Method and device for machining internal teeth of planetary cycloidal pin gear reducer housing

A cycloidal pin wheel deceleration and processing device technology, which is applied to gear tooth manufacturing devices, gear teeth, metal processing, etc., can solve the problems of low processing efficiency and precision, easy deformation of semicircular holes, low processing efficiency, etc., to improve production Efficiency, easy alignment, and convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0027] In order to facilitate the understanding of this processing method, the device used in the processing process is first explained:

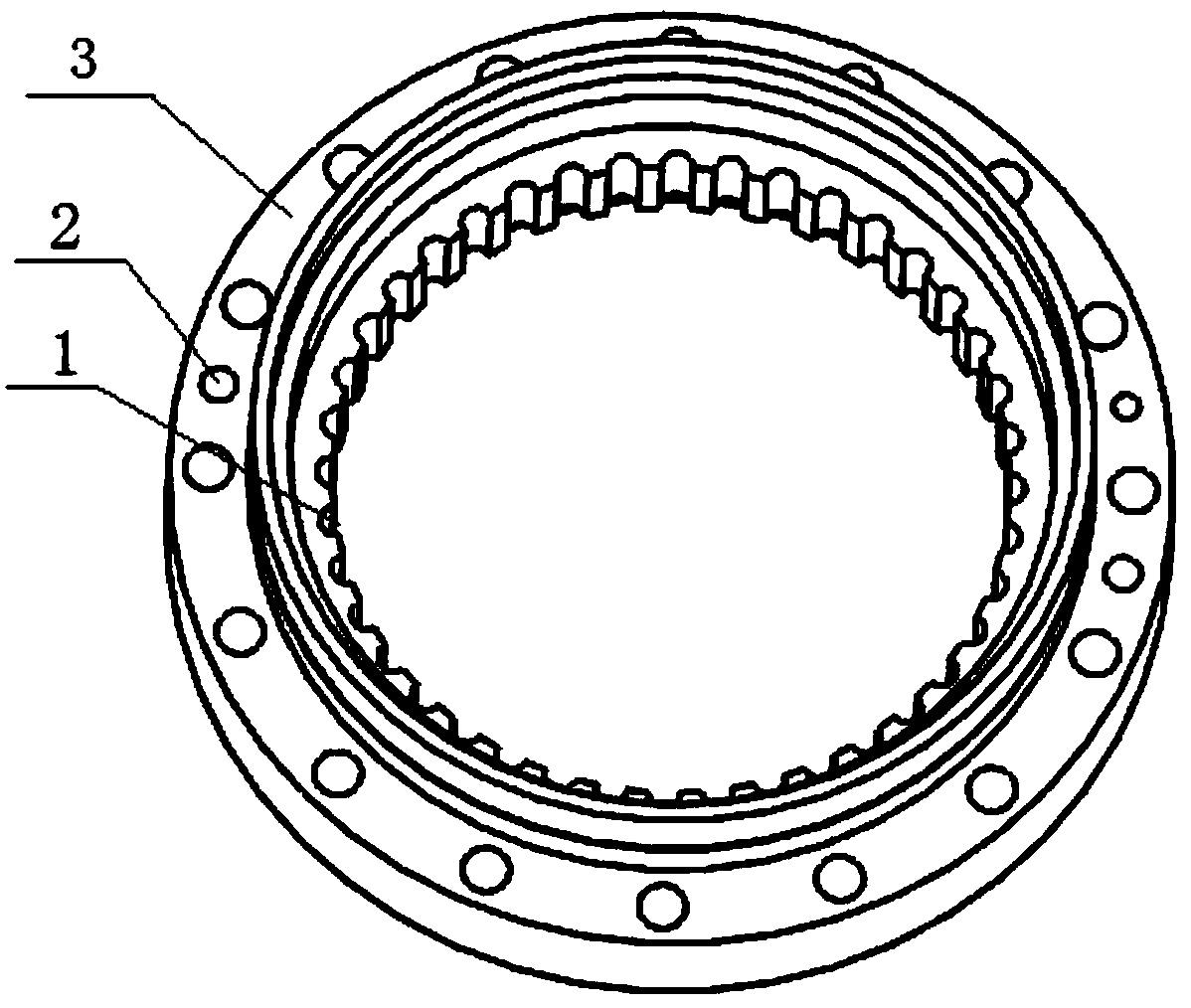

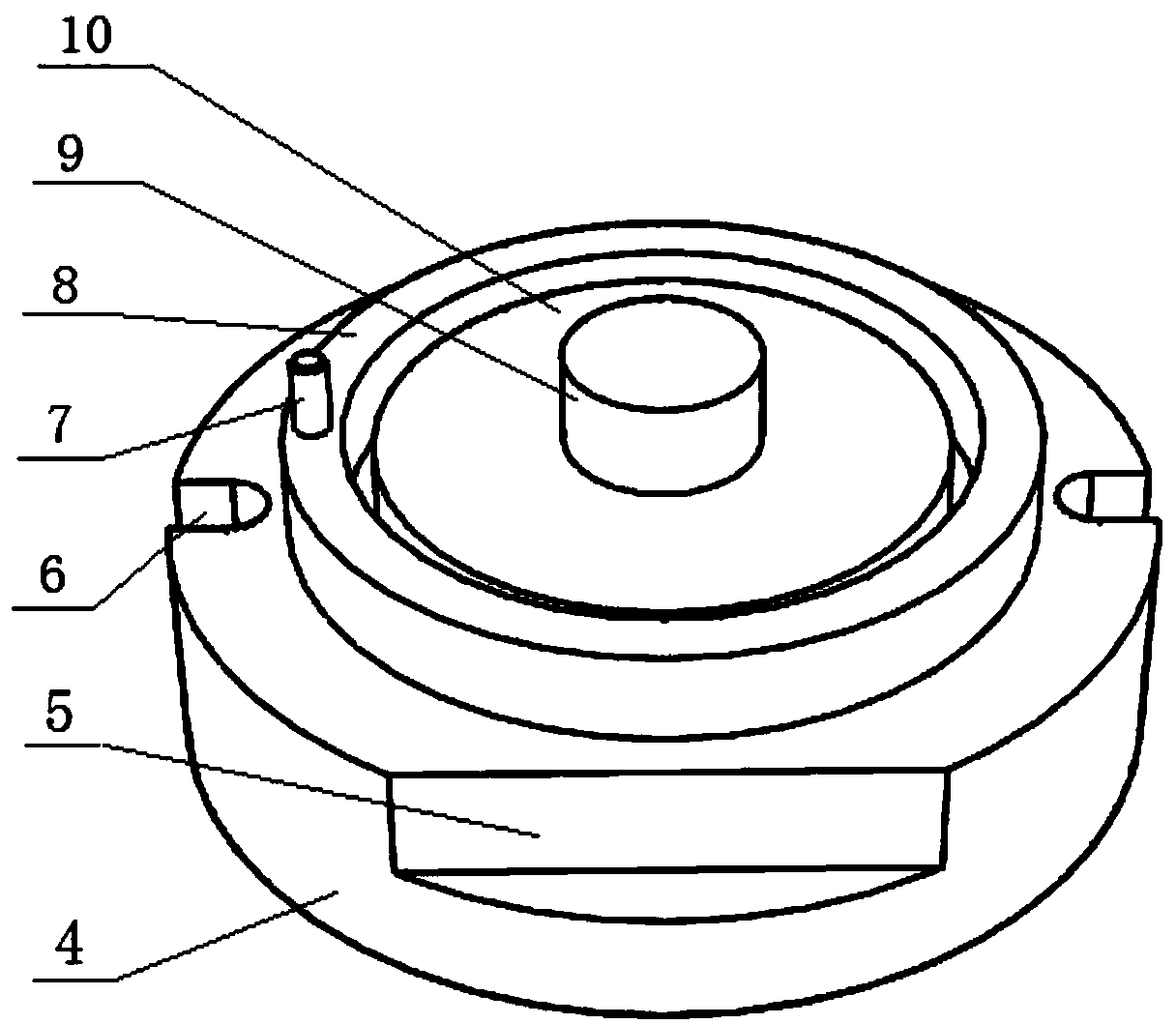

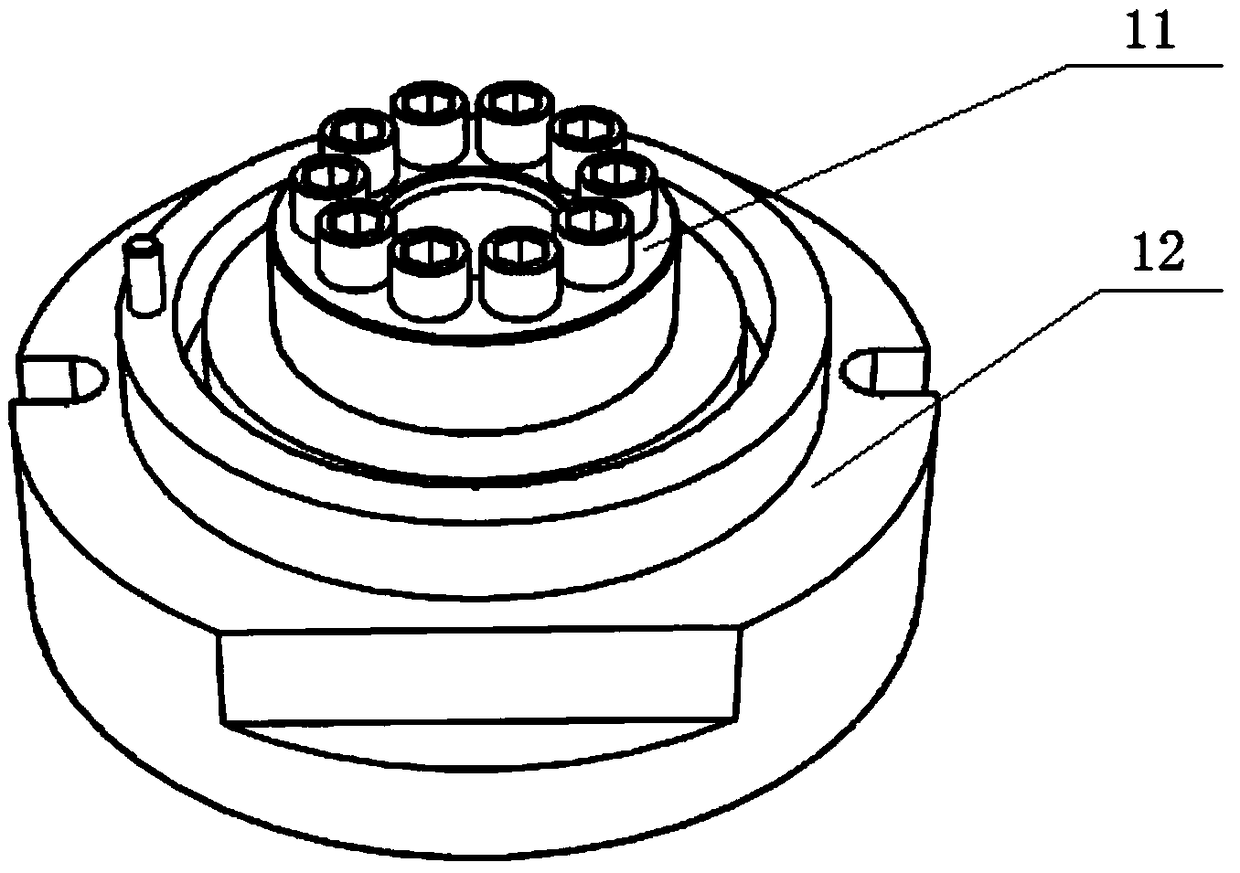

[0028] An internal gear processing device for a planetary cycloid reducer housing, including a base 12, a tensioning sleeve 11, and an open sleeve 13. The base includes a base 4, a circular table 10, and an annular table. The base is cylindrical as a whole, and its side wall A plurality of vertically arranged machine tool clamping grooves 6 are made, and the base can be installed on the machine tool through the machine tool clamping grooves. An L-shaped groove is made on the upper surface of the base, and the vertical limit of this L-shaped groove is to find the front 5 for i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com