-walled ring-block parts, which is used for clamping thin-walled ring-block parts with thin walls that need to be processed. , the fixture is a circular disk surface, and a plurality of independent fixed blocks are evenly and symmetrically arranged on it. All the fixed blocks form a ring that is concentric with the circular disk surface of the fixture; Arrange the same number of unit fixtures as the fixed block, and evenly open square holes at the bottom of the fixed block, corresponding to the position of the unit fixture; each set of unit fixtures includes a pressing platen and a tensioning platen to fix the process edge and thin-walled ring block parts on the fixture in multiple directions . The invention effectively improves the clamping rigidity of the thin-walled ring block type parts by turning, avoids the chattering in the parts processing, reduces the processing deformation, greatly improves the qualified rate of the parts, and saves the cost.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

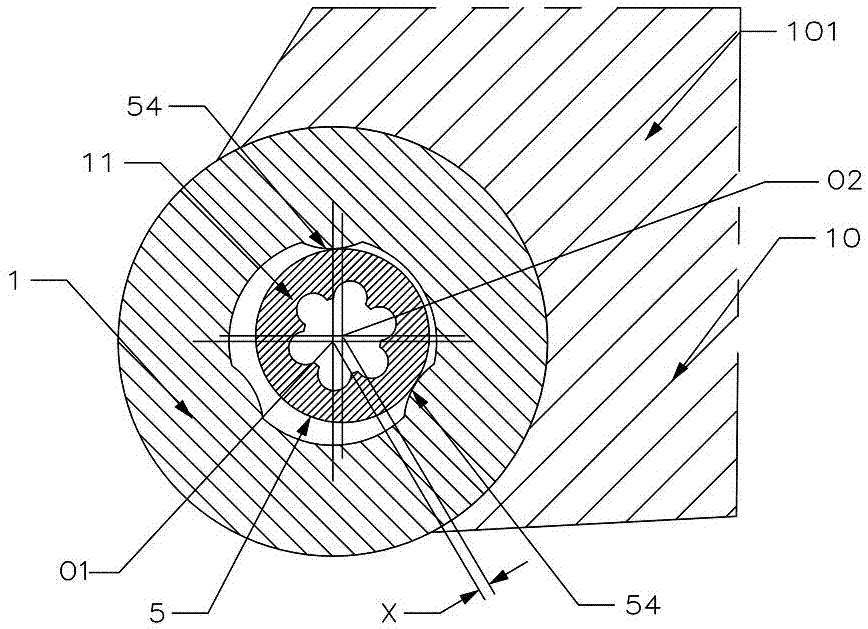

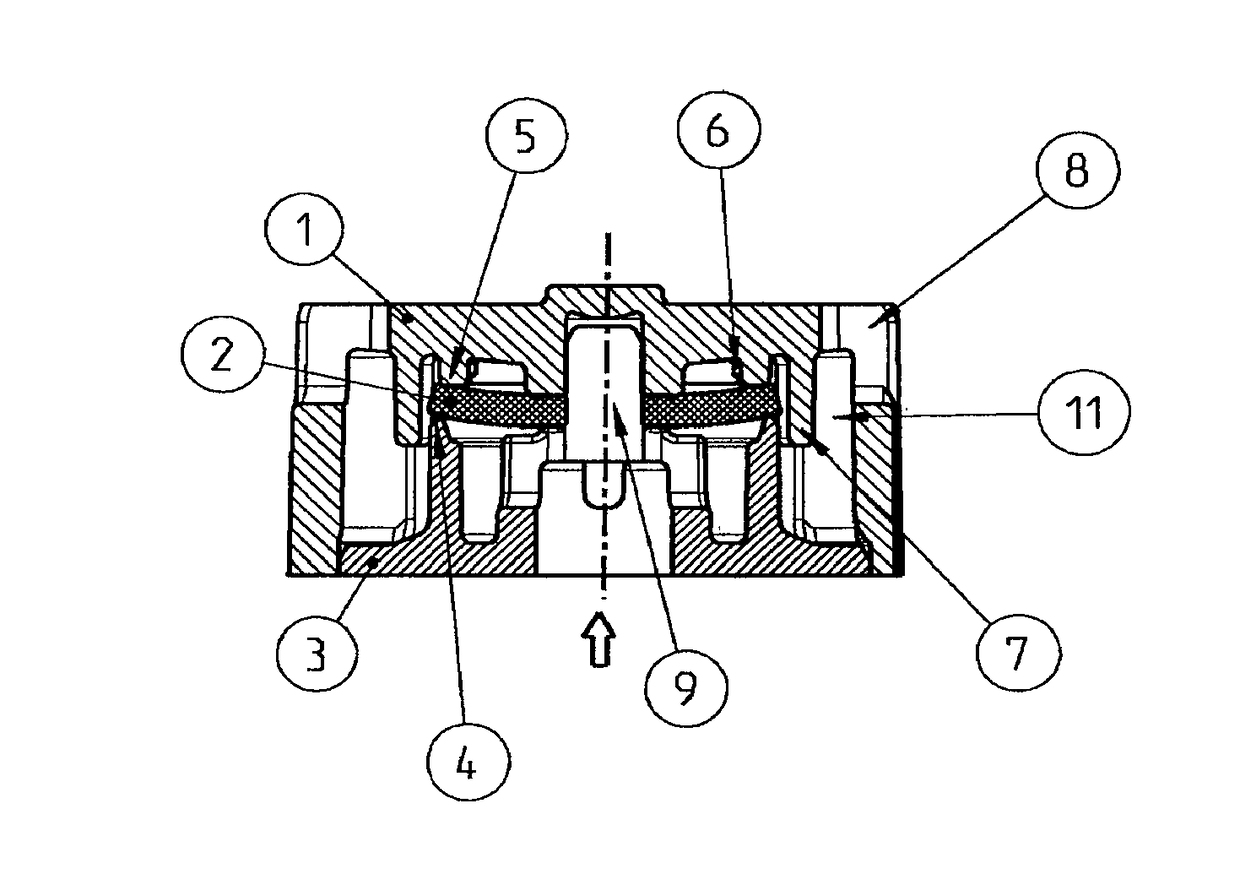

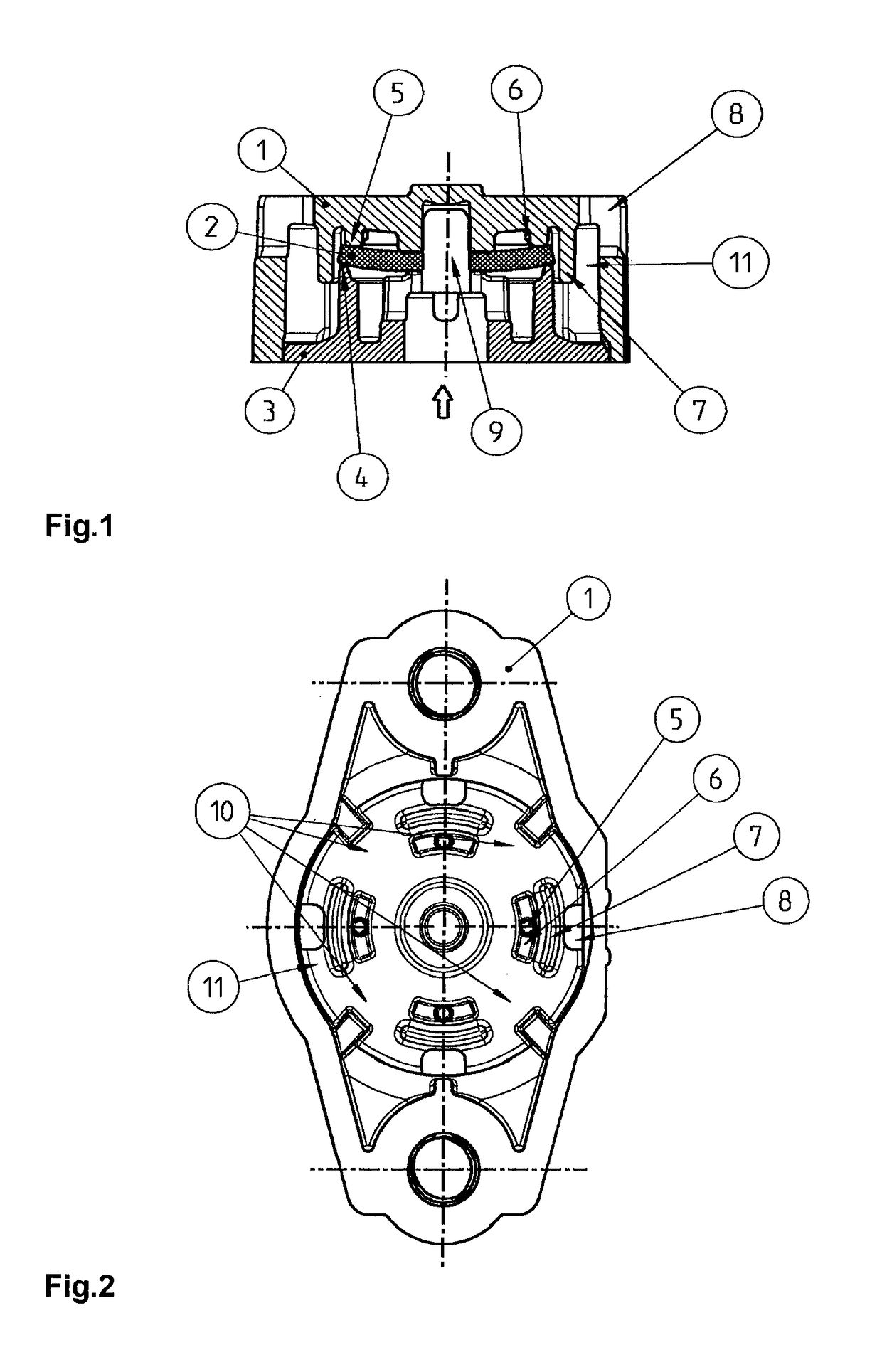

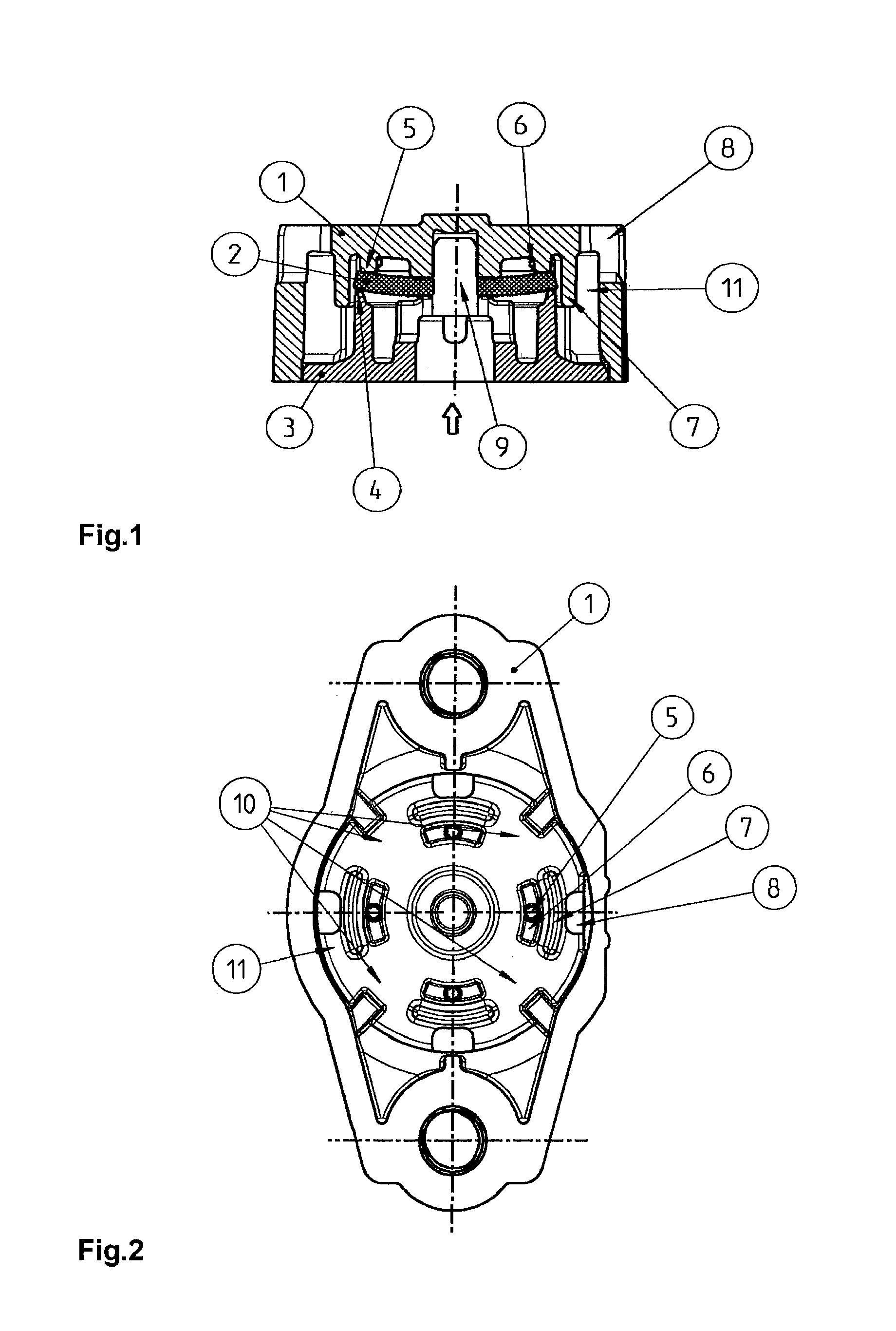

Check valve for ventilation or outlet openings of compressed air apparatuses in vehicles

ActiveUS9909675B2Low noise developmentSatisfactory sealing propertyDiaphragm valvesOperating means/releasing devices for valvesCircular discIn vehicle

A ventilation or check valve for ventilation or outlet openings of compressed air apparatuses of vehicles, includes at least one diaphragm disk which is made from flexible material, is held with a central region in a bore of a valve housing and is prestressed with a radially outer region against a valve seat on the valve housing, to lift up from the valve seat in a pressure-induced manner in the case of a pressure gradient between an inlet space and an outlet space or atmosphere and to open a flow cross section between the inlet space and the outlet space or atmosphere, in which, as viewed in the circumferential direction of the diaphragm disk, a plurality of hold-downs which are arranged at a circumferential spacing from one another and hold down the radially outer region of the diaphragm disk locally against the valve seat are provided on the valve housing.

Owner:KNORR BREMSE SYST FUER NUTZFAHRZEUGE GMBH

Symmetric double-spindle cutter groove grinding machine

PendingCN107225471AImprove grinding efficiencyImprove clamping rigidityGrinding carriagesGrinding machinesStructural engineeringManufacturing engineering

The invention discloses a symmetric double-spindle cutter groove grinding machine. The symmetric double-spindle cutter groove grinding machine comprises a workpiece shaft vertical column, grinding spindle vertical columns and a grinding machine base arranged at the bottoms of the workpiece shaft vertical column and the grinding spindle vertical columns, wherein a workpiece shaft is fixedly connected onto the workpiece shaft vertical column; a workpiece shaft working table is fixedly connected with the lower part of the workpiece shaft vertical column; the grinding spindle vertical columns are oppositely arranged on the left side and the right side of the front part of the workpiece shaft vertical column separately; a height adjustment sliding groove is formed in each of the grinding spindle vertical columns in the vertical direction; a swinging groove is formed in each of the height adjustment sliding grooves; a grinding spindle is connected with the interior of each of the swinging grooves; and two grooving grinding wheels are arranged on each of the grinding spindles.

Owner:极云机械科技上海有限公司

Check valve for ventilation or outlet openings of compressed air apparatuses in vehicles

ActiveUS20150369383A1Low noise developmentSatisfactory sealing propertyDiaphragm valvesOperating means/releasing devices for valvesIn vehicleCheck valve

A ventilation or check valve for ventilation or outlet openings of compressed air apparatuses of vehicles, includes at least one diaphragm disk which is made from flexible material, is held with a central region in a bore of a valve housing and is prestressed with a radially outer region against a valve seat on the valve housing, to lift up from the valve seat in a pressure-induced manner in the case of a pressure gradient between an inlet space and an outlet space or atmosphere and to open a flow cross section between the inlet space and the outlet space or atmosphere, in which, as viewed in the circumferential direction of the diaphragm disk, a plurality of hold-downs which are arranged at a circumferential spacing from one another and hold down the radially outer region of the diaphragm disk locally against the valve seat are provided on the valve housing.

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

A circular blade and cutting tool with accurate positioning structure

ActiveCN107498610BEasy to installImprove clamping rigidityMetal working apparatusTurning toolsStructural engineeringKnife blades

The invention discloses a circular blade and a cutting tool with an accurate positioning structure. The circular blade includes a circular plate-shaped blade body composed of an upper surface, a lower surface and a side surface connecting the upper surface and the lower surface. The blade body There is a central hole penetrating the upper surface and the lower surface. The blade body is symmetrical about the central axis of the central hole. The upper surface intersects with the side surface to form a cutting edge. The inner surface of the central hole is provided with at least two protrusions. , the angle between two adjacent protrusions is less than 180°. The cutting insert has the characteristics of reliable and stable positioning, multiple clamping capabilities and long service life. The cutting tool has the above-mentioned circular blade, which can eliminate the sliding or rotation of the circular blade in the circumferential direction during use, ensure the stability of the cutting area participating in the cutting edge, prevent other cutting from participating in cutting, effectively stabilize the circular blade on the cutting tool, and increase the number of times the circular blade can be used. improve the life of cutting tools.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

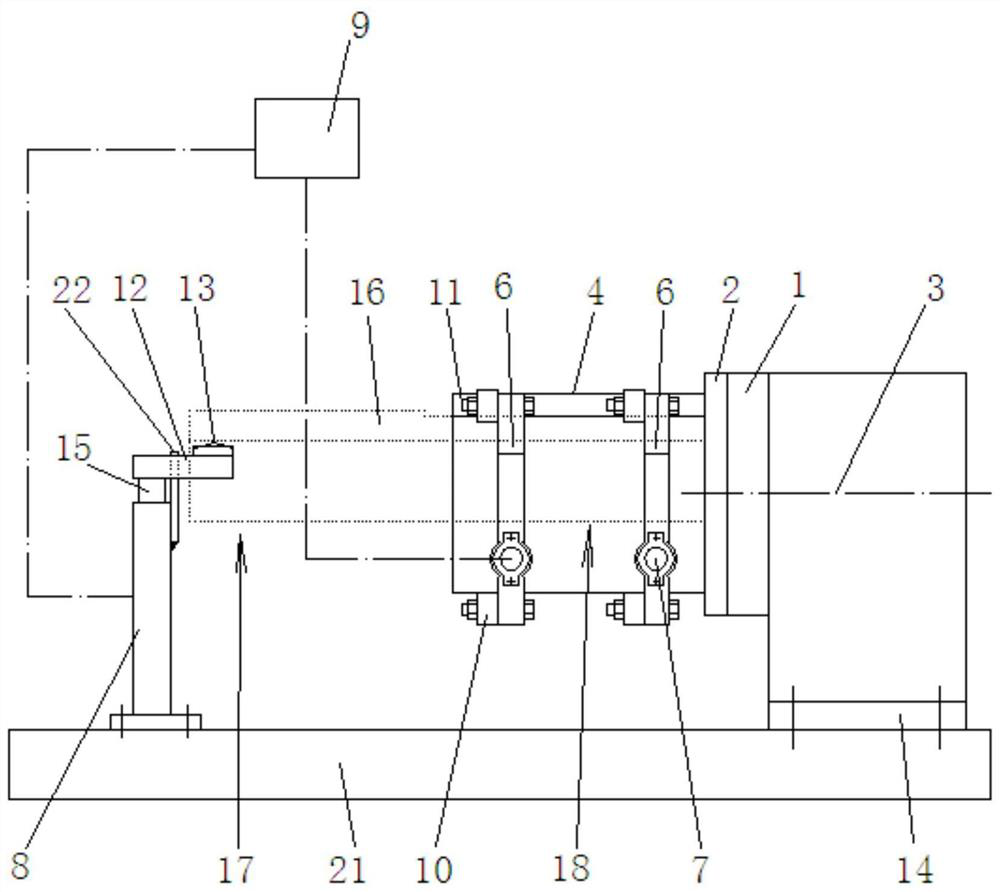

Machine tool and method for processing slender shaft parts

ActiveCN104827056BIncrease productivityIncrease production capacityTailstocks/centresTurning machinesEngineeringCutting force

The invention discloses a machining tool and method for slender shaft type parts. The machining tool comprises a machine frame, a left spindle box, a left tail clamping and pulling mechanism, a left tool rest, a left tool following mechanical hand unit, a left X axis transmission unit, a left Z1 axis transmission unit, a left Z2 axis transmission unit, a left chip removal mechanism, a right spindle box, a right tail clamping and pulling mechanism, a right tool rest, a right tool following mechanical hand unit, a right X axis transmission unit, a right Z1 axis transmission unit, a right Z2 axis transmission unit and a right chip removal mechanism. The two ends of a workpiece are clamped at the same time through two sets of tailstock clamping mechanisms and a main transmission mechanism, and the tail throwing phenomenon of clamped slender parts is avoided; through the tail clamping and pulling mechanisms, tool following mechanical hands solve the problem that clamping rigidity of slender parts is not enough, and part machining precision is guaranteed; machining is carried out at the same time through two sets of executing devices, and the requirement for clamping force is lowered through the main cutting force equivalent counteraction principle; the purpose of obviously improving productivity is achieved.

Owner:上海奇灏特自动化工程有限公司

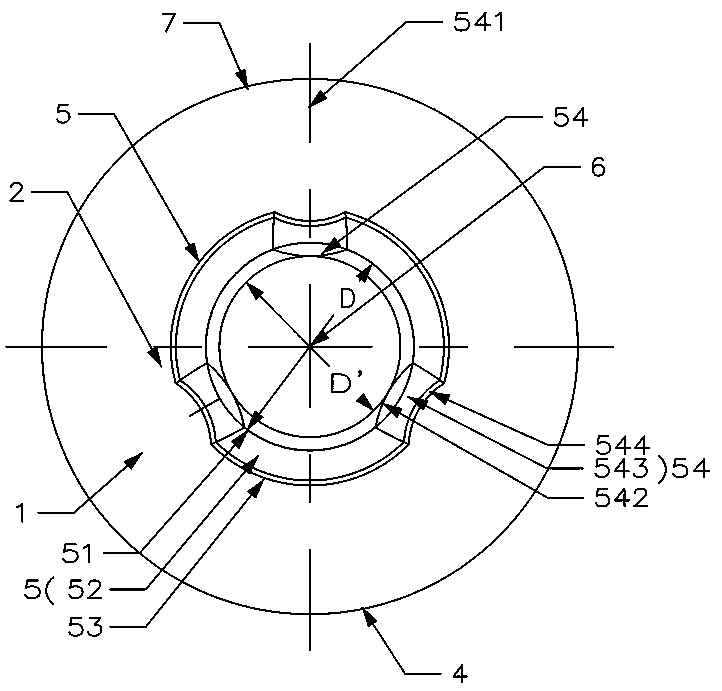

A circular cutting blade and cutting tool with accurate positioning structure

ActiveCN107538020BImprove clamping rigidityHigh strengthTurning toolsStructural engineeringKnife blades

The invention discloses a circular cutting blade with an accurate positioning structure and a cutting tool. The circular cutting blade comprises a circular blade body which consists of an upper surface, a lower surface and side surfaces connecting the upper surface to the lower surface, wherein a central hole which penetrates through the upper surface and the lower surface is formed in the blade body; the blade body is centrosymmetric with respect to a central axis of the central hole; the upper surface is crossed with the side surfaces to form cutting edges; at least one circular-arc-shaped groove which is matched with the surface of a fastening screw for fixing the circular cutting blade is formed in the inner surface of the central hole; and offset distance is formed between the groovecentral axis of the circular-arc-shaped groove and the central axis. The cutting tool adopts the cutting blade. The circular cutting blade has the advantages of being reliable and stable in positioning, prolonging the service life of the cutting blade and being capable of preventing the circular blade from rotating in the peripheral direction.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Machine special for cutting waist-shaped arc groove

ActiveCN102091816BImprove clamping efficiencyImprove clamping rigidityMilling equipment detailsEngineeringMotive power

The invention relates to a machine for cutting a groove on a semi-round tube, in particular to a machine special for cutting a waist-shaped arc groove. The machine comprises a workbench, a groove cutting mechanism, a workpiece clamping mechanism, a groove cutting feed mechanism and a cooling mechanism; the groove cutting mechanism comprises a motive power mechanism, a groove cutting cutter, and acutter shaft bracket; the motive power mechanism transfers motive power to the grove cutting cutter to rotate the groove cutting cutter so as to perform groove cutting operation; the workpiece clamping mechanism comprises a workpiece clamping hand, a motive power transfer joint and a motive power device; and the motive power device transfers the motive power to the workpiece clamping hand throughthe motive power transfer joint, and the workpiece clamping hand works to tightly clasp a workpiece. The groove cutting feed mechanism comprises a carriage and a carriage diving mechanism arranged onthe workbench and used for driving the carriage to be fed or retreated; and a workpiece clamping mechanism is arranged on the carriage. The machine can radially cut arc grooves or waist-shaped arc grooves on a cambered surface of the semi-round tube conveniently, efficiently and accurately.

Owner:CHANGZHOU TENGLONG AUTO PARTS CO LTD

A polygonal cutting insert and a cutting tool with a raised portion in the hole

ActiveCN107775019BImprove clamping rigidityHigh strengthCutting insertsTurning toolsKnife bladesIndustrial engineering

The invention discloses a polygonal cutting blade with bulge parts in a hole and a cutter. The polygonal cutting blade comprises a blade body consisting of an upper surface, a lower surface and a plurality of side surfaces connected with the upper surface and the lower surface, wherein a center hole penetrating through the upper surface and the lower surface is formed in the blade body, the bladebody is in central symmetry about the central axis of the center hole, each side surface and the upper surface intersect to form a plurality of cutting edges, one bulge part is arranged in the position, corresponding to each side surface, of the inner surface of the center hole, and the bulge parts directly face the corresponding side surfaces. The cutting blade has the characteristics of positioning reliability and stability, multiple clamping and long service life. The cutter comprises the cutting blade, fastening screws and the center hole of the cutting blade produce over-positioning multidirectional clamping under multiple constraints, deformation directions and areas unfavorable for fasteners are effectively controlled, the vibration of the cutting blade can be effectively attenuated during cutting, and the service life of the cutter is prolonged.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

A tool box fixture for machining piston ring grooves

ActiveCN105033678BImprove installation accuracyGuaranteed installation accuracyPositioning apparatusMaintainance and safety accessoriesBlade platePiston ring

The invention discloses a knife box clamp for machining piston ring grooves. The knife box clamp for machining piston ring grooves comprises a knife box body (1), a side face knife clip (3), a ring groove knife (9) and a ring groove knife clamp. The knife box body (1) is provided with an installing groove (25). The ring groove knife (9) and the ring groove knife clamp are installed in the installing groove (25). The side face knife clip (3) is installed on the side, with the installing groove (25), of the knife box body (1) through side face knife clip installing screws (10). The ring groove knife clamp comprises a knife cushion block A (5), a knife cushion block B (6), side face pressing screws (16), an elastic expanding block (31) and elastic expanding screws (27). The bottom of the installing groove (25) is further provided with an elastic expanding screw installing block (2) through threads. The elastic expanding block (31) is arranged outside the elastic expanding screw installing block (2). The knife box clamp for machining piston ring grooves has the advantages that the knife box clamp can be used for clamping the ring groove knife for machining, and is high in rigidity, convenient to use, good in cooling and the like.

Owner:成都银河动力有限公司

A Milling Fixture for Right Angle Fishplate

ActiveCN109926850BImprove installation and connection accuracyGood relative position accuracyPositioning apparatusMetal-working holdersStructural engineeringTower crane

The invention relates to the technical field of tower crane manufacturing, and discloses a milling clamp for a right-angle splice bar. The milling clamp comprises a dividing head and a connecting plate, wherein the connecting plate is arranged on a dividing head main shaft and can rotate with the indexing head main shaft for indexing. The axis of the indexing head main shaft is horizontally arranged. Angle steel used for positioning two outer right-angle surfaces at the front end of the right-angle splice bar is arranged on the connecting plate. Two inner side surfaces of the angle steel are used as the positioning surfaces of the two outer right-angle surfaces at the front end of the right-angle splice bar and are parallel to the axis of the indexing head main shaft. Supporting plates arearranged across two side edges of the angle steel. The supporting plates are provided with propping elements for propping the right-angle splice bar to the positioning surfaces. By means of the milling clamp, the clamping and machining efficiency, the machining precision and the product quality are improved.

Owner:江阴听阳机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com