A Milling Fixture for Right Angle Fishplate

A fishplate and right-angle technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the uneven machining allowance of the two outer right-angle surfaces at the end of the right-angle fishplate, which affects the appearance and installation connection Accuracy, affecting processing accuracy and other issues, to achieve the effect of improving appearance quality, enhancing clamping rigidity, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

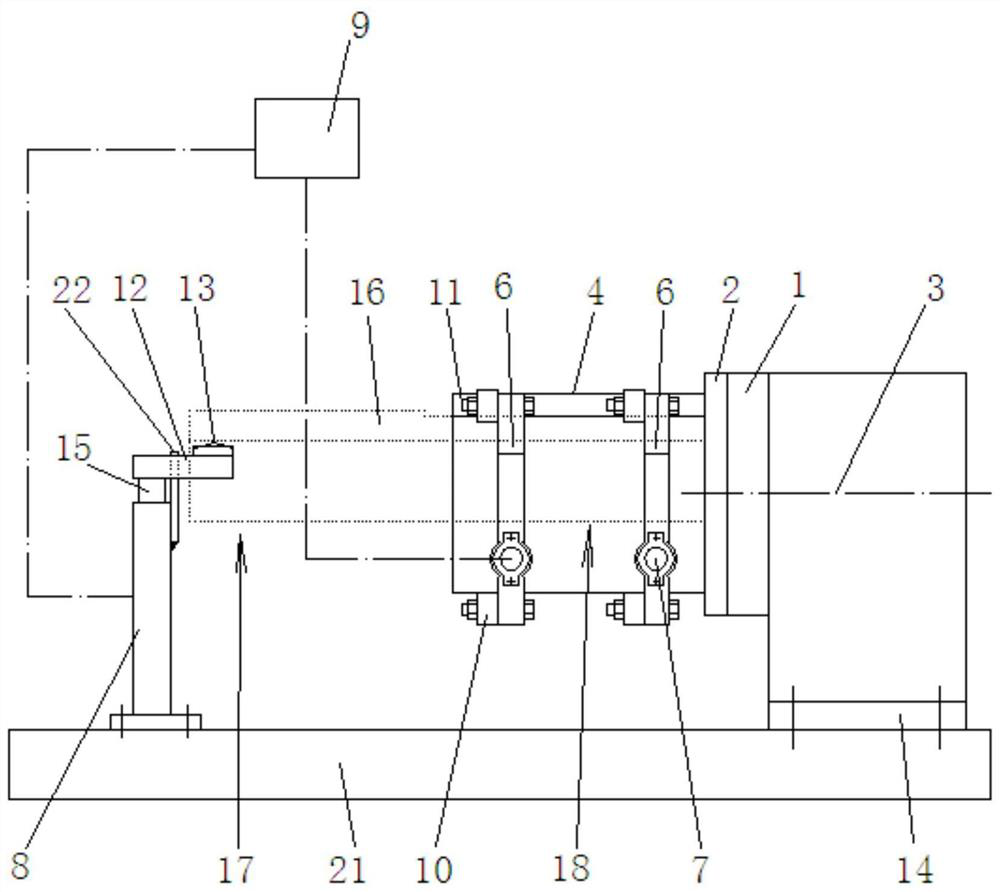

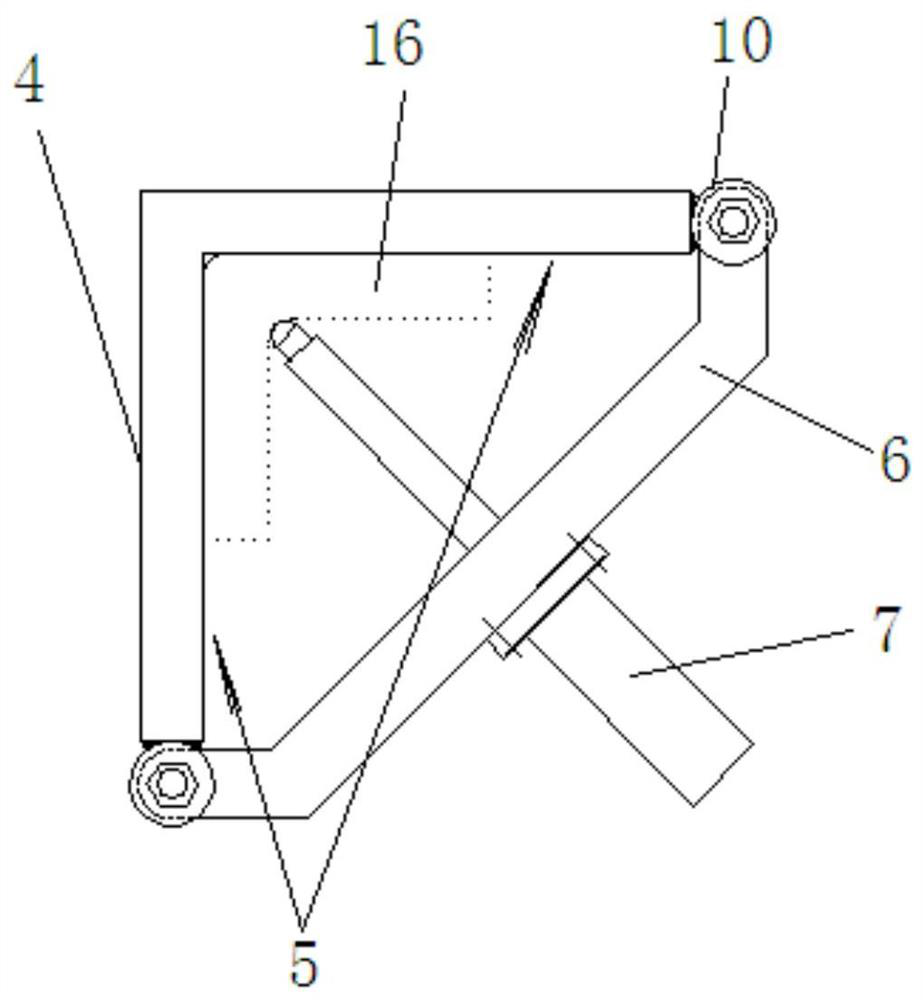

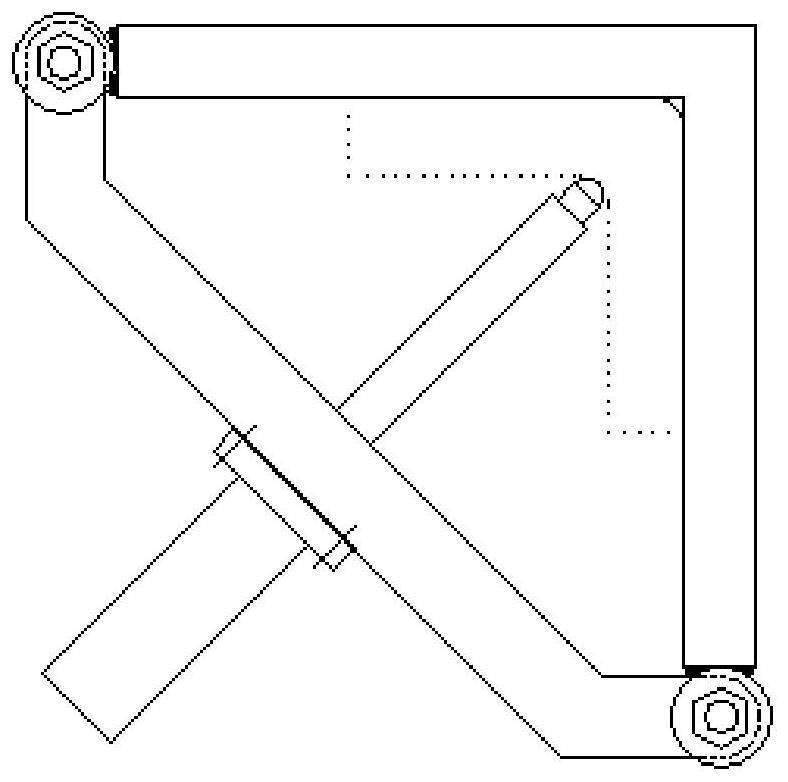

[0048] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0049] Such as Figures 1 to 4 Shown is an embodiment of a milling fixture for a right-angle fishplate of the present invention, including an indexing head 1 and a connection that is installed on the main shaft of the indexing head 1 and can rotate and index along with the main shaft of the indexing head 1 Disk 2, the axis of the main shaft of the dividing head 1 is set horizontally, the connecting disk 2 is provided with angle steel 4 for positioning the two outer right angle surfaces 20 of the front end of the right angle fishplate, and the two inner surfaces of the angle steel 4 As the positioning surfaces of the two outer right-angle surfaces 20 at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com